Development of a Position Measuring Device of a Deep-Sea Pipeline Based on Flange Center Positioning

Abstract

:1. Introduction

2. Measurement System and Experimental Method Based on Pipeline Circular Positioning

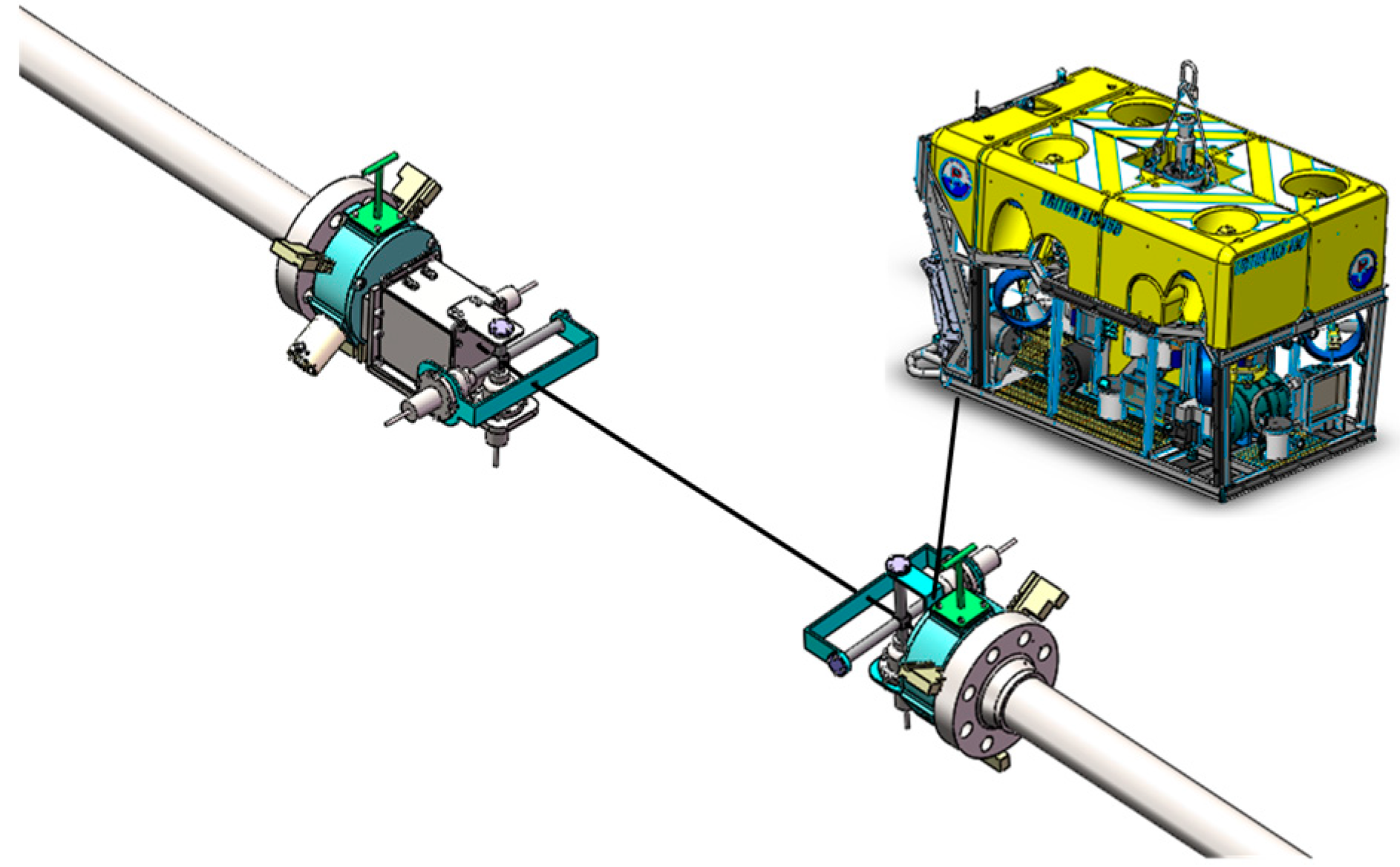

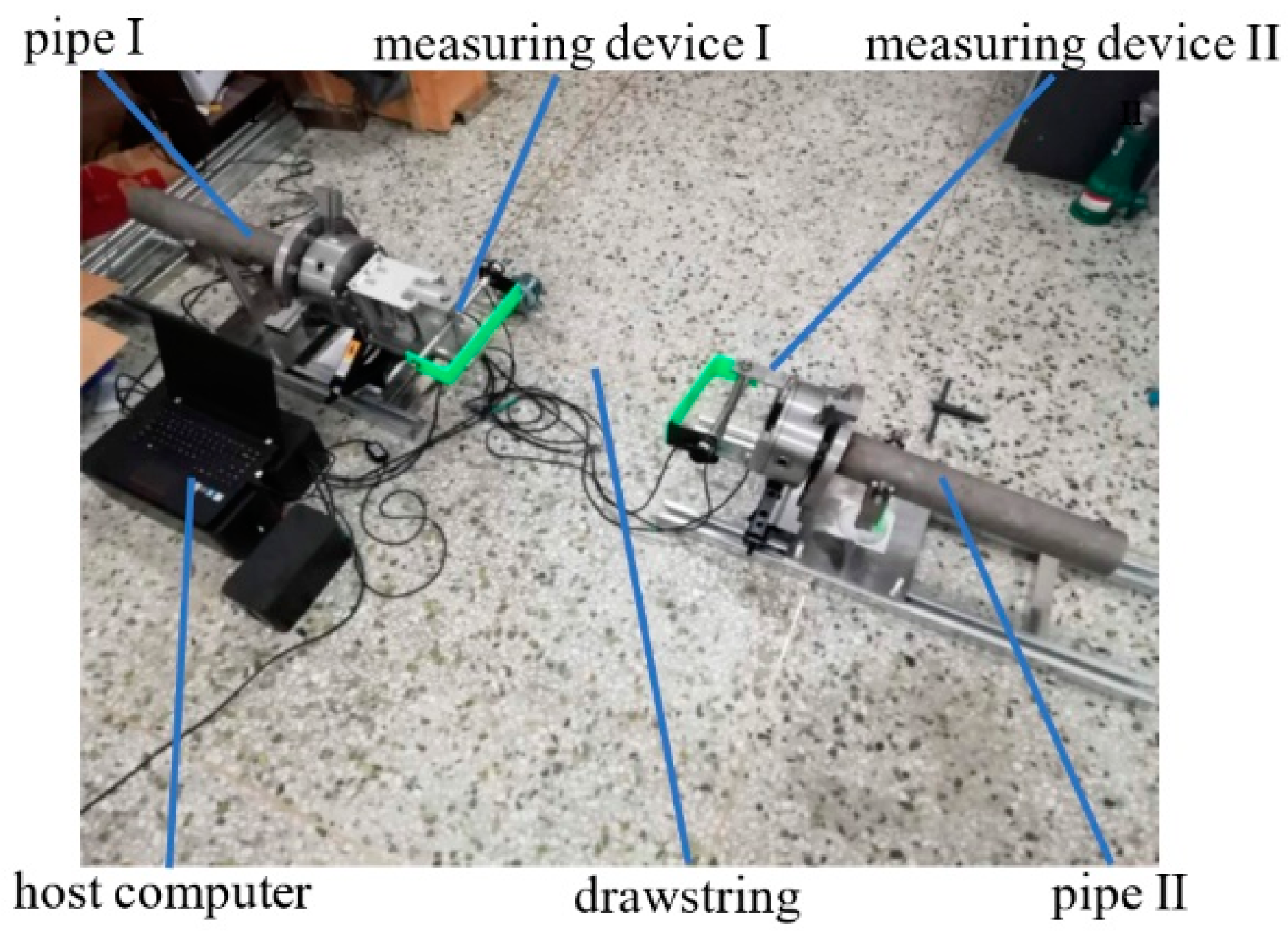

2.1. Composition of the Measurement System

2.2. Method for Measuring the Relative Position of Two Pipes

