Experimental Study on a Prediction Model of the Shrinkage and Creep of Recycled Aggregate Concrete

Abstract

:Featured Application

Abstract

1. Introduction

2. Shrinkage and Creep Test of Recycled Aggregate Concrete

2.1. Materials

2.2. Mix Proportion Design

2.3. Specimen Design

2.4. Test Loading Process

- (1)

- The creep specimens were maintained for 28 days. The prism compressive strength of the specimens under the same conditions was tested before loading. The electronic displacement meter was checked for zero and the initial reading was recorded.

- (2)

- After the completion of the alignment, it started loading in time and the creep stress was taken as 60% of the measured prismatic compressive strength.

- (3)

- The deformation values of the test piece were read at 1 day, 3 days, 7 days, 14 days, 28 days, 45 days, 60 days, 90 days, 120 days, 150 days, and 180 days after loading, and the shrinkage value of the shrinkage test piece in the same environment was recorded.

- (4)

- The load was checked regularly after loading. If the load changed by more than 2%, the correct load was applied, and the nut on the screw was tightened to make up for it.

3. Test Results and Analysis

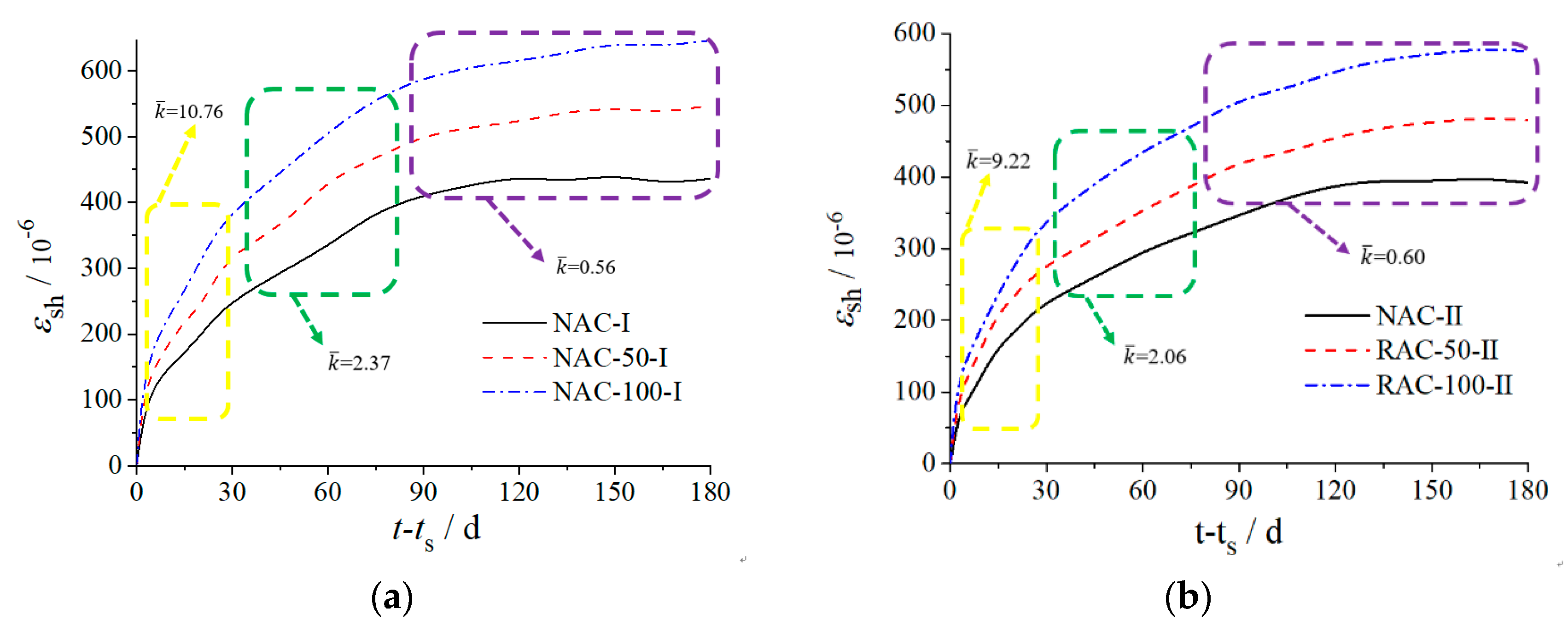

3.1. Analysis of Shrinkage Test Results

3.2. Analysis of Creep Test Results

4. Creep and Shrinkage Model of Recycled Aggregate Concrete

4.1. Creep Increasing Coefficient of Attached Mortar

4.2. Shrinkage Increasing Coefficient of Attached Mortar

5. Conclusions

- (1)

