Water-Weakening Effects on the Mechanical Behavior of Different Rock Types: Phenomena and Mechanisms

Abstract

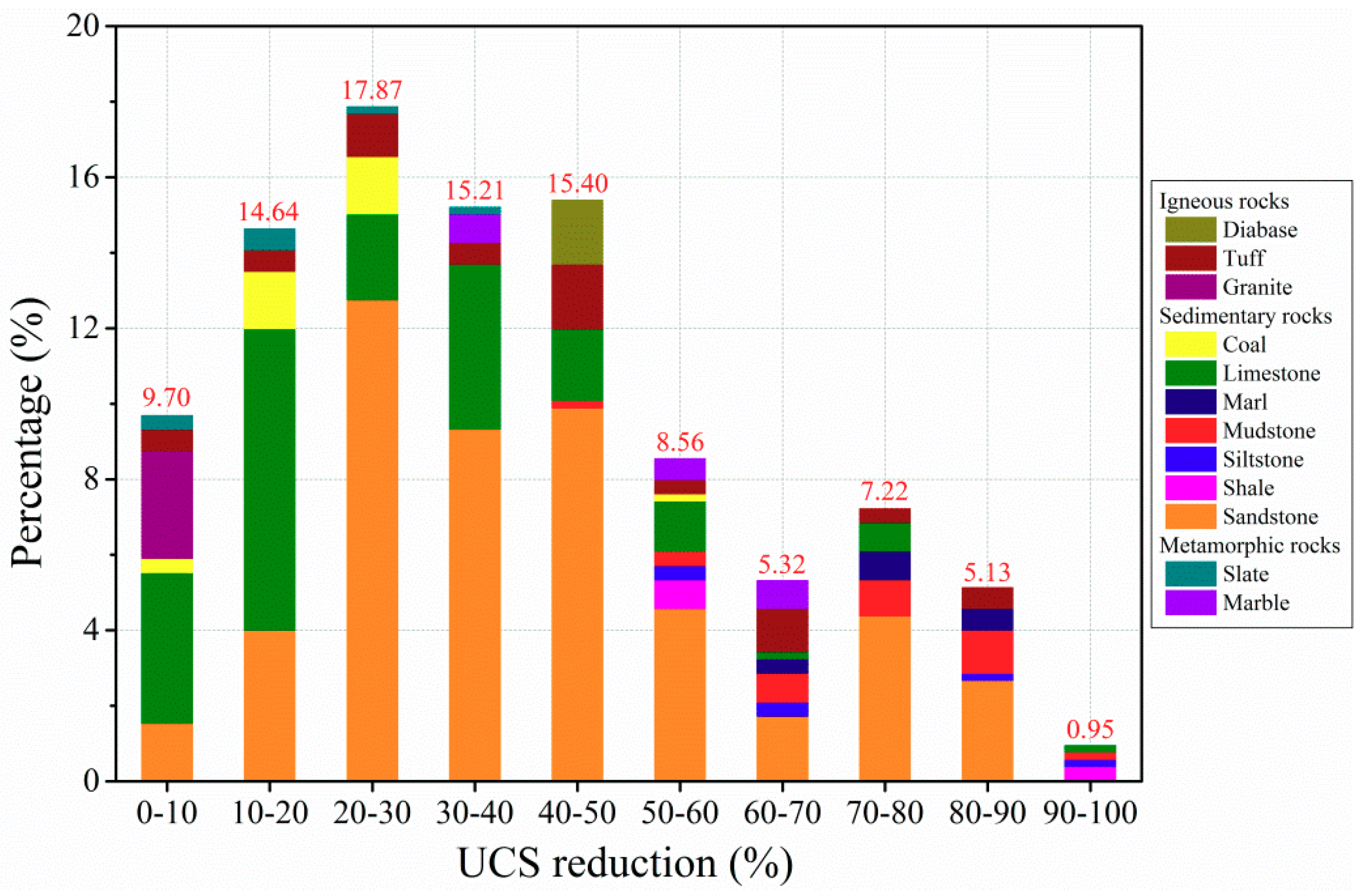

:1. Introduction

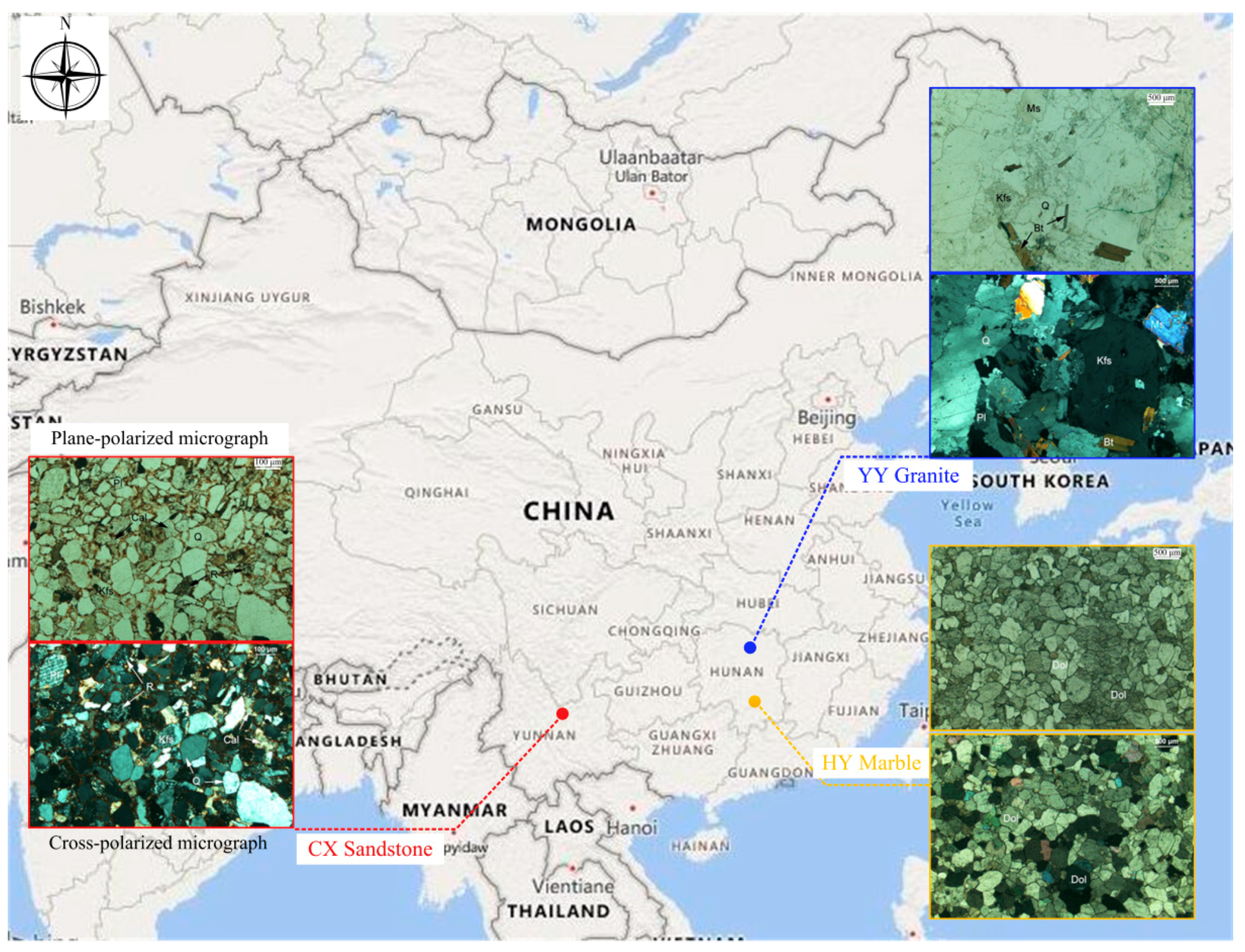

2. Test Material and Method

2.1. Material Characterization

2.2. Specimen Preparation

2.3. Experimental Techniques and Test Condition

3. Test Results

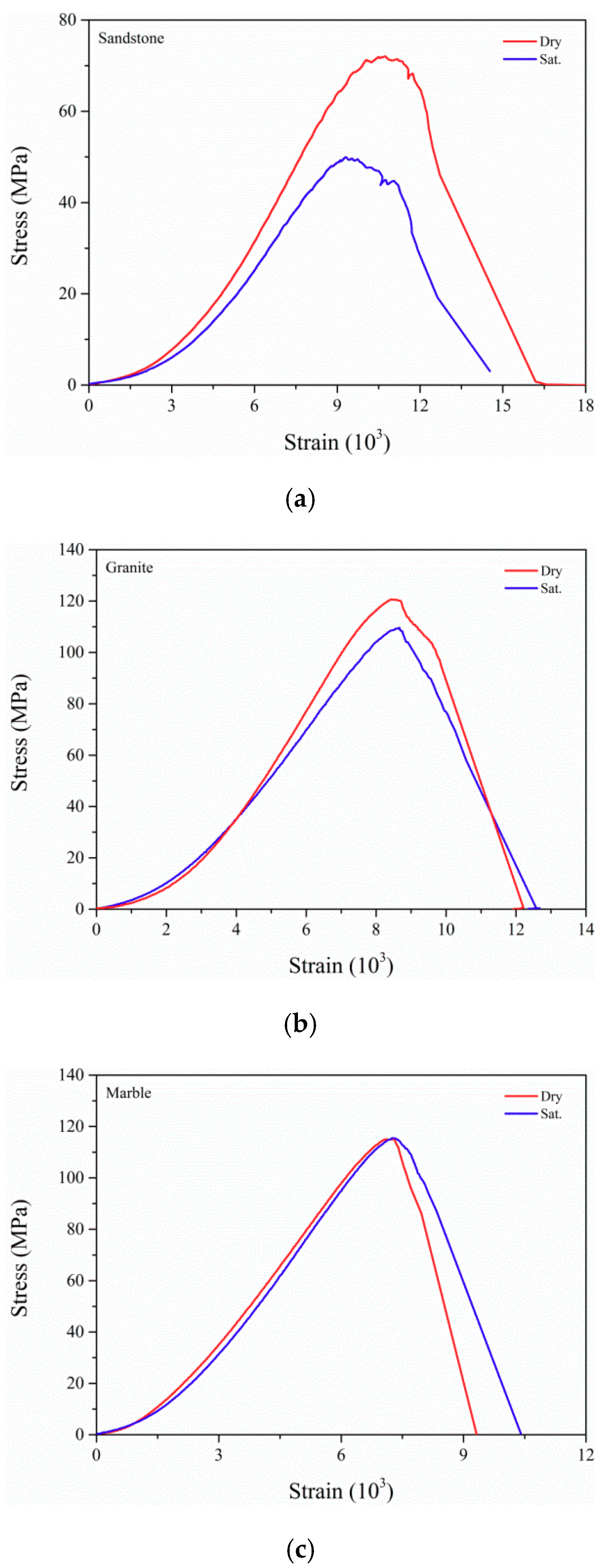

3.1. Effect of Water on Mechanical Behavior

3.1.1. Stress–Strain Response of Dry and Saturated Rocks

3.1.2. Water-Weakening Effect on Mechanical Behavior

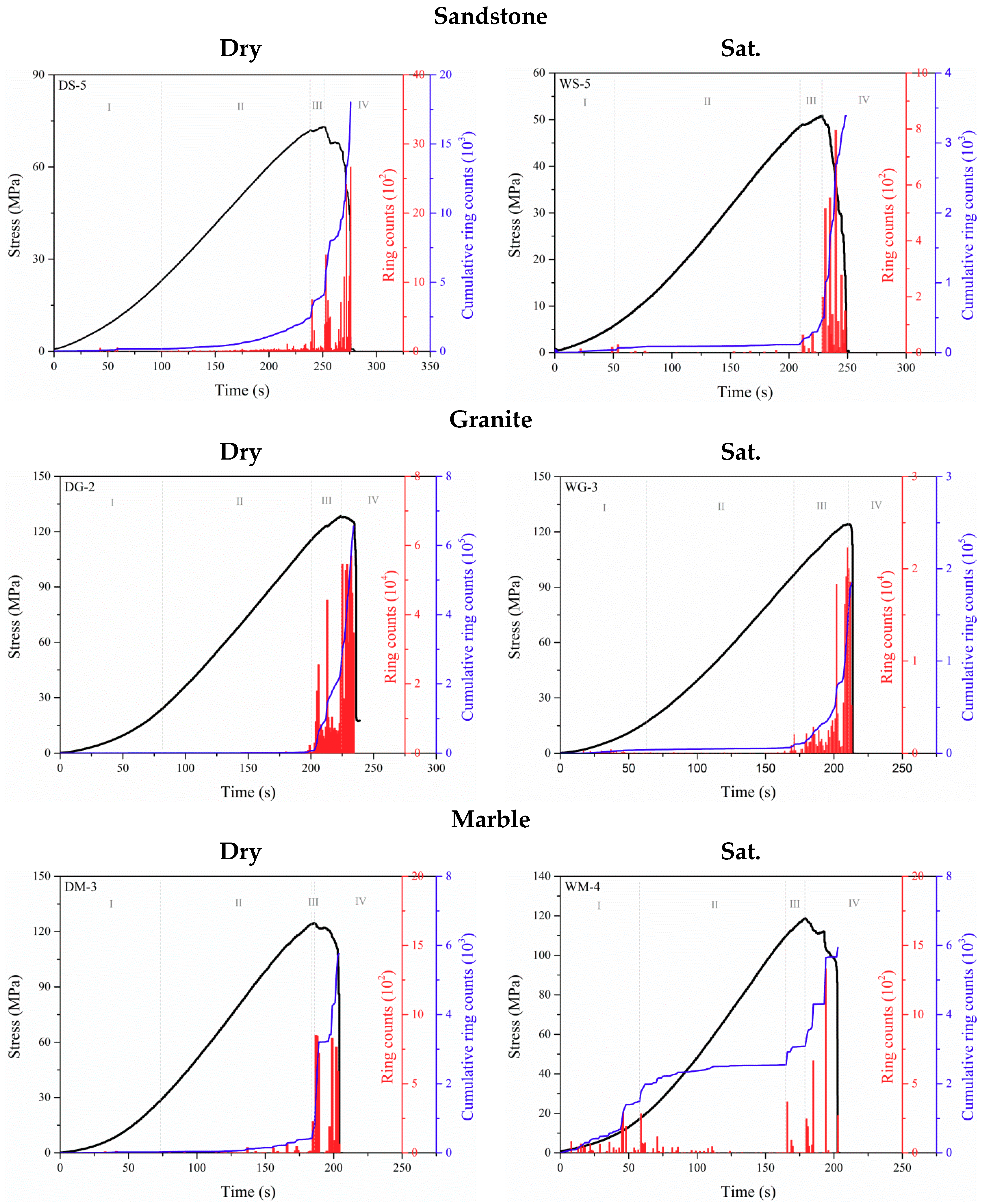

3.2. Effect of Water on AE Characteristics

3.2.1. Cumulative and Evolution of Ring Counts

- (1)

- (2)

- Elastic deformation stage (stage II), where the rock specimen deforms elastically. The stress increases linearly accompanied by the slow and stable accumulation of ring counts. This implies that microcracks initiate steadily.

