Transparent Pullulan/Mica Nanocomposite Coatings with Outstanding Oxygen Barrier Properties

Abstract

:1. Introduction

2. Results and Discussion

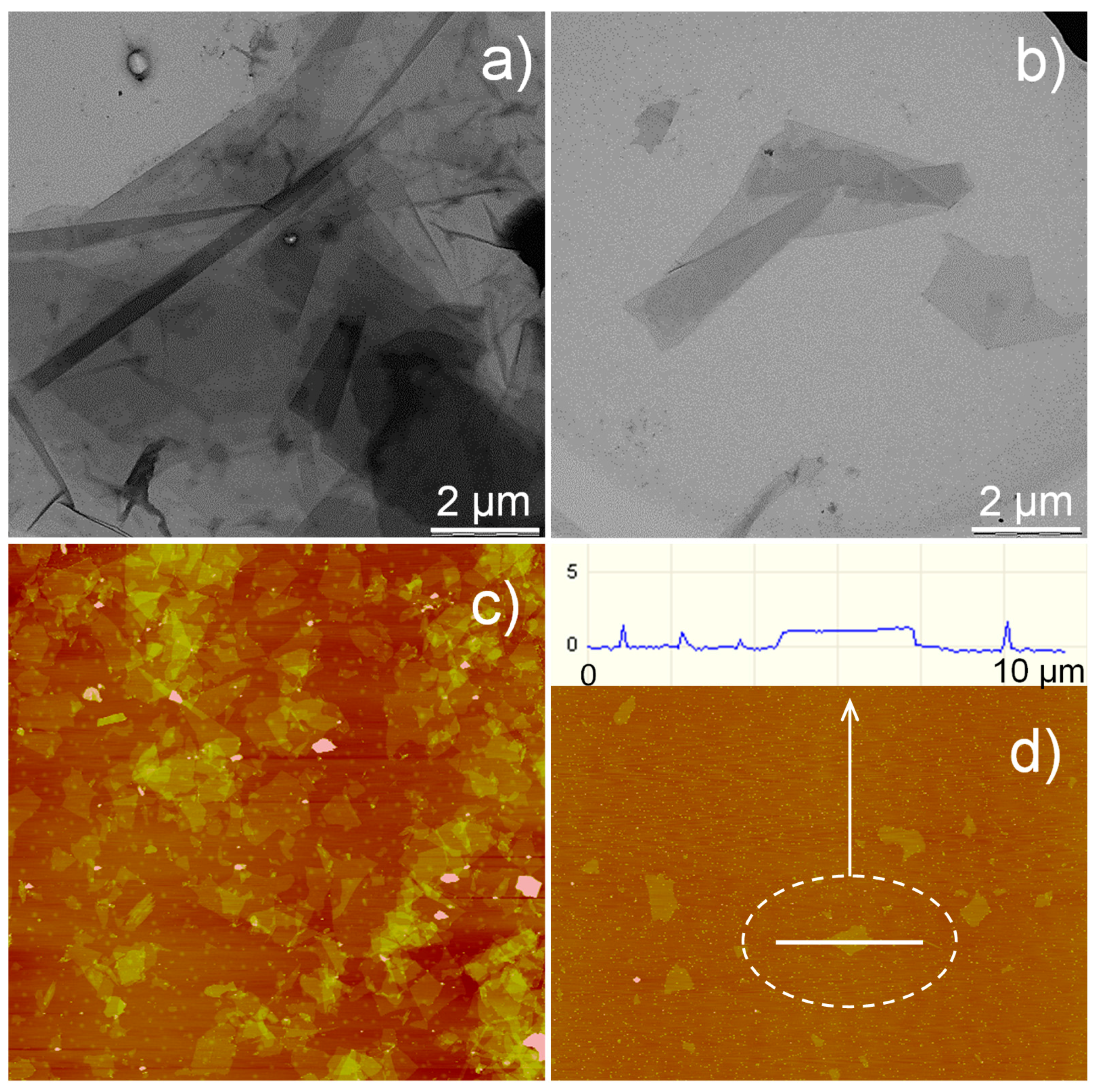

2.1. Morphological Characterization of Mica

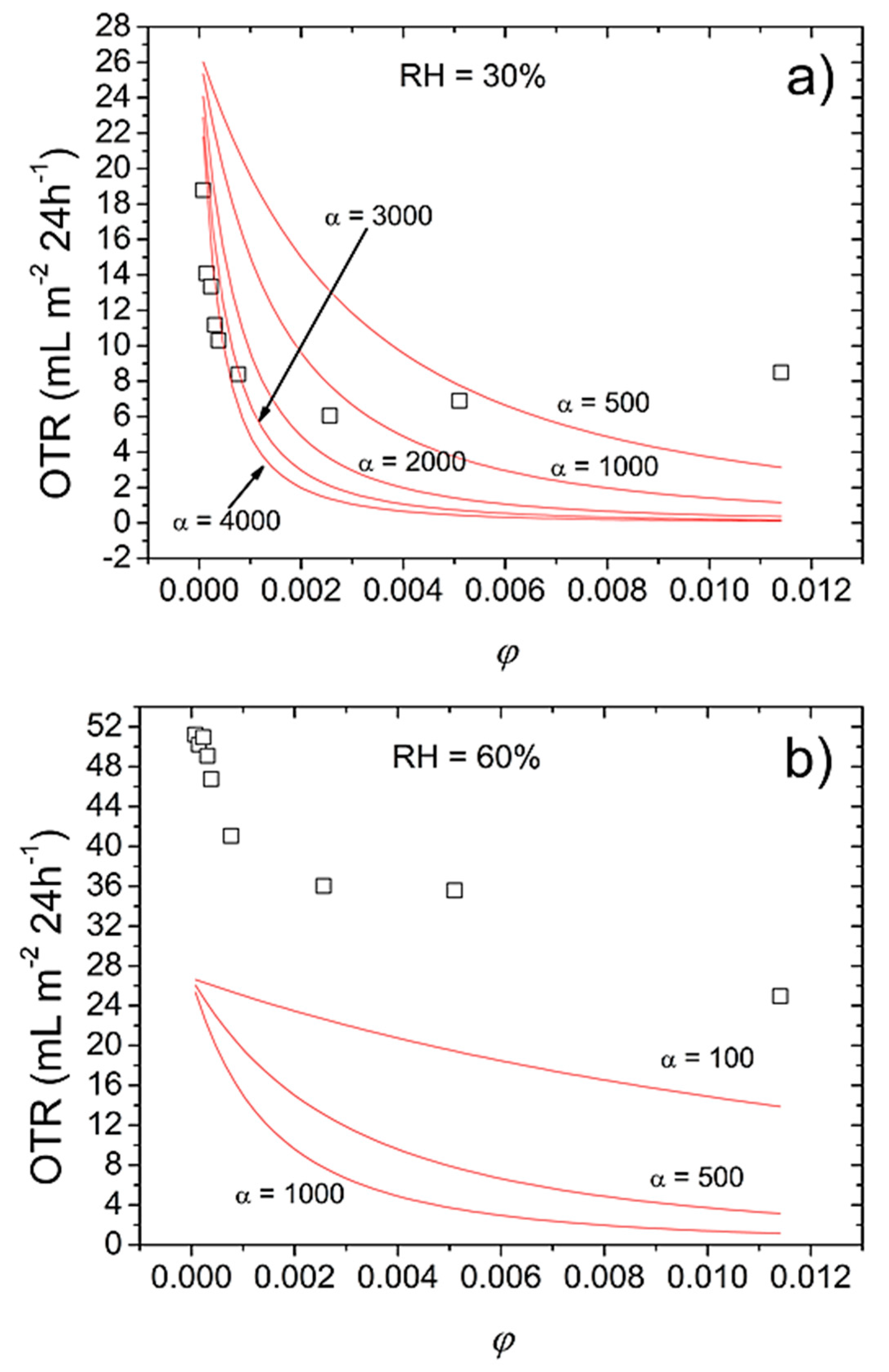

2.2. Oxygen Barrier Performance

2.3. Mechanical Properties

2.3.1. Friction Behavior

2.3.2. Tensile Properties

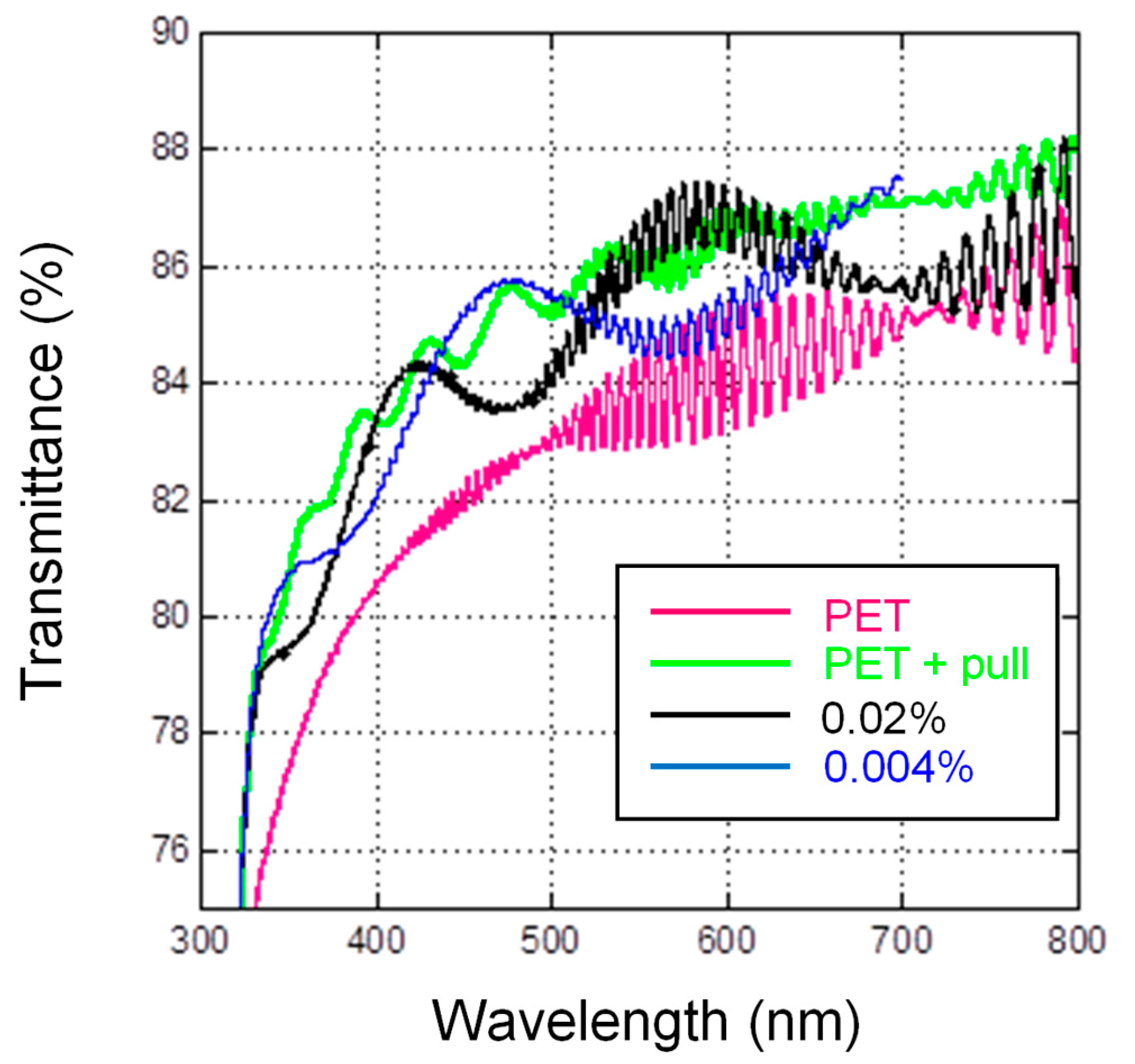

2.4. Optical Properties

3. Materials and Methods

3.1. Raw Materials and Reagents

3.2. Preparation of the Bionanocomposite Coatings

3.3. Analyses

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Unalan, I.U.; Cerri, G.; Marcuzzo, E.; Cozzolino, C.A.; Farris, S. Nanocomposite films and coatings using inorganic nanobuilding blocks (NBB): Current applications and future opportunities in the food packaging sector. RSC Adv. 2014, 4, 29393–29428. [Google Scholar] [CrossRef]

