Nanotubes: Carbon-Based Fibers and Bacterial Nano-Conduits Both Arousing a Global Interest and Conflicting Opinions

Abstract

:1. Introduction

2. Approaching CNTs: Properties, Uses and Current Hurdles

2.1. Impediments to the Extensive Application of CNTs

2.1.1. Environmental and Human Safety: Some Case Studies

2.1.2. Other Hurdles

3. Approaching Bacterial Nanotubes (BNTs)

3.1. Main Tubular Membranous Nanostructures in Bacteria

3.2. Classes of BNTs Observed

4. Synthesis of CNTs and Biogenesis of BNTs

4.1. Synthesis of CNTs

4.1.1. Arc Discharge (AD)

4.1.2. Laser Ablation (LA)

4.1.3. Chemical Vapor Deposition (CVD)

High-Pressure Carbon Monoxide (HiPco) Process

Super-Growth CVD

4.1.4. Other Methods

Plasma Torch (PT)

Liquid Electrolysis Method (LEM)

Natural, Incidental, and Controlled Flame Environments

4.2. Biogenesis of Bacterial Nanotubes: Among Sheared and Conflicting Opinions

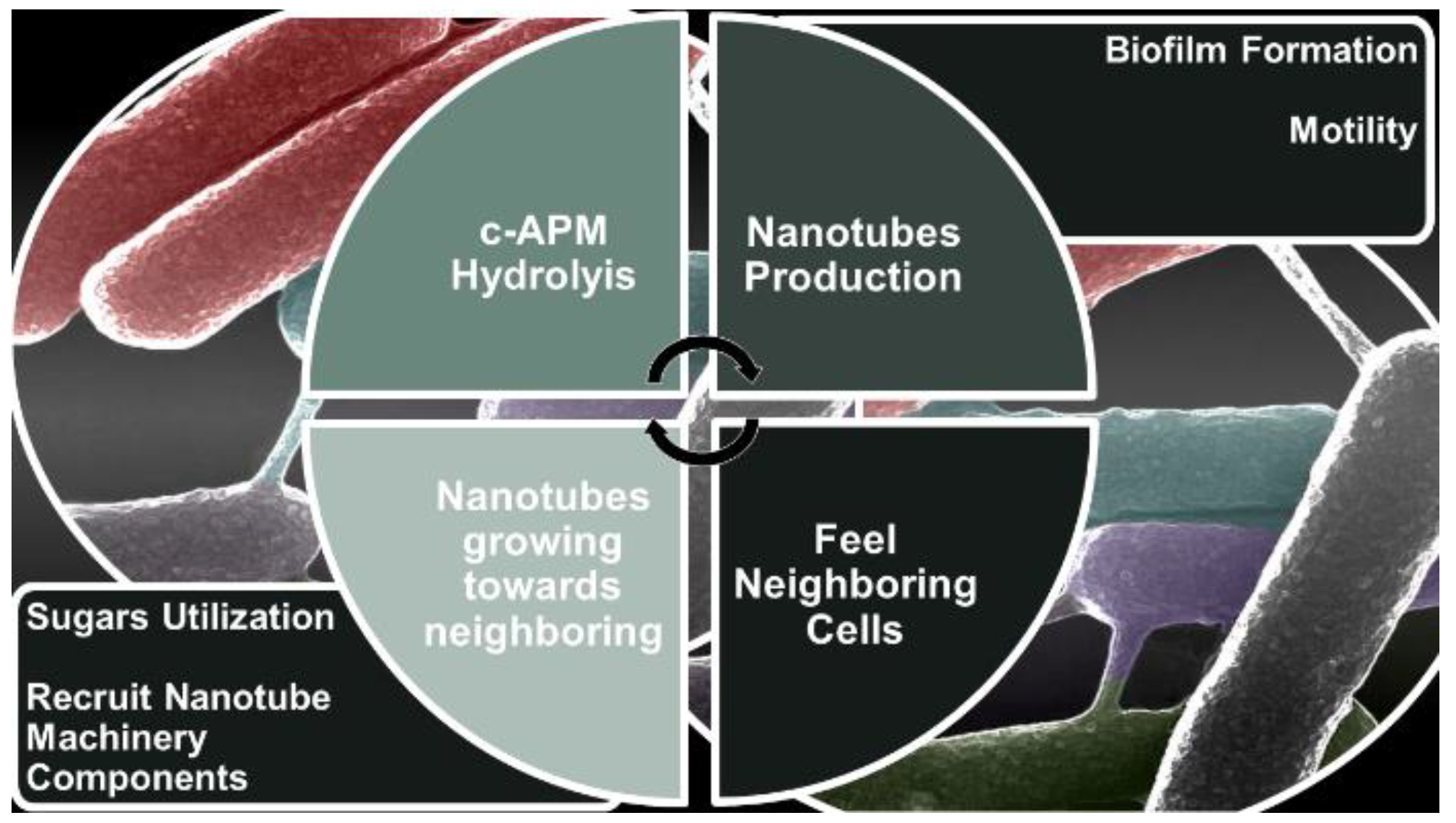

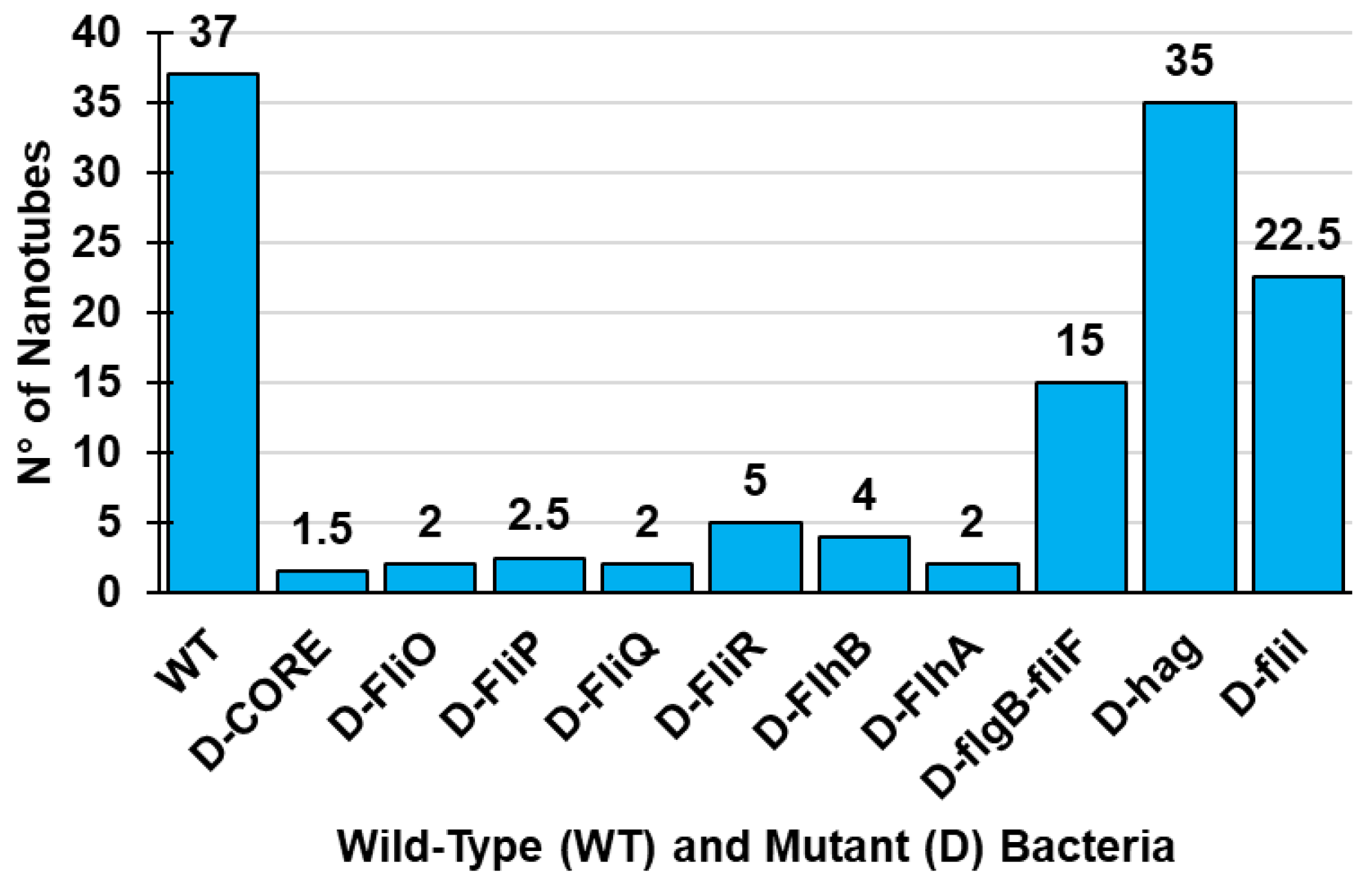

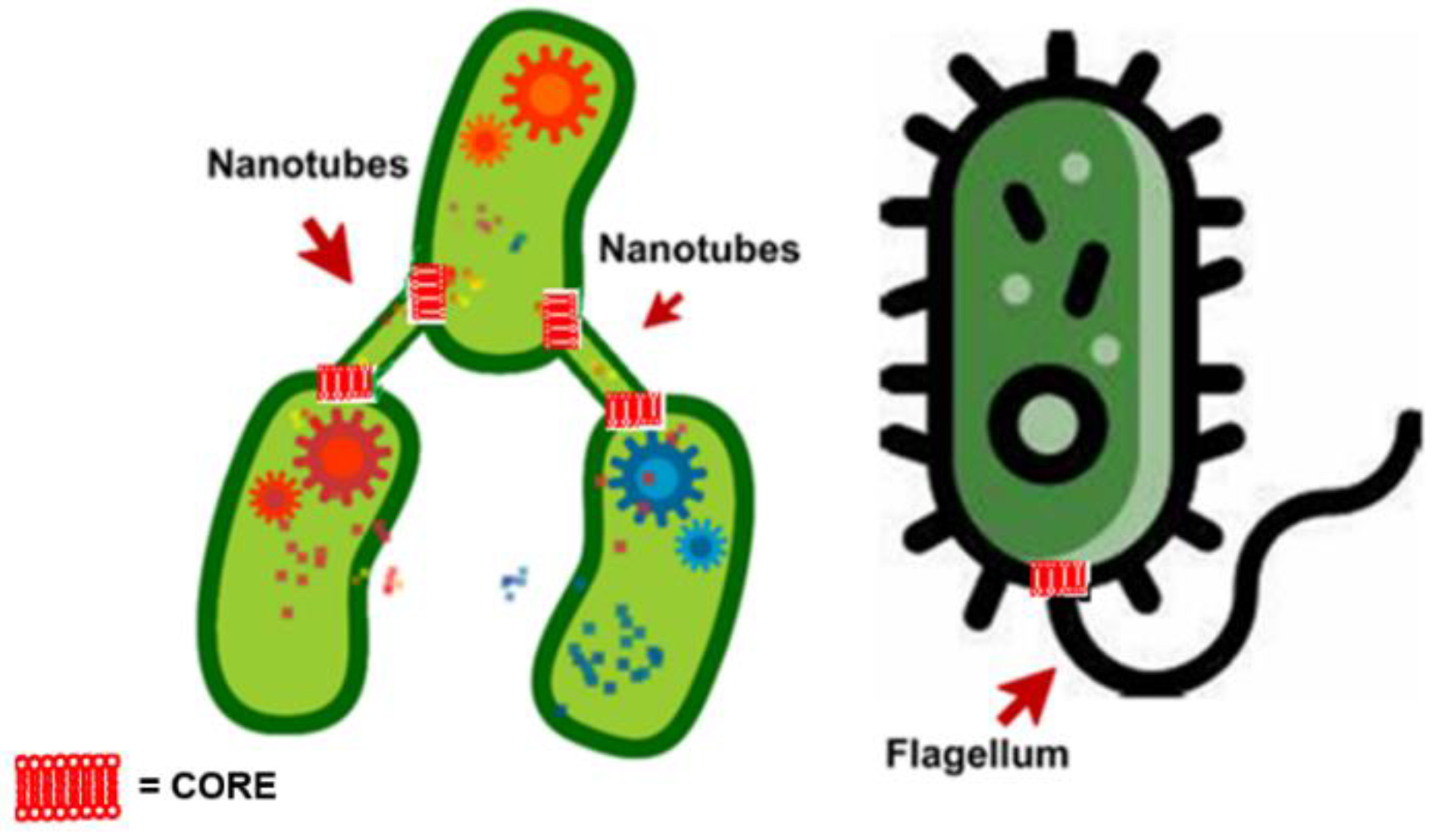

Recent Reports on Conditions and Requirements Promoting NT Formation

Not Only in B. subtilis

5. Architecture and Other Features of CNTs and of BNTs

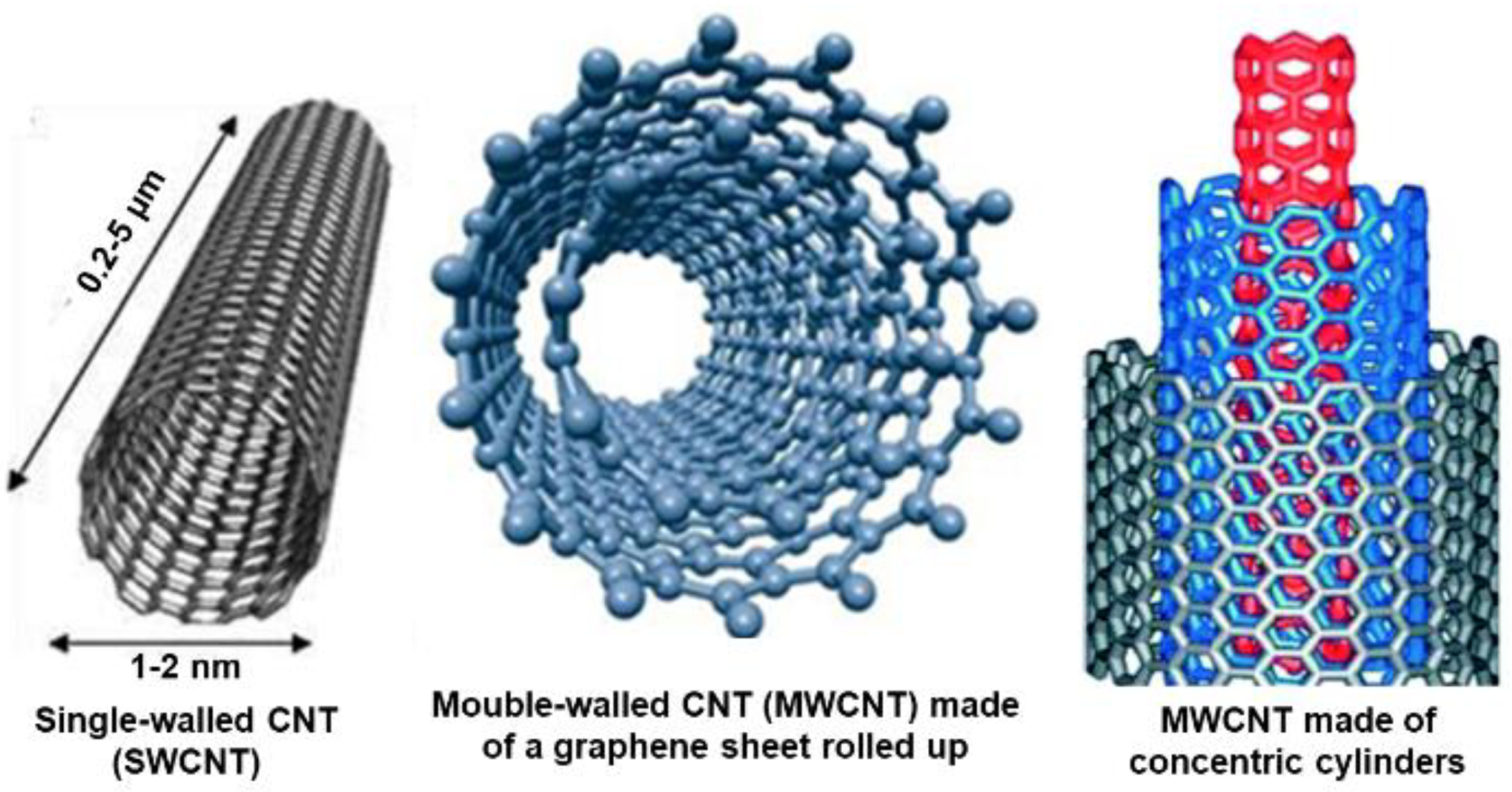

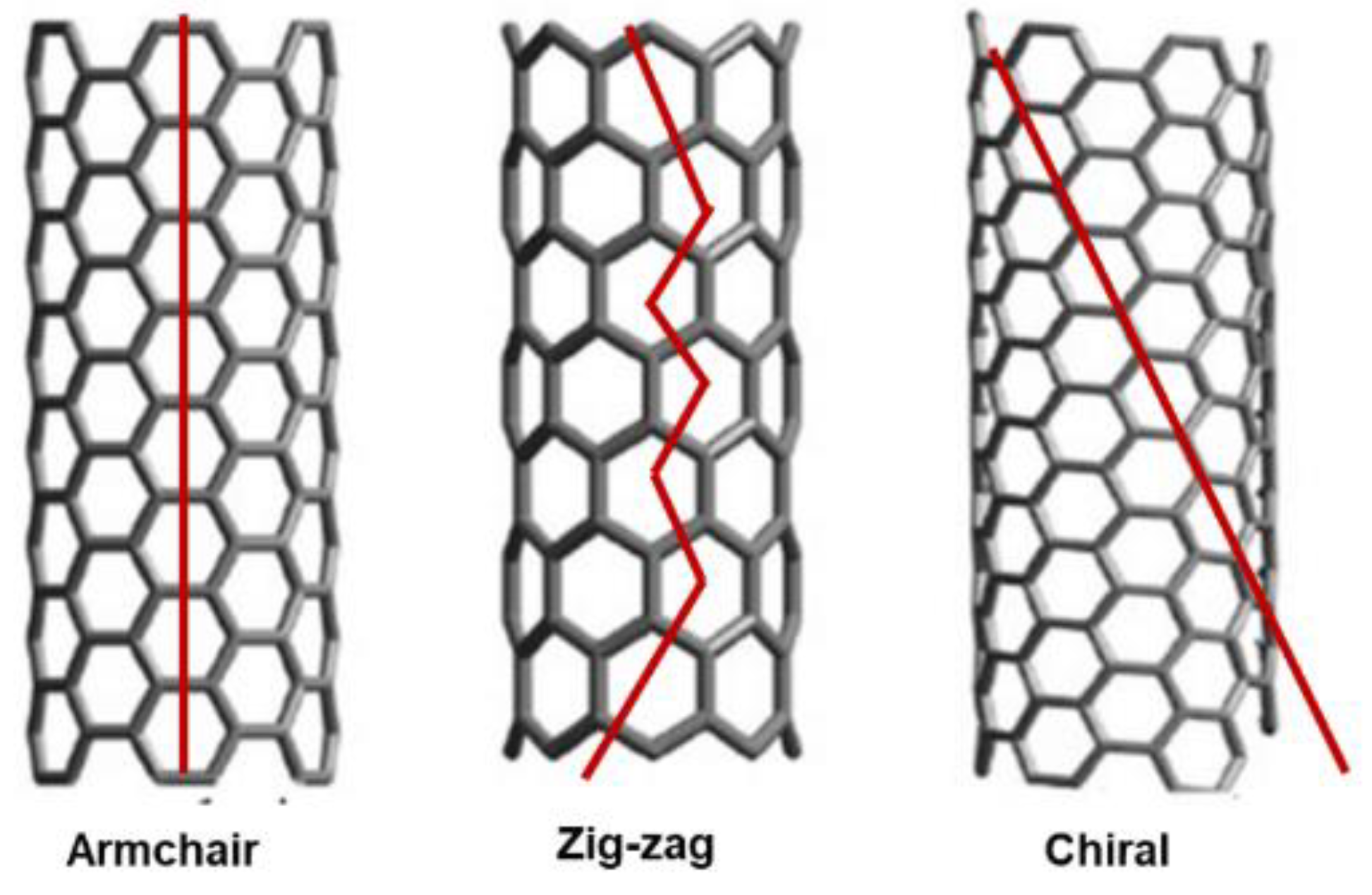

5.1. Structure of CNTs

5.1.1. From Traditional CNTs-Structures to CNTs-Base Derivatives or Particular Morphologies

Carbon Nanobud Structures (CNBs)