- (3)

- Unstable crack propagation stage (stage III), where ring counts exponentially burst with the increasing stress due to the energy storage enough to trigger the eruption of microcracks.

- (4)

- Post-peak stage (stage IV), where the stress drops suddenly with the majority of ring counts occurrence.

- (1)

- In crack closure stage, the ring counts of the dry sandstone were slightly less than that of the saturated one. On the contrary, for the granite and the marble, the number of ring counts in the saturated state was larger than that in dry state, indicating saturated specimens generate more microcracks during this stage.

- (2)

- The stress at the onset of ring counts outburst, i.e., the transition point between stages II and III is defined as the threshold of crack damage [52]. For all rock types, the crack damage stress decreased when the rock became water-saturated. As an example, the crack damage stress of the dry granite specimen was approximately 115.72 MPa (90.1% of UCS), which was 1.20 times greater than that of the saturated one (77.6% of UCS). This implies that the presence of water lowered the threshold of elastic energy release.

- (3)

- The cumulative ring counts of dry rocks were dramatically greater than that of saturated ones, meaning that the rocks tested under dry conditions suffered more violent failures. This could be due to the increasing storage of elastic energy before failure, which can be reflected by the larger shaded area under the pre-peak portion of stress–strain curves. Another reason may be due to the higher slope of the stress drop in post-peak stage (i.e., greater unloading rate) causing a catastrophic fracture of the rock [53,54].

3.2.2. Water Induced Variation in Microscale Crack Type

4. Discussion

4.1. Chemical and Physical Deterioration

- (1)

