Electronic Eye Based on RGB Analysis for the Identification of Tequilas

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tequilas under Study

2.2. Electronic Eye System

2.3. Experimental Procedure

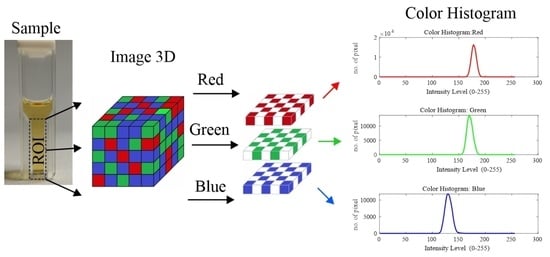

2.4. Image Analysis

2.5. Data Processing and Modelling

3. Results

3.1. RGB Image Processing

3.2. EE Preliminary Recognition Model

3.3. Tequila Categories Discrimination

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Norma Oficial Mexicana NOM-006-SCFI-2012. Available online: http://www.dof.gob.mx/nota_detalle.php?codigo=5282165&fecha=13/12/2012 (accessed on 21 February 2021).

- Electronic Code of Federal Regulations Title 27, 5.22(g). Available online: https://www.ecfr.gov/cgi-bin/text-idx?node=pt27.1.5&rgn=div5 (accessed on 21 February 2021).

- Council of the European Union. Agreement between the European Community and the United Mexican States on the Mutual Recognition and Protection of Designations for Spirit Drinks. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A21997A0611%2801%29 (accessed on 21 February 2021).

- Consejo Regulador del Tequila. Available online: https://www.crt.org.mx/index.php/en/pages-2/proteccion-del-tequila-a-nivel-internacional (accessed on 21 February 2021).

- Barbosa-García, O.; Ramos-Ortíz, G.; Maldonado, J.L.; Pichardo-Molina, J.L.; Meneses-Nava, M.A.; Landgrave, J.E.A.; Cervantes-Martínez, J. UV–vis absorption spectroscopy and multivariate analysis as a method to discriminate tequila. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2007, 66, 129–134. [Google Scholar] [CrossRef]

- Frausto-Reyes, C.; Medina-Gutiérrez, C.; Sato-Berrú, R.; Sahagún, L.R. Qualitative study of ethanol content in tequilas by Raman spectroscopy and principal component analysis. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2005, 61, 2657–2662. [Google Scholar] [CrossRef]

- De León-Rodríguez, A.; Escalante-Minakata, P.; Jiménez-García, M.I.; Ordoñez-Acevedo, L.G.; Flores, J.L.F.; Barba De La Rosa, A.P. Characterization of volatile compounds from ethnic Agave alcoholic beverages by gas chromatography-mass spectrometry. Food Technol. Biotechnol. 2008, 46, 448–455. [Google Scholar]

- Muñoz-Muñoz, A.C.; Grenier, A.C.; Gutiérrez-Pulido, H.; Cervantes-Martínez, J. Development and validation of a High Performance Liquid Chromatography-Diode Array Detection method for the determination of aging markers in tequila. J. Chromatogr. A 2008, 1213, 218–223. [Google Scholar] [CrossRef] [PubMed]

- Martínez-López, G.; Luna-Moreno, D.; Monzón-Hernández, D.; Valdivia-Hernández, R. Optical method to differentiate tequilas based on angular modulation surface plasmon resonance. Opt. Lasers Eng. 2011, 49, 675–679. [Google Scholar] [CrossRef]

- Oliveira, P.R.; Lamy-Mendes, A.C.; Rezende, E.I.P.; Mangrich, A.S.; Marcolino Junior, L.H.; Bergamini, M.F. Electrochemical determination of copper ions in spirit drinks using carbon paste electrode modified with biochar. Food Chem. 2015, 171, 426–431. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kiani, S.; Minaei, S.; Ghasemi-Varnamkhasti, M. Fusion of artificial senses as a robust approach to food quality assessment. J. Food Eng. 2016, 171, 230–239. [Google Scholar] [CrossRef]

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Orlandi, G.; Calvini, R.; Pigani, L.; Foca, G.; Vasile Simone, G.; Antonelli, A.; Ulrici, A. Electronic eye for the prediction of parameters related to grape ripening. Talanta 2018, 186, 381–388. [Google Scholar] [CrossRef]

