Chalcogenide Microstructured Optical Fibers for Mid-Infrared Supercontinuum Generation: Interest, Fabrication, and Applications

Abstract

:1. Introduction

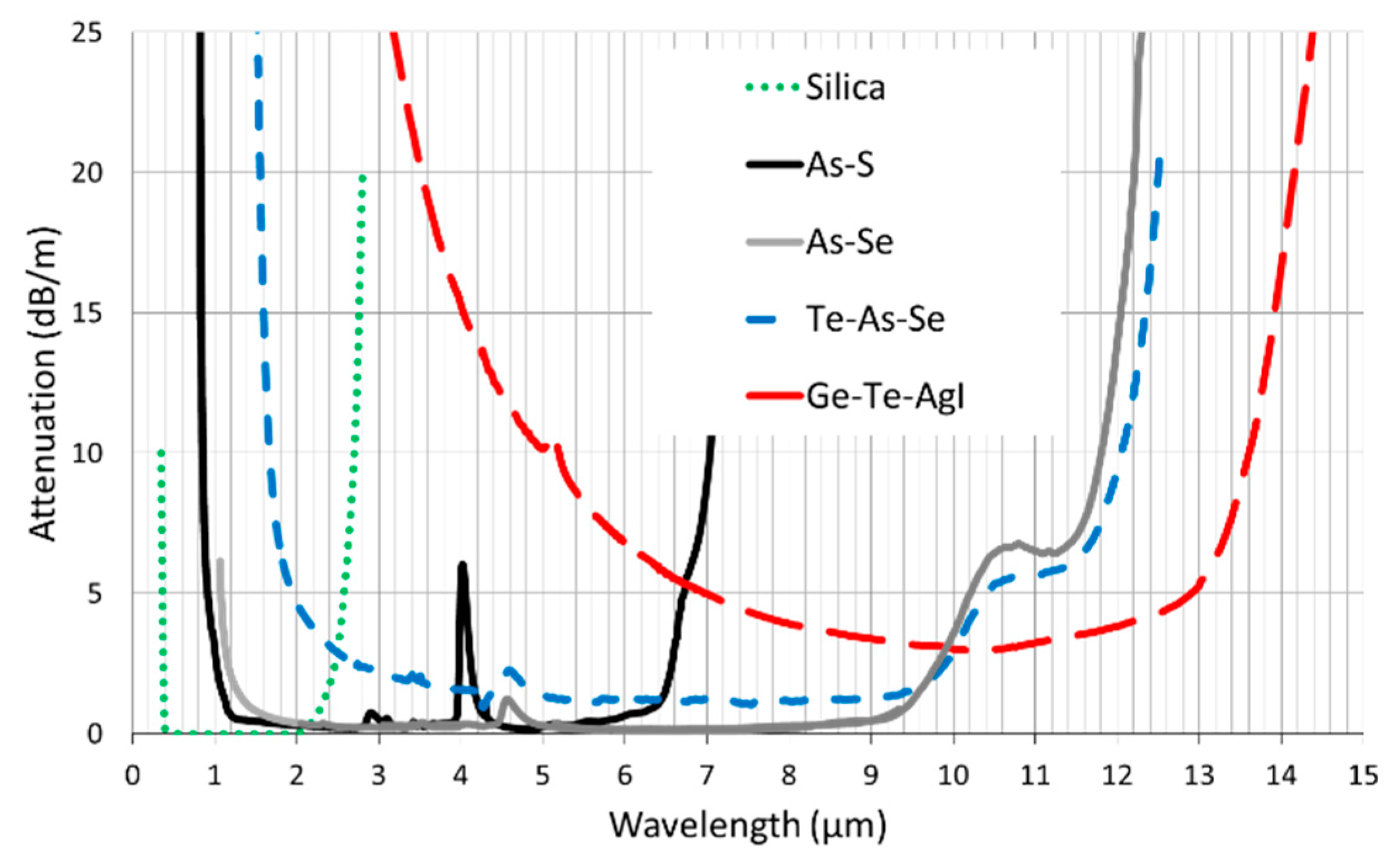

2. Why Choose Chalcogenide Microstructured Optical Fibers for Mid-Infrared Supercontinuum Generation?

3. Fabrications of Chalcogenide Fibers

4. Supercontinuum Generation in Chalcogenide MOFs

5. Applications of Mid-IR Supercontinuum Generation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dudley, J.M.; Genty, G.; Coen, S. Supercontinuum generation in photonics crystal fiber. Rev. Mod. Phys. 2006, 78, 1135–1184. [Google Scholar] [CrossRef]

- Schliesser, A.; Picqué, N.; Hänsch, T.W. Mid-infrared frequency combs. Nat. Photonics 2012, 6, 440–449. [Google Scholar] [CrossRef] [Green Version]

- Swiderski, J.; Michalska, M. Mid-infrared supercontinuum generation in a single-mode thulium-doped fiber amplifier. Laser Phys. Lett. 2013, 10, 035105. [Google Scholar] [CrossRef]

- Yin, K.; Zhu, R.; Zhang, B.; Jiang, T.; Chen, S.; Hou, J. Ultrahigh-brightness, spectrally-flat, short-wave infrared supercontinuum source for long-range atmospheric applications. Opt. Express 2016, 24, 20010–20020. [Google Scholar] [CrossRef] [PubMed]

- Lægsgaard, J.; Tu, H. How long wavelengths can one extract from silica-core fibers? Opt. Lett. 2013, 38, 4518–4521. [Google Scholar] [CrossRef] [PubMed]

