Directional Force Feedback: Mechanical Force Concentration for Immersive Experience in Virtual Reality

Abstract

:1. Introduction

2. Related Works

3. Methodology

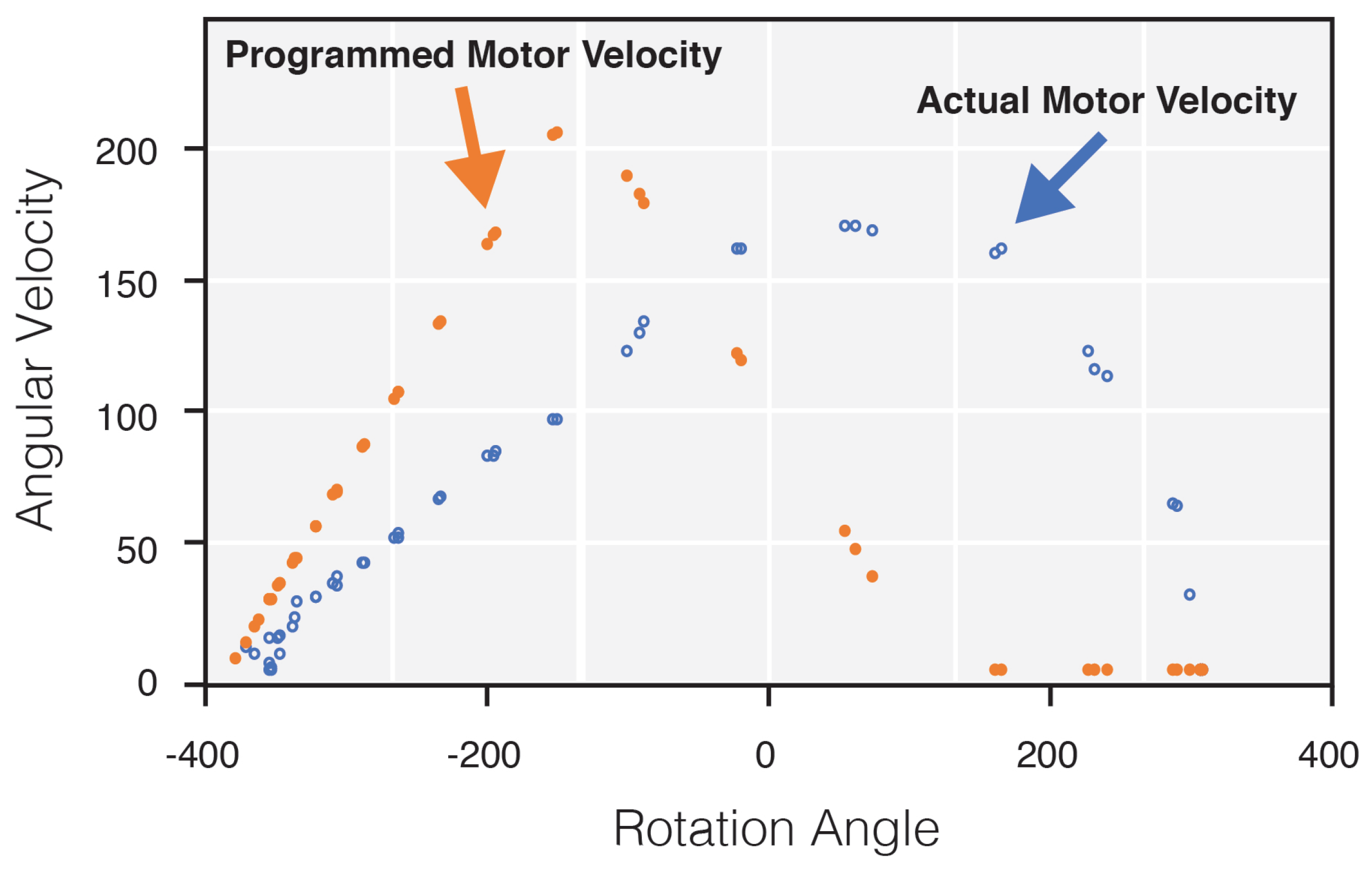

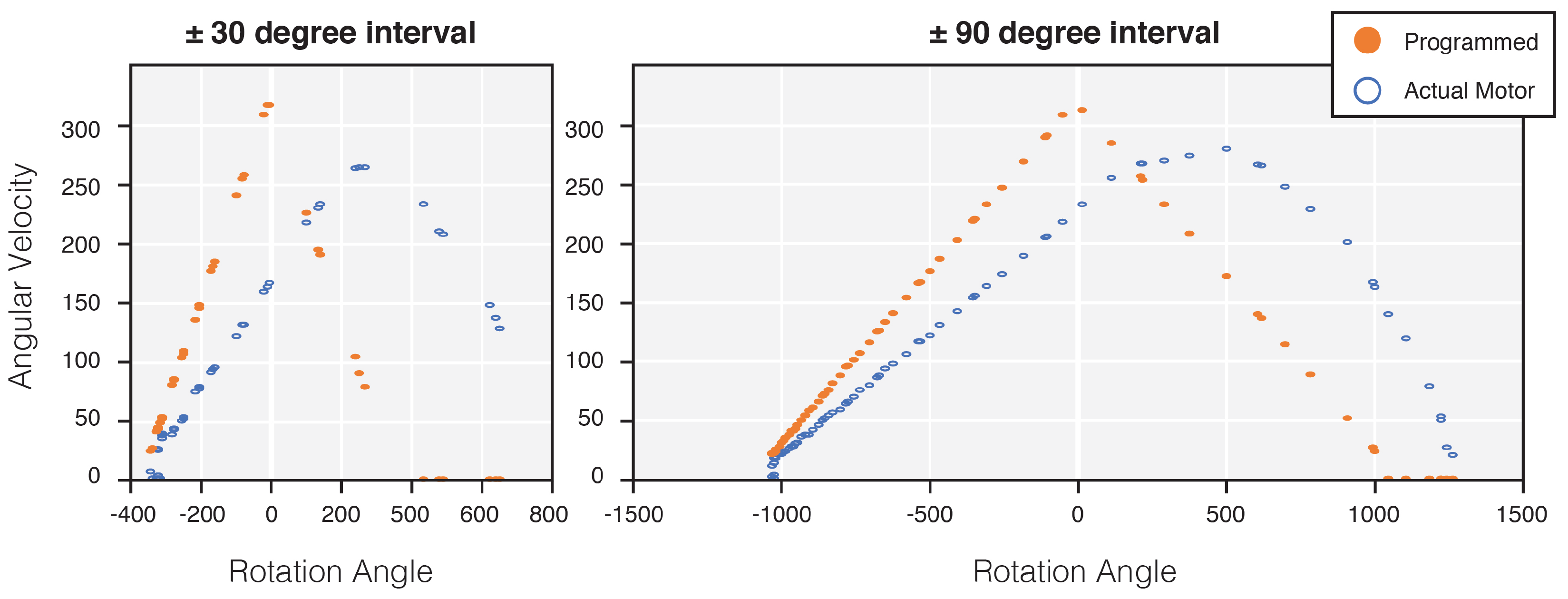

3.1. Rotational Speed Control

3.2. Rotation Angle Interval Control

3.3. Motor Control on Gravity and Rotational Rebound

3.4. Degree of Force Concentration

4. Implementation

4.1. Device Design

4.2. Device Performance Optimization

4.3. User Study

4.3.1. Participants

4.3.2. Study 1

4.3.3. Study 2

4.3.4. Study 3

5. Conclusions and Discussion

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DFF | Directional Force Feedback |

| VR | Virtual Reality |

References

- Mazuryk, T.; Gervautz, M. Virtual Reality-History, Applications, Technology and Future, 1996.

- Azmandian, M.; Hancock, M.; Benko, H.; Ofek, E. Haptic retargeting: Dynamic repurposing of passive haptics for enhanced virtual reality experiences. In Proceedings of the CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016. [Google Scholar]

- Fang, Y.-M.; Lin, C. The Usability Testing of VR Interface for Tourism Apps. Appl. Sci. 2019, 9, 3215. [Google Scholar] [CrossRef]

