Processing of Single-Walled Carbon Nanotubes with Femtosecond Laser Pulses

Abstract

:1. Introduction

2. Materials and Methods

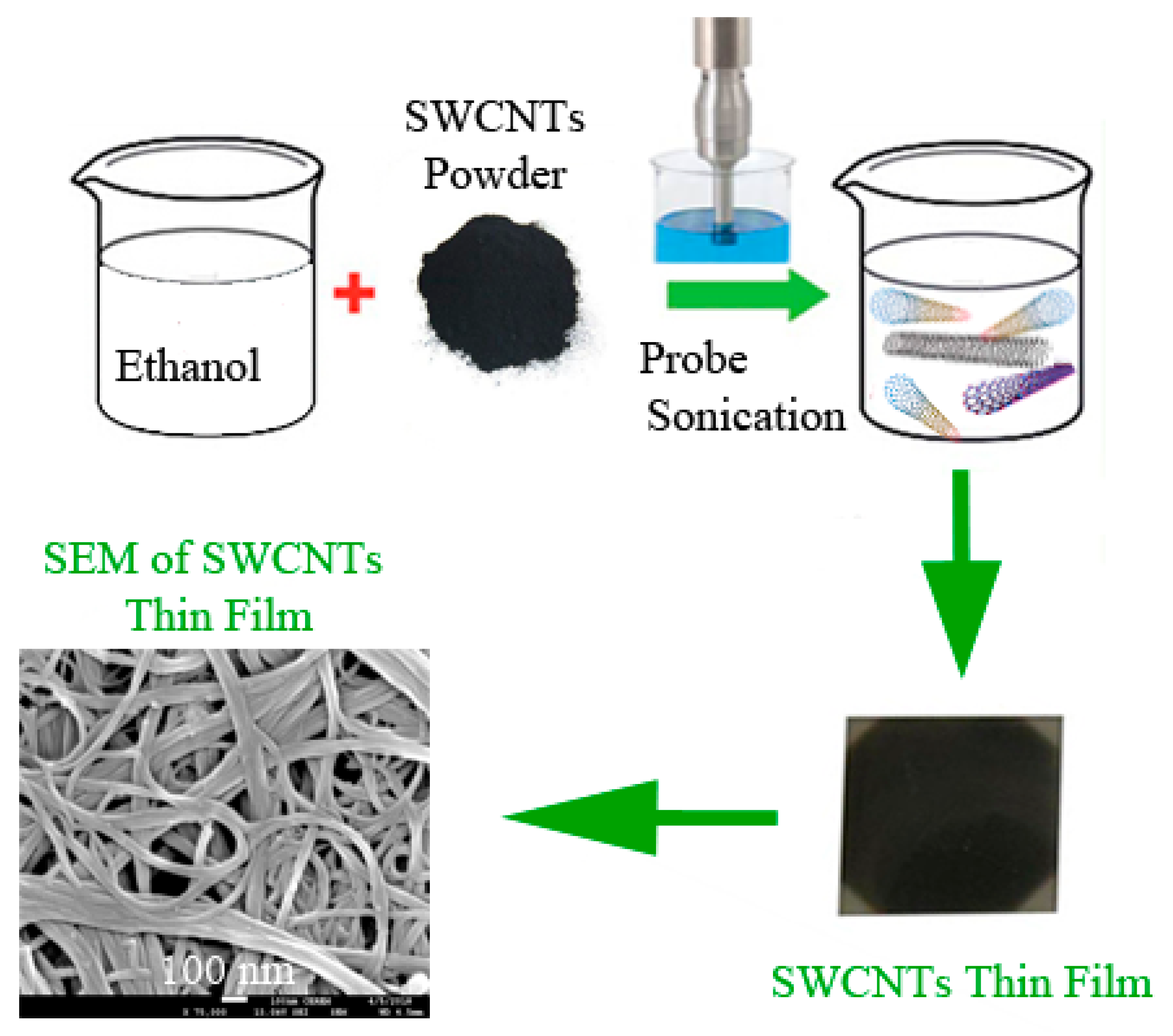

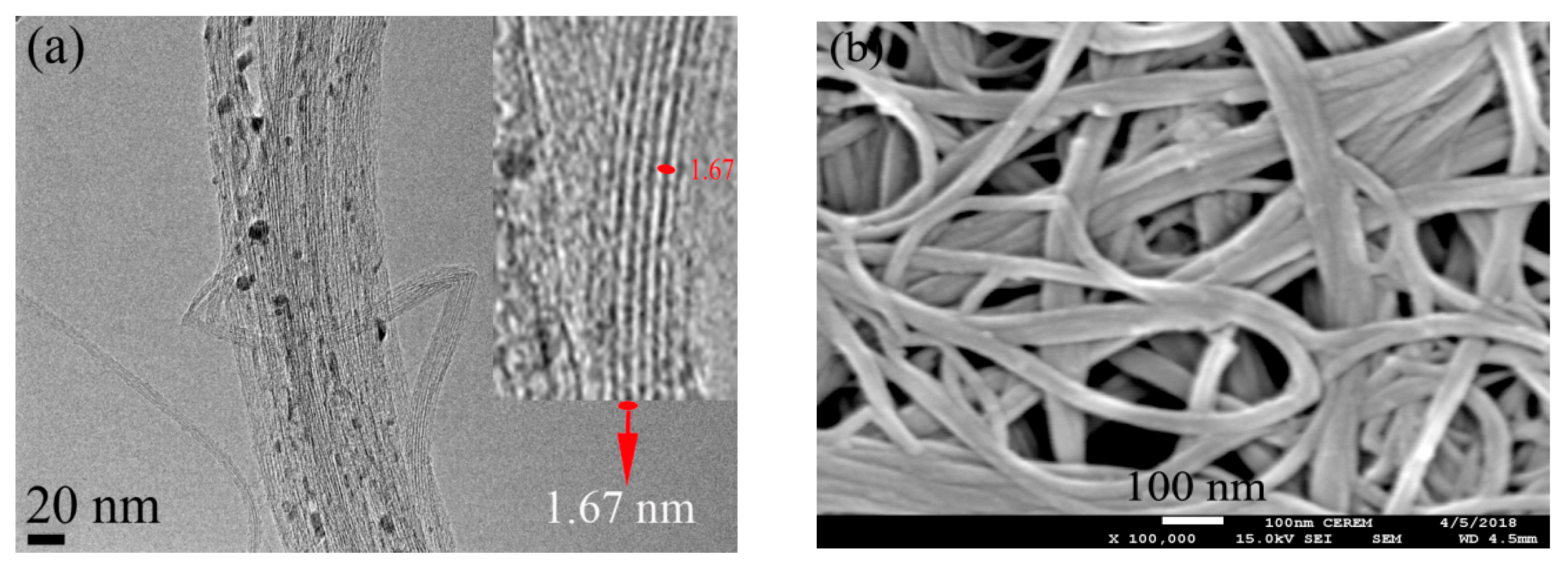

2.1. Sample Preparation