- Savelii, I.; Mouawad, O.; Fatome, J.; Kibler, B.; Désévédavy, F.; Gadret, G.; Jules, J.-C.; Bony, P.-Y.; Kawashima, H.; Gao, W.; et al. Mid-infrared 2000-nm bandwidth supercontinuum generation in suspended–core microstructuered Sulfide and Tellurite optical fibers. Opt. Express 2012, 20, 27083–27093. [Google Scholar] [CrossRef] [PubMed]

- Domachuk, P.; Wolchover, N.A.; Cronin-Golomb, M.; Wang, A.; George, A.K.; Cordeiro, C.M.B.; Knight, J.C.; Omenetto, F.G. Over 4000 nm Bandwidth of Mid-IR Supercontinuum Generation in sub-centimeter Segments of Highly Nonlinear Tellurite PCFs. Opt. Express 2008, 16, 7161–7168. [Google Scholar] [CrossRef] [PubMed]

- Théberge, F.; Daigle, J.-F.; Vincent, D.; Mathieu, P.; Fortin, J.; Schmidt, B.E.; Thiré, N.; Légaré, F. Mid-infrared supercontinuum generation in fluoroindate fiber. Opt. Lett. 2013, 38, 4683–4685. [Google Scholar] [CrossRef] [PubMed]

- Qin, G.; Yan, X.; Kito, C.; Liao, M.; Chaudhari, C.; Suzuki, T.; Ohishi, Y. Ultrabroadband supercontinuum generation from ultraviolet to 6.28 μm in a fluoride fiber. Appl. Phys. Lett. 2009, 95, 161103. [Google Scholar] [CrossRef]

- Petersen, C.R.; Møller, U.; Kubat, I.; Zhou, B.; Dupont, S.; Ramsay, J.; Benson, T.; Sujecki, S.; Abdel-Moneim, N.; Tang, Z.; et al. Mid-infrared supercontinuum covering the 1.4–13.3 μm molecular fingerprint region using ultra-high NA chalcogenide step-index fibre. Nat. Photonics 2014, 8, 830–834. [Google Scholar] [CrossRef]