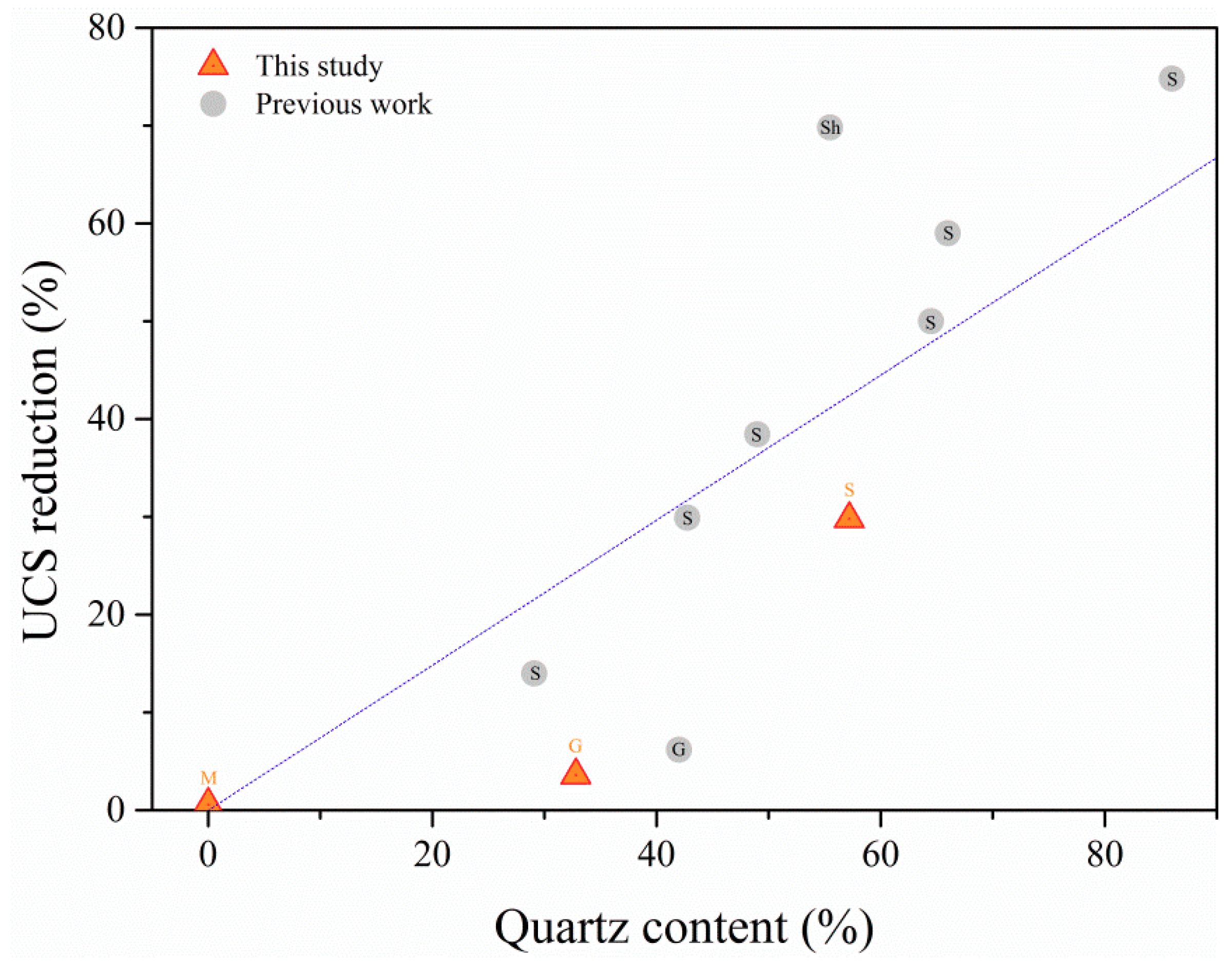

- The hydrolysis of quartz. In the case of silicate rocks under conditions of moisture, water as a corrosive agent hydrolyzes the quartz minerals. The hydrolysis of Si–O–Si bond in quartz lowers the activation barrier to subcritical crack growth as strong Si–O–Si bonds at crack tips are replaced by weaker hydrogen bonds [35,36,37,38,48]:At the same time, the increasing external stress inducing crack creation and propagation also promotes the quartz hydrolysis.Theoretically, the higher content of quartz leads to the greater UCS reduction due to water presence, as shown in Figure 8. Therefore, quartz hydrolysis plays an important role in weakening the UCS of the sandstone and the granite, while it is absent for the marble according to the mineral compositions of the three rock types listed in Table 1. From Figure 8, it is worth noting that the UCS reduction of granite is apparently lower than the predicted value, probably due to the hydrolysis of quartz being limited by its extremely low porosity (lower permeability).

- (2)

- The swelling of clay minerals. It is well-known that expandable clay minerals (e.g., smectite) cause high swelling stresses after water absorption, further expanding existing microfractures as well as creating new micro-fractures [28,56]. The increase of crack density decreases the rock strength [57,58]. In this study, this effect only acts on the sandstone containing smectite.

- (3)

- The dissolution of calcite. Calcite minerals are vulnerable to dissolution even in weak acidic environment [20,56,59,60], as:This will increase the porosity of rock and decrease the intergranular cohesion, which results in the UCS reduction of the sandstone and the marble.