- Ziadeh, M.; Weiss, S.; Fischer, B.; Förster, S.; Altstädt, V.; Müller, A.H.; Breu, J. Towards completely miscible PMMA nanocomposites reinforced by shear-stiff, nano-mica. J. Colloid Interface Sci. 2014, 425, 143–151. [Google Scholar] [CrossRef] [PubMed]

- Alves, V.D.; Costa, N.; Coelhoso, I.M. Barrier properties of biodegradable composite films based on kappa-carrageenan/pectin blends and mica flakes. Carbohydr. Polym. 2010, 79, 269–276. [Google Scholar] [CrossRef]

- Soon, K.; Harkin-Jones, E.; Rajeev, R.S.; Menary, G.; Martin, P.J.; Armstrong, C.G. Morphology, barrier, and mechanical properties of biaxially deformed poly(ethylene terephthalate)-mica nanocomposites. Polym. Eng. Sci. 2012, 52, 532–548. [Google Scholar] [CrossRef]

- Krzesińska, M.; Celzard, A.; Grzyb, B.; Mareche, J.F. Elastic properties and electrical conductivity of mica/expanded graphite nanocomposites. Mater. Chem. Phys. 2006, 97, 173–181. [Google Scholar] [CrossRef]

- Chang, J.H.; Mun, M.K. Nanocomposite fibers of poly(ethylene terephthalate) with montmorillonite and mica: Thermomechanical properties and morphology. Polym. Int. 2007, 56, 57–66. [Google Scholar] [CrossRef]

- Kothmann, M.H.; Ziadeh, M.; Bakis, G.; de Anda, A.R.; Breu, J.; Altstädt, V. Analyzing the influence of particle size and stiffness state of the nanofiller on the mechanical properties of epoxy/clay nanocomposites using a novel shear-stiff nano-mica. J. Mater. Sci. 2015, 50, 4845–4859. [Google Scholar] [CrossRef]

- Farris, S.; Introzzi, L.; Piergiovanni, L. Evaluation of a bio-coating as a solution to improve barrier, friction and optical properties of plastic films. Packag. Technol. Sci. 2009, 22, 69–83. [Google Scholar] [CrossRef]

- Introzzi, L.; Blomfeldt, T.O.; Trabattoni, S.; Tavazzi, S.; Santo, N.; Schiraldi, A.; Piergiovanni, L.; Farris, S. Ultrasound-assisted pullulan/montmorillonite bionanocomposite coating with high oxygen barrier properties. Langmuir 2012, 28, 11206–11214. [Google Scholar] [CrossRef] [PubMed]

- Unalan, I.U.; Boyacı, D.; Ghaani, M.; Trabattoni, S.; Farris, S. Graphene oxide bionanocomposite coatings with high oxygen barrier properties. Nanomaterials 2016, 6, 244. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, C.A.; Cerri, G.; Brundu, A.; Farris, S. Microfibrillated cellulose (MFC)-pullulan bionanocomposite films. Cellulose 2014, 21, 4323–4335. [Google Scholar] [CrossRef]

- Cozzolino, C.A.; Campanella, G.; Türe, H.; Olsson, R.T.; Farris, S. Microfibrillated cellulose and borax as mechanical, O2-barrier, and surface-modulating agents of pullulan biocomposite coatings on BOPP. Carbohydr. Polym. 2016, 143, 179–187. [Google Scholar] [CrossRef] [PubMed]