- Xu, C. Electronic eye for food sensory evaluation. In Evaluation Technologies for Food Quality; Zhong, J., Wang, X., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 37–59. [Google Scholar]

- Wu, D.; Sun, D.W. Food colour measurement using computer vision. In Instrumental Assessment of Food Sensory Quality; Kilcast, D., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 165–195. [Google Scholar]

- Wu, D.; Sun, D.-W. Colour measurements by computer vision for food quality control—A review. Trends Food Sci. Technol. 2013, 29, 5–20. [Google Scholar] [CrossRef]

- Gomes, J.F.S.; Leta, F.R. Applications of computer vision techniques in the agriculture and food industry: A review. Eur. Food Res. Technol. 2012, 235, 989–1000. [Google Scholar] [CrossRef]

- Ware, C. Color. In Information Visualization, 4th ed.; Ware, C., Ed.; Morgan Kaufmann: Burlington, MA, USA, 2021; pp. 95–141. [Google Scholar]

- Jerram, P.; Stefanov, K. CMOS and CCD image sensors for space applications. In High Performance Silicon Imaging, 2nd ed.; Durini, D., Ed.; Woodhead Publishing: Cambridge, UK, 2020; pp. 255–287. [Google Scholar]

- Patel, K.K.; Kar, A.; Jha, S.N.; Khan, M.A. Machine vision system: A tool for quality inspection of food and agricultural products. J. Food Sci. Technol. 2012, 49, 123–141. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Vázquez, R.; Stinco, C.M.; Meléndez-Martínez, A.J.; Heredia, F.J.; Vicario, I.M. Visual and instrumental evaluation of orange juice color: A consumers’ preference study. J. Sens. Stud. 2011, 26, 436–444. [Google Scholar] [CrossRef]

- Buratti, S.; Benedetti, S.; Giovanelli, G. Application of electronic senses to characterize espresso coffees brewed with different thermal profiles. Eur. Food Res. Technol. 2017, 243, 511–520. [Google Scholar] [CrossRef]

- Apetrei, C.; Apetrei, I.M.; Villanueva, S.; de Saja, J.A.; Gutierrez-Rosales, F.; Rodriguez-Mendez, M.L. Combination of an e-nose, an e-tongue and an e-eye for the characterisation of olive oils with different degree of bitterness. Anal. Chim. Acta 2010, 663, 91–97. [Google Scholar] [CrossRef]

- Figueroa, A.; Caballero-Villalobos, J.; Angón, E.; Arias, R.; Garzón, A.; Perea, J.M. Using multivariate analysis to explore the relationships between color, composition, hygienic quality, and coagulation of milk from Manchega sheep. J. Dairy Sci. 2020, 103, 4951–4957. [Google Scholar] [CrossRef] [PubMed]

- Shafiee, S.; Minaei, S.; Moghaddam-Charkari, N.; Ghasemi-Varnamkhasti, M.; Barzegar, M. Potential application of machine vision to honey characterization. Trends Food Sci. Technol. 2013, 30, 174–177. [Google Scholar] [CrossRef]

- Abildgaard, O.H.A.; Kamran, F.; Dahl, A.B.; Skytte, J.L.; Nielsen, F.D.; Thomsen, C.L.; Andersen, P.E.; Larsen, R.; Frisvad, J.R. Non-Invasive Assessment of Dairy Products Using Spatially Resolved Diffuse Reflectance Spectroscopy. Appl. Spectrosc. 2015, 69, 1096–1105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martin, M.L.G.-M.; Ji, W.; Luo, R.; Hutchings, J.; Heredia, F.J. Measuring colour appearance of red wines. Food Qual. Prefer. 2007, 18, 862–871. [Google Scholar] [CrossRef]

- Ouyang, Q.; Zhao, J.; Chen, Q. Instrumental intelligent test of food sensory quality as mimic of human panel test combining multiple cross-perception sensors and data fusion. Anal. Chim. Acta 2014, 841, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Benedetti, L.P.d.S.; dos Santos, V.B.; Silva, T.A.; Filho, E.B.; Martins, V.L.; Fatibello-Filho, O. A digital image-based method employing a spot-test for quantification of ethanol in drinks. Anal. Methods 2015, 7, 4138–4144. [Google Scholar] [CrossRef]