Carbon Peapods (CPPs)

Nanotori (NTRs)

Graphenated Carbon Nanotubes (GCNTs)

Cup-Stacked Carbon Nanotubes (CSCNTs)

5.1.2. More Insights in the CNTs’ Structure: Relationships Structure/Properties

Structure-Related Mechanical Properties

Structure-Related Electrical and Thermal Properties

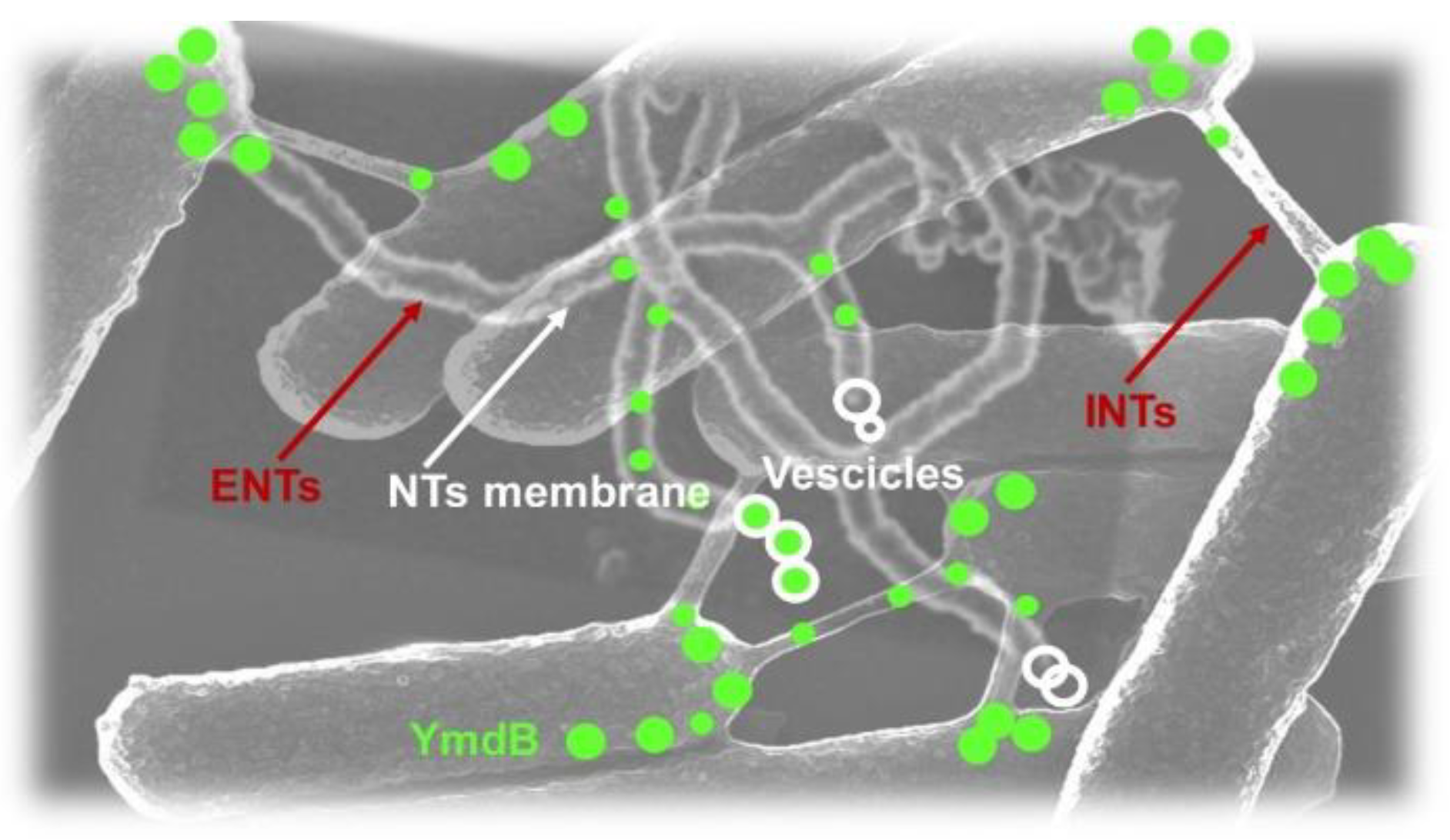

5.2. Architecture, Dynamics, Molecular Components, and Other Concerning BNTs

5.2.1. Ten Years of Studies and Discoveries

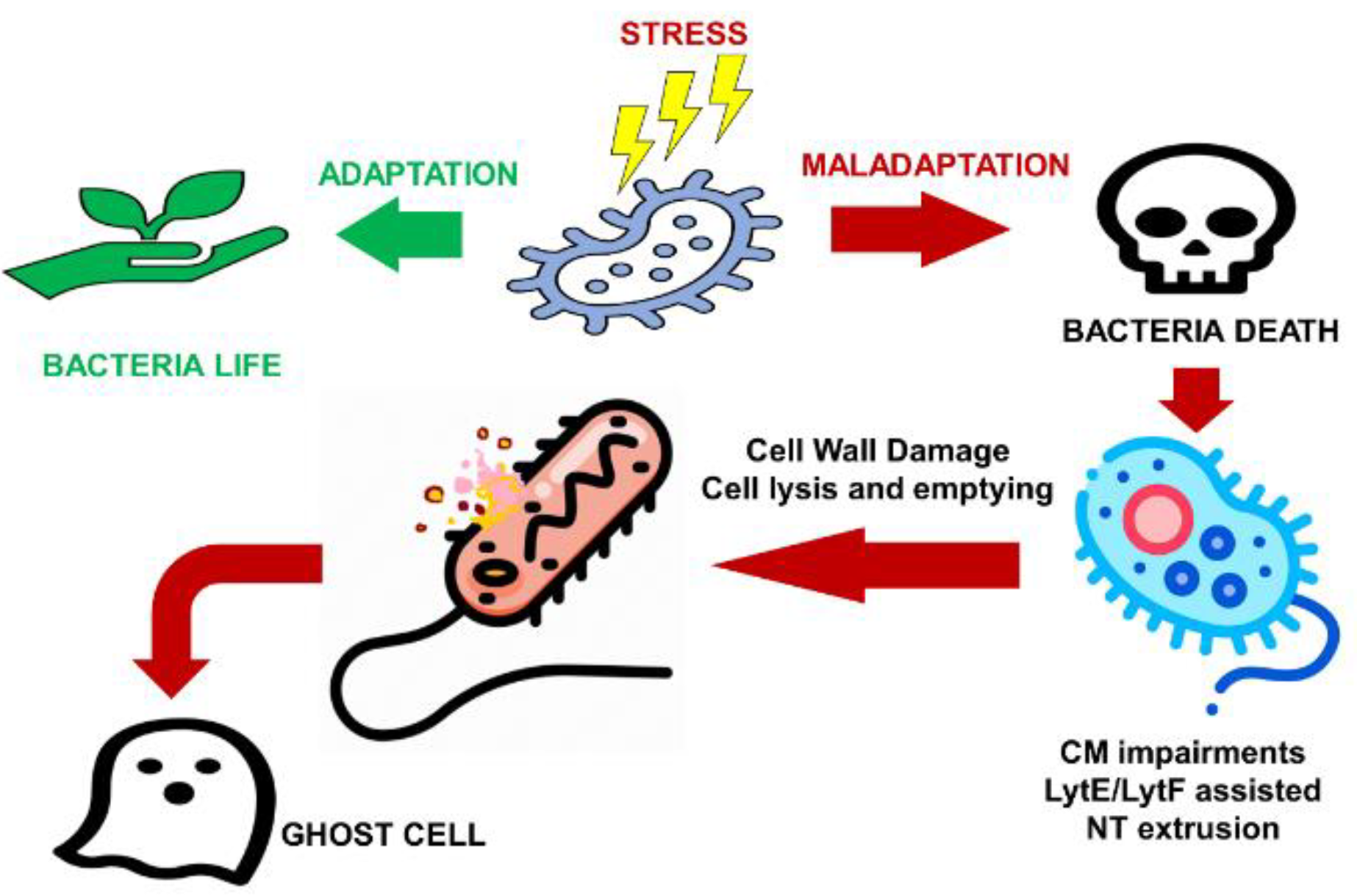

5.2.2. The Conflicting Recent Reports

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ciambelli, P.; La Guardia, G.; Vitale, L. Nanotechnology for Green Materials and Processes. In Studies in Surface Science and Catalysis; Elsevier: Amsterdam, The Netherlands, 2020; Chapter 7; Volume 179, pp. 97–116. [Google Scholar] [CrossRef]

- Anzar, N.; Hasan, R.; Tyagi, M.; Yadav, N.; Narang, I. Carbon nanotube-A review on Synthesis, Properties and plethora of applications in the field of biomedical science. Sens. Int. 2020, 1, 100003. [Google Scholar] [CrossRef]

- Yang, N.; Chen, X.; Liu, D.; He, H.; Yang, D.; Zhang, G. Molecular modeling of the mechanical properties and electrical conductivity of modified carbon nanotube with hydroxyl under the tensile behavior. In Proceedings of the 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; pp. 520–523. [Google Scholar] [CrossRef]