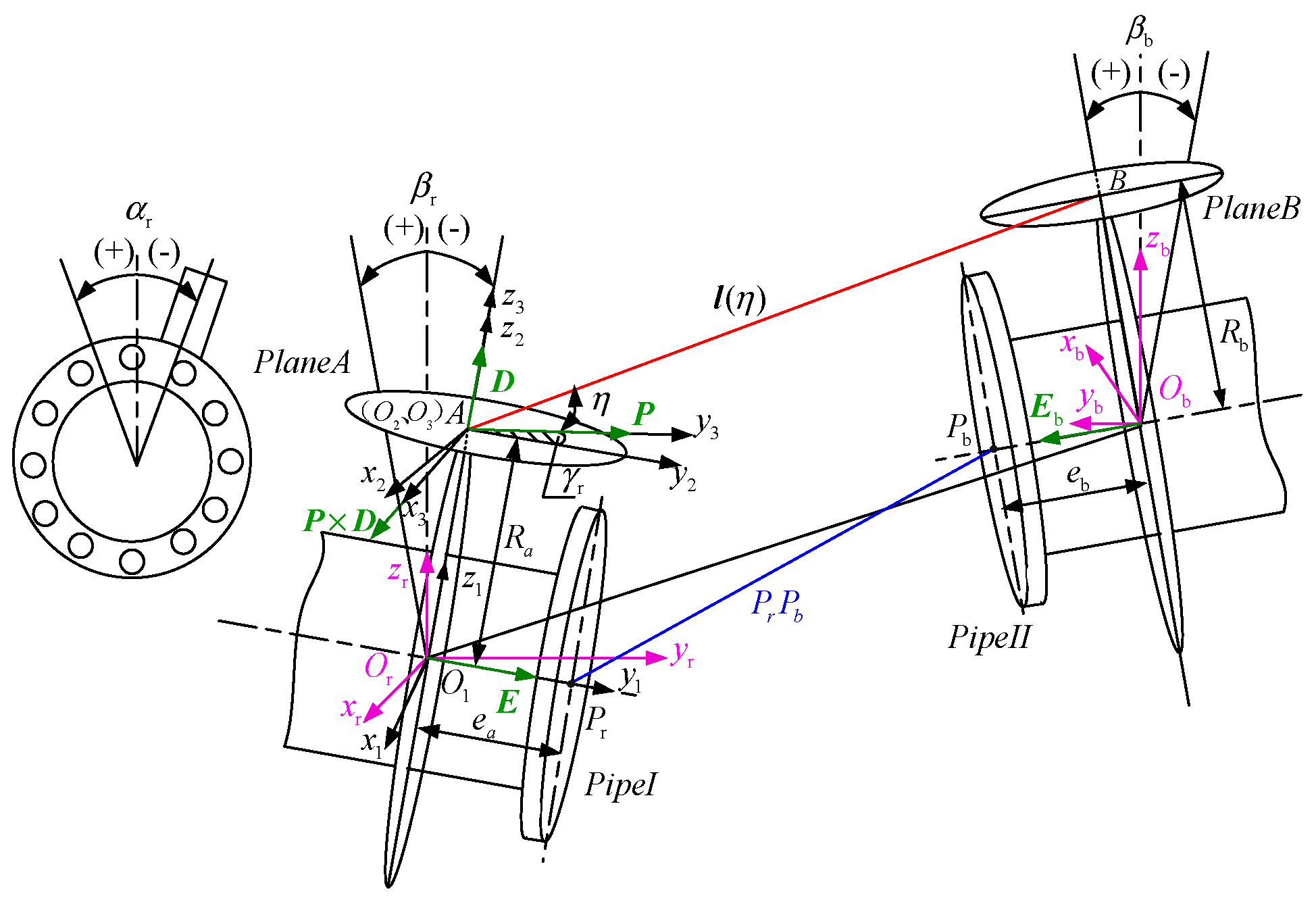

2.2.1. Mathematical Model and Solution Formula of the Measuring Device Based on the Outer Circle Positioning of the Pipeline

