Nonwoven Ion-Exchange Membranes with High Protein Binding Capacity for Bioseparations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

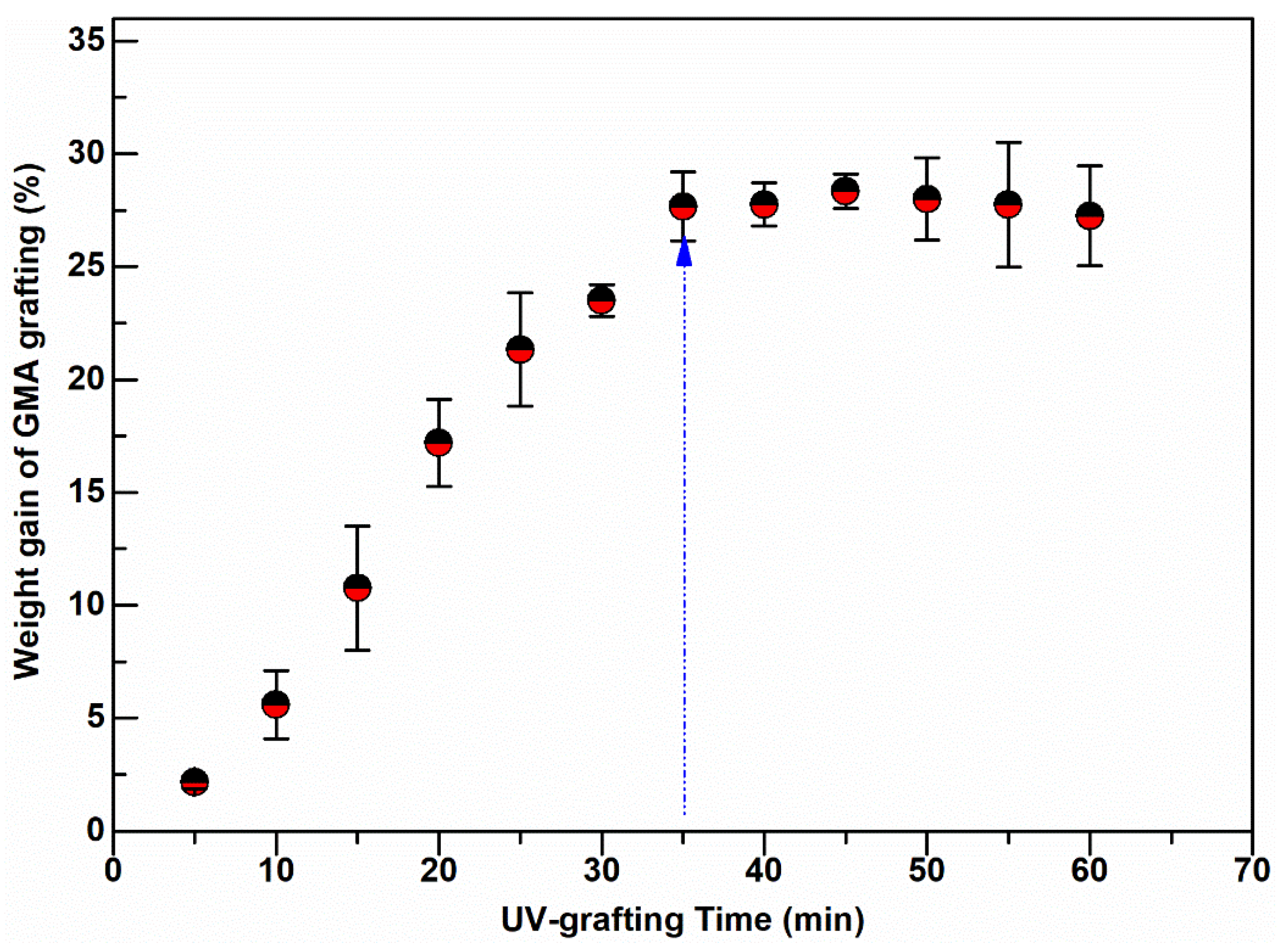

2.2. Membrane UV-Grafting with GMA

2.3. Preparation of Ion-Exchanger Nonwoven Membranes

2.4. Characterization of Grafted Membranes

2.4.1. Morphology

2.4.2. Thickness and Porosity

2.4.3. Determination of Ligand Density

2.4.4. Permeability Measurements

2.5. Determination of the Membrane Binding Capacity and Selectivity

2.5.1. Static Equilibrium Binding Capacity

2.5.2. Flow Experiments—Dynamic Binding Capacity

2.6. Analytical Methods

2.6.1. Host cell Protein and DNA Levels Determination

2.6.2. SEC-HPLC Analysis of Collected Fractions

2.6.3. Protein G Chromatography

2.6.4. SDS-PAGE and Total Protein

3. Results and Discussion

