Numerical Simulation of Early Age Cracking of Reinforced Concrete Bridge Decks with a Full-3D Multiscale and Multi-Chemo-Physical Integrated Analysis

Abstract

:1. Introduction

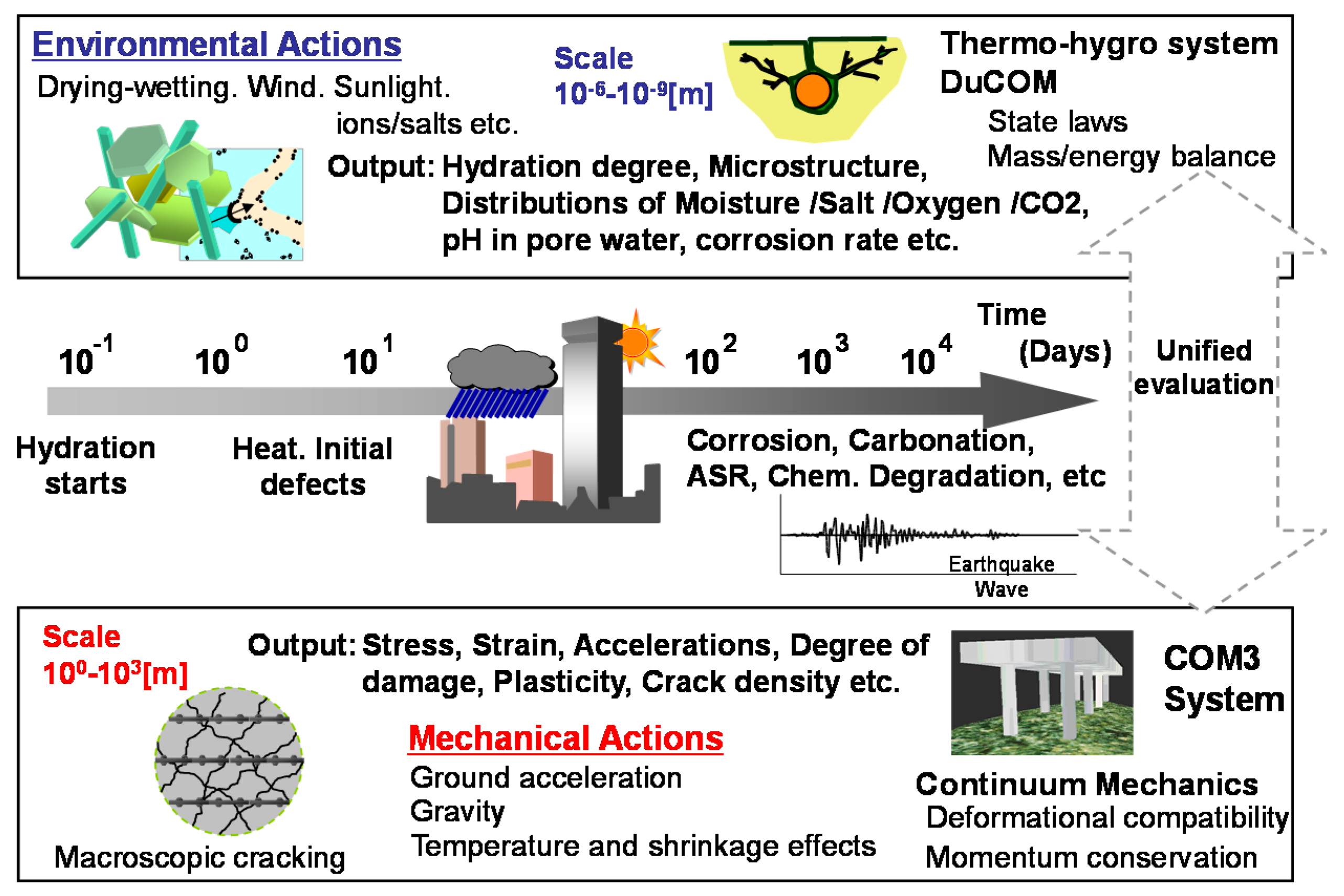

2. Overview of Multiscale and Multi-Physical Modelling

3. Numerical Simulation of Early-Age Behaviour of Small Specimens to Actual Rc Deck Slabs

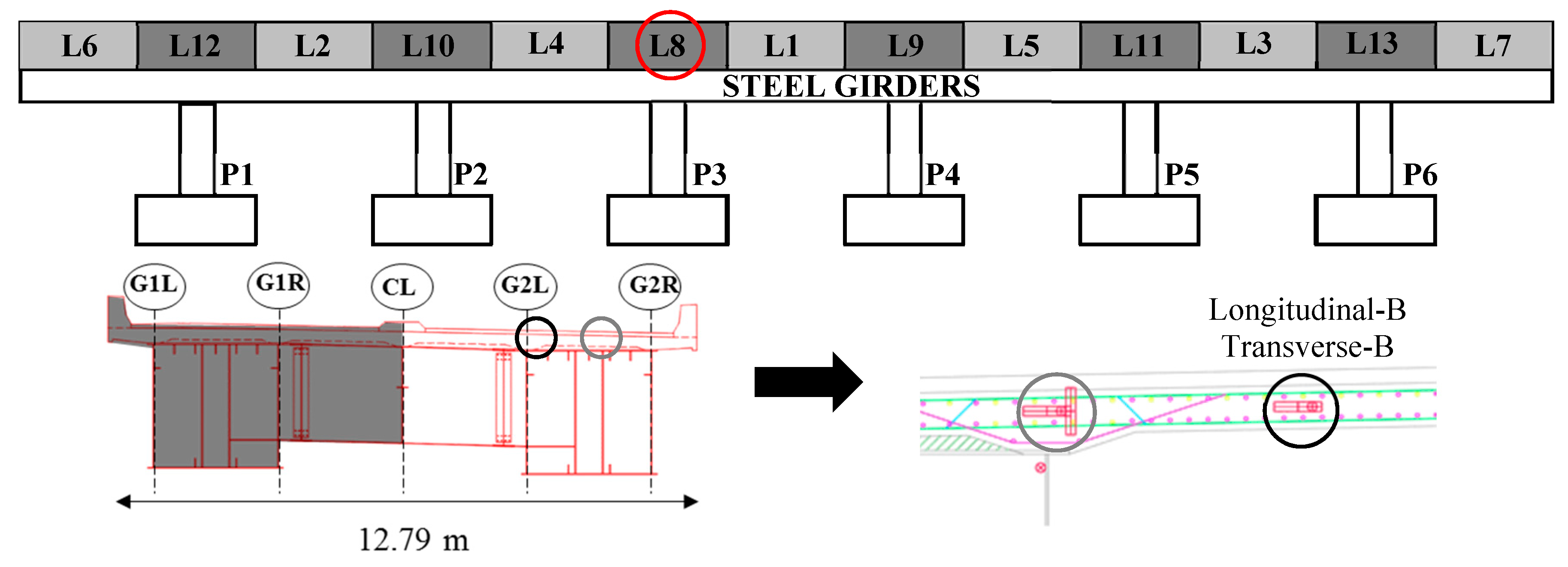

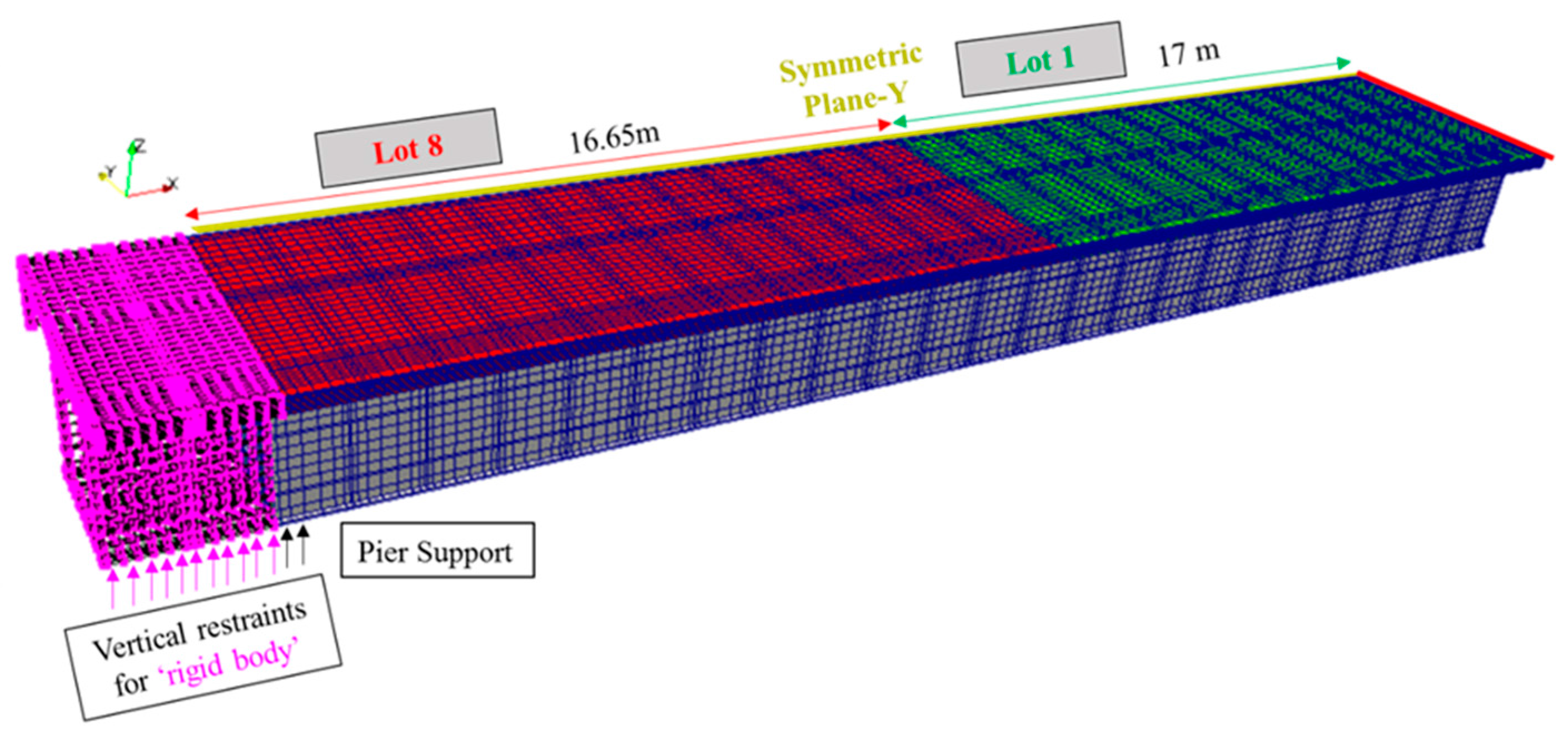

3.1. Target of Analysis

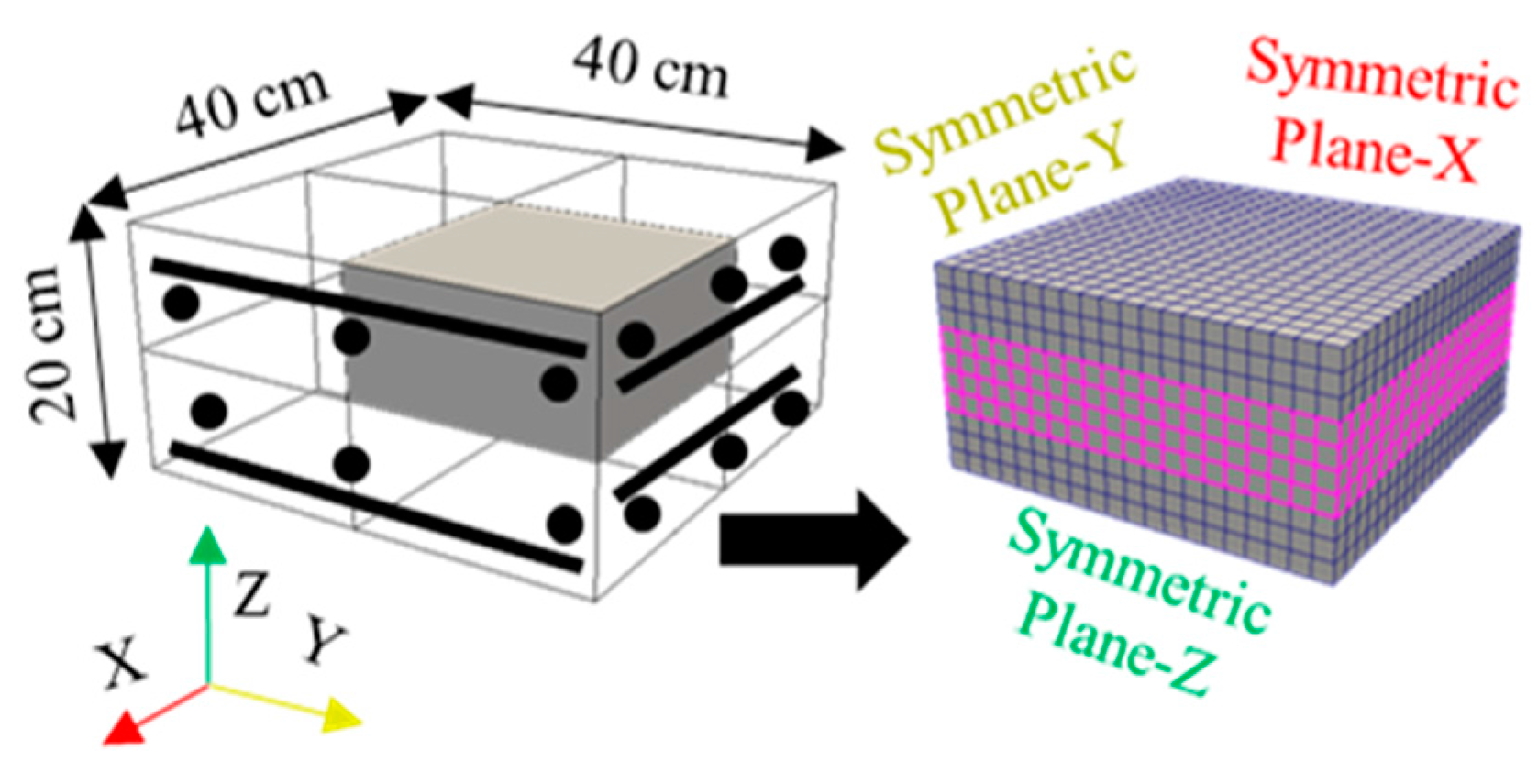

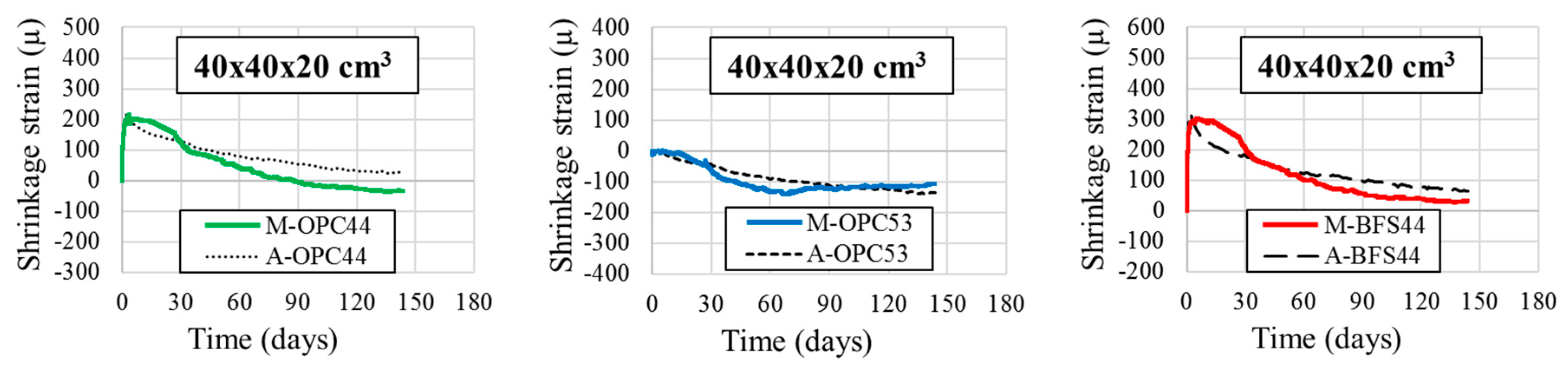

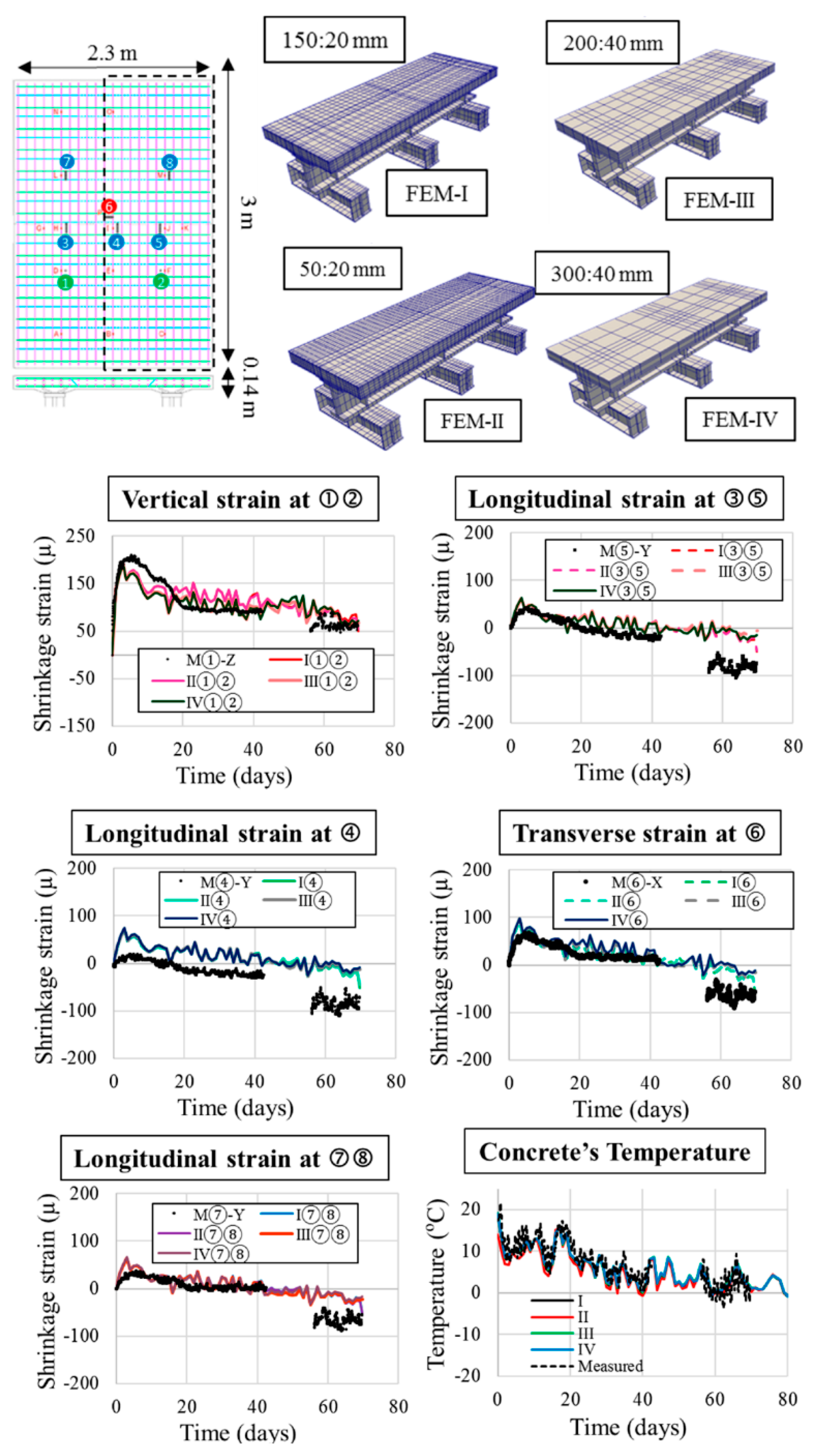

3.2. Experimental Outline and Model Validation via Small-Scale Specimens (Decimetres)

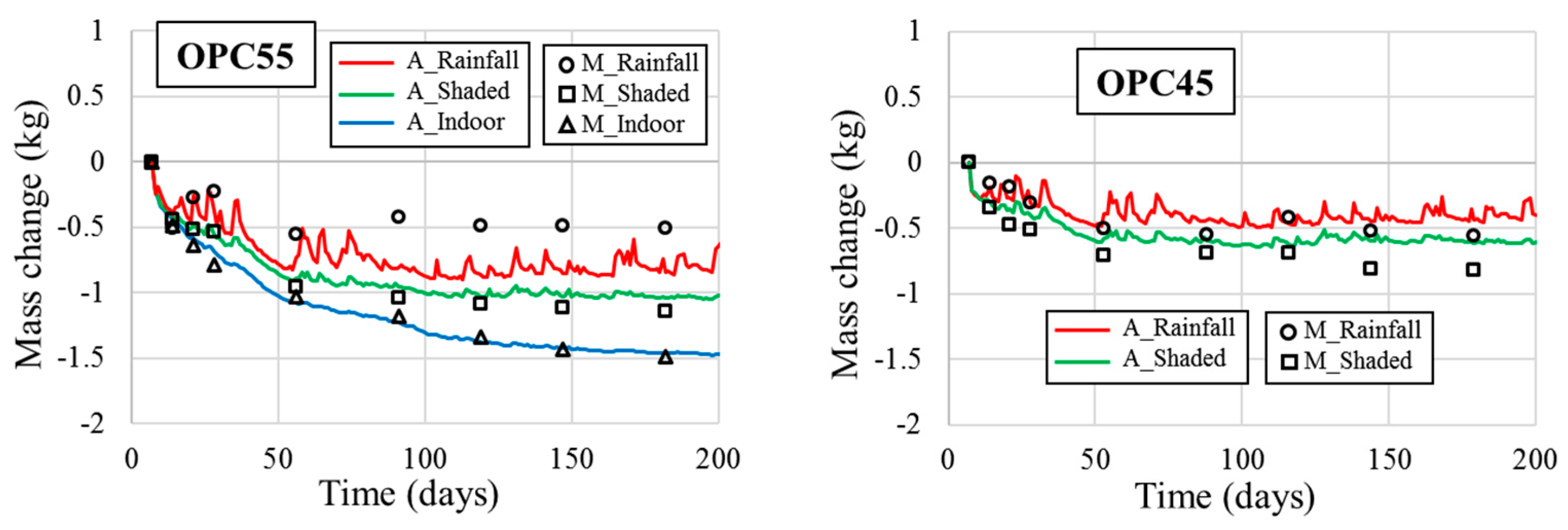

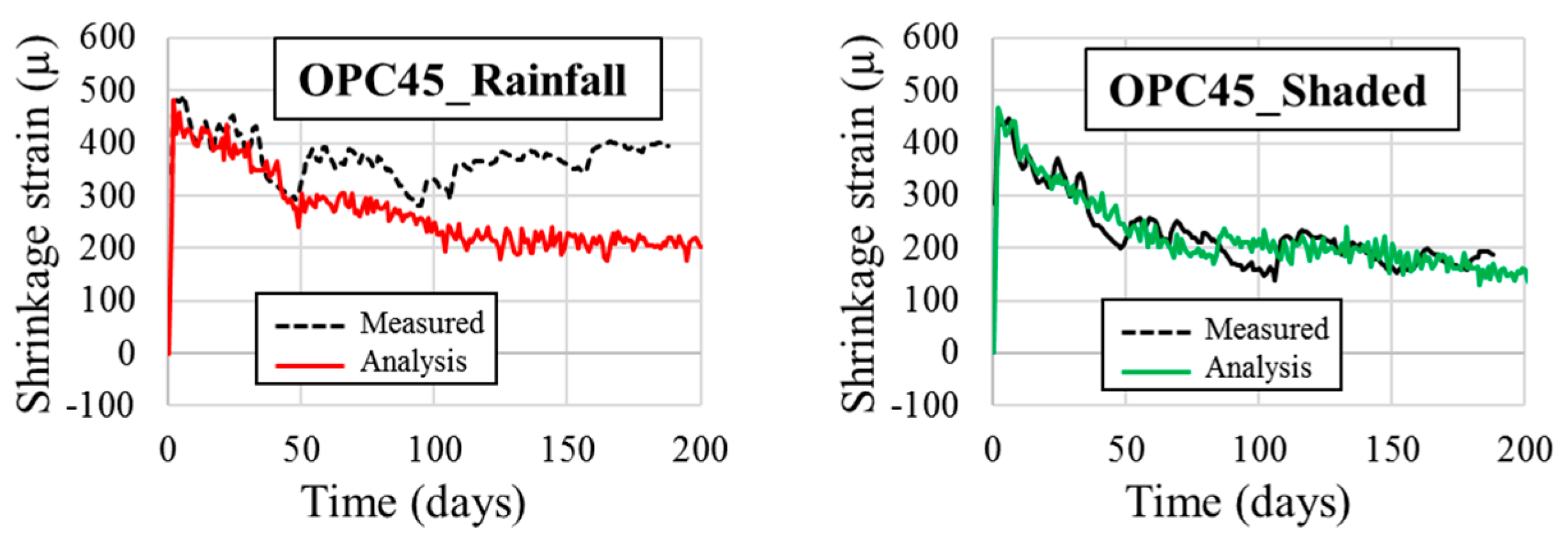

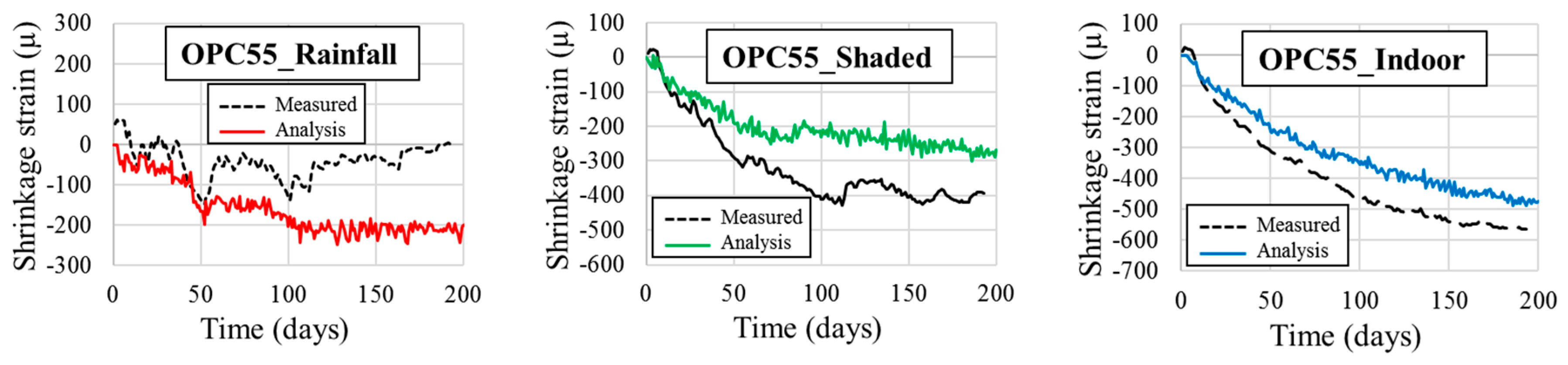

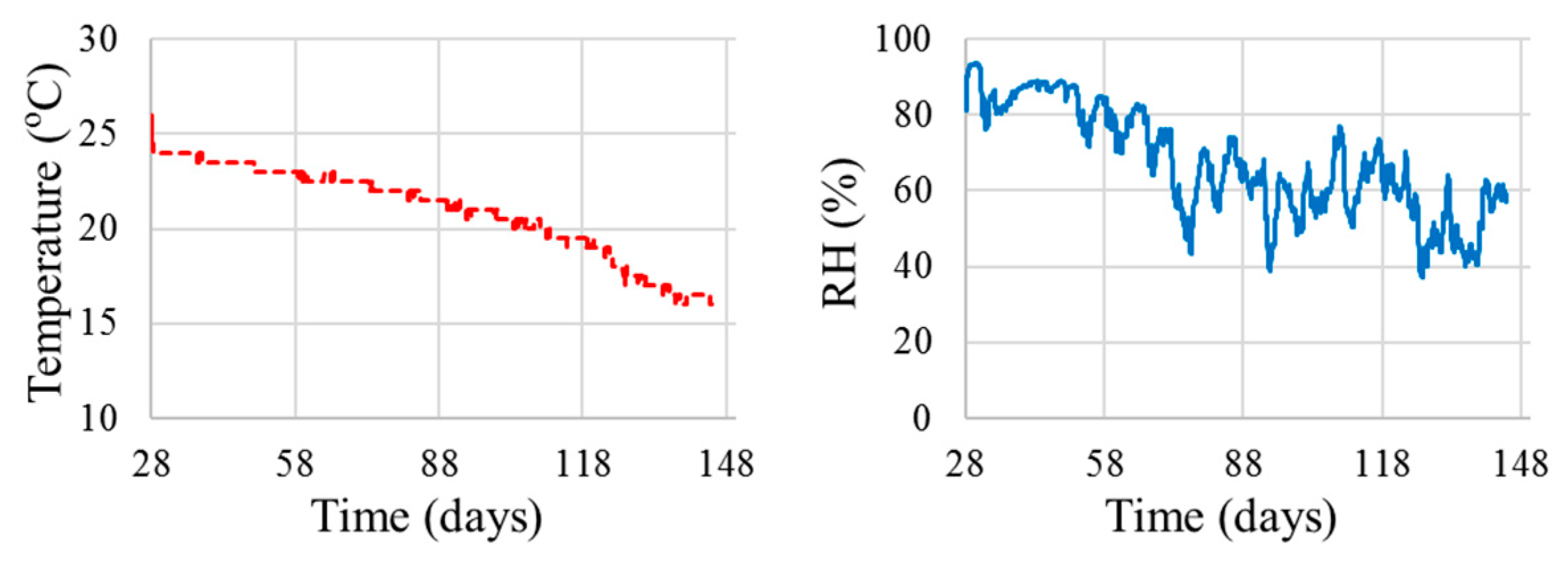

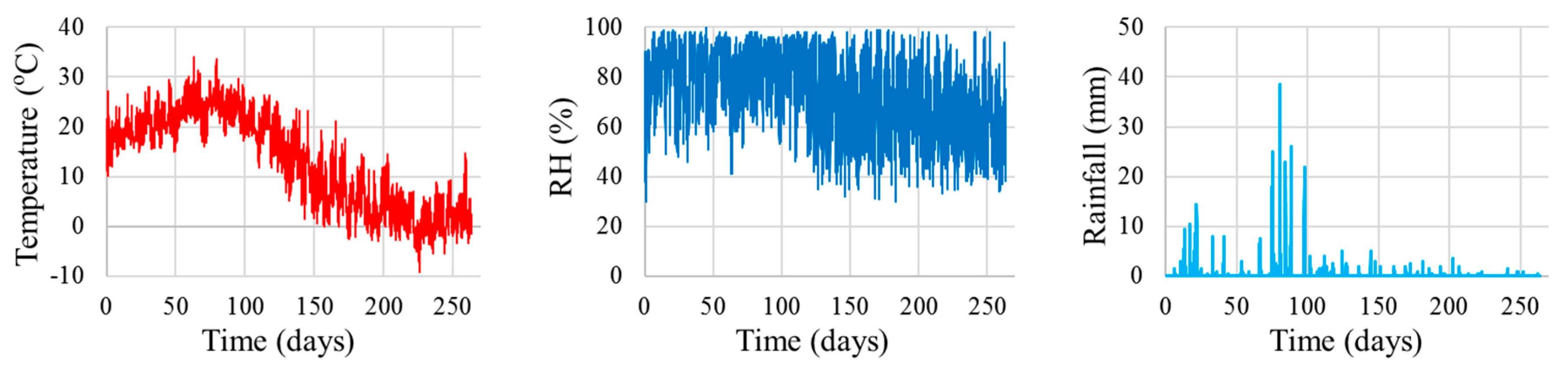

