Towards a Self-Powered Amperometric Glucose Biosensor Based on a Single-Enzyme Biofuel Cell

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation of Solutions

2.3. Preparation of Bioelectrodes and Current Measurements

2.4. Interpretation of Experimental Data

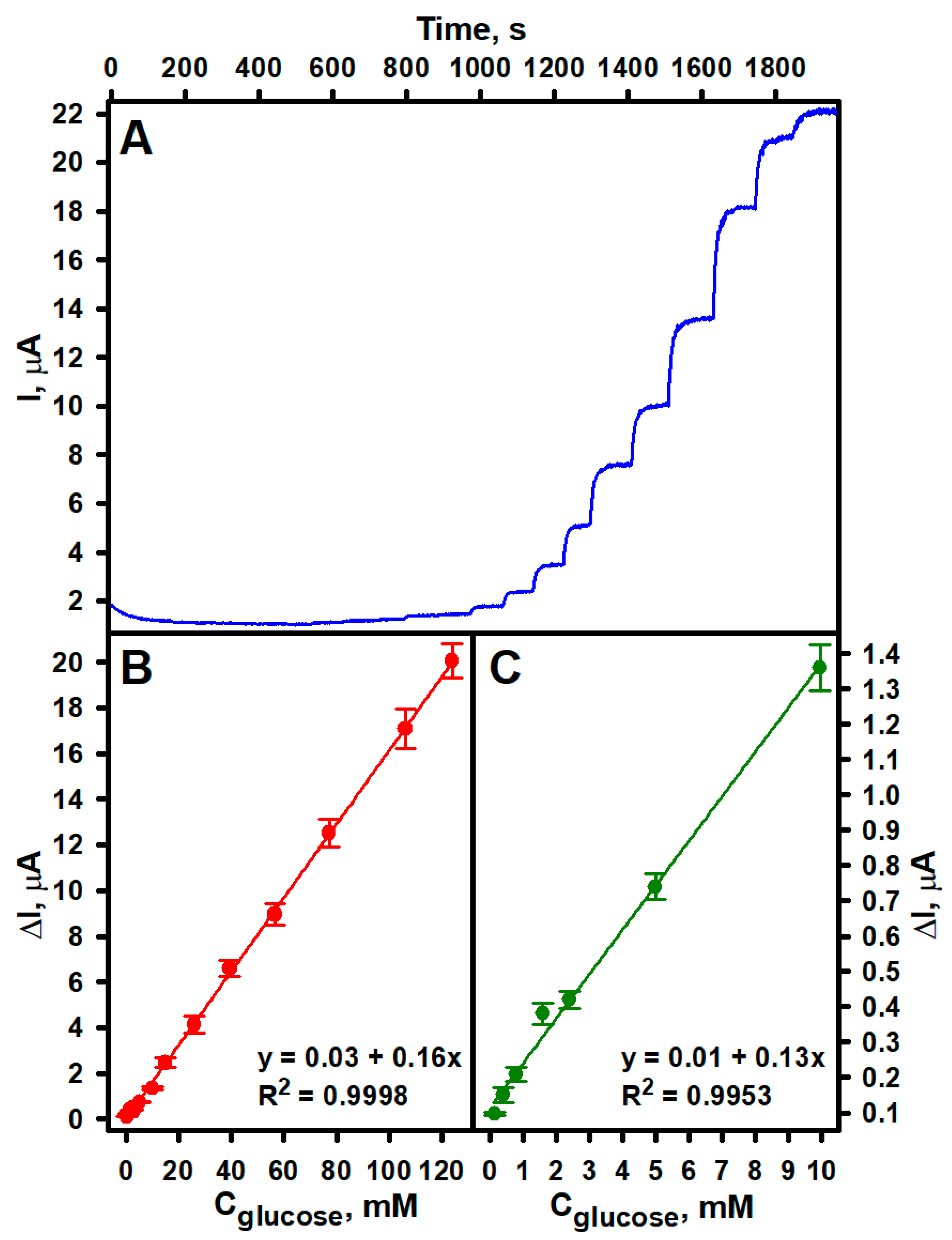

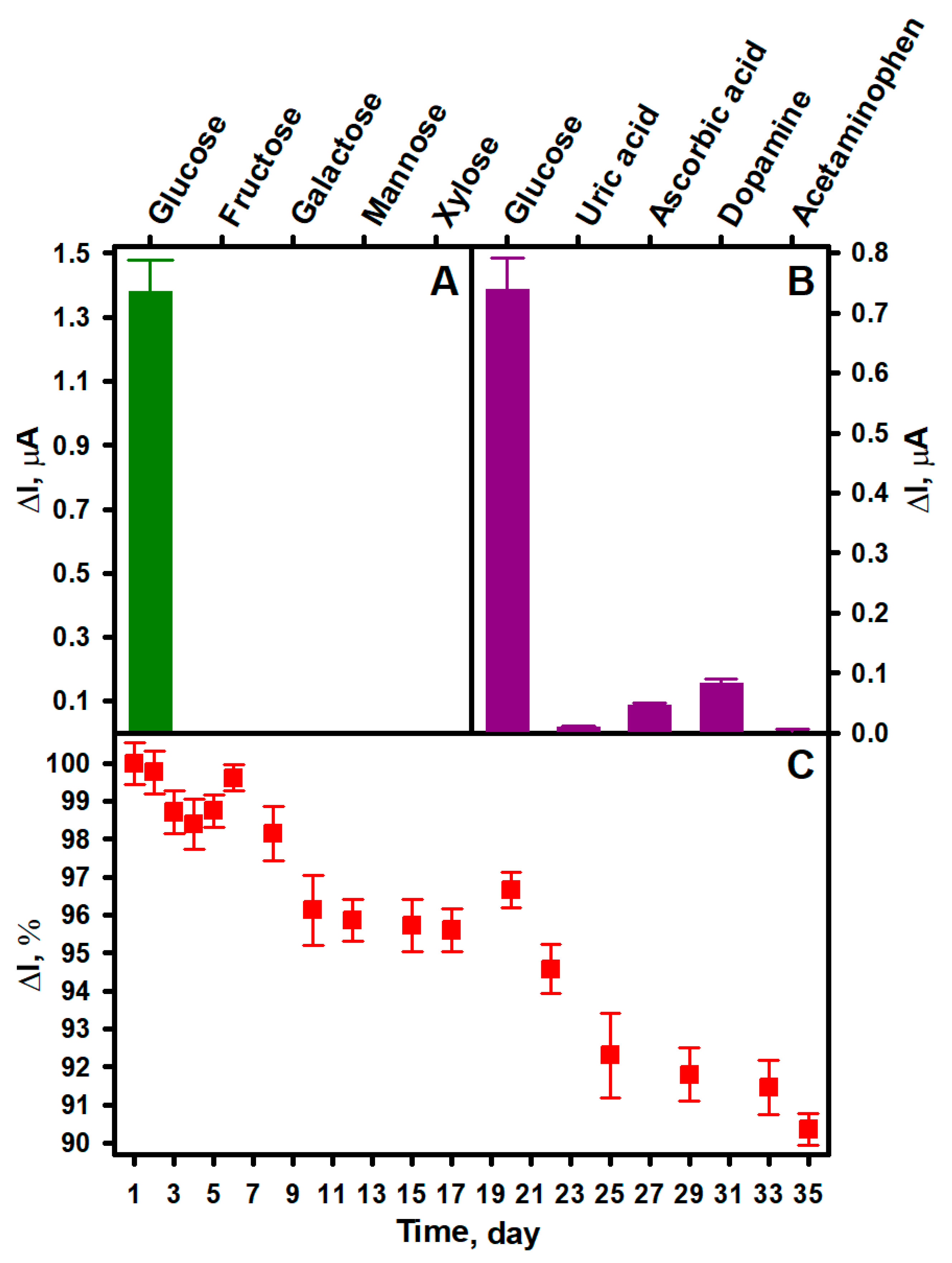

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, X. The direct use of enzymatic biofuel cells as functional bioelectronics. eScience 2022, 2, 1–9. [Google Scholar] [CrossRef]

- Wang, L.; Wu, X.; Su, B.S.Q.; Song, R.; Zhang, J.-R.; Zhu, J.-J. Enzymatic biofuel cell: Opportunities and intrinsic challenges in futuristic applications. Adv. Energy Sustain. Res. 2021, 2, 2100031. [Google Scholar] [CrossRef]