- Villanueva-Rodríguez, S.J.; Rodríguez-Garay, B.; Prado-Ramírez, R.; Gschaedler, A. Tequila: Raw Material, Classification, Process, and Quality Parameters. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 283–289. [Google Scholar]

- Prado-Ramírez, R.; Gonzáles-Alvarez, V.; Pelayo-Ortiz, C.; Casillas, N.; Estarrón, M.; Gómez-Hernández, H.E. The role of distillation on the quality of tequila. Int. J. Food Sci. Technol. 2005, 40, 701–708. [Google Scholar] [CrossRef]

- Martín-del-Campo, S.T.; López-Ramírez, J.E.; Estarrón-Espinosa, M. Evolution of volatile compounds during the maturation process of silver tequila in new French oak barrels. LWT 2019, 115, 108386. [Google Scholar] [CrossRef]

- López-Ramírez, J.E.; Martín-del-Campo, S.T.; Escalona-Buendía, H.; García-Fajardo, J.A.; Estarrón-Espinosa, M. Physicochemical quality of tequila during barrel maturation. A preliminary study. Cyta-J. Food 2013, 11, 223–233. [Google Scholar] [CrossRef]

- Ceballos-Magaña, S.G.; de Pablos, F.; Jurado, J.M.; Martín, M.J.; Alcázar, Á.; Muñiz-Valencia, R.; Gonzalo-Lumbreras, R.; Izquierdo-Hornillos, R. Characterisation of tequila according to their major volatile composition using multilayer perceptron neural networks. Food Chem. 2013, 136, 1309–1315. [Google Scholar] [CrossRef]

- Pérez-Caballero, G.; Andrade, J.M.; Olmos, P.; Molina, Y.; Jiménez, I.; Durán, J.J.; Fernandez-Lozano, C.; Miguel-Cruz, F. Authentication of tequilas using pattern recognition and supervised classification. Trac Trends Anal. Chem. 2017, 94, 117–129. [Google Scholar] [CrossRef] [Green Version]

- Contreras, U.; Barbosa-García, O.; Pichardo-Molina, J.L.; Ramos-Ortíz, G.; Maldonado, J.L.; Meneses-Nava, M.A.; Ornelas-Soto, N.E.; López-de-Alba, P.L. Screening method for identification of adulterate and fake tequilas by using UV–VIS spectroscopy and chemometrics. Food Res. Int. 2010, 43, 2356–2362. [Google Scholar] [CrossRef]

- Wyszecki, G.; Stiles, W. Color Science: Concepts and Methods, Quantitative Data and Formulae, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2000; p. 968. [Google Scholar]

- Foca, G.; Masino, F.; Antonelli, A.; Ulrici, A. Prediction of compositional and sensory characteristics using RGB digital images and multivariate calibration techniques. Anal. Chim. Acta 2011, 706, 238–245. [Google Scholar] [CrossRef]

- Herrero-Latorre, C.; Barciela-García, J.; García-Martín, S.; Peña-Crecente, R.M. Detection and quantification of adulterations in aged wine using RGB digital images combined with multivariate chemometric techniques. Food Chem. X 2019, 3, 100046. [Google Scholar] [CrossRef]

- Mutlu, A.Y.; Kılıç, V.; Özdemir, G.K.; Bayram, A.; Horzum, N.; Solmaz, M.E. Smartphone-based colorimetric detection via machine learning. Analyst 2017, 142, 2434–2441. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pennebaker, W.B.; Mitchell, J.L. JPEG: Still Image Data Compression Standard; Kluwer Academic Publishers: Drive Norwell, MA, USA, 1993; p. 638. [Google Scholar]

- Tkalcic, M.; Tasic, J.F. Colour spaces: Perceptual, historical and applicational background. In Proceedings of the IEEE Region 8 EUROCON 2003. Computer as a Tool, Ljubljana, Slovenia, 22–24 September 2003; pp. 304–308. [Google Scholar]

- Burger, W.; Burge, M.J. Color Images. In Digital Image Processing: An Algorithmic Introduction Using Java; Gries, D., Schneider, F.B., Eds.; Springer London: London, UK, 2016; pp. 291–328. [Google Scholar]