2.2. Laser Irradiation

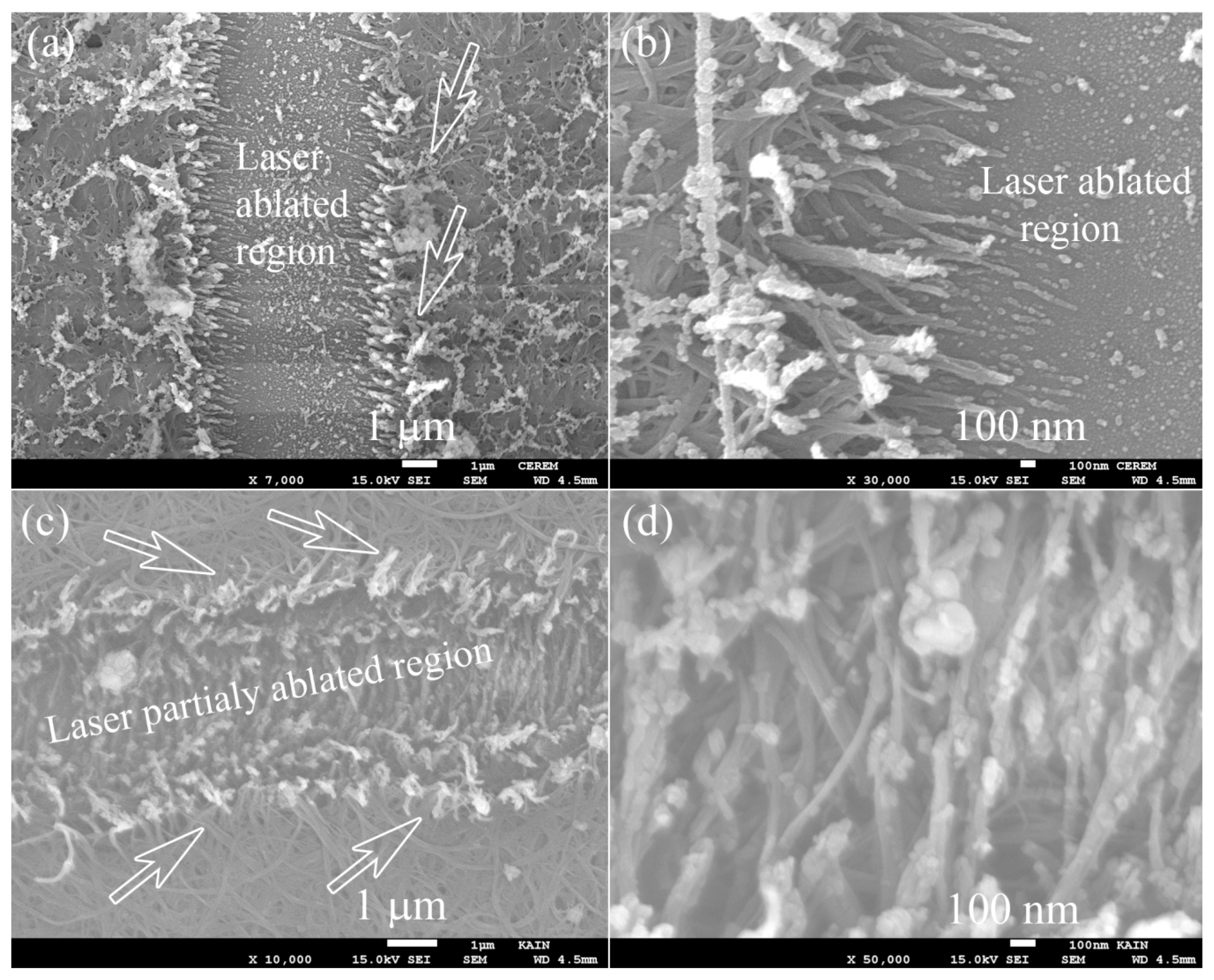

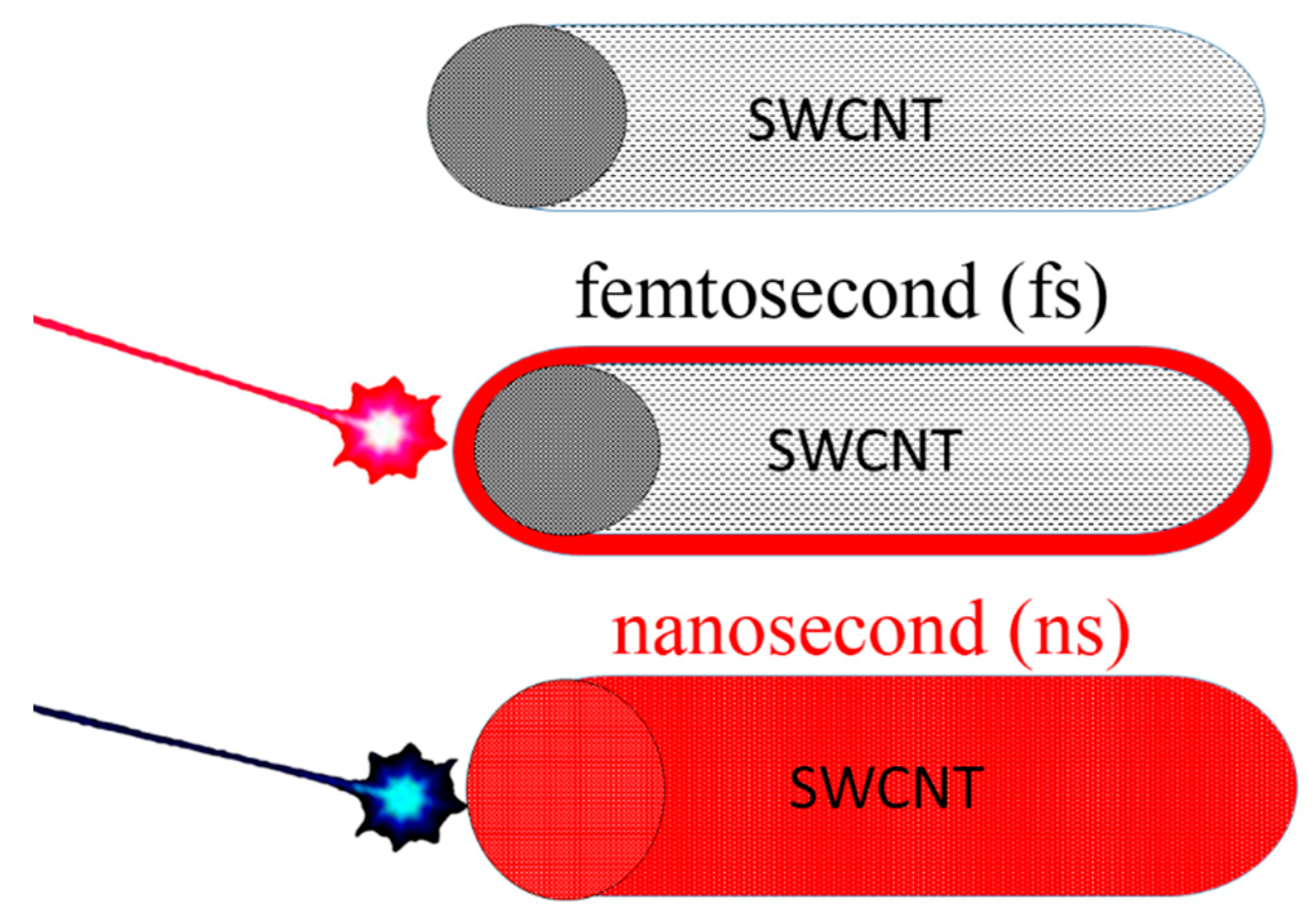

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, B.; Liu, X.F.; Qiu, J.R. Single femtosecond laser beam induced nanogratings in transparent media-mechanisms and applications. J. Mater. 2019, 5, 1–14. [Google Scholar] [CrossRef]

- Ha, J.; Jung, H.Y.; Hao, J.; Li, B.; Raeliarijaona, A.; Alarcón, J.; Terrones, H.; Ajayan, P.M.; Jung, Y.J.; Kim, J.; et al. Ultrafast structural evolution and formation of linear carbon chains in single-walled carbon nanotube networks by femtosecond laser irradiation. Nanoscale 2017, 9, 16627–16631. [Google Scholar] [CrossRef] [PubMed]