3.2.1. Influence of Environmental Conditions: Rainfall, Shade and Indoors

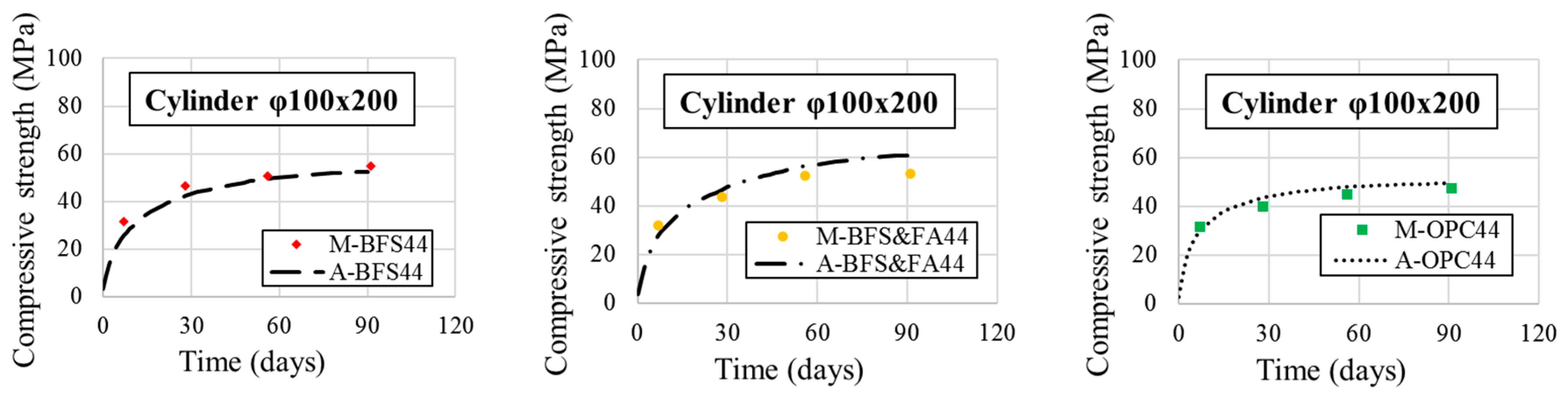

3.2.2. Compressive Strength

3.2.3. Influence of Curing Conditions on Concrete

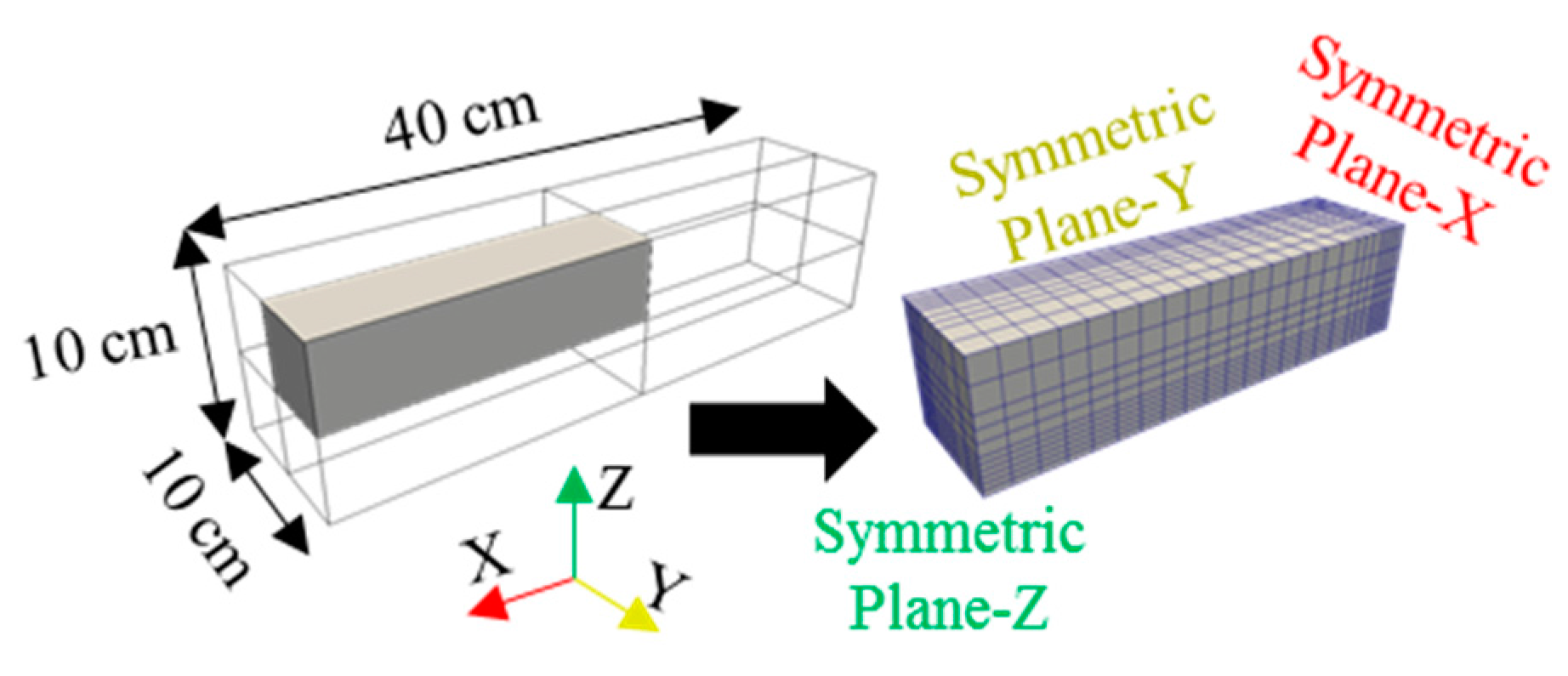

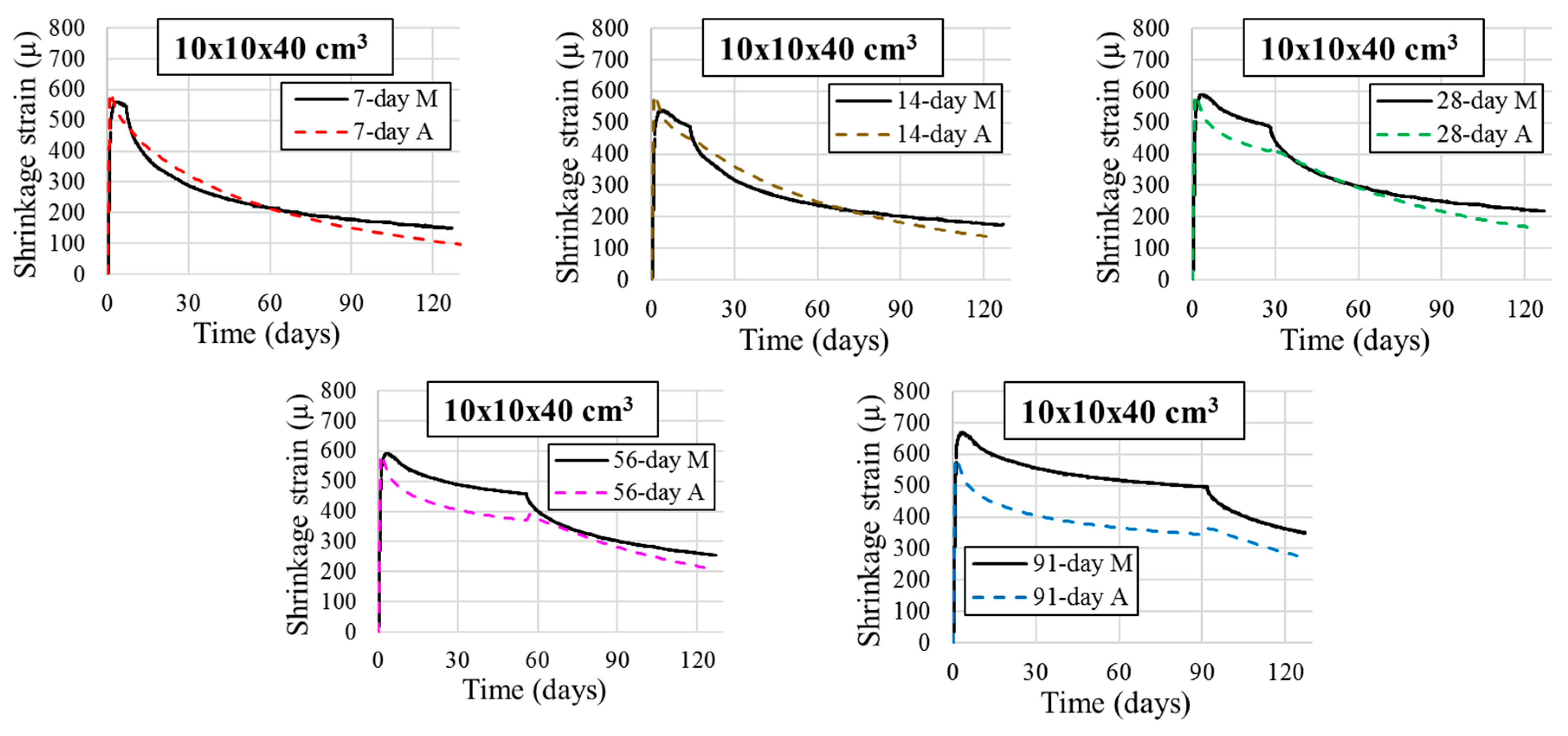

3.2.4. Influence of Reinforcing Bars on Concrete

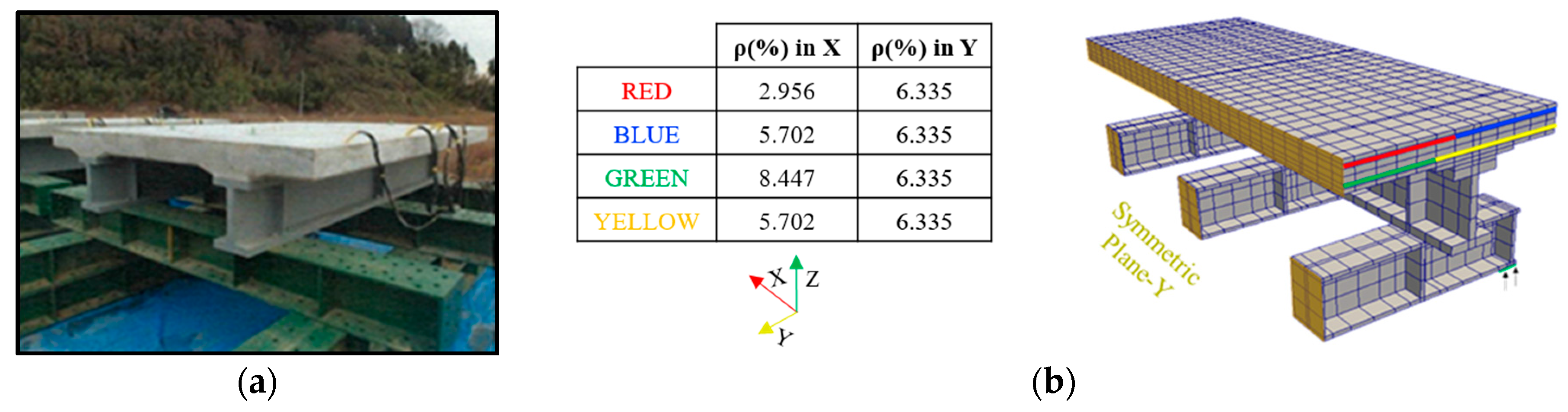

3.3. Application of the Analytical Model on a Mock-Up Slab Specimen

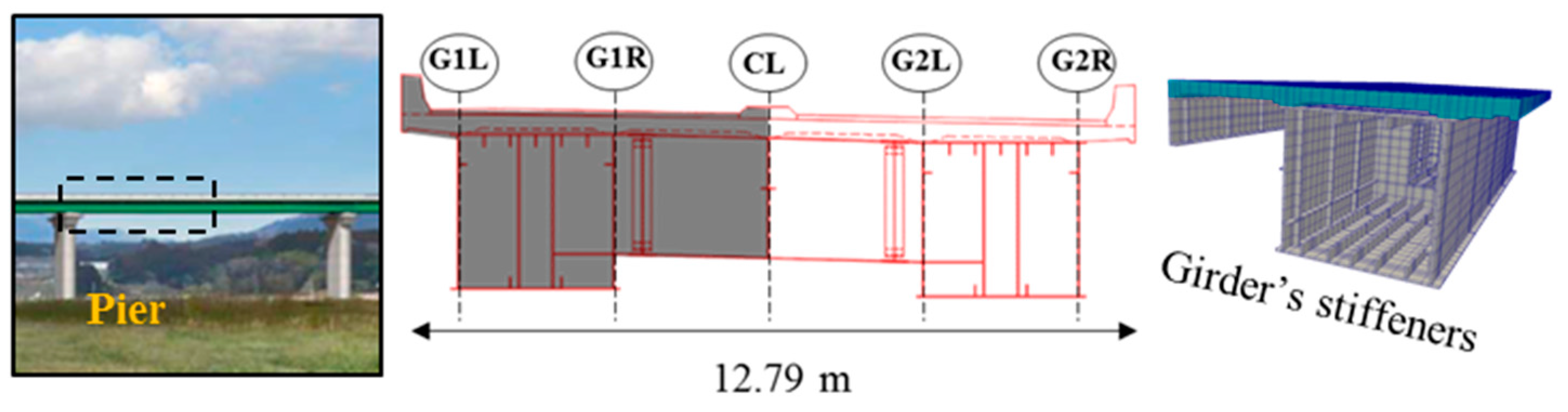

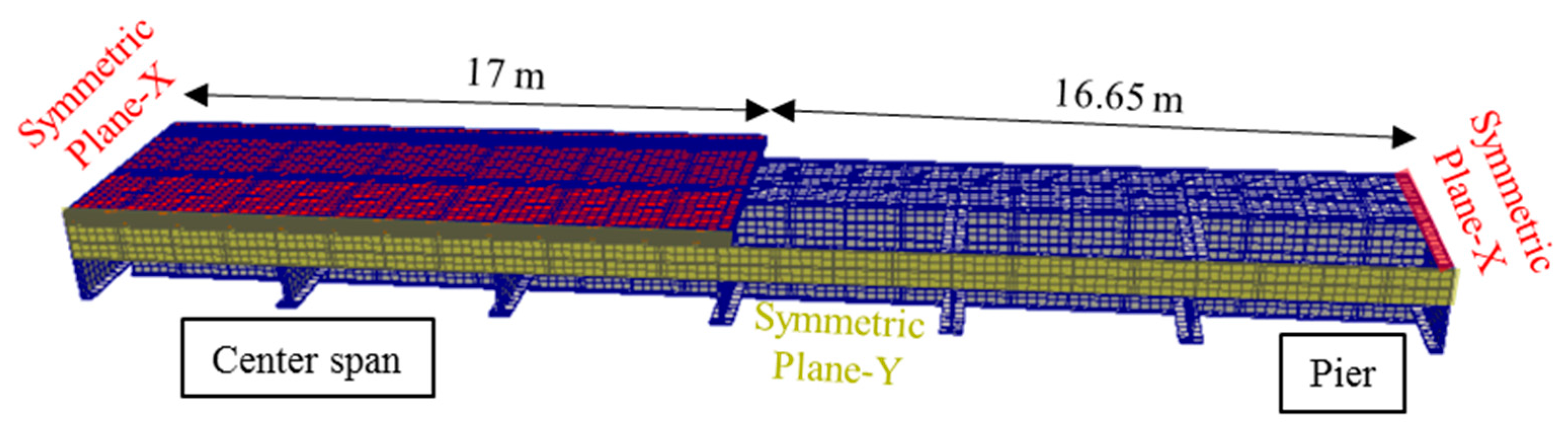

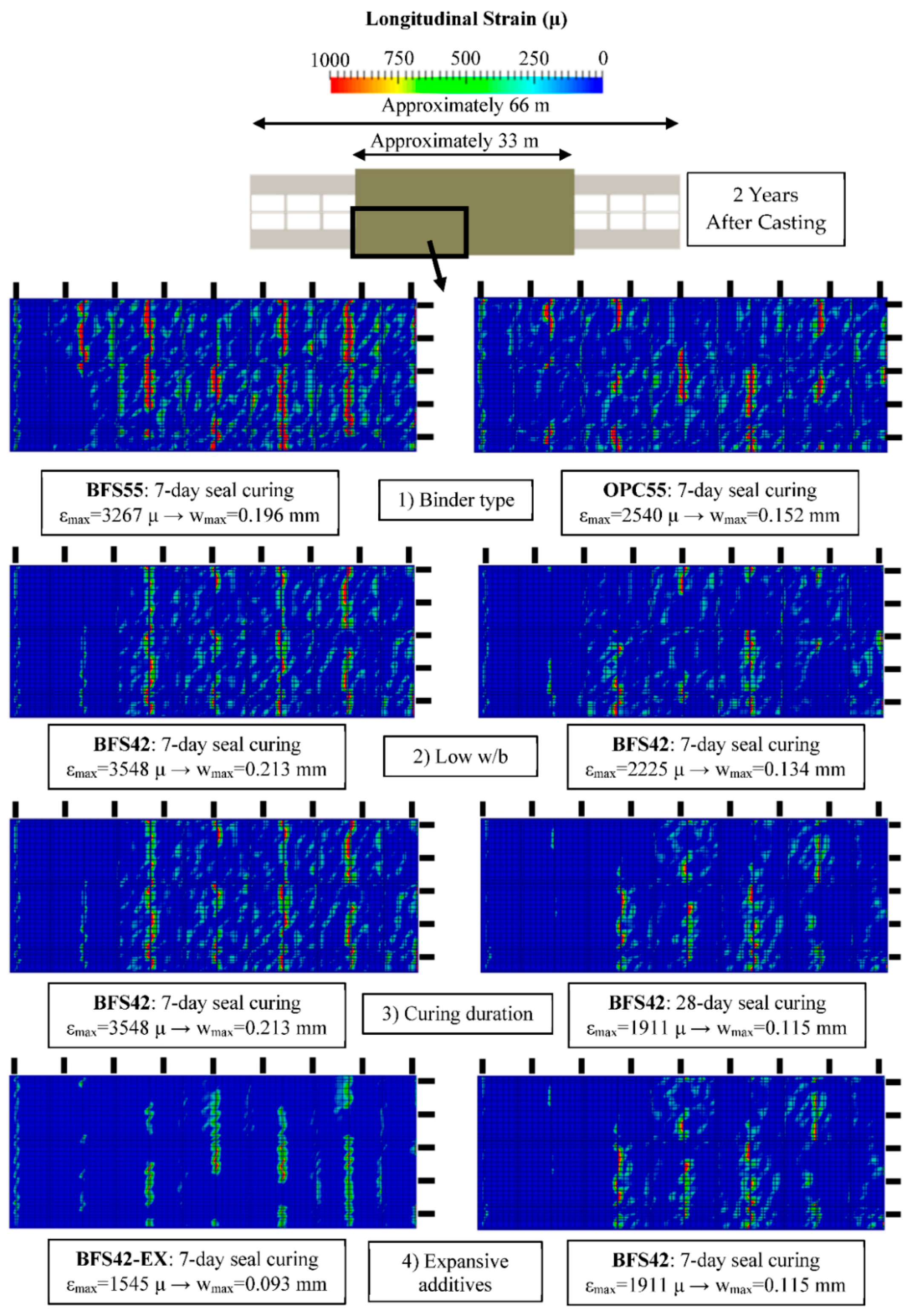

3.4. Preliminary Analysis on Concrete Deck Slab of Shinkesen Bridge to Evaluate the Occurrence of Cracks

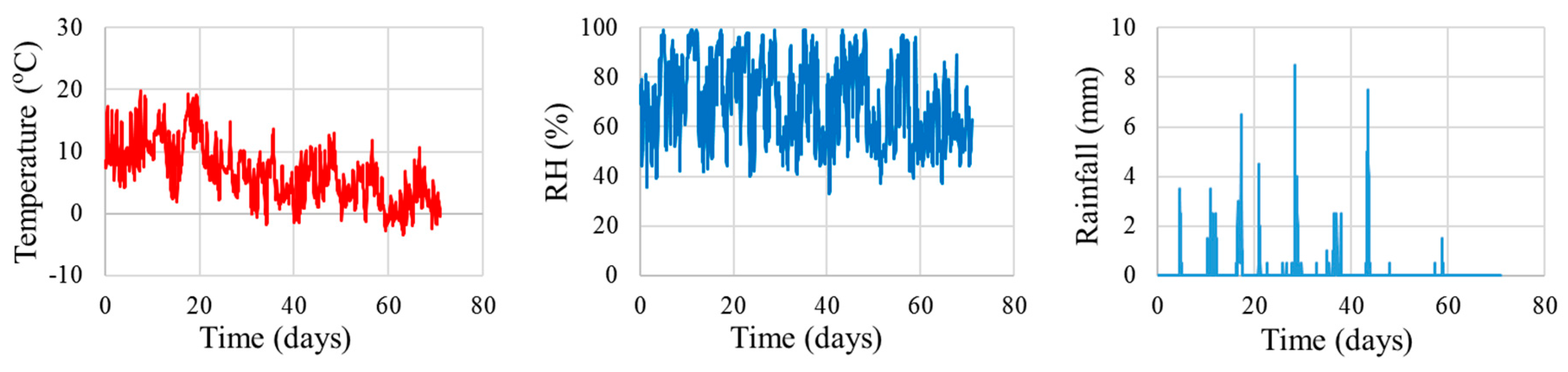

3.5. Post-Construction Analysis on Concrete Deck of Shinkesen Bridge: Verification with on-Site Measured Data

4. Conclusions

