2.2. Statistical Analysis of Distress Distribution in an Urban Road Network

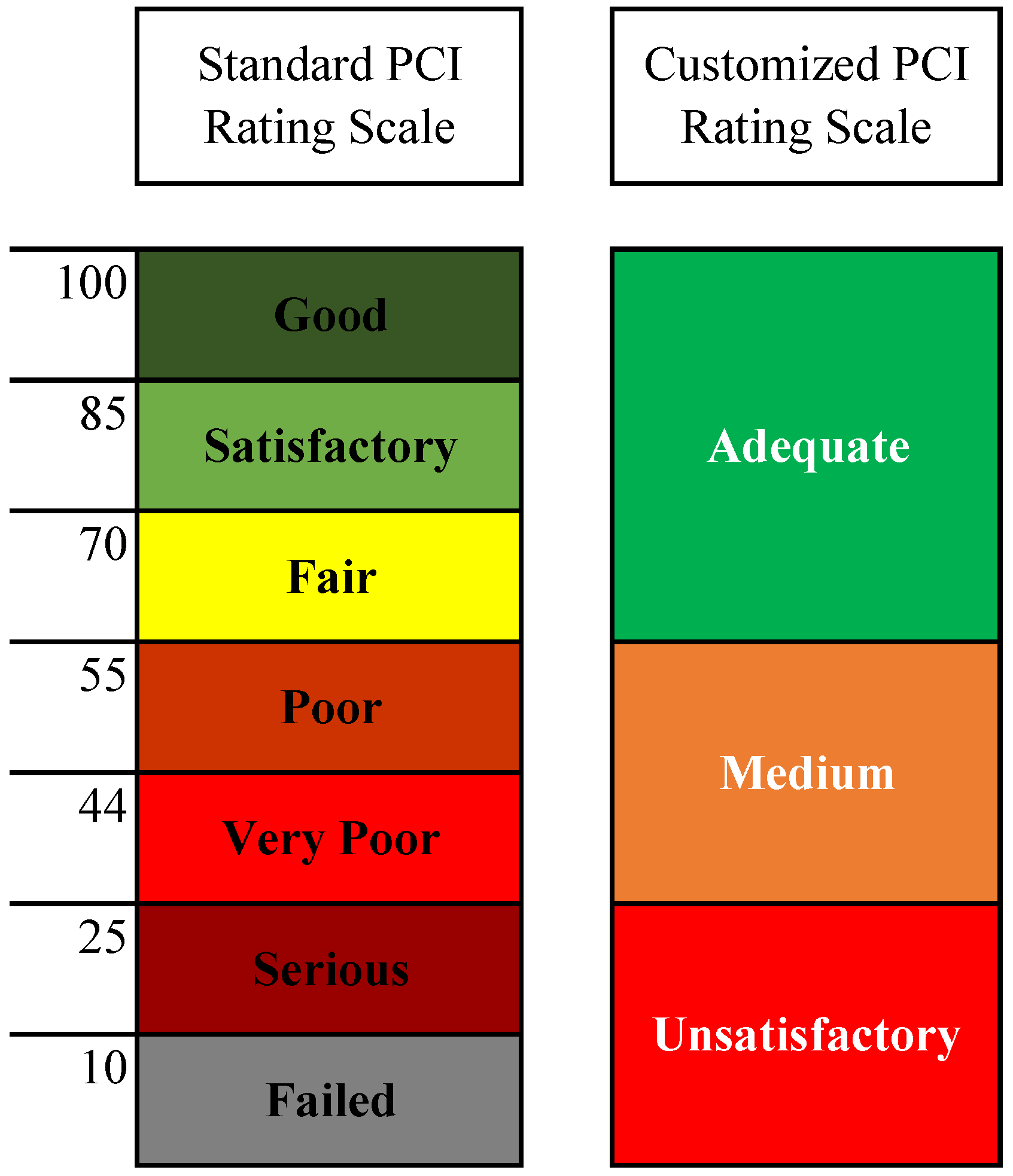

The PCI methodology is a rating system that measures the pavement integrity and surface operational condition based on a numerical scale (

Figure 2). According to this methodology, the pavement network is divided into branches, sections and sample units [

15]. Pavement surveys are performed in sample units. It is an accurate, consistent, systematic and repeatable rating method based on a visual survey to assess pavement surface distresses by the identification of the type, severity and density of each distress.

The ASTM D6433 defines 20 distress types for AC pavement (

Table 1). Each combination of distress density, distress severity and distress type has an associated deduct value as a weighting factor that indicates the influence of each combination on the pavement condition. The ASTM D6433 Distress Identification manual provides guidelines to pavement inspectors to correctly identify each distress type and severity. Each deduct value is determined by using available master curves provided in the Distress Identification Catalogue documented in the ASTM D6433 Appendix X3 [

16].

In the context of a previous case study [

36,

37] aimed to implement a Pavement Management System (PMS) for urban areas considering the Vehicle Operating Costs (VOC), an Italian urban road network was inspected using visual surveys. The pavement distress data were assessed manually by two inspectors with simple tools (a hand odometer wheel and a straightedge). The evaluators were able to inspect the entire Network 1 for a low cost, in a short period of time (a total of two weeks) without high economic commitments, and with minimal road interruptions.

The inspected urban road network (total area of 33,190 m2) was divided into branches and sections according to the definition of the ASTM D6433. A total of 58 Sample Units (SU) at the network level and 127 SU at the project level was inspected. A total sample of 109 AC SU (25,711 m2) was considered in this study, excluding the parking lot areas and those SU related to particular types of pavements (low traffic, pedestrian roads, etc.). This sampling is considered as representative of an Italian road network including SU with different construction dates and characteristics.

To accomplish the objectives of this paper, some statistical analyses were performed within the same sample to determine the distress frequency classified according to ASTM D6433.

The distress density and associated deduct values of each distress type were summed for the entire sample. Distress types were grouped into distinct categories separating those that have a low distress density, those that cannot be grouped with other distresses and those with high density. The results are reported in

Table 2.

As observed, there are 7 distresses whose density quantities associated in the inspected urban road network has a very low frequency value (1%); other distresses can be grouped under two different categories by their similar characteristics (4 distresses into category Cracking and 3 distresses into category Surface deformations). Moreover, there are some distress types that cannot be considered under the same group due to their characteristics or due to frequencies or total deduct values that are very high (Raveling, Alligator cracking, Block cracking, Rutting, Patching and Utility Cut Patching and Potholes). This analysis highlights the influence of weight in the network pavement condition of certain defects that have reduced density values but a higher percentage of total deduct value as Potholes. This result agrees with the PCI methodology that assigns a greater weight with respect to other distresses. In another case, (i.e., rutting), the PCI methodology assigns a lower weight with respect to other distresses. However, this does not mean that this distress is less important with respect to other distresses. In fact, the distress rutting appears in the pavement at the end of the degradation process. The same happens for the distress alligator cracking: it appears in the pavement as the final stage of the degradation process.