- The development law of the shrinkage and creep of RAC is similar to that of ordinary concrete. At 180 days, compared with ordinary concrete, the shrinkage of group I RAC with a substitution rate of 50% and 100% was increased by 26% and 48%, respectively, and the group II RAC was increased by 22% and 47%, respectively. When the load was 180 days old, compared with ordinary concrete, the creep rate of group I RAC with a substitution rate of 50% and 100% was increased by 19.6% and 39.6%, respectively, and group II was increased by 23.6% and 44.3%, respectively. With the increase of the replacement rate of recycled aggregate, the shrinkage and creep of RAC increased significantly, which indicates that the substitution rate is an important factor affecting the shrinkage and creep of RAC, and the water–cement ratio has more significant effects on the creep of RAC.

- (2)

- The effect of the substitution rate on the shrinkage and creep of RAC is caused by the adhesion of mortar. As the substitution rate increases, the porosity of the attached mortar increases the degree of concrete shrinkage. The increase of the water–cement ratio leads to an increase in the proportion of the attached mortar in the RAC. More adherence of the mortar pores weakens the restraint performance of the RAC, which in turn reduces the resistance of the RAC to creep.

- (3)

- The key difference between recycled aggregate and natural aggregate is the difference in the content of the attached mortar. In this paper, the contraction point was used to calculate the shrinkage strain and creep coefficient of the RAC shrinkage model, and the attached mortar increase coefficient method was also used. The calculated value of the model takes into account the effect of the recycled mortar itself on the shrinkage and creep of the recycled concrete. The difference between the calculated value and the experimental value is small and can meet the accuracy requirements well.

- (4)

- Based on the difference of the attached mortar, effective shrinkage and creep of RAC can be established, and the shrinkage and creep of RAC will show a different development trend from ordinary concrete as the age increases. At the same time, according to the same research ideas, a complete prediction model of the shrinkage and creep of RAC with a full-service life cycle can be established, and the calculation method of the long-term deformation of RAC with significant influence on shrinkage and creep can be carried out.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xiao, J.Z. Recycled Aggregate Concrete; China Building Industry Press: Beijing, China, 2008. [Google Scholar]

- Huang, G.X.; Hui, R.Y.; Wang, X.J. Concrete Creep and Shrinkage; China Electric Power Press: Beijing, China, 2012. [Google Scholar]

- Asamoto, S.; Ohtsuka, A.; Kuwahara, Y.; Miura, C. Study on effects of solar radiation and rain on shrinkage, shrinkage cracking and creep of concrete. Cem. Concr. Res. 2011, 41, 590–601. [Google Scholar] [CrossRef]

- Ma, J.X.; Dehn, F. Shrinkage and creep behavior of an alkali-activated slag concrete. Struct. Concr. 2017, 18, 801–810. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, W.; Fan, Y.H.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gholampour, A.; Xie, T.Y. Mechanical and Durability Properties of Recycled Aggregate Concrete: Effect of Recycled Aggregate Properties and Content. J. Mater. Civ. Eng. 2018, 30, 2. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, S.C. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Zhou, C.H.; Chen, Z.P. Mechanical properties of recycled concrete made with different types of coarse aggregate. Constr. Build. Mater. 2017, 134, 497–506. [Google Scholar] [CrossRef]

- Pandurangan, K.; Dayanithy, A.; Prakash, S.O. Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Seara-Paz, S.; Gonzalez-Fonteboa, B.; Martinez-Abella, F.; Gonzalez-Taboada, I. Time-dependent behaviour of structural concrete made with recycled coarse aggregates Creep and shrinkage. Constr. Build. Mater. 2016, 122, 95–109. [Google Scholar] [CrossRef]

