Time Domain NMR in Polymer Science: From the Laboratory to the Industry

Abstract

:1. Introduction

2. Sequences

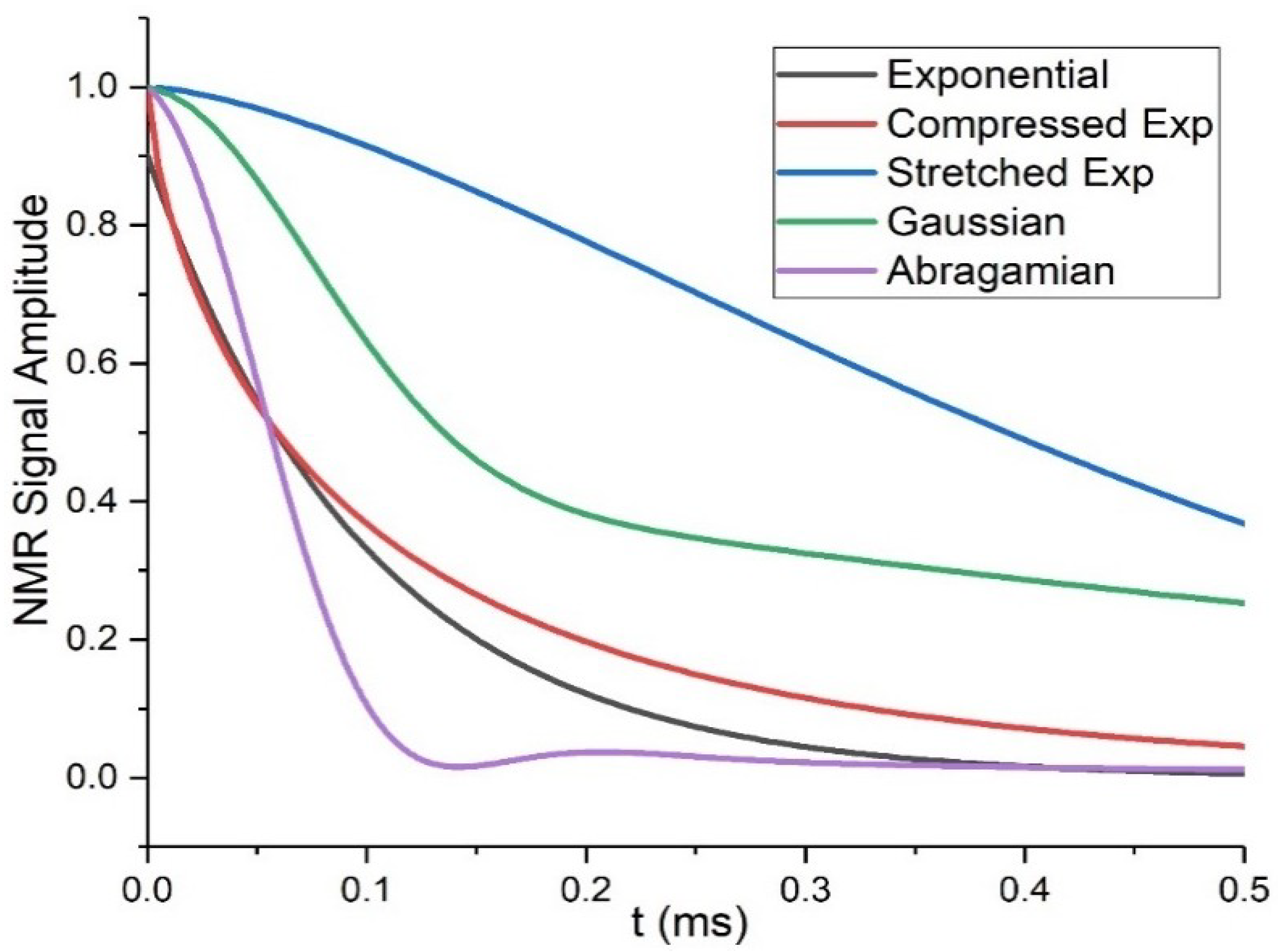

2.1. 1H T2 Relaxation

2.2. 1H T1 Relaxation

2.3. 1H T1 in the Rotating Frame (1H T1ρ)

2.4. Multiple-Quantum (MQ)

2.5. Spins’ Manipulation

2.6. Spin-diffusion

2.7. Steady-state Free Precession (CP-CWFP Sequence)

2.8. Data Processing

3. Applications

3.1. Discovery and Characterization of New Materials

3.2. Polymer Physics

3.3. Bioplastics

3.4. Industrial Applications

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Bicerano, J. Prediction of Polymers, 3rd ed.; Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2002; ISBN 0824708210. [Google Scholar]

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1977–1984. [Google Scholar] [CrossRef] [Green Version]

- Schmidt-Rohr, K.; Spiess, H.W. Multidimensional Solid-State NMR and Polymers; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- McBrierty, V.J.; Douglass, D.C. Recent advances in the NMR of solid polymers. J. Polym. Sci. Macromol. Rev. 1981, 16, 295–366. [Google Scholar] [CrossRef]

- McBrierty, V.J.; Douglass, D.C. Nuclear Magnetic-Resonance of Solid Polymers. Phys. Rep. Rev. Sec. Phys. Lett. 1980, 63, 63–147. [Google Scholar] [CrossRef]

- Eidmann, G.; Savelsberg, R.; Blümler, P.; Blümich, B. The NMR MOUSE, a Mobile Universal Surface Explorer. J. Magn. Reson. Ser. A 1996, 122, 104–109. [Google Scholar] [CrossRef]

- Goldman, M. Quantum Description of High-Resolution NMR in Liquids; Oxford University Press: Oxford, UK, 1988. [Google Scholar]