- Khan, M.U.; Reddy, K.R.; Snguanwongchai, T.; Haque, E.; Gomes, V.G. Polymer Brush Synthesis on Surface Modified Carbon Nanotubes via in Situ Emulsion Polymerization. Colloid Polym. Sci. 2016, 294, 1599–1610. [Google Scholar] [CrossRef]

- Che, J.; Çagin, T.; Goddard, W.A. Thermal Conductivity of Carbon Nanotubes. Nanotechnology 2000, 11, 65–69. [Google Scholar] [CrossRef]

- Smart, S.K.; Cassady, A.I.; Lu, G.Q.; Martin, D.J. The Biocompatibility of Carbon Nanotubes. Carbon 2006, 44, 1034–1047. [Google Scholar] [CrossRef]

- Kumar, S.; Rani, R.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.-H. Carbon Nanotubes: A Novel Material for Multifaceted Applications in Human Healthcare. Chem. Soc. Rev. 2017, 46, 158–196. [Google Scholar] [CrossRef] [PubMed]

- Dey, P.; Das, N. Carbon Nanotubes: It’s Role in Modern Health Care. Int. J. Pharm. Pharm. Sci. 2013, 5, 9–13. [Google Scholar]

- Beden, N.; Hamidi, H.; Palecek, E. Subnanomolar determination of dopamine by electrochemical sensor based on Au-NPs-MWCNTs and mannopentose-Os (VI) adducts. Insights Anal. Electrochem. 2015, 1, 1–8. [Google Scholar]

- Gutiérrez, F.A.; Rubianes, M.D.; Rivas, G.A. Electrochemical Sensor for Amino Acids and Glucose Based on Glassy Carbon Electrodes Modified with Multi-Walled Carbon Nanotubes and Copper Microparticles Dispersed in Polyethylenimine. J. Electroanal. Chem. 2016, 765, 16–21. [Google Scholar] [CrossRef]

- Liu, X.; Du, C.; Ni, D.; Ran, Q.; Liu, F.; Jiang, D.; Pu, X. A Simple and Sensitive Electrochemical Sensor for Rapid Detection of Clostridium Tetani Based on Multi-Walled Carbon Nanotubes. Anal. Methods 2016, 8, 8280–8287. [Google Scholar] [CrossRef]

- Palisoc, S.T.; Chua, R.V.M.; Natividad, M.T. Highly sensitive determination of heavy metals in upland and lowland rice using AgNP/BiNP/MWCNT/nafion modified glassy carbon electrode via anodic stripping voltammetry. Mat. Res. Express 2020, 7, 015081. [Google Scholar] [CrossRef]

- Shetti, N.P.; Malode, S.J.; Nayak, D.S.; Reddy, K.R. Novel Heterostructured Ru-Doped TiO2/CNTs Hybrids with Enhanced Electrochemical Sensing Performance for Cetirizine. Mater. Res. Express 2019, 6, 115085. [Google Scholar] [CrossRef]

- Shetti, N.P.; Malode, S.J.; Nayak, D.S.; Reddy, C.V.; Reddy, K.R. Novel Biosensor for Efficient Electrochemical Detection of Methdilazine Using Carbon Nanotubes-Modified Electrodes. Mater. Res. Express 2019, 6, 116308. [Google Scholar] [CrossRef]

- Shetti, N.P.; Nayak, D.S.; Malode, S.J.; Kakarla, R.R.; Shukla, S.S.; Aminabhavi, T.M. Sensors Based on Ruthenium-Doped TiO2 Nanoparticles Loaded into Multi-Walled Carbon Nanotubes for the Detection of Flufenamic Acid and Mefenamic Acid. Anal. Chim. Acta 2019, 1051, 58–72. [Google Scholar] [CrossRef]

- Manasa, G.; Bhakta, A.K.; Mekhalif, Z.; Mascarenhas, R.J. Bismuth-Nanoparticles Decorated Multi-Wall-Carbon-Nanotubes Cast-Coated on Carbon Paste Electrode; an Electrochemical Sensor for Sensitive Determination of Gallic Acid at Neutral PH. Mater. Sci. Energy Technol. 2020, 3, 174–182. [Google Scholar] [CrossRef]

- Khan, S.A.; Gao, M.; Zhu, Y.; Yan, Z.; Lin, Y. MWCNTs Based Flexible and Stretchable Strain Sensors. J. Semicond. 2017, 38, 053003. [Google Scholar] [CrossRef]

- Ali, A.; Khan, A.; Karimov, K.S.; Ali, A.; Daud Khan, A. Pressure Sensitive Sensors Based on Carbon Nanotubes, Graphene, and Its Composites. J. Nanomater. 2018, 2018, 9592610. [Google Scholar] [CrossRef]

- Park, K.; Tran, P.; Deaton, N.; Desai, J.P. Multi-Walled Carbon Nanotube (MWCNT)/PDMS-Based Flexible Sensor for Medical Applications. In Proceedings of the 2019 International Symposium on Medical Robotics (ISMR), Atlanta, GA, USA, 3 April 2019; pp. 1–8. [Google Scholar]

- He, Z.; Zhou, G.; Byun, J.-H.; Lee, S.-K.; Um, M.-K.; Park, B.; Kim, T.; Lee, S.B.; Chou, T.-W. Highly Stretchable Multi-Walled Carbon Nanotube/Thermoplastic Polyurethane Composite Fibers for Ultrasensitive, Wearable Strain Sensors. Nanoscale 2019, 11, 5884–5890. [Google Scholar] [CrossRef]

- Ramalingame, R.; Hu, Z.; Gerlach, C.; Rajendran, D.; Zubkova, T.; Baumann, R.R.; Kanoun, O. Flexible Piezoresistive Sensor Matrix Based on a Carbon Nanotube PDMS Composite for Dynamic Pressure Distribution Measurement. J. Sens. Sens. Syst. 2019, 8, 1–7. [Google Scholar] [CrossRef]

- George, J.; Abdelghani, A.; Bahoumina, P.; Tantot, O.; Baillargeat, D.; Frigui, K.; Bila, S.; Hallil, H.; Dejous, C. CNT-Based Inkjet-Printed RF Gas Sensor: Modification of Substrate Properties during the Fabrication Process. Sensors 2019, 19, 1768. [Google Scholar] [CrossRef]

- Kim, J.; Yoo, H.; Ba, V.A.P.; Shin, N.; Hong, S. Dye-Functionalized Sol-Gel Matrix on Carbon Nanotubes for Refreshable and Flexible Gas Sensors. Sci. Rep. 2018, 8, 11958. [Google Scholar] [CrossRef] [Green Version]

- Duong, V.T.; Nguyen, C.T.; Luong, H.B.; Luu, L.A.N.; Nguyen, D.C.; Nguyen, H.L. Enhancement of the NH 3 Gas Sensitivity by Using the WO 3/MWCNT Composite-Based Sensors. Adv. Nat. Sci. Nanosci. Nanotechnol. 2019, 10, 015001. [Google Scholar] [CrossRef]

- Seyfoori, A.; Sarfarazijami, S.; Seyyed Ebrahimi, S.A. PH-Responsive Carbon Nanotube-Based Hybrid Nanogels as the Smart Anticancer Drug Carrier. Artif. Cells Nanomed. Biotechnol 2019, 47, 1437–1443. [Google Scholar] [CrossRef] [PubMed]

- Mehrjouei, E.; Akbarzadeh, H.; Shamkhali, A.N.; Abbaspour, M.; Salemi, S.; Abdi, P. Delivery of Cisplatin Anti-Cancer Drug from Carbon, Boron Nitride, and Silicon Carbide Nanotubes Forced by Ag-Nanowire: A Comprehensive Molecular Dynamics Study. Mol. Pharm. 2017, 14, 2273–2284. [Google Scholar] [CrossRef]

- Servant, A.; Methven, L.; Williams, R.; Kostarelos, K. Electroresponsive Polymer–Carbon Nanotube Hydrogel Hybrids for Pulsatile Drug Delivery in Vivo. Adv. Healthc. Mater. 2013, 2, 806–811. [Google Scholar] [CrossRef]

- Mandal, B.; Das, D.; Rameshbabu, A.P.; Dhara, S.; Pal, S. A Biodegradable, Biocompatible Transdermal Device Derived from Carboxymethyl Cellulose and Multi-Walled Carbon Nanotubes for Sustained Release of Diclofenac Sodium. RSC Adv. 2016, 6, 19605–19611. [Google Scholar] [CrossRef]

- Samorì, C.; Ali-Boucetta, H.; Sainz, R.; Guo, C.; Toma, F.M.; Fabbro, C.; da Ros, T.; Prato, M.; Kostarelos, K.; Bianco, A. Enhanced Anticancer Activity of Multi-Walled Carbon Nanotube–Methotrexate Conjugates Using Cleavable Linkers. Chem. Commun. 2010, 46, 1494–1496. [Google Scholar] [CrossRef]

- Wen, S.; Liu, H.; Cai, H.; Shen, M.; Shi, X. Targeted and PH-Responsive Delivery of Doxorubicin to Cancer Cells Using Multifunctional Dendrimer-Modified Multi-Walled Carbon Nanotubes. Adv. Healthc. Mater. 2013, 2, 1267–1276. [Google Scholar] [CrossRef]

- Guo, C.; Al-Jamal, W.T.; Toma, F.M.; Bianco, A.; Prato, M.; Al-Jamal, K.T.; Kostarelos, K. Design of Cationic Multiwalled Carbon Nanotubes as Efficient SiRNA Vectors for Lung Cancer Xenograft Eradication. Bioconjugate Chem. 2015, 26, 1370–1379. [Google Scholar] [CrossRef]

- Mohamed, N.A.; El-Ghany, N.A.A. Novel Aminohydrazide Cross-Linked Chitosan Filled with Multi-Walled Carbon Nanotubes as Antimicrobial Agents. Int. J. Biol. Macromol. 2018, 115, 651–662. [Google Scholar] [CrossRef]