3.1. Surface Modification of Nonwoven Membranes

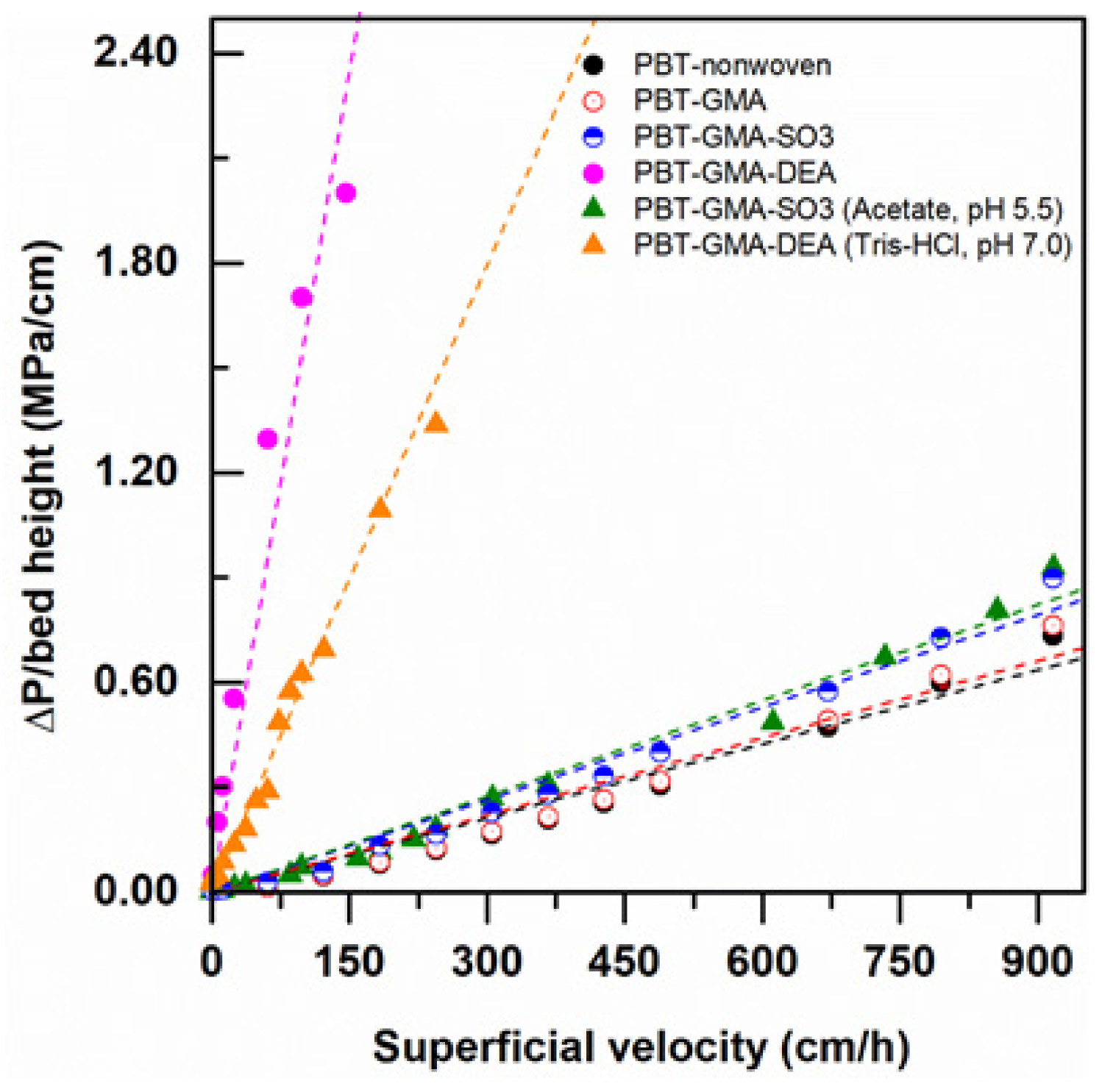

3.2. Membrane Porosity and Permeability

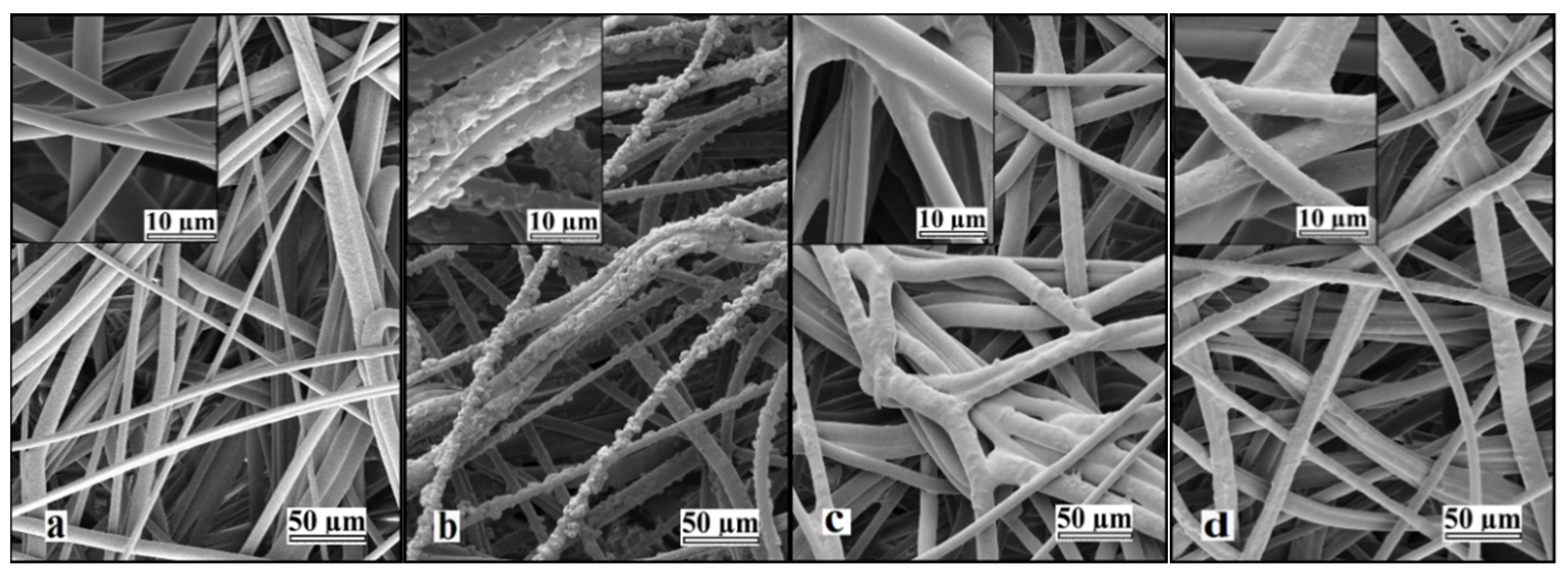

3.2.1. Porosity and Morphological Changes

3.2.2. Permeability of Nonwoven Membranes

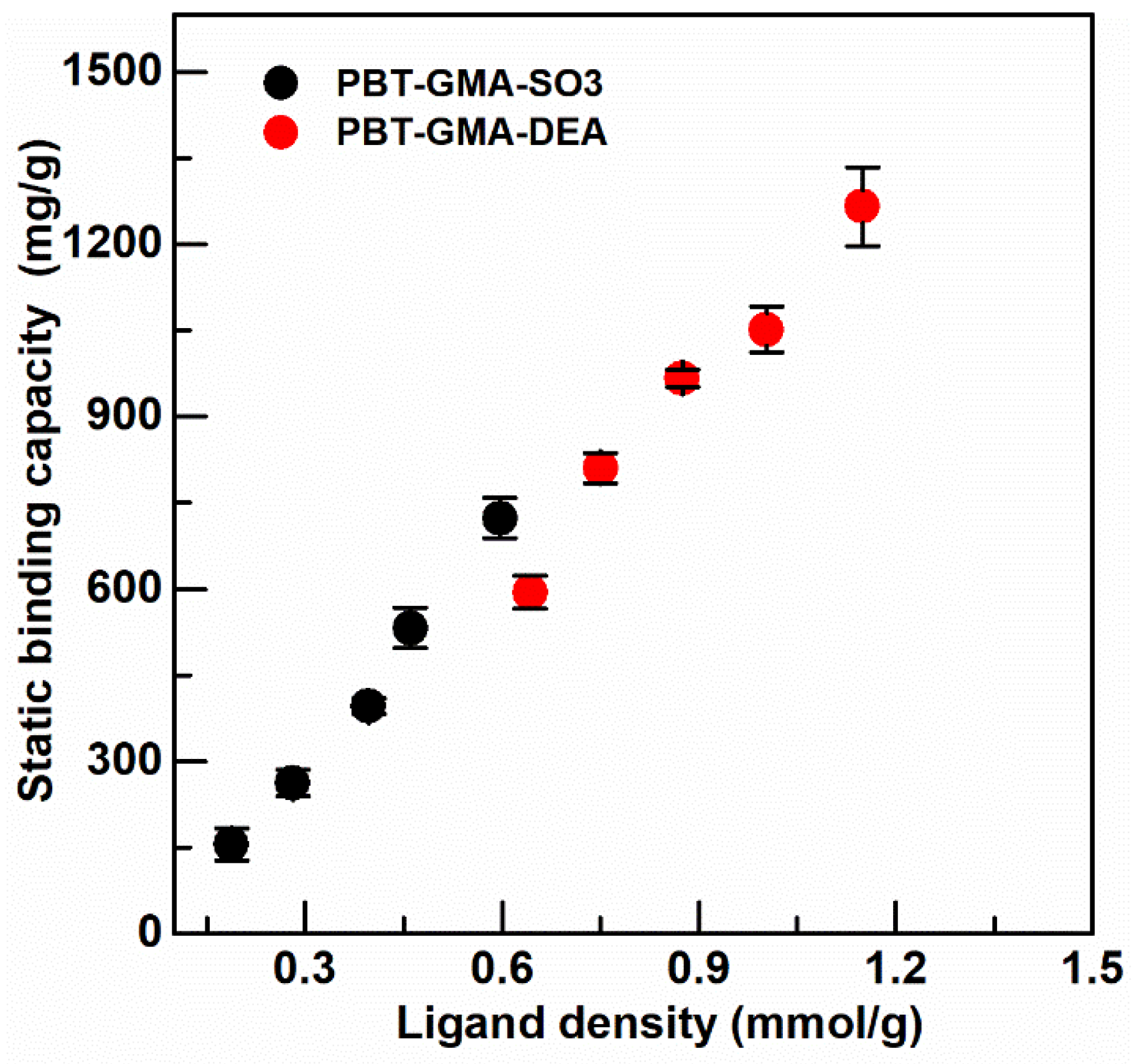

3.3. Static Binding Capacity

3.4. Dynamic Binding Capacity

3.5. Purification

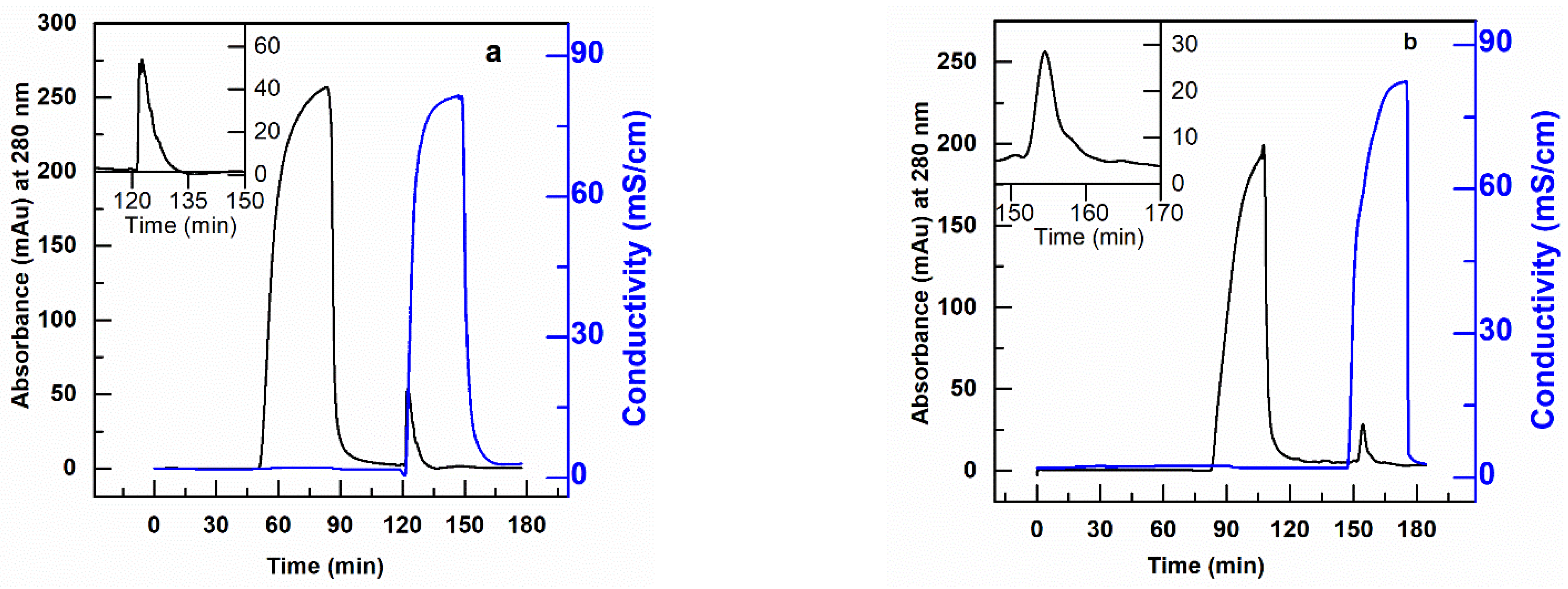

3.5.1. Antibody Purification Using Cation Exchanger PBT-GMA-SO3

3.5.2. PBT-GMA-DEA Membrane for DNA Removal

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- PRN Newswire, 16 July 2018. Allied Market Research Report “Biopharmaceuticals Market by Type and Application: Global Opportunity Analysis and Industry Forecast, 2018–2025”. Available online: https://www.prnewswire.com/news-releases/ (accessed on 1 October 2020).