- Steele, R.M.; Korb, J.P.; Ferrante, G.; Bubici, S. New applications and perspectives of fast field cycling NMR relaxometry. Magn. Reson. Chem. 2016, 54, 502–509. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, M.; Gainaru, C.; Cetinkaya, B.; Valiullin, R.; Fatkullin, N.; Rössler, E.A. Field-Cycling Relaxometry as a Molecular Rheology Technique: Common Analysis of NMR, Shear Modulus and Dielectric Loss Data of Polymers vs Dendrimers. Macromolecules 2015, 48, 7521–7534. [Google Scholar] [CrossRef]

- Håkansson, B.; Nydén, M.; Söderman, O. The influence of polymer molecular-weight distributions on pulsed field gradient nuclear magnetic resonance self-diffusion experiments. Colloid Polym. Sci. 2000, 278, 399–405. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, L.; Liao, G.; Song, Y.Q. Direct correlation of diffusion and pore size distributions with low field NMR. J. Magn. Reson. 2016, 269, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Abrami, M.; Chiarappa, G.; Farra, R.; Grassi, G.; Marizza, P.; Grassi, M. Use of low-field NMR for the characterization of gels and biological tissues. Admet Dmpk 2018, 6, 34–46. [Google Scholar] [CrossRef] [Green Version]

- Hahn, E.L. Spin echoes. Phys. Rev. 1950, 80, 580–594. [Google Scholar] [CrossRef]

- Meiboom, S.; Gill, D. Modified spin-echo method for measuring nuclear relaxation times. Rev. Sci. Instrum. 1958, 29, 688–691. [Google Scholar] [CrossRef]

- Song, Y. Categories of Coherence Pathways for the CPMG Sequence. J. Magn. Reson. 2002, 91, 82–91. [Google Scholar] [CrossRef]

- Schäler, K.; Roos, M.; Micke, P.; Golitsyn, Y.; Seidlitz, A.; Thurn-albrecht, T.; Schneider, H.; Hempel, G.; Saalwächter, K. Basic principles of static proton low-resolution spin diffusion NMR in nanophase-separated materials with mobility contrast. Solid State Nucl. Magn. Reson. 2015, 72, 50–63. [Google Scholar] [CrossRef]

- Markley, J.L.; Horsley, W.J.; Klein, M.P. Spin-Lattice Relaxation Measurements in Slowly Relaxing Complex Spectra. J. Chem. Phys. 1971, 55, 3604–3605. [Google Scholar] [CrossRef]

- Carr, H.Y.; Purcell, E.M. Effects of diffusion on free precession in nuclear magnetic resonance experiments. Phys. Rev. 1954, 94, 630–638. [Google Scholar] [CrossRef]

- Jones, G.P. Spin-Lattice Relaxation in the Rotating Frame: Weak-Collision Case. Phys. Rev. 1966, 148, 3437–3441. [Google Scholar] [CrossRef]

- Monteiro, M.; Cucinelli Neto, R.P.; Santos, I.C.S.; da Silva, E.O.; Tavares, M.I.B. Inorganic-organic hybrids based on poly (ε-Caprolactone) and silica oxide and characterization by relaxometry applying low-field NMR. Mater. Res. 2012, 15, 825–832. [Google Scholar] [CrossRef] [Green Version]

- Saalwächter, K. Multiple-Quantum NMR Studies of Anisotropic Polymer Chain Dynamics. In Modern Magnetic Resonance; Springer International Publishing AG: Cham, Switzerland, 2017; ISBN 978-3-319-28275-6. [Google Scholar]

- Baum, J.; Pines, A. NMR Studies of Clustering in Solids. J. Am. Chem. Soc. 1986, 108, 7447–7454. [Google Scholar] [CrossRef]

- Saalwächter, K. Proton multiple-quantum NMR for the study of chain dynamics and structural constraints in polymeric soft materials. Prog. Nucl. Magn. Reson. Spectrosc. 2007, 51, 1–35. [Google Scholar] [CrossRef]

- Schneider, M.; Gasper, L.; Demco, D.E.; Blümich, B. Residual dipolar couplings by 1H dipolar-encoded longitudinal magnetization, double- and triple-quantum nuclear magnetic resonance in cross-linked elastomers. J. Chem. Phys. 1999, 111, 402–415. [Google Scholar] [CrossRef]

- Voda, M.A.; Demco, D.E.; Perlo, J.; Orza, R.A.; Blümich, B. Multispin moments edited by multiple-quantum NMR: Application to elastomers. J. Magn. Reson. 2005, 172, 98–109. [Google Scholar] [CrossRef]

- Maus, A.; Hertlein, C.; Saalwächter, K. A Robust Proton NMR Method to Investigate Hard/Soft Ratios, Crystallinity, and Component Mobility in Polymers. Macromol. Chem. Phys. 2006, 207, 1150–1158. [Google Scholar] [CrossRef]

- Saalwächter, K.; Ziegler, P.; Spyckerelle, O.; Haidar, B.; Vidal, A.; Sommer, J.U. 1H multiple-quantum nuclear magnetic resonance investigations of molecular order distributions in poly(dimethylsiloxane) networks: Evidence for a linear mixing law in bimodal systems. J. Chem. Phys. 2003, 119, 3468–3482. [Google Scholar] [CrossRef]

- Buda, A.; Demco, D.E.; Bertmer, M.; Blümich, B.; Reining, B.; Keul, H.; Höcker, H. Domain sizes in heterogeneous polymers by spin diffusion using single-quantum and double-quantum dipolar filters. Solid State Nucl. Magn. Reson. 2003, 24, 39–67. [Google Scholar] [CrossRef]

- Suter, D.; Ernst, R.R. Spin diffusion in resolved solid-state NMR spectra. Phys. Rev. B 1985, 32, 5608–5627. [Google Scholar] [CrossRef] [Green Version]