- He, S.Y.; Lai, J.X.; Wang, L.X.; Wang, K. A literature review on properties and applications of grouts for shield tunnel. Constr. Build. Mater. 2020, 231, 468–482. [Google Scholar]

- Li, P.L.; Lu, Y.Q.; Lai, J.X.; Liu, H.Q. A comparative study of protective schemes for shield tunneling adjacent to pile groups. Adv. Civ. Eng. 2020, 12, 1874137. [Google Scholar]

- Domingo-Cabo, A.; Lázaro, C.; López-Gayarre, F. Creep and shrinkage of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2545–2553. [Google Scholar] [CrossRef]

- Geng, Y.; Wang, Y.; Chen, J. Creep behaviour of concrete using recycled coarse aggregates obtained from source concrete with different strengths. Constr. Build. Mater. 2016, 128, 199–213. [Google Scholar] [CrossRef]

- Adam, M.K.; Yahya, C.K. Creep and Shrinkage of Normal-Strength Concrete with recycled aggregate concrete Aggregates. ACI Mater. J. 2015, 3, 112. [Google Scholar] [CrossRef]

- Guo, M.H.; Frédéric, G.; Ahmed, L. Numerical method to model the creep of recycled aggregate concrete by considering the old attached mortar. Cem. Concr. Res. 2019, 118, 14–24. [Google Scholar] [CrossRef]

- Miguel, B.; Jorge, P.; Jorge, B.; Luís, E. Shrinkage and creep performance of concrete with recycled aggregates from CDW plants. Mag. Concr. Res. 2017, 3, 20. [Google Scholar] [CrossRef]

- Fathifazl, G.; Razaqpur, A.G.; Isgor, O.B. Creep and drying shrinkage characteristics of concrete produced with coarse recycled concrete aggregate. Cem. Concr. Compos. 2011, 33, 1026–1037. [Google Scholar] [CrossRef]

- De Brito, J.; Robles, R. Recycled aggregate concrete methodology for estimating its long-term properties. Indian J. Eng. Mater. Sci. 2010, 17, 449–462. [Google Scholar] [CrossRef]

- Tošić, N.; de la Fuente, A.; Marinković, S. Creep of recycled aggregate concrete: Experimental database and creep prediction model according to the fib Model Code 2010. Constr. Build. Mater. 2019, 195, 590–599. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J.; Dhir, R. Comparative analysis of existing prediction models on the creep behaviour of recycled aggregate concrete. Eng. Struct. 2015, 100, 31–42. [Google Scholar] [CrossRef]

- Liu, C.; Lv, Z.Y.; Zhu, C.; Bai, G.L.; Zhang, Y. Study on Calculation Method of Long Term Deformation of RAC Beam based on Creep Adjustment Coefficient. KSCE J. Civ. Eng. 2019, 23, 260–267. [Google Scholar] [CrossRef]

- Luo, J.L.; Xu, Z.S.; Xiong, W. Comparative Experimental Study on Shrinkage and Creep of Recycled High-performance Concrete. Ind. Constr. 2014, 44, 79–83. (In Chinese) [Google Scholar] [CrossRef]

- Luo, S.R.; Zheng, X.; Huang, H.S. Experimental study on pretreatment of recycled coarse aggregate and creep of recycled aggregate concrete. J. Build. Mater. 2016, 19, 242–247. (In Chinese) [Google Scholar] [CrossRef]

- Xiao, J.Z.; Xu, X.D.; Fan, Y.H. The Shrinkage and Creep Test of recycled aggregate concrete and Prediction of Creep Neural Network. J. Build. Mater. 2013, 16, 752–757. (In Chinese) [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Design Rules for Mix Proportion of Ordinary Concrete; Standard No. JGJ55-2011; China Building Industry Press: Beijing, China, 2011.

- GB/T50082-2009. Test Method Standard for Long-Term Performance and Durability of Ordinary Concrete; China Building Industry Press: Beijing, China, 2009.