- Hao, S.; Sun, X.; Zhang, H.; Zhai, J.; Dong, S. Recent development of biofuel cell based self-powered biosensors. J. Mater. Chem. B 2020, 8, 3393–3407. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Solino, C.; Bernalte, E.; Royo, C.B.; Bennett, R.; Leech, D.; Di Lorenzo, M. Self-powered detection of glucose by enzymatic glucose/oxygen fuel cells on printed circuit boards. ACS Appl. Mater. Interfaces 2021, 13, 26704–26711. [Google Scholar] [CrossRef] [PubMed]

- Rasmussen, M.; Ritzmann, R.E.; Lee, I.; Pollack, A.J.; Scherson, D. An implantable biofuel cell for a live insect. J. Am. Chem. Soc. 2012, 134, 1458–1460. [Google Scholar] [CrossRef] [PubMed]

- Szczupak, A.; Halamek, J.; Halamkova, L.; Bocharova, V.; Alfonta, L.; Katz, E. Living battery–biofuel cells operating in vivo in clams. Energy Environ. Sci. 2012, 5, 8891–8895. [Google Scholar] [CrossRef]

- Halamkova, L.; Halamek, J.; Bocharova, V.; Szczupak, A.; Alfonta, L.; Katz, E. Implanted biofuel cell operating in a living snail. J. Am. Chem. Soc. 2012, 134, 5040–5043. [Google Scholar] [CrossRef] [PubMed]

- Cinquin, P.; Gondran, C.; Giroud, F.; Mazabrard, S.; Pellissier, A.; Boucher, F.; Alcaraz, J.-P.; Gorgy, K.; Lenouvel, F.; Mathe, S.; et al. A glucose biofuel cell implanted in rats. PLoS ONE 2010, 5, e10476. [Google Scholar] [CrossRef] [PubMed]

- Ichi-Ribault, S.E.; Alcaraz, J.-P.; Boucher, F.; Boutaud, B.; Dalmolin, R.; Boutonnat, J.; Cinquin, P.; Zebda, A.; Martin, D.K. Remote wireless control of an enzymatic biofuel cell implanted in a rabbit for 2 months. Electrochim. Acta 2018, 269, 360–366. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, W.; Yan, K.; Gao, J.; Zhang, J. Fuel cell-based self-powered electrochemical sensors for biochemical detection. Nano Energy 2019, 61, 173–193. [Google Scholar] [CrossRef]

- Xue, Z.; Wu, L.; Yuan, J.; Xu, G.; Wu, Y. Self-powered biosensors for monitoring human physiological changes. Biosensors 2023, 13, 236. [Google Scholar] [CrossRef]

- Katz, E.; Buckmann, A.F.; Willner, I.J. Self-powered enzyme-based biosensors. Am. Chem. Soc. 2001, 123, 10752–10753. [Google Scholar] [CrossRef]

- Zloczewska, A.; Celebanska, A.; Szot, K.; Tomaszewska, D.; Opallo, M.; Jonsson-Niedziolka, M. Self-powered biosensor for ascorbic acid with a Prussian blue electrochromic display. Biosens. Bioelectron. 2014, 54, 455–461. [Google Scholar] [CrossRef] [PubMed]

- Baingane, A.; Slaughter, G. Self-powered electrochemical lactate biosensing. Energies 2017, 10, 1582. [Google Scholar] [CrossRef]

- Roy, B.G.; Rutherford, J.L.; Weaver, A.E.; Beaver, K.; Rasmussen, M. A self-powered biosensor for the detection of glutathione. Biosensors 2020, 10, 114. [Google Scholar] [CrossRef] [PubMed]

- Moreira, F.T.C.; Sale, M.G.F.; Lorenzo, M.D. Towards timely Alzheimer diagnosis: A self-powered amperometric biosensor for the neurotransmitter acetylcholine. Biosens. Bioelectron. 2017, 87, 607–614. [Google Scholar] [CrossRef] [PubMed]

- Ruff, A.; Pinyou, P.; Nolten, M.; Conzuelo, F.; Schuhmann, W. A self-powered ethanol biosensor. Chem. Electro. Chem. 2017, 4, 890–897. [Google Scholar] [CrossRef]

- Quah, T.; Abdellaoui, S.; Milton, R.D.; Hickey, D.P.; Minteer, S.D. Cholesterol as a promising alternative energy source: Bioelectrocatalytic oxidation using NAD-dependent cholesterol dehydrogenase in human serum. J. Electrochem. Soc. 2017, 164, H3024–H3029. [Google Scholar] [CrossRef]