2.2.2. Measurement Test

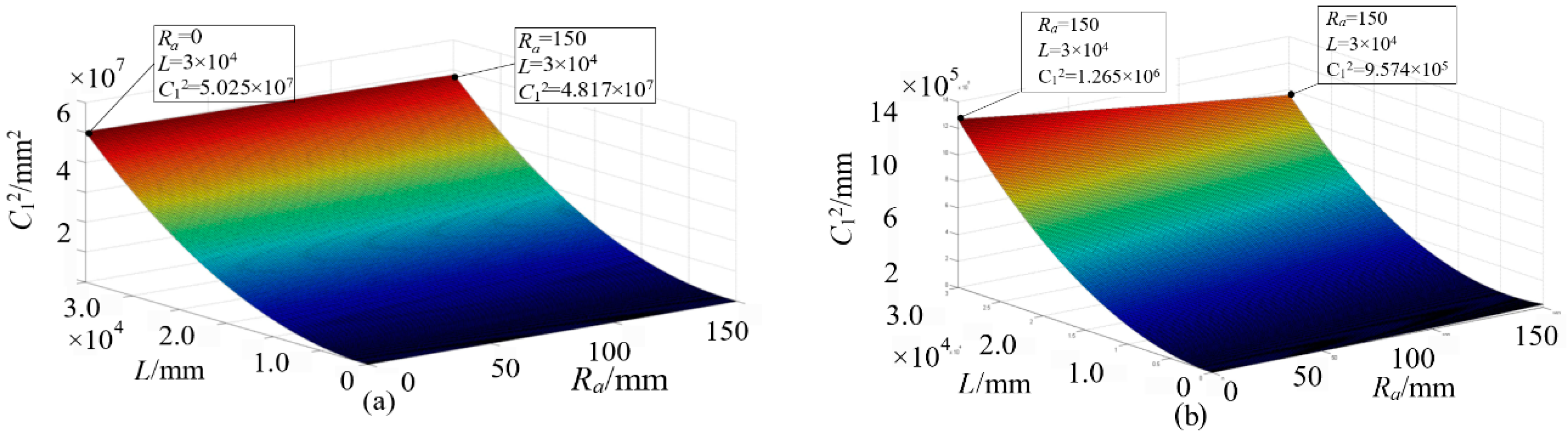

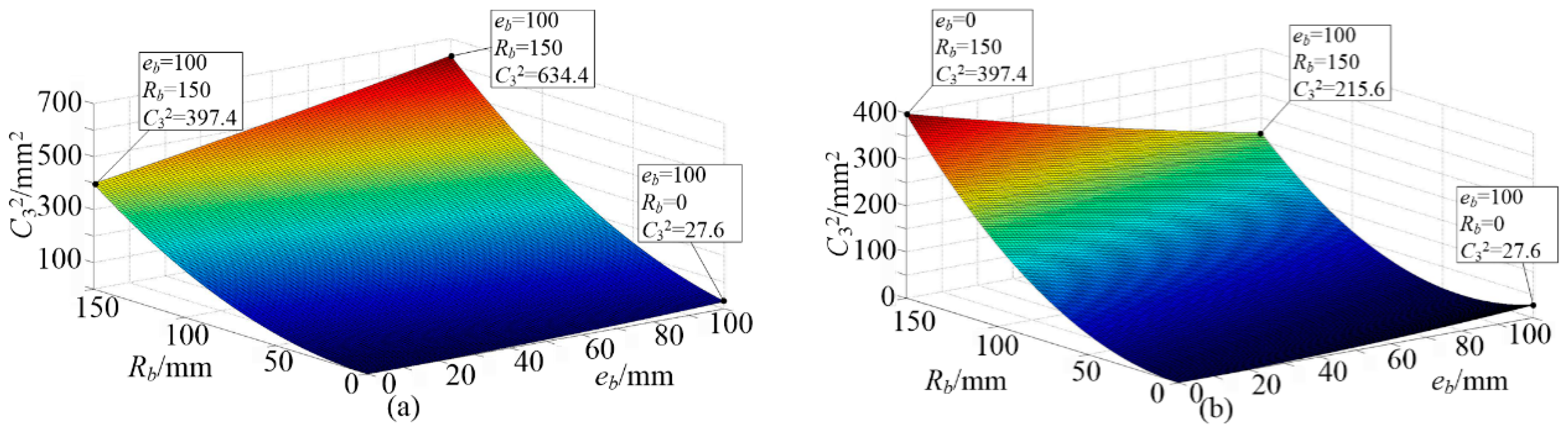

2.3. Error Analysis

