Use of Nanoparticles for Enhancing the Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints—A Review

Abstract

:1. Introduction

1.1. Interlaminar Properties Improvement Techniques Not Using Nanoparticles

1.2. Brief Introduction to Nanoparticles

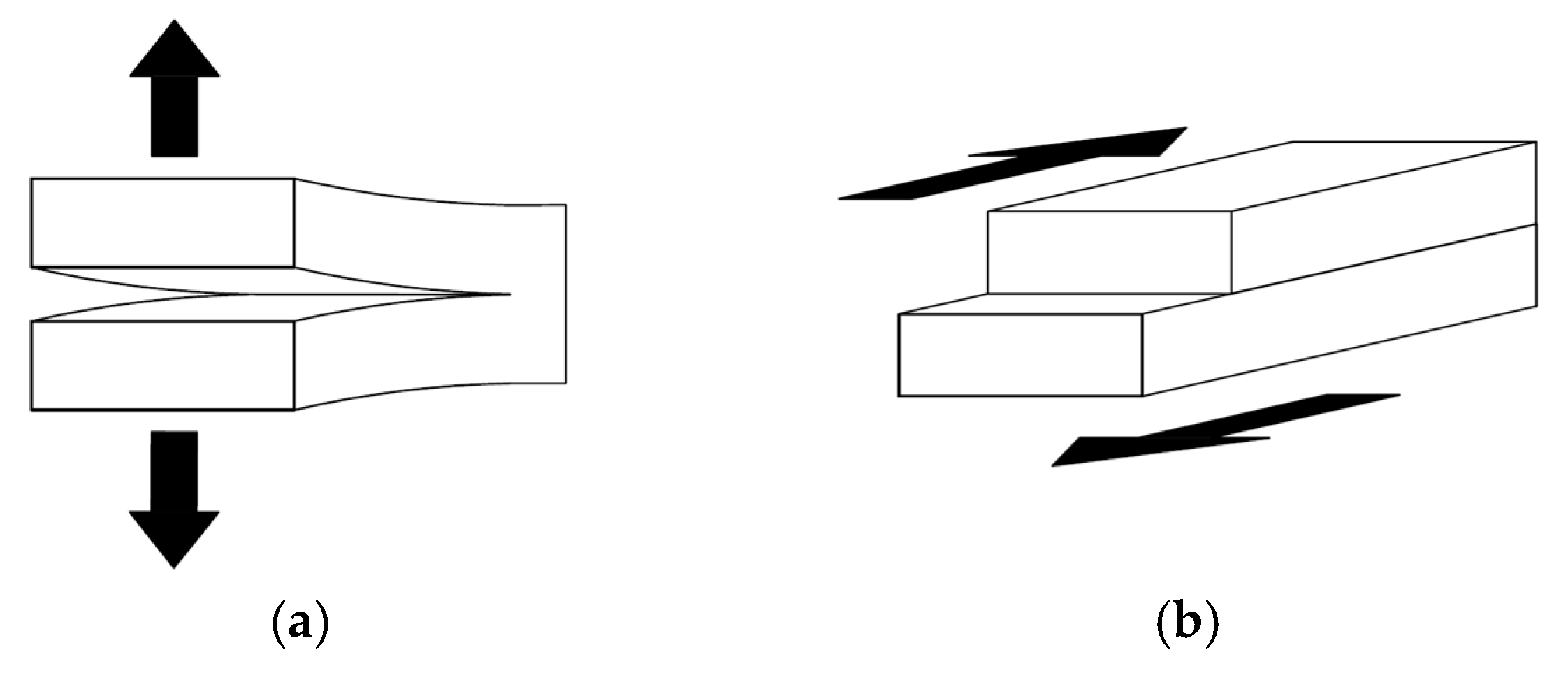

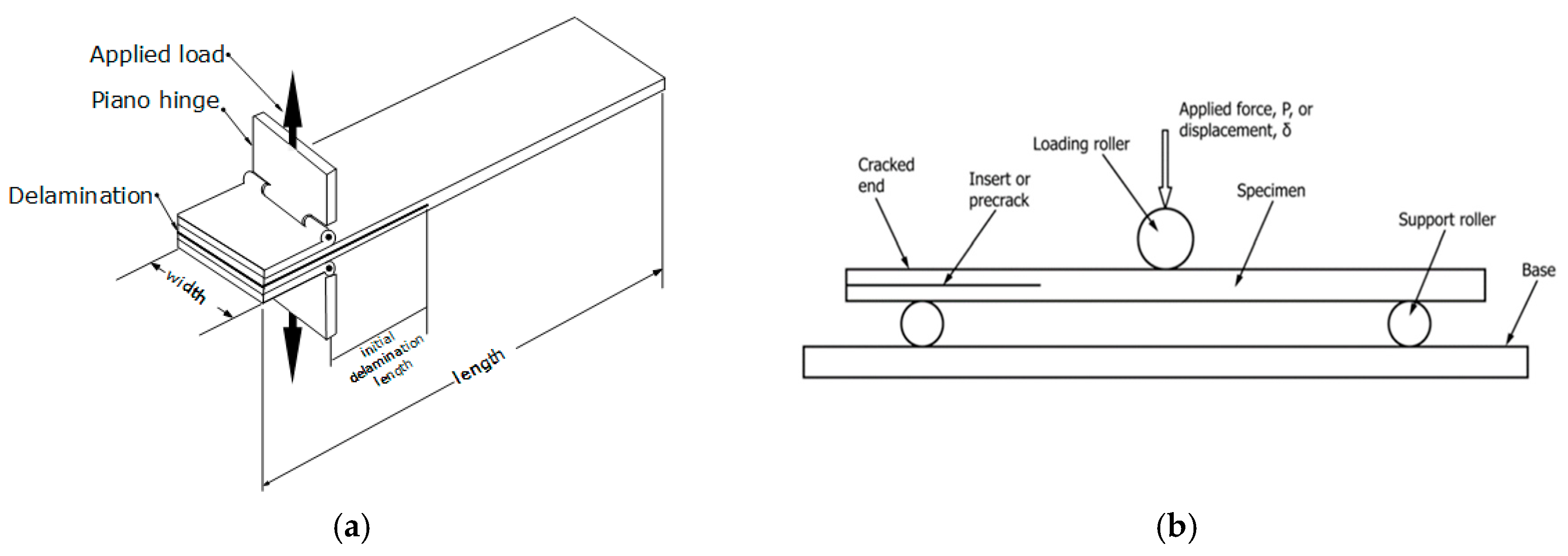

1.3. Mode I and II Fracture Testing Methods

2. Effect of Nanoparticles on Delamination-Related Properties and ABJs

2.1. Enhancement of Interlaminar Shear Strength

2.2. Enhancement of Interlaminar Fracture Strength and Toughness

2.3. Enhancement of Fatigue Resistance

2.4. Effects on Delamination

2.5. Enhancement of Adhesively Bonded Joints

2.6. Other Notable Effects

3. Numerical Modelling of Delamination in FRPs and ABJs

3.1. Cohesive and Extended Finite Elements (XFEM) Modeling Techniques

3.2. Various Scale Modeling Techniques

3.2.1. Macroscopic Scale Modelling

3.2.2. Microscopic Modeling Scale

3.2.3. Molecular Modeling Scale

3.2.4. Multiscale Modeling Approach

4. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviation and Acronyms

| ABJ | adhesively bonded joint |

| CF | carbon fiber |

| CF/EP | carbon fiber-epoxy composite laminate |

| CFRP | carbon fiber reinforced plastic |

| CNT | carbon nano-tube |

| CNF | carbon nano-fiber |

| CSCNT | cup-stacked carbon nano-tube |

| CZM | cohesive zone model(ing) |

| FML | fiber-metal laminate |

| FRP | fiber-reinforced polymer composite |

| GF/EP | glass fiber-epoxy composite laminate |

| GNP | graphene nano-platelet |

| GO | graphene oxide |

| ILFS | interlaminar fracture strength |

| ILFT | interlaminar fracture toughness |

| ILSS | interlaminar shear strength |

| MD | molecular dynamics |

| MWCNT | multi-walled carbon nano-tube |

| NP | nanoparticle |

| SWCNT | single-walled carbon nano-tube |

| TRGO | thermally reduced graphene oxide |

| Note: “s” following above acronyms makes them plural | |

References

- Pipes, R.B. The Place for Thermoplastic Composites in Structural Components: Report of the Committee on Thermoplastic Composites as Structural Components; National Academies Press: Washington, DC, USA, 1987. [Google Scholar]

- Kim, J.-K.; Mai, Y.-W. Engineered Interfaces in Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Oehlers, D.J.; Liu, I.S.T.; Seracino, R. Shear deformation debonding of adhesively bonded plates. Proc. Inst. Civ. Eng. Struct. Build. 2005, 158, 77–84. [Google Scholar] [CrossRef]

- Abot, J.L.; Song, Y.; Schulz, M.J.; Shanov, V.N. Novel carbon nanotube array-reinforced laminated composite materials with higher interlaminar elastic properties. Compos. Sci. Technol. 2008, 68, 2755–2760. [Google Scholar] [CrossRef]

- Gay, D.; Hoa, S.V.; Tsai, S.W. Composite Materials Design and Applications; CRC Press LLC.: Boca Raton, FL, USA, 2003. [Google Scholar]