- Rahim, K.; Mian, A. A review on laser processing in electronic and mems packaging. J. Electron. Packag. 2017, 139, 030801. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, A.D.; Li, B.; Cui, T.H.; Lu, Y.F. Electrons dynamics control by shaping femtosecond laser pulses in micro/nanofabrication: Modeling, method, measurement and application. Light Sci. Appl. 2018, 7, 17134. [Google Scholar] [CrossRef] [PubMed]

- Hélie, D.; Bégin, M.; Lacroix, F.; Vallée, R. Reinforced direct bonding of optical materials by femtosecond laser welding. Appl. Opt. 2012, 51, 2098–2106. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Cheng, G. Direct welding of glass and metal by 1 khz femtosecond laser pulses. Appl. Opt. 2015, 54, 8957–8961. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.F.; Long, J.Y.; Cai, M.Y.; Lin, Y.; Fan, P.X.; Zhang, H.J.; Zhong, M.L. Femtosecond laser fabricated micro/nano interface structures toward enhanced bonding strength and heat transfer capability of w/cu joining. Mater. Des. 2017, 114, 185–193. [Google Scholar] [CrossRef]

- Jiang, D.F.; Long, J.Y.; Han, J.P.; Cai, M.Y.; Lin, Y.; Fan, P.X.; Zhang, H.J.; Zhong, M.L. Comprehensive enhancement of the mechanical and thermo-mechanical properties of w/cu joints via femtosecond laser fabricated micro/nano interface structures. Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process. 2017, 696, 429–436. [Google Scholar] [CrossRef]

- Mizuguchi, Y.; Tamaki, T.; Fukuda, T.; Hatanaka, K.; Juodkazis, S.; Watanabe, W. Dendrite-joining of air-gap-separated pmma substrates using ultrashort laser pulses. Opt. Mater. Express 2017, 7, 2141–2149. [Google Scholar] [CrossRef]

- Ringleb, F.; Eylers, K.; Teubner, T.; Schramm, H.P.; Symietz, C.; Bonse, J.; Andree, S.; Heidmann, B.; Schmid, M.; Kruger, J.; et al. Growth and shape of indium islands on molybdenum at micro-roughened spots created by femtosecond laser pulses. Appl. Surf. Sci. 2017, 418, 548–553. [Google Scholar] [CrossRef]

- Roth, G.L.; Rung, S.; Hellmann, R. Ultrashort pulse laser micro-welding of cyclo-olefin copolymers. Opt. Lasers Eng. 2017, 93, 178–181. [Google Scholar] [CrossRef]

- Zhang, G.D.; Bai, J.; Zhao, W.; Zhou, K.M.; Cheng, G.H. Interface modification based ultrashort laser microwelding between sic and fused silica. Opt. Express 2017, 25, 1702–1709. [Google Scholar] [CrossRef]

- Zhang, G.D.; Stoian, R.; Zhao, W.; Cheng, G.H. Femtosecond laser bessel beam welding of transparent to non-transparent materials with large focal-position tolerant zone. Opt. Express 2018, 26, 917–926. [Google Scholar] [CrossRef]

- Li, R.; Gong, W.; He, Q.; Li, Q.; Lu, W.; Zhu, W. Joining cross-stacked carbon nanotube architecture with covalent bonding. Appl. Phys. Lett. 2017, 110, 183101. [Google Scholar] [CrossRef]

- Nanostructure evolution in joining of al and fe nanoparticles with femtosecond laser irradiation. J. Appl. Phys. 2014, 115, 134305. [CrossRef]

- Zolotovskaya, S.A.; Tang, G.; Wang, Z.; Abdolvand, A. Surface plasmon resonance assisted rapid laser joining of glass. Appl. Phys. Lett. 2014, 105, 083109. [Google Scholar] [CrossRef] [Green Version]

- Poklonski, N.A.; Vyrko, S.A.; Siahlo, A.I.; Poklonskaya, O.N.; Ratkevich, S.V.; Hieu, N.N.; Kocherzhenko, A.A. Synergy of physical properties of low-dimensional carbon-based systems for nanoscale device design. Mater. Res. Express 2019, 6, 042002. [Google Scholar] [CrossRef]