- Román-Ibáñez, V.; Pujol-López, F.A.; Mora-Mora, H.; Pertegal-Felices, M.L.; Jimeno-Morenilla, A. A Low-Cost Immersive Virtual Reality System for Teaching Robotic Manipulators Programming. Sustainability 2018, 10, 1102. [Google Scholar] [CrossRef]

- Tang, M. From agent to avatar. In Proceedings of the Conference Association Comput Aided Architectural Design Research in Asia, Beijing, China, 17–19 May 2018. [Google Scholar]

- Pedroli, E.; Greci, L.; Colombo, D.; Serino, S.; Cipresso, P.; Arlati, S.; Mondellini, M.; Boilini, L.; Giussani, V.; Goulene, K.; et al. Characteristics, usability, and users experience of a system combining cognitive and physical therapy in a virtual environment: Positive bike. Sensors 2018, 18, 2343. [Google Scholar] [CrossRef]

- Fan, Y.C.; Chih, W. A Virtual Reality Soldier Simulator with Body Area Networks for Team Training. Sensors 2019, 19, 451. [Google Scholar] [CrossRef]

- Leite, S.; Dias, M.S.; Eloy, S.; Freitas, J.; Marques, S.; Pedro, T.; Ourique, L. Physiological Arousal Quantifying Perception of Safe and Unsafe Virtual Environments by Older and Younger Adults. Sensors 2019, 19, 2447. [Google Scholar] [CrossRef]

- Placidi, G.; Cinque, L.; Polsinelli, M.; Spezialetti, M. Measurements by A LEAP-Based Virtual Glove for the Hand Rehabilitation. Sensors 2018, 18, 834. [Google Scholar] [CrossRef]