Therefore, the rutting and the alligator cracking distresses are more likely to be found in pavement with low PCI value.

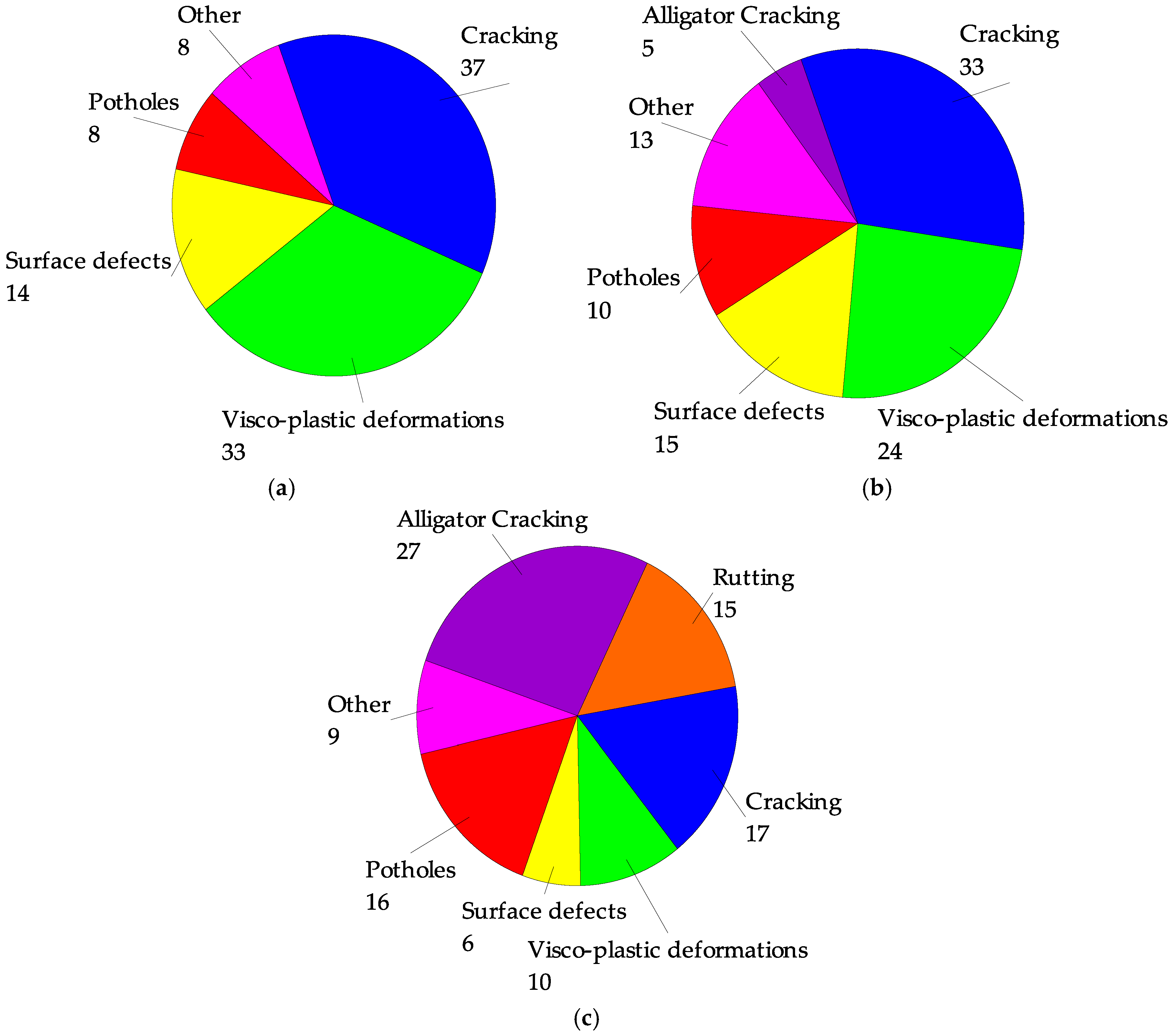

Those findings have been confirmed in other statistical analyses performed on the same network. Therefore, distress types had been grouped according to the 4 categories defined above (cracking, visco-elastic deformations, surface defects and others) plus the 3 individual distresses (rutting, potholes and alligator cracking).

Considering the results of the statistical analysis of these 7 distresses, grouping the value of the SU into one of three PCI categories (adequate, medium or unsatisfactory) it is possible to evaluate the global progressive degradation in all SU inspected.

In this way, deduct values associated with distress type, severity levels and quantities have been summed and classified under the same PCI category, see

Figure 3 and

Table 3.

When the PCI value is still high (adequate condition,

Figure 3a) the most frequent distresses that occur in the sections are

cracking,

visco-plastic deformations and

surface defects; accounting for 84% of total deduct value in SU. The distresses

rutting and

alligator cracking are still missing in the pavement, confirming our earlier assumption.

When the pavement degradation is medium (Medium Condition,

Figure 3c) the categories

Visco-plastic deformations,

Cracking,

Surface defects and

other are the most frequent distresses that occur in the sections; accounting for 85% of the total deduct value in the SU. Finally, the typical distresses associated with the last stages of the degradation progress (

potholes and

alligator cracking) begin to appear in some pavement sections. When the PCI value is very low (unsatisfactory condition,

Figure 3c) the most frequent distresses that occur in the sections are

rutting,

potholes and

alligator cracking. This account for 58% of total deduct value in the SU, along with other distresses from different stages of the degradation progress.

