The Effects of TiO2 Diffuser-Loaded Encapsulation on Corrected Color Temperature Uniformity of Remote Phosphor White LEDs

Abstract

:1. Introduction

2. Experiment

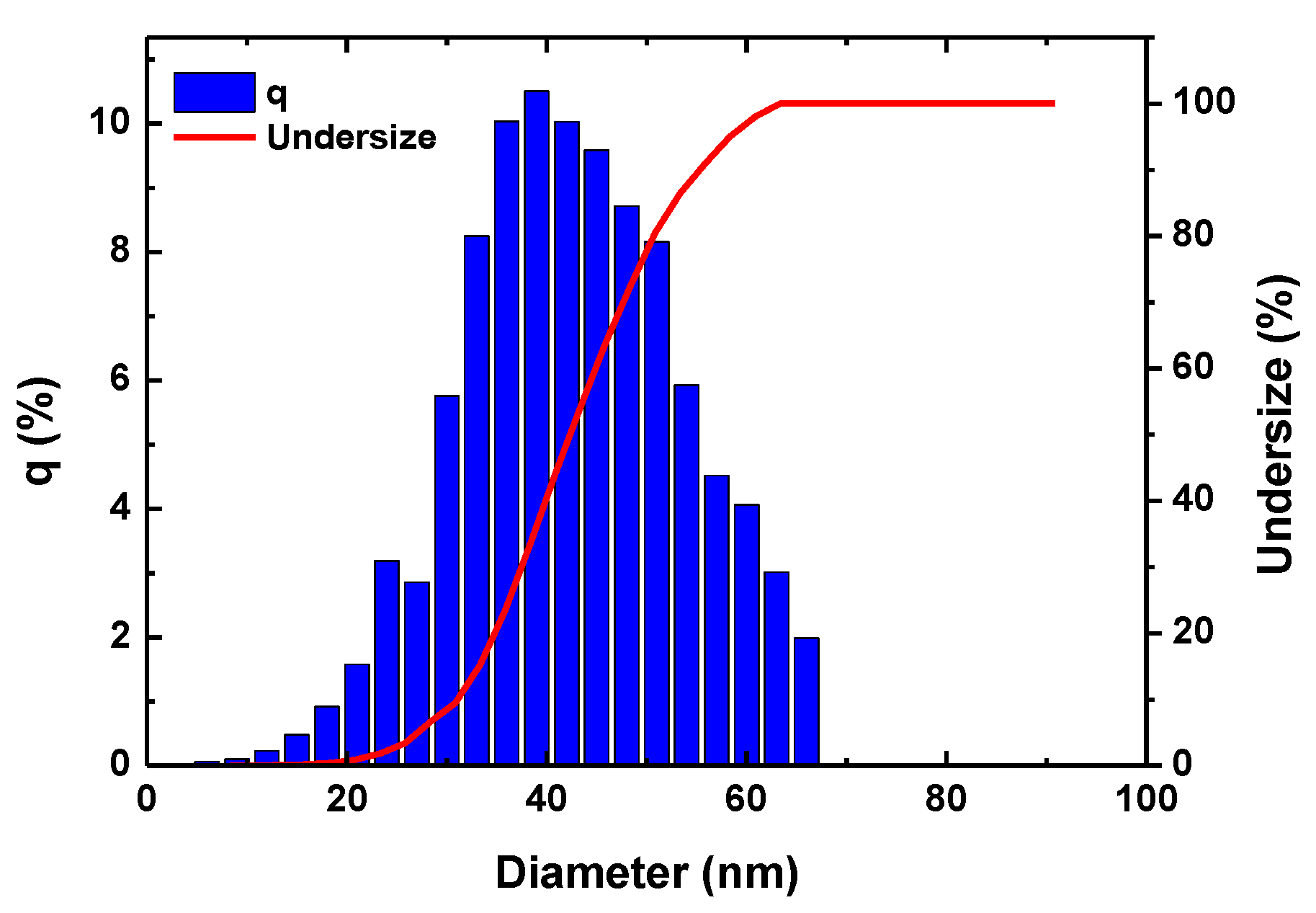

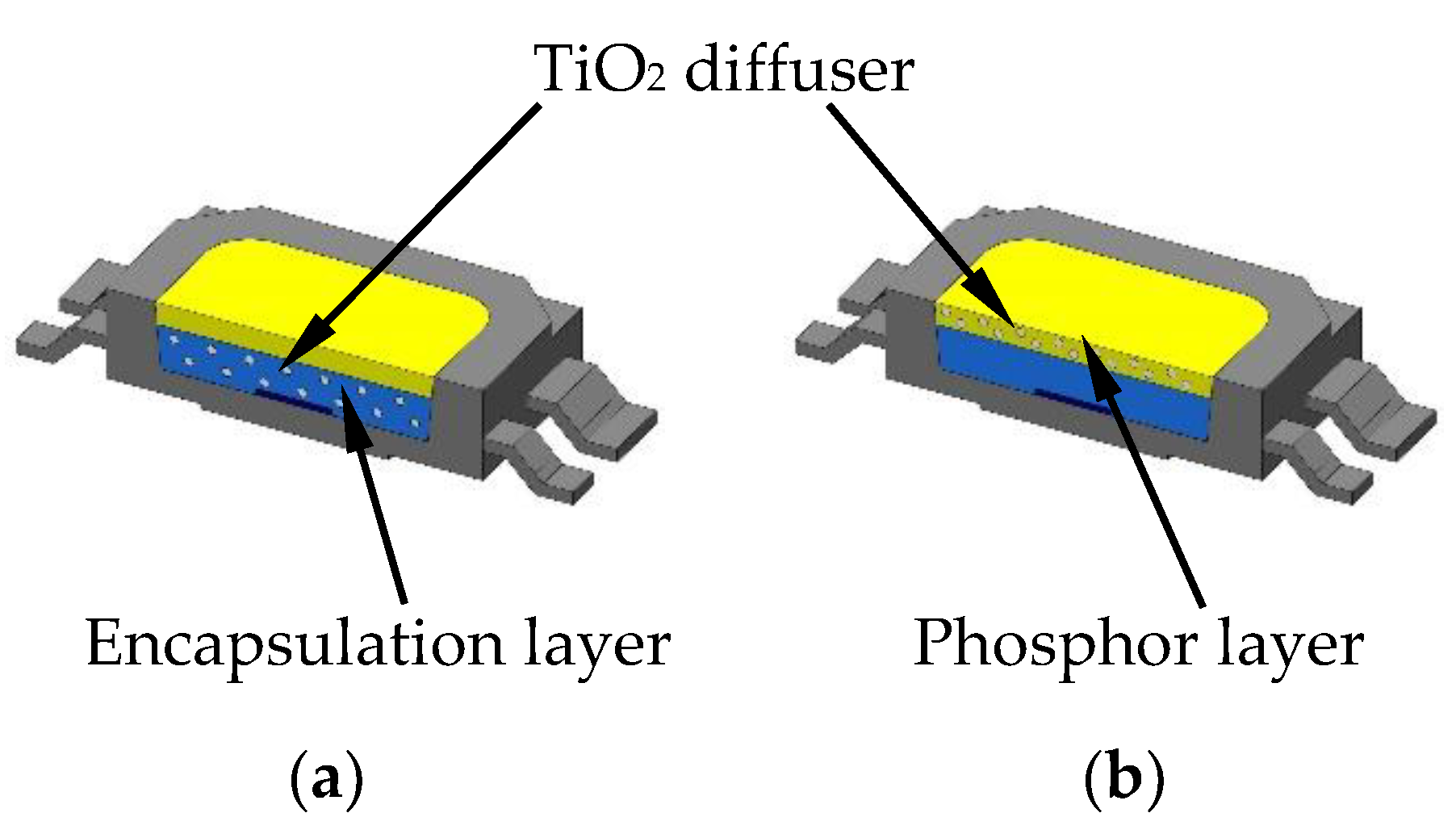

2.1. Diffuser in the Encapsulation Layer

2.2. Diffuser in the Phosphor Layer

2.3. Optical Properties Measurement

3. Discussion