3. Design of the Measuring Device Based on Flange Center Positioning

3.1. Overall Design

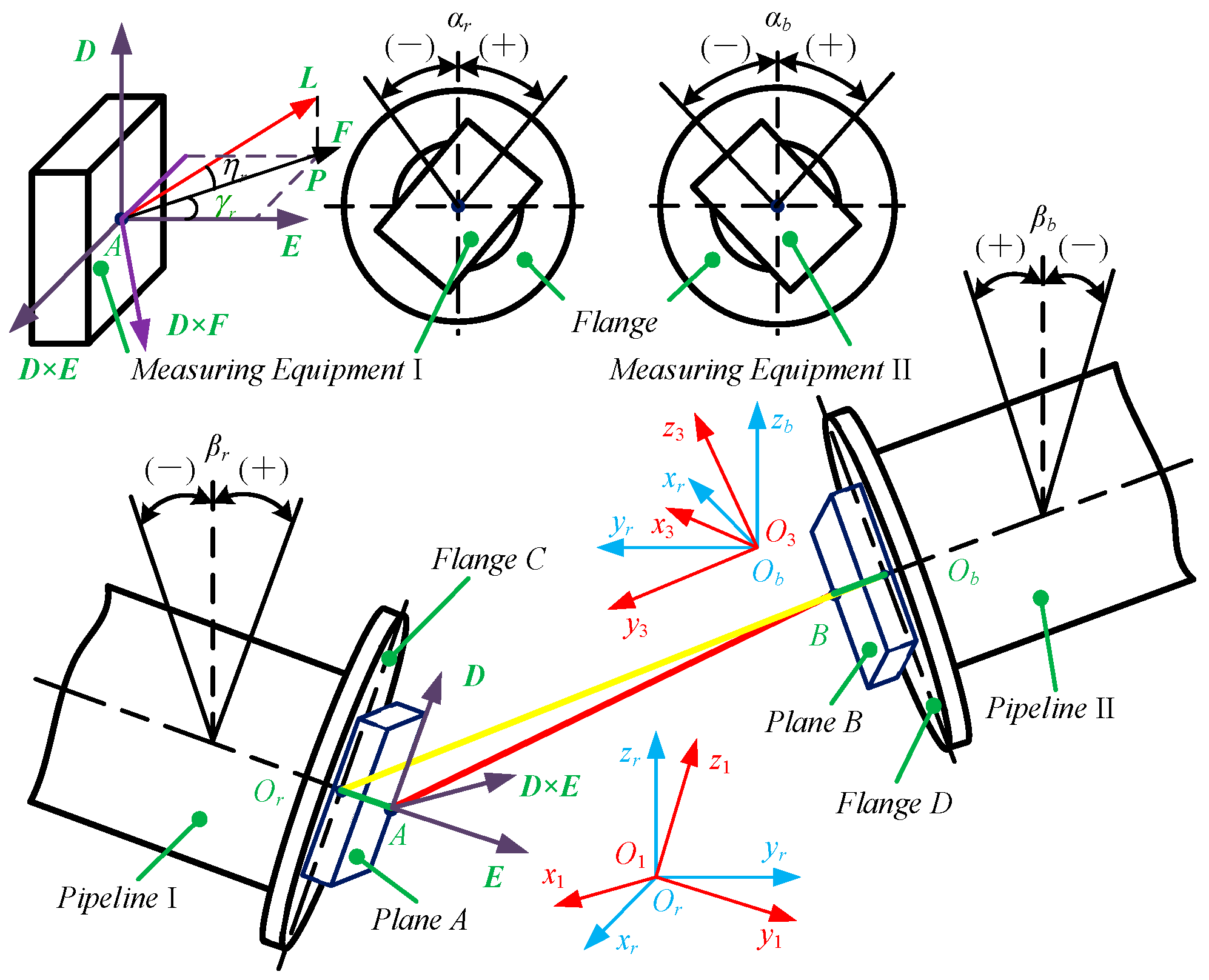

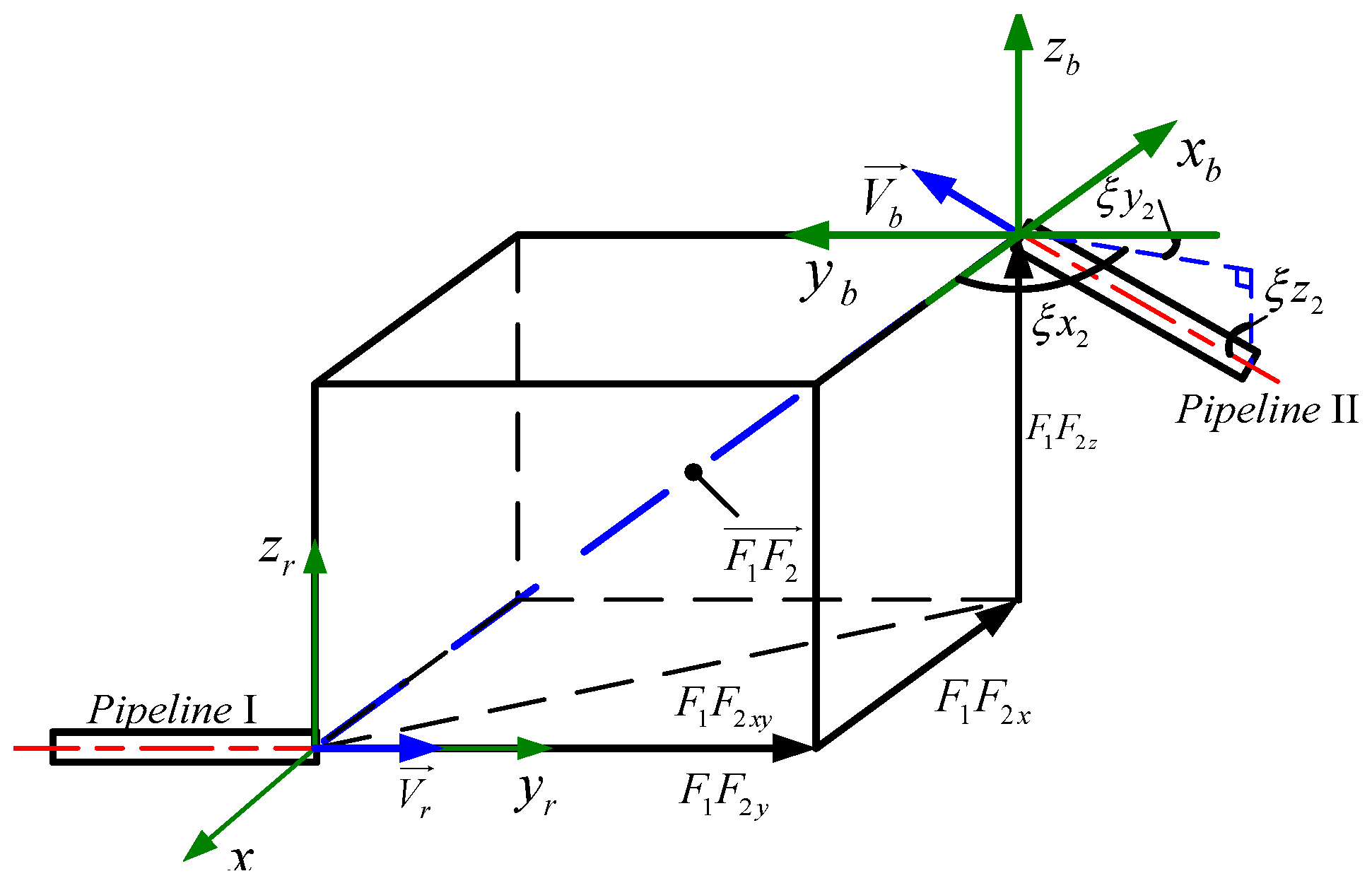

3.2. Building and Solving the Mathematical Model of the Deep-Sea Pipeline Pose Measurement Device Based on Flange Positioning