- Assink, R.A. Nuclear Spin Diffusion between Polyurethane Microphases. Macromolecules 1978, 11, 1233–1237. [Google Scholar] [CrossRef]

- Goldman, M.; Shen, L. Spin-Spin Relaxation in LaF3. Phys. Rev. 1966, 144, 321–331. [Google Scholar] [CrossRef]

- Zhang, S.; Mehring, M. A Modified Goldman-Shen NMR Pulse Sequence. Chem. Phys. Lett. 1989, 160, 644–646. [Google Scholar] [CrossRef]

- Filgueiras, J.G.; da Silva, U.B.; Paro, G.; d’Eurydice, M.N.; Cobo, M.F.; DeAzevedo, E.R. Dipolar filtered magic-sandwich-echoes as a tool for probing molecular motions using time domain NMR. J. Magn. Reson. 2017, 285, 47–54. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adams, A. Analysis of solid technical polymers by compact NMR. TrAC Trends Anal. Chem. 2016, 83, 107–119. [Google Scholar] [CrossRef]

- Schäler, K. Low-Field Nmr Studies of Structure and Dynamics in Semicrystalline Polymers. Ph.D. Thesis, Institut für Physik der Naturwissenschaftlichen Fakultät II der Martin-Luther-Universität Halle-Wittenberg, Halle, Germany, 2013. [Google Scholar]

- Mauri, M.; Thomann, Y.; Schneider, H.; Saalwa, K. Spin-diffusion NMR at low field for the study of multiphase solids. Solid State Nucl. Magn. Reson. 2008, 34, 125–141. [Google Scholar] [CrossRef]

- Moraes, T.B.; Monaretto, T.; Colnago, L.A. Rapid and simple determination of T1 relaxation times in time-domain NMR by Continuous Wave Free Precession sequence. J. Magn. Reson. 2016, 270, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Venâncio, T.; Colnago, L.A. Simultaneous measurements of T1 and T2 during fast polymerization reaction using continuous wave-free precession NMR method. Magn. Reson. Chem. 2012, 50, 534–538. [Google Scholar] [CrossRef]

- Barone, P.; Ramponi, A.; Sebastiani, G. On the numerical inversion of the Laplace transform for nuclear magnetic resonance relaxometry. Inverse Probl. 2001, 17, 77–94. [Google Scholar] [CrossRef]

- McWhirter, J.G.; Pike, E.R. On the numerical inversion of the Laplace transform and similar Fredholm integral equations of the first kind. J. Phys. A. Math. Gen. 1978, 11, 1729–1745. [Google Scholar] [CrossRef]

- Moldovan, D.; Fechete, R.; Demco, D.E.; Culea, E.; Blümich, B.; Herrmann, V.; Heinz, M. Heterogeneity of nanofilled EPDM elastomers investigated by inverse laplace transform 1H NMR relaxometry and rheometry. Macromol. Chem. Phys. 2010, 211, 1579–1594. [Google Scholar] [CrossRef]

- Groetsch, C.W. The Theory of Tikhonov Regularization for Fredholm Equations of the First Kind. SIAM Rev. 2005, 28, 116–118. [Google Scholar]

- Dobrzański, L.A. Significance of materials science for the future development of societies. J. Mater. Process. Technol. 2006, 175, 133–148. [Google Scholar] [CrossRef]

- Zhang, R.; Yan, T.; Lechner, B.D.; Schröter, K.; Liang, Y.; Li, B.; Furtado, F.; Sun, P.; Saalwächter, K. Heterogeneity, segmental and hydrogen bond dynamics, and aging of supramolecular self-healing rubber. Macromolecules 2013, 46, 1841–1850. [Google Scholar] [CrossRef]

- Wittmer, A.; Wellen, R.; Saalwächter, K.; Koschek, K. Moisture-mediated self-healing kinetics and molecular dynamics in modified polyurethane urea polymers. Polymer 2018, 151, 125–135. [Google Scholar] [CrossRef]

- Malmierca, M.A.; González-Jiménez, A.; Mora-Barrantes, I.; Posadas, P.; Rodríguez, A.; Ibarra, L.; Nogales, A.; Saalwächter, K.; Valentín, J.L. Characterization of network structure and chain dynamics of elastomeric ionomers by means of 1H Low-Field NMR. Macromolecules 2014, 47, 5655–5667. [Google Scholar] [CrossRef]