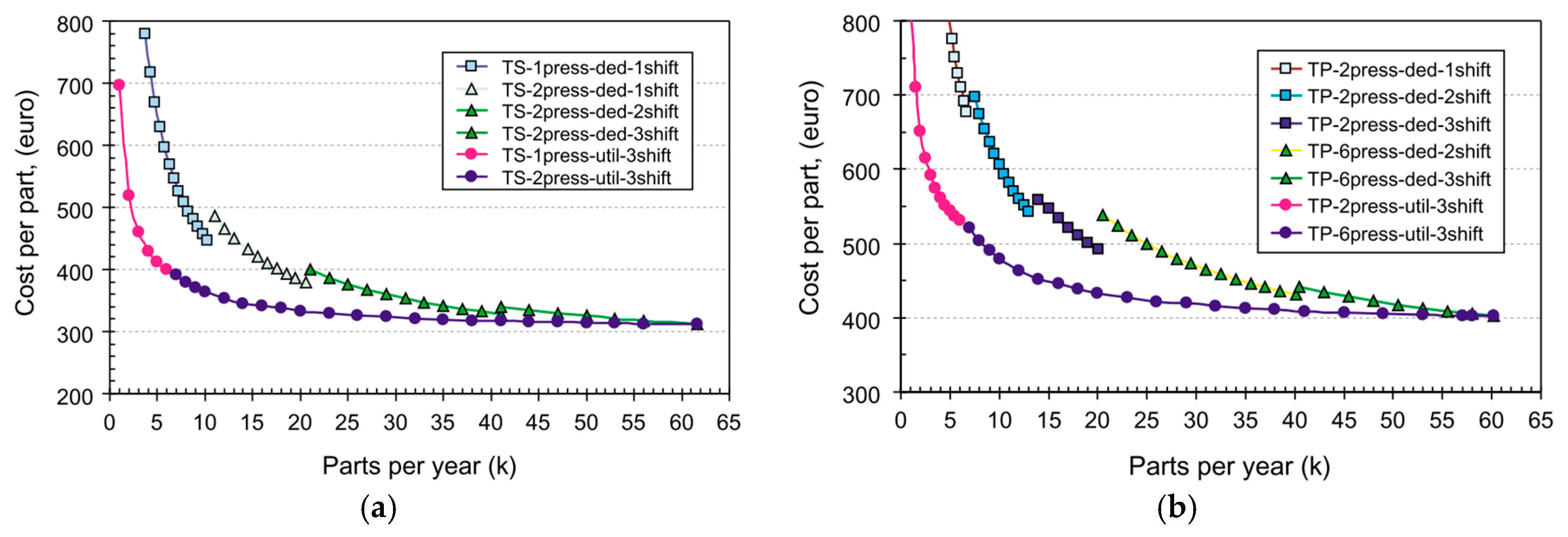

- Verrey, J.; Wakeman, M.D.; Michaud, V.; Månson, J.A.E. Manufacturing cost comparison of thermoplastic and thermoset RTM for an automotive floor pan. Compos. Part A Appl. Sci. Manuf. 2006, 37, 9–22. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Bannister, M.K.; Falzon, P.J.; Leong, K.H. Review of applications for advanced three-dimensional fibre textile composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1445–1461. [Google Scholar] [CrossRef]

- Tong, L.; Mouritz, A.P.; Bannister, M.K. 3D Fibre Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Dransfield, K.A.; Jain, L.K.; Mai, Y.-W. On the effects of stitching in CFRPs—I. Mode I delamination toughness. Compos. Sci. Technol. 1998, 58, 815–827. [Google Scholar] [CrossRef]

- Dransfield, K.; Baillie, C.; Mai, Y.-W. Improving the delamination resistance of CFRP by stitching—A review. Compos. Sci. Technol. 1994, 50, 305–317. [Google Scholar] [CrossRef]

- Reeder, J.R. Stitching vs. A Toughned Matrix: Compression Strength Effects. J. Compos. Mater. 1995, 29, 2464–2487. [Google Scholar] [CrossRef]

- Brown, R.T.; Crow, E.C., Jr. Automatic through-the-thickness braiding. In 37th International SAMPE Symposium and Exhibition; SAMPE International Business Office: Covina, CA, USA, 1992; pp. 832–842. [Google Scholar]

- Dickinson, L.C.; Farley, G.L.; Hinders, M.K. Prediction of Effective Three-Dimensional Elastic Constants of Translaminar Reinforced Composites. J. Compos. Mater. 1999, 33, 1002–1029. [Google Scholar] [CrossRef]

- Abe, T.; Hayashi, K.; Sato, T.; Yamane, S.; Hirokawa, T. A-VARTM process and z-anchor technology for primary aircraft structures. In Proceedings of the 24th International SAMPE Europe Conference, Paris, France, 1–3 April 2003; Sampe Europe: Niederglatt, Switzerland, 2003. [Google Scholar]

- Mouritz, A.P. Review of z-pinned composite laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2383–2397. [Google Scholar] [CrossRef]

- Chang, P.; Mouritz, A.P.; Cox, B.N. Flexural properties of z-pinned laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 244–251. [Google Scholar] [CrossRef]

- Steeves, C.A.; Fleck, N.A. In-plane properties of composite laminates with through-thickness pin reinforcement. Int. J. Solids Struct. 2006, 43, 3197–3212. [Google Scholar] [CrossRef]

- Harris, A.F.; Beevers, A. The ffects of grit-blasting on surface properties for adhesion. Int. J. Adhes. Adhes. 1999, 19, 445–452. [Google Scholar] [CrossRef]

- Baldan, A. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Shahid, M.; Hashim, S.A. Effect of surface roughness on the strength of cleavage joints. Int. J. Adhes. Adhes. 2002, 22, 235–244. [Google Scholar] [CrossRef]

- Pärnänen, T.; Alderliesten, R.; Rans, C.; Brander, T.; Saarela, O. Applicability of AZ31B-H24 magnesium in Fibre Metal Laminates—An experimental impact research. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1578–1586. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Zhang, Y.; Xu, T.; Liu, W. A facile approach to formation of through-hole porous anodic aluminum oxide film. Mater. Lett. 2005, 59, 40–43. [Google Scholar] [CrossRef]

- Gan, Y.X. Effect of interface structure on mechanical properties of advanced composite materials. Int. J. Mol. Sci. 2009, 10, 5115–5134. [Google Scholar] [CrossRef] [PubMed]

- Collaud, M.; Groening, P.; Nowak, S.; Schlapbach, L. Plasma treatment of polymers: The effect of the plasma parameters on the chemical, physical, and morphological states of the polymer surface and on the metal-polymer interface. J. Adhes. Sci. Technol. 1994, 8, 1115–1127. [Google Scholar] [CrossRef]

- Difelice, R.A.; Dillard, J.G.; Yang, D. An investigation of plasma processes in titanium(iv) isobutoxide: The formation of films on Ti and Si. Int. J. Adhes. Adhes. 2005, 25, 277–287. [Google Scholar] [CrossRef]

- Williams, T.S.; Yu, H.; Hicks, R.F. Atmospheric pressure plasma activation as a surface pre-treatment for the adhesive bonding of aluminum 2024. J. Adhes. Sci. Technol. 2014, 28, 653–674. [Google Scholar] [CrossRef]

- Williams, T.S. Surface Modification by Atmospheric Pressure Plasma for Improved Bonding; University of California: Oackland, CA, USA, 2013. [Google Scholar]

- Williams, T.S.; Yu, H.; Hicks, R.F. Atmospheric pressure plasma activation of polymers and composites for adhesive bonding. Rev. Adhes. Adhes. 2013, 1, 46–87. [Google Scholar] [CrossRef]

- Gonzalez, E.; Hicks, R.F. Surface Analysis of Polymers Treated by Remote Atmospheric Pressure Plasma. Langmuir 2009, 26, 3710–3719. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, E.; Barankin, M.D.; Guschl, P.C.; Hicks, R.F. Surface Activation of Poly(methyl methacrylate) via Remote Atmospheric Pressure Plasma. Plasma Process. Polym. 2010, 7, 482–493. [Google Scholar] [CrossRef]

- Kim, M.C.; Yang, S.H.; Boo, J.-H.; Han, J.G. Surface treatment of metals using an atmospheric pressure plasma jet and their surface characteristics. Surf. Coat. Technol. 2003, 174–175, 839–844. [Google Scholar] [CrossRef]

- Noeske, M.; Degenhardt, J.; Strudthoff, S.; Lommatzsch, U. Plasma jet treatment of five polymers at atmospheric pressure: Surface modifications and the relevance for adhesion. Int. J. Adhes. Adhes. 2004, 24, 171–177. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Kim, H.I.H.; Steckel, G.L.; Nokes, J.P.; Morgan, B.A. Effect of Processing Parameter Changes on the Adhesion of Plasma-treated Carbon Fiber Reinforced Epoxy Composites. J. Compos. Mater. 2010, 44, 1435–1453. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Nokes, J.; Steckel, G.L.; Kim, H.I.; Morgan, B.A. The Effect of Atmospheric Plasma Treatment on the Chemistry, Morphology and Resultant Bonding Behavior of a Pan-Based Carbon Fiber-Reinforced Epoxy Composite. J. Compos. Mater. 2010, 44, 137–156. [Google Scholar] [CrossRef]

- Shenton, M.J.; Lovell-Hoare, M.C.; Stevens, G.C. Adhesion enhancement of polymer surfaces by atmospheric plasma treatment. J. Phys. D. Appl. Phys. 2001, 34, 2754–2760. [Google Scholar] [CrossRef]

