Weathering of Two Anti-Graffiti Protective Coatings on Concrete Paving Slabs

Abstract

:1. Introduction

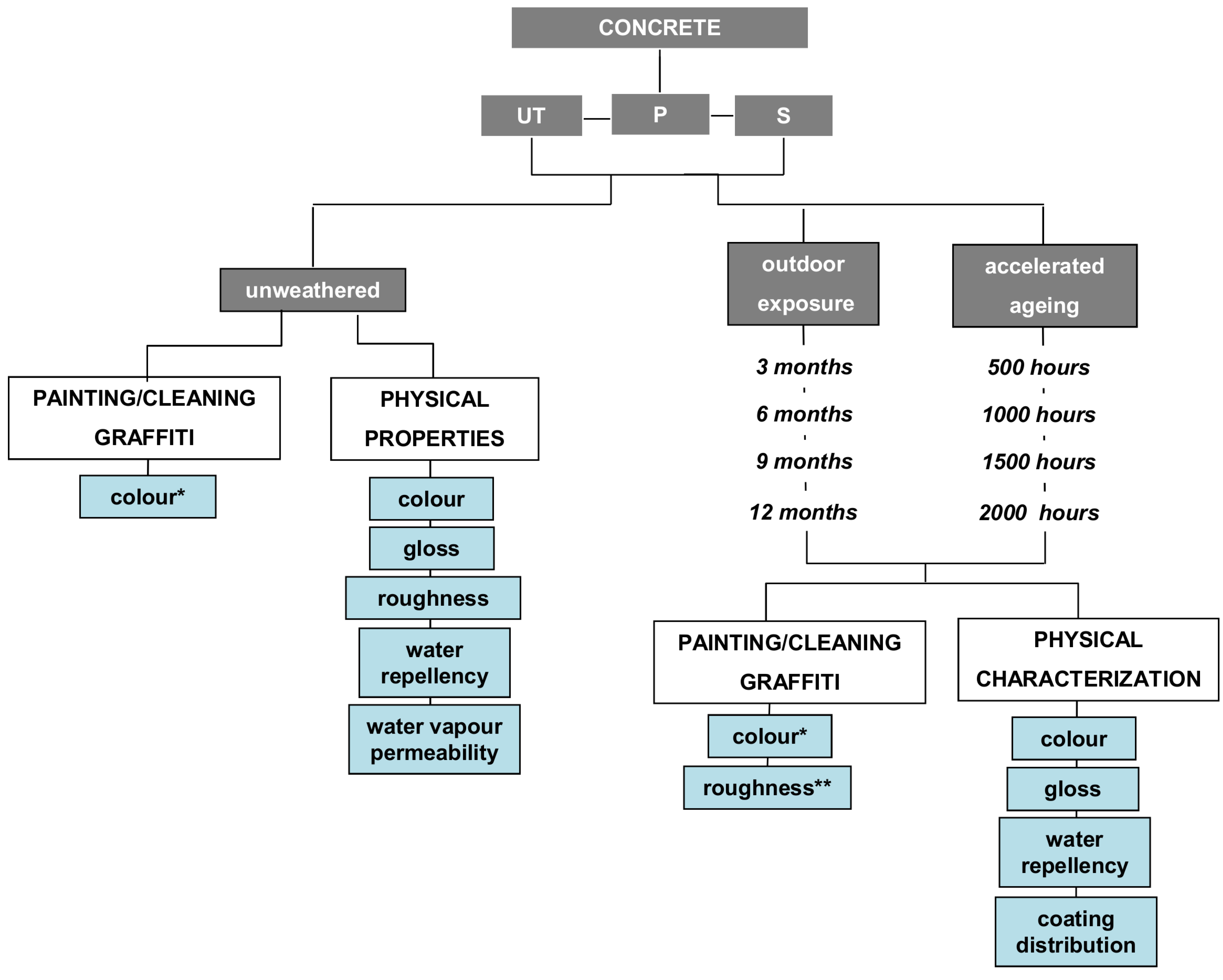

2. Materials and Methods

2.1. Application of Anti-Graffiti Coatings

2.2. Ageing Trials