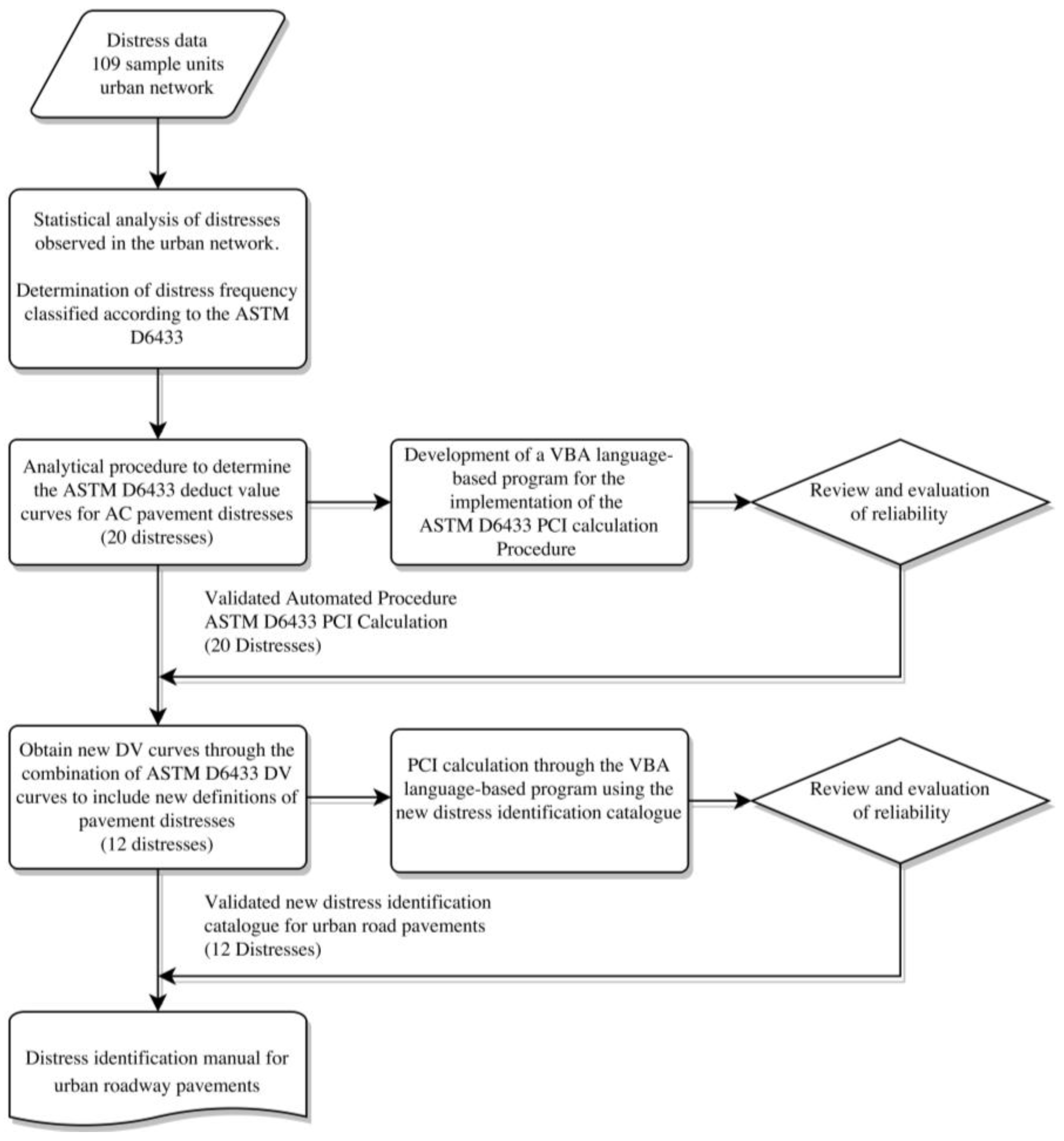

2.3. Computerization of ASTM D6433 Procedure

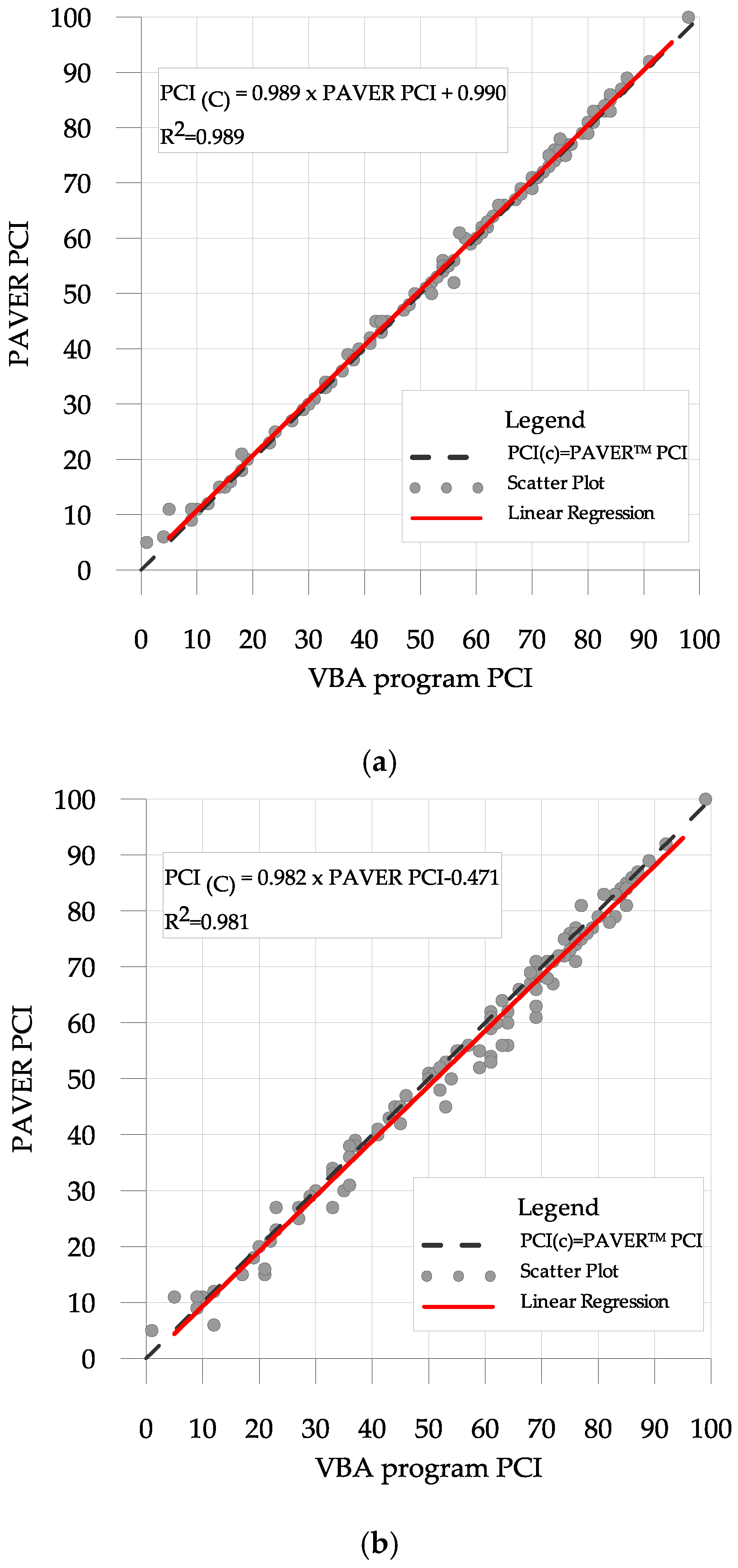

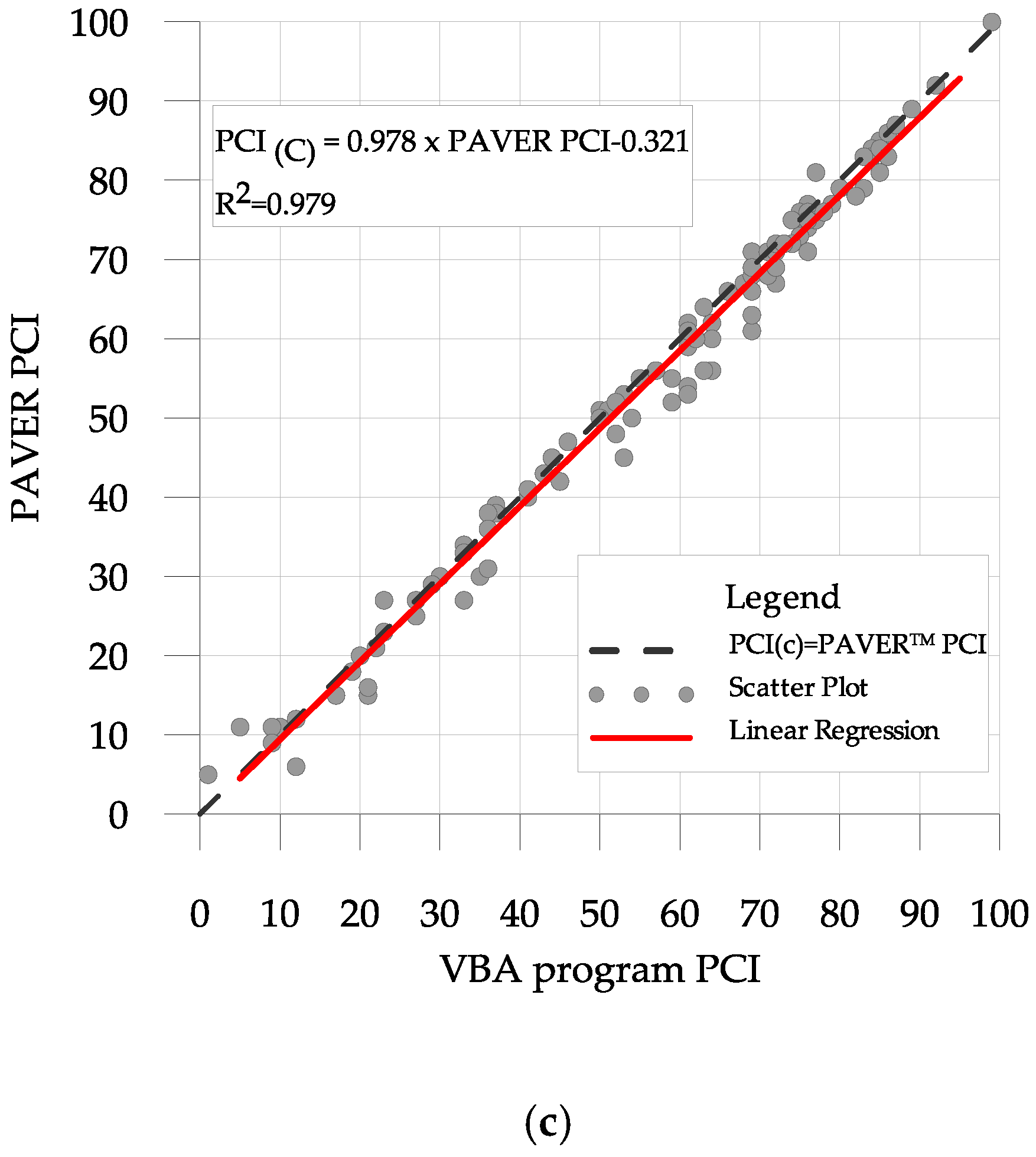

To accomplish the objective of this work, the PCI calculation standardized procedure (1) described in ASTM D6433 was implemented through a VBA language based program to calculate the PCI of each SU.

Figure 4 shows the main program window, which enables data entry for a given SU (distress, severity level and quantity), the deduct values and overall sample unit PCI is provided.

where: PCI = pavement condition index;

a = deduct weighting value depending on distress type

Ti, level of severity

Sj, and density of distress

Dij;

i = counter for distress types;

j = counter for severity levels;

p = total number of distress types of pavement type under consideration;

mi = number of severity levels on the

i-th type of distress; and

F(

t,

d) = an adjustment factor for distresses that varies with total summed deduct value

t and number of deducts

d.

It is necessary to use an adequate Distress Identification Catalogue reflecting the characteristics of pavement surveyed and a standardized procedure to make repeatable investigations for the entire network. To this end, some US highway agencies that apply PMS procedures have developed internal reference catalogues for pavement distress identification.

The PCI of each SU is calculated as described in Equation (1), by adding up the total quantity of each type distress, severity level from inspection data, and recording them in the “total severity”. The units for the quantities may be square meters, linear meters, or number of occurrences, depending on the distress type.