3.3. Analysis of Error Transfer Coefficient

4. Measurement Experiment of Measuring Device Based on Flange Center Positioning

4.1. Composition of the Measuring Device

4.2. Testing Method and Recording Data

4.3. Analysis of Measurement Data

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yu, X.C.; Wang, C.S.; Li, B.; Cheng, B.; Li, Y.; Wang, Q. Pigging Solutions Study of Subsea Tieback Flow line for Deep-water Oil and Gas Fields in the South China Sea. Ocean Eng. Equip. Technol. 2017, 4, 199–205. [Google Scholar]

- Gao, Y.B.; Li, H.Q.; Chai, Y.P.; Ma, C.L. The Development of Deep Ocean High Technology. Ocean Technol. 2010, 29, 119–125. [Google Scholar]

- De Lucena, R.R.; Baioco, J.S.; De Lima, B.S.L.P.; Albrecht, C.H.; Jacob, B.P. Optimal design of submarine pipeline routes by genetic algorithm with different constraint handling techniques. Adv. Eng. Softw. 2014, 76, 110–118. [Google Scholar] [CrossRef]

- Laye, A.; Victoire, K.; Cocault-Duverger, V. Model-Centric Digital Subsea Pipeline Design Process and Framework. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar]

- Wang, L.Q.; Pan, Z.J.; Zhao, D.Y.; He, N.; Zhang, L. Technology of Pipeline Alignment in Subsea. Mach. Tool Hydraul. 2010, 38, 16–27. [Google Scholar]

- Wang, D.Y.; Zhu, A.D. Current Situation of Offshore Petroleum Equipment and Development Orientation of Localization. Chin. Pet. Mach. 2014, 42, 33–39. [Google Scholar]

- Liu, F. Method Study for Subsea Pipeline Spool Installation and Design in Special Working Condition. Pipeline Technol. Equip. 2018, 151, 34–41. [Google Scholar]

- Zhao, J.H.; Ouyang, Y.Z.; Wang, A.X. Status and Development Tendency for Seafloor Terrain Measurement Technology. Acta Geod. Cartogr. Sin. 2017, 46, 1786–1792. [Google Scholar]

- Dariusz, P.; Tomasz, T.; Michał, L. Using the geodetic and hydroacoustic measurements to investigate the bathymetric and morphometric parameters of Lake Hańcza. Open Geosci. 2015, 7, 1–8. [Google Scholar]

- Getmanov, V.G.; Modyaev, A.D.; Firsov, A.A. A method of measurement of the coordinates of a moving object with the use of a passive hydroacoustic detection and ranging system. Meas. Technol. 2012, 55, 248–256. [Google Scholar] [CrossRef]

- Tomasz, P. Correction of Navigational Information Supplied to Biomimetic Autonomous Underwater Vehicle. Pol. Marit. Res. 2018, 25, 13–22. [Google Scholar]

- Gamroth, E.; Kennedy, J.; Bradley, C. Design and testing of an acoustic ranging technique applicable for an underwater positioning system. Underwater Technol. 2011, 29, 4467–4477. [Google Scholar] [CrossRef]

- Wang, L.Q.; Wang, W.M.; Zhao, D.Y.; Cao, W.; Wang, C.D. A research into the Flange Connection Tooling for deep-sea pipelines. Nat. Gas Ind. 2009, 29, 89–97. [Google Scholar]

- Zhu, S.H.; Wei, X.C.; Liu, B. Study and application of measure technology by flange measure instrument to spool piece connection of subsea pipelines. Chin. Offshore Oil Gas 2008, 20, 342–349. [Google Scholar]