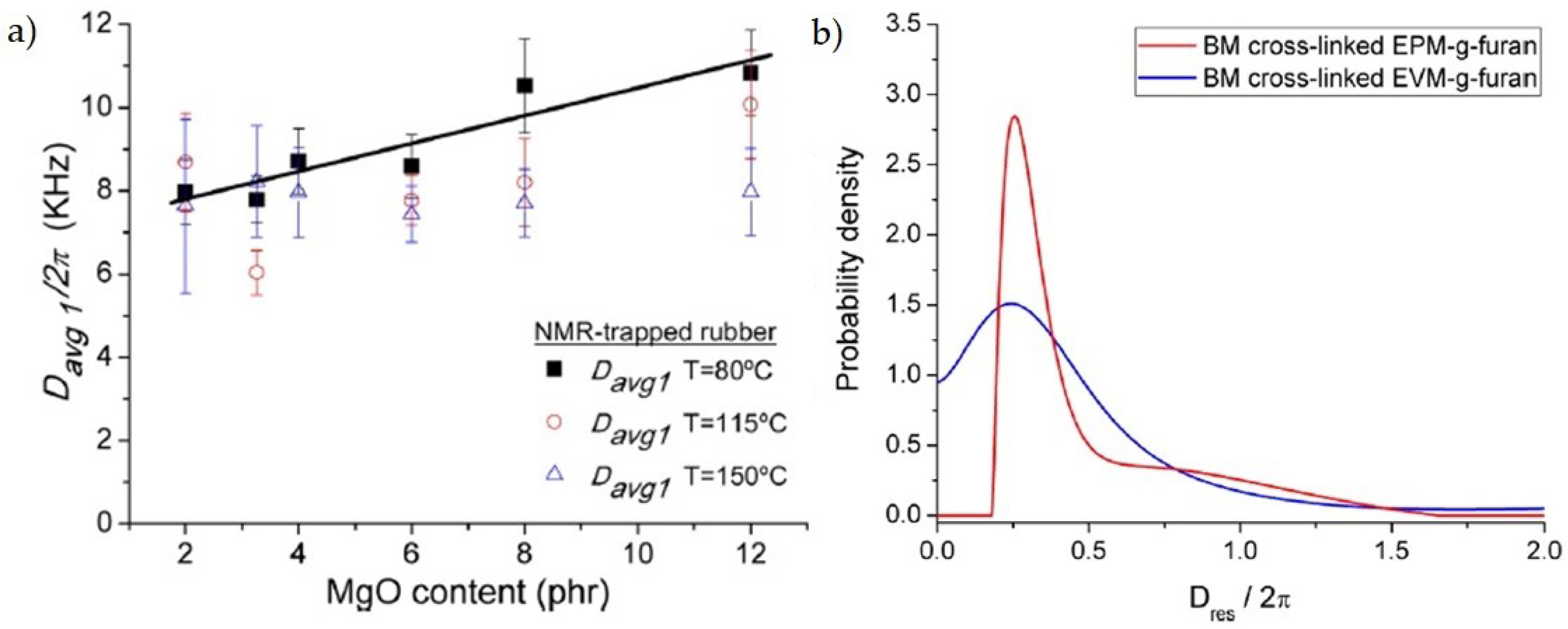

- Polgar, L.M.; Hagting, E.; Raffa, P.; Mauri, M.; Simonutti, R.; Picchioni, F.; Van Duin, M. Effect of Rubber Polarity on Cluster Formation in Rubbers Cross-Linked with Diels-Alder Chemistry. Macromolecules 2017, 50, 8955–8964. [Google Scholar] [CrossRef]

- Kucinska-Lipka, J.; Sinyavsky, N.; Mershiev, I.; Kupriyanova, G.; Haponiuk, J. Study of Aliphatic Polyurethanes by the Low-Field 1H NMR Relaxometry Method with the Inversion of the Integral Transformation. Appl. Magn. Reson. 2018, 50, 347–356. [Google Scholar] [CrossRef]

- Somekawa, S.; Masutani, K.; Hsu, Y.; Mahara, A.; Kimura, Y.; Yamaoka, T. Size-Controlled Nanomicelles of Poly(lactic acid)–Poly(ethylene glycol) Copolymers with a Multiblock Configuration. Polymers 2015, 7, 1177–1191. [Google Scholar] [CrossRef] [Green Version]

- Monguzzi, A.; Vanhecke, D.; Vadrucci, R.; Meinardi, F.; Simon, Y.C.; Weder, C. Thermoresponsive low-power light upconverting polymer nanoparticles. Mater. Horizons 2016, 3, 602–607. [Google Scholar]

- Bonetti, S.; Farina, M.; Mauri, M.; Koynov, K.; Butt, H.J.; Kappl, M.; Simonutti, R. Core@shell Poly(n-butylacrylate)@polystyrene Nanoparticles: Baroplastic Force-Responsiveness in Presence of Strong Phase Separation. Macromol. Rapid Commun. 2016, 37, 584–589. [Google Scholar] [CrossRef]

- Musgrave, C.S.A.; Nazarov, W.; Bazin, N. The Effect of para-divinyl benzene on styrenic emulsion-templated porous polymers: A chemical trojan horse. J. Mater. Sci. 2017, 52, 3179–3187. [Google Scholar] [CrossRef]

- Valentín, J.L.; López, D.; Hernández, R.; Mijangos, C.; Saalwächter, K. Structure of polyvinyl alcohol cryo-hydrogels as studied by proton low-field NMR spectroscopy. Macromolecules 2009, 42, 263–272. [Google Scholar] [CrossRef] [PubMed]

- Jorge, E.; Rodrigues, R.; De, M.; Cavalcante, P.; Inês, M.; Tavares, B. Time domain NMR evaluation of poly(vinyl alcohol) xerogels. Polímeros 2016, 26, 221–227. [Google Scholar] [Green Version]

- Monguzzi, A.; Mauri, M.; Bianchi, A.; Dibbanti, M.K.; Simonutti, R.; Meinardi, F. Solid-State Sensitized Upconversion in Polyacrylate Elastomers. J. Phys. Chem. C 2016, 120, 2609–2614. [Google Scholar] [CrossRef]

- Litvinov, V.M.; Ries, M.E.; Baughman, T.W.; Henke, A.; Matloka, P.P. Chain Entanglements in Polyethylene Melts. Why Is It Studied Again? Macromolecules 2013, 46, 541–547. [Google Scholar] [CrossRef]

- De Gennes, P.G. Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 1971, 55, 572–579. [Google Scholar] [CrossRef]

- Edwards, S.F.; Doi, M. Dynamics of Concentrated Polymer Systems Part 3. J. Chem. Soc. Faraday Trans. 2 Mol. Chem. Phys. 1978, 74, 1818–1832. [Google Scholar]

- Collignon, J.; Sillescu, H.; Spiess, H.W. Pseudo-solid echoes of proton and deuteron NMR in polyethvlene melts. Colloid Polym. Sci. Kolloid Zeitschrift Zeitschrift Polym. 1981, 259, 220–226. [Google Scholar] [CrossRef]

- Vaca Chávez, F.; Saalwächter, K. Time-domain NMR observation of entangled polymer dynamics: Analytical theory of signal functions. Macromolecules 2011, 44, 1560–1569. [Google Scholar] [CrossRef]