- Rathore, A.S.; Bhargava, A. Biosimilars in Developed Economies: Overview, Status, and Regulatory Considerations. Regul. Toxicol. Pharmacol. 2020, 110, 104525. [Google Scholar] [CrossRef]

- Banga, A.K. Pharmaceutical Biotechnology: The Arrival of Recombinant Proteins. In Therapeutic Peptides and Proteins, 3rd ed.; Banga, A.K., Ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Liu, H.F.; Ma, J.; Winter, C.; Bayer, R. Recovery and purification process development for monoclonal antibody production. mAbs 2010, 2, 480–499. [Google Scholar] [CrossRef] [Green Version]

- Chenette, H.C.; Robinson, J.R.; Hobley, E.; Husson, S.M. Development of high-productivity, strong cation-exchange adsorbers for protein capture by graft polymerization from membranes with different pore sizes. J. Membr. Sci. 2012, 423–424, 43–52. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Gurgel, P.V.; Carbonell, R.G. Preparation and characterization of anion exchange adsorptive nonwoven membranes with high protein binding capacity. J. Membr. Sci. 2015, 493, 349–359. [Google Scholar] [CrossRef]

- Coleman, T.S. Early Developments in the Regulation of Biologics. Food Drug Law J. 2016, 71, 544–607. [Google Scholar]

- Kawai, T.; Saito, K.; Lee, W. Protein binding to polymer brush, based on ion-exchange, hydrophobic, and affinity interactions. J. Chromatogr. B 2003, 790, 131–142. [Google Scholar] [CrossRef]

- Boi, C.; Malavasi, A.; Carbonell, R.G.; Gilleskie, G. A direct comparison between membrane adsorber and packed column chromatography performance. J. Chromatogr. A 2020, 1612, 460629. [Google Scholar] [CrossRef] [PubMed]

- Muthukumar, S.; Muralikrishnan, T.; Mendhe, R.; Rathore, A.S. Economic benefits of membrane chromatography versus packed bed column purification of therapeutic proteins expressed in microbial and mammalian hosts. J. Chem. Technol. Biotechnol. 2017, 92, 59–68. [Google Scholar] [CrossRef]

- Xenopoulos, A. A new, integrated, continuous purification process template for monoclonal antibodies: Process modeling and cost of goods studies. J. Biotechnol. 2015, 213, 42–53. [Google Scholar] [CrossRef] [PubMed]

- Shukla, A.A.; Hubbard, B.; Tressel, T.; Guhan, S.; Low, D. Downstream processing of monoclonal antibodies—Application of platform approaches. J. Chromatogr. B 2007, 848, 28–39. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Liu, H.; Gurgel, P.V.; Carbonell, R.G. Polypropylene nonwoven fabrics with conformal grafting of poly(glycidyl methacrylate) for bioseparations. J. Membr. Sci. 2010, 364, 362–371. [Google Scholar] [CrossRef]