- Farris, S.; Uysal Unalan, I.; Introzzi, L.; Fuentes-Alventosa, J.M.; Cozzolino, C.A. Pullulan-based films and coatings for food packaging: Present applications, emerging opportunities, and future challenges. J. Appl. Polym. Sci. 2014, 131, 40539–40551. [Google Scholar] [CrossRef]

- Aulin, C.; Gällstedt, M.; Lindström, T. Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 2010, 17, 559–574. [Google Scholar] [CrossRef]

- Kurek, M.; Guinault, A.; Voilley, A.; Galić, K.; Debeaufort, F. Effect of relative humidity on carvacrol release and permeation properties of chitosan based films and coatings. Food Chem. 2014, 144, 9–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sanchez-Garcia, M.D.; Hilliou, L.; Lagaron, J.M. Nanobiocomposites of carrageenan, zein, and mica of interest in food packaging and coating applications. J. Agric. Food Chem. 2010, 58, 6884–6894. [Google Scholar] [CrossRef] [PubMed]

- Lape, N.K.; Nuxoll, E.E.; Cussler, E.L. Polydisperse flakes in barrier films. J. Membr. Sci. 2004, 236, 29–37. [Google Scholar] [CrossRef]

- DeRocher, J.P.; Gettelfinger, B.T.; Wang, J.; Nuxoll, E.E.; Cussler, E.L. Barrier membranes with different sizes of aligned flakes. J. Membr. Sci. 2005, 254, 21–30. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater. Sci. Eng. 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Fuentes-Alventosa, J.M.; Introzzi, L.; Santo, N.; Cerri, G.; Brundu, A.; Farris, S. Self-assembled nanostructured biohybrid coatings by an integrated ‘sol–gel/intercalation’ approach. RSC Adv. 2013, 3, 25086–25096. [Google Scholar] [CrossRef]

- Jung, J.C.; Chen, T. Measurement of friction force between two mica surfaces with multiple beam interferometry. In Proceedings of the EPJ Web of Conferences, Paris, France, 24–28 May 2010; EDP Sciences: Les Ulis, France, 2010; Volume 6, p. 06002. [Google Scholar]

- Sakuma, H. Adhesion energy between mica surfaces: Implications for the frictional coefficient under dry and wet conditions. J. Geophys. Res. Solid Earth 2013, 118, 6066–6075. [Google Scholar] [CrossRef]

- Farris, S.; Introzzi, L.; Biagioni, P.; Holz, T.; Schiraldi, A.; Piergiovanni, L. Wetting of biopolymer coatings: Contact angle kinetics and image analysis investigation. Langmuir 2011, 27, 7563–7574. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, C.A.; Castelli, G.; Trabattoni, S.; Farris, S. Influence of colloidal silica nanoparticles on pullulan-coated BOPP film. Food Packag. Shelf Life 2016, 8, 50–55. [Google Scholar] [CrossRef]

- Gualtieri, E.; Pugno, N.; Rota, A.; Spagni, A.; Lepore, E.; Valeri, S. Role of roughness on the tribology of randomly nano-textured silicon surface. J. Nanosci. Nanotechnol. 2011, 11, 9244–9250. [Google Scholar] [CrossRef] [PubMed]

- Shah, D.; Maiti, P.; Jiang, D.D.; Batt, C.A.; Giannelis, E.P. Effect of nanoparticle mobility on toughness of polymer nanocomposites. Adv. Mater. 2005, 17, 525–528. [Google Scholar] [CrossRef]

- Fischer, B.; Ziadeh, M.; Pfaff, A.; Breu, J.; Altstädt, V. Impact of large aspect ratio, shear-stiff, mica-like clay on mechanical behaviour of PMMA/clay nanocomposites. Polymer 2012, 53, 3230–3237. [Google Scholar] [CrossRef]