- Vaca Chávez, F.; Saalwächter, K. Time-domain NMR observation of entangled polymer dynamics: Universal behavior of flexible homopolymers and applicability of the tube model. Macromolecules 2011, 44, 1549–1559. [Google Scholar] [CrossRef]

- Kariyo, S.; Brodin, A.; Gainaru, C.; Hermann, A.; Schick, H.; Novikov, V.N.; Rössler, E.A. From Simple Liquid to a Polymer Melt. Glassy and Polymer Dynamics Studied by Fast Field Cycling NMR Relaxometry: Low and High Molecular Weight Limit. Macromolecules 2008, 41, 5313–5321. [Google Scholar] [CrossRef]

- Hofmann, M.; Herrmann, A.; Ok, S.; Franz, C.; Kruk, D.; Saalwächter, K.; Steinhart, M.; Rössler, E.A. Polymer dynamics of polybutadiene in nanoscopic confinement as revealed by field cycling 1H NMR. Macromolecules 2011, 44, 4017–4021. [Google Scholar] [CrossRef]

- Hofmann, M.; Herrmann, A.; Abou Elfadl, A.; Kruk, D.; Wohlfahrt, M.; Rössler, E.A. Glassy, rouse, and entanglement dynamics as revealed by field cycling 1H NMR relaxometry. Macromolecules 2012, 45, 2390–2401. [Google Scholar] [CrossRef]

- Mordvinkin, A.; Saalwächter, K. Microscopic observation of the segmental orientation autocorrelation function for entangled and constrained polymer chains. J. Chem. Phys. 2017, 146. [Google Scholar] [CrossRef]

- Campise, F.; Agudelo, D.C.; Acosta, R.H.; Villar, M.A.; Vallés, E.M.; Monti, G.A.; Vega, D.A. Contribution of Entanglements to Polymer Network Elasticity. Macromolecules 2017, 50, 2964–2972. [Google Scholar] [CrossRef]

- Dibbanti, M.K.; Mauri, M.; Mauri, L.; Medaglia, G.; Simonutti, R. Probing small network differences in sulfur-cured rubber compounds by combining nuclear magnetic resonance and swelling methods. J. Appl. Polym. Sci. 2015, 132, 1–8. [Google Scholar] [CrossRef]

- Gotlib, Y.Y.; Lifshits, M.I.; Shevelev, V.A.; Lishanskii, I.S.; Balanina, I.V. The influence of the chemical crosslinking network on the spin-spin relaxation of crosslinked and swelling polymer systems. Polym. Sci. U.S.S.R. 1976, 18. [Google Scholar] [CrossRef]

- Wu, B.; Chassé, W.; Peters, R.; Brooijmans, T.; Dias, A.A.; Heise, A.; Duxbury, C.J.; Kentgens, A.P.M.; Brougham, D.F.; Litvinov, V.M. Network Structure in Acrylate Systems: Effect of Junction Topology on Cross-Link Density and Macroscopic Gel Properties. Macromolecules 2016, 49, 6531–6540. [Google Scholar] [CrossRef]

- Magusin, P.C.M.M.; Orza, R.A.; Litvinov, V.M.; Van Duin, M.; Saalwächter, K. Chain mobility in crosslinked EPDM rubbers. Comparison of 1H NMR T2 relaxometry and double-quantum 1H NMR. ACS Symp. Ser. 2011, 1077, 207–220. [Google Scholar]

- Di, X.; Che, J.; Toki, S.; Valentin, J.L.; Brasero, J.; Nimpaiboon, A.; Rong, L.; Hsiao, B.S. Chain Dynamics and Strain-Induced Crystallization of Pre- and Postvulcanized Natural Rubber Latex Using Proton Multiple Quantum NMR and Uniaxial Deformation by in Situ Synchrotron X-ray Diffraction. Macromolecules 2012, 45, 6491–6503. [Google Scholar]

- Orza, R.A.; Magusin, P.C.M.M.; Litvinov, V.M.; Van Duin, M.; Michels, M.A.J. Mechanism for Peroxide Cross-Linking of EPDM Rubber from MAS 13C NMR Spectroscopy. Macromolecules 2009, 42, 8914–8924. [Google Scholar] [CrossRef]

- Toki, S.; Sics, I.; Ran, S.; Liu, L.; Hsiao, B.S. New Insights into Structural Development in Natural Rubber during Uniaxial Deformation by In Situ Synchrotron X-ray Diffraction. Macromolecules 2002, 35, 6578–6584. [Google Scholar] [CrossRef]

- Naumova, A.; Tschierske, C.; Saalwächter, K. Orientation-dependent proton double-quantum NMR build-up function for soft materials with anisotropic mobility. Solid State Nucl. Magn. Reson. 2017, 82–83, 22–28. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Gonzàlez-Jiménez, A.; Verdejo, R.; Lopez-Manchado, M.A.; Valentin, J.L. Epoxy resin curing reaction studied by proton multiple-quantum NMR. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1324–1332. [Google Scholar] [CrossRef] [Green Version]

- Patel, J.P.; Hsu, S.L. Development of low field NMR technique for analyzing segmental mobility of crosslinked polymers. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 639–643. [Google Scholar] [CrossRef]

- Litvinov, V.M.; Orza, R.A.; Klüppel, M.; Van Duin, M.; Magusin, P.C.M.M. Rubber-filler interactions and network structure in relation to stress-strain behavior of vulcanized, carbon black filled EPDM. Macromolecules 2011, 44, 4887–4900. [Google Scholar] [CrossRef]

- Papon, A.; Saalwächter, K.; Schäler, K.; Guy, L.; Lequeux, F.; Montes, H. Low-field NMR investigations of nanocomposites: Polymer dynamics and network effects. Macromolecules 2011, 44, 913–922. [Google Scholar] [CrossRef]