- Livadifiis, G.J. A chemical etching system for creating micromechanical retention in resin-bonded retainers. J. Prosthet. Dent. 1986, 56, 181–188. [Google Scholar] [CrossRef]

- Sang Park, Y.; Choi, W.J.; Choi, H.S.; Kwon, H. Effects of surface pre-treatment and void content on GLARE laminate process characteristics. J. Mater. Process. Technol. 2010, 210, 1008–1016. [Google Scholar] [CrossRef]

- Lefebvre, D.R.; Ahn, B.K.; Dillard, D.A.; Dillard, J.G. The effect of surface treatments on interfacial fatigue crack initiation in aluminum/epoxy bonds. Int. J. Fract. 2002, 114, 191–202. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Ureña, A. Effect of surface pre-treatment on the adhesive strength of epoxy-aluminium joints. Int. J. Adhes. Adhes. 2009, 29, 23–31. [Google Scholar] [CrossRef]

- Kim, J.; Baillie, C.; Poh, J.; Mai, Y.-W. Fracture toughness of CFRP with modified epoxy resin matrices. Compos. Sci. Technol. 1992, 43, 283–297. [Google Scholar] [CrossRef]

- Liao, F.-S.; Su, A.-C.; Hsu, T.-C. Vibration Damping of Interleaved Carbon Fiber-Epoxy Composite Beams. J. Compos. Mater. 1994, 28, 1840–1854. [Google Scholar] [CrossRef]

- Singh, S.; Partridge, I.K. Mixed-mode fracture in an interleaved carbon-fibre/epoxy composite. Compos. Sci. Technol. 1995, 55, 319–327. [Google Scholar] [CrossRef]

- Hojo, M.; Ando, T.; Tanaka, M.; Adachi, T.; Ochiai, S.; Endo, Y. Modes I and II interlaminar fracture toughness and fatigue delamination of CF/epoxy laminates with self-same epoxy interleaf. Int. J. Fatigue 2006, 28, 1154–1165. [Google Scholar] [CrossRef]

- Palazzetti, R.; Yan, X.; Zucchelli, A. Influence of Geometrical Features of Electrospun Nylon 6,6 Interleave on the CFRP Laminates Mechanical Properties. Polym. Compos. 2014, 35, 137–150. [Google Scholar] [CrossRef]

- Yasaee, M.; Bond, I.P.; Trask, R.S.; Greenhalgh, E.S. Mode II interfacial toughening through discontinuous interleaves for damage suppression and control. Compos. Part A Appl. Sci. Manuf. 2012, 43, 198–207. [Google Scholar] [CrossRef]

- Hojo, M.; Matsuda, S.; Tanaka, M.; Ochiai, S.; Murakami, A. Mode I delamination fatigue properties of interlayer-toughened CF/epoxy laminates. Compos. Sci. Technol. 2006, 66, 665–675. [Google Scholar] [CrossRef]

- Lu, W.H.; Liao, F.S.; Su, A.C.; Kao, P.W.; Hsu, T.J. Effect of interleaving on the impact response of a unidirectional carbon/epoxy composite. Composites 1995, 26, 215–222. [Google Scholar] [CrossRef]

- Taheri, F. Improvement of Strength and Ductility of Adhesively Bonded Joints by Inclusion of SiC Whiskers. J. Compos. Technol. Res. 1997, 19, 86–92. [Google Scholar]

- Khoramishad, H.; Razavi, S.M.J. Metallic fiber-reinforced adhesively bonded joints. Int. J. Adhes. Adhes. 2014, 55, 114–122. [Google Scholar] [CrossRef]

- Ebnesajjad, S.; Landrock, A.H. Adhesives Technology Handbook; William Andrew: New York, NY, USA, 2014. [Google Scholar]

- Garg, A.C. Delamination—A damage mode in composite structures. Eng. Fract. Mech. 1988, 29, 557–584. [Google Scholar] [CrossRef]

- Herakovich, C.T. On the relationship between engineering properties and delamination of composite materials. J. Compos. Mater. 1981, 15, 336–348. [Google Scholar] [CrossRef]

- Chandrasekaran, V.C.S.; Advani, S.G.; Santare, M.H. Influence of resin properties on interlaminar shear strength of glass/epoxy/MWNT hybrid composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1007–1016. [Google Scholar] [CrossRef]

- Eskizeybek, V.; Avci, A.; Gülce, A. The Mode I interlaminar fracture toughness of chemically carbon nanotube grafted glass fabric/epoxy multi-scale composite structures. Compos. Part A Appl. Sci. Manuf. 2014, 63, 94–102. [Google Scholar] [CrossRef]

- Yan, N.; Xia, H.; Zhan, Y.; Fei, G. New insights into fatigue crack growth in graphene-filled natural rubber composites by microfocus hard-X-ray beamline radiation. Macromol. Mater. Eng. 2013, 298, 38–44. [Google Scholar] [CrossRef]

- Ávila, A.F.; Neto, A.S.; Nascimento Junior, H. Hybrid nanocomposites for mid-range ballistic protection. Int. J. Impact Eng. 2011, 38, 669–675. [Google Scholar] [CrossRef]

- Sydlik, S.A.; Lee, J.H.; Walish, J.J.; Thomas, E.L.; Swager, T.M. Epoxy functionalized multi-walled carbon nanotubes for improved adhesives. Carbon 2013, 59, 109–120. [Google Scholar] [CrossRef]

- Wu, L.X.; Hoa, S.V.; Wang, H. Improvement of flammability resistance of epoxy adhesives used in infrastructure applications. Can. J. Civ. Eng. 2007, 34, 323–330. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Korotcenkov, G. Fundamentals of Sensing Materials Volume 2: Nanostructured Materials; Momentum Press: New York, NY, USA, 2010. [Google Scholar]

- Alishahi, E.; Shadlou, S.; Doagou-R, S.; Ayatollahi, M.R. Effects of carbon nanoreinforcements of different shapes on the mechanical properties of epoxy-based nanocomposites. Macromol. Mater. Eng. 2013, 298, 670–678. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Shadlou, S.; Shokrieh, M.M.; Chitsazzadeh, M. Effect of multi-walled carbon nanotube aspect ratio on mechanical and electrical properties of epoxy-based nanocomposites. Polym. Test. 2011, 30, 548–556. [Google Scholar] [CrossRef]

- Choi, Y.K.; Sugimoto, K.I.; Song, S.M.; Endo, M. Mechanical and thermal properties of vapor-grown carbon nanofiber and polycarbonate composite sheets. Mater. Lett. 2005, 59, 3514–3520. [Google Scholar] [CrossRef]

- Gao, J.; Li, W.; Shi, H.; Hu, M.; Li, R.K.Y. Preparation, morphology, and mechanical properties of carbon nanotube anchored polymer nanofiber composite. Compos. Sci. Technol. 2014, 92, 95–102. [Google Scholar] [CrossRef]

- Hone, J.; Llaguno, M.C.; Biercuk, M.J.; Johnson, A.T.; Batlogg, B.; Benes, Z.; Fischer, J.E. Thermal properties of carbon nanotubes and nanotube-based materials. Appl. Phys. A Mater. Sci. Process. 2002, 74, 339–343. [Google Scholar] [CrossRef]

- Poveda, R.L.; Gupta, N. Electrical properties of carbon nanofiber reinforced multiscale polymer composites. Mater. Des. 2014, 56, 416–422. [Google Scholar] [CrossRef]

- Shadlou, S.; Alishahi, E.; Ayatollahi, M.R. Fracture behavior of epoxy nanocomposites reinforced with different carbon nano-reinforcements. Compos. Struct. 2013, 95, 577–581. [Google Scholar] [CrossRef]

- Zhang, H.; Lee, G.; Gong, C.; Colombo, L.; Cho, K. Grain Boundary Effect on Electrical Transport Properties of Graphene. J. Phys. Chem. C 2014, 118, 2338–2343. [Google Scholar] [CrossRef]

- Chou, C.-W.; Hsu, S.-H.; Chang, H.; Tseng, S.-M.; Lin, H.-R. Enhanced thermal and mechanical properties and biostability of polyurethane containing silver nanoparticles. Polym. Degrad. Stab. 2006, 91, 1017–1024. [Google Scholar] [CrossRef]

- Kucheryavy, P.; He, J.; John, V.T.; Maharjan, P.; Spinu, L.; Goloverda, G.Z.; Kolesnichenko, V.L. Superparamagnetic iron oxide nanoparticles with variable size and an iron oxidation state as prospective imaging agents. Langmuir 2013, 29, 710–716. [Google Scholar] [CrossRef] [PubMed]

- Sardana, S.K.; Chava, V.S.N.; Thouti, E.; Chander, N.; Kumar, S.; Reddy, S.R.; Komarala, V.K. Influence of surface plasmon resonances of silver nanoparticles on optical and electrical properties of textured silicon solar cell. Appl. Phys. Lett. 2014, 104, 073903. [Google Scholar] [CrossRef]

- Park, J.H.; Jana, S.C. The relationship between nano-and micro-structures and mechanical properties in PMMA–epoxy–nanoclay composites. Polymer 2003, 44, 2091–2100. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Water barrier properties of nanoclay filled sisal fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 385–393. [Google Scholar] [CrossRef]

- Ji, G.; Li, G. Effects of nanoclay morphology on the mechanical, thermal, and fire-retardant properties of vinyl ester based nanocomposite. Mater. Sci. Eng. A 2008, 498, 327–334. [Google Scholar] [CrossRef]