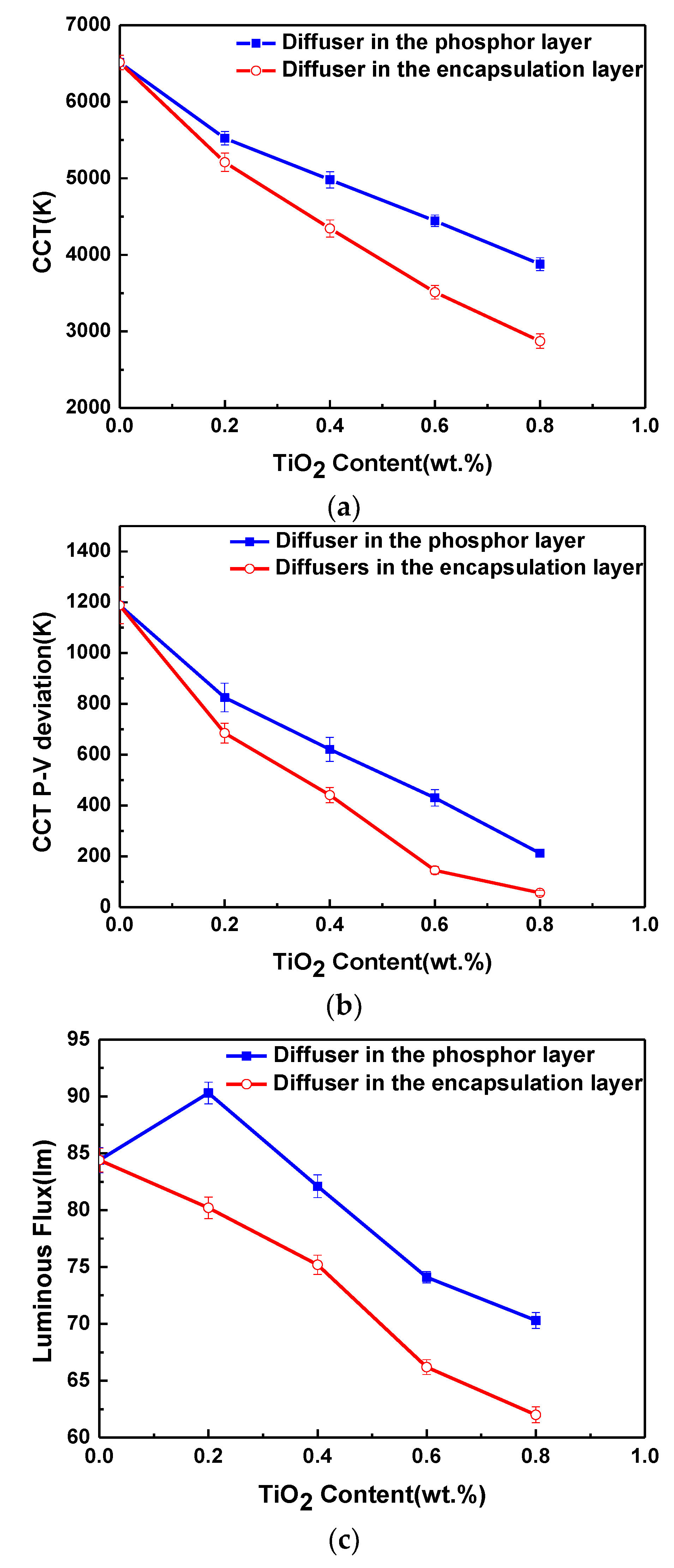

3.1. Results of Different Diffuser Positions and Diffuser Contents in the Remote Phosphor LEDs

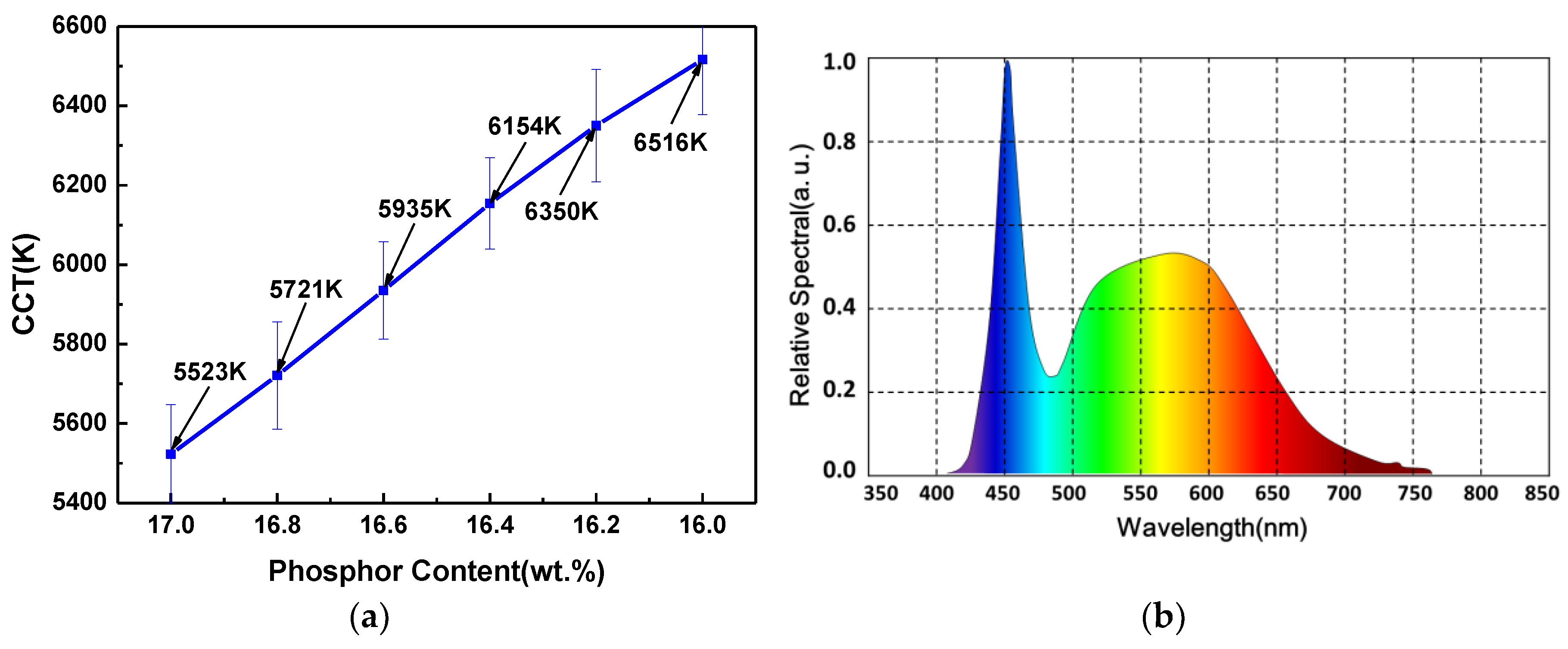

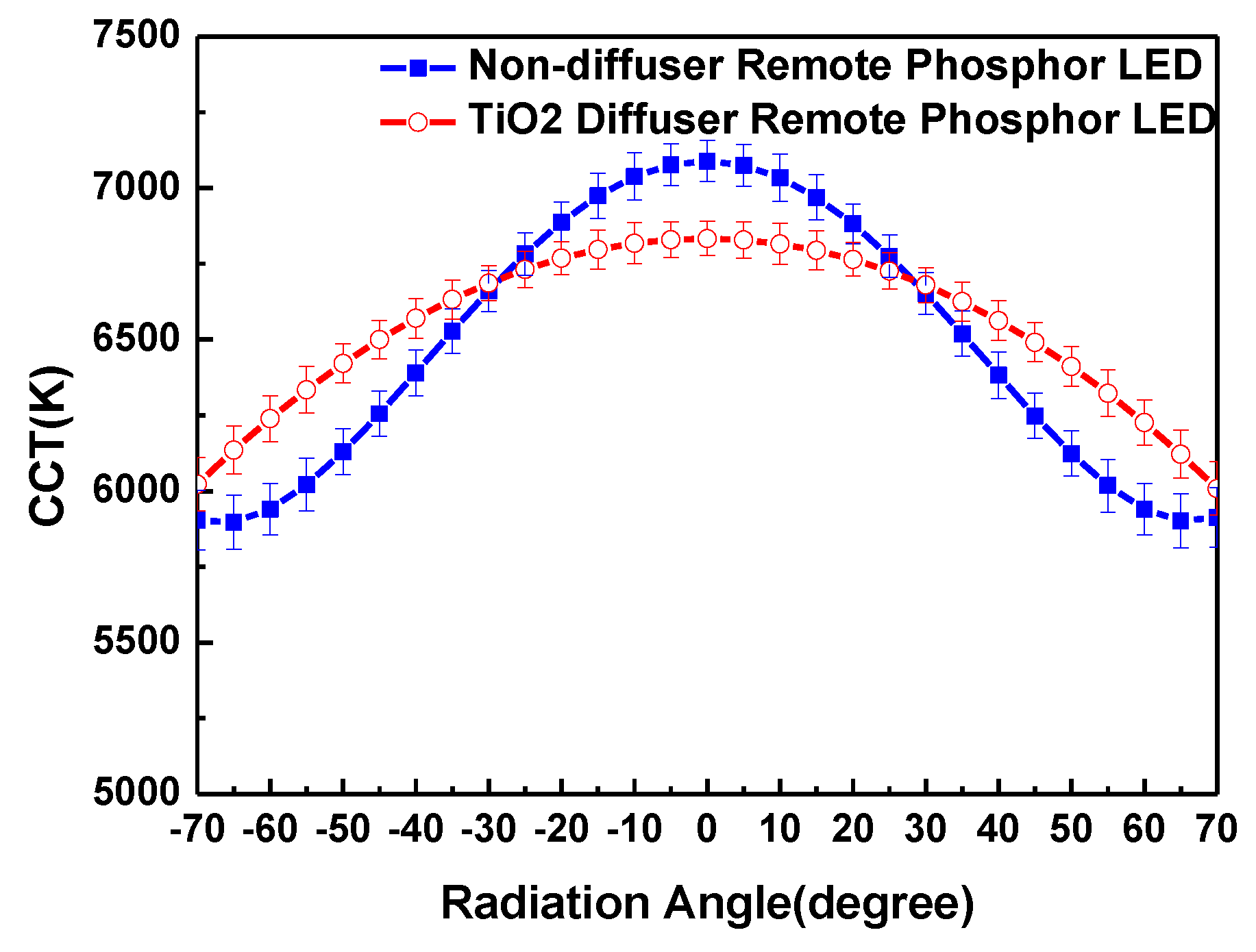

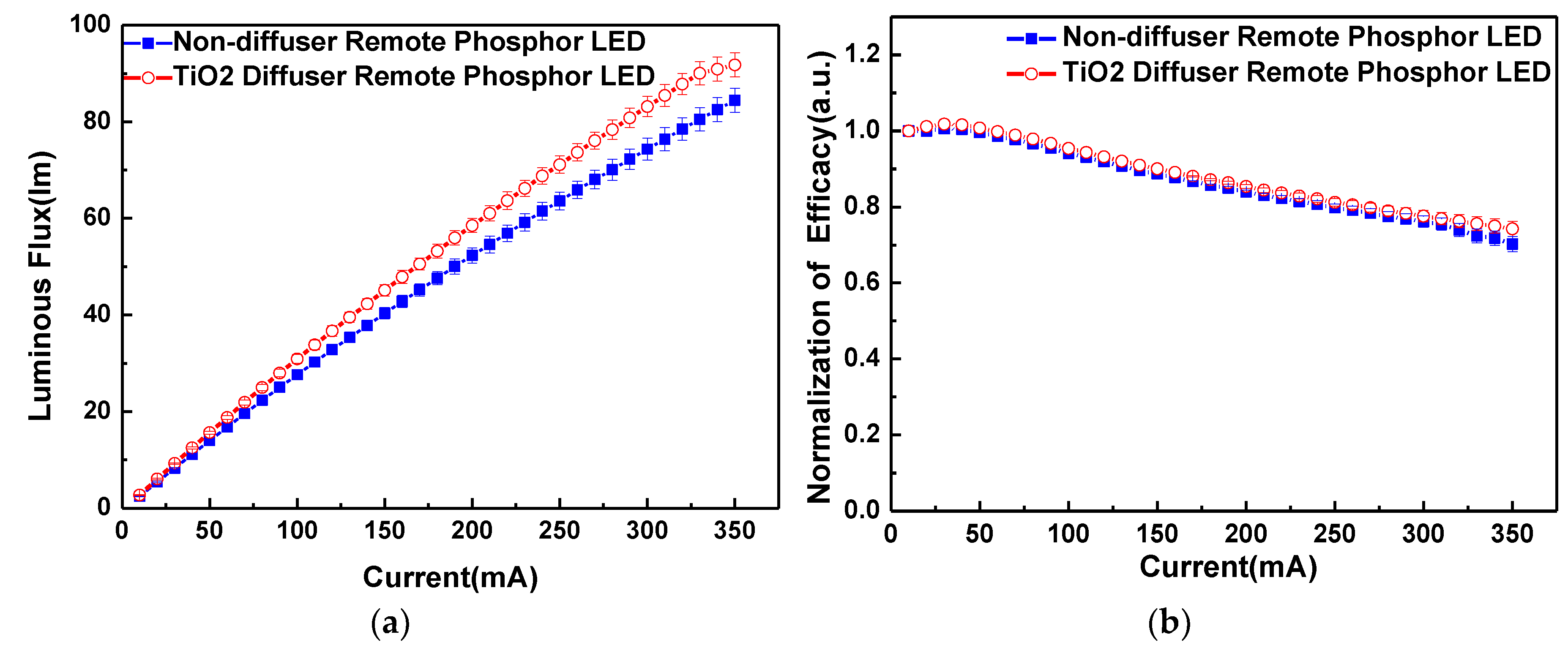

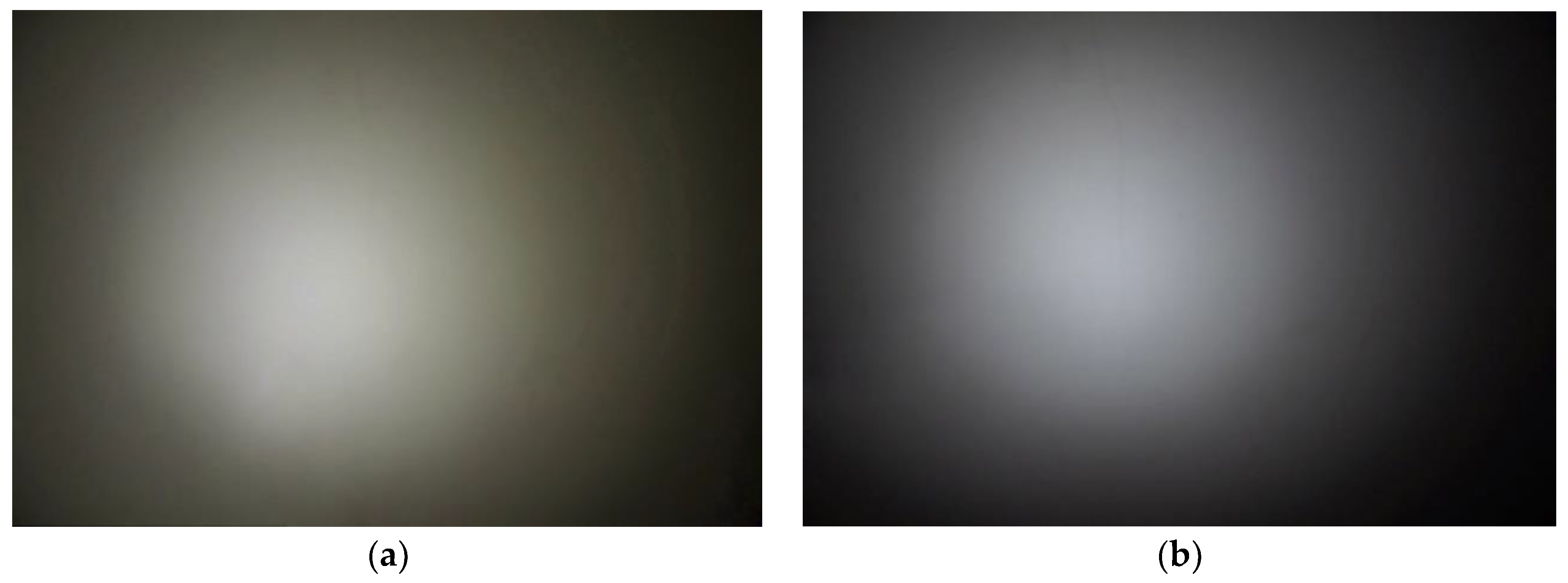

3.2. Optimum Design of the Remote Phosphor LED

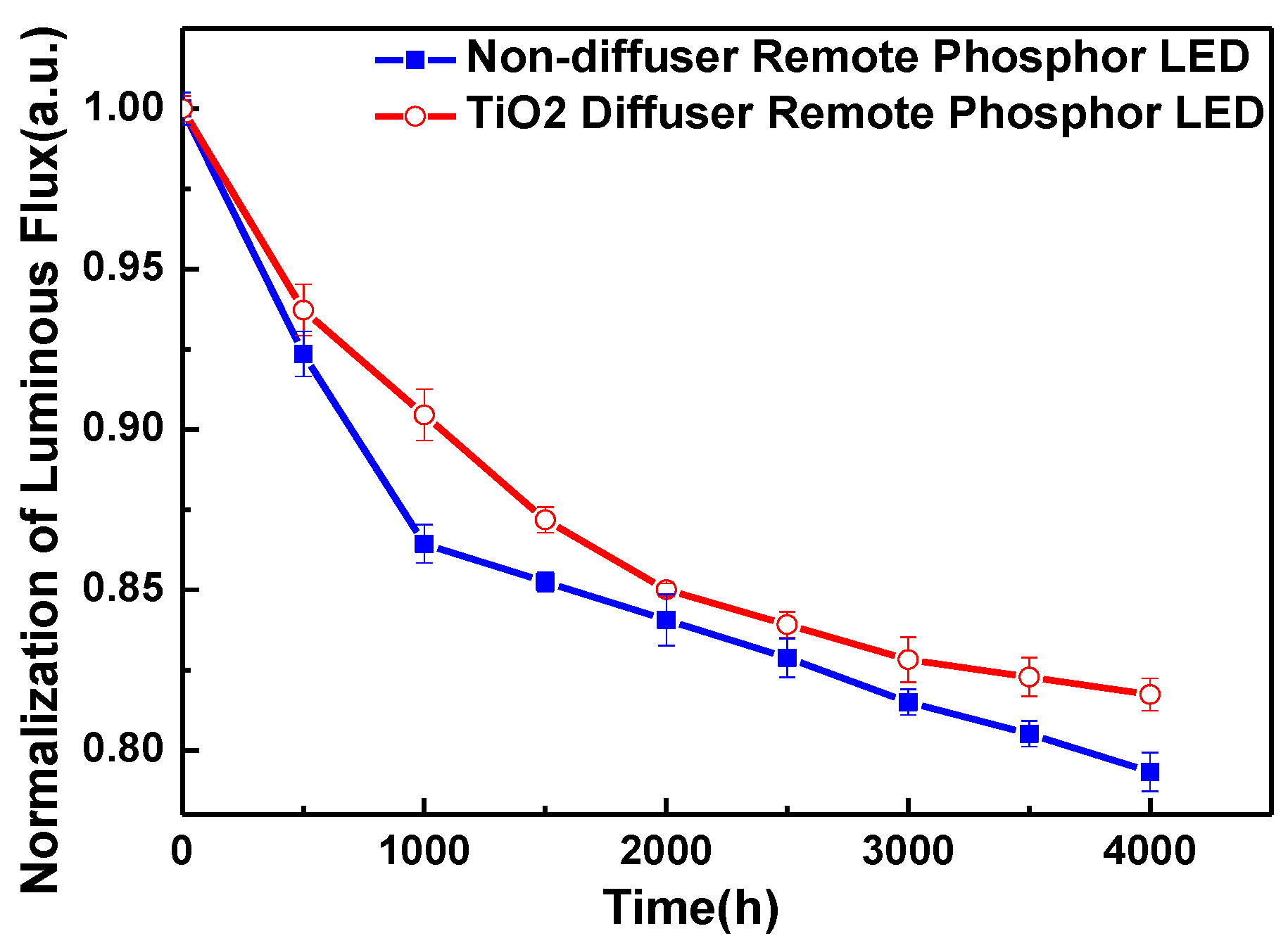