- Tadiello, L.; D’Arienzo, M.; Di Credico, B.; Hanel, T.; Matejka, L.; Mauri, M.; Morazzoni, F.; Simonutti, R.; Spirkova, M.; Scotti, R. The filler-rubber interface in styrene butadiene nanocomposites with anisotropic silica particles: Morphology and dynamic properties. Soft Matter 2015, 11, 4022–4033. [Google Scholar] [CrossRef] [PubMed]

- Borsacchi, S.; Sudhakaran, U.P.; Calucci, L.; Martini, F.; Carignani, E.; Messori, M.; Geppi, M. Rubber-filler interactions in polyisoprene filled with in situ generated silica: A solid state NMR study. Polymers 2018, 10, 822. [Google Scholar] [CrossRef]

- Valentìn, J.L.; Mora-Barrantes, I.; Carretero-Gonzalez, J.; Lopez-Manchado, M.A.; Sotta, P.; Long, D.R.; Saalwachter, K. Novel Experimental Approach to Evaluate Filler-Elastomer Interactions. Macromolecules 2010, 43, 334–346. [Google Scholar] [CrossRef]

- Mauri, M.; Floudas, G.; Simonutti, R. Local order and dynamics of nanoconstrained ethylene-butylene chain segments in SEBS. Polymers 2018, 10, 655. [Google Scholar] [CrossRef] [PubMed]

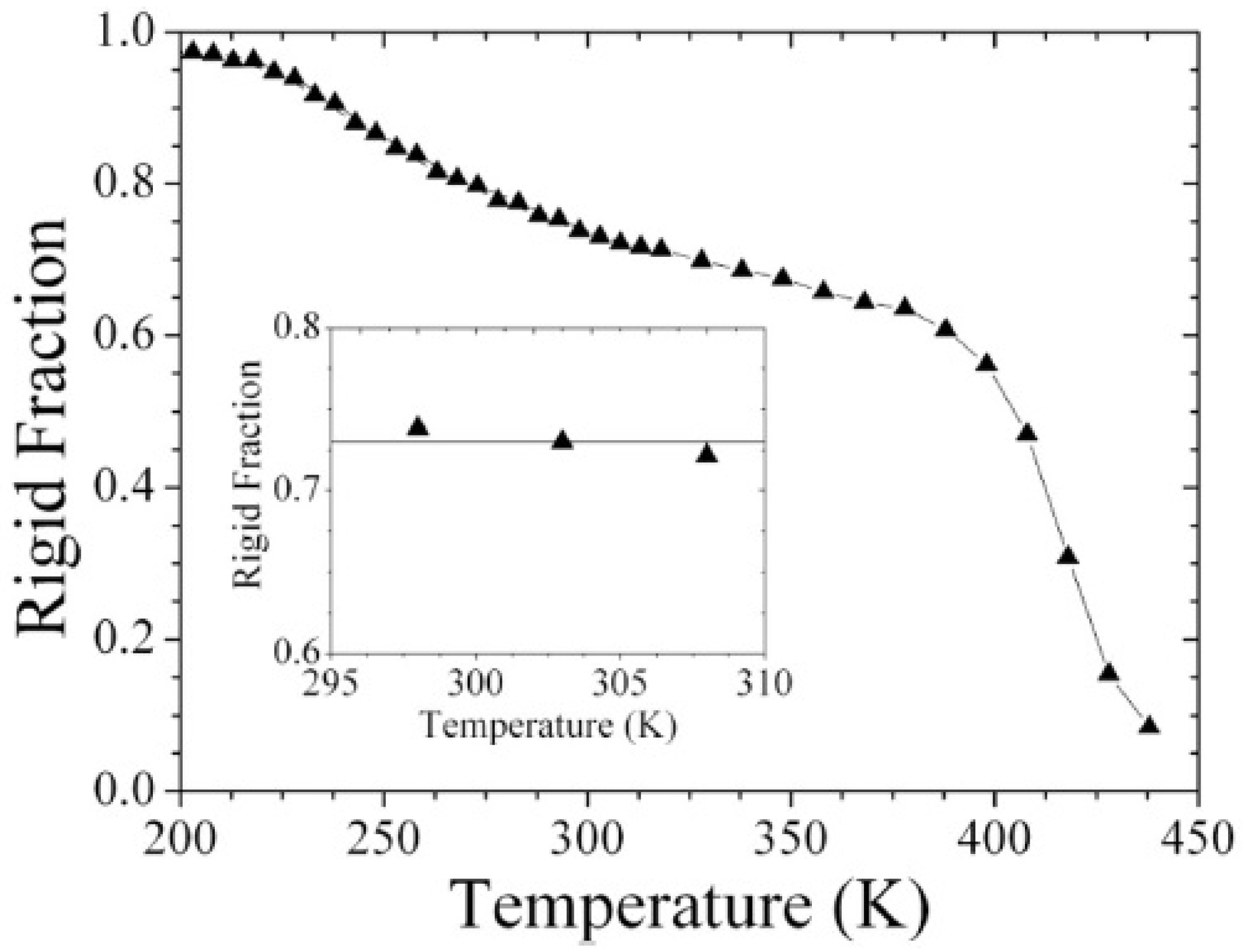

- Hertlein, C.; Saalwächter, K.; Strobl, G. Low-field NMR studies of polymer crystallization kinetics: Changes in the melt dynamics. Polymer 2006, 47, 7216–7221. [Google Scholar] [CrossRef]

- Roos, M.; Schäler, K.; Seidlitz, A.; Thurn-Albrecht, T.; Saalwächter, K. NMR study of interphase structure in layered polymer morphologies with mobility contrast: Disorder and confinement effects vs. dynamic heterogeneities. Colloid Polym. Sci. 2014, 292, 1825–1839. [Google Scholar] [CrossRef]

