Wet Snow Flashover Characteristics of 500-kV AC Insulator Strings with Different Arrangements

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Setup, Specimens, and Test Procedure

2.1. Experimental Setup

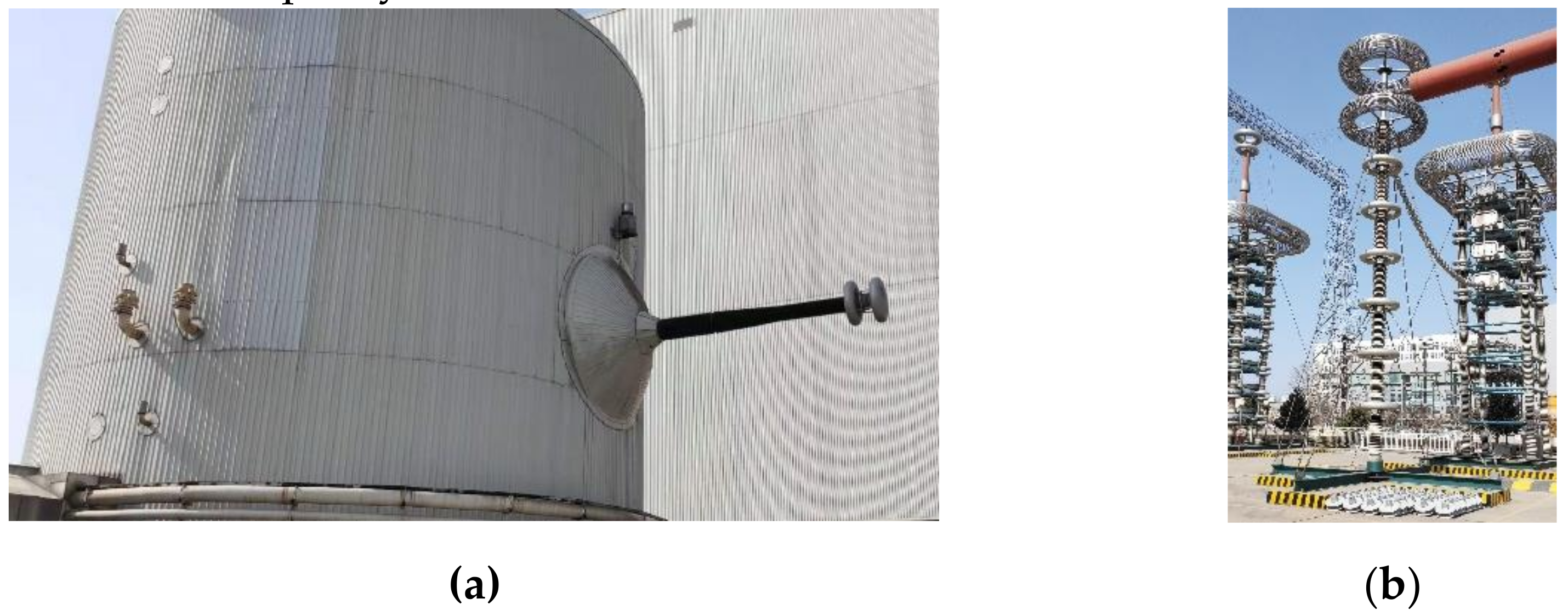

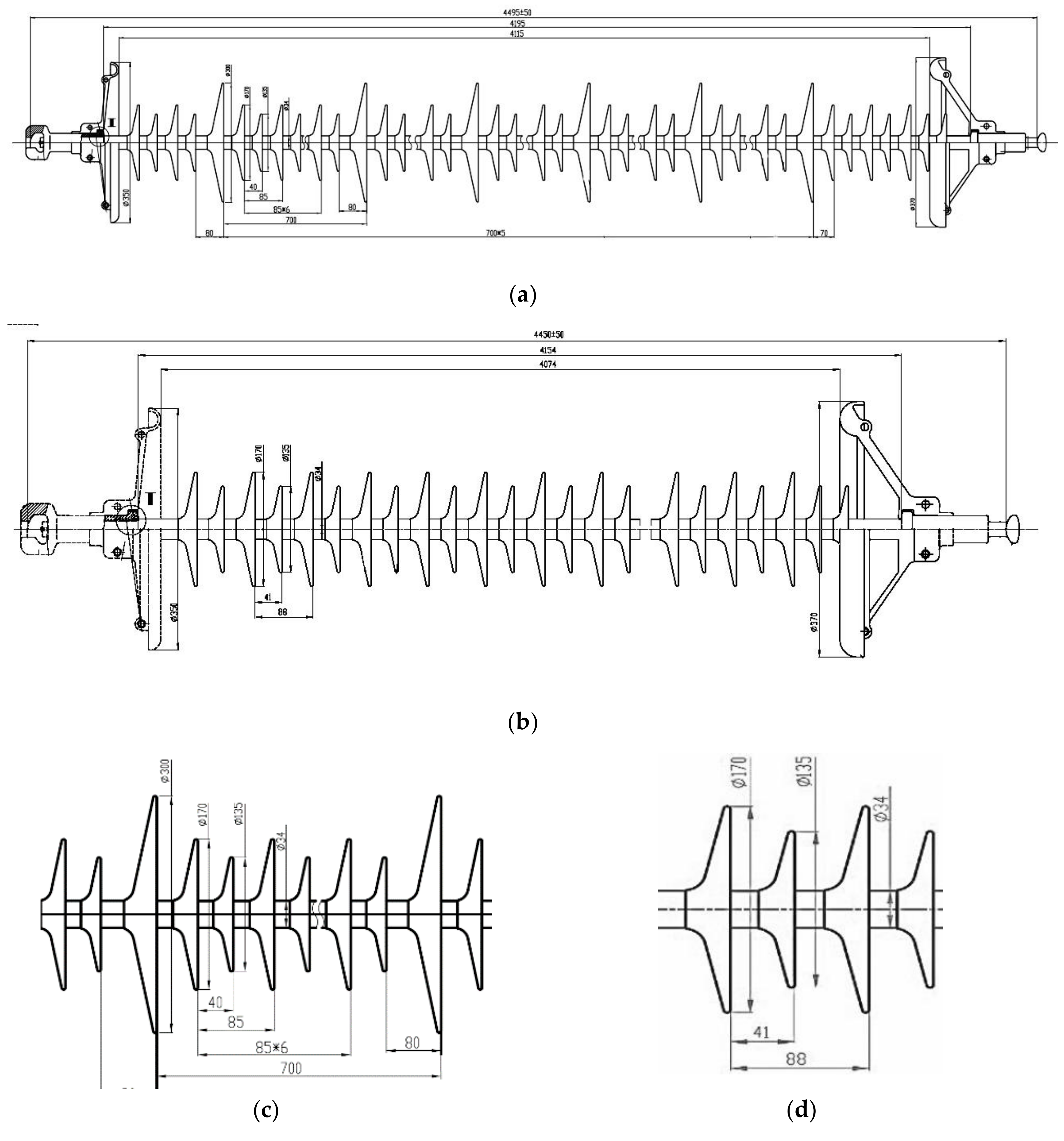

2.2. Specimen

2.3. Test Procedure

3. Results

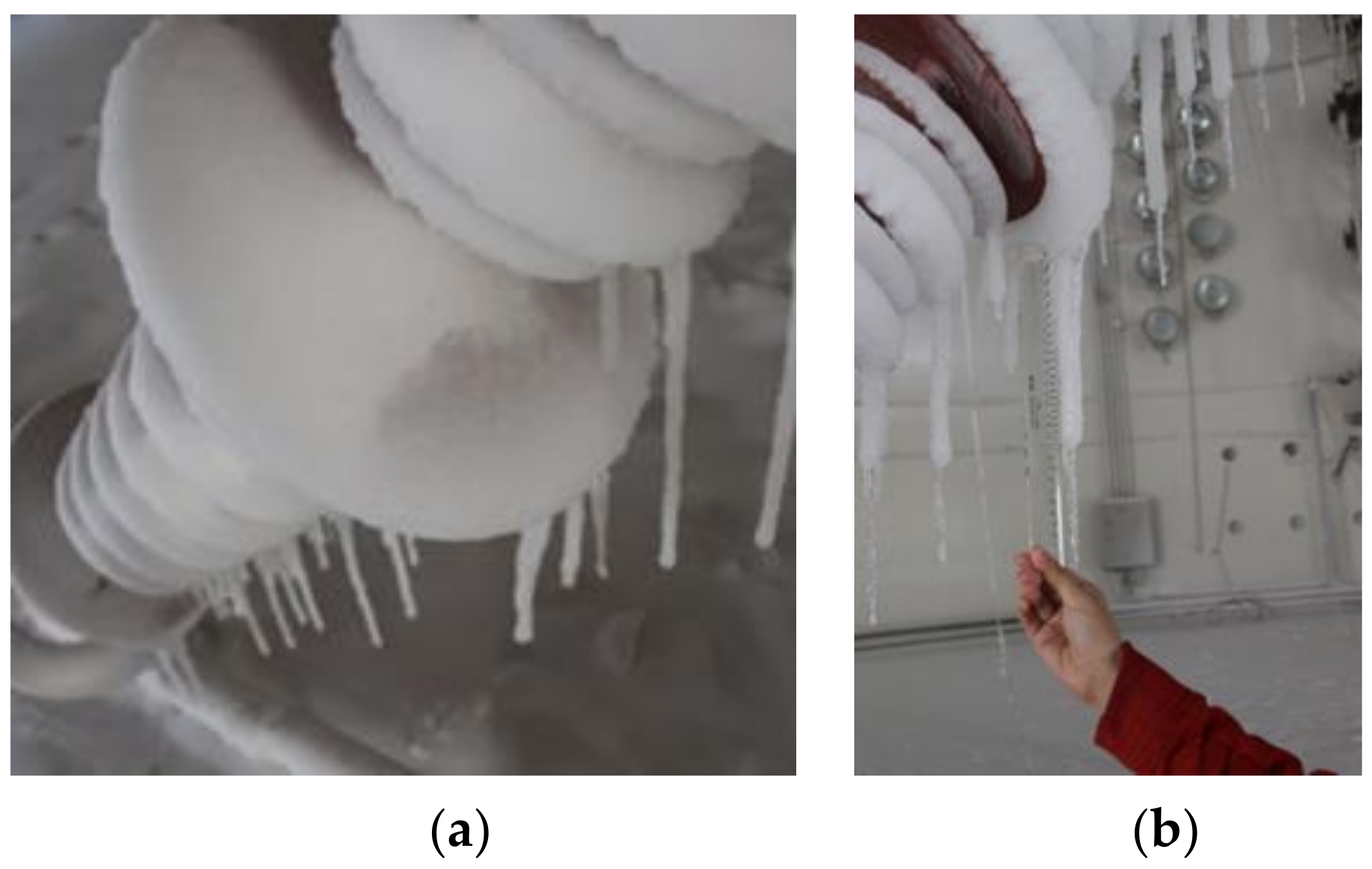

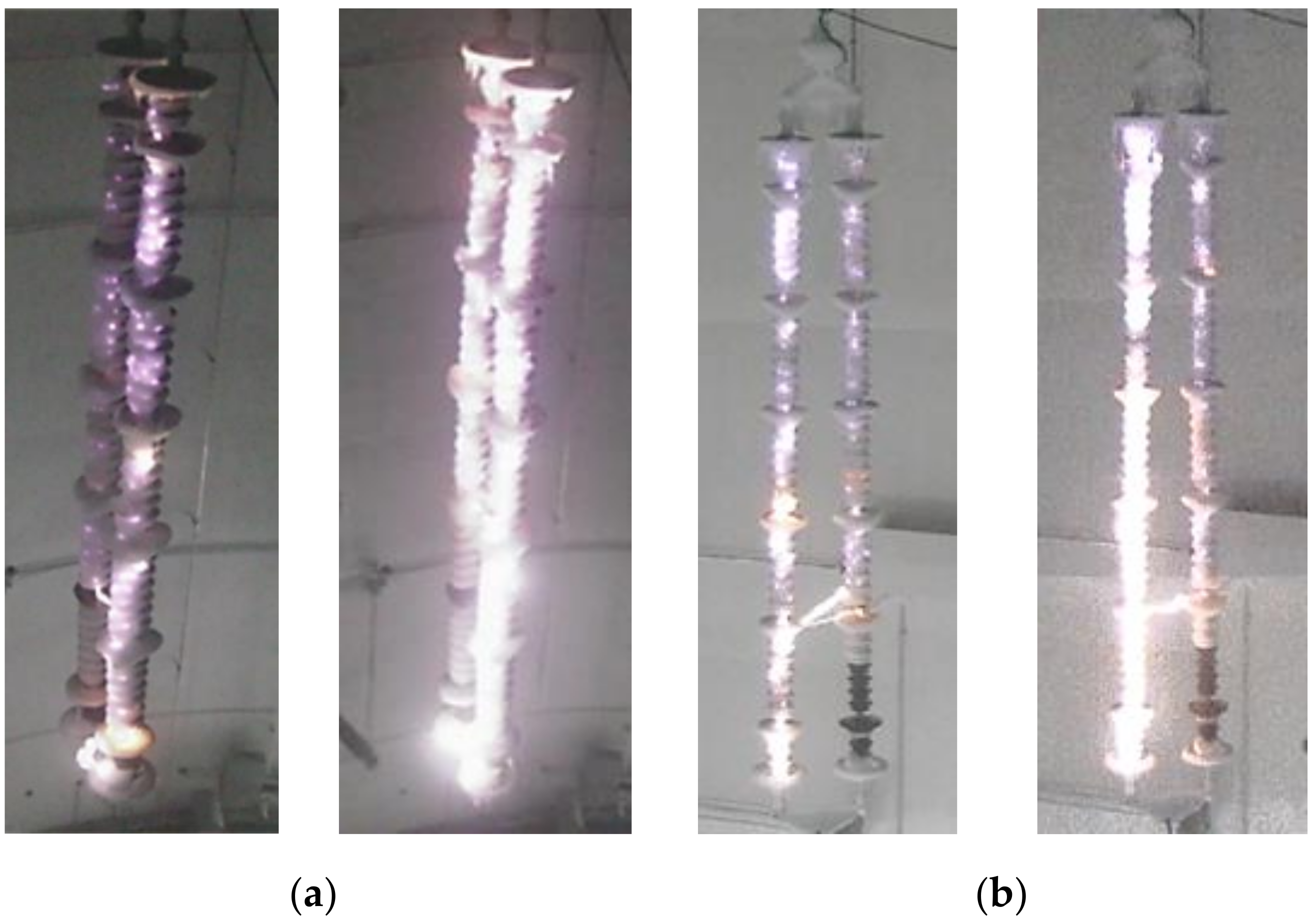

3.1. The Flashover Test of Λ-string

3.2. The Flashover Test of II-String

3.3. The Influence of Shed Type on Flashover

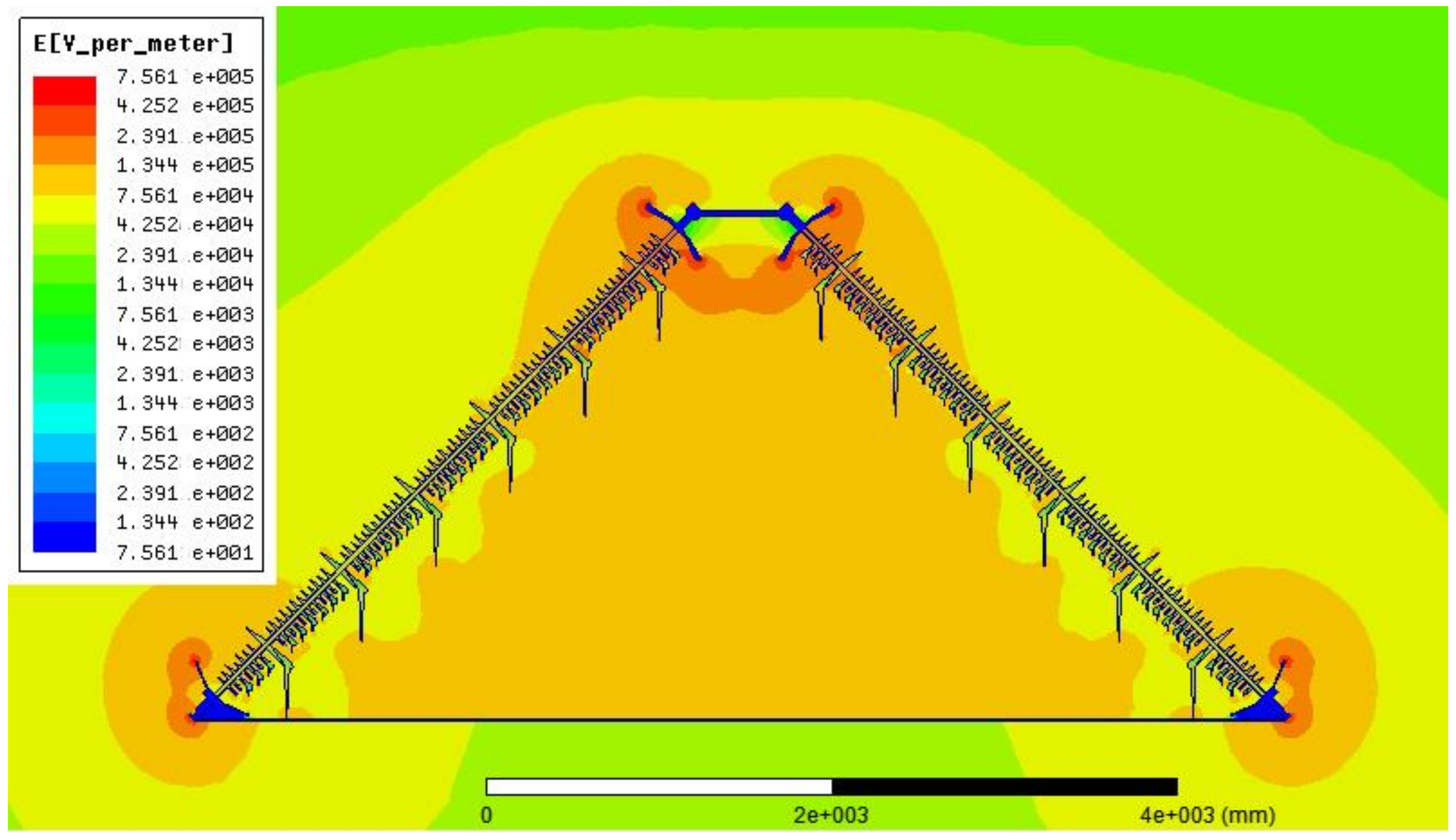

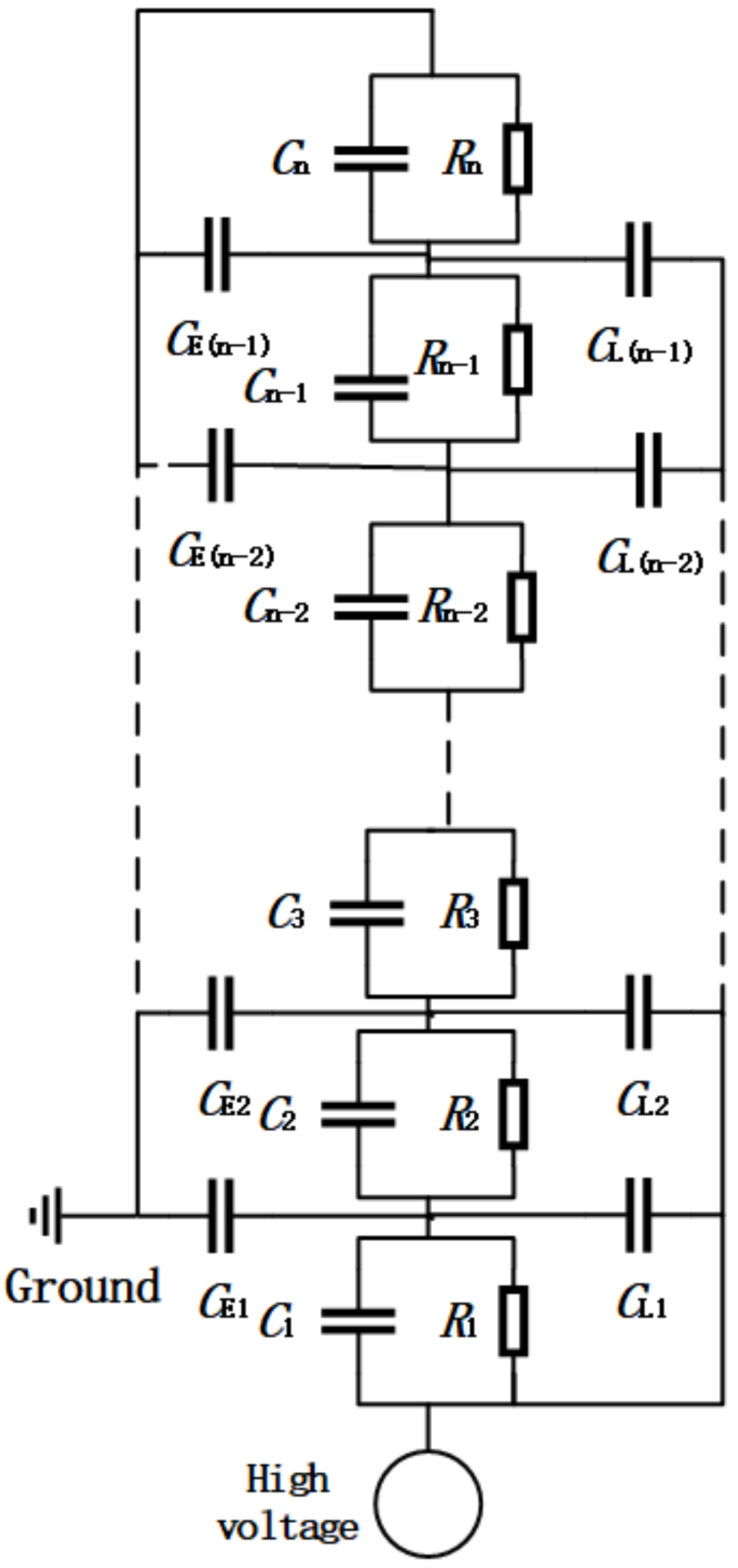

- (1)

- The insulation distance of the insulator string with anti-icing sheds is a little longer than that with common sheds for all arrangements.

- (2)