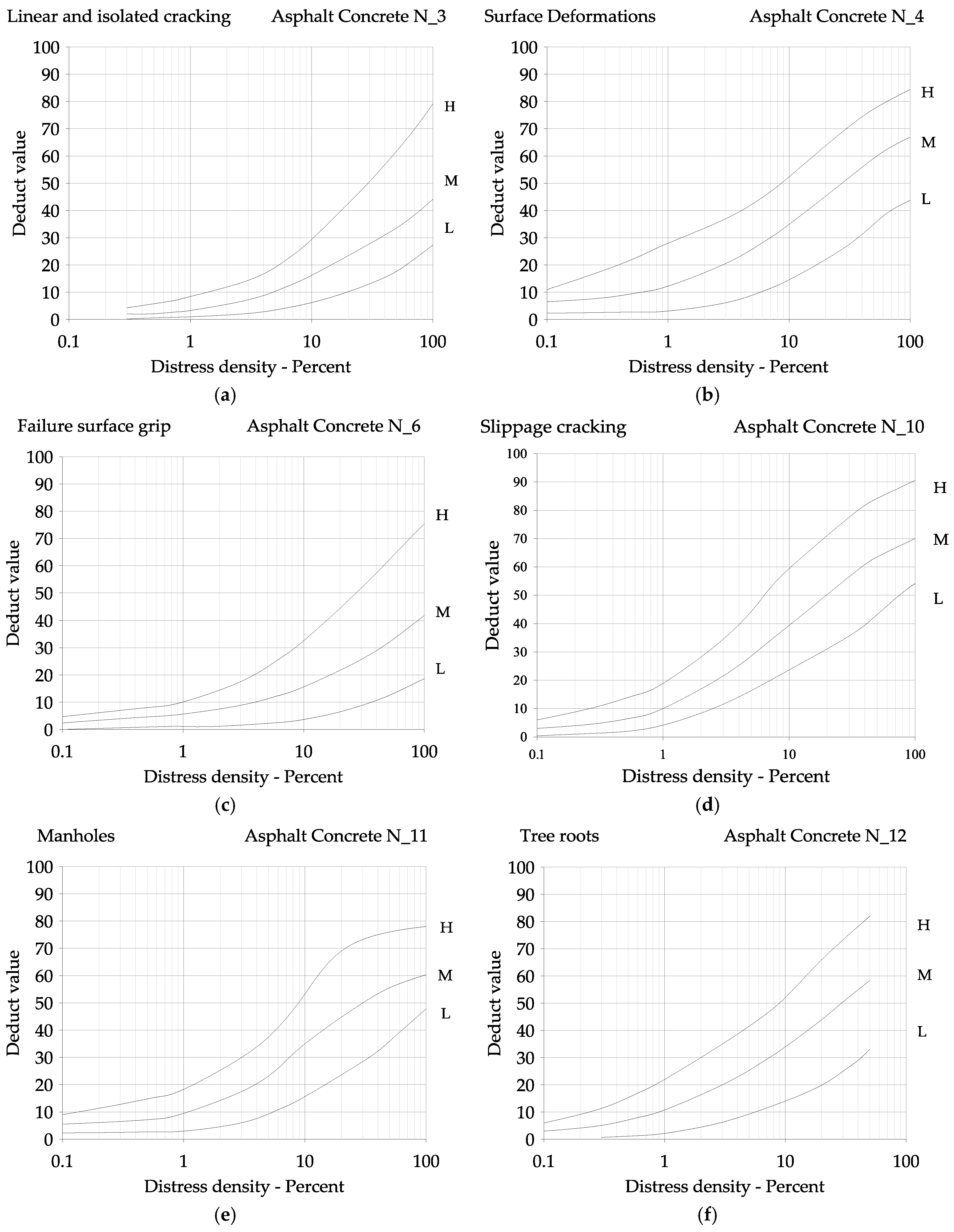

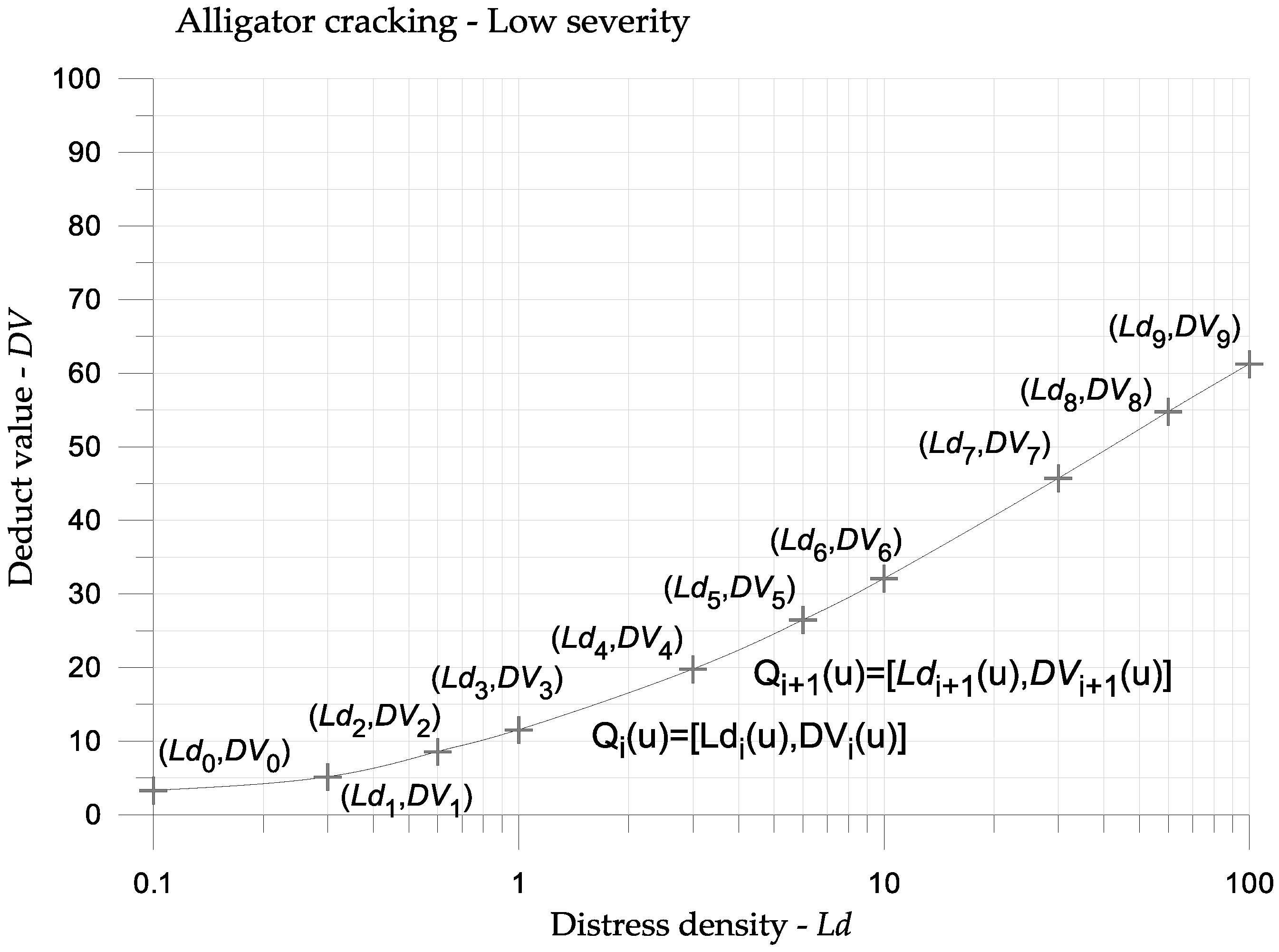

PCI calculation involves the determination of the Deduct value to weight each combination of type, severity and density of distress within each SU. Therefore, it was necessary to digitize each density/deduct value curve (master curves collected in ASTM D6433 on paper) to accurately determine the value of the deduct value in an Automated PCI calculation Procedure.

For each distress type (20 in total for AC pavement) and level of severity (generally (L) low, (M) medium and (H) high), an interpolation curve can be determined using a Hermite Polynomial Interpolating Curve. For each density/deduct value curve, the coordinates of 10 points

Qi were determined (log

10d

i =

Ldi: logarithm of density,

DVi: deduct value) from ASTM D6433 Appendix X3 [

16]. These points were used to obtain a smooth continuous function in which each piecewise polynomial is a parametric cubic spline specified in Hermite procedure (

Figure 5).

For each segment

Qi(

u) (

Ldi(

u),

DVi(

u)), between each pair of known data points, the parametric cubic polynomial expressions can be written as follows:

with

u ∈ [0,1] and

i = 0, 1, 2, … 9.