- The multiscale thermodynamic integrated analysis was verified and validated from the laboratory scale on the order of decimetres up to the structural scale on the order of decametres, which adequately confirms its ability to assess the behaviour of actual structures.

- By conducting the preliminary analyses before bridge construction, the superiority and inferiority of each mix proportion could be displayed to a great extent, which helped the engineers to be more decisive and confident when designing their mix proportions.

- Through the success of the study, the multi-scale thermodynamic computational platform would be implemented for long-term performance study by tracing the behavior of concrete through the course of time to propose maintenance plan abiding with preventive maintenance strategy currently endorsed in Japanese civil engineering situation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tanaka, Y.; Ishida, T.; Iwaki, I.; Sato, K. Multiple protection design for durable concrete bridge deck in cold regions. JSCE 2017, 5, 68–77. [Google Scholar] [CrossRef]

- Faria, R.; Azenha, M.; Figueiras, J.A. Modelling of concrete at early ages: Application to an externally restrained slab. Cem. Concr. Compos. 2006, 28, 572–585. [Google Scholar] [CrossRef]

- Jendele, L.; Smilauer, V.; Cervenka, J. Multiscale hydro-thermo-mechanical model for early-age and mature concrete structures. Adv. Eng. Softw. 2014, 72, 134–146. [Google Scholar] [CrossRef]

- Maekawa, K.; Ishida, T.; Kishi, T. Multi-Scale Modeling of Structural Concrete, 1st ed.; Taylor & Francis: New York, NY, USA, 2009; ISBN 978-0-415-46554-0. [Google Scholar]

- Maekawa, K.; Okamura, H.; Pimanmas, A. Non-Linear Mechanics of Reinforced Concrete; Spon Press: London, UK, 2003; ISBN 978-0-415-27126-4. [Google Scholar]

- Maekawa, K.; Ishida, T.; Kishi, T. Multi-scale Modeling of Concrete Performance—Integrated Material and Structural Mechanics. J. Adv. Concr. Technol. 2003, 1, 91–126. [Google Scholar] [CrossRef]