- Burger, W.; Burge, M.J. Histograms and Image Statistics. In Digital Image Processing: An Algorithmic Introduction Using Java; Gries, D., Schneider, F.B., Eds.; Springer London: London, UK, 2016; pp. 37–56. [Google Scholar]

- Oldham, K.B.; Parnis, J.M. Shining light on Beer’s law. ChemTexts 2017, 3, 5. [Google Scholar] [CrossRef]

- Corke, P. Light and Color. In Robotics, Vision and Control: Fundamental Algorithms In MATLAB, 2nd ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 287–318. [Google Scholar]

- Jolliffe, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef]

- Mitteroecker, P.; Bookstein, F. Linear Discrimination, Ordination, and the Visualization of Selection Gradients in Modern Morphometrics. Evol. Biol. 2011, 38, 100–114. [Google Scholar] [CrossRef]

- Swets, D.L.; Weng, J.J. Using discriminant eigenfeatures for image retrieval. IEEE Trans. Pattern Anal. Mach. Intell. 1996, 18, 831–836. [Google Scholar] [CrossRef] [Green Version]

- Belhumeur, P.N.; Hespanha, J.P.; Kriegman, D.J. Eigenfaces vs. Fisherfaces: Recognition using class specific linear projection. IEEE Trans. Pattern Anal. Mach. Intell. 1997, 19, 711–720. [Google Scholar] [CrossRef] [Green Version]

- Carpena, M.; Pereira, A.G.; Prieto, M.A.; Simal-Gandara, J. Wine aging technology: Fundamental role of wood barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef] [PubMed]

- Delgado-González, M.J.; García-Moreno, M.V.; Sánchez-Guillén, M.M.; García-Barroso, C.; Guillén-Sánchez, D.A. Colour evolution kinetics study of spirits in their ageing process in wood casks. Food Control 2021, 119. [Google Scholar] [CrossRef]

- Sharififar, A.; Sarmadian, F.; Malone, B.P.; Minasny, B. Addressing the issue of digital mapping of soil classes with imbalanced class observations. Geoderma 2019, 350, 84–92. [Google Scholar] [CrossRef]

- Congalton, R.G. A review of assessing the accuracy of classifications of remotely sensed data. Remote Sens. Environ. 1991, 37, 35–46. [Google Scholar] [CrossRef]

| Type | Brand | Tag | Alcoholic Strength (vol %) |

|---|---|---|---|

| Silver | Hornitos | S1 | 38 |

| Orendain | S2 | 38 | |

| Don Nacho | S3 | 38 | |

| Corralejo | S4 | 38 | |

| Dos Coronas | S5 | 38 | |

| Sombrero Negro | S6 | 35 | |

| Antigua Cruz | S7 | 40 | |

| Herradura | S8 | 46 | |

| Aged | Hornitos | A1 | 38 |

| Jimador | A2 | 35 | |

| Jarana | A3 | 35 | |

| Don Nacho | A4 | 38 | |

| Cabrito | A5 | 38 | |

| Antigua Cruz | A6 | 40 | |

| Don Julio | A7 | 40 | |

| Dos coronas | A8 | 38 | |

| Sombrero Negro | A9 | 38 | |

| Reserva del Señor | A10 | 35 | |

| Cazadores | A11 | 38 | |

| Jose Cuervo | A12 | 38 | |

| Extra-aged | Corralejo | EA1 | 38 |

| Don Nacho | EA2 | 38 | |

| Antigua Cruz | EA3 | 40 | |

| Cazadores | EA4 | 38 | |

| Hornitos | EA5 | 35 |

| Average Components of RGB Pixel | Absorbance by Component | ||||||

|---|---|---|---|---|---|---|---|

| Tag | R | G | B | R | G | B | |

| Blank | 255 | 251 ± 4.0970 | 253 ± 3.4674 | 0 | 0.0026 ± 0.0040 | 0.0012 ± 0.0027 | 0.0016 ± 0.0038 |

| S1 | 215 ± 0.6915 | 215 ± 1.1861 | 215 ± 1.0148 | 0.0729 ± 0.0014 | 0.0720 ± 0.0024 | 0.0729 ± 0.0021 | 0.0726 ± 0.0020 |

