Detection and Treatment Methods for Perfluorinated Compounds in Wastewater Treatment Plants

Abstract

:1. Introduction

2. Research Content and Method

2.1. Current Status of Wastewater Treatment Plants

2.1.1. Survey Area

2.1.2. Analysis of PFCs

2.1.3. Pilot Test

3. Results and Discussion

3.1. Variation in Amount of Inflow Water

3.2. Monthly PFCs Concentration Change

3.3. Correlation of PFCs between Cities

3.4. PFCs Removal Efficiency Through Pilot Test

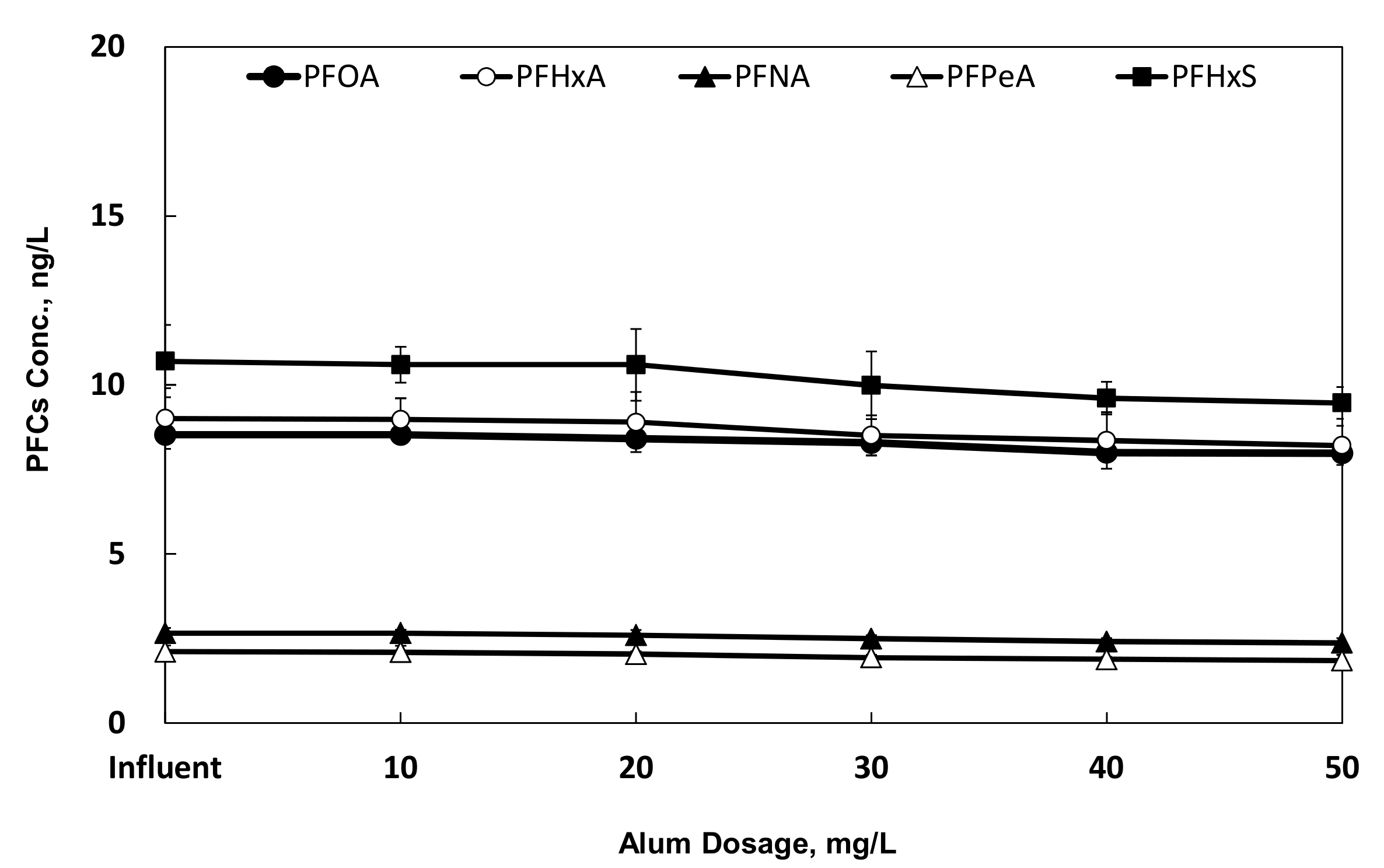

3.4.1. Removal Variation by Coagulation-Sedimentation

3.4.2. Removal Variation by Ozone Oxidation

3.4.3. Removal Change by Chlorine Injection

3.4.4. Removal Variation by Activated Carbon Adsorption

3.5. Proposal of an Optimal PFCs Treatment Process

4. Conclusions

- (1)

- The influent/effluent removal of the existing biological treatment process was able to remove some PFNA, PFPeA, and PFHxS, but most of the other compounds could not be removed through biological treatment.