- Hou, C.; Fan, S.; Lang, Q.; Liu, A. Biofuel cell based self-powered sensing platform for L-cysteine detection. Anal. Chem. 2015, 87, 3382–3387. [Google Scholar] [CrossRef] [PubMed]

- Wen, D.; Deng, L.; Guo, S.; Dong, S. Self-powered sensor for trace Hg2+ detection. Anal. Chem. 2011, 83, 3968–3972. [Google Scholar] [CrossRef]

- Wang, Y.; Ge, L.; Wang, P.; Yan, M.; Yu, J.; Ge, S. A three-dimensional origami-based immuno-biofuel cell for self-powered, low-cost, and sensitive point-of-care testing. Chem. Commun. 2014, 50, 1947–1949. [Google Scholar] [CrossRef] [PubMed]

- Slaughter, G.; Kulkarni, T. Detection of human plasma glucose using a self-powered glucose biosensor. Energies 2019, 12, 825. [Google Scholar] [CrossRef]

- Becker, J.M.; Lielpetere, A.; Szczesny, J.; Bichon, S.; Gounel, S.; Mano, N.; Schuhmann, W. Wiring of bilirubin oxidases with redox polymers on gas diffusion electrodes for increased stability of self-powered biofuel cells-based glucose sensing. Bioelectrochemistry 2023, 149, 108314. [Google Scholar] [CrossRef] [PubMed]

- Pinyou, P.; Conzuelo, F.; Sliozberg, K.; Vivekananthan, J.; Contin, A.; Poller, S.; Plumere, N.; Schuhmann, W. Coupling of an enzymatic biofuel cell to an electrochemical cell for self-powered glucose sensing with optical readout. Bioelectrochemistry 2015, 106, 22–27. [Google Scholar] [CrossRef] [PubMed]

- Chansaenpak, K.; Kamkaew, A.; Lisnund, S.; Prachai, P.; Ratwirunkit, P.; Jingpho, T.; Blay, V.; Pinyou, P. Development of a sensitive self-powered glucose biosensor based on an enzymatic biofuel cell. Biosensors 2021, 11, 16. [Google Scholar] [CrossRef]

- Escalona-Villalpando, R.A.; Sandoval-Garcia, A.; Espinosa, L.J.R.; Miranda-Silva, M.G.; Arriaga, L.G.; Minteer, S.D.; Ledesma-Garcia, J. A self-powered glucose biosensor device based on microfluidics using human blood. J. Power Sources 2021, 515, 230631. [Google Scholar] [CrossRef]

- Sekretaryova, A.N.; Beni, V.; Eriksson, M.; Karyakin, A.A.; Turner, A.P.F.; Vagin, M.Y. Cholesterol self-powered biosensor. Anal. Chem. 2014, 86, 9540–9547. [Google Scholar] [CrossRef]

- Li, X.; Li, D.; Zhang, Y.; Lv, P.; Feng, Q.; Wei, Q. Encapsulation of enzyme by metal-organic framework for single-enzymatic biofuel cell-based self-powered biosensor. Nano Energy 2020, 68, 104308. [Google Scholar] [CrossRef]

- Kausaite-Minkstimiene, A.; Kaminskas, A.; Ramanaviciene, A. Development of a membraneless single-enzyme biofuel cell powered by glucose. Biosens. Bioelectron. 2022, 216, 114657. [Google Scholar] [CrossRef]

- Kausaite-Minkstimiene, A.; Kaminskas, A.; Popov, A.; Ramanavicius, A.; Ramanaviciene, A. Development of a new biocathode for a single enzyme biofuel cell fuelled by glucose. Sci. Rep. 2021, 11, 18568. [Google Scholar] [CrossRef]

- Kausaite-Minkstimiene, A.; Glumbokaite, L.; Ramanaviciene, A.; Ramanavicius, A. Reagent-less amperometric glucose biosensor based on nanobiocomposite consisting of poly(1,10-phenanthroline-5,6-dione), poly(pyrrole-2-carboxylic acid), gold nanoparticles and glucose oxidase. Microchem. J. 2020, 154, 104665. [Google Scholar] [CrossRef]