| S2 | 216 ± 1.1059 | 216 ± 0.8137 | 216 ± 0.9248 | 0.0706 ± 0.0023 | 0.0696 ± 0.0017 | 0.0708 ± 0.0019 | 0.0703 ± 0.0019 |

| S3 | 217 ± 1.7991 | 216 ± 1.7340 | 216 ± 1.6046 | 0.0685 ± 0.0036 | 0.0696 ± 0.0035 | 0.0711 ± 0.0033 | 0.0697 ± 0.0035 |

| S4 | 225 ± 3.0820 | 227 ± 3.5519 | 227 ± 2.8720 | 0.0529 ± 0.0061 | 0.0487 ± 0.0070 | 0.0496 ± 0.0056 | 0.0504 ± 0.0062 |

| S5 | 216 ± 1.1427 | 216 ± 1.1427 | 216 ± 1.1427 | 0.0705 ± 0.0023 | 0.0705 ± 0.0023 | 0.0705 ± 0.0023 | 0.0705 ± 0.0023 |

| S6 | 215 ± 1.0417 | 215 ± 2.4542 | 215 ± 1.3113 | 0.0727 ± 0.0021 | 0.0717 ± 0.0050 | 0.0723 ± 0.0027 | 0.0722 ± 0.0033 |

| S7 | 223 ± 1.4794 | 224 ± 2.2733 | 225 ± 2.8816 | 0.0556 ± 0.0029 | 0.0545 ± 0.0045 | 0.0530 ± 0.0056 | 0.0544 ± 0.0044 |

| S8 | 223 ± 3.1220 | 224 ± 1.8144 | 224 ± 1.8144 | 0.0559 ± 0.0062 | 0.0543 ± 0.0035 | 0.0543 ± 0.0035 | 0.0549 ± 0.0044 |

| A1 | 196 ± 1.3730 | 199 ± 1.2972 | 199 ± 1.3730 | 0.1118 ± 0.0031 | 0.1055 ± 0.0029 | 0.1053 ± 0.0030 | 0.1076 ± 0.0030 |

| A2 | 211 ± 1.7682 | 213 ± 1.4794 | 208 ± 0.8193 | 0.0812 ± 0.0037 | 0.0755 ± 0.0031 | 0.0870 ± 0.0017 | 0.0813 ± 0.0028 |

| A3 | 209 ± 0.6215 | 212 ± 0.7849 | 209 ± 3.6928 | 0.0855 ± 0.0013 | 0.0784 ± 0.0016 | 0.0850 ± 0.0076 | 0.0830 ± 0.0036 |

| A4 | 219 ± 1.2243 | 222 ± 1.0417 | 211 ± 1.7207 | 0.0635 ± 0.0025 | 0.0576 ± 0.0021 | 0.0811 ± 0.0036 | 0.0674 ± 0.0027 |

| A5 | 204 ± 0.7303 | 207 ± 0.4498 | 206 ± 0.6433 | 0.0955 ± 0.0016 | 0.0887 ± 0.0010 | 0.0910 ± 0.0014 | 0.0917 ± 0.0013 |

| A6 | 207 ± 0.6915 | 210 ± 0.6288 | 206 ± 0.7849 | 0.0887 ± 0.0015 | 0.0817 ± 0.0013 | 0.0908 ± 0.0017 | 0.0871 ± 0.0015 |

| A7 | 229 ± 0.6288 | 234 ± 0.5252 | 231 ± 0.6065 | 0.0459 ± 0.0012 | 0.0356 ± 0.0010 | 0.0406 ± 0.0012 | 0.0407 ± 0.0011 |

| A8 | 212 ± 1.0807 | 217 ± 0.9965 | 204 ± 0.8023 | 0.0784 ± 0.0023 | 0.0680 ± 0.0020 | 0.0945 ± 0.0017 | 0.0803 ± 0.0020 |

| A9 | 200 ± 1.8889 | 204 ± 1.2794 | 197 ± 2.4011 | 0.1048 ± 0.0042 | 0.0955 ± 0.0028 | 0.1113 ± 0.0054 | 0.1039 ± 0.0041 |