- El-Amraoui, M.; Fatome, J.; Jules, J.C.; Kibler, B.; Gadret, G.; Fortier, C.; Smektala, F.; Skripatchev, I.; Polacchini, C.F.; Messaddeq, Y.; et al. Strong infrared spectral broadening in low-loss As-S chalcogenide suspended core microstructured optical fibers. Opt. Express 2010, 18, 4547–4556. [Google Scholar] [CrossRef] [PubMed]

- Cheng, T.; Kanou, Y.; Deng, D.; Xue, X.; Matsumoto, M.; Misumi, T.; Suzuki, T.; Ohishi, Y. Fabrication and characterization of a hybrid four-hole AsSe2-As2S5 microstructured optical fiber with a large refractive index difference. Opt. Express 2014, 22, 13322–13329. [Google Scholar] [CrossRef] [PubMed]

- Martinez, R.A.; Plant, G.; Guo, K.; Janiszewski, B.; Freeman, M.J.; Maynard, R.L.; Islam, M.N.; Terry, F.L.; Alvarez, O.; Chenard, F.; et al. Mid-infrared supercontinuum generation from 1.6 to >11 um using concatenated step-index fluoride and chalcogenide fibers. Opt. Lett. 2018, 43, 296–299. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Zhang, B.; Xue, G.; Yin, K.; Hou, J. Thirteen watt all-fiber mid-infrared supercontinuum generation in a single mode ZBLAN fiber pumped by a 2 μm MOPA system. Opt. Lett. 2014, 39, 1849–1852. [Google Scholar] [CrossRef] [PubMed]

- Troles, J.; Brilland, L.; Caillaud, C.; Adam, J.L. Original designs of chalcogenide microstuctured optical fibers. Adv. Device Mater. 2017, 3, 7–13. [Google Scholar] [CrossRef] [Green Version]

- Savage, J.A. Optical properties of chalcogenide glasses. J. Non-Cryst. Solids 1982, 47, 101–116. [Google Scholar] [CrossRef]

- Snopatin, G.; Shiryaev, V.; Plotnichenko, V.; Dianov, E.; Churbanov, M. High-purity chalcogenide glasses for fiber optics. Inorg. Mater. 2009, 45, 1439–1460. [Google Scholar] [CrossRef]

- Churbanov, M.F. High-purity chalcogenide glasses as materials for fiber optics. J. Non-Cryst. Solids 1995, 184, 25–29. [Google Scholar] [CrossRef]

- Birks, T.A.; Knight, J.C.; Russell, P.S. Endlessly single-mode photonic crystal fiber. Opt. Lett. 1997, 22, 961–963. [Google Scholar] [CrossRef] [PubMed]

- Renversez, G.; Bordas, F.; Kuhlmey, B.T. Second mode transition in microstructured optical fibers: Determination of the critical geometrical parameter and study of the matrix refractive index and effects of cladding size. Opt. Lett. 2005, 30, 1264–1266. [Google Scholar] [CrossRef] [PubMed]

- Ballato, J.; Ebendorff-Heidepriem, H.; Zhao, J.; Petit, L.; Troles, J. Glass and Process Development for the Next Generation of Optical Fibers: A Review. Fibers 2017, 5, 11. [Google Scholar] [CrossRef]

- Petersen, C.; Engelsholm, R.D.; Markos, C.; Brilland, L.; Caillaud, C.; Trolès, J.; Bang, O. Increased mid-infrared supercontinuum bandwidth and average power by tapering large-mode-area chalcogenide photonic crystal fibers. Opt. Express 2017, 25, 15336–15347. [Google Scholar] [CrossRef] [PubMed]

- Hocdé, S.; Boussard-Plédel, C.; Fonteneau, G.; Lucas, J. Chalcogens based glasses for IR fiber chemical sensors. Solid State Sci. 2001, 3, 279–284. [Google Scholar] [CrossRef]

- Danto, S.; Thompson, D.; Wachtel, P.; Musgraves, J.D.; Richardson, K.; Giroire, B. A comparative study of purification routes for As2Se3 chalcogenide glass. Int. J. Appl. Glass Sci. 2013, 4, 31–41. [Google Scholar] [CrossRef]