- Neto, S.A.; Milton, R.D.; Crepaldi, L.B.; Hickey, D.P.; de Andrade, A.R.; Minteer, S.D. Co-immobilization of gold nanoparticles with glucose oxidase to improve bioelectrocatalytic glucose oxidation. J. Power Sources 2015, 285, 493–498. [Google Scholar] [CrossRef]

- Yang, Y.-L.; Tseng, T.-F.; Yeh, J.-M.; Chen, C.-A.; Lou, S.-L. Performance characteristic studies of glucose biosensors modified by (3-mercaptopropyl)trimethoxysilane sol–gel and non-conducting polyaniline. Sens. Actuators B Chem. 2008, 131, 533–540. [Google Scholar] [CrossRef]

- Kausaite-Minkstimiene, A.; Mazeiko, V.; Ramanaviciene, A.; Ramanavicius, A. Enzymatically synthesized polyaniline layer for extension of linear detection region of amperometric glucose biosensor. Biosens. Bioelectron. 2010, 26, 790–797. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, A. Study of structural and electro-catalytic behaviour of amperometric biosensor based on chitosan/polypyrrole nanotubes-gold nanoparticles nanocomposites. Synth. Met. 2016, 220, 551–559. [Google Scholar] [CrossRef]

- Mazeiko, V.; Kausaite-Minkstimiene, A.; Ramanaviciene, A.; Balevicius, Z.; Ramanavicius, A. Gold nanoparticle and conducting polymer–polyaniline–based nanocomposites for glucose biosensor design. Sens. Actuators B Chem. 2013, 189, 187–193. [Google Scholar] [CrossRef]

- Olea, D.; Viratelle, O.; Faure, C. Polypyrrole-glucose oxidase biosensor: Effect of enzyme encapsulation in multilamellar vesicles on analytical properties. Biosens. Bioelectron. 2008, 23, 788–794. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Conducting polymers in the design of biosensors and biofuel cells. Polymers 2021, 13, 49. [Google Scholar] [CrossRef]

- Torrinha, A.; Tavares, M.; Delerue-Matos, C.; Morais, S. A self-powered biosensor for glucose detection using modified pencil graphite electrodes as transducers. Chem. Eng. J. 2021, 426, 131835. [Google Scholar] [CrossRef]

- Zhang, Y.; Hao, S.; Sun, X.; Zhang, H.; Ma, Q.; Zhai, J.; Dong, S. A self-powered glucose biosensor based on mediator-free hybrid Cu/glucose biofuel cell for flow sensing of glucose. Electroanalysis 2022, 34, 1953–1960. [Google Scholar] [CrossRef]

- Hao, S.; Zhang, H.; Sun, X.; Zhai, J.; Dong, S. A mediator-free self-powered glucose biosensor based on a hybrid glucose/MnO2 enzymatic biofuel cell. Nano Res. 2021, 14, 707–714. [Google Scholar] [CrossRef]

- Khan, H.; Choi, J.H.; Ullah, A.; Kim, Y.H.; Kim, G.M. Continuous determination of glucose using a membraneless, microfluidic enzymatic biofuel cell. Micromachines 2020, 11, 1129. [Google Scholar] [CrossRef]

- Lv, P.; Zhou, H.; Mensah, A.; Feng, Q.; Wang, D.; Hu, X.; Cai, Y.; Lucia, L.A.; Li, D.; Wei, Q. A highly flexible self-powered biosensor for glucose detection by epitaxial deposition of gold nanoparticles on conductive bacterial cellulose. Chem. Eng. J. 2018, 351, 177–188. [Google Scholar] [CrossRef]

- Sun, L.; Ma, Y.; Zhang, P.; Chao, L.; Huang, T.; Xie, Q.; Chen, C.; Yao, S. An amperometric enzyme electrode and its biofuel cell based on a glucose oxidase-poly(3-anilineboronic acid)-Pd nanoparticles bionanocomposite for glucose biosensing. Talanta 2015, 138, 100–107. [Google Scholar] [CrossRef]

- Fischer, C.; Fraiwan, A.; Choi, S. A 3D paper-based enzymatic fuel cell for self-powered, low-cost glucose monitoring. Biosens. Bioelectron. 2016, 79, 193–197. [Google Scholar] [CrossRef] [PubMed]