- The anti-icing sheds, due to their larger diameter, can hinder or delay the arc development.

- (3)

- Compared with an insulator string with common sheds, the air gaps between big sheds can increase the capacitance of the snowed insulator string. As a larger insulator capacitance can weaken the influence of stray capacitance, the distribution of voltage along the insulator string will be relatively uniform and result in a higher flashover.

4. Conclusions

- Installing anti-icing sheds is an effective method to improve the flashover performance of insulators used in cold regions.

- Increasing the connection angle can reduce the severity of snow bridging, and therefore increase the flashover performance of insulators with common sheds as the connection angle is increased. However, it was found that for insulators with anti-icing sheds and connection angle higher than 60°, with a small angle between the insulator string and the conductor, the air gap between the icicle and the conductor can breakdown readily if long icicles are accreted on the big shed. According to the test results, when it comes to the electrical performance, the recommended connection angles for Λ-string arrangements with common sheds and with anti-icing sheds are 90° and 60°, respectively.

- Increasing the distance between two insulators can improve the flashover voltage performance. When the distance between the two insulators is too close, the flashover voltage will be reduced due to the floating arcs bridging two parallel insulators. For an II-string arrangement, when the distance was increased from 450 mm to 650 mm, the flashover voltages were increased 3.2% and 7.1% for common shed and anti-icing shed insulators. The recommended distance between the two high-voltage terminals is at least 600 mm for the strings with common sheds and at least 650 mm for the strings with anti-icing sheds.

- When the connection angle is 60°, which is widely adopted in transmission lines, the flashover performance of common insulators under Λ-string and V-string arrangements are almost same for the same snowing conditions. However, due to the presence of long icicles, the flashover voltage of anti-icing insulators under a V-string arrangement is higher than that of a Λ-string arrangement.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Farzaneh, M. Atmospheric Icing of Power Networks; Springer: Dordrecht, The Netherlands, 2008. [Google Scholar]