- Jalili, M.M.; Moradian, S.; Dastmalchian, H.; Karbasi, A. Investigating the variations in properties of 2-pack polyurethane clear coat through separate incorporation of hydrophilic and hydrophobic nano-silica. Prog. Org. Coat. 2007, 59, 81–87. [Google Scholar] [CrossRef]

- Javni, I.; Zhang, W.; Karajkov, V.; Petrovic, Z.S.; Divjakovic, V. Effect of Nano- and Micro-Silica Fillers on Polyurethane Foam Properties. J. Cell. Plast. 2002, 38, 229–239. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Zheng, Y.X.; Zeng, H.M.; Friedrich, K. Improvement of tensile properties of nano-SiO2/PP composites in relation to percolation mechanism. Polymer 2001, 42, 3301–3304. [Google Scholar] [CrossRef]

- Van der Heijden, S.; De Bruycker, K.; Simal, R.; Du Prez, F.; De Clerck, K. Use of Triazolinedione Click Chemistry for Tuning the Mechanical Properties of Electrospun SBS-Fibers. Macromolecules 2015, 48, 6474–6481. [Google Scholar] [CrossRef]

- Dzenis, Y.A.; Reneker, D.H. Delamination Resistant Composites Prepared by Small Diameter Fiber Reinforcement at Ply Interfaces. U.S. Patent 6,265,333, 24 July 2001. [Google Scholar]

- ASTM D5528: Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites; ASTM International: West Conshohocken, PA, USA, 2013; Volume 3, pp. 1–12. [CrossRef]

- ASTM D7905/7905M: Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites; ASTM International: West Conshohocken, PA, USA, 2014; Volume 15.03, pp. 1–18. [CrossRef]

- Liu, Y.; Yang, J.P.; Xiao, H.M.; Qu, C.B.; Feng, Q.P.; Fu, S.Y.; Shindo, Y. Role of matrix modification on interlaminar shear strength of glass fibre/epoxy composites. Compos. Part B Eng. 2012, 43, 95–98. [Google Scholar] [CrossRef]

- Fan, Z.; Santare, M.H.; Advani, S.G. Interlaminar shear strength of glass fiber reinforced epoxy composites enhanced with multi-walled carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2008, 39, 540–554. [Google Scholar] [CrossRef]

- Wichmann, M.H.G.; Sumfleth, J.; Gojny, F.H.; Quaresimin, M.; Fiedler, B.; Schulte, K. Glass-fibre-reinforced composites with enhanced mechanical and electrical properties—Benefits and limitations of a nanoparticle modified matrix. Eng. Fract. Mech. 2006, 73, 2346–2359. [Google Scholar] [CrossRef]

- Shen, X.-J.; Meng, L.-X.; Yan, Z.-Y.; Sun, C.-J.; Ji, Y.-H.; Xiao, H.-M.; Fu, S.-Y. Improved cryogenic interlaminar shear strength of glass fabric/epoxy composites by graphene oxide. Compos. Part B Eng. 2015, 73, 126–131. [Google Scholar] [CrossRef]

- Qin, W.; Vautard, F.; Drzal, L.T.; Yu, J. Mechanical and electrical properties of carbon fiber composites with incorporation of graphene nanoplatelets at the fiber-matrix interphase. Compos. Part B Eng. 2015, 69, 335–341. [Google Scholar] [CrossRef]

- Haro, E.E.; Odeshi, A.G.; Szpunar, J.A. The energy absorption behavior of hybrid composite laminates containing nano-fillers under ballistic impact. Int. J. Impact Eng. 2016, 96, 11–22. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Seidel, C.; Schulte, K. Preparation and characterization of graphite nano-platelet (GNP)/epoxy nano-composite: Mechanical, electrical and thermal properties. Eur. Polym. J. 2013, 49, 3878–3888. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Ghoreishi, S.M.; Esmkhani, M.; Zhao, Z. Effects of graphene nanoplatelets and graphene nanosheets on fracture toughness of epoxy nanocomposites. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1116–1123. [Google Scholar] [CrossRef]

- Wang, P.; Liu, W.; Zhang, X.; Lu, X.; Yang, J. Enhanced fracture toughness of carbon fabric/epoxy laminates with pristine and functionalized stacked-cup carbon nanofibers. Eng. Fract. Mech. 2015, 148, 73–81. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.R. Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes. Polymers 2015, 7, 1020–1045. [Google Scholar] [CrossRef]

- Siegfried, M.; Tola, C.; Claes, M.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Impact and residual after impact properties of carbon fiber/epoxy composites modified with carbon nanotubes. Compos. Struct. 2014, 111, 488–496. [Google Scholar] [CrossRef]

- Bortz, D.R.; Heras, E.G.; Martin-Gullon, I. Impressive Fatigue Life and Fracture Toughness Improvements in Graphene Oxide/Epoxy Composites. Macromolecules 2012, 45, 238–245. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.; Koratkar, N. Enhanced Mechanical Properties of Nanocomposites at Low Graphene Content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Fracture and fatigue in graphene nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef] [PubMed]

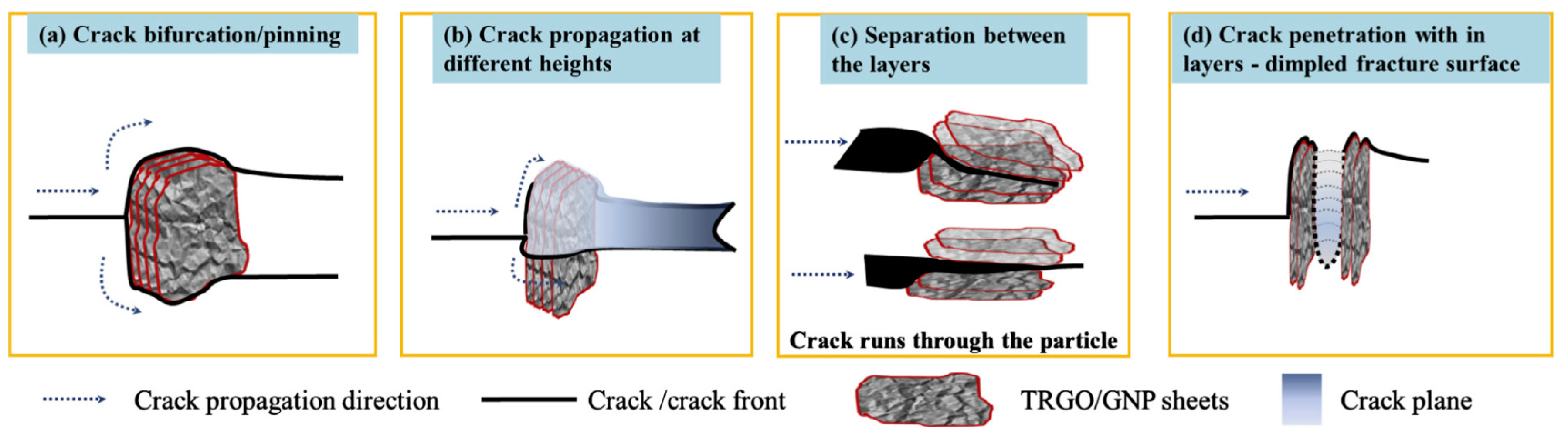

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B.; Sharafimasooleh, M.; Shadlou, S.; Taheri, F. Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater. Des. 2015, 66, 142–149. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B.; Taheri, F. Influence of graphene nanoplatelets on modes I, II and III interlaminar fracture toughness of fiber-reinforced polymer composites. Eng. Fract. Mech. 2015, 143, 97–107. [Google Scholar] [CrossRef]

- Walker, L.S.; Marotto, V.R.; Rafiee, M.A.; Koratkar, N.; Corral, E.L. Toughening in graphene ceramic composites. ACS Nano 2011, 5, 3182–3190. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.-C.; Wan, Y.-J.; Yan, D.; Pei, Y.-B.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon N.Y. 2013, 60, 16–27. [Google Scholar] [CrossRef]

- Mahmood, H.; Tripathi, M.; Pugno, N.; Pegoretti, A. Enhancement of interfacial adhesion in glass fiber/epoxy composites by electrophoretic deposition of graphene oxide on glass fibers. Compos. Sci. Technol. 2016, 126, 149–157. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, H.-Y.; Mai, Y.-W.; Du, X.-S. Improving interlaminar fracture toughness of carbon fibre/epoxy laminates by incorporation of nano-particles. Compos. Part B Eng. 2012, 43, 90–94. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Sohn Lee, J.; Taylor, A.C.; Sprenger, S. The toughness of epoxy polymers and fibre composites modified with rubber microparticles and silica nanoparticles. J. Mater. Sci. 2010, 45, 1193–1210. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Eger, C.; Sprenger, S.; Egan, D. The effect of silica nano particles and rubber particles on the toughness of multiphase thermosetting epoxy polymers. J. Mater. Sci. 2005, 40, 5083–5086. [Google Scholar] [CrossRef]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Ma, J.; Mo, M.-S.; Du, X.-S.; Rosso, P.; Friedrich, K.; Kuan, H.-C. Effect of inorganic nanoparticles on mechanical property, fracture toughness and toughening mechanism of two epoxy systems. Polymer 2008, 49, 3510–3523. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S.; Egan, D. The interlaminar toughness of carbon-fibre reinforced plastic composites using “hybrid-toughened” matrices. J. Mater. Sci. 2006, 41, 5043–5046. [Google Scholar] [CrossRef]