For 10 control points given in the plane (Ld, DV), interpolated by 9 cubic polynomial segments, 4 × 2 = 8 coefficients are needed to define each segment, therefore 8 × 9 = 72 coefficients should be determined (4 × 9 = 36 coefficients for each Ld(u) and DV(u) parametric function).

The available equations (for each Ld and DV variable) are the following:

2 × 10 = 20 equations for each polynomial segment passing through each pair of adjacent control points;

9 equations for first derivative continuity in contact points (C1 continuity);

9 equations for second derivative continuity in contact points (C2 continuity).

The total equation count is 4 × 10 − 2 = 38 (76 in total) while the needed equations are 4 × 10 = 40 (80 in total).

To obtain the other 2 equations (4 in total) it was necessary to set tangent and/or curvature values at the first and at the last control points, through first and/or second parametric derivative values. The system of equations can be expressed through control point coordinates, first and second derivatives of the 9 internal and the 2 external control points.

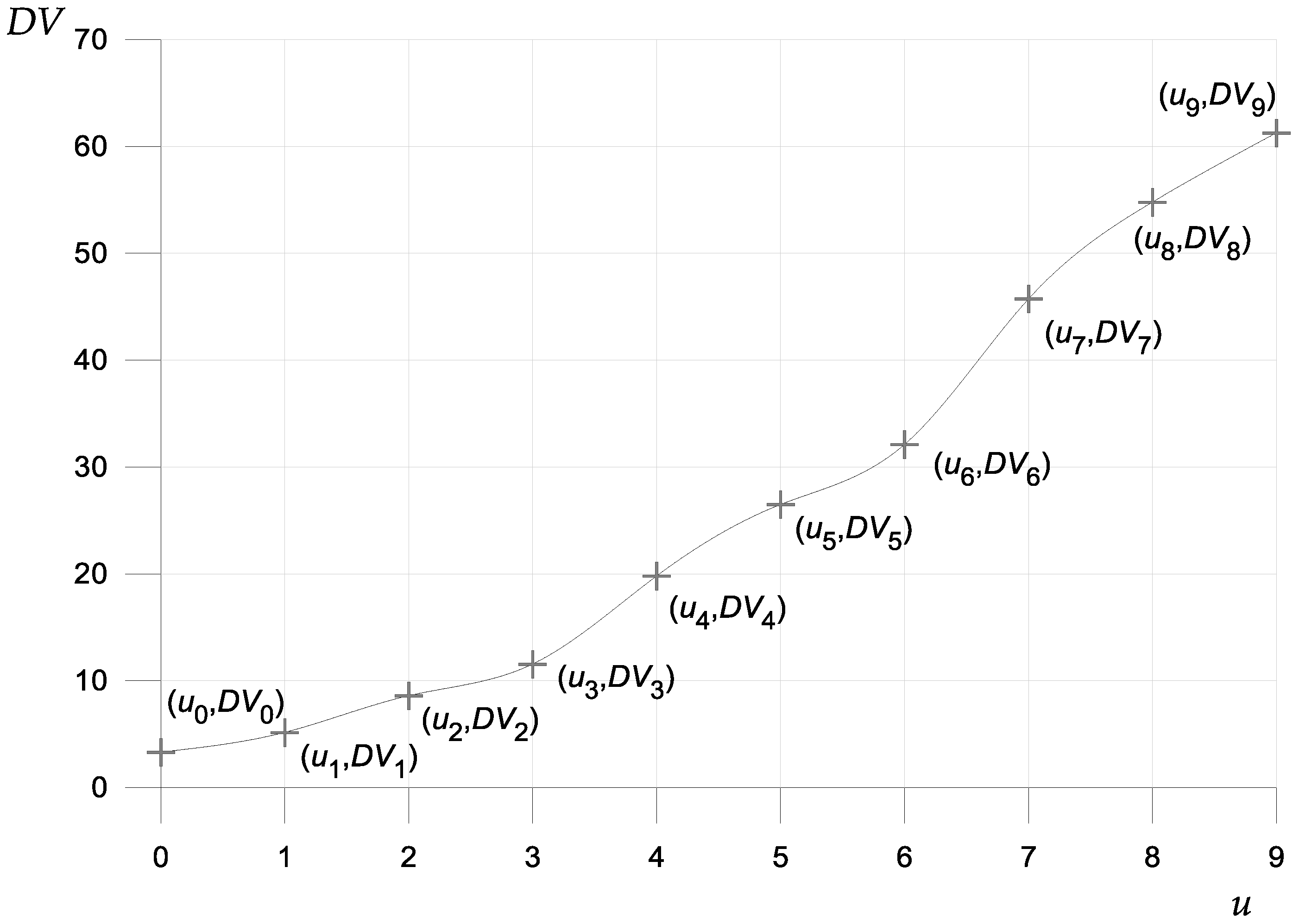

In this way, for the

i-th polynomial segment of each curve in the parametric plane (

u,

Ld or

u,

DV), see

Figure 6, the equations, for example, consider the variable

DV (the same for

Ld):

and the equations expressing the first derivative at the beginning (

Di−1) and at the end (

Di) of

i-th polynomial segments are:

In the Equations (3) and (4),

DVi−1,

DVi,

Di−1 and

Di are respectively the control points coordinates and the first derivative value (at the beginning and at the end of

i-th segment). From Equations (3) and (4) it is possible to obtain algebraic expressions of coefficients:

To obtain the C

2 continuity, it is necessary to impose the following second derivative conditions in the 9 internal control points (6):

with

i = 1, 2, …, 10; obtaining (7):

Then, substituting the algebraic expressions of coefficient (5) in (7) the expressions of second derivative of curve are obtained (8):

and simplifying (9):

If the second derivative at the endpoints is equal to zero, the “

natural” cubic spline is obtained. By imposing the second derivative condition at the first subdomain of the piecewise (

i = 0), Equation (10) is obtained:

Substitute the algebraic expression of coefficient (5) with (10), the following expression (11) is obtained and simplified (12):

Similarly, for the last subinterval of the piecewise (

i =

9):

The Equations (9), (12) and (13) can be collected in matrix form. The 10 unknowns are grouped in

D = [

D0,

D1, …,

D9] that can be calculated by inverting the tridiagonal matrix

H (and similarly for

Ld variable):

Knowing the coefficients of each segment of the curve (for all distress and for all levels of severity), it is possible to calculate, starting by a value of density, the corresponding value of deduct value and so on.

The next step is the calculation of maximum Corrected Deduct Value (CDV) that will be subtracted from 100 obtaining the PCI of the sample unit. The PCI within each section is calculated by averaging the PCI of each sample unit.

The whole algorithm was implemented writing a code in VBA (see

Figure 4) and capable of calculating the PCI of a section starting from its distress.