- Feng, Q.L.; Wu, J.; Chen, G.Q.; Cui, F.Z.; Kim, T.N.; Kim, J.O. A Mechanistic Study of the Antibacterial Effect of Silver Ions on Escherichia Coli and Staphylococcus Aureus. J. Biomed. Mater. Res. 2000, 52, 662–668. [Google Scholar] [CrossRef]

- Wang, D.; Huang, B.; Liu, J.; Guo, X.; Abudukeyoumu, G.; Zhang, Y.; Ye, B.-C.; Li, Y. A Novel Electrochemical Sensor Based on Cu@Ni/MWCNTs Nanocomposite for Simultaneous Determination of Guanine and Adenine. Biosens. Bioelectron. 2018, 102, 389–395. [Google Scholar] [CrossRef] [PubMed]

- Hadwiger, L.A.; Kendra, D.F.; Fristensky, B.W.; Wagoner, W. Chitosan Both Activates Genes in Plants and Inhibits RNA Synthesis in Fungi. In Chitin in Nature and Technology; Muzzarelli, R., Jeuniaux, C., Gooday, G.W., Eds.; Springer: Boston, MA, USA, 1986; pp. 209–214. ISBN 978-1-4613-2167-5. [Google Scholar]

- Al-Jumaili, A.; Alancherry, S.; Bazaka, K.; Jacob, M.V. Review on the Antimicrobial Properties of Carbon Nanostructures. Materials 2017, 10, 1066. [Google Scholar] [CrossRef] [PubMed]

- Eatemadi, A.; Daraee, H.; Karimkhanloo, H.; Kouhi, M.; Zarghami, N.; Akbarzadeh, A.; Abasi, M.; Hanifehpour, Y.; Joo, S.W. Carbon Nanotubes: Properties, Synthesis, Purification, and Medical Applications. Nanoscale Res. Lett. 2014, 9, 393. [Google Scholar] [CrossRef] [PubMed]

- Kerfahi, D.; Tripathi, B.M.; Singh, D.; Kim, H.; Lee, S.; Lee, J.; Adams, J.M. Effects of Functionalized and Raw Multi-Walled Carbon Nanotubes on Soil Bacterial Community Composition. PLoS ONE 2015, 10, e0123042. [Google Scholar] [CrossRef] [PubMed]

- Engel, M.; Hadar, Y.; Belkin, S.; Lu, X.; Elimelech, M.; Chefetz, B. Bacterial Inactivation by a Carbon Nanotube–Iron Oxide Nanocomposite: A Mechanistic Study Using E. Coli Mutants. Environ. Sci. Nano 2018, 5, 372–380. [Google Scholar] [CrossRef]

- Bhaduri, B.; Engel, M.; Polubesova, T.; Wu, W.; Xing, B.; Chefetz, B. Dual Functionality of an Ag-Fe3O4-Carbon Nanotube Composite Material: Catalytic Reduction and Antibacterial Activity. J. Environ. Chem. Eng. 2018, 6, 4103–4113. [Google Scholar] [CrossRef]

- Rananga, L.E.; Magadzu, T. Comparative studies of silver doped carbon nanotubes and β-cyclodextrin for water disinfection. Dig. J. Nanomater. Bios. 2015, 10, 831–836. [Google Scholar]

- Zhu, A.; Liu, H.; Long, F.; Su, E.; Klibanov, A.M. Inactivation of Bacteria by Electric Current in the Presence of Carbon Nanotubes Embedded Within a Polymeric Membrane. Appl. Biochem. Biotechnol. 2014, 175, 666–676. [Google Scholar] [CrossRef]

- Hussein, M.A.; El-Shishtawy, R.M.; Alamry, K.A.; Asiri, A.M.; Mohamed, S.A. Efficient Water Disinfection Using Hybrid Polyaniline/Graphene/Carbon Nanotube Nanocomposites. Environ. Technol. 2018, 40, 2813–2824. [Google Scholar] [CrossRef]

- Aslan, S.; Deneufchatel, M.; Hashmi, S.; Li, N.; Pfefferle, L.D.; Elimelech, M.; Pauthe, E.; Van Tassel, P.R. Carbon Nanotube-Based Antimicrobial Biomaterials Formed via Layer-by-Layer Assembly with Polypeptides. J. Colloid Interface Sci. 2012, 388, 268–273. [Google Scholar] [CrossRef]

- Vecitis, C.D.; Schnoor, M.H.; Rahaman, M.S.; Schiffman, J.D.; Elimelech, M. Electrochemical Multiwalled Carbon Nanotube Filter for Viral and Bacterial Removal and Inactivation. Environ. Sci. Technol. 2011, 45, 3672–3679. [Google Scholar] [CrossRef] [PubMed]

- Zardini, H.Z.; Davarpanah, M.; Shanbedi, M.; Amiri, A.; Maghrebi, M.; Ebrahimi, L. Microbial Toxicity of Ethanolamines—Multiwalled Carbon Nanotubes. J. Biomed. Mater. Res. Part. A 2014, 102, 1774–1781. [Google Scholar] [CrossRef] [PubMed]

- Ursu, E.-L.; Rosca, I.; Bahrin, L.G.; Clima, L.; Bejan, D.; Sardaru, M.C.; Marangoci, N.L.; Lozan, V.; Rotaru, A. Aqueous Dispersion of Single-Walled Carbon Nanotubes Using Tetra-Phenyl Bimesitylene Derivative via Noncovalent Modification and Improved Antimicrobial Activity. J. Nanosci. Nanotechnol. 2019, 19, 7960–7966. [Google Scholar] [CrossRef] [PubMed]

- Rathore, H.S.; Mittal, S.; Kumar, S. Synthesis, Characterization and antifungal activities of 3d-transition metal complexes of 1-acetylpiperazinyldithiocarbamate, M (acpdtc) 2. Pestic. Res. J. 2000, 73, 103–107. [Google Scholar]

- Zare-Zardini, H.; Amiri, A.; Shanbedi, M.; Memarpoor-Yazdi, M.; Asoodeh, A. Studying of Antifungal Activity of Functionalized Multiwalled Carbon Nanotubes by Microwave-Assisted Technique. Surf. Interface Anal. 2013, 45, 751–755. [Google Scholar] [CrossRef]

- Abounit, S.; Zurzolo, C. Wiring through Tunneling Nanotubes—From Electrical Signals to Organelle Transfer. J. Cell Sci. 2012, 125, 1089–1098. [Google Scholar] [CrossRef]

- Dubey, G.P.; Ben-Yehuda, S. Intercellular Nanotubes Mediate Bacterial Communication. Cell 2011, 144, 590–600. [Google Scholar] [CrossRef]

- Costa, T.R.D.; Felisberto-Rodrigues, C.; Meir, A.; Prevost, M.S.; Redzej, A.; Trokter, M.; Waksman, G. Secretion Systems in Gram-Negative Bacteria: Structural and Mechanistic Insights. Nat. Rev. Microbiol. 2015, 13, 343–359. [Google Scholar] [CrossRef]

- Hayes, C.S.; Aoki, S.K.; Low, D.A. Bacterial Contact-Dependent Delivery Systems. Annu. Rev. Genet. 2010, 44, 71–90. [Google Scholar] [CrossRef]

- Dubey, G.P.; Malli Mohan, G.B.; Dubrovsky, A.; Amen, T.; Tsipshtein, S.; Rouvinski, A.; Rosenberg, A.; Kaganovich, D.; Sherman, E.; Medalia, O.; et al. Architecture and Characteristics of Bacterial Nanotubes. Dev. Cell 2016, 36, 453–461. [Google Scholar] [CrossRef]

- McCaig, W.D.; Koller, A.; Thanassi, D.G. Production of Outer Membrane Vesicles and Outer Membrane Tubes by Francisella Novicida. J. Bacteriol. 2013, 195, 1120–1132. [Google Scholar] [CrossRef] [PubMed]

- Pande, S.; Shitut, S.; Freund, L.; Westermann, M.; Bertels, F.; Colesie, C.; Bischofs, I.B.; Kost, C. Metabolic Cross-Feeding via Intercellular Nanotubes among Bacteria. Nat. Commun. 2015, 6, 6238. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, X.; Vassallo, C.N.; Pathak, D.T.; Wall, D. Myxobacteria Produce Outer Membrane-Enclosed Tubes in Unstructured Environments. J. Bacteriol. 2014, 196, 1807–1814. [Google Scholar] [CrossRef] [PubMed]

- Patel, N.; Yamada, Y.; Azam, F. Bacterial Nanotubes as Intercellular Linkages in Marine Assemblages. Front. Mar. Sci. 2021, 8, 768814. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Baidya, A.K.; Pal, R.R.; Mamou, G.; Gatt, Y.E.; Margalit, H.; Rosenshine, I.; Ben-Yehuda, S. A Ubiquitous Platform for Bacterial Nanotube Biogenesis. Cell Rep. 2019, 27, 334–342.e10. [Google Scholar] [CrossRef]

- Pospíšil, J.; Vítovská, D.; Kofroňová, O.; Muchová, K.; Šanderová, H.; Hubálek, M.; Šiková, M.; Modrák, M.; Benada, O.; Barák, I.; et al. Bacterial Nanotubes as a Manifestation of Cell Death. Nat. Commun. 2020, 11, 4963. [Google Scholar] [CrossRef]

- Scoville, C.; Cole, R.; Hogg, J.; Farooque, O.; Russell, A. Carbon Nanotubes. Available online: https://courses.cs.washington.edu/courses/csep590a/08sp/projects/CarbonNanotubes.pdf#:~:text=The%20structure%20of%20a%20carbon%20nanotube%20is%20formed,and%20bonded%20together%20to%20form%20a%20carbon%20nanotube (accessed on 9 June 2022).

- Huston, L.R. Mechanics of Centriole Microtubules. Adv. Biosci. Biotechnol. 2016, 7, 266–277. [Google Scholar] [CrossRef]

- Salvetat, J.-P.; Bonard, J.-M.; Bacsa, R.; Stöckli, T.; Forró, L. Physical properties of carbon nanotubes. AIP Conf. Proc. 1998, 442, 467. [Google Scholar] [CrossRef]

- CheapTubes.com CNT. Available online: http://www.cheaptubesinc.com/cnt101.htm (accessed on 9 June 2022).