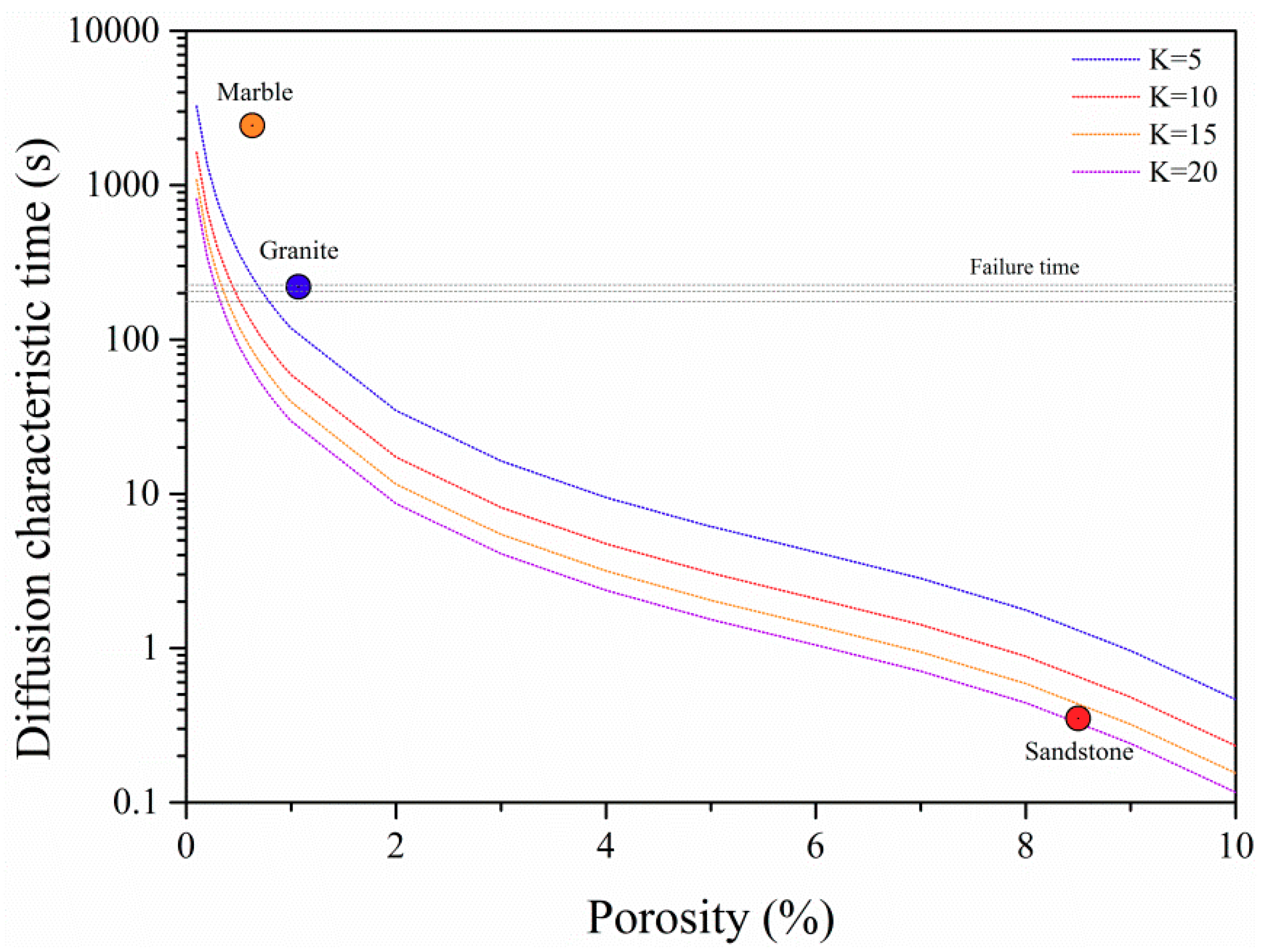

4.2. The Increase of Pore Pressure

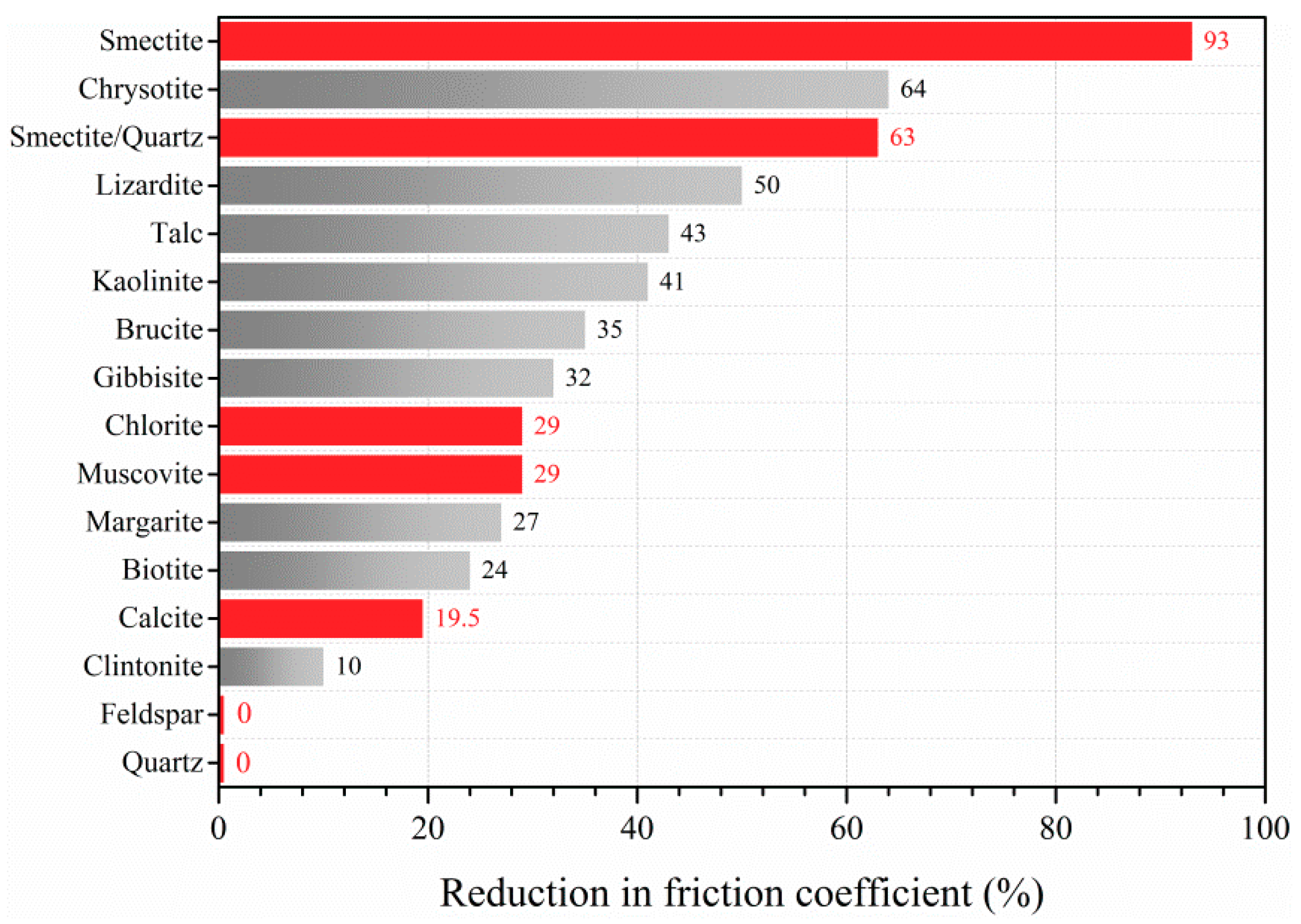

4.3. Frictional Reduction

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hawkins, A.B.; McConnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. Hydrogeol. 1992, 25, 115–130. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Yilmaz, I. Influence of water content on the strength and deformability of gypsum. Int. J. Rock Mech. Min. Sci. 2010, 47, 342–347. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Cao, W.; Li, X.; Xiong, C. Influence of Water Content on Mechanical Properties of Rock in Both Saturation and Drying Processes. Rock Mech. Rock Eng. 2016, 49, 3009–3025. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G. Water-weakening behavior of Hawkesbury sandstone in brittle regime. Eng. Geol. 2014, 178, 91–101. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Ma, D.; Du, X.; Chen, L.; Wang, H.; Zang, H. Water saturation effects on dynamic fracture behavior of sandstone. Int. J. Rock Mech. Min. Sci. 2019, 114, 46–61. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Maruvanchery, V.; Liu, G. Water effects on rock strength and stiffness degradation. Acta Geotech. 2016, 11, 713–737. [Google Scholar] [CrossRef]