- Shiryaev, V.S.; Churbanov, M.F. Recent advances in preparation of high-purity chalcogenide glasses for mid-IR photonics. J. Non-Cryst. Solids 2017, 475, 1–9. [Google Scholar] [CrossRef]

- Churbanov, M.F.; Shiryaev, V.S.; Scripachev, I.V.; Snopatin, G.E.; Gerasimenko, V.V.; Smetanin, S.V.; Fadin, I.E.; Plotnichenko, V.G. Optical fibers based on As-S-Se glass system. J. Non-Cryst. Solids 2001, 284, 146–152. [Google Scholar] [CrossRef]

- Kim, W.H.; Nguyen, V.Q.; Shaw, L.B.; Busse, L.E.; Florea, C.; Gibson, D.J.; Gattass, R.R.; Bayya, S.S.; Kung, F.H.; Chin, G.D.; et al. Recent progress in chalcogenide fiber technology at NRL. J. Non-Cryst. Solids 2016, 431, 8–15. [Google Scholar] [CrossRef]

- Kobelke, J.; Kirchhof, J.; Scheffler, M.; Schwuchow, A. Chalcogenide glass single mode fibres—Preparation and properties. J. Non-Cryst. Solids 1999, 256, 226–231. [Google Scholar] [CrossRef]

- Houizot, P.; Smektala, F.; Couderc, V.; Troles, J.; Grossard, L. Selenide glass single mode optical fiber for nonlinear optics. Opt. Mater. 2007, 29, 651–656. [Google Scholar]

- Troles, J.; Niu, Y.; Duverger-Arfuso, C.; Smektala, F.; Brilland, L.; Nazabal, V.; Moizan, V.; Desevedavy, F.; Houizot, P. Synthesis and characterization of chalcogenide glasses from the system Ga-Ge-Sb-S and preparation of a single-mode fiber at 1.55 μm. Mater. Res. Bull. 2008, 43, 976–982. [Google Scholar] [CrossRef]

- Chenard, F.; Alvarez, O.; Moawad, H. MIR chalcogenide fiber and devices. In Proceedings of the SPIE Conference on Optical Fibers and Sensors for Medical Diagnostics and Treatment Applications XV, San Francisco, CA, USA, 7–12 February 2015; Volume 9317, p. 93170B. [Google Scholar]

- Lafond, C.; Couillard, J.-F.; Delarosbil, J.-L.; Sylvain, F.; de Sandro, P. Recent improvements on mid-IR chalcogenide optical fibers. In Proceedings of the SPIE 40th Conference on Infrared Technology and Applications XL, Batimore, MD, USA, 5–9 May 2014; Volume 9070, p. 90701C. [Google Scholar]

- Monro, T.M.; West, Y.D.; Hewak, D.W.; Broderick, N.G.R.; Richardson, D.J. Chalcogenide holey fibres. Electron. Lett. 2000, 36, 1998–2000. [Google Scholar] [CrossRef]

- Brilland, L.; Smektala, F.; Renversez, G.; Chartier, T.; Troles, J.; Nguyen, T.N.; Traynor, N.; Monteville, A. Fabrication of complex structures of Holey fibers in chalcogenide glass. Opt. Express 2006, 14, 1280–1285. [Google Scholar] [CrossRef] [PubMed]

- Le Person, J.; Smektala, F.; Chartier, T.; Brilland, L.; Jouan, T.; Troles, J.; Bosc, D. Light guidance in new chalcogenide holey fibres from GeGaSbS glass. Mater. Res. Bull. 2006, 41, 1303–1309. [Google Scholar] [CrossRef]

- Sanghera, J.S.; Aggarwal, I.D.; Shaw, L.B.; Florea, C.M.; Pureza, P.; Nguyen, V.Q.; Kung, F. Nonlinear properties of chalcogenide glass fibers. J. Optoelectron. Adv. Mater. 2006, 8, 2148–2155. [Google Scholar]