- Den, N.S.; Oljeselskap, A.S. System for subsea diverless metrology and hard-pipe connection of pipelines. U.S. Patent 6700835, 2 March 2004. [Google Scholar]

- Wang, W.M.; Wang, C.D.; Wang, L.Q. A novel deepwater structures pose measurement method and experimental study. Measurement 2012, 45, 1151–1159. [Google Scholar] [CrossRef]

- Shabani, M.; Gholami, A. Improved Underwater Integrated Navigation System using Unscented Filtering Approach. J. Navig. 2016, 69, 561–570. [Google Scholar] [CrossRef] [Green Version]

- Mallios, A.; Vidal, E.; Campos, R.; Carreras, M. Underwater caves sonar data set. Int. J. Rob. Res. 2017, 36, 1247–1256. [Google Scholar] [CrossRef]

- Han, W.H.; Zhou, J. Comparative Research of Corrosion Models for Corroded Submarine Pipelines. Pet. Eng. Constr. 2014, 40, 9–17. [Google Scholar]

| Component of Measurements | Classification | 2 m | 3 m | 4 m | 5 m | 6 m | 7 m |

|---|---|---|---|---|---|---|---|

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | 5.4 | 11.2 | 25.4 | 21.3 | 38.3 | 40.4 | |

| actual value (mm) | 2000.0 | 3000.0 | 4000.0 | 5000.0 | 6000.0 | 7000.0 | |

| measurements (mm) | 1981.5 | 3009.9 | 4012.4 | 5022.5 | 6025.7 | 7032.6 | |

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | −6.6 | 12.2 | 12.8 | 27.7 | 54.5 | 68.8 | |

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | 0.2 | 0.5 | 0.8 | 1.1 | 1.2 | 1.1 | |

| actual value (mm) | 90.0 | 90.0 | 90.0 | 90.0 | 90.0 | 90.0 | |

| measurements (mm) | 89.8 | 89.5 | 89.2 | 88.9 | 88.8 | 88.9 | |

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | 0.3 | 0.2 | 0.8 | 0.5 | 0.7 | 1.2 |

| Component of Measurements | Classification | 2 m | 3 m | 4 m | 5 m | 6 m | 7 m |

|---|---|---|---|---|---|---|---|

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | 4.7 | 9.2 | 13.1 | 16.8 | 23.1 | 30.5 | |

| actual value (mm) | 2000.0 | 3000.0 | 4000.0 | 5000.0 | 6000.0 | 7000.0 | |

| measurements (mm) | 1994.8 | 3004.1 | 4008.3 | 5014.8 | 6016.8 | 7025.2 | |

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | −2.1 | 9.6 | 11.9 | 18.8 | 32.5 | 46.9 | |

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | 0.2 | 0.3 | 0.6 | 0.9 | 1.0 | 1.1 | |

| actual value (mm) | 90.0 | 90.0 | 90.0 | 90.0 | 90.0 | 90.0 | |

| measurements (mm) | 89.8 | 89.5 | 89.3 | 89.0 | 89.1 | 88.9 | |

| actual value (mm) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| measurements (mm) | 0.2 | 0.3 | 0.7 | 0.6 | 0.8 | 0.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Dang, H.-x.; Wang, T.; Zhang, B. Development of a Position Measuring Device of a Deep-Sea Pipeline Based on Flange Center Positioning. J. Mar. Sci. Eng. 2020, 8, 86. https://doi.org/10.3390/jmse8020086

Wang Z, Dang H-x, Wang T, Zhang B. Development of a Position Measuring Device of a Deep-Sea Pipeline Based on Flange Center Positioning. Journal of Marine Science and Engineering. 2020; 8(2):86. https://doi.org/10.3390/jmse8020086

Chicago/Turabian StyleWang, Zhuo, Hong-xing Dang, Tao Wang, and Bo Zhang. 2020. "Development of a Position Measuring Device of a Deep-Sea Pipeline Based on Flange Center Positioning" Journal of Marine Science and Engineering 8, no. 2: 86. https://doi.org/10.3390/jmse8020086