- Iverson, R.M. Landslide triggering by rain infiltration. Water Resour. Res. 2000, 36, 1897–1910. [Google Scholar] [CrossRef] [Green Version]

- Ma, D.; Cai, X.; Li, Q.; Duan, H. In-Situ and Numerical Investigation of Groundwater Inrush Hazard from Grouted Karst Collapse Pillar in Longwall Mining. Water 2018, 10, 1187. [Google Scholar] [CrossRef]

- Lu, C.; Zilong, Z.; Chuanwei, Z.; Ling, Z.; Yuan, Z. Failure pattern of large-scale goaf collapse and a controlled roof caving method used in gypsum mine. Geomech. Eng. 2019, 18, 449–457. [Google Scholar]

- Zang, A.; Zimmermann, G.; Hofmann, H.; Stephansson, O.; Min, K.-B.; Kim, K.Y. How to Reduce Fluid-Injection-Induced Seismicity. Rock Mech. Rock Eng. 2015, 34, 249–260. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Liu, J.; Li, X.; Zhou, Z. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci. Total Environ. 2019, 664, 436–448. [Google Scholar] [CrossRef] [PubMed]

- Ma, D.; Duan, H.; Li, X.; Li, Z.; Zhou, Z.; Li, T. Effects of seepage-induced erosion on nonlinear hydraulic properties of broken red sandstones. Tunn. Undergr. Space Technol. 2019, 91, 102993. [Google Scholar] [CrossRef]

- Török, Á.; Vásárhelyi, B. The influence of fabric and water content on selected rock mechanical parameters of travertine, examples from Hungary. Eng. Geol. 2010, 115, 237–245. [Google Scholar] [CrossRef]

- Dyke, C.G.; Dobereiner, L. Evaluating the strength and deformability of sandstones. Q. J. Eng. Geol. Hydrogeol. 1991, 24, 123–134. [Google Scholar] [CrossRef]

- Jiang, Q.; Cui, J.; Feng, X.; Jiang, Y. Application of computerized tomographic scanning to the study of water-induced weakening of mudstone. Bull. Eng. Geol. Environ. 2014, 73, 1293–1301. [Google Scholar] [CrossRef]

- Zang, A.; Wagner, C.F.; Dresen, G. Acoustic emission, microstructure, and damage model of dry and wet sandstone stressed to failure. J. Geophys. Res. Solid Earth 1996, 101, 17507–17521. [Google Scholar] [CrossRef]

- Li, H.; Shen, R.; Li, D.; Jia, H.; Li, T.; Chen, T.; Hou, Z. Acoustic Emission Multi-Parameter Analysis of Dry and Saturated Sandstone with Cracks under Uniaxial Compression. Energies 2019, 12, 1959. [Google Scholar] [CrossRef]

- Yao, Q.; Chena, T.; Tang, C.; Sedighic, M.; Wang, S.; Huang, Q. Influence of moisture on crack propagation in coal and its failure modes. Eng. Geol. 2019, 258, 2019. [Google Scholar] [CrossRef]

- Liu, X.; Wu, L.; Zhang, Y.; Liang, Z.; Yao, X.; Liang, P. Frequency properties of acoustic emissions from the dry and saturated rock. Environ. Earth Sci. 2019, 78, 67. [Google Scholar] [CrossRef]

- Yao, Q.; Li, X.; Zhou, J.; Ju, M.; Chong, Z.; Zhao, B. Experimental study of strength characteristics of coal specimens after water intrusion. Arab. J. Geosci. 2015, 8, 6779–6789. [Google Scholar] [CrossRef]

- Yao, Q.; Chen, T.; Ju, M.; Liang, S.; Liu, Y.; Li, X. Effects of Water Intrusion on Mechanical Properties of and Crack Propagation in Coal. Rock Mech. Rock Eng. 2016, 49, 4699–4709. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Jasinge, D.; Song, J.Y.; Choi, S.K. A study of the effect of displacement rate and moisture content on the mechanical properties of concrete: Use of acoustic emission. Mech. Mater. 2008, 40, 453–469. [Google Scholar] [CrossRef]

- Hashiba, K.; Fukui, K.; Kataoka, M.; Chu, S.Y. Effect of water on the strength and creep lifetime of andesite. Int. J. Rock Mech. Min. Sci. 2018, 108, 37–42. [Google Scholar] [CrossRef]

- Miao, S.; Cai, M.; Guo, Q.; Wang, P.; Liang, M. Damage effects and mechanisms in granite treated with acidic chemical solutions. Int. J. Rock Mech. Min. Sci. 2016, 88, 77–86. [Google Scholar] [CrossRef]

- Aydan, Ö.; Ulusay, R. Geomechanical evaluation of derinkuyu antique underground city and its implications in geoengineering. Rock Mech. Rock Eng. 2013, 46, 731–754. [Google Scholar] [CrossRef]

- Hadizadeh, J.; Law, R.D. Water-weakening of sandstone and quartzite deformed at various stress and strain rates. Int. J. Rock Mech. Min. Sci. 1991, 28, 431–439. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G.; Permata, G.; Bing, D. Damage evolution and deformation behaviour of dry and saturated sandstones: Insights gleaned from optical measurements. Meas. J. Int. Meas. Confed. 2018, 130, 8–17. [Google Scholar] [CrossRef]

- Rajabzadeh, M.A.; Moosavinasab, Z.; Rakhshandehroo, G. Effects of rock classes and porosity on the relation between uniaxial compressive strength and some rock properties for carbonate rocks. Rock Mech. Rock Eng. 2012, 45, 113–122. [Google Scholar] [CrossRef]

- Gholami, R.; Rasouli, V. Mechanical and elastic properties of transversely isotropic slate. Rock Mech. Rock Eng. 2014, 47, 1763–1773. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Zhao, Y.; Chen, L.; Xiong, C.; Li, X. Strength characteristics of dry and saturated rock at different strain rates. Trans. Nonferrous Met. Soc. China 2016, 26, 1919–1925. [Google Scholar] [CrossRef]

- Hammond, M.L.; Ravitz, S.F. Influence of Environment on Brittle Fracture of Silica. J. Am. Ceram. Soc. 1963, 46, 329–332. [Google Scholar] [CrossRef]