2.4. Definition of New Distress Identification Catalogue for Asphalt Concrete Pavements in Urban Areas

One of the objectives of this work is to achieve a simplified new distress identification catalogue for urban road AC pavements to assess the pavement condition in a PCI based scale. This section is intended to propose a simplified distresses catalogue comparing that one contained in ASTM D6433 considering the results of statistical analysis presented in this article (

Table 2 and

Table 3) on a representative sample of an urban pavement road network.

Although the list of distresses in ASTM D6433 appears complete and exhaustive, the use of such a catalogue for urban pavements could be difficult to apply for the road network operators and maintenance agencies have little incentive to adopt a PMS.

In addition, the use of ASTM D6433 catalogue has shown difficulties for some inspectors of urban pavements due to the widespread presence of pavements distresses that are not listed in ASTM D6433.

Specifically, Manholes and Tree roots. These distresses, before this proposal of integration, were associated with other distresses respectively as Patching and Swell. However, it was often very difficult to instruct the inspectors on the choice of the type of distress to be attributed, so much so that often these distresses were completely neglected during inspections.

For this reason, it was considered appropriate to drastically reduce the number of distresses (from 20 to 10 distresses) present in the catalogue for the calculation of the PCI and add the two missing distresses. These adjustments should be made in order to avoid distorting the PCI numerical significance in its rating scale that appears to be universally accepted.

Consequently, to upgrade the ASTM D6433 catalogue for application on Italian urban roads, some distress types collected in the ASTM Standard Guide and whose quantities are measured in the same unit of measurement and belonging to the same group are combined with each other to facilitate the inspection activity as indicated in

Table 4. Four new defects have been defined by combining others—N_3.

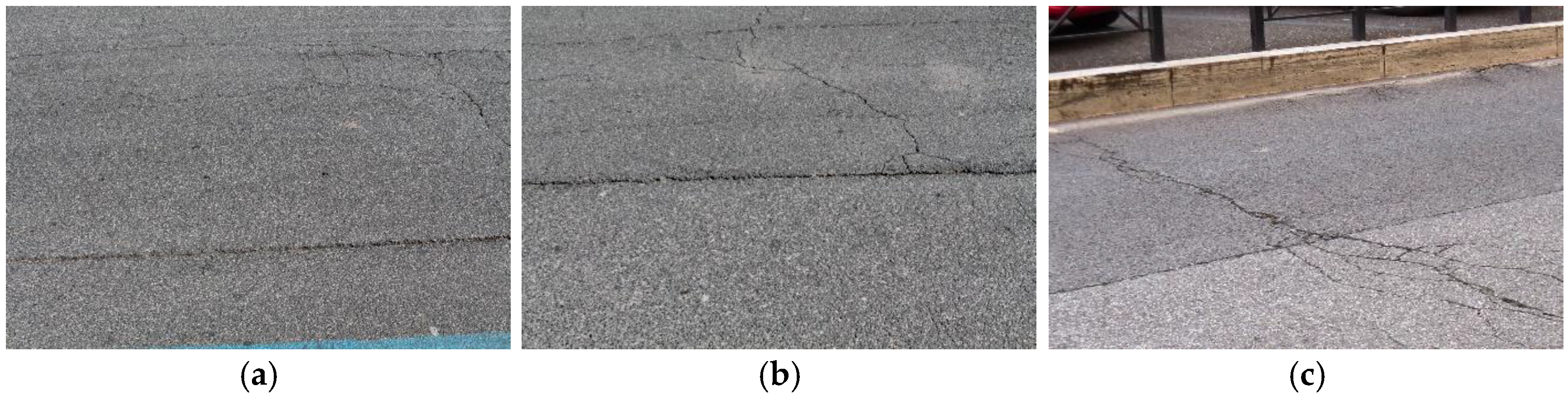

Linear and isolated cracking (

Figure A1), N_4.

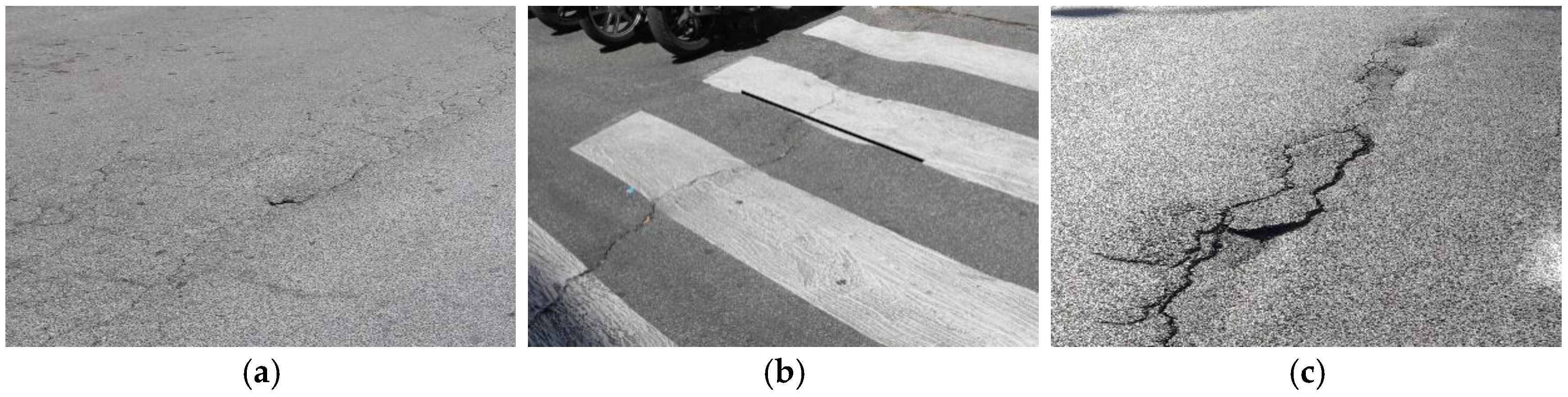

Surface deformations (

Figure A2), N_6.