- Ando, T. The electronic properties of graphene and carbon nanotubes. NPG Asia Mater. 2009, 1, 17–21. [Google Scholar] [CrossRef]

- Srivastava, A.; Liu, X.H.; Banadaki, Y.M. Overview of carbon nanotube interconnects. In Carbon Nanotubes for Interconnects: Process, Design and Applications; Todri-Sanial, A., Dijon, J., Maffucci, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 37–80. [Google Scholar]

- Naeemi, A.; Sarvari, R.; Meindl, J.D. Performance comparison between carbon nanotube and copper interconnects for gigascale integration (gsi). IEEE Electron Device Lett. 2005, 26, 84–86. [Google Scholar] [CrossRef]

- Zhou, W.; Bai, X.; Wang, E.; Xie, S. Synthesis, structure, and properties of single-walled carbon nanotubes. Adv. Mater. 2009, 21, 4565–4583. [Google Scholar] [CrossRef]

- Liu, C.; Cheng, H.M. Controlled growth of semiconducting and metallic single-wall carbon nanotubes. J. Am. Chem. Soc. 2016, 138, 6690–6698. [Google Scholar] [CrossRef] [PubMed]

- Roberts, G.S.; Singjai, P. Joining carbon nanotubes. Nanoscale 2011, 3, 4503–4514. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Wang, X.J.; Meng, P.; Yue, H.X.; Zheng, R.T.; Wu, X.L.; Cheng, G.A. High current density and low emission field of carbon nanotube array microbundle. Appl. Phys. Lett. 2018, 112, 013101. [Google Scholar] [CrossRef]

- Kis, A.; Csányi, G.; Salvetat, J.P.; Lee, T.N.; Couteau, E.; Kulik, A.J.; Benoit, W.; Brugger, J.; Forró, L. Reinforcement of single-walled carbon nanotube bundles by intertube bridging. Nat. Mater. 2004, 3, 153. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Chen, J. Nano-welding of multi-walled carbon nanotubes on silicon and silica surface by laser irradiation. Nanomaterials 2016, 6, 36. [Google Scholar] [CrossRef] [PubMed]

- Danilov, P.A.; Ionin, A.A.; Kudryashov, S.I.; Makarov, S.V.; Mel’nik, N.N.; Rudenko, A.A.; Yurovskikh, V.I.; Zayarny, D.V.; Lednev, V.N.; Obraztsova, E.D.; et al. Femtosecond laser ablation of single-wall carbon nanotube-based material. Laser Phys. Lett. 2014, 11, 106101. [Google Scholar] [CrossRef]

- Arutyunyan, N.R.; Komlenok, M.S.; Kononenko, V.V.; Pashinin, V.P.; Pozharov, A.S.; Konov, V.I.; Obraztsova, E.D. Resonant ablation of single-wall carbon nanotubes by femtosecond laser pulses. Laser Phys. 2014, 25, 015902. [Google Scholar] [CrossRef]

- Ha, J.; Lee, B.J.; Hwang, D.J.; Kim, D. Femtosecond laser nanowelding of silver nanowires for transparent conductive electrodes. RSC Adv. 2016, 6, 86232–86239. [Google Scholar] [CrossRef] [Green Version]

- Herrmann, L.O.; Valev, V.K.; Tserkezis, C.; Barnard, J.S.; Kasera, S.; Scherman, O.A.; Aizpurua, J.; Baumberg, J.J. Threading plasmonic nanoparticle strings with light. Nat. Commun. 2014, 5, 4568. [Google Scholar] [CrossRef] [Green Version]

- Romero, A.H.; Garcia, M.E.; Valencia, F.; Terrones, H.; Terrones, M.; Jeschke, H.O. Femtosecond laser nanosurgery of defects in carbon nanotubes. Nano Lett. 2005, 5, 1361–1365. [Google Scholar] [CrossRef]