- Farzaneh, M.; Chisholm, W.A. Insulators for Icing and Polluted Environments; John Wiley & Sons Press: Piscataway, NJ, USA, 2009. [Google Scholar]

- Yin, F.; Farzaneh, M.; Jiang, X. Influence of AC electric field on conductor icing. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2134–2144. [Google Scholar] [CrossRef]

- Yin, F.; Jiang, X.; Farzaneh, M. Electrical performance of composite insulators under icing conditions. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2584–2593. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, X.; Yin, F.; Zhang, Z. DC flashover performance of ice-covered composite insulators with parallel air gaps. Energies 2015, 8, 4983–4999. [Google Scholar] [CrossRef]

- Berlijn, S.; Gutman, I.; Halsan, K.; Eilertsten, M.; Gu, I.Y.H. Laboratory tests and web based surveillance to determine the ice-and snow performance of insulators. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 1373–1380. [Google Scholar] [CrossRef]

- Farzaneh, J.; Zhang, J.; Farzaneh, M. Experimental study and mathematical modelling of flashover on extra-high voltage insulators covered with ice. Hydrol. Proc. 2004, 18, 3471–3480. [Google Scholar] [CrossRef]

- Farzaneh, M.; Baker, T.; Bernstorf, A.; Burnham, J.T.; Carreira, T.; Cherney, E.; Chisholm, W.; Christman, R.; Cole, R.; Cortinas, J.; et al. Selection of station insulators with respect to ice and snow—Part I: Technical context and environmental exposure. IEEE Trans. Power Deliv. 2005, 20, 264–270. [Google Scholar] [CrossRef]