- (2)

- The correlational analysis results showed that there was a high correlation in the wastewater among PFOA, PFHxA, and PFNA, which contain carboxyl groups. The PFCs correlational research did not produce data that could be representative. Thus, further research is required.

- (3)

- The pilot batch test with the influent to the treatment plant showed that about 10% of PFCs was removed by an injection of 40 to 50 mg/L of Alum in the coagulation-sedimentation test. For the pilot continuous test, the removal in the ozone test and chlorine injection test was negligible regardless of the oxidant dose. The activated carbon adsorption test showed that about 60% to 70% of PFCs was removed after EBCT 5 min, and removing over 90% of PFCs after 15 min EBCT was found to be possible.

- (4)

- The pilot test results showed that PFHxS removal in single ozone or activated carbon process was low. However, it improved in the continuous ozone process followed by the activated carbon process. This demonstrated that ozone oxidization would promote the removal during the next process. Therefore, the continuous oxidization process, such as the ozone process, followed by an adsorption process using activated carbon, would be a desirable process enabling high removal.

Author Contributions

Funding

Conflicts of Interest

References

- Cho, C.R.; Eom, I.C.; Kim, E.J.; Kim, S.J.; Choi, K.H.; Cho, H.S.; Yoon, J.H. Evaluation of the level of PFOS and PFOA in environmental media from industrial area and four major river basin. J. Kor. Soc. Environ. Anal. 2009, 12, 296–306. [Google Scholar]

- Cho, C.; Cho, J.-G.; Eom, I.-C.; Lee, B.-C.; Kim, S.-J.; Choi, K.; Yoon, J. Bioconcentration of perfluorinated compounds in fish from Gulpo stream. Environ. Health Toxicol. 2010, 25, 229–240. [Google Scholar]

- Cho, C.R.; Lee, D.H.; Lee, B.C.; Kim, S.J.; Choi, K.H.; Yoon, J.H. Residual concentrations of perfluorinated compounds in water samples of Anseong and Gyeongan streams and their spectroscopic characteristics. J. Kor. Soc. Environ. Anal. 2010, 13, 226–236. [Google Scholar]

- Hardell, E.; Kärrman, A.; van Bavel, B.; Bao, J.; Carlberg, M.; Hardell, L. Case–control study on perfluorinated alkyl acids (PFAAs) and the risk of prostate cancer. Environ. Int. 2014, 63, 35–39. [Google Scholar]

- United Nations Environmental Programme; UNEP/POPS/COP.4/38; United Nations: New York, NY, USA, 2009.

- Ding, G.H.; Frmel, T.; van den Brandhof, E.J.; Baerselman, R.; Peijnenburg, W.J. Acute toxicity of poly- and perfluorinated compounds to two cladocerans, Daphnia magna and Chydorus sphaericus. Environ. Toxicol. Chem. 2012, 31, 605–610. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Niu, J.; Zhang, L.; Shi, J. Toxicity assessment of perfluorinated carboxylic acids (PFCAs) towards the rotifer Brachionus calyciflorus. Sci. Total Environ. 2014, 491–492, 266–270. [Google Scholar] [CrossRef] [PubMed]

- Stahl, L.L.; Snyder, B.D.; Olsen, A.R.; Kincaid, T.M.; Wathen, J.B.; McCarty, H.B. Perfluorinated compounds in fish from U.S. urban rivers and the Great Lakes. Sci. Total Environ. 2014, 499, 185–195. [Google Scholar] [CrossRef] [PubMed]

- Park, C.-G. Study on concentration distribution and removal characteristics of micro-pollutants in the middle Nakdong river basin. Ph.D. Thesis, Yeungnam University, Gyeongsan, Korea, 2013. [Google Scholar]

- Roth, N.; Wilks, M.F. Neurodevelopmental and neurobehavioural effects of polybrominated and perfluorinated chemicals: A systematic review of the epidemiological literature using a quality assessment scheme. Toxicol. Lett. 2014, 230, 271–281. [Google Scholar] [CrossRef] [PubMed]