2.3. Painting and Cleaning Graffiti

2.4. Characterization of the Physical Properties

3. Results and Discussion

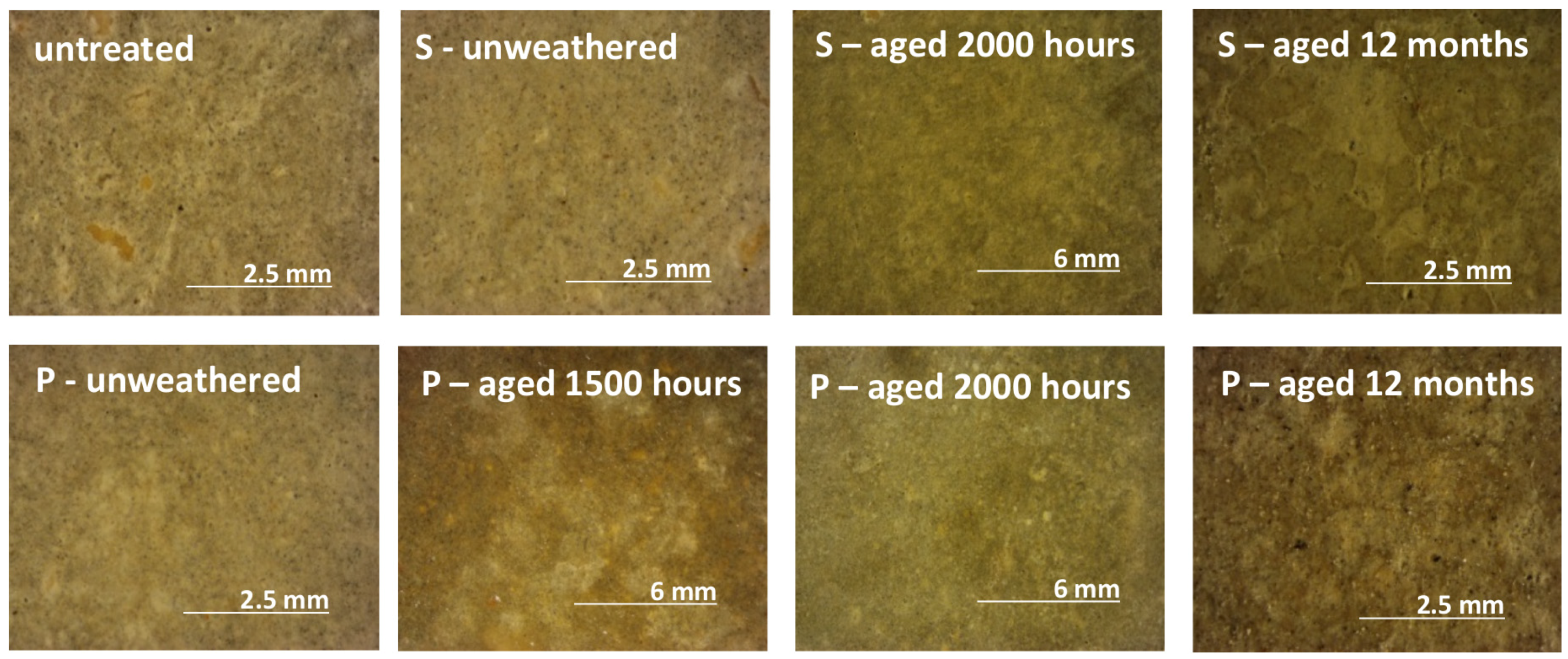

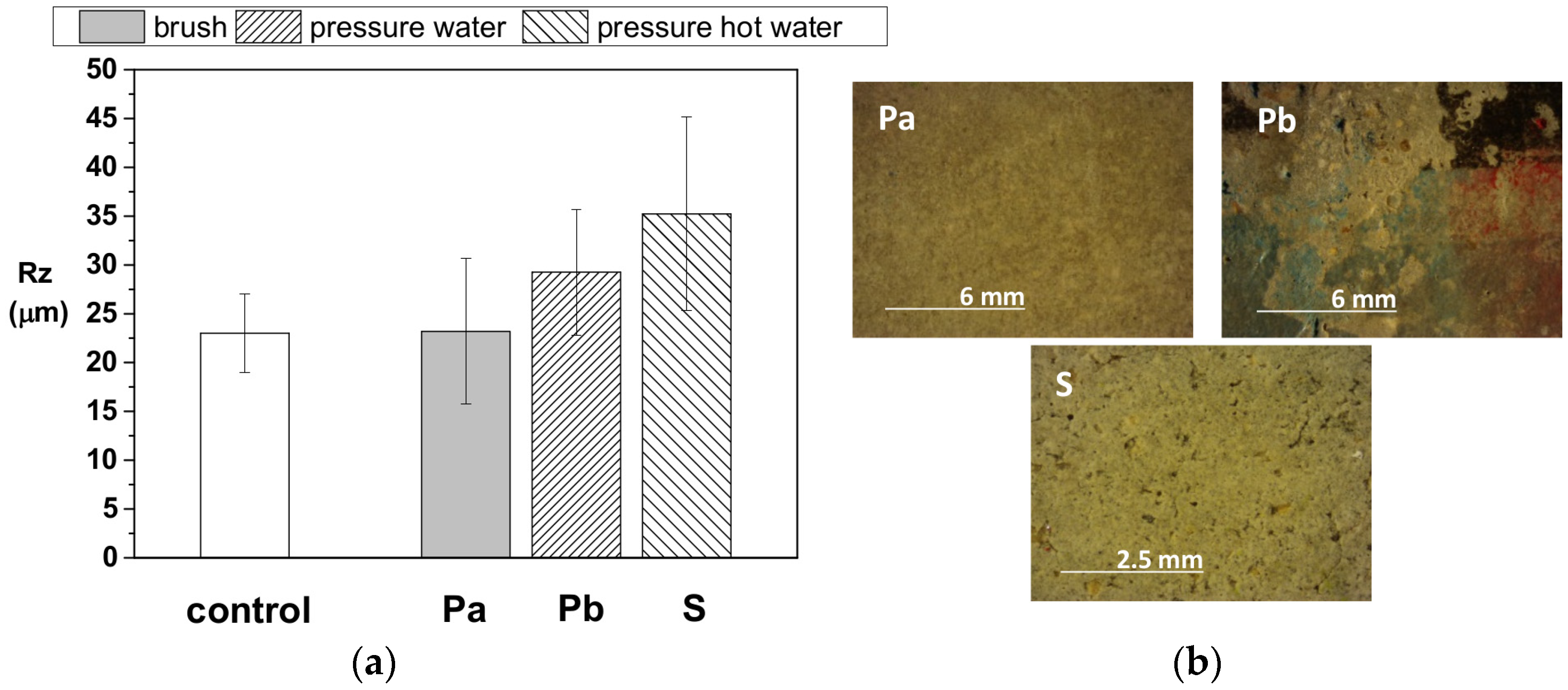

3.1. Characterization of the Surface Properties of Concrete