- Bhut, B.V.; Christensen, K.A.; Husson, S.M. Membrane chromatography: Protein purification from E. coli lysate using newly designed and commercial anion-exchange stationary phases. J. Chromatogr. A 2010, 1217, 4946–4957. [Google Scholar] [CrossRef]

- Ghosh, R. Protein separation using membrane chromatography: Opportunities and challenges. J. Chromatogr. A 2002, 952, 13–27. [Google Scholar] [CrossRef]

- Woo, M.; Khan, N.Z.; Royce, J.; Mehta, U.; Gagnon, B.; Ramaswamy, S.; Soice, N.; Morelli, M.; Cheng, K.-S. A novel primary amine-based anion exchange membrane adsorber. J. Chromatogr. A 2011, 1218, 5386–5392. [Google Scholar] [CrossRef]

- Heller, M.; Wimbish, R.; Gurgel, P.V.; Pourdeyhimi, B.; Carbonell, R.G. Reducing diffusion limitations in Ion exchange grafted membranes using high surface area nonwovens. J. Membr. Sci. 2016, 514, 53–64. [Google Scholar] [CrossRef]

- Tennikova, T.B.; Svec, F. High-performance membrane chromatography: Highly efficient separation method for proteins in ion-exchange, hydrophobic interaction and reversed-phase modes. J. Chromatogr. A 1993, 646, 279–288. [Google Scholar] [CrossRef]

- Bondar, Y.V.; Kim, H.J.; Lim, Y.J. Sulfonation of (glycidyl methacrylate) chains grafted onto nonwoven polypropylene fabric. J. Appl. Polym. Sci. 2007, 104, 3256–3260. [Google Scholar] [CrossRef]

- Vicente, T.; Sousa, M.F.; Peixoto, C.; Mota, J.P.; Alves, P.M.; Carrondo, M.J. Anion-exchange membrane chromatography for purification of rotavirus-like particles. J. Membr. Sci. 2008, 311, 270–283. [Google Scholar] [CrossRef]

- Heller, M.; Li, Q.; Esinhart, K.; Pourdeyhimi, B.; Boi, C.; Carbonell, R.G. Heat Induced Grafting of Poly(glycidyl methacrylate) on Polybutylene Terephthalate Nonwovens for Bioseparations. Ind. Eng. Chem. Res. 2020, 59, 5371–5380. [Google Scholar] [CrossRef]

- Wang, J.; Jenkins, E.W.; Robinson, J.R.; Wilson, A.; Husson, S.M. A new multimodal membrane adsorber for monoclonal antibody purifications. J. Membr. Sci. 2015, 492, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Orr, V.; Zhong, L.; Moo-Young, M.; Chou, C.P. Recent advances in bioprocessing application of membrane chromatography. Biotechnol. Adv. 2013, 31, 450–465. [Google Scholar] [CrossRef]

- Weaver, J.; Husson, S.M.; Murphy, L.; Wickramasinghe, S.R. Anion exchange membrane adsorbers for flow-through polishing steps: Part I. clearance of minute virus of mice. Biotechnol. Bioeng. 2012, 110, 491–499. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zheng, Y.; Gurgel, P.V.; Carbonell, R.G. Affinity membrane development from PBT nonwoven by photo-induced graft polymerization, hydrophilization and ligand attachment. J. Membr. Sci. 2013, 428, 562–575. [Google Scholar] [CrossRef]

- Hong, K.H.; Liu, N.; Sun, G. UV-induced graft polymerization of acrylamide on cellulose by using immobilized benzophenone as a photo-initiator. Eur. Polym. J. 2009, 45, 2443–2449. [Google Scholar] [CrossRef]

- Nasef, M.M. Preparation and applications of ion exchange membranes by radiation-induced graft copolymerization of polar monomers onto non-polar films. Prog. Polym. Sci. 2004, 29, 499–561. [Google Scholar] [CrossRef]

- Khan, F.; Ahmad, S.R.; Kronfli, E. UV-radiation-induced preirradiation grafting of methyl methacrylate onto lignocellulose fiber in an aqueous medium and characterization. J. Appl. Polym. Sci. 2003, 91, 1667–1675. [Google Scholar] [CrossRef]