- Schneider, H.; Saalwächter, K.; Roos, M. Complex Morphology of the Intermediate Phase in Block Copolymers and Semicrystalline Polymers as Revealed by 1H NMR Spin Diffusion Experiments. Macromolecules 2017, 50, 8598–8610. [Google Scholar] [CrossRef]

- Ramakrishnan, N.; Sharma, S.; Gupta, A.; Alashwal, B.Y. Keratin based bioplastic film from chicken feathers and its characterization. Int. J. Biol. Macromol. 2018, 111, 352–358. [Google Scholar] [CrossRef]

- Zárate-Ramíreza, L.S.; Romero, A.; Bengoecheab, C.; Partalc, P.; Guerrero, A. Thermo-mechanical and hydrophilic properties of polysaccharide/gluten-based bioplastics. Carbohydr. Polym. 2014, 112, 24–31. [Google Scholar] [CrossRef]

- Liebeck, B.M.; Hidalgo, N.; Roth, G.; Popescu, C.; Böker, A. Synthesis and Characterization of Methyl Cellulose/Keratin Hydrolysate Composite Membranes. Polymers 2017, 9, 91. [Google Scholar] [CrossRef] [PubMed]

- Bernard, M. Industrial potential of polyhydroxyalkanoate bioplastic: A brief review. Univ. Saskatchewan Undergrad. Res. J. 2014, 1, 1–14. [Google Scholar] [CrossRef]

- Lörcks, J. Properties and applications of compostable starch-based plastic material. Polym. Degrad. Stab. 1998, 59, 245–249. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Partal, P.; Garcia-Morales, M.; Gallegos, C. Development of highly-transparent protein/starch-based bioplastics. Bioresour. Technol. 2010, 101, 2007–2013. [Google Scholar] [CrossRef]

- Mose, B.R.; Maranga, S.M. A Review on Starch Based Nanocomposites for Bioplastic Materials. J. Mater. Sci. Eng. B 2011, 1, 239–245. [Google Scholar]

- Vismara, E.; Bongio, C.; Coletti, A.; Edelman, R.; Serafini, A.; Mauri, M.; Simonutti, R.; Bertini, S.; Urso, E.; Assaraf, Y.G.; et al. Albumin and hyaluronic acid-coated superparamagnetic iron oxide nanoparticles loaded with paclitaxel for biomedical applications. Molecules 2017, 22, 1030. [Google Scholar] [CrossRef] [PubMed]

- Vanderhart, D.L.; Asano, A.; Gilman, J.W. Solid-State NMR Investigation of Paramagnetic Nylon-6 Clay Nanocomposites. 1. Crystallinity, Morphology, and the Direct Influence of Fe3+ on Nuclear Spins. Chem. Mater. 2001, 13, 3781–3795. [Google Scholar] [CrossRef]

- Cucinelli Neto, R.P.; da Rocha Rodrigues, E.J.; Tavares, M.I.B. Proton NMR relaxometry as probe of gelatinization, plasticization and montmorillonite-loading effects on starch-based materials. Carbohydr. Polym. 2018, 182, 123–131. [Google Scholar] [CrossRef]

- Brito, L.M.; Sebastião, P.J.O.; Tavares, M.I.B. NMR relaxometry evaluation of nanostructured starch-PLA blends. Polym. Test. 2015, 45, 161–167. [Google Scholar] [CrossRef]

- Wang, P.; Sheng, F.; Tang, S.W.; ud-Din, Z.; Chen, L.; Nawaz, A.; Hu, C.; Xiong, H. Synthesis and Characterization of Corn Starch Crosslinked with Oxidized Sucrose. Starch Stärke 2018, 1800152. [Google Scholar] [CrossRef]

- Perotto, G.; Ceseracciu, L.; Simonutti, R.; Paul, U.C.; Guzman-Puyol, S.; Tran, T.N.; Bayer, I.S.; Athanassiou, A. Bioplastics from vegetable waste: Via an eco-friendly water-based process. Green Chem. 2018, 20, 894–902. [Google Scholar] [CrossRef]

- Grunin, L.Y.; Grunin, Y.B.; Nikolskaya, E.A.; Sheveleva, N.N.; Nikolaev, I.A. An NMR relaxation and spin diffusion study of cellulose structure during water adsorption. Biophysics 2017, 62, 198–206. [Google Scholar] [CrossRef]

- Cavalcante, M.P.; Toledo, A.L.M.M.; Rodrigues, E.J.R.; Neto, R.P.C.; Tavares, M.I.B. Correlation between traditional techniques and TD-NMR to determine the morphology of PHB/PCL blends. Polym. Test. 2017, 58, 159–165. [Google Scholar] [CrossRef]

- Vargas, M.A.; Scheubner, M.; Guthausen, G. Reaction Kinetics of Polyfurfuryl Alcohol Bioresin and Nanoparticles by 1H-NMR Transverse Relaxation Measurements. Polym. Compos. 2018, 39, 3280–3288. [Google Scholar] [CrossRef]

- Kock, F.V.C.; Monaretto, T.; Colnago, L.A. Time-domain NMR relaxometry as an alternative method for analysis of chitosan-paramagnetic ion interactions in solution. Int. J. Biol. Macromol. 2017, 98, 228–232. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhao, J.; Yang, R.; Iervolino, R.; Barbera, S. Effect of lubricating oil on thermal aging of nitrile rubber. Polym. Degrad. Stab. 2018, 151, 136–143. [Google Scholar] [CrossRef]

- Sun, N.; Wenzel, M.; Adams, A. Morphology of high-density polyethylene pipes stored under hydrostatic pressure at elevated temperature. Polymer 2014, 55, 3792–3800. [Google Scholar] [CrossRef]