- CEB-FIP Model Code for Concrete Structures; Committee Euro-international du Beton/Federation International de la Precon-straine: Paris, France, 1990.

- ACI Committee 209. Prediction of Creep Shrinkage and Temperature Effects in Concrete Structures (209R-92); America Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Gardner, N.J.; Lockman, M.J. Design Provisions for Drying shrinkage and creep of normal-strength concrete. ACI Mater. J. 2001, 98, 159–167. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Baweja, S. Creep and shrinkage prediction model for analysis and design of concrete structures-model B3. Mater. Struc. 2000, 29, 126. [Google Scholar] [CrossRef]

- GB50010-2010. Code for Design of Concrete Structures; China Building Industry Press: Beijing, China, 2010.

- Mindess, S.; Young, J.F. Concrete; Prentice-Hall Incorporation: Upper Saddle River, NJ, USA, 1981. [Google Scholar]

| Aggregate Type | Apparent Density/kg·m−3 | Crushing Index/% | Moisture Content/% | Water Absorption Rate/% | Initial Stone/% | Secondary Aggregate/% | Mortar Block/% | Impurity/% |

|---|---|---|---|---|---|---|---|---|

| Recycled coarse aggregate | 2458 | 17.0 | 1.33 | 3.83 | 29.5 | 51.2 | 16.0 | 3.3 |

| Natural coarse aggregate | 2658 | 10.6 | 4.21 | 0.69 | 98.7 | — | 1.3 | |

| Group Number | r/% | Effective Water–Cement Ratio | Material Consumption/kg·m−3 | Compressive Strength/N/mm2 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | Water | Natural Coarse Aggregate | Recycled Coarse Aggregate | Fine Aggregate | Additional Water | ||||

| NAC-I | 0 | 0.527 | 370 | 195 | 1185 | - | 660 | - | 33.3 |

| RAC-50-I | 50 | 0.527 | 370 | 195 | 592.5 | 592.5 | 660 | 22.69 | 31.6 |

| RAC-100-I | 100 | 0.527 | 370 | 195 | - | 1185 | 660 | 45.38 | 32.4 |

| NAC-II | 0 | 0.40 | 500 | 200 | 1086 | - | 611 | - | 35.1 |

| RAC-50-II | 50 | 0.40 | 500 | 200 | 543 | 543 | 611 | 20.8 | 32.3 |

| RAC-100-II | 100 | 0.40 | 500 | 200 | - | 1086 | 611 | 41.6 | 30.9 |

| Test Piece Number | Specimen Number | Specimen Use | |||

|---|---|---|---|---|---|

| Cube | Prism | Shrinkage Specimen | Creep Specimen | ||

| NAC-I | 3 | 6 | 3 | 2 | A Cube: Cube used to determine the compressive strength. B Prisms: Three were used to determine the ultimate bearing capacity and three were used to determine the elastic modulus. |

| RAC-50-I | 3 | 6 | 3 | 2 | |

| RAC-100-I | 3 | 6 | 3 | 2 | |

| NAC-II | 3 | 6 | 3 | 2 | |

| RAC-50-II | 3 | 6 | 3 | 2 | |

| RAC-100-II | 3 | 6 | 3 | 2 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Z.; Liu, C.; Zhu, C.; Bai, G.; Qi, H. Experimental Study on a Prediction Model of the Shrinkage and Creep of Recycled Aggregate Concrete. Appl. Sci. 2019, 9, 4322. https://doi.org/10.3390/app9204322

Lv Z, Liu C, Zhu C, Bai G, Qi H. Experimental Study on a Prediction Model of the Shrinkage and Creep of Recycled Aggregate Concrete. Applied Sciences. 2019; 9(20):4322. https://doi.org/10.3390/app9204322

Chicago/Turabian StyleLv, Zhenyuan, Chao Liu, Chao Zhu, Guoliang Bai, and Hao Qi. 2019. "Experimental Study on a Prediction Model of the Shrinkage and Creep of Recycled Aggregate Concrete" Applied Sciences 9, no. 20: 4322. https://doi.org/10.3390/app9204322