- Tatárová, I.; Fáber, R.; Denoyel, R.; Polakovič, M. Characterization of pore structure of a strong anion-exchange membrane adsorbent under different buffer and salt concentration conditions. J. Chromatogr. A 2009, 1216, 941–947. [Google Scholar] [CrossRef]

- Kamcev, J.; Paul, D.R.; Manning, G.S.; Freeman, B.D. Predicting Salt Permeability Coefficients in Highly Swollen, Highly Charged Ion Exchange Membranes. ACS Appl. Mater. Interfaces 2017, 9, 4044–4056. [Google Scholar] [CrossRef]

- Kozmai, A.; Nikonenko, V.; Zyryanova, S.; Pismenskaya, N.; Dammak, L.; Baklouti, L. Modelling of anion-exchange membrane transport properties with taking into account the change in exchange capacity and swelling when varying bathing solution concentration and pH. J. Membr. Sci. 2019, 590, 117291. [Google Scholar] [CrossRef]

- Sýkora, D.; Svec, F.; Fréchet, J.M. Separation of oligonucleotides on novel monolithic columns with ion-exchange functional surfaces. J. Chromatogr. A 1999, 852, 297–304. [Google Scholar] [CrossRef]

- Farkas, T.; Zhong, G.; Guiochon, G. Validity of Darcy’s law at low flow-rates in liquid chromatography. J. Chromatogr. A 1999, 849, 35–43. [Google Scholar] [CrossRef]

- Tennikov, M.B.; Gazdina, N.V.; Tennikova, T.B.; Svec, F. Effect of porous structure of macroporous polymer supports on resolution in high-performance membrane chromatography of proteins. J. Chromatogr. A 1998, 798, 55–64. [Google Scholar] [CrossRef]

- Trilisky, E.I.; Koku, H.; Czymmek, K.J.; Lenhoff, A.M. Relation of structure to performance characteristics of monolithic and perfusive stationary phases. J. Chromatogr. A 2009, 1216, 6365–6376. [Google Scholar] [CrossRef] [Green Version]

- Herigstad, M.O.; DiMartino, S.; Boi, C.; Sarti, G.C. Experimental characterization of the transport phenomena, adsorption, and elution in a protein A affinity monolithic medium. J. Chromatogr. A 2015, 1407, 130–138. [Google Scholar] [CrossRef] [PubMed]

- Tatárová, I.; Dreveňák, P.; Kosior, A.; Polakovič, M. Equilibrium and kinetics of protein binding on ion-exchange cellulose membranes with grafted polymer layer. Chem. Pap. 2013, 67, 1527–1536. [Google Scholar] [CrossRef]

- Hahn, R.; Panzer, M.; Hansen, E.; Mollerup, J.; Jungbauer, A. Mass transfer properties of monoliths. Sep. Sci. Technol. 2002, 37, 1545–1565. [Google Scholar] [CrossRef]

- He, D.; Ulbricht, M. Preparation and characterization of porous anion-exchange membrane adsorbers with high protein-binding capacity. J. Membr. Sci. 2008, 315, 155–163. [Google Scholar] [CrossRef]

- Tsuneda, S.; Saito, K.; Sugo, T.; Makuuchi, K. Protein adsorption characteristics of porous and tentacle anion-exchange membrane prepared by radiation-induced graft polymerization. Radiat. Phys. Chem. 1995, 46, 239–245. [Google Scholar] [CrossRef]

- Dods, S.R.; Hardick, O.; Stevens, B.; Bracewell, D.G. Fabricating electrospun cellulose nanofibre adsorbents for ion-exchange chromatography. J. Chromatogr. A 2015, 1376, 74–83. [Google Scholar] [CrossRef] [PubMed]

- Vicente, T.; Faber, R.; Alves, P.M.; Carrondo, M.J.; Mota, J. Impact of ligand density on the optimization of ion-exchange membrane chromatography for viral vector purification. Biotechnol. Bioeng. 2011, 108, 1347–1359. [Google Scholar] [CrossRef] [PubMed]