- Chisholm, N.; Mahfuz, H.; Rangari, V.K.; Ashfaq, A.; Jeelani, S. Fabrication and mechanical characterization of carbon/SiC-epoxy nanocomposites. Compos. Struct. 2005, 67, 115–124. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Masania, K.; Taylor, A.C.; Sprenger, S.; Egan, D. The fracture of glass-fibre-reinforced epoxy composites using nanoparticle-modified matrices. J. Mater. Sci. 2008, 43, 1151–1154. [Google Scholar] [CrossRef]

- Zheng, Y.; Zheng, Y.; Ning, R. Effects of nanoparticles SiO2 on the performance of nanocomposites. Mater. Lett. 2003, 57, 2940–2944. [Google Scholar] [CrossRef]

- Rosso, P.; Ye, L.; Friedrich, K.; Sprenger, S. A toughened epoxy resin by silica nanoparticle reinforcement. J. Appl. Polym. Sci. 2006, 100, 1849–1855. [Google Scholar] [CrossRef]

- Liu, H.-Y.; Wang, G.-T.; Mai, Y.-W.; Zeng, Y. On fracture toughness of nano-particle modified epoxy. Compos. Part B Eng. 2011, 42, 2170–2175. [Google Scholar] [CrossRef]

- Zunjarrao, S.C.; Singh, R.P. Characterization of the fracture behavior of epoxy reinforced with nanometer and micrometer sized aluminum particles. Compos. Sci. Technol. 2006, 66, 2296–2305. [Google Scholar] [CrossRef]

- Singh, R.P.; Zhang, M.; Chan, D. Toughening of a brittle thermosetting polymer: Effects of reinforcement particle size and volume fraction. J. Mater. Sci. 2002, 37, 781–788. [Google Scholar] [CrossRef]

- Shahid, N.; Villate, R.G.; Barron, A.R. Chemically functionalized alumina nanoparticle effect on carbon fiber/epoxy composites. Compos. Sci. Technol. 2005, 65, 2250–2258. [Google Scholar] [CrossRef]

- Kelkar, A.D.; Mohan, R.; Bolick, R.; Shendokar, S. Effect of nanoparticles and nanofibers on Mode I fracture toughness of fiber glass reinforced polymeric matrix composites. Mater. Sci. Eng. B 2010, 168, 85–89. [Google Scholar] [CrossRef]

- Miyagawa, H.; Drzal, L.T. The effect of chemical modification on the fracture toughness of montmorillonite clay/epoxy nanocomposites. J. Adhes. Sci. Technol. 2004, 18, 1571–1588. [Google Scholar] [CrossRef]

- Zerda, A.S.; Lesser, A.J. Intercalated clay nanocomposites: Morphology, mechanics, and fracture behavior. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 1137–1146. [Google Scholar] [CrossRef]

- Deng, S.; Zhang, J.; Ye, L.; Wu, J. Toughening epoxies with halloysite nanotubes. Polymer 2008, 49, 5119–5127. [Google Scholar] [CrossRef]

- Kotoul, M.; Dlouhy, I. Metal particles constraint in glass matrix composites and its impact on fracture toughness enhancement. Mater. Sci. Eng. A 2004, 387–389, 404–408. [Google Scholar] [CrossRef]

- Ning, H.; Li, Y.; Li, J.; Hu, N.; Liu, Y.; Wu, L.; Liu, F. Toughening effect of CB-epoxy interleaf on the interlaminar mechanical properties of CFRP laminates. Compos. Part A Appl. Sci. Manuf. 2015, 68, 226–234. [Google Scholar] [CrossRef]

- Ning, H.; Li, J.; Hu, N.; Yan, C.; Liu, Y.; Wu, L.; Liu, F.; Zhang, J. Interlaminar mechanical properties of carbon fiber reinforced plastic laminates modified with graphene oxide interleaf. Carbon 2015, 91, 224–233. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Du, X.; Liu, H.-Y.; Zhou, H.; Zhang, Y.; Mai, Y.-W. Delamination toughening of carbon fiber/epoxy laminates by hierarchical carbon nanotube-short carbon fiber interleaves. Compos. Sci. Technol. 2017, 140, 46–53. [Google Scholar] [CrossRef]

- Zheng, N.; Huang, Y.; Liu, H.Y.; Gao, J.; Mai, Y.W. Improvement of interlaminar fracture toughness in carbon fiber/epoxy composites with carbon nanotubes/polysulfone interleaves. Compos. Sci. Technol. 2017, 140, 8–15. [Google Scholar] [CrossRef]

- Du, X.; Zhou, H.; Sun, W.; Liu, H.-Y.; Zhou, G.; Zhou, H.; Mai, Y.-W. Graphene/epoxy interleaves for delamination toughening and monitoring of crack damage in carbon fibre/epoxy composite laminates. Compos. Sci. Technol. 2017, 140, 123–133. [Google Scholar] [CrossRef]

- Shen, M.-Y.; Chang, T.-Y.; Hsieh, T.-H.; Li, Y.-L.; Chiang, C.-L.; Yang, H.; Yip, M.-C. Mechanical Properties and Tensile Fatigue of Graphene Nanoplatelets Reinforced Polymer Nanocomposites. J. Nanomater. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Manjunatha, C.M.; Anil Chandra, A.R.; Jagannathan, N. Fracture and Fatigue Behavior of Polymer Nanocomposites—A Review. J. Indian Inst. Sci. 2015, 95, 249–266. [Google Scholar]

- Zhang, W.; Picu, R.C.; Koratkar, N. The effect of carbon nanotube dimensions and dispersion on the fatigue behavior of epoxy nanocomposites. Nanotechnology 2008, 19. [Google Scholar] [CrossRef] [PubMed]

- Yavari, F.; Rafiee, M.A.; Rafiee, J.; Yu, Z.-Z.; Koratkar, N. Dramatic increase in fatigue life in hierarchical graphene composites. ACS Appl. Mater. Interfaces 2010, 2, 2738–2743. [Google Scholar] [CrossRef] [PubMed]

- Manjunatha, C.M.; Taylor, A.C.; Kinloch, A.J.; Sprenger, S. The tensile fatigue behaviour of a silica nanoparticle-modified glass fibre reinforced epoxy composite. Compos. Sci. Technol. 2010, 70, 193–199. [Google Scholar] [CrossRef]

- Blackman, B.R.K.; Kinloch, A.J.; Sohn Lee, J.; Taylor, A.C.; Agarwal, R.; Schueneman, G.; Sprenger, S. The fracture and fatigue behaviour of nano-modified epoxy polymers. J. Mater. Sci. 2007, 42, 7049–7051. [Google Scholar] [CrossRef]

- Akinyede, O.; Mohan, R.; Kelkar, A.; Sankar, J. Static and Fatigue Behavior of Epoxy/Fiberglass Composites Hybridized with Alumina Nanoparticles. J. Compos. Mater. 2009, 43, 769–781. [Google Scholar] [CrossRef]

- Kamar, N.T.; Hossain, M.M.; Khomenko, A.; Haq, M.; Drzal, L.T.; Loos, A. Interlaminar reinforcement of glass fiber/epoxy composites with graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2015, 70, 82–92. [Google Scholar] [CrossRef]

- Yokozeki, T.; Iwahori, Y.; Ishiwata, S.; Enomoto, K. Mechanical properties of CFRP laminates manufactured from unidirectional prepregs using CSCNT-dispersed epoxy. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2121–2130. [Google Scholar] [CrossRef]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Damage-Resistant Composites Using Electrospun Nanofibers: A Multiscale Analysis of the Toughening Mechanisms. ACS Appl. Mater. Interfaces 2016, 8, 11806–11818. [Google Scholar] [CrossRef] [PubMed]

- Moghim, M.H.; Zebarjad, S.M. Effect of strain rate on tensile properties of polyurethane/(multiwalled carbon nanotube) nanocomposite. J. Vinyl Addit. Technol. 2016, 22, 356–361. [Google Scholar] [CrossRef]

- Shadlou, S.; Ahmadi-Moghadam, B.; Taheri, F. The effect of strain-rate on the tensile and compressive behavior of graphene reinforced epoxy/nanocomposites. Mater. Des. 2014, 59, 439–477. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, H.Y.; Zhou, H.; Zhang, Y.; Gao, X.; Mai, Y.W. On adhesive properties of nano-silica/epoxy bonded single-lap joints. Mater. Des. 2016, 95, 212–218. [Google Scholar] [CrossRef]

- Tutunchi, A.; Kamali, R.; Kianvash, A. Steel-Epoxy Composite Joints Bonded with Nano-TiO2 Reinforced Structural Acrylic Adhesive. J. Adhes. 2015, 91, 663–676. [Google Scholar] [CrossRef]

- Shadlou, S.; Ahmadi-Moghadam, B.; Taheri, F. Nano-Enhanced Adhesives: A Critical Review. Rev. Adhes. Adhes. 2014, 2, 371–412. [Google Scholar] [CrossRef]

- Wernik, J.M.; Meguid, S.A. On the mechanical characterization of carbon nanotube reinforced epoxy adhesives. Mater. Des. 2014, 59, 19–32. [Google Scholar] [CrossRef]

- Gude, M.R.; Prolongo, S.G.; Ureña, A. Toughening effect of carbon nanotubes and carbon nanofibres in epoxy adhesives for joining carbon fibre laminates. Int. J. Adhes. Adhes. 2015, 62, 139–145. [Google Scholar] [CrossRef]