- A 1 GHz Integrated Circuit with Carbon Nanotube Interconnects and Silicon Transistors. Available online: http://nano.stanford.edu/publication.php?id=135 (accessed on 9 June 2022).

- Misewich, J.A.; Martel, R.; Avouris, P.; Tsang, J.C.; Heinze, S.; Tersoff, J. Electrically Induced Optical Emission from a Carbon Nanotube FET. Science 2003, 300, 783–786. [Google Scholar] [CrossRef]

- Chen, J.; Perebeinos, V.; Freitag, M.; Tsang, J.; Fu, Q.; Liu, J.; Avouris, P. Bright Infrared Emission from Electrically Induced Excitons in Carbon Nanotubes. Science 2005, 310, 1171–1174. [Google Scholar] [CrossRef]

- Qiu, X.; Freitag, M.; Perebeinos, V.; Avouris, P. Photoconductivity Spectra of Single-Carbon Nanotubes: Implications on the Nature of Their Excited States. Nano Lett. 2005, 5, 749–752. [Google Scholar] [CrossRef]

- Itkis, M.E.; Borondics, F.; Yu, A.; Haddon, R.C. Bolometric Infrared Photoresponse of Suspended Single-Walled Carbon Nanotube Films. Science 2006, 312, 413–416. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Star, A.; Lu, Y.; Bradley, A.K.; Grüner, G. Nanotube Optoelectronic Memory Devices. Nano Lett. 2004, 4, 1587–1591. [Google Scholar] [CrossRef]

- Nanotubes Pack Power. Available online: http://www.trnmag.com/Stories/2002/022702/Nanotubes_pack_power_022702.html (accessed on 9 June 2022).

- Carbon-Nanotube Wiring Gets Real. Available online: http://blogs.spectrum.ieee.org/articles/2008/03/carbonnanotube_wiring_gets_rea.html (accessed on 9 June 2022).

- Postma, H.W.C.; Teepen, T.; Yao, Z.; Grifoni, M.; Dekker, C. Carbon Nanotube Single-Electron Transistors at Room Temperature. Science 2001, 293, 76–79. [Google Scholar] [CrossRef]

- Field Effect Transistors Based on Carbon Nanotube. Available online: https://miscircuitos.com/field-effect-transistors-based-carbon-nanotubes-cntfets (accessed on 9 June 2022).

- Nano-Manhattan: 3D Solar Cells Boost Efficiency While Reducing Size, Weight and Complexity of Photovoltaic Arrays. Available online: http://www.gtri.gatech.edu/casestudy/3d-solar-cells-boost-efficiency (accessed on 9 June 2022).

- Future of Computing: Carbon Nanotubes and Superconductors to Replace the Silicon Chip. ScienceDaily. Available online: https://www.sciencedaily.com/releases/2008/03/080328070113.htm (accessed on 9 June 2022).

- Barbarino, M.; Giordano, A. Assessment of the Carcinogenicity of Carbon Nanotubes in the Respiratory System. Cancers 2021, 13, 1318. [Google Scholar] [CrossRef] [PubMed]

- Zumwalde, R.D. Occupational Exposure to Carbon Nanotubes and Nanofibers; Department of Health and Human Services, Centers for Disease and Prevention, National Institute for Occupational Safety and Health: Washington, DC, USA, 2013; p. 156. [Google Scholar]

- REACH Registration Completed for Single-Wall Carbon Nanotubes. Available online: https://www.pcimag.com/articles/102634-reach-registration-completed-for-single-wall-carbon-nanotubes (accessed on 9 June 2022).

- CBC News. Researchers Monitor Nanotubes Fed to Fruit Flies. Available online: https://www.cbc.ca/news/science/researchers-monitor-nanotubes-fed-to-fruit-flies-1.693374 (accessed on 9 June 2022).

- Cheng, J.; Flahaut, E.; Cheng, S.H. Effect of Carbon Nanotubes on Developing Zebrafish (Danio Rerio) Embryos. Environ. Toxicol. Chem. 2007, 26, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Li, J.G.; Li, Q.N.; Xu, J.Y.; Cai, X.Q.; Liu, R.; Li, Y.; Ma, J.Q.; Li, W.X. The Pulmonary Toxicity of Multi-Wall Carbon Nanotubes in Mice 30 and 60 Days after Inhalation Exposure. J. Nanosci. Nanotechnol. 2009, 9, 1384–1387. [Google Scholar] [CrossRef] [PubMed]

- The Future is Still the Future. Available online: http://www.rpi.edu/dept/phys/ScIT/FutureTechnologies/nano/nanotubes.html (accessed on 9 June 2022).

- Barchinger, S.E.; Pirbadian, S.; Sambles, C.; Baker, C.S.; Leung, K.M.; Burroughs, N.J.; El-Naggar, M.Y.; Golbeck, J.H.; Spormann, A.M. Regulation of Gene Expression in Shewanella Oneidensis MR-1 during Electron Acceptor Limitation and Bacterial Nanowire Formation. Appl. Environ. Microbiol. 2016, 82, 5428–5443. [Google Scholar] [CrossRef]

- Subramanian, P.; Pirbadian, S.; El-Naggar, M.Y.; Jensen, G.J. Ultrastructure of Shewanella Oneidensis MR-1 Nanowires Revealed by Electron Cryotomography. Proc. Natl. Acad. Sci. USA 2018, 115, E3246–E3255. [Google Scholar] [CrossRef]

- Marguet, E.; Gaudin, M.; Gauliard, E.; Fourquaux, I.; le Blond du Plouy, S.; Matsui, I.; Forterre, P. Membrane Vesicles, Nanopods and/or Nanotubes Produced by Hyperthermophilic Archaea of the Genus Thermococcus. Biochem. Soc. Trans. 2013, 41, 436–442. [Google Scholar] [CrossRef]

- Shetty, A.; Hickey, W.J. Effects of Outer Membrane Vesicle Formation, Surface-Layer Production and Nanopod Development on the Metabolism of Phenanthrene by Delftia Acidovorans Cs1-4. PLoS ONE 2014, 9, e92143. [Google Scholar] [CrossRef]

- Shetty, A.; Chen, S.; Tocheva, E.I.; Jensen, G.J.; Hickey, W.J. Nanopods: A New Bacterial Structure and Mechanism for Deployment of Outer Membrane Vesicles. PLoS ONE 2011, 6, e20725. [Google Scholar] [CrossRef]

- Mamou, G.; Malli Mohan, G.B.; Rouvinski, A.; Rosenberg, A.; Ben-Yehuda, S. Early Developmental Program Shapes Colony Morphology in Bacteria. Cell Rep. 2016, 14, 1850–1857. [Google Scholar] [CrossRef]

- Stempler, O.; Baidya, A.K.; Bhattacharya, S.; Malli Mohan, G.B.; Tzipilevich, E.; Sinai, L.; Mamou, G.; Ben-Yehuda, S. Interspecies Nutrient Extraction and Toxin Delivery between Bacteria. Nat. Commun. 2017, 8, 315. [Google Scholar] [CrossRef]

- Pal, R.R.; Baidya, A.K.; Mamou, G.; Bhattacharya, S.; Socol, Y.; Kobi, S.; Katsowich, N.; Ben-Yehuda, S.; Rosenshine, I. Pathogenic E. Coli Extracts Nutrients from Infected Host Cells Utilizing Injectisome Components. Cell 2019, 177, 683–696.e18. [Google Scholar] [CrossRef]

- Baidya, A.K.; Bhattacharya, S.; Dubey, G.P.; Mamou, G.; Ben-Yehuda, S. Bacterial Nanotubes: A Conduit for Intercellular Molecular Trade. Curr. Opin. Microbiol. 2018, 42, 1–6. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Ajayan, P.M. Large-Scale Synthesis of Carbon Nanotubes. Nature 1992, 358, 220–222. [Google Scholar] [CrossRef]

- Guo, T.; Nikolaev, P.; Rinzler, A.G.; Tomanek, D.; Colbert, D.T.; Smalley, R.E. Self-Assembly of Tubular Fullerenes. J. Phys. Chem. 1995, 99, 10694–10697. [Google Scholar] [CrossRef]

- Guo, T.; Nikolaev, P.; Thess, A.; Colbert, D.T.; Smalley, R.E. Catalytic Growth of Single-Walled Manotubes by Laser Vaporization. Chem. Phys. Lett. 1995, 243, 49–54. [Google Scholar] [CrossRef]

- Kumar, M.; Ando, Y. Chemical vapor deposition of carbon nanotubes: A review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 2010, 10, 6. [Google Scholar] [CrossRef]

- Inami, N.; Ambri Mohamed, M.; Shikoh, E.; Fujiwara, A. Synthesis-Condition Dependence of Carbon Nanotube Growth by Alcohol Catalytic Chemical Vapor Deposition Method. Sci. Technol. Adv. Mater. 2007, 8, 292–295. [Google Scholar] [CrossRef]

- Ishigami, N.; Ago, H.; Imamoto, K.; Tsuji, M.; Iakoubovskii, K.; Minami, N. Crystal Plane Dependent Growth of Aligned Single-Walled Carbon Nanotubes on Sapphire. J. Am. Chem. Soc. 2008, 130, 9918–9924. [Google Scholar] [CrossRef]

- Naha, S.; Puri, I.K. A Model for Catalytic Growth of Carbon Nanotubes. J. Phys. D Appl. Phys. 2008, 41, 065304. [Google Scholar] [CrossRef]

- Banerjee, S.; Naha, S.; Puri, I.K. Molecular Simulation of the Carbon Nanotube Growth Mode during Catalytic Synthesis. Appl. Phys. Lett. 2008, 92, 233121. [Google Scholar] [CrossRef]

- Eftekhari, A.A.; Jafarkhani, P.; Moztarzadeh, F. High-Yield Synthesis of Carbon Nanotubes Using a Water-Soluble Catalyst Support in Catalytic Chemical Vapor Deposition. Carbon 2006, 44, 1343–1345. [Google Scholar] [CrossRef]

- Ren, Z.F.; Huang, Z.P.; Xu, J.W.; Wang, J.H.; Bush, P.; Siegal, M.P.; Provencio, P.N. Synthesis of Large Arrays of Well-Aligned Carbon Nanotubes on Glass. Science 1998, 282, 1105–1107. [Google Scholar] [CrossRef]

- Nanolab. Aligned Carbon Nanotube Arrays, And Nanoparticles. Nano-Lab.com. Available online: https://www.nano-lab.com/imagegallery.html (accessed on 10 June 2022).