- Hardin, A.M.; Harinarayan, C.; Malmquist, G.; Axén, A.; Van Reis, R. Ion exchange chromatography of monoclonal antibodies: Effect of resin ligand density on dynamic binding capacity. J. Chromatogr. A 2009, 1216, 4366–4371. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| PBT Nonwoven | PBT-GMA | PBT-GMA-SO3 | PBT-GMA-DEA | |

|---|---|---|---|---|

| Φ (%) | 78.48 ± 0.45 | 75.20 ± 0.47 | 74.19 ± 0.53 | 73.06 ± 0.67 |

| Basis Weight (g/m2) | 55.50 ± 0.26 | 65.58 ± 0.28 | 71.47 ± 0.21 | 75.29 ± 0.39 |

| κ (m2) | 3.28 × 10−15 | 3.15 × 10−15 | 2.69 × 10−15 | 1.82 × 10−16 |

| Nonwoven Membrane | SBC (mg BSA/g Membrane) | SBC (mg hIgG/g Membrane) |

|---|---|---|

| PBT | 9.68 ± 0.13 | 7.17 ± 0.86 |

| PBT-GMA | 8.22 ± 3.20 | 5.57 ± 0.19 |

| Membrane | Load BSA or hIgG c (mg /mL) | DBC (mg/mL) | ΔP/Bed Height (MPa/cm) | ||

|---|---|---|---|---|---|

| RT 0.1 min | RT 0.5 min | RT 2 min | |||

| 1 PBT-GMA-SO3 (CEX-membranes) | 2 | 106.20 ± 4.81 | 165.41 ± 2.05 | 199.08 ± 1.75 | 0.35 |

| 4 | 118.11 ± 1.31 | 176.52 ± 0.98 | 199.64 ± 0.95 | 0.40 | |

| 6 | 116.60 ± 3.27 | 181.71 ± 1.53 | 200.28 ± 1.08 | 0.42 | |

| 8 | 98.31 ± 6.24 | 180.72 ± 1.03 | 199.01 ± 1.10 | 0.36 | |

| 10 | 91.38 ± 5.17 | 178.27 ± 2.48 | 193.56 ± 2.39 | 0.37 | |

| 2 PBT-GMA-DEA (AEX-membranes) | 2 | 40.62 ± 3.61 | 48.01 ± 1.11 | 60.19 ± 0.93 | 0.81 |

| 4 | 37.69 ± 3.04 | 44.78 ± 1.63 | 58.20 ± 1.32 | 0.96 | |

| 6 | 36.51 ± 2.96 | 42.61 ± 1.84 | 54.62 ± 1.78 | 1.02 | |

| 8 | 35.06 ± 3.48 | 41.93 ± 2.47 | 52.20 ± 2.03 | 1.11 | |

| 10 | 34.19 ± 2.61 | 41.16 ± 3.05 | 49.39 ± 2.97 | 1.16 | |

| Protein | RT (min) | DBC (mg/mL) | 1 Yield (%) | Purity (%) | HCP (LRV) | DNA (LRV) |

|---|---|---|---|---|---|---|

| hIgG | 0.1 | 144.97 | 91.90 | 95.92 | 1.16 | 1.92 |

| 6 | 180.03 | 97.54 | 96.68 | 1.26 | 2.18 | |

| 10 | 189.17 | 98.00 | 97.07 | 1.55 | 2.22 | |

| scFv | 0.1 | 63.73 | 89.58 | 91.87 | 1.22 | 1.36 |

| 2 | 87.32 | 93.55 | 92.07 | 1.52 | 1.39 | |

| 6 | 106.17 | 96.14 | 97.99 | 1.70 | 1.48 | |

| 10 | 174.00 | 98.91 | 98.93 | 1.81 | 1.51 |

| Protein | RT (min) | DBC (µg/mL) | Recovery hIgG/scFV (%) | DNA (LRV) |

|---|---|---|---|---|

| hIgG | 5 | 3.44 | 90.05 | 2.61 |

| 1 scFv | 2 | 2.04 | 90.30 | 0.95 |

| 5 | 2.26 | 93.17 | 1.29 | |

| 10 | 4.06 | 94.87 | 1.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemma, S.M.; Boi, C.; Carbonell, R.G. Nonwoven Ion-Exchange Membranes with High Protein Binding Capacity for Bioseparations. Membranes 2021, 11, 181. https://doi.org/10.3390/membranes11030181

Lemma SM, Boi C, Carbonell RG. Nonwoven Ion-Exchange Membranes with High Protein Binding Capacity for Bioseparations. Membranes. 2021; 11(3):181. https://doi.org/10.3390/membranes11030181

Chicago/Turabian StyleLemma, Solomon Mengistu, Cristiana Boi, and Ruben G. Carbonell. 2021. "Nonwoven Ion-Exchange Membranes with High Protein Binding Capacity for Bioseparations" Membranes 11, no. 3: 181. https://doi.org/10.3390/membranes11030181