- Vutukuri, V.S. The effect of liquids on the tensile strength of limestone. Int. J. Rock Mech. Min. Sci. 1974, 11, 27–29. [Google Scholar] [CrossRef]

- Michalske, T.A.; Freiman, S.W. A molecular interpretation of stress corrosion in silica. Nature 1982, 295, 511–512. [Google Scholar] [CrossRef]

- Freiman, S.W. Effects of chemical environments on slow crack growth in glasses and ceramics. J. Geophys. Res. Solid Earth 1984, 89, 4072–4076. [Google Scholar] [CrossRef]

- Eppes, M.C.; Keanini, R. Mechanical weathering and rock erosion by climate-dependent subcritical cracking. Rev. Geophys. 2017, 55, 470–508. [Google Scholar] [CrossRef]

- Atkinson, B.K.; Meredith, P.G. Stress corrosion cracking of quartz: A note on the influence of chemical environment. Tectonophysics 1981, 77, T1–T11. [Google Scholar] [CrossRef]

- Handin, J.; Rex, V.; Hager, J.; Melvin, F.; Feather, J.N. Experimental Deformation of Sedimentary Rocks Under Confining Pressure: Pore Pressure Tests. Am. Assoc. Pet. Geol. Bull. 1963, 47, 717–755. [Google Scholar]

- Zhong, C.; Zhang, Z.; Ranjith, P.G.; Lu, Y.; Choi, X. The role of pore water plays in coal under uniaxial cyclic loading. Eng. Geol. 2019, 257, 105125. [Google Scholar] [CrossRef]

- Homand, S.; Shao, J.F. Mechanical behaviour of a porous chalk and effect of saturating fluid. Mech. Cohesive-Frictional Mater. 2000, 5, 583–606. [Google Scholar] [CrossRef]

- Van Eeckhout, E.M. The mechanisms of strength reduction due to moisture in coal mine shales. Int. J. Rock Mech. Min. Sci. Geomech. 1976, 13, 61–67. [Google Scholar] [CrossRef]

- Morrow, C.A.; Moore, D.E.; Lockner, D.A. The effect of mineral bond strength and adsorbed water on fault gouge frictional strength. Geophys. Res. Lett. 2000, 27, 815–818. [Google Scholar] [CrossRef] [Green Version]

- Moore, D.E. Crystallographic controls on the frictional behavior of dry and water-saturated sheet structure minerals. J. Geophys. Res. 2004, 109, B03401. [Google Scholar] [CrossRef]

- Kawai, K.; Sakuma, H.; Katayama, I.; Tamura, K. Frictional characteristics of single and polycrystalline muscovite and influence of fluid chemistry. J. Geophys. Res. Solid Earth 2015, 120, 6209–6218. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.Q.; Zhu, J.B.; Zhao, J. A review of mechanisms of induced earthquakes: From a view of rock mechanics. Geomech. Geophys. Geo-Energy Geo-Resour. 2019, 5, 171–196. [Google Scholar] [CrossRef]

- Mcconnell, B.J. Factors Controlling Sandstone Strength and Deformability in Uniaxial Compression. Ph.D. Thesis, University of Bristol, Bristol, UK, 1989. [Google Scholar]

- Zhou, Z.; Cai, X.; Ma, D.; Cao, W.; Chen, L.; Zhou, J. Effects of water content on fracture and mechanical behavior of sandstone with a low clay mineral content. Eng. Fract. Mech. 2018, 193, 47–65. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Yao, J.; Gong, F.; Li, X.; Du, K.; Tao, M.; Huang, L.; Du, S. Experimental investigation of rock breakage by a conical pick and its application to non-explosive mechanized mining in deep hard rock. Int. J. Rock Mech. Min. Sci. 2019, 122, 104063. [Google Scholar] [CrossRef]

- Song, Z.; Konietzky, H.; Herbst, M. Bonded-particle model-based simulation of artificial rock subjected to cyclic loading. Acta Geotech. 2019, 14, 955–971. [Google Scholar] [CrossRef]

- Ma, D.; Wang, J.; Cai, X.; Ma, X.; Zhang, J.; Zhou, Z.; Tao, M. Effects of height/diameter ratio on failure and damage properties of granite under coupled bending and splitting deformation. Eng. Fract. Mech. 2019, 220, 106640. [Google Scholar] [CrossRef]

- Martin, C.D.; Chandler, N.A. The progressive fracture of Lac du Bonnet granite. Int. J. Rock Mech. Min. Sci. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Zhao, X.G.; Wang, J.; Cai, M.; Cheng, C.; Ma, L.K.; Su, R.; Zhao, F.; Li, D.J. Influence of unloading rate on the strainburst characteristics of beishan granite under true-triaxial unloading conditions. Rock Mech. Rock Eng. 2014, 47, 467–483. [Google Scholar] [CrossRef]

- Tao, M.; Li, X.; Wu, C. Characteristics of the unloading process of rocks under high initial stress. Comput. Geotech. 2012, 45, 83–92. [Google Scholar] [CrossRef]

- Ohtsu, M.; Isoda, T.; Tomoda, Y. Acoustic Emission Techniques Standardized for Concrete Structures. J. Acoust. Emiss. 2007, 25, 21–32. [Google Scholar]

- Ahamed, M.A.A.; Perera, M.S.A.; Matthai, S.K.; Ranjith, P.G.; Dong-yin, L. Journal of Petroleum Science and Engineering Coal composition and structural variation with rank and its influence on the coal-moisture interactions under coal seam temperature conditions—A review article. J. Pet. Sci. Eng. 2019, 180, 901–917. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Ma, D.; Chen, L.; Wang, S.; Tan, L. Dynamic tensile properties of sandstone subjected to wetting and drying cycles. Constr. Build. Mater. 2018, 182, 215–232. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Li, X.; Cao, W.; Du, X. Dynamic Response and Energy Evolution of Sandstone Under Coupled Static—ynamic Compression: Insights from Experimental Study into Deep Rock Engineering Applications. Rock Mech. Rock Eng. 2019, 1–27. [Google Scholar] [CrossRef]

- Ciantia, M.O.; Castellanza, R.; di Prisco, C. Experimental Study on the Water-Induced Weakening of Calcarenites. Rock Mech. Rock Eng. 2014, 48, 441–461. [Google Scholar] [CrossRef]