- Neupane, S.; Lastres, M.; Chiarella, M.; Li, W.; Su, Q.; Du, G. Synthesis and Field Emission Properties of Vertically Aligned Carbon Nanotube Arrays on Copper. Carbon 2012, 50, 2641–2650. [Google Scholar] [CrossRef]

- High Pressure Carbon Monoxide HiPco Process. Available online: https://nanohub.org/groups/gng/highpressure_carbonmonoxide_hipco_process (accessed on 9 June 2022).

- Hata, K.; Futaba, D.N.; Mizuno, K.; Namai, T.; Yumura, M.; Iijima, S. Water-Assisted Highly Efficient Synthesis of Impurity-Free Single-Walled Carbon Nanotubes. Science 2004, 306, 1362–1364. [Google Scholar] [CrossRef]

- Futaba, D.N.; Hata, K.; Yamada, T.; Hiraoka, T.; Hayamizu, Y.; Kakudate, Y.; Tanaike, O.; Hatori, H.; Yumura, M.; Iijima, S. Shape-Engineerable and Highly Densely Packed Single-Walled Carbon Nanotubes and Their Application as Super-Capacitor Electrodes. Nat. Mater. 2006, 5, 987–994. [Google Scholar] [CrossRef]

- Smiljanic, O.; Stansfield, B.L.; Dodelet, J.-P.; Serventi, A.; Désilets, S. Gas-Phase Synthesis of SWNT by an Atmospheric Pressure Plasma Jet. Chem. Phys. Lett. 2002, 356, 189–193. [Google Scholar] [CrossRef]

- Smiljanic, O.; Stansfield, B.L. Method and apparatus for producing single-wall carbon nanotubes. Australia Patent AU2003223807A1, 11 December 2003. [Google Scholar]

- Kim, K.S.; Cota-Sanchez, G.; Kingston, C.T.; Imris, M.; Simard, B.; Soucy, G. Large-Scale Production of Single-Walled Carbon Nanotubes by Induction Thermal Plasma. J. Phys. D Appl. Phys. 2007, 40, 2375–2387. [Google Scholar] [CrossRef]

- Ren, J.; Li, F.-F.; Lau, J.; González-Urbina, L.; Licht, S. One-Pot Synthesis of Carbon Nanofibers from CO2. Nano Lett. 2015, 15, 6142–6148. [Google Scholar] [CrossRef]

- A Carbon Capture Strategy That Pays. Science 19-08-2015. Available online: https://www.science.org/content/article/carbon-capture-strategy-pays (accessed on 10 June 2022).

- Robert, R.F. Conjuring Chemical Cornucopias out of Thin Air. Science 2015, 349, 1160. [Google Scholar] [CrossRef]

- BBC News. Carbon Fibres Made From Air. Available online: https://bbcnews2u.blogspot.com/2015/08/carbon-fibres-made-from-air.html (accessed on 10 June 2022).

- Orcutt, M. Researcher Demonstrates How to Suck Carbon from the Air, Make Stuff from It. MIT Technology Review. 2015. Available online: https://www.technologyreview.com/2015/08/19/166478/researcher-demonstrates-how-to-suck-carbon-from-the-air-make-stuff-from-it (accessed on 10 June 2022).

- Yuan, L.; Saito, K.; Pan, C.; Williams, F.A.; Gordon, A.S. Nanotubes from Methane Flames. Chem. Phys. Lett. 2001, 340, 237–241. [Google Scholar] [CrossRef]

- Yuan, L.; Saito, K.; Hu, W.; Chen, Z. Ethylene Flame Synthesis of Well-Aligned Multi-Walled Carbon Nanotubes. Chem. Phys. Lett. 2001, 346, 23–28. [Google Scholar] [CrossRef]

- Duan, H.M.; McKinnon, J.T. Nanoclusters Produced in Flames. J. Phys. Chem. 1994, 98, 12815–12818. [Google Scholar] [CrossRef]

- Murr, L.E.; Bang, J.J.; Esquivel, E.V.; Guerrero, P.A.; Lopez, D.A. Carbon Nanotubes, Nanocrystal Forms, and Complex Nanoparticle Aggregates in Common Fuel-Gas Combustion Sources and the Ambient Air. J. Nanoparticle Res. 2004, 6, 241–251. [Google Scholar] [CrossRef]

- Vander Wal, R.L. Fe-Catalyzed Single-Walled Carbon Nanotube Synthesis within a Flame Environment. Combust. Flame 2002, 130, 37–47. [Google Scholar] [CrossRef]

- Saveliev, A.; Merchan-Merchan, W.; Kennedy, L. Metal Catalyzed Synthesis of Carbon Nanostructures in an Opposed Flow Methane Oxygen Flame. Combust. Flame 2003, 135, 27–33. [Google Scholar] [CrossRef]

- Height, M.J.; Howard, J.B.; Tester, J.W.; Vander Sande, J.B. Flame Synthesis of Single-Walled Carbon Nanotubes. Carbon 2004, 42, 2295–2307. [Google Scholar] [CrossRef]

- Sen, S.; Puri, I.K. Flame Synthesis of Carbon Nanofibres and Nanofibre Composites Containing Encapsulated Metal Particles. Nanotechnology 2004, 15, 264–268. [Google Scholar] [CrossRef]

- Naha, S.; Sen, S.; De, A.K.; Puri, I.K. A Detailed Model for the Flame Synthesis of Carbon Nanotubes and Nanofibers. Proc. Combust. Inst. 2007, 31, 1821–1829. [Google Scholar] [CrossRef]

- Diethmaier, C.; Pietack, N.; Gunka, K.; Wrede, C.; Lehnik-Habrink, M.; Herzberg, C.; Hübner, S.; Stülke, J. A Novel Factor Controlling Bistability in Bacillus Subtilis: The YmdB Protein Affects Flagellin Expression and Biofilm Formation. J. Bacteriol. 2011, 193, 5997–6007. [Google Scholar] [CrossRef]

- Diethmaier, C.; Newman, J.A.; Kovács, Á.T.; Kaever, V.; Herzberg, C.; Rodrigues, C.; Boonstra, M.; Kuipers, O.P.; Lewis, R.J.; Stülke, J. The YmdB Phosphodiesterase Is a Global Regulator of Late Adaptive Responses in Bacillus Subtilis. J. Bacteriol. 2014, 196, 265–275. [Google Scholar] [CrossRef]

- Boyd, C.D.; O’Toole, G.A. Second Messenger Regulation of Biofilm Formation: Breakthroughs in Understanding c-Di-GMP Effector Systems. Annu. Rev. Cell Dev. Biol. 2012, 28, 439–462. [Google Scholar] [CrossRef]

- Hengge, R. Principles of C-Di-GMP Signalling in Bacteria. Nat. Rev. Microbiol. 2009, 7, 263–273. [Google Scholar] [CrossRef]

- Kubori, T.; Okumura, M.; Kobayashi, N.; Nakamura, D.; Iwakura, M.; Aizawa, S. Purification and characterization of the flagellar hook-basal body complex of Bacillus subtilis. Mol. Microbiol. 1997, 24, 399–410. [Google Scholar] [CrossRef]

- Baidya, A.K.; Rosenshine, I.; Ben-Yehuda, S. Donor-Delivered Cell Wall Hydrolases Facilitate Nanotube Penetration into Recipient Bacteria. Nat. Commun. 2020, 11, 1938. [Google Scholar] [CrossRef]

- Smith, T.J.; Blackman, S.A.; Foster, S.J. Autolysins of Bacillus Subtilis: Multiple Enzymes with Multiple Functions. Microbiology 2000, 146, 249–262. [Google Scholar] [CrossRef]

- Whatmore, A.M.; Reed, R.H. Determination of Turgor Pressure in Bacillus Subtilis: A Possible Role for K+ in Turgor Regulation. Microbiology 1990, 136, 2521–2526. [Google Scholar] [CrossRef]

- Beltrán-Heredia, E.; Tsai, F.-C.; Salinas-Almaguer, S.; Cao, F.J.; Bassereau, P.; Monroy, F. Membrane Curvature Induces Cardiolipin Sorting. Commun. Biol. 2019, 2, 225. [Google Scholar] [CrossRef] [Green Version]

- Danne, L.; Aktas, M.; Unger, A.; Linke, W.A.; Erdmann, R.; Narberhaus, F.; Fischer, R. Membrane Remodeling by a Bacterial Phospholipid-Methylating Enzyme. mBio 2017, 8, e02082-16. [Google Scholar] [CrossRef]

- Ducret, A.; Fleuchot, B.; Bergam, P.; Mignot, T. Direct Live Imaging of Cell–Cell Protein Transfer by Transient Outer Membrane Fusion in Myxococcus Xanthus. eLife 2013, 2, e00868. [Google Scholar] [CrossRef]

- Pathak, D.T.; Wei, X.; Bucuvalas, A.; Haft, D.H.; Gerloff, D.L.; Wall, D. Cell Contact–Dependent Outer Membrane Exchange in Myxobacteria: Genetic Determinants and Mechanism. PLoS Genet. 2012, 8, e1002626. [Google Scholar] [CrossRef]

- Sampath, V.; McCaig, W.D.; Thanassi, D.G. Amino Acid Deprivation and Central Carbon Metabolism Regulate the Production of Outer Membrane Vesicles and Tubes by Francisella. Mol. Microbiol. 2018, 107, 523–541. [Google Scholar] [CrossRef]