| A10 | 223 ± 0.8996 | 224 ± 0.8996 | 211 ± 3.1397 | 0.0574 ± 0.0018 | 0.0537 ± 0.0018 | 0.0811 ± 0.0067 | 0.0641 ± 0.0033 |

| A11 | 214 ± 1.3493 | 220 ± 0.8137 | 218 ± 1.3322 | 0.0748 ± 0.0028 | 0.0616 ± 0.0016 | 0.0654 ± 0.0027 | 0.0673 ± 0.0024 |

| A12 | 217 ± 0.6288 | 222 ± 1.2576 | 213 ± 0.8841 | 0.0681 ± 0.0013 | 0.0590 ± 0.0025 | 0.0771 ± 0.0018 | 0.0681 ± 0.0019 |

| EA1 | 207 ± 0.7611 | 207 ± 1.2015 | 180 ± 0.4983 | 0.0884 ± 0.0016 | 0.0887 ± 0.0026 | 0.1486 ± 0.0012 | 0.1086 ± 0.0018 |

| EA2 | 206 ± 0.7240 | 210 ± 0.8193 | 191 ± 0.8683 | 0.0918 ± 0.0016 | 0.0836 ± 0.0017 | 0.1236 ± 0.0020 | 0.0997 ± 0.0018 |

| EA3 | 221 ± 0.9248 | 224 ± 0.7303 | 208 ± 0.8469 | 0.0600 ± 0.0019 | 0.0537 ± 0.0014 | 0.0872 ± 0.0018 | 0.0670 ± 0.0086 |

| EA4 | 215 ± 1.0283 | 220 ± 0.5509 | 209 ± 0.8137 | 0.0731 ± 0.0021 | 0.0628 ± 0.0011 | 0.0855 ± 0.0017 | 0.0738 ± 0.0016 |

| EA5 | 211 ± 1.2576 | 206 ± 1.1059 | 169 ± 0.9685 | 0.0807 ± 0.0026 | 0.0912 ± 0.0024 | 0.1780 ± 0.0025 | 0.1166±0.0025 |

| Tequila Category | Classification Rate (%) | Accuracy | Precision | Sensitivity | Specificity |

|---|---|---|---|---|---|

| Silver | 100.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Aged | 91.67 | 0.92 | 0.91 | 0.92 | 0.92 |

| Extra-aged | 78.40 | 0.92 | 0.80 | 0.78 | 0.95 |

| Average | 90.02 | 0.94 | 0.90 | 0.90 | 0.96 |

| Reference | Analytical Method | Classification Model | Tequila Category | Sensitivity | Specificity |

|---|---|---|---|---|---|

| Ceballos-Magaña et al. [34] | GC-MS | LDA | S | 0.66 | 0.75 |

| A | 0.33 | 0.92 | |||

| EA | 0.66 | 0.73 | |||

| MLP-ANN | S | 1.00 | 1.00 | ||

| A | 0.83 | 1.00 | |||

| EA | 1.00 | 0.93 | |||

| Pérez-Caballero et al. [35] | UV-Vis | PLS-DA | S | 0.81 | 0.89 |

| A | 0.71 | 0.88 | |||

| EA | 1.00 | 0.93 | |||

| SVM | S | 1.00 | 1.00 | ||

| A | 1.00 | 0.99 | |||

| EA | 0.96 | 1.00 | |||

| This work | Electronic Eye | PCA-LDA | S | 1.00 | 1.00 |

| A | 0.92 | 0.92 | |||

| EA | 0.78 | 0.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez, A.; Bueno, D.; Gutiérrez, J.M. Electronic Eye Based on RGB Analysis for the Identification of Tequilas. Biosensors 2021, 11, 68. https://doi.org/10.3390/bios11030068

Gómez A, Bueno D, Gutiérrez JM. Electronic Eye Based on RGB Analysis for the Identification of Tequilas. Biosensors. 2021; 11(3):68. https://doi.org/10.3390/bios11030068

Chicago/Turabian StyleGómez, Anais, Diana Bueno, and Juan Manuel Gutiérrez. 2021. "Electronic Eye Based on RGB Analysis for the Identification of Tequilas" Biosensors 11, no. 3: 68. https://doi.org/10.3390/bios11030068