- Brilland, L.; Troles, J.; Houizot, P.; Desevedavy, F.; Coulombier, Q.; Renversez, G.; Chartier, T.; Nguyen, T.N.; Adam, J.L.; Traynor, N. Interfaces impact on the transmission of chalcogenide photonic crystal fibres. J. Ceram. Soc. Jpn. 2008, 116, 1024–1027. [Google Scholar] [CrossRef]

- El-Amraoui, M.; Gadret, G.; Jules, J.C.; Fatome, J.; Fortier, C.; Désévédavy, F.; Skripatchev, I.; Messaddeq, Y.; Troles, J.; Brilland, L.; et al. Microstructured chalcogenide optical fibers from As2S3 glass: Towards new IR broadband sources. Opt. Express 2010, 18, 26655–26665. [Google Scholar] [CrossRef] [PubMed]

- Coulombier, Q.; Brilland, L.; Houizot, P.; Chartier, T.; Nguyen, T.N.; Smektala, F.; Renversez, G.; Monteville, A.; Méchin, D.; Pain, T.; et al. Casting method for producing low-loss chalcogenide microstructured optical fibers. Opt. Express 2010, 18, 9107–9112. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhang, J.; Yang, P.; Dai, S.; Wang, X.; Zhang, W. Fabrication of chalcogenide glass photonic crystal fibers with mechanical drilling. Opt. Fiber Technol. 2015, 26, 176–179. [Google Scholar] [CrossRef]

- Hudson, D.D.; Antipov, S.; Li, L.; Alamgir, I.; Hu, T.; El Amraoui, M.; Messaddeq, Y.; Rochette, M.; Jackson, S.D.; Fuerbach, A. Toward all-fiber supercontinuum spanning the mid-infrared. Optica 2017, 4, 1163–1166. [Google Scholar] [CrossRef]

- Deng, D.H.; Liu, L.; Tuan, H.T.; Kanou, Y.; Matsumoto, M.; Tezuka, H.; Suzuki, T.; Ohishi, Y. Mid-infrared supercontinuum covering 3–10 μm using a As2Se3 core and As2S5 cladding step-index chalcogenide fiber. J. Ceram. Soc. Jpn. 2016, 124, 103–105. [Google Scholar] [CrossRef]

- Mouawad, O.; Picot-Clemente, J.; Amrani, F.; Strutynski, C.; Fatome, J.; Kibler, B.; Desevedavy, F.; Gadret, G.; Jules, J.C.; Deng, D.; et al. Multioctave midinfrared supercontinuum generation in suspended-core chalcogenide fibers. Opt. Lett. 2014, 39, 2684–2687. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.Q.; El Amraoui, M.; Liao, M.S.; Kawashima, H.; Duan, Z.C.; Deng, D.H.; Cheng, T.L.; Suzuki, T.; Messaddeq, Y.; Ohishi, Y. Mid-infrared supercontinuum generation in a suspended-core As2S3 chalcogenide microstructured optical fiber. Opt. Express 2013, 21, 9573–9583. [Google Scholar] [CrossRef] [PubMed]

- Petersen, C.R.; Moselund, P.M.; Petersen, C.; Moller, U.; Bang, O. Spectral-temporal composition matters when cascading supercontinua into the mid-infrared. Opt. Express 2016, 24, 749–758. [Google Scholar] [CrossRef] [PubMed]

- Cheng, T.L.; Kanou, Y.; Xue, X.J.; Deng, D.H.; Matsumoto, M.; Misumi, T.; Suzuki, T.; Ohishi, Y. Mid-infrared supercontinuum generation in a novel AsSe2-As2S5 hybrid microstructured optical fiber. Opt. Express 2014, 22, 23019–23025. [Google Scholar] [CrossRef] [PubMed]

- Toupin, P.; Brilland, L.; Boussard-Pledel, C.; Bureau, B.; Mechin, D.; Adam, J.-L.; Troles, J. Comparison between chalcogenide glass single index and microstructured exposed-core fibers for chemical sensing. J. Non-Cryst. Solids 2013, 377, 217–219. [Google Scholar] [CrossRef]