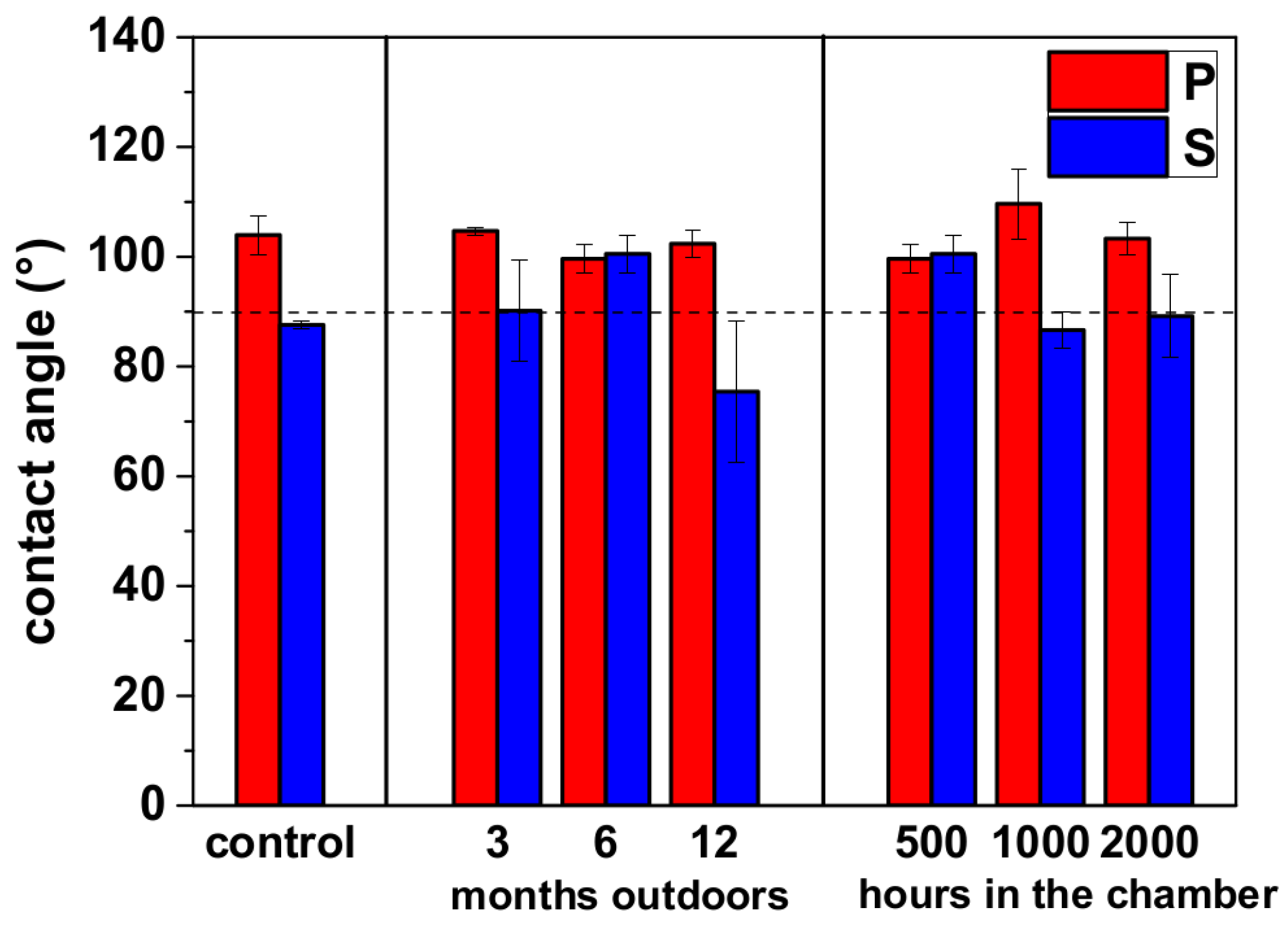

3.2. Ageing of the Anti-Graffiti Coatings

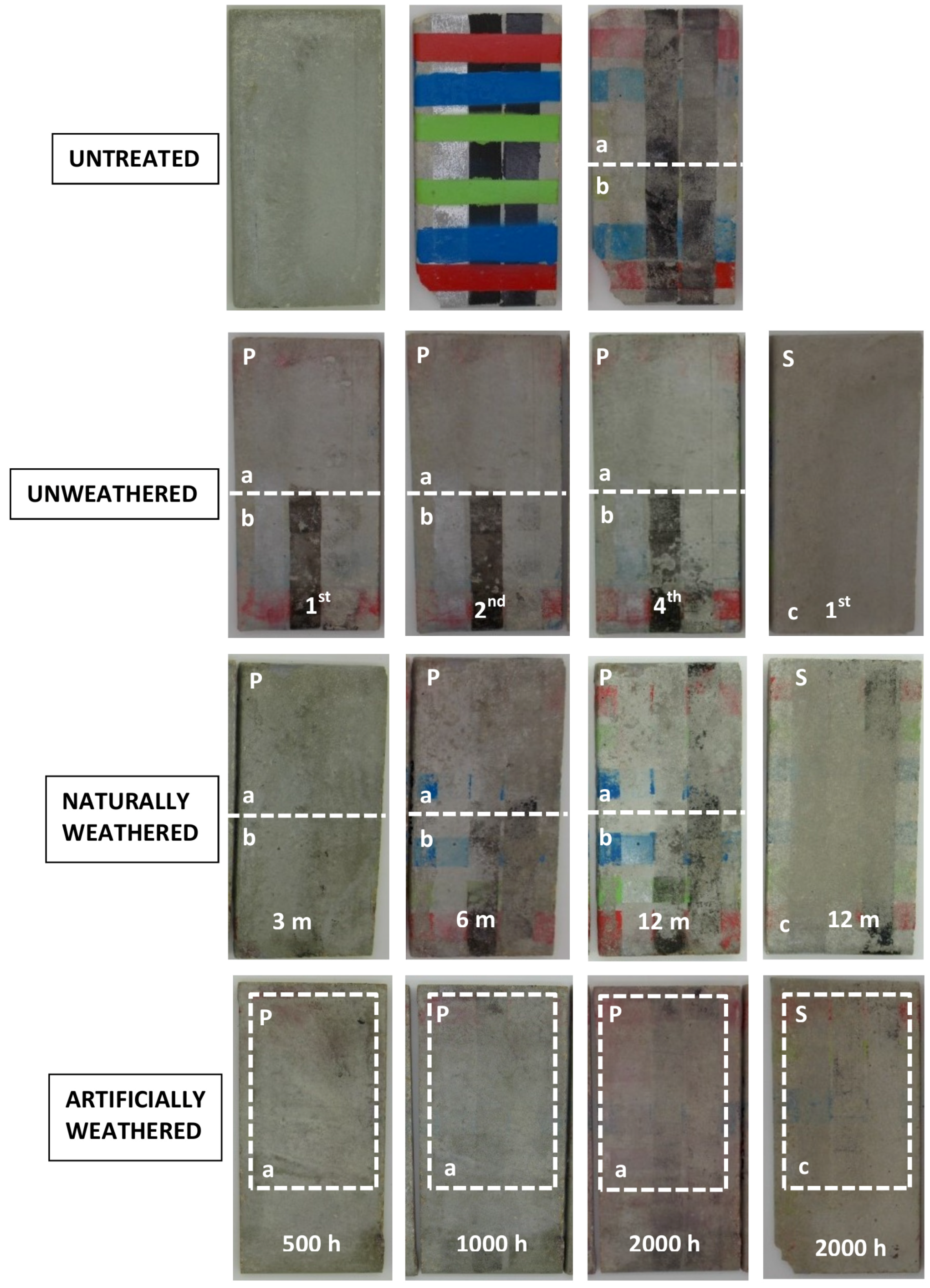

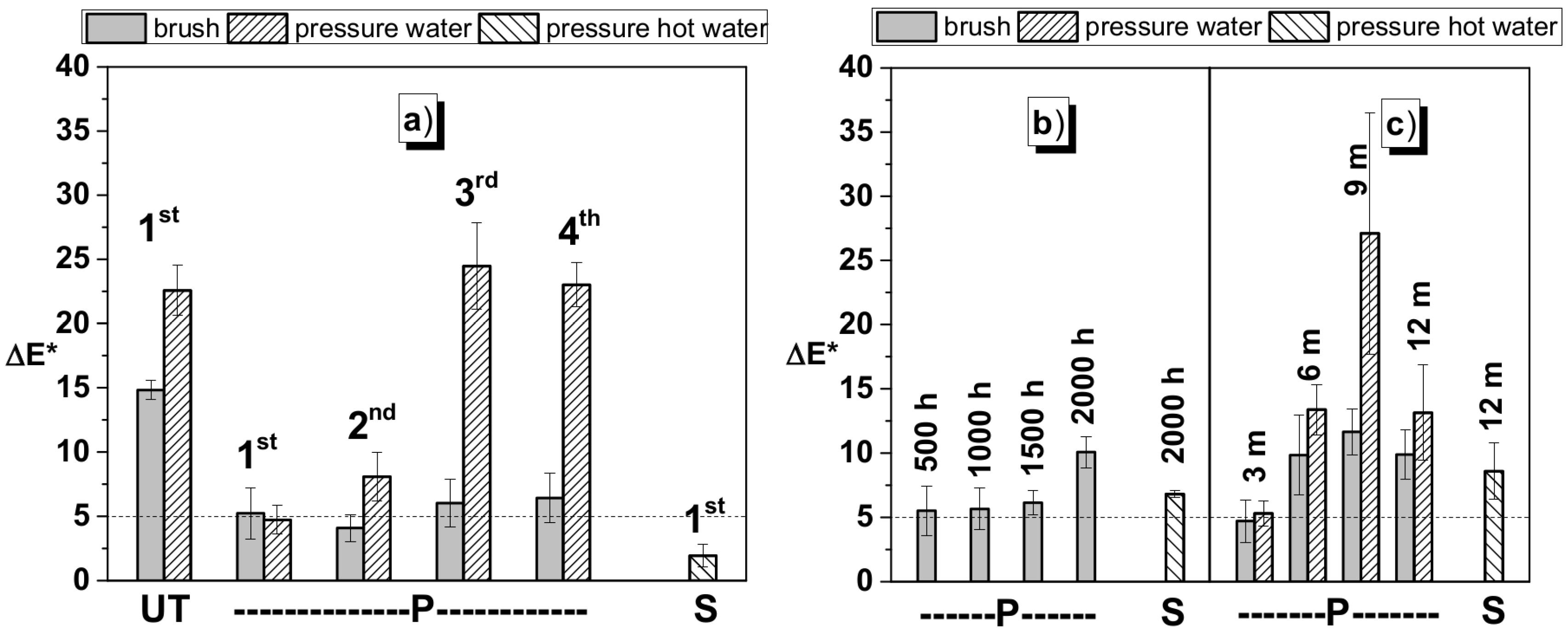

3.3. Graffiti Removal

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kramer, R. Moral Panics and Urban Growth Machines: Official Reactions to Graffiti in New York City, 1990–2005. Qual. Sociol. 2010, 33, 297–311. [Google Scholar] [CrossRef]

- Carmona-Quiroga, P.M.; Martínez-Ramírez, S.; Sobrados, I.; Blanco-Varela, M.T. Interaction between two anti-graffiti treatments and cement mortar (paste). Cem. Concr. Res. 2010, 40, 723–727. [Google Scholar] [CrossRef]

- Carmona-Quiroga, P.M.; Martínez-Ramírez, S.; Sánchez-Cortés, S.; Oujja, M.; Castillejo, M.; Blanco-Varela, M.T. Effectiveness of antigraffiti treatments in connection with penetration depth determined by different techniques. J. Cult. Heritage 2010, 11, 297–303. [Google Scholar] [CrossRef]