3.3. Reliability Analysis of the TiO2 Diffuser-Loaded Encapsulation Remote Phosphor LED

4. Conclusions

Author Contributions

Funding

Acknowledgment

Conflicts of Interest

References

- Sun, C.; Zhang, Y.; Wang, Y.; Liu, W.; Kalytchuk, S.; Kershaw, S.V.; Zhang, T.; Zhang, X.; Zhao, J.; Yu, W.W.; Rogach, A.L. High color rendering index white light emitting diodes fabricated from a combination of carbon dots and zinc copper indium sulfide quantum dots. Appl. Phys. Lett. 2014, 104, 261106. [Google Scholar] [CrossRef]

- Narendran, N.; Gu, Y.; Freyssinier-Nova, J.P.; Zhu, Y. Extracting phosphor-scattered photons to improve white LED efficiency. Phys. Status Solidi 2005, 202, R60–R62. [Google Scholar] [CrossRef]

- Kim, J.K.; Luo, H.; Schubert, E.F.; Cho, J.; Sone, C.; Park, Y. Strongly enhanced phosphor efficiency in GaInN white light-emitting diodes using remote phosphor configuration and diffuse reflector cup. Jpn. J. Appl. Phys. 2005, 44, 649. [Google Scholar] [CrossRef]

- Luo, H.; Kim, J.K.; Schubert, E.F.; Cho, J.; Sone, C.; Park, Y. Analysis of high-power packages for phosphor-based white-light-emitting diodes. Appl. Phys. Lett. 2005, 86, 243505. [Google Scholar] [CrossRef] [Green Version]

- Fan, B.F.; Wu, H.; Zhao, Y.; Xian, Y.L.; Wang, G. Study of phosphor thermal-isolated packing technologies for high-power white light-emiting diode. IEEE Photon. Technol. Lett. 2007, 19, 1121–1123. [Google Scholar] [CrossRef]

- Sommer, C.; Hartmann, P.; Pachler, P.; Schweighart, M.; Tasch, S.; Leising, G.; Wenzl, F.P. The effect of the phosphor particle sizes on the angular homogeneity of phosphor-converted high-power white LED light sources. Opt. Mater. 2009, 31, 1181–1188. [Google Scholar] [CrossRef]

- Hong, L.A.; Ou, C.J.; Chang, Y.C.; Juang, F.S. Practical issues for two-light-sources model of phosphor-based white light-emitting diode. Opt. Rev. 2011, 18, 76–79. [Google Scholar] [CrossRef]