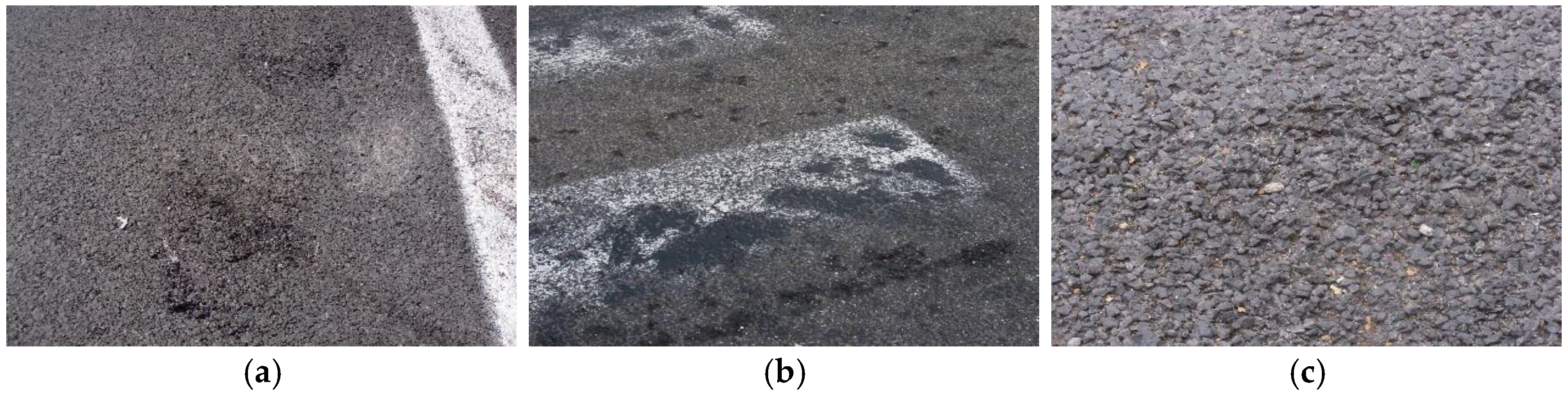

Failure surface grip (

Figure A3) and N_10.

Slippage cracking (

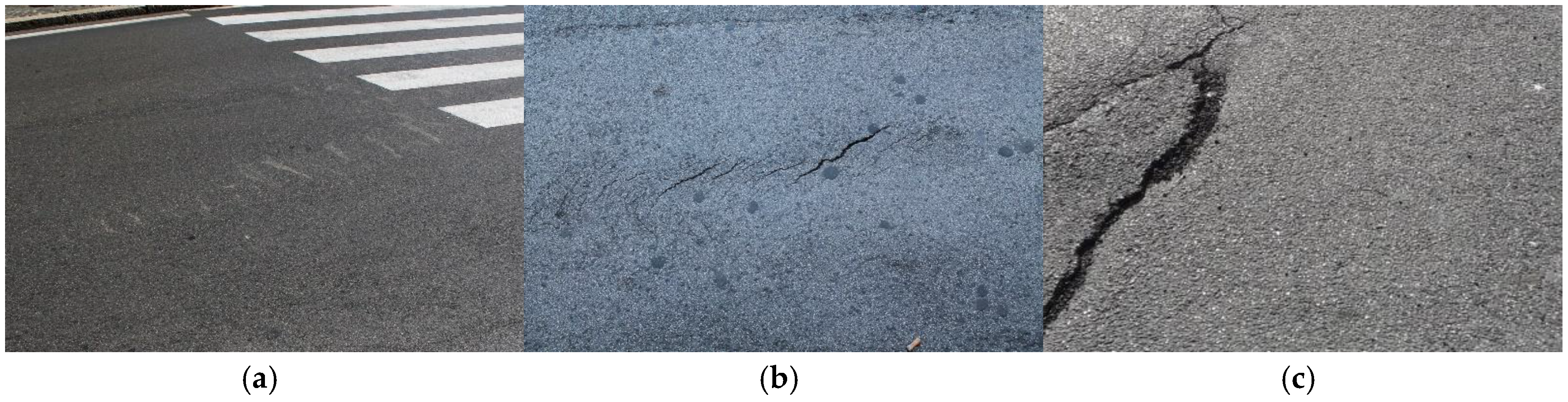

Figure A4); and two new distress types are defined—N_11.

Patching (

Figure A5) and N_12.

Tree Roots (

Figure A6); six distresses remain unchanged (N_1.

Alligator cracking, N_2.

Block cracking, N_5.

Rutting, N_7.

Potholes, N_8.

Patching and N_9.

Railroad crossing).

The proposed Distress Identification Catalogue is composed of 12 distress types, listed and classified in different groups. In the same way, the Distress Identification Catalogue defines for each distress type, (1) a description of the distress type; (2) a guide to determine the severity levels; (3) how to measure and count the distress type and severity; (4) representative photo (s) to help inspectors to identify the severity level of distress and; (5) the deduct value curve for each distress type.

The deduct value curve of new distresses is obtained as a combination of the ASTM D6433 deduct value curves of they are composed. The new deduct value curve was written as a continuous function using the Polynomial Interpolating Curve Hermite for the interpolating of ten pairs of values (density,

DV) obtained by averaging the ten pairs of values (density,

DV) of each deduct value curve that has to be combined (

Figure A7). These inspection guidelines for the new distress definitions for urban road pavements are defined in

Table 5 and

Appendix A.

The new distress type N_3. Linear and Isolated Cracking definition was obtained as the combination of ASTM D6433 7. Edge cracking; 8. Joint reflection; 9. Lane/Shoulder drop-off and 10. Longitudinal and transverse cracking, all of those distresses classified as cracking and measured in linear meters, allowing the inspector recording these distresses under the same code.

Likewise, the new distress N_4. Surface deformations is defined as the union of distresses classified under the same, group Visco-plastic deformations: ASTM D6433 distress 4. Bumps and sags, 5. Please check. Corrugation, 6. Depression and 18. Swell, measured in square meters, being much simpler to identify.

Distress N_6. Failure surface grip, classified under the Surface defects group is obtained as the combination of ASTM D6433 distress 2. Bleeding, 12. Polished Aggregate, 19. Raveling and 20. Weathering, measured in square meters.

Similarly, distress N_10. Slippage cracking is defined as the combination of ASTM D6433 distresses 16. Shoving, 17. Slippage cracking, both distresses are measured in square meters, to consider the traffic tangential action. These distresses can be found in roadway points where there are repeated braking and accelerations linked to roadway areas overlays are poorly bonded with the underlying layer.

The main novelty of proposed distress identification catalogue for urban road pavements assimilates two innovative distress definitions in the catalogue that ASTM D6433 does not consider; N_11. Manholes and N_12. Tree roots.

For the first distress, this choice is motivated to catalog the catch basins and manholes in pavement condition assessment due to their importance as a singular and very common distress in Italian Urban Roads (

Figure A5). This innovative definition allows considerations of the catch basins, manholes. These features have a strong presence in urban roadways and induce other distresses in surrounding areas that very negatively affects drive quality and causes damage to the vehicles. These distress are not currently considered by the ASTM D6433 PCI calculation procedure. The quantities of this distress are measured in square meters

Another distress that the Standard Practice ASTM D6433 does not include is N_12.

Tree roots distress. This defined on the new distress identification catalogue for urban areas for its importance and its wide presence in Italian Urban Roads (

Figure A6). The appearance of this distress is linked to the presence of large trees in the roadside of urban streets which may create a raise in the pavement on the road side and /or a break in the pavement leading to accidents and vehicle damage.

The density-deduct value curve associated with N_12.

Tree roots is calculated as the combination of ASTM D6433 11.

Patching and Utility Patching and 18.

Swell. The severity level should be considered by the

Table A1. The quantities of this defect are measured in square meters.