- Luan, Y.; Ishida, T. Enhanced shrinkage model based on early age hydration and moisture status in pore structure. J. Adv. Concr. Technol. 2013, 11, 360–373. [Google Scholar] [CrossRef]

- Biot, M.A. General Theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Gebreyouhannes, E.; Yoneda, T.; Ishida, T.; Maekawa, K. Multi-scale based simulation of shear critical reinforced concrete beams subjected to drying. J. Adv. Concr. Technol. 2014, 12, 363–377. [Google Scholar] [CrossRef]

- Hussain, S.E. Effect of microsilica and blast furnace slag on pore solution composition and alkali-silica reaction. Cem. Concr. Compos. 1991, 13, 219–225. [Google Scholar] [CrossRef]

- Dhir, R.K.; El-Mohr, M.A.K.; Dyer, T.D. Chloride binding in GGBS concrete. Cem. Concr. Res. 1996, 26, 1767–1773. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006; ISBN 978-0-07-158919-2. [Google Scholar]

- Iqbal, P.O.; Ishida, T. Modeling of chloride transport coupled with enhanced moisture conductivity in concrete exposed to marine environment. Cem. Concr. Res. 2009, 39, 329–339. [Google Scholar] [CrossRef]

- Ishida, T.; Luan, Y.; Sagawa, T.; Nawa, T. Modeling of early age behavior of blast furnace slag concrete based on micro-physical properties. Cem. Concr. Res. 2009, 41, 1357–1367. [Google Scholar] [CrossRef]

- Collepardi, M.; Borsoi, A.; Collepardi, S.; Olagot, J.J.O.; Troli, R. Effects of shrinkage reducing admixture in shrinkage compensating concrete under non-wet curing conditions. Cem. Concr. Res. 2005, 27, 704–708. [Google Scholar] [CrossRef]

- JSCE. Standard Specification for Concrete Structures—2007; JSCE: Tokyo, Japan, 2010; ISBN 978-4-8106-0752-9. [Google Scholar]

| Series | w/b (%) | Air (%) | Unit Content (kg/m3) | Seal-Cured | ||||