- Neto, E.; Magina, S.; Camões, A.; Begonha, A.; Evtuguin, D.V.; Cachim, P. Characterization of concrete surface in relation to graffiti protection coatings. Constr. Build. Mater. 2016, 102, 435–444. [Google Scholar] [CrossRef]

- Malaga, K.; Mueller, U. Relevance of hydrophobic and oleophobic properties of antigraffiti systems on their cleaning efficiency on concrete and stone surfaces. J. Mater. Civ. Eng. 2013, 25, 755–762. [Google Scholar] [CrossRef]

- Mueller, U.; Malaga, K. Study on the Application of Anti-Graffiti Systems on Natural Stones and Concrete. In Hydrophobe VI: Water Repellent Treatment of Building Materials, Proceedings of the 6th International Conference on Water Repellent Treatment of Building Materials, Rome, Italy, 12–13 May 2011; Borrelli, E., Fassina, V., Eds.; Aedificatio Publishers: Freiburg, Germany, 2011; pp. 1–13. [Google Scholar]

- Rossi, S.; Fedel, M.; Petrolli, S.; Deflorian, F. Behaviour of different removers on permanent anti-graffiti organic coatings. J. Build. Eng. 2016, 5, 104–113. [Google Scholar] [CrossRef]

- Jacques, L.F.E. Accelerated and outdoor/natural exposure testing of coatings. Prog. Polym. Sci. 2000, 25, 1337–1362. [Google Scholar] [CrossRef]

- Rabea, A.M.; Mirabedini, S.M.; Mohseni, M. Investigating the surface properties of polyurethane based anti-graffiti coatings against UV exposure. J. Appl. Polym. Sci. 2012, 124, 3082–3091. [Google Scholar] [CrossRef]

- Rabea, A.M.; Mohseni, M.; Mirabedini, S.M.; Tabatabaei, M.H. Surface analysis and anti-graffiti behavior of a weathered polyurethane-based coating embedded with hydrophobic nano silica. Apply Surf. Sci. 2012, 258, 4391–4396. [Google Scholar] [CrossRef]

- Goidanich, S.; Toniolo, L.; Jafarzadeh, S.; Wallinder, I.O. Effects of wax-based anti-graffiti on copper patina composition and dissolution during four years of outdoor urban exposure. J. Cult. Heritage 2010, 11, 288–296. [Google Scholar] [CrossRef]

- Deflorian, F.; Rossi, S.; Fedrizzi, L.; Zanella, C. Comparison of organic coating accelerated tests and natural weathering considering meteorological data. Prog. Org. Coat. 2007, 59, 244–250. [Google Scholar] [CrossRef]

- ISO 16474–3 Paints and Varnishes—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps; International Organization for Standardization (ISO): Geneva, Switzerland, 2013.

- The PVGIS Solar Radiation Database; Institute for Energy and Transport (IET), Joint Research Centre, European Commission: Ispra, Italy, 2012.

- EN 1015–19 Methods of Test for Mortar for Masonry. Determination of Water Vapour Permeability of Hardened Rendering and Plastering Mortars; European Committee for Standardization: Brussels, Belgium, 1999.

- ISO 4287 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; International Organization for Standardization (ISO): Geneva, Switzerland, 1999.

- Gagné, L. Evaluation of Two Sacrificial Anti-Graffiti Polysaccharide Coatings for the Conservation of Outdoor Contemporary Murals. Ph.D. Thesis, Queen’s University, Kingston, ON, Canada, 2014. [Google Scholar]

- Maxová, I.; Slesinger, R.; Kubová, O. Test of some antigraffiti systems for preservation of sandstone monuments. In Safeguarded Cultural Heritage: Understanding & Viability for the Enlarged Europe, Proceedings of the 7th European Conference “SAUVEUR”, Prague, Czech Republic, 31 May–3 June 2006; Drdácký, M., Chapuis, M., Eds.; ITAM: Prague, Czech Republic, 2006; Volume 2, pp. 831–833. [Google Scholar]