- Huang, K.C.; Lai, T.H.; Chen, C.Y. Improved CCT uniformity of white LED using remote phosphor with patterned sapphire substrate. Appl. Opt. 2013, 52, 7376–7381. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.C.; Chen, K.J.; Lin, C.C.; Wang, C.H.; Han, H.V.; Tsai, H.H.; Kuo, H.T.; Chien, S.H.; Shih, M.H.; Kuo, H.C. Improvement in uniformity of emission by ZrO₂ nano-particles for white LEDs. Nanotechnology 2012, 23, 265201. [Google Scholar] [CrossRef] [PubMed]

- Kuo, H.C.; Hung, C.W.; Chen, H.C.; Chen, K.J.; Wang, C.H.; Sher, C.W.; Yeh, C.C.; Lin, C.C.; Chen, C.H.; Cheng, Y.J. Patterned structure of REMOTE PHOSPHOR for phosphor-converted white LEDs. Opt. Express 2011, 19, A930–A936. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Li, J.; Chen, Q.; Tang, Y.; Li, Z.; Yu, B. Improving LED CCT uniformity using micropatterned films optimized by combining ray tracing and FDTD methods. Opt. Express 2015, A180–A191. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Lv, Z.C.; Yuan, J.J.; Liu, S. Effects of melamine formaldehyde resin and CaCO3 diffuser-loaded encapsulation on correlated color temperature uniformity of phosphor-converted LEDs. Appl. Opt. 2013, 52, 5539–5544. [Google Scholar] [CrossRef] [PubMed]

- Lai, M.F.; Anh, N.D.Q.; Ma, H.Y.; Lee, H.Y. Scattering effect of SiO2 particles on correlated color temperature uniformity of multi-chip white light LEDs. J. Chin. Inst. Eng. 2016, 39, 468–472. [Google Scholar] [CrossRef]

- Minh, T.H.Q.; Nhan, N.H.K.; Anh, N.D.Q.; Nam, T.T.; Lee, H.Y. Improving color uniformity and color rending index of remote-phosphor packaging white LEDs by co-doping SiO2 and Sr2Si5N8:Eu2+ particles. Mater. Sci.-Pl. 2018, 36, 370–374. [Google Scholar] [CrossRef]

- Yuce, H.; Guner, T.; Balci, S.; Demir, M.M. Phosphor-based white LED by various glassy particles: control over luminous efficiency. Opt. Lett. 2019, 44, 479–482. [Google Scholar] [CrossRef] [PubMed]

- Qi, R. Particle Size and Distribution of Titanium Dioxide Produced by Chloride Procedure. Mod. Paint Finish. 2007, 10, 44–50. [Google Scholar]

- van de Hulst, H.C. Light Scattering by Small Particles; Dover: New York, NY, USA, 1981. [Google Scholar]

- Luo, H.; Kim, J.K.; Xi, Y.A.; Schubert, E.F.; Cho, J.; Sone, C.; Park, Y. A nearly ideal phosphor-converted white light-emitting diode. Appl. Phys. Lett. 2006, 89, 041125. [Google Scholar] [CrossRef]

- Li, Y.Q.; Fu, S.Y.; Yang, Y.; Mai, Y.W. Facile Synthesis of Highly Transparent Polymer Nanocomposites by Introduction of Core–Shell Structured Nanoparticles. Chem. Mater. 2008, 20, 2637–2643. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.Q.; Fu, S.Y.; Xiao, H.M. Transparent and Light-Emitting Epoxy Nanocomposites Containing ZnO Quantum Dots as Encapsulating Materials for Solid State Lighting. J. Phys. Chem. C 2008, 112, 10553–10558. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chou, Y.-F.; Chen, C.-F.; Ying, S.-P.; Yeh, Y.-Y. The Effects of TiO2 Diffuser-Loaded Encapsulation on Corrected Color Temperature Uniformity of Remote Phosphor White LEDs. Appl. Sci. 2019, 9, 675. https://doi.org/10.3390/app9040675

Chou Y-F, Chen C-F, Ying S-P, Yeh Y-Y. The Effects of TiO2 Diffuser-Loaded Encapsulation on Corrected Color Temperature Uniformity of Remote Phosphor White LEDs. Applied Sciences. 2019; 9(4):675. https://doi.org/10.3390/app9040675

Chicago/Turabian StyleChou, Yung-Fang, Chi-Feng Chen, Shang-Ping Ying, and Yun-Ying Yeh. 2019. "The Effects of TiO2 Diffuser-Loaded Encapsulation on Corrected Color Temperature Uniformity of Remote Phosphor White LEDs" Applied Sciences 9, no. 4: 675. https://doi.org/10.3390/app9040675