- Jeschke, H.O.; Romero, A.H.; Garcia, M.E.; Rubio, A. Microscopic investigation of laser-induced structural changes in single-wall carbon nanotubes. Phys. Rev. B 2007, 75, 125412. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Yang, L.M.; Liu, J. Direct Welding of Fused Silica with Femtosecond Fiber Laser; SPIE: Bellingham, WA, USA, 2012; Volume 8244. [Google Scholar]

- Takagi, D.; Homma, Y.; Hibino, H.; Suzuki, S.; Kobayashi, Y. Single-walled carbon nanotube growth from highly activated metal nanoparticles. Nano Lett. 2007, 6, 2642–2645. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.W.; Aziz, A.; Chai, S.P.; Mohamed, A.R.; Hashim, U. Synthesis of single-walled carbon nanotubes: Effects of active metals, catalyst supports, and metal loading percentage. J. Nanomater. 2013, 2013, 8. [Google Scholar] [CrossRef]

- Keller, U. Recent developments in compact ultrafast lasers. Nature 2003, 424, 831. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Miao, J.; Yang, Z.; Xiao, F.X.; Yang, H.B.; Liu, B.; Yang, Y. Carbon nanotube catalysts: Recent advances in synthesis, characterization and applications. Chem. Soc. Rev. 2015, 44, 3295–3346. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Hou, P.X.; Liu, C.; Wang, B.W.; Jiang, H.; Chen, M.L.; Sun, D.M.; Li, J.C.; Cong, H.T.; Kauppinen, E.I.; et al. Growth of semiconducting single-wall carbon nanotubes with a narrow band-gap distribution. Nat. Commun. 2016, 7, 11160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Terakawa, M. Femtosecond laser processing of biodegradable polymers. Appl. Sci. 2018, 8, 1123. [Google Scholar] [CrossRef]

- Farkas, J.P.; Hoopman, J.E.; Kenkel, J.M. Five parameters you must understand to master control of your laser/light-based devices. Aesthet. Surg. J. 2013, 33, 1059–1064. [Google Scholar] [CrossRef]

- Hu, A.; Peng, P.; Alarifi, H.; Zhang, X.Y.; Guo, J.Y.; Zhou, Y.; Duley, W.W. Femtosecond laser welded nanostructures and plasmonic devices. J. Laser Appl. 2012, 24, 042001. [Google Scholar] [CrossRef] [Green Version]

- Hu, A.; Zhou, Y.; Duley, W. Femtosecond laser-induced nanowelding: Fundamentals and applications. Open Surf. Sci. J. 2011, 311, 42–49. [Google Scholar] [CrossRef]

- Hu, A.; Rybachuk, M.; Lu, Q.B.; Duley, W.W. Direct synthesis of sp-bonded carbon chains on graphite surface by femtosecond laser irradiation. Appl. Phys. Lett. 2007, 91, 131906. [Google Scholar] [CrossRef] [Green Version]

- von der Linde, D.; Sokolowski-Tinten, K.; Bialkowski, J. Laser–solid interaction in the femtosecond time regime. Appl. Surf. Sci. 1997, 109–110, 1–10. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almutairi, Z.; Ahmad, K.; Alanazi, M.; Alhazaa, A. Processing of Single-Walled Carbon Nanotubes with Femtosecond Laser Pulses. Appl. Sci. 2019, 9, 4022. https://doi.org/10.3390/app9194022

Almutairi Z, Ahmad K, Alanazi M, Alhazaa A. Processing of Single-Walled Carbon Nanotubes with Femtosecond Laser Pulses. Applied Sciences. 2019; 9(19):4022. https://doi.org/10.3390/app9194022

Chicago/Turabian StyleAlmutairi, Zeyad, Kaleem Ahmad, Mosaad Alanazi, and Abdulaziz Alhazaa. 2019. "Processing of Single-Walled Carbon Nanotubes with Femtosecond Laser Pulses" Applied Sciences 9, no. 19: 4022. https://doi.org/10.3390/app9194022