- Baker, R.; Rogers, K.D.; Shepherd, N.; Stone, N. New relationships between breast microcalcifications and cancer. Br. J. Cancer 2010, 103, 1034–1039. [Google Scholar] [CrossRef] [PubMed]

- Kwak, J.T.; Kajdacsy-Balla, A.; Macias, V.; Walsh, M.; Sinha, S.; Bhargava, R. Improving Prediction of Prostate Cancer Recurrence using Chemical Imaging. Sci. Rep. 2015, 5, 8758. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernandez, D.C.; Bhargava, R.; Hewitt, S.M.; Levin, I.W. Infrared spectroscopic imaging for histopathologic recognition. Nat. Biotechnol. 2005, 23, 469–474. [Google Scholar] [CrossRef] [PubMed]

- Nallala, J.; Diebold, M.D.; Gobinet, C.; Bouche, O.; Sockalingum, G.D.; Piot, O.; Manfait, M. Infrared spectral histopathology for cancer diagnosis: A novel approach for automated pattern recognition of colon adenocarcinoma. Analyst 2014, 139, 4005–4015. [Google Scholar] [CrossRef] [PubMed]

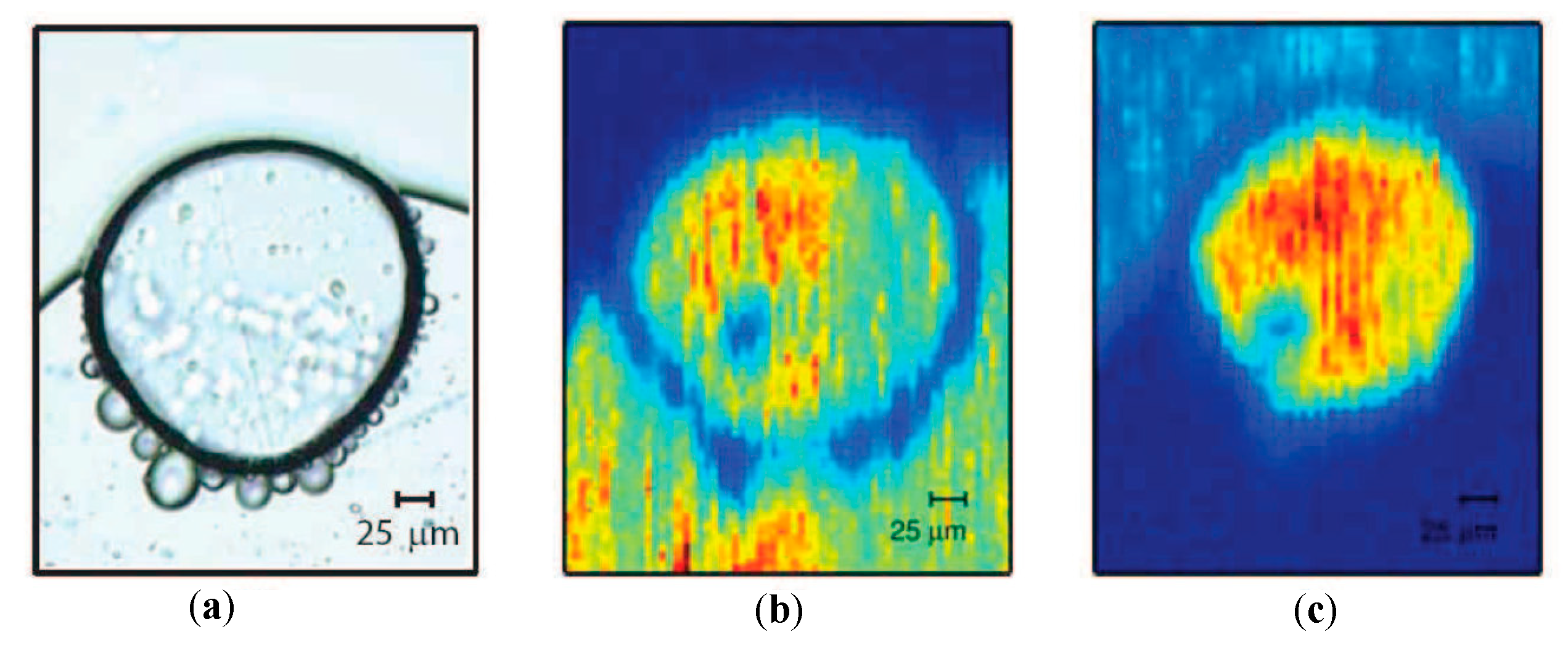

- Peterson, C.R.; Prtljaga, N.; Farries, M.; Ward, J.; Napier, B.; Lloyd, G.R.; Nallala, J.; Stone, N.; Bang, O. Mid-infrared multispectral tissue imaging using a chalcogenide fiber supercontinuum source. Opt. Lett. 2018, 43, 999–1002. [Google Scholar] [CrossRef] [PubMed]

- Dupont, S.; Peterson, C.; Thogerson, J.; Agger, C.; Bang, O. IR microscopy utilizing intense supercontinuum light source. Opt. Express 2012, 20, 4887–4892. [Google Scholar] [CrossRef] [PubMed]

- Farries, M.; Ward, J.; Lindsay, I.; Nallala, J.; Moselund, P. Fast hyper-spectral imaging of cytological samples in the mid-infrared wavelength region. In Proceedings of the Conference on Optical Biopsy XV-Toward Real-Time Spectroscopic Imaging and Diagnosis, San Francisco, CA, USA, 28 January–2 February 2017; Volume 10060, p. 100600Y. [Google Scholar]