- Mauri, M.; Ponting, M.; Causin, V.; Pisciotti, F.; Simonutti, R. Morphological Reorganization and Mechanical Enhancement in Multilayered Polyethylene/Polypropylene Films by Layer Multiplication or Mild Annealing. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 520–531. [Google Scholar] [CrossRef]

- Zhang, J.; Adams, A. Understanding thermal aging of non-stabilized and stabilized polyamide 12 using 1H solid-state NMR. Polym. Degrad. Stab. 2016, 134, 169–178. [Google Scholar] [CrossRef]

- Teymouri, Y.; Adams, A.; Blümich, B. Impact of Exposure Conditions on the Morphology of Polyethylene by Compact NMR. Macromol. Symp. 2018, 378, 1–8. [Google Scholar] [CrossRef]

- Silva, L.M.A.; Andrade, F.D.; Filho, E.G.A.; Monteiro, M.R.; de Azevedo, E.R.; Venâncio, T. NMR investigation of commercial carbon black filled vulcanized natural rubber exposed to petrodiesel/biodiesel mixtures. Fuel 2016, 186, 50–57. [Google Scholar] [CrossRef]

- Mansilla, M.A.; Valentín, J.L.; López-manchado, M.A.; González-jiménez, A.; Marzocca, A.J. Effect of entanglements in the microstructure of cured NR / SBR blends prepared by solution and mixing in a two-roll mill. Eur. Polym. J. 2016, 81, 365–375. [Google Scholar] [CrossRef]

- Harley, S.J.; Mayer, B.P.; Glascoe, E.A.; Maxwell, R.S.; Von White, G.; Bernstein, R. Multi-Method Characterization of Compression Set in Fluorosilicone O-Rings. Silicon 2014, 1–7. [Google Scholar] [CrossRef]

- Mauri, M.; Dibbanti, M.K.; Calzavara, M.; Mauri, L.; Simonutti, R.; Causin, V. Time domain nuclear magnetic resonance: A key complementary technique for the forensic differentiation of foam traces. Anal. Methods 2013, 5, 4336–4344. [Google Scholar] [CrossRef]

- Tawfilas, M.; Mauri, M.; De Trizio, L.; Lorenzi, R.; Simonutti, R. Surface Characterization of TiO2 Polymorphic Nanocrystals through 1H-TD-NMR. Langmuir 2018, 34, 9460–9469. [Google Scholar] [CrossRef]

- Litvinov, V.M.; Penning, J.P. Phase composition and molecular mobility in nylon 6 fibers as studied by proton NMR transverse magnetization relaxation. Macromol. Chem. Phys. 2004, 205, 1721–1734. [Google Scholar] [CrossRef]

- Nestle, N.; Heckmann, W.; Steininger, H.; Knoll, K. Towards quantification of butadiene content in styrene-butadiene block copolymers and their blends with general purpose polystyrene (GPPS) and the relation between mechanical properties and NMR relaxation times. Anal. Chim. Acta 2007, 604, 54–61. [Google Scholar] [CrossRef]

- Nestle, N.; Häberle, K. Non-invasive analysis of swelling in polymer dispersions by means of time-domain(TD)-NMR. Anal. Chim. Acta 2009, 654, 35–39. [Google Scholar] [CrossRef]

- Aou, K.; Ge, S.; Mowery, D.M.; Zeigler, R.C.; Gamboa, R.R. Two-domain morphology in viscoelastic polyurethane foams. Polymer 2015, 56, 37–45. [Google Scholar] [CrossRef]

- Contreras, M.M.; Nascimento, C.R.; Cucinelli Neto, R.P.; Teixeira, S.; Berry, N.; Costa, M.F.; Costa, C.A. TD-NMR analysis of structural evolution in PVDF induced by stress relaxation. Polym. Test. 2018, 68, 153–159. [Google Scholar] [CrossRef]

- Patel, J.P.; Xiang, Z.G.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. Characterization of the crosslinking reaction in high performance adhesives. Int. J. Adhes. Adhes. 2017, 78, 256–262. [Google Scholar] [CrossRef]

- Patel, J.P.; Deshmukh, S.; Zhao, C.; Wamuo, O.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. An analysis of the role of reactive plasticizers in the crosslinking reactions of a rigid resin. Polymer 2016, 107, 12–18. [Google Scholar] [CrossRef]

- Patel, J.P.; Deshmukh, S.; Zhao, C.; Wamuo, O.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. An analysis of the role of nonreactive plasticizers in the crosslinking reactions of a rigid resin. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 206–213. [Google Scholar] [CrossRef]

- Danieli, E.; Perlo, J.; Duchateau, A.L.L.; Verzijl, G.K.M.; Litvinov, V.M.; Blümich, B.; Casanova, F. On-Line Monitoring of Chemical Reactions by using Bench-Top Nuclear Magnetic Resonance Spectroscopy. ChemPhysChem 2014, 15, 3060–3066. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, E.J.R.; Sebastião, P.J.O.; Tavares, M.I.B. 1H time domain NMR real time monitoring of polyacrylamide hydrogels synthesis. Polym. Test. 2017, 60, 396–404. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Besghini, D.; Mauri, M.; Simonutti, R. Time Domain NMR in Polymer Science: From the Laboratory to the Industry. Appl. Sci. 2019, 9, 1801. https://doi.org/10.3390/app9091801

Besghini D, Mauri M, Simonutti R. Time Domain NMR in Polymer Science: From the Laboratory to the Industry. Applied Sciences. 2019; 9(9):1801. https://doi.org/10.3390/app9091801

Chicago/Turabian StyleBesghini, Denise, Michele Mauri, and Roberto Simonutti. 2019. "Time Domain NMR in Polymer Science: From the Laboratory to the Industry" Applied Sciences 9, no. 9: 1801. https://doi.org/10.3390/app9091801