- García, O.; Rz-Maribona, I.; Gardei, A.; Riedl, M.; Vanhellemont, Y.; Santarelli, M.L.; Suput, J.S. Comparative study of the variation of the hydric properties and aspect of natural stone and brick after the application of 4 types of anti-graffiti. Mater. Constr. 2010, 60, 69–82. [Google Scholar] [CrossRef]

- García, O.; Malaga, K. Definition of the procedure to determine the suitability and durability of an anti-graffiti product for application on cultural heritage porous materials. J. Cult. Heritage 2012, 13, 77–82. [Google Scholar] [CrossRef]

- TL AGS-Beton. Technische Lieferbedingungen für Anti-Graffiti-Systeme auf Beton; Federal Highway Research Institute (BASt): Bergisch Gladbach, Germany, 2012. (In German) [Google Scholar]

- Yang, X.F.; Tallman, D.E.; Bierwagen, G.P.; Croll, S.G.; Rohlik, S. Blistering and degradation of polyurethane coatings under different accelerated weathering tests. Polym. Degrad. Stab. 2002, 77, 103–109. [Google Scholar] [CrossRef]

- García Mercero, O. Design and Study of the Behaviour of a New Antigraffiti Concept Specific for Its Application in Cultural Heritage. Ph.D. Thesis, Universidad del País Vasco, Bilbao, Spain, 2008. [Google Scholar]

- Urquhart, D. The Treatment of Graffiti on Historic Surfaces; Technical Advice Note 18; Historic Scotland: Edinburgh, UK, 1999.

| Weather Conditions | Apr.–Jul. 2015 | Aug.–Nov. 2015 | Nov. 2015–Feb. 2016 | Feb.–May 2016 | Total |

|---|---|---|---|---|---|

| Sun (h) | 653 | 305 | 178 | 490 | 1626 |

| Rain (mm) | 105 | 160 | 215 | 196 | 676 |

| Warmest daily mean air temperature (°C) | 24.7 | 22.05 | 13.7 | 18.25 | 24.7 |

| Coolest daily mean air temperature (°C) | 6.2 | 7.25 | –0.25 | 2 | –0.25 |

| Surface Parameters | UT | P | S |

|---|---|---|---|

| L* | 68.54 (1.68) | 67.06 (0.38) | 70.21 (0.32) |

| a* | 0.13 (0.08) | 0.17 (0.11) | 0.27 (0.02) |

| b* | 7.71 (0.40) | 8.31 (0.44) | 9.26 (0.45) |

| ΔE* | – | 1.78 (0.33) | 1.91 (0.36) |

| Gloss at 85° | 4.02 (1.53) | 8.28 (3.83) | 17.46 (2.57) |

| Rz (µm) | 23 (4) | 21 (4) | 18 (3) |

| contact angle (°) | 18.3 (7.6) | 104 (3.5) | 87.6 (0.7) |

| δ × 10−12 (kg/m·s·Pa) | 2.62 (0.21) | 2.65 (0.79) | 3.12 (0.94) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carmona-Quiroga, P.M.; Jacobs, R.M.J.; Viles, H.A. Weathering of Two Anti-Graffiti Protective Coatings on Concrete Paving Slabs. Coatings 2017, 7, 1. https://doi.org/10.3390/coatings7010001

Carmona-Quiroga PM, Jacobs RMJ, Viles HA. Weathering of Two Anti-Graffiti Protective Coatings on Concrete Paving Slabs. Coatings. 2017; 7(1):1. https://doi.org/10.3390/coatings7010001

Chicago/Turabian StyleCarmona-Quiroga, Paula M., Robert M. J. Jacobs, and Heather A. Viles. 2017. "Weathering of Two Anti-Graffiti Protective Coatings on Concrete Paving Slabs" Coatings 7, no. 1: 1. https://doi.org/10.3390/coatings7010001