- Shin, M.Y.; Im, J.K.; Kho, Y.L.; Choi, K.S.; Zoh, K.D. Quantitative determination of PFOA and PFOS in the effluent of sewage treatment plants and in Han river. J. Environ. Health Sci. 2009, 35, 334–342. [Google Scholar] [CrossRef]

- Ahrens, L.; Barber, J.L.; Xie, Z.; Ebinshaus, R. Longitudinal and latitudinal distribution of perfluoroalkaly compounds in surface water of the Atlantic ocean. Environ. Sci. Technol. 2009, 43, 3122–3127. [Google Scholar] [CrossRef] [PubMed]

- So, M.K.; Miyake, Y. Perfluorinated compounds in the Pearl river and Yangtze river of China. Chemosphere 2007, 68, 2085–2095. [Google Scholar] [CrossRef] [PubMed]

- Du, Z.; Deng, S.; Bei, Y.; Huang, Q.; Wang, B.; Huang, J.; Yu, G. Adsorption behavior and mechanism of perfluorinated compounds on various adsorbents-a review. J. Hazard Mater. 2014, 274, 443–454. [Google Scholar] [CrossRef] [PubMed]

- Ochoa-Herrera, V.; Sierra-Alvarez, R. Removal of perfluorinated surfactants by sorption onto granular activated carbon, Zeolite and sludge. Chemosphere 2008, 72, 1588–1593. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Conditions |

|---|---|

| LC | Waters, ACQUITY, HPLC |

| MS | SCIEX, API-4000, Q-Trap |

| Column | Waters, BEH C18, 2.1 × 50 mm, 1.7μm |

| Mobile phase | A: 10 mM ammonium acetate in water |

| B: Acetonitrile | |

| Gradient | Time (min) |

| Solvent B (%) | |

| Flow rate | 270 μL/min |

| Injection volume | 5 μL |

| Column temp. | 40 °C |

| Ionization mode | Negative |

| Curtain Gas | 40 |

| Collision Gas | 8 |

| Ion Spray Voltage | −4500 V |

| R2 | Other Cities | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Compounds | PFOA | PFHxA | PFNA | PFPeA | PFHxS | |||||

| PFOA | 1 | - | 0.050 | xx | 0.013 | xx | 0.141 | xx | 0.486 | △ |

| PFHxA | - | - | 1 | - | 0.516 | △ | 0.583 | △ | 0.090 | xx |

| PFNA | - | - | - | - | 1 | - | 0.160 | xx | 0.019 | xx |

| PFPeA | - | - | - | - | - | - | 1 | - | 0.098 | xx |

| PFHxS | - | - | - | - | - | - | - | - | 1 | - |

| Process | PFCs | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PFOA | PFHxA | PFNA | PFPeA | PFHxS | |||||||

| Bat * | Conti ** | Bat | Conti | Bat | Conti | Bat | Conti | Bat | Conti | ||

| Bioreactor | X | X | △ | △ | X | X | △ | △ | X | X | |

| Coagulation-Sedimentation | X | △ | X | △ | △ | △ | △ | △ | △ | △ | |

| Ozonation | X | △ | X | △ | X | △ | X | △ | X | △ | |

| Activated carbon treatment | EBCT 5 min | ◎ | ◎ | O | O | ◎ | ◎ | O | O | O | ◎ |

| EBCT 15 min | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| Chlorination | X | ◎ | X | ◎ | X | ◎ | X | ◎ | X | ◎ | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-h.; Cho, Y.-j.; Lee, M.; Lee, B.-D. Detection and Treatment Methods for Perfluorinated Compounds in Wastewater Treatment Plants. Appl. Sci. 2019, 9, 2500. https://doi.org/10.3390/app9122500

Lee S-h, Cho Y-j, Lee M, Lee B-D. Detection and Treatment Methods for Perfluorinated Compounds in Wastewater Treatment Plants. Applied Sciences. 2019; 9(12):2500. https://doi.org/10.3390/app9122500

Chicago/Turabian StyleLee, Shun-hwa, Yeon-jung Cho, Miran Lee, and Byung-Dae Lee. 2019. "Detection and Treatment Methods for Perfluorinated Compounds in Wastewater Treatment Plants" Applied Sciences 9, no. 12: 2500. https://doi.org/10.3390/app9122500

APA StyleLee, S.-h., Cho, Y.-j., Lee, M., & Lee, B.-D. (2019). Detection and Treatment Methods for Perfluorinated Compounds in Wastewater Treatment Plants. Applied Sciences, 9(12), 2500. https://doi.org/10.3390/app9122500