- Baingane, A.; Narayanan, J.S.; Slaughter, G. Sensitive electrochemical detection of glucose via a hybrid self-powered biosensing system. Sens. Bio-Sens. Res. 2018, 20, 41–46. [Google Scholar] [CrossRef]

- Giorgi, G.; Tonello, S. Wearable biosensor standardization: How to make them smarter. Standards 2022, 2, 366–384. [Google Scholar] [CrossRef]

- Bucur, B.; Purcarea, C.; Andreescu, S.; Vasilescu, A. Addressing the selectivity of enzyme biosensors: Solutions and perspectives. Sensors 2021, 21, 3038. [Google Scholar] [CrossRef]

- Babadi, A.A.; Wan-Mohtar, W.A.A.Q.I.; Chang, J.-S.; Ilham, Z.; Jamaludin, A.A.; Zamiri, G.; Akbarzadeh, O.; Basirun, W.J. High-performance enzymatic biofuel cell based on three-dimensional graphene. Int. J. Hydrogen Energy 2019, 44, 30367–30374. [Google Scholar] [CrossRef]

- Collier, B.B.; McShane, M.J. Enzymatic glucose sensor compensation for variations in ambient oxygen concentration. Proc. SPIE Int. Soc. Opt. Eng. 2015, 8591, 859104. [Google Scholar] [CrossRef] [PubMed]

- Ramanavicius, A.; Kausaite-Minkstimiene, A.; Morkvenaite-Vilkonciene, I.; Genys, P.; Mikhailova, R.; Semashko, T.; Voronovic, J.; Ramanaviciene, A. Biofuel cell based on glucose oxidase from Penicillium funiculosum 46.1 and horseradish peroxidase. Chem. Eng. J. 2015, 264, 165–173. [Google Scholar] [CrossRef]

- Zor, E.; Oztekin, Y.; Ramanaviciene, A.; Anusevicius, Z.; Bingol, H.; Barkauskas, J.; Ersoz, M.; Ramanavicius, A. Amperometric glucose biosensor based on glucose oxidase, 1,10-phenanthroline-5,6-dione and carbon nanotubes. J. Electrochem. Soc. 2014, 161, H3064–H3069. [Google Scholar] [CrossRef]

- Krikstolaityte, V.; Oztekin, Y.; Kuliesius, J.; Ramanaviciene, A.; Yazicigil, Z.; Mustafa, E.; Okumus, A.; Kausaite-Minkstimiene, A.; Kilic, Z.; Solak, A.O.; et al. Biofuel cell based on anode and cathode modified by glucose oxidase. Electroanalysis 2013, 25, 2677–2683. [Google Scholar] [CrossRef]

- Gao, Z.D.; Qu, Y.; Li, T.; Shrestha, N.K.; Song, Y.-Y. Development of amperometric glucose biosensor based on prussian blue functionlized TiO2 nanotube arrays. Sci. Rep. 2014, 4, 6891. [Google Scholar] [CrossRef]

- Lin, K.-C.; Yang, C.-Y.; Chen, S.-M.; Zhao, D.-H.; Hou, Y.-S. An interference study with different working potentials for an amperometric glucose sensor. Int. J. Electrochem. Sci. 2015, 10, 2755–2763. [Google Scholar] [CrossRef]

- Kausaite-Minkstimiene, A.; Glumbokaite, L.; Ramanaviciene, A.; Dauksaite, E.; Ramanavicius, A. An amperometric glucose biosensor based on poly(pyrrole-2-carboxylic acid)/glucose oxidase biocomposite. Electroanalysis 2018, 30, 1642–1652. [Google Scholar] [CrossRef]

- Jia, W.-Z.; Wang, K.; Xia, X.-H. Elimination of electrochemical interferences in glucose biosensors. TrAC Trends Anal. Chem. 2010, 29, 306–318. [Google Scholar] [CrossRef]

- Kulkarni, T.; Slaughter, G. Characteristics of two self-powered glucose biosensors. IEEE Sens. J. 2017, 17, 3607–3612. [Google Scholar] [CrossRef]