- Introzzi, L.; Fuentes-Alventosa, J.M.; Cozzolino, C.A.; Trabattoni, S.; Tavazzi, S.; Bianchi, C.L.; Schiraldi, A.; Piergiovanni, L.; Farris, S. ‘Wetting enhancer’ pullulan coating for anti-fogpackaging applications. ACS Appl. Mater. Interfaces 2012, 4, 3692–3700. [Google Scholar] [CrossRef] [PubMed]

- Tilley, R.J.D. Colour and the Optical Properties of Materials, 2nd ed.; Wiley: Hoboken, NJ, USA, 2008; p. 42. [Google Scholar]

- Laskarakis, A.; Logothetidis, S. Study of the electronic and vibrational properties of poly(ethylene terephthalate) and poly(ethylene naphthalate) films. J. Appl. Phys. 2007, 101. [Google Scholar] [CrossRef]

- Gradwell, S.E. Self-Assembly of Pullulan Abietate on Cellulose Surfaces. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2004. [Google Scholar]

- Xiao, Q.; Tong, Q.; Zhou, Y.; Deng, F. Rheological properties of pullulan–sodium alginate based solutions during film formation. Carbohydr. Polym. 2015, 130, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Brown, W.E. Plastics in Food Packaging: Properties: Design and Fabrication; Dekker: New York, NY, USA, 1992; pp. 200–202. [Google Scholar]

| Mica Content | l (µm) | OTR (mL m−2 24 h−1) | ||||

|---|---|---|---|---|---|---|

| wt % | ϕ † | 0% RH | 30% RH | 60% RH | 90% RH | |

| uncoated PET | - | 12.00 ± 0.03 b | 129.23 ± 2.6 a | 120.67 ± 0.9 a | 115.10 ± 2.76 a | 107.47 ± 0.74 1 |

| PET/pullulan | - | 12.75 ± 0.07 a | 5.99 ± 0.02 b | 26.74 ± 0.3 b | 45.80 ± 2.65 bc | 100.73 ± 3.23 cd |

| 0.02 | 0.00008 | 12.76 ± 0.06 a | 1.27 ± 0.24 c | 18.79 ± 2.23 c | 51.21 ± 4.98 b | 100.63 ± 1.45 cd |

| 0.04 | 0.00015 | 12.75 ± 0.07 a | 1.12 ± 0.29 c | 14.09 ± 2.74 d | 50.20 ± 4.28 b | 100.79 ± 4.27 cd |

| 0.06 | 0.00023 | 12.78 ± 0.01 a | N.D. | 13.35 ± 0.51 d | 50.94 ± 0.1 b | 99.56 ± 0.63 cd |

| 0.08 | 0.00031 | 12.80 ± 0.05 a | N.D. | 11.18 ± 2.24 de | 49.10 ± 0.31 b | 97.47 ± 0.42 d |

| 0.1 | 0.00038 | 12.76 ± 0.05 a | N.D. | 10.29 ± 0.3 e | 46.76 ± 1.1 bc | 96.62 ± 0.58 d |

| 0.2 | 0.00077 | 12.77 ± 0.05 a | N.D. | 8.39 ± 0.44 ef | 41.05 ± 0.65 cd | 102.40 ± 1.17 bc |

| 0.5 | 0.00256 | 12.75 ± 0.01 a | N.D. | 6.05 ± 0.48 f | 36.01 ± 3.97 d | 101.11 ± 0.71 cd |

| 1 | 0.00510 | 12.80 ± 0.06 a | N.D. | 6.89 ± 0.6 f | 35.56 ± 5.6 d | 105.88 ± 3.28 ab |

| 1.5 | 0.01141 | 12.77 ± 0.06 a | N.D. | 8.50 ± 0.6 ef | 24.95 ± 1.16 e | 103.22 ± 2.04 abc |

| Sample | COF (Coating/Metal) | Emod (GPa) | ε (%) | TS (MPa) | |

|---|---|---|---|---|---|

| µs | µk | ||||

| uncoated PET | 0.35 ± 0.01 a | 0.26 ± 0.02 a | 3.65 ± 0.20 a | 15.80 ± 3.23 a | 104.99 ± 9.65 ab |