- Farzaneh, M.; Baker, T.; Bernstorf, A.; Burnham, J.T.; Carreira, T.; Cherney, E.; Chisholm, W.; Christman, R.; Cole, R.; Cortinas, J.; et al. Selection of station insulators with respect to ice and snow—Part II: Methods of selection and options for mitigation. IEEE Trans. Power Deliv. 2005, 20, 271–277. [Google Scholar] [CrossRef]

- Farzaneh, M.; Baker, A.C.; Bernstorf, R.; Burnham, J.T.; Carreira, T.; Cherney, E.; Chisholm, W.; Christman, R.; Cole, R.; Cortinas, J.; et al. Selection of line insulators with respect to ice and snow—Part II: Selection methods and mitigation options. IEEE Trans. Power Deliv. 2007, 22, 2297–2304. [Google Scholar] [CrossRef]

- Xun, K.; He, C.; Du, Y.; Yuan, Z. Development and application of transmission line inversed V-shape insulator string. Electr. Power Construct. 2008, 29, 31–34. [Google Scholar]

- Guan, Z.; Peng, G.; Zhao, F. DC pollution flashover characteristics on porcelain insulators of parallel double-strings form at high altitude. High Voltage Eng. 2010, 36, 2613–2620. [Google Scholar]

- Zheng, J. Research on optimum angle of the insulator strings in “Λ” shape on 500 kV transmission lines. J. Electr. Power 2010, 25, 328–331. [Google Scholar]

- Zhang, C.; Wang, L.; Zhou, J. AC and DC pollution flashover performance of multiple parallel suspension insulators. High Volt. Eng. 2014, 40, 3357–3364. [Google Scholar]

- Zhao, Q.; Xu, W.; Liu, W.; Zhou, K. Application suggestion and force analysis of backward V-type insulators. Smart Grid 2017, 5, 142–146. [Google Scholar]

- Wei, M.; Huo, F.; Ruan, J.; Huang, C.; Wan, X. Study on electric field distribution and grading ring’s parameters design of backward V-type insulator string on UHV AC transmission line. Adv. Technol. Electr. Eng. Energy 2016, 35, 23–28. [Google Scholar]

- Yan, S.; Wan, Q.; Xu, Z. Experimental study on the flashover characteristics of 500 kV AC ice-covered insulator string under different arrangement. High Volt. Eng. 2011, 37, 3129–3134. [Google Scholar]

- Ma, K.; Li, G.; Yang, W.; Ma, B. Test on power frequency flashover property of 110 kV single and double composite insulator strings. Ningxia Electr. Power 2011, 6, 22–25. [Google Scholar]

- Hu, W.; Huo, F.; Xu, T.; Nan, J.; Ye, Q.; Ma, Y. Air-gaps flashover characteristics and insulation coordination of inverse V-type insulator string tower for UHV AC transmission line. High Volt. Eng. 2017, 43, 4117–4122. [Google Scholar]

- IEC TS 60815-1. Selection and Dimensioning of High-Voltage Insulators Intended for Use in Polluted Conditions—Part 1: Definitions, Information and General Principles; International Electrotechnical Commission: Worcester, MA, USA, 2008. [Google Scholar]

- IEC TS 60815-3. Selection and Dimensioning of High-Voltage Insulators Intended for Use in Polluted Conditions—Part 3: Polymer Insulators for a. c. Systems; International Electrotechnical Commission: Worcester, MA, USA, 2008. [Google Scholar]

- GB T 4585. Artificial Pollution Tests on High-Voltage Insulators to Be Used on AC Systems; Standards Press of China: Beijing, China, 2004. [Google Scholar]

- IEC 60507:2013. Artificial Pollution Tests on High-Voltage Insulators to Be Used on a. c. Systems; International Electrotechnical Commission: Worcester, MA, USA, 2013. [Google Scholar]

- IEEE Std 1783-2009. IEEE Guide for Test Methods and Procedures to Evaluate the Electrical Performance of Insulators in Freezing Conditions; Institute of Electronics Engineers: New York, NY, USA, 2009. [Google Scholar]

- Li, Z.; Cui, J.; Zhou, Y.; Wang, L. Influence of insulator installation form on its pollution flashover voltage. Power Syst. Technol. 2005, 29, 52–55. [Google Scholar]