- Gültekin, K.; Akpinar, S.; Gürses, A.; Eroglu, Z.; Cam, S.; Akbulut, H.; Keskin, Z.; Ozel, A. The effects of graphene nanostructure reinforcement on the adhesive method and the graphene reinforcement ratio on the failure load in adhesively bonded joints. Compos. Part B Eng. 2016, 98, 362–369. [Google Scholar] [CrossRef]

- Guadagno, L.; Sarno, M.; Vietri, U.; Raimondo, M.; Cirillo, C.; Ciambelli, P. Graphene-based structural adhesive to enhance adhesion performance. RSC Adv. 2015, 5, 27874–27886. [Google Scholar] [CrossRef]

- Mohamed, M.; Taheri, F. Influence of graphene nanoplatelets (GNPs) on mode I fracture toughness of an epoxy adhesive under thermal fatigue. J. Adhes. Sci. Technol. 2017, 31, 2105–2123. [Google Scholar] [CrossRef]

- Kubit, A.; Bucior, M.; Zielecki, W. The impact of the multiwall carbon nanotubes on the fatigue properties of adhesive joints of 2024-T3 aluminium alloy subjected to peel. Proc. Struct. Integr. 2016, 2, 334–341. [Google Scholar] [CrossRef]

- Zielecki, W.; Kubit, A.; Trzepieciński, T.; Narkiewicz, U.; Czech, Z. Impact of multiwall carbon nanotubes on the fatigue strength of adhesive joints. Int. J. Adhes. Adhes. 2017, 73, 16–21. [Google Scholar] [CrossRef]

- Soltannia, B.; Taheri, F. Influence of nano-reinforcement on the mechanical behavior of adhesively bonded single-lap joints subjected to static, quasi-static, and impact loading. J. Adhes. Sci. Technol. 2014, 29, 424–442. [Google Scholar] [CrossRef]

- Jojibabu, P.; Jagannatham, M.; Haridoss, P.; Janaki Ram, G.D.; Deshpande, A.P.; Bakshi, S.R. Effect of different carbon nano-fillers on rheological properties and lap shear strength of epoxy adhesive joints. Compos. Part A Appl. Sci. Manuf. 2016, 82, 53–64. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Nemati Giv, A.; Razavi, S.M.J.; Khoramishad, H. Mechanical properties of adhesively single lap-bonded joints reinforced with multi-walled carbon nanotubes and silica nanoparticles. J. Adhes. 2016, 8464, 1–18. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, Z.; Hong, Y.; Cheng, L.; Li, Z. Bonding strength and water resistance of starch-based wood adhesive improved by silica nanoparticles. Carbohydr. Polym. 2011, 86, 72–76. [Google Scholar] [CrossRef]

- Mactabi, R.; Rosca, I.D.; Hoa, S.V. Monitoring the integrity of adhesive joints during fatigue loading using carbon nanotubes. Compos. Sci. Technol. 2013, 78, 1–9. [Google Scholar] [CrossRef]

- Kim, C.-H.; Choi, J.-H. Effects of dispersion methods and surface treatment of carbon nano-tubes on defect detectability and static strengths of adhesive joints. Compos. Struct. 2017, 176, 684–691. [Google Scholar] [CrossRef]

- Jakubinek, M.B.; Ashrafi, B.; Zhang, Y.; Martinez-Rubi, Y.; Kingston, C.T.; Johnston, A.; Simard, B. Single-walled carbon nanotube-epoxy composites for structural and conductive aerospace adhesives. Compos. Part B Eng. 2015, 69, 87–93. [Google Scholar] [CrossRef]

- Kang, M.-H.; Choi, J.-H.; Kweon, J.-H. Fatigue life evaluation and crack detection of the adhesive joint with carbon nanotubes. Compos. Struct. 2014, 108, 417–422. [Google Scholar] [CrossRef]

- Vietri, U.; Guadagno, L.; Raimondo, M.; Vertuccio, L.; Lafdi, K. Nanofilled epoxy adhesive for structural aeronautic materials. Compos. Part B Eng. 2014, 61, 73–83. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B. Development of a Highly Resilient Graphene Nanoplatelet Resin/Adhesive; Dalhousie University: Halifax, NS, Canada, 2015. [Google Scholar]

- Ahmadi-Moghadam, B.; Soltannia, B.; Taheri, F. Detection in graphene nanoplatelet/ CFRP composites using electric resistance change. In Proceedings of the 19th International Conference on Composite Materials ICCM19, Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Marney, D.C.O.; Russell, L.J.; Wu, D.Y.; Nguyen, T.; Cramm, D.; Rigopoulos, N.; Wright, N.; Greaves, M. The suitability of halloysite nanotubes as a fire retardant for nylon 6. Polym. Degrad. Stab. 2008, 93, 1971–1978. [Google Scholar] [CrossRef]

- Hapuarachchi, T.D.; Peijs, T. Multiwalled carbon nanotubes and sepiolite nanoclays as flame retardants for polylactide and its natural fibre reinforced composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 954–963. [Google Scholar] [CrossRef]

- Wu, L.; Hoa, S.V.; Wang, H. Improvement of Flammability Resistance of Epoxy Using Nanocomposites. In Proceedings of the Sixth Joint Canada-Japan Workshop on Composites, Toronto, ON, Canada, 24–26 August 2006; DEStech Publications, Inc.: Toronto, ON, Canada, 2006; pp. 81–89. [Google Scholar]

- Yang, W.; Hu, Y.; Tai, Q.; Lu, H.; Song, L.; Yuen, R.K.K. Fire and mechanical performance of nanoclay reinforced glass-fiber/PBT composites containing aluminum hypophosphite particles. Compos. Part A Appl. Sci. Manuf. 2011, 42, 794–800. [Google Scholar] [CrossRef]

- Duquesne, S.; Jama, C.; Le Bras, M.; Delobel, R.; Recourt, P.; Gloaguen, J.M. Elaboration of EVA-nanoclay systems—Characterization, thermal behaviour and fire performance. Compos. Sci. Technol. 2003, 63, 1141–1148. [Google Scholar] [CrossRef]

- Porter, D.; Metcalfe, E.; Thomas, M.J.K. Nanocomposite fire retardants—A review. Fire Mater. 2000, 24, 45–52. [Google Scholar] [CrossRef]

- Bernardo, L.F.A.; Amaro, A.P.B.M.; Pinto, D.G.; Lopes, S.M.R. Modeling and simulation techniques for polymer nanoparticle composites—A review. Comput. Mater. Sci. 2016, 118, 32–46. [Google Scholar] [CrossRef]

- Alfano, G.; de Barros, S.; Champaney, L.; Valoroso, N. Comparison Between Two Cohesive-Zone Models for the Analysis of Interface Debonding. In European Congress on Computational Methods in Applied Sciences and Engineering; European Commission: Brussels, Belgium, 2004; pp. 1–18. [Google Scholar]

- Ranatunga, V. Finite Element Modeling of Delamination Crack Propagation in Laminated Composites. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2011; Volume III. [Google Scholar]

- Kim, Y.T.; Lee, M.J.; Lee, B.C. Simulation of adhesive joints using the superimposed finite element method and a cohesive zone model. Int. J. Adhes. Adhes. 2011, 31, 357–362. [Google Scholar] [CrossRef]

- Diehl, T. Modeling Surface-Bonded Structures with ABAQUS Cohesive Elements: Beam-Type Solutions. In Proceedings of the 2004 ABAQUS Users’ Conference, Boston, MA, USA, 25–27 May 2004; pp. 1–27. [Google Scholar]

- Yelve, N.P.; Khan, N.N. Analysis of Traction Separation in Double Cantilever Beam Using Cohesive Zone Modeling. In Proceedings of the International Conference on Mechanical and Industrial Engineering (ICMIE), Maharastra, India, 20 January 2013; pp. 47–50. [Google Scholar]

- May, M.; Voß, H.; Hiermaier, S. Predictive modeling of damage and failure in adhesively bonded metallic joints using cohesive interface elements. Int. J. Adhes. Adhes. 2014, 49, 7–17. [Google Scholar] [CrossRef]

- Giuliese, G.; Pirondi, A.; Moroni, F. A Cohesive Zone Model for Three-dimensional Fatigue Debonding/Delamination. Procedia Mater. Sci. 2014, 3, 1473–1478. [Google Scholar] [CrossRef]

- Khoramishad, H.; Crocombe, A.D.; Katnam, K.B.; Ashcroft, I.A. Fatigue damage modelling of adhesively bonded joints under variable amplitude loading using a cohesive zone model. Eng. Fract. Mech. 2011, 78, 3212–3225. [Google Scholar] [CrossRef] [Green Version]

- Johar, M.; Kosnan, M.S.E.; Tamin, M.N. Cyclic Cohesive Zone Model for Simulation of Fatigue Failure Process in Adhesive Joints. Appl. Mech. Mater. 2014, 606, 217–221. [Google Scholar] [CrossRef]

- De Moura, M.F.S.F.; Gonçalves, J.P.M. Cohesive zone model for high-cycle fatigue of adhesively bonded joints under mode I loading. Int. J. Solids Struct. 2014, 51, 1123–1131. [Google Scholar] [CrossRef]

- Sugiman, S.; Crocombe, A.D.; Aschroft, I.A. Experimental and numerical investigation of the static response of environmentally aged adhesively bonded joints. Int. J. Adhes. Adhes. 2013, 40, 224–237. [Google Scholar] [CrossRef] [Green Version]