- Bhalla, N.; Jolly, P.; Formisano, N.; Estrela, P. Introduction to biosensors. Essays Biochem. 2016, 60, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Milton, R.D.; Giroud, F.; Thumser, A.E.; Minteer, S.D.; Slade, R.C.T. Bilirubin oxidase bioelectrocatalytic cathodes: The impact of hydrogen peroxide. Chem. Commun. 2014, 50, 94–96. [Google Scholar] [CrossRef] [PubMed]

| Biocathode | Bioanode | Linear Range, mM | LOD, mM | LQD, mM | Stability, % from the Initial | Ref. |

|---|---|---|---|---|---|---|

| GRE/PB-PPCA/PPCA–GOx | GRE/PPD/(AuNPs) PPCA–GOx | 0.15−124.0 | 0.07 | 0.23 | 90.35% after 35 days | this work |

| PGE/SWCNT/PBSE/BOx | PGE/SWCNT/PBSE/PQQ-GDH | up to 1.0 | 0.084 | 0.25 | 94% after 12 days | [39] |

| Cu | ITO/PB/GOx | 0.10−1.20 | 14.34 × 10−3 | − | >61% after 25 days | [40] |

| BP/PBA/CoPc/GOx | BP/PBA/MnO2 | 0.5−8.0 | 4.69 × 10−3 | − | >82% after 31 days | [41] |

| ITO/MWCNTs/GOx | ITO/MWCNTs/Lac | up to 4.0 | − | − | − | [42] |

| SPE/PBSE/BOx | SPE/Os/PQQ-GDH | 0.1−0.6 | − | − | 7 days | [24] |

| BP/PBSE/BOx | BP/PBSE/PQQ-GDH | 2.78–11.11 | 2.31 | − | − | [22] |

| GCE/MWCNTs/ PBSE/HRP/GOx | GCE/rGO/poly(TBO)/NAD-GDH | 0.1–0.7 | − | − | − | [25] |

| BC/c-MWCNTs/AuNPs/Lac | BC/c-MWCNTs/AuNPs/GOx | 0–50 | 2.87 × 10−3 | − | 60% after 30 days | [43] |

| Au/MWCNTs/Ptplate | Au/MWCNTs/PdNPs-PABA-GOx/CS | 0.002–4.5 | 0.1 × 10−3 | − | 78.9% after 30 days | [44] |

| SPE/NiC/Nf | SPE/GOx/CS | 1–5 | − | − | − | [45] |

| Au/hPG/BOx | Au/hPG/OsPVI/PEGDGE/GOx | 0.05−1.0 | 0.05 | − | 90% after 20 days | [46] |

| Study | ΔI, µA | Average of ΔI, µA | STDEV | RSD, % (N = 5) |

|---|---|---|---|---|

| Reproducibility | 1.40 | 1.25 | 0.10 | 7.71 |

| 1.21 | ||||

| 1.27 | ||||

| 1.20 | ||||

| 1.15 | ||||

| Repeatability | 1.40 | 1.33 | 0.06 | 4.45 |

| 1.39 | ||||

| 1.27 | ||||

| 1.29 | ||||

| 1.31 |

| Added Glucose, mM | Detected Glucose, mM | Recovery, % | Average, % | RSD, % (N = 3) |

|---|---|---|---|---|

| 0.40 | 0.42 | 105.00 | 103.33 | 5.04 |

| 0.40 | 0.43 | 107.50 | ||

| 0.40 | 0.39 | 97.50 | ||

| 0.80 | 0.79 | 98.75 | 99.58 | 3.83 |

| 0.80 | 0.77 | 96.25 | ||

| 0.80 | 0.83 | 103.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausaite-Minkstimiene, A.; Kaminskas, A.; Gayda, G.; Ramanaviciene, A. Towards a Self-Powered Amperometric Glucose Biosensor Based on a Single-Enzyme Biofuel Cell. Biosensors 2024, 14, 138. https://doi.org/10.3390/bios14030138

Kausaite-Minkstimiene A, Kaminskas A, Gayda G, Ramanaviciene A. Towards a Self-Powered Amperometric Glucose Biosensor Based on a Single-Enzyme Biofuel Cell. Biosensors. 2024; 14(3):138. https://doi.org/10.3390/bios14030138

Chicago/Turabian StyleKausaite-Minkstimiene, Asta, Algimantas Kaminskas, Galina Gayda, and Almira Ramanaviciene. 2024. "Towards a Self-Powered Amperometric Glucose Biosensor Based on a Single-Enzyme Biofuel Cell" Biosensors 14, no. 3: 138. https://doi.org/10.3390/bios14030138