| PET/Pullulan | 0.42 ± 0.02 b | 0.27 ± 0.01 a | 3.65 ± 0.15 a | 15.52 ± 3.50 a | 105.33 ± 8.98 ab |

| Mica 0.02% | 0.35 ± 0.01 a | 0.23 ± 0.01 b | 3.63 ± 0.15 a | 16.37 ± 1.67 a | 109.43 ± 2.33 ab |

| Mica 0.2% | 0.31 ± 0.02 c | 0.20 ± 0.02 c | 3.71 ± 0.12 ab | 18.82 ± 5.16 a | 113.45 ± 7.04 a |

| Mica 0.5% | 0.31 ± 0.02 c | 0.20 ± 0.01 c | 3.79 ± 0.17 ab | 18.61 ± 2.99 a | 105.23 ± 7.88 ab |

| Mica 1.0% | 0.31 ± 0.02 c | 0.21 ± 0.02 bc | 3.81 ± 0.06 ab | 18.97 ± 2.68 a | 105.51 ± 10.23 ab |

| Mica 1.5% | 0.31 ± 0.01 c | 0.20 ± 0.01 c | 3.90 ± 0.20 b | 16.79 ± 3.15 a | 102.21 ± 9.81 b |

| Sample | H (%) | T (%) 550 nm | T (%) 400–700 nm † | Tsimul † | R (%) 400–700 nm † |

|---|---|---|---|---|---|

| uncoated PET | 2.72 ± 0.08 bc | 82.88 ± 0.77 a | 83.4 ± 1.3 | 83.3 ± 0.1 | 10.4 ± 0.1 |

| PET-pullulan | 2.63 ± 0.22 bc | 86.30 ± 0.94 b | 86.9 ± 1.0 | 86.4 ± 1.2 | 6.4 ± 1.6 |

| Mica 0.04% | 2.81 ± 0.21 b | 85.04 ± 0.41 b | N.A. | N.A. | N.A. |

| Mica 0.02% | 2.69 ± 0.11 bc | 85.72 ± 1.02 b | 85.3 ± 1.2 | 84.9 ± 0.3 | 8.4 ± 0.4 |

| Mica 1.5% | 3.23 ± 0.17 a | 83.28 ± 0.32 a | N.D. | N.D. | N.D. |

| Samples | nA | nB (μm2) | t (nm) | tn-u (%) | MSE | n589 | nmean ± std dev |

|---|---|---|---|---|---|---|---|

| uncoated PET | 1.8564 | 0.0019896 | - | - | - | - | 1.864 ± 0.002 |

| PET-pullulan | 1.5593 | 0.0020923 | 470.50 | 20.6 | 4.71 | 1.559 | 1.569 ± 0.002 |

| Mica 0.04 wt % | 1.6552 | 0.021063 | 465.53 | 41.6 | 1.58 | 1.716 | 1.731 ± 0.026 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uysal Unalan, I.; Boyacı, D.; Trabattoni, S.; Tavazzi, S.; Farris, S. Transparent Pullulan/Mica Nanocomposite Coatings with Outstanding Oxygen Barrier Properties. Nanomaterials 2017, 7, 281. https://doi.org/10.3390/nano7090281

Uysal Unalan I, Boyacı D, Trabattoni S, Tavazzi S, Farris S. Transparent Pullulan/Mica Nanocomposite Coatings with Outstanding Oxygen Barrier Properties. Nanomaterials. 2017; 7(9):281. https://doi.org/10.3390/nano7090281

Chicago/Turabian StyleUysal Unalan, Ilke, Derya Boyacı, Silvia Trabattoni, Silvia Tavazzi, and Stefano Farris. 2017. "Transparent Pullulan/Mica Nanocomposite Coatings with Outstanding Oxygen Barrier Properties" Nanomaterials 7, no. 9: 281. https://doi.org/10.3390/nano7090281