- Sapora, A.; Paggi, M. A coupled cohesive zone model for transient analysis of thermoelastic interface debonding. Comput. Mech. 2014, 53, 845–857. [Google Scholar] [CrossRef] [Green Version]

- Moes, N.; Dolbow, J.; Belytschko, T. A finite element method method for crack growth without remeshing. Int. J. Numer. Methods Eng. 1999, 46, 131–150. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Krueger, R. Virtual crack closure technique: History, approach, and applications. Appl. Mech. Rev. 2004, 57, 109–143. [Google Scholar] [CrossRef]

- Goyal, V.K.; Johnson, E.R.; Dávila, C.G. Irreversible constitutive law for modeling the delamination process using interfacial surface discontinuities. Compos. Struct. 2004, 65, 289–305. [Google Scholar] [CrossRef]

- Mohammadi, S. XFEM Fracture Analysis of Composites; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Motamedi, D.; Mohammadi, S. Fracture analysis of composites by time independent moving-crack orthotropic XFEM. Int. J. Mech. Sci. 2012, 54, 20–37. [Google Scholar] [CrossRef]

- Wang, Y.; Waisman, H. Progressive delamination analysis of composite materials using XFEM and a discrete damage zone model. Comput. Mech. 2015, 55, 1–26. [Google Scholar] [CrossRef]

- Jiang, H. Cohesive Zone Model for Carbon Nanotube Adhesive Simulation and Fracture/Fatigue Crack Growth; University of Akron: Akron, OH, USA, 2010. [Google Scholar]

- Grail, G.; Pimenta, S.; Pinho, S.T.; Robinson, P. Exploring the potential of interleaving to delay catastrophic failure in unidirectional composites under tensile loading. Compos. Sci. Technol. 2015, 106, 100–109. [Google Scholar] [CrossRef]

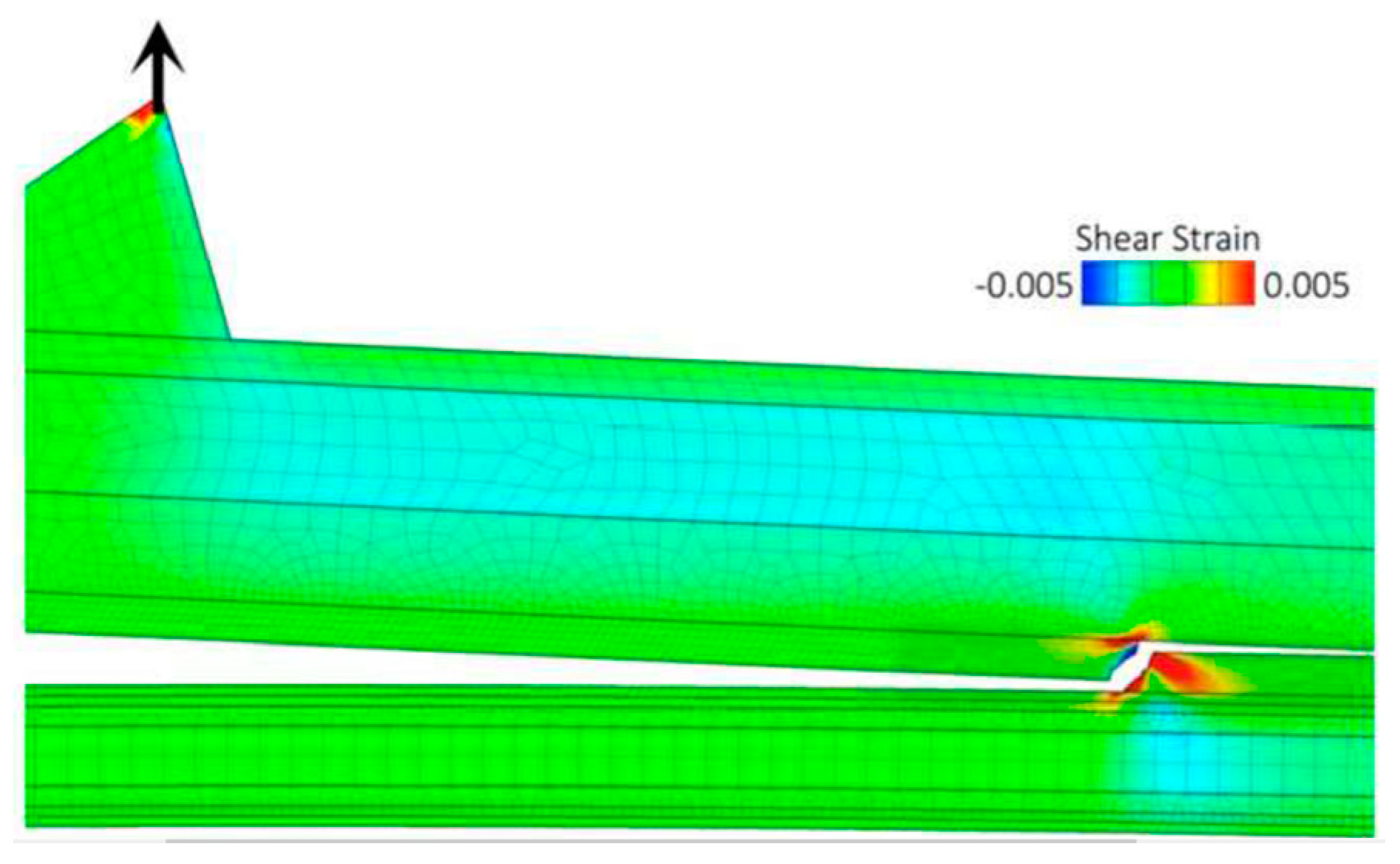

- Asaee, Z.; Mohamed, M.; De Cicco, D.; Taheri, F. Low-Velocity Impact Response and Damage Mechanism of 3D Fiber-Metal Laminates Reinforced with Amino-Functionalized Graphene Nanoplatelets. Int. J. Compos. Mater. 2017, 7, 20–36. [Google Scholar] [CrossRef]

- Asaee, Z.; Mohamed, M.; Soumik, S.; Taheri, F. Experimental and numerical characterization of delamination buckling behavior of a new class of GNP-reinforced 3D fiber-metal laminates. Thin-Walled Struct. 2017, 112, 208–216. [Google Scholar] [CrossRef]

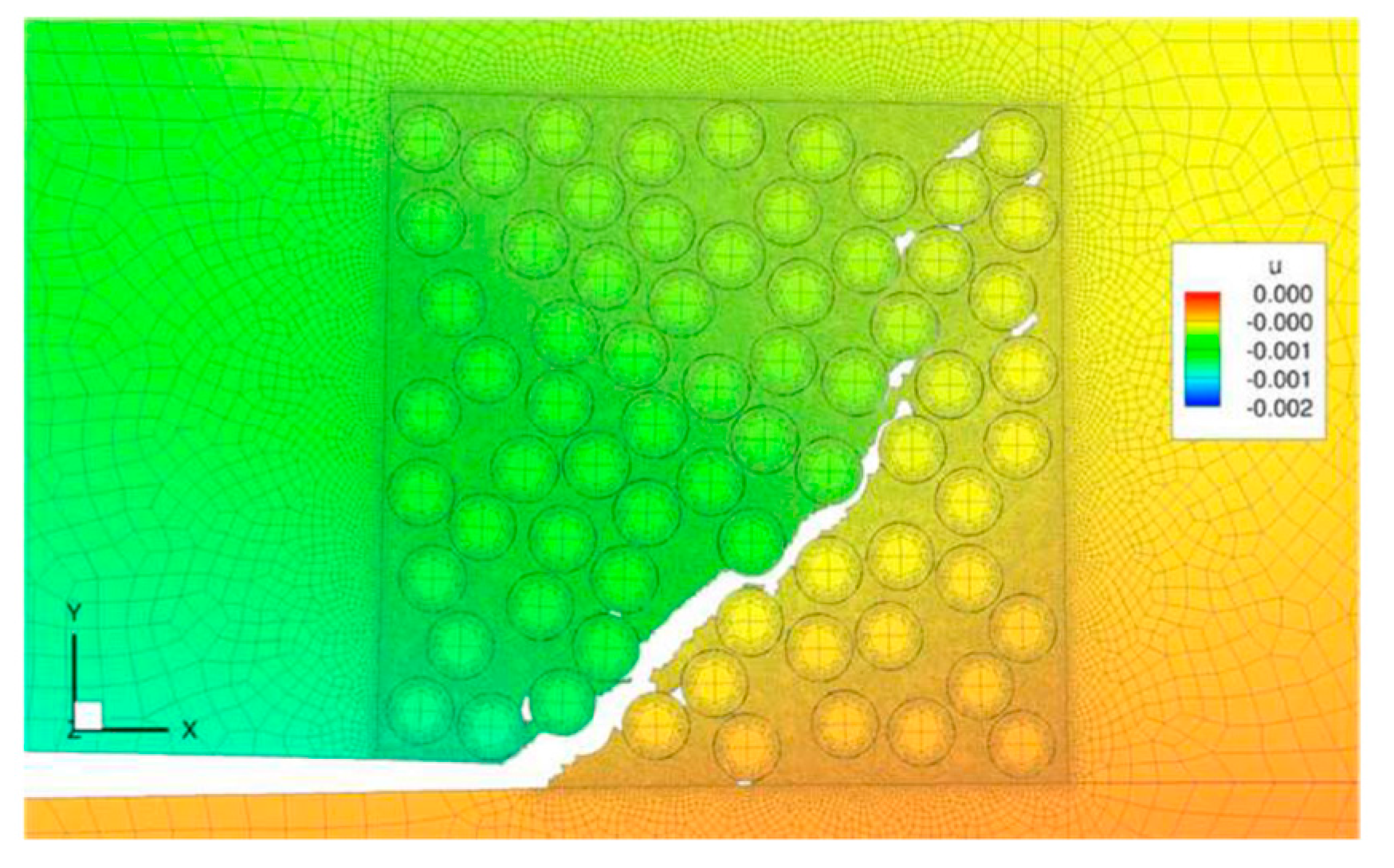

- Safaei, M.; Sheidaei, A.; Baniassadi, M.; Ahzi, S.; Mosavi Mashhadi, M.; Pourboghrat, F. An interfacial debonding-induced damage model for graphite nanoplatelet polymer composites. Comput. Mater. Sci. 2015, 96, 191–199. [Google Scholar] [CrossRef]