- Zhang, Z.; Zhang, D.; You, J. Study on the DC flashover performance of various types of insulators with fan-shaped nonuniform pollution. IEEE Trans. Power Deliv. 2015, 30, 1871–1879. [Google Scholar] [CrossRef]

- Taherian, R.; Kausar, A. Electrical Conductivity in Polymer-Based Composites: Experiments, Modelling, and Applications; William Andrew Publisher: Oxford, UK, 2019. [Google Scholar]

- Volat, C.; Farzaneh, M. Three-dimensional modeling of potential and electric-field distributions along an EHV ceramic post insulator covered with ice—Part I: Simulations of a melting period. IEEE Trans. Power Deliv. 2005, 20, 2006–2013. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Power voltage | 380 V |

| Air supply pressure | 90 PSI |

| Water supply pressure | 105–500 PSI |

| Snow production capacity | 0–30 m3/h |

| Operating temperature | 0–30 °C |

| Shed Type | Arcing Distance (mm) | Leakage Distance (mm) | Shed Diameters D1/D2/D3 (mm) | Shed Numbers N1/N2/N3 | Rod Diameter D (mm) | Shed Spacing d1/d2/d3/d4 (mm) |

|---|---|---|---|---|---|---|

| The anti-icing type | 4195 | 14,000 | 300/170/135 | 6/35/36 | 34 | 40/45/70/80 |

| The common type | 4154 | 14,000 | 170/135 | 46/47 | 34 | 41/47 |

| String Arrangements | Common Shed | Anti-Icing Shed | ||||

|---|---|---|---|---|---|---|

| Flashover Voltage (kV) | σ (%) | β (%) | Flashover Voltage (kV) | σ (%) | β (%) | |

| Single string | 391.0 | 15.5 | 0.0 | 450.0 | 5.1 | 15.1 |

| II-string(450 mm) | 373.5 | 5.1 | −4.5 | 416.3 | 3.3 | 6.5 |

| 2°Λ-string | 381.5 | 10.1 | −2.4 | 435.0 | 12.2 | 11.2 |

| 30°Λ-string | 410.6 | 1.2 | 5.0 | 458.2 | 9.4 | 17.2 |

| 60°Λ-string | 439.4 | 11.8 | 12.4 | 499.5 | 7.3 | 27.7 |

| 90°Λ-string | 450.1 | 13.7 | 15.1 | 479.8 | 13.2 | 22.7 |

| II-string(650 mm) | 385.6 | 17.3 | -1.3 | 444.3 | 2.6 | 13.6 |

| 60°V-string | 436.0 | 5.2 | 11.5 | 512.3 | 6.7 | 31.0 |

| Parameters | Silicone Rubber | Ice | Snow | Water Film | Air |

|---|---|---|---|---|---|

| Relative permittivity, εr | 6.0 | 70 | 6.0 | 81 | 1.02 |

| Conductivity (μS/cm) | 0 | 1 | 100 | 670 | 0 |

| Thickness (mm) | - | Variable | Variable | 0.15 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Yin, F.; Li, L.; Wen, Q.; Wang, H.; Liu, S.; Jia, Z.; Farzaneh, M. Wet Snow Flashover Characteristics of 500-kV AC Insulator Strings with Different Arrangements. Appl. Sci. 2019, 9, 930. https://doi.org/10.3390/app9050930

Xu J, Yin F, Li L, Wen Q, Wang H, Liu S, Jia Z, Farzaneh M. Wet Snow Flashover Characteristics of 500-kV AC Insulator Strings with Different Arrangements. Applied Sciences. 2019; 9(5):930. https://doi.org/10.3390/app9050930

Chicago/Turabian StyleXu, Jingwei, Fanghui Yin, Longji Li, Qingfeng Wen, Hao Wang, Shunnan Liu, Zhidong Jia, and Masoud Farzaneh. 2019. "Wet Snow Flashover Characteristics of 500-kV AC Insulator Strings with Different Arrangements" Applied Sciences 9, no. 5: 930. https://doi.org/10.3390/app9050930

APA StyleXu, J., Yin, F., Li, L., Wen, Q., Wang, H., Liu, S., Jia, Z., & Farzaneh, M. (2019). Wet Snow Flashover Characteristics of 500-kV AC Insulator Strings with Different Arrangements. Applied Sciences, 9(5), 930. https://doi.org/10.3390/app9050930