|---|---|---|---|---|---|---|---|---|

| W | C | Ex | S | G | ||||

| OPC55 | 55 | 4.5 | 172 | 313 | - | 834 | 997 | 7 days |

| OPC45 | 45 | 6 | 164 | 338 | 20 | 791 | 992 | 7 days |

| Series | w/b (%) | Air (%) | Unit Proportion (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|

| W | C | Ex | S | G | Ad | |||

| OPC53 | 52.9 | 4.5 | 166 | 314 | - | 802 | 1044 | 3.14 |

| OPC44 | 44 | 6 | 164 | 353 | 20 | 653 | 1112 | 2.24 |

| BFS44 | 44 | 6 | 160 | 344 | 20 | 662 | 1112 | 2.18 |

| Series | w/b (%) | Air (%) | Unit Proportion (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|

| W | C | Ex | S | G | Ad | |||

| OPC55 | 55 | 4.5 | 170 | 310 | - | 802 | 1044 | 3.14 |

| BFS55 | 55 | 4.5 | 170 | 310 | - | 802 | 1044 | 3.14 |

| OPC42 | 42 | 6 | 153 | 364 | - | 653 | 1112 | 2.24 |

| BFS42 | 42 | 6 | 153 | 364 | - | 662 | 1112 | 2.18 |

| BFS42-EX | 42 | 6 | 153 | 364 | 20 | 662 | 1112 | 2.18 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishida, T.; Pen, K.; Tanaka, Y.; Kashimura, K.; Iwaki, I. Numerical Simulation of Early Age Cracking of Reinforced Concrete Bridge Decks with a Full-3D Multiscale and Multi-Chemo-Physical Integrated Analysis. Appl. Sci. 2018, 8, 394. https://doi.org/10.3390/app8030394

Ishida T, Pen K, Tanaka Y, Kashimura K, Iwaki I. Numerical Simulation of Early Age Cracking of Reinforced Concrete Bridge Decks with a Full-3D Multiscale and Multi-Chemo-Physical Integrated Analysis. Applied Sciences. 2018; 8(3):394. https://doi.org/10.3390/app8030394

Chicago/Turabian StyleIshida, Tetsuya, Kolneath Pen, Yasushi Tanaka, Kosuke Kashimura, and Ichiro Iwaki. 2018. "Numerical Simulation of Early Age Cracking of Reinforced Concrete Bridge Decks with a Full-3D Multiscale and Multi-Chemo-Physical Integrated Analysis" Applied Sciences 8, no. 3: 394. https://doi.org/10.3390/app8030394