- Guo, G.; Zhu, Y. Cohesive-Shear-Lag Modeling of Interfacial Stress Transfer Between a Monolayer Graphene and a Polymer Substrate. J. Appl. Mech. 2015, 82, 31005. [Google Scholar] [CrossRef]

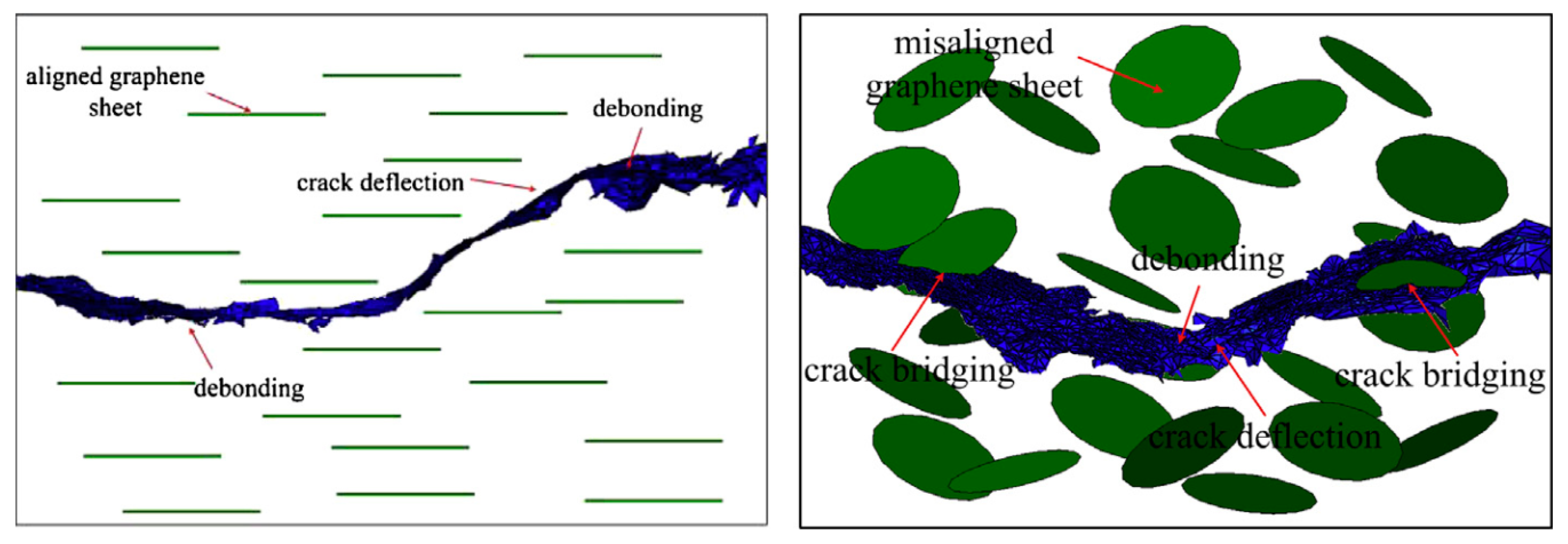

- Dai, G.; Mishnaevsky, L.J. Graphene reinforced nanocomposites: 3D simulation of damage and fracture. Comput. Mater. Sci. 2014, 95, 684–692. [Google Scholar] [CrossRef] [Green Version]

- Jia, Y.; Yan, W. Numerical Modeling of Graphene/polymer Interfacial Behaviour Using Peel Test. Adv. Mater. Res. 2014, 891–892, 1119–1124. [Google Scholar] [CrossRef]

- Sheidaei, A. Multiscale Modeling of Polymer Nanocomposites; Michigan State University: East Lansing, MI, USA, 2015. [Google Scholar]

- Wang, H.W.; Zhou, H.W.; Peng, R.D.; Mishnaevsky, L.J. Nanoreinforced polymer composites: 3D FEM modeling with effective interface concept. Compos. Sci. Technol. 2011, 71, 980–988. [Google Scholar] [CrossRef]

- Awasthi, A.P.; Lagoudas, D.C.; Hammerand, D.C. Modeling of graphene–polymer interfacial mechanical behavior using molecular dynamics. Model. Simul. Mater. Sci. Eng. 2009, 17, 015002. [Google Scholar] [CrossRef]

- Wernik, J.M.; Meguid, S.A. Multiscale micromechanical modeling of the constitutive response of carbon nanotube-reinforced structural adhesives. Int. J. Solids Struct. 2014, 51, 2575–2589. [Google Scholar] [CrossRef]

- Odegard, G.M.; Clancy, T.C.; Gates, T.S. Modeling of the mechanical properties of nanoparticle/polymer composites. Polymer 2005, 46, 553–562. [Google Scholar] [CrossRef]

- Mollenhauer, D.; Zhou, E.; Hoos, K.; Iarve, E.; Braginsky, M.; Breitzman, T.; Rapking, D. Multi-Scale Simulation of Delamination Migration. In Proceedings of the American Society for Composites: Thirty-First Technical Conference, Williamsburg, VA, USA, 19–22 September 2016; DEStech Publications, Inc.: Williamsburg, VA, USA, 2016; p. 10. [Google Scholar]

- Hadden, C.M.; Klimek-Mcdonald, D.R.; Pineda, E.J.; King, J.A.; Reichanadter, A.M.; Miskioglu, I.; Gowtham, S.; Odegard, G.M. Mechanical properties of graphene nanoplatelet/carbon fiber/epoxy hybrid composites: Multiscale modeling and experiments. Carbon 2015, 95, 100–112. [Google Scholar] [CrossRef]

| Resins | Density ρ (kg/m2) | Elastic Modulus E (MPa) | Shear Modulus G (MPa) | Poisson Ratio ν | Tensile Strength σult (MPa) | Elongation ε (%) | Coefficient of Thermal Expansion α (°C−1) | Price 1993 ($/kg) |

|---|---|---|---|---|---|---|---|---|

| Epoxy | 1200 | 4500 | 1600 | 0.4 | 130 | 2 (100 °C) | 0.2 | 6 to 20 |

| 6 (200 °C) | ||||||||

| Phenolic | 1300 | 3000 | 1100 | 0.4 | 70 | 2.5 | 0.3 | - |

| Polyester | 1200 | 4000 | 1400 | 0.4 | 80 | 2.5 | 0.2 | 2.4 |

| Polyether-ether-ketone (Peek) | 1300 | 4000 | - | - | 90 | 50 | 0.3 | 96 |

| Treatments | Nature of Treatments | Reference |

|---|---|---|

| Grit blasting | Mechanical | 26–29 |

| Chromic-sulphuric acid (CAE) | Acid etching | 30,33 |

| Sulfo-ferric acid (P2) | Acid etching | 31 |

| Forest Product Laboratory (FPL) | Acid etching | 32 |

| Alkaline | Etching | 25,30 |

| Chromic acid anodizing (CAA) | DC-anodizing | 46 |

| Phosphoric acid anodizing (PAA) | DC-anodizing | 23,34,36 |

| Sulphuric acid anodizing (SAA) | DC-anodizing | 36,45 |

| Boric-sulphuric acid anodizing (BSAA) | DC-anodizing | 24 |

| Phosphoric acid anodizing (AC-SAA) | AC-anodizing | 36 |

| Sulphuric acid anodizing | AC-anodizing | 36 |

| Silane | Coupling/oxidation | 28,47,49–52 |

| Sol-gel | Coupling/oxidation | 53–57 |

| Excimer laser texturing | Mechanical | 54,58–62 |

| Plasma sprayed coating | Ablation/oxidation | 35,63–67,69 |

| Ion beam enhancement deposition (IBED) | Ablation/oxidation | 62,68 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Cicco, D.; Asaee, Z.; Taheri, F. Use of Nanoparticles for Enhancing the Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints—A Review. Nanomaterials 2017, 7, 360. https://doi.org/10.3390/nano7110360

De Cicco D, Asaee Z, Taheri F. Use of Nanoparticles for Enhancing the Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints—A Review. Nanomaterials. 2017; 7(11):360. https://doi.org/10.3390/nano7110360

Chicago/Turabian StyleDe Cicco, Davide, Zohreh Asaee, and Farid Taheri. 2017. "Use of Nanoparticles for Enhancing the Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints—A Review" Nanomaterials 7, no. 11: 360. https://doi.org/10.3390/nano7110360