- Ciantia, M.O.; Castellanza, R.; Crosta, G.B.; Hueckel, T. Efects of mineral suspension and dissolution on strength and compressibility of soft carbonate rocks. Eng. Geol. 2015, 184, 1–18. [Google Scholar] [CrossRef]

- Qiao, L.; Wang, Z.; Huang, A. Alteration of Mesoscopic Properties and Mechanical Behavior of Sandstone Due to Hydro-Physical and Hydro-Chemical Effects. Rock Mech. Rock Eng. 2017, 50, 255–267. [Google Scholar] [CrossRef]

- Lyu, Q.; Long, X.; Ranjith, P.G.; Tan, J.; Kang, Y. Experimental investigation on the mechanical behaviours of a low-clay shale under water-based fluids. Eng. Geol. 2018, 233, 124–138. [Google Scholar] [CrossRef]

- Verstrynge, E.; Adriaens, R.; Elsen, J.; Van Balen, K. Multi-scale analysis on the influence of moisture on the mechanical behavior of ferruginous sandstone. Constr. Build. Mater. 2014, 54, 78–90. [Google Scholar] [CrossRef]

- Masoumi, H.; Horne, J.; Timms, W. Establishing Empirical Relationships for the Effects of Water Content on the Mechanical Behavior of Gosford Sandstone. Rock Mech. Rock Eng. 2017, 50, 2235–2242. [Google Scholar] [CrossRef]

- Nicolas, A.; Fortin, J.; Regnet, J.B.; Dimanov, A.; Gúeguen, Y. Brittle and semi-brittle behaviours of a carbonate rock: Influence of water and temperature. Geophys. J. Int. 2016, 206, 438–456. [Google Scholar] [CrossRef]

- Duda, M.; Renner, J. The weakening effect of water on the brittle failure strength of sandstone. Geophys. J. Int. 2013, 192, 1091–1108. [Google Scholar] [CrossRef]

- Kümpel, H. Poroelasticity: Parameters reviewed. Geophys. J. Int. 1991, 105, 783–799. [Google Scholar] [CrossRef]

- Aben, F.M.; Doan, M.L.; Gratier, J.P.; Renard, F. High strain rate deformation of porous sandstone and the asymmetry of earthquake damage in shallow fault zones. Earth Planet. Sci. Lett. 2017, 463, 81–91. [Google Scholar] [CrossRef] [Green Version]

- Ikari, M.J.; Saffer, D.M.; Marone, C. Effect of hydration state on the frictional properties of montmorillonite-based fault gouge. J. Geophys. Res. Solid Earth 2007, 112, B06423. [Google Scholar] [CrossRef]

| Rock Type | Mineral Composition | Percentage a/% | Grain Size b/mm | Average Grain Size/mm |

|---|---|---|---|---|

| Sandstone | Quartz | 57.20 | 0.02–0.25 | 0.055 |

| Feldspar | 13.48 | 0.05–0.24 | ||

| Calcite | 5.26 | 0.01–0.15 | ||

| Mica | 3.84 | 0.04–0.14 | ||

| Smectite | 9.72 | 0.01–0.03 | ||

| Chlorite | 4.05 | 0.01–0.05 | ||

| Granite | Feldspar | 38.77 | 0.1–2.5 | 1.970 |

| Quartz | 32.82 | 0.2–2.2 | ||

| Muscovite | 22.85 | 0.05–2.2 | ||

| Chlorite | 5.56 | 0.01–0.2 | ||

| Marble | Dolomite | 96.98 | 0.1–0.6 | 0.083 |

| Calcite | 3.02 | 0.1–0.4 |

| Rock Type | State | ϕ | ρ | Aw | tsa | Cp | κ | K |

|---|---|---|---|---|---|---|---|---|

| /% | /kg·m−3 | /% | /h | /m·s−1 | /nm2 | /GPa | ||

| Sandstone | Dry | 8.50 | 2368.5 | 0.00 | 48 | 3094.0 | 3.76 × 102 | 4.70 |

| Sat. | 2453.5 | 2.29 | 3614.5 | N.A. | ||||

| Granite | Dry | 1.07 | 2620.3 | 0.00 | 168 | 4333.4 | 0.23 | 12.24 |

| Sat. | 2625.8 | 0.52 | 5105.6 | N.A. | ||||

| Marble | Dry | 0.63 | 2821.2 | 0.00 | 168 | 5241.5 | 1.72 × 10−2 | 14.91 |

| Sat. | 2824.6 | 0.13 | 6498.9 | N.A. |

| Rock Type | State | tf | σc | E | εc | Nc |

|---|---|---|---|---|---|---|

| /s | /MPa | /GPa | /‰ | /103 | ||

| Sandstone | Dry | 253.0 | 71.91 | 7.05 | 10.21 | 18.0 |

| Sat. | 225.9 | 50.48 | 5.52 | 9.16 | 3.7 | |

| Granite | Dry | 216.6 | 123.82 | 15.18 | 8.46 | 985.7 |

| Sat. | 204.8 | 119.39 | 14.34 | 8.32 | 184.5 | |

| Marble | Dry | 174.0 | 119.48 | 16.82 | 7.12 | 8.1 |

| Sat. | 176.5 | 118.77 | 16.78 | 7.08 | 5.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, X.; Zhou, Z.; Liu, K.; Du, X.; Zang, H. Water-Weakening Effects on the Mechanical Behavior of Different Rock Types: Phenomena and Mechanisms. Appl. Sci. 2019, 9, 4450. https://doi.org/10.3390/app9204450

Cai X, Zhou Z, Liu K, Du X, Zang H. Water-Weakening Effects on the Mechanical Behavior of Different Rock Types: Phenomena and Mechanisms. Applied Sciences. 2019; 9(20):4450. https://doi.org/10.3390/app9204450

Chicago/Turabian StyleCai, Xin, Zilong Zhou, Kewei Liu, Xueming Du, and Haizhi Zang. 2019. "Water-Weakening Effects on the Mechanical Behavior of Different Rock Types: Phenomena and Mechanisms" Applied Sciences 9, no. 20: 4450. https://doi.org/10.3390/app9204450