- Borondics, F.; Jossent, M.; Sandt, C.; Lavoute, L.; Gaponov, D.; Hideur, A.; Dumas, P.; Février, S. Supercontinuum-based Fourier transform infrared spectromicroscopy. Optica 2018, 5, 378–381. [Google Scholar] [CrossRef]

| Fiber Composition | Spectral Coverage | Pump Wavelength (Pulse Duration) | Output Average Power | References |

|---|---|---|---|---|

| As2S3 | 2.1–3.2 μm | 2.5 μm (100 fs) | - | [36] |

| As2S3 | 1–2.6 μm | 1.55 μm (400 fs) | - | [38] |

| AsSe2-As2S5 | 1.2–5.37 μm | 3.3 μm (200 fs) | 214 mW (input) | [46] |

| As38Se62 | 1.9–7.1 μm | Cascading from 1.55 to 4.5 µm (3 ns) | 6.5 mW | [45] |

| Ge10As22Se68 | 1–11.5 μm | 4 μm (252 fs) | 35.4 mW | [22] |

| Ge10As22Se68 | 1–8 μm | 4 μm (252 fs) | 57.3 mW | [22] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Meneghetti, M.; Troles, J.; Adam, J.-L. Chalcogenide Microstructured Optical Fibers for Mid-Infrared Supercontinuum Generation: Interest, Fabrication, and Applications. Appl. Sci. 2018, 8, 1637. https://doi.org/10.3390/app8091637

Wu Y, Meneghetti M, Troles J, Adam J-L. Chalcogenide Microstructured Optical Fibers for Mid-Infrared Supercontinuum Generation: Interest, Fabrication, and Applications. Applied Sciences. 2018; 8(9):1637. https://doi.org/10.3390/app8091637

Chicago/Turabian StyleWu, Yiming, Marcello Meneghetti, Johann Troles, and Jean-Luc Adam. 2018. "Chalcogenide Microstructured Optical Fibers for Mid-Infrared Supercontinuum Generation: Interest, Fabrication, and Applications" Applied Sciences 8, no. 9: 1637. https://doi.org/10.3390/app8091637