- Serino, S.; Morganti, F.; Colombo, D.; Pedroli, E.; Cipresso, P.; Riva, G. Disentangling the contribution of spatial reference frames to executive functioning in healthy and pathological aging: An experimental study with virtual reality. Sensors 2018, 18, 1783. [Google Scholar] [CrossRef]

- Kim, H.; Choi, Y. Performance Comparison of User Interface Devices for Controlling Mining Software in Virtual Reality Environments. Appl. Sci. 2019, 9, 2584. [Google Scholar] [CrossRef]

- Mihelj, M.; Novak, D.; Beguš, S. Virtual Reality Technology and Applications; Tzafestas, S.G., Ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Benko, H.; Holz, C.; Sinclair, M.J.; Ofek, E. Normaltouch and texturetouch: High-fidelity 3D haptic shape rendering on handheld virtual reality controllers. In Proceedings of the 29th Annual Symposium on User Interface Software and Technology, Tokyo, Japan, 16–19 October 2016. [Google Scholar]

- Tsalamlal, M.Y.; Issartel, P.; Ouarti, N.; Ammi, M. HAIR: Haptic feedback with a mobile AIR jet. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014. [Google Scholar]

- Hachisu, T.; Fukumoto, M. VacuumTouch: Attractive force feedback interface for haptic interactive surface using air suction. IEEE Comput. Graph. Appl. 2014, 25, 44–47. [Google Scholar]

- Gu, X.; Zhang, Y.; Sun, W.; Bian, Y.; Zhou, D.; Kristensson, P.O. Dexmo: An inexpensive and lightweight mechanical exoskeleton for motion capture and force feedback in VR. In Proceedings of the CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016. [Google Scholar]

- Shigeyama, J.; Hashioto, T.; Yoshida, S.; Aoki, T.; Narumi, T.; Tanikawa, T.; Hirose, M. Transcalibur: Weight moving VR controller for dynamic rendering of 2D shape using haptic shape illusion. In Proceedings of the ACM SIGGRAPH 2018 Emerging Technologies, Vancouver, BC, Canada, 12–16 August 2018. [Google Scholar]

- Maimani, A.A.; Roudaut, A. Frozen suit: Toward a changeable stiffness suit and its application for haptic games. In Proceedings of the CHI Conference on Human Factors in Computing Systems, Denver, CO, USA, 6–11 May 2017. [Google Scholar]

- Rietzler, M.; Geiselhart, F.; Gugenheimer, J.; Rukzio, E. Breaking the tracking: Enabling weight perception using perceivable tracking offsets. In Proceedings of the CHI Conference on Human Factors in Computing Systems, Montreal QC, Canada, 21–26 April 2018. [Google Scholar]

- Zenner, A.; Krüger, A. Shifty: A weight-shifting dynamic passive haptic proxy to enhance object perception in virtual reality. IEEE Trans. Vis. Comput. Graph. 2017, 23, 1285–1294. [Google Scholar] [CrossRef] [PubMed]

- Choi, I.; Culbertson, H.; Miller, M.R.; Olwal, A.; Follmer, S. Grabity: A wearable haptic interface for simulating weight and grasping in virtual reality. In Proceedings of the 30th Annual ACM Symposium on User Interface Software and Technology, Quebec City, QC, Canada, 22–25 October 2017. [Google Scholar]

- Suzuki, Y.; Kobayash, M. Air jet driven force feedback in virtual reality. IEEE Comput. Graph. Appl. 2005, 25, 44–47. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.W.; Duh, H.B.; Parker, D.E.; Abi–Rached, H.; Furness, T. Effects of field of view on presence, enjoyment, memory, and simulator sickness in a virtual environment. In Proceedings of the Virtual Reality, Orlando, FL, USA, 24–28 March 2002. [Google Scholar]

| AX-18A | MX-64R | MX-106R | |

|---|---|---|---|

| Resolution (deg/step) | 0.2930 | 0.0879 | 0.0879 |

| Stall Torque (Nm) | 1.8 | 6.0 | 8.4 |

| Max Baud Rate (Mbps) | 1 | 4.5 | 4.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ban, S.; Hyun, K.H. Directional Force Feedback: Mechanical Force Concentration for Immersive Experience in Virtual Reality. Appl. Sci. 2019, 9, 3692. https://doi.org/10.3390/app9183692

Ban S, Hyun KH. Directional Force Feedback: Mechanical Force Concentration for Immersive Experience in Virtual Reality. Applied Sciences. 2019; 9(18):3692. https://doi.org/10.3390/app9183692

Chicago/Turabian StyleBan, Seonghoon, and Kyung Hoon Hyun. 2019. "Directional Force Feedback: Mechanical Force Concentration for Immersive Experience in Virtual Reality" Applied Sciences 9, no. 18: 3692. https://doi.org/10.3390/app9183692