- Li, T.; Weng, Y.; Ma, X.; Tian, B.; Dai, S.; Jin, Y.; Liu, M.; Li, J.; Yu, J.; Hua, Y. Deinococcus Radiodurans Toxin–Antitoxin MazEF-Dr Mediates Cell Death in Response to DNA Damage Stress. Front. Microbiol. 2017, 8, 1427. [Google Scholar] [CrossRef]

- Hanna, S.J.; McCoy-Simandle, K.; Leung, E.; Genna, A.; Condeelis, J.; Cox, D. Tunneling nanotubes, a novel mode of tumor cell macrophage communication in tumor cell invasion. J. Cell Sci. 2019, 132, jcs223321. [Google Scholar] [CrossRef] [PubMed]

- Birmingham, C.L.; Jiang, X.; Ohlson, M.B.; Miller, S.I.; Brumell, J.H. Salmonella-Induced Filament Formation Is a Dynamic Phenotype Induced by Rapidly Replicating Salmonella Enterica Serovar Typhimurium in Epithelial Cells. Infect. Immun. 2005, 73, 1204–1208. [Google Scholar] [CrossRef] [PubMed]

- Drab, M.; Stopar, D.; Kralj-Iglič, V.; Iglič, A. Inception Mechanisms of Tunneling Nanotubes. Cells 2019, 8, 626. [Google Scholar] [CrossRef]

- Souriant, S.; Balboa, L.; Dupont, M.; Pingris, K.; Kviatcovsky, D.; Cougoule, C.; Lastrucci, C.; Bah, A.; Gasser, R.; Poincloux, R.; et al. Tuberculosis Exacerbates HIV-1 Infection through IL-10/STAT3-Dependent Tunneling Nanotube Formation in Macrophages. Cell Rep. 2019, 26, 3586–3599.e7. [Google Scholar] [CrossRef]

- Structure of Nanotubes. Available online: https://www.rpi.edu/dept/phys/ScIT/FutureTechnologies/nano/nanotubes.html (accessed on 9 June 2022).

- Rathinavel, S.; Priyadharshini, K.; Panda, D. A review on carbon nanotube: An overview of synthesis, properties, functionalization, characterization, and the application. Mater. Sci. Eng. B 2021, 268, 115095. [Google Scholar] [CrossRef]

- Carbon Nanotubes. Available online: https://en.wikipedia.org/wiki/Carbon_nanotube (accessed on 13 June 2022).

- Monthioux, M.; Kuznetsov, V.L. Who Should Be given the Credit for the Discovery of Carbon Nanotubes. Carbon 2006, 44, 1621–1623. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, Y.; Inoue, S.; Suzuki, T.; Jones, R.; Ando, Y. Smallest Carbon Nanotube Is 3 Å in Diameter. Phys. Rev. Lett. 2004, 92, 125502. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, Y.; Zhang, Q.; Xie, H.; Qian, W.; Wei, F. Growth of Half-Meter Long Carbon Nanotubes Based on Schulz-Flory Distribution. ACS Nano 2013, 7, 6156–6161. [Google Scholar] [CrossRef]

- Jasti, R.; Bhattacharjee, J.; Neaton, J.B.; Bertozzi, C.R. Synthesis, Characterization, and Theory of [9]-, [12]-, and [18] Cycloparaphenylene: Carbon Nanohoop Structures. J. Am. Chem. Soc. 2008, 130, 17646–17647. [Google Scholar] [CrossRef]

- Densest Array of Carbon Nanotubes Grown to Date 27 September 2013. Available online: https://www.rdworldonline.com/densest-array-of-carbon-nanotubes-grown-to-date (accessed on 10 June 2022).

- Sugime, H.; Esconjauregui, S.; Yang, J.; D’Arsié, L.; Oliver, R.A.; Bhardwaj, S.; Cepek, C.; Robertson, J. Low Temperature Growth of Ultra-High Mass Density Carbon Nanotube Forests on Conductive Supports. Appl. Phys. Lett. 2013, 103, 073116. [Google Scholar] [CrossRef]

- Chernozatonskii, L.A. Carbon Nanotube Connectors and Planar Jungle Gyms. Phys. Lett. A 1992, 172, 173–176. [Google Scholar] [CrossRef]

- Menon, M.; Srivastava, D. Carbon Nanotube T Junctions: Nanoscale Metal-Semiconductor-Metal Contact Devices. Phys. Rev. Lett. 1997, 79, 4453–4456. [Google Scholar] [CrossRef]

- Ma, K.L.; Yan, X.H.; Guo, Y.D.; Xiao, Y. Electronic Transport Properties of Junctions between Carbon Nanotubes and Graphene Nanoribbons. Eur. Phys. J. B 2011, 83, 487–492. [Google Scholar] [CrossRef]

- Harris, P.J.F.; Suarez-Martinez, I.; Marks, N.A. The Structure of Junctions between Carbon Nanotubes and Graphene Shells. Nanoscale 2016, 8, 18849–18854. [Google Scholar] [CrossRef] [PubMed]

- Lambin, P.; Vigneron, J.-P.; Fonseca, A.; Nagy, J.B.; Lucas, A.A. Atomic Structure and Electronic Properties of a Bent Carbon Nanotube. Synth. Met. 1996, 77, 249–252. [Google Scholar] [CrossRef]

- Dimitrakakis, G.K.; Tylianakis, E.; Froudakis, G.E. Pillared Graphene: A New 3-D Network Nanostructure for Enhanced Hydrogen Storage. Nano Lett. 2008, 8, 3166–3170. [Google Scholar] [CrossRef]

- Lalwani, G.; Kwaczala, A.T.; Kanakia, S.; Patel, S.C.; Judex, S.; Sitharaman, B. Fabrication and Characterization of Three-Dimensional Macroscopic All-Carbon Scaffolds. Carbon 2013, 53, 90–100. [Google Scholar] [CrossRef]

- Lalwani, G.; Gopalan, A.; D’Agati, M.; Sankaran, J.S.; Judex, S.; Qin, Y.-X.; Sitharaman, B. Porous Three-Dimensional Carbon Nanotube Scaffolds for Tissue Engineering. J. Biomed. Mater. Res. A 2015, 103, 3212–3225. [Google Scholar] [CrossRef] [PubMed]

- Noyce, S.G.; Vanfleet, R.R.; Craighead, H.G.; Davis, R.C. High Surface-Area Carbon Microcantilevers. Nanoscale Adv. 2019, 1, 1148–1154. [Google Scholar] [CrossRef]

- Nasibulin, A.G.; Pikhitsa, P.V.; Jiang, H.; Brown, D.P.; Krasheninnikov, A.V.; Anisimov, A.S.; Queipo, P.; Moisala, A.; Gonzalez, D.; Lientschnig, G.; et al. A Novel Hybrid Carbon Material. Nat. Nanotechnol. 2007, 2, 156–161. [Google Scholar] [CrossRef]

- Smith, B.W.; Monthioux, M.; Luzzi, D.E. Encapsulated C60 in Carbon Nanotubes. Nature 1998, 396, 323–324. [Google Scholar] [CrossRef]

- Smith, B.W.; Luzzi, D.E. Formation Mechanism of Fullerene Peapods and Coaxial Tubes: A Path to Large Scale Synthesis. Chem. Phys. Lett. 2000, 321, 169–174. [Google Scholar] [CrossRef]

- Su, H.; Goddard, W.A.; Zhao, Y. Dynamic Friction Force in a Carbon Peapod Oscillator. Nanotechnology 2006, 17, 5691–5695. [Google Scholar] [CrossRef]

- Wang, M.; Li, C.M. An Oscillator in a Carbon Peapod Controllable by an External Electric Field: A Molecular Dynamics Study. Nanotechnology 2009, 21, 035704. [Google Scholar] [CrossRef]

- Liu, L.; Guo, G.Y.; Jayanthi, C.S.; Wu, S.Y. Colossal Paramagnetic Moments in Metallic Carbon Nanotori. Phys. Rev. Lett. 2002, 88, 217206. [Google Scholar] [CrossRef] [Green Version]

- Huhtala, M.; Kuronen, A.; Kaski, K.K. Carbon Nanotube Structures: Molecular Dynamics Simulation at Realistic Limit. Comput. Phys. Commun. 2002, 146, 30–37. [Google Scholar] [CrossRef]

- Parker, C.B.; Raut, A.S.; Brown, B.; Stoner, B.R.; Glass, J.T. Three-Dimensional Arrays of Graphenated Carbon Nanotubes. J. Mater. Res. 2012, 27, 1046–1053. [Google Scholar] [CrossRef]

- Stoner, B.R.; Glass, J.T. Carbon Nanostructures: A Morphological Classification for Charge Density Optimization. Diam. Relat. Mater. 2012, 23, 130–134. [Google Scholar] [CrossRef]

- Liu, Z.; Tabakman, S.; Welsher, K.; Dai, H. Carbon Nanotubes in Biology and Medicine: In Vitro and in Vivo Detection, Imaging and Drug Delivery. Nano Res. 2009, 2, 85–120. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef]

- Peng, B.; Locascio, M.; Zapol, P.; Li, S.; Mielke, S.L.; Schatz, G.C.; Espinosa, H.D. Measurements of Near-Ultimate Strength for Multiwalled Carbon Nanotubes and Irradiation-Induced Crosslinking Improvements. Nat. Nanotechnol. 2008, 3, 626–631. [Google Scholar] [CrossRef]

- Jensen, K.; Mickelson, W.; Kis, A.; Zettl, A. Buckling and Kinking Force Measurements on Individual Multiwalled Carbon Nanotubes. Phys. Rev. B 2007, 76, 195436. [Google Scholar] [CrossRef]

- Lu, X.; Chen, Z. Curved Pi-Conjugation, Aromaticity, and the Related Chemistry of Small Fullerenes (<C60) and Single-Walled Carbon Nanotubes. Chem. Rev. 2005, 105, 3643–3696. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Xie, J.; Jin, Z.; Wang, J.; Li, Y.; Jiang, K.; Fan, S. Fabrication of Ultralong and Electrically Uniform Single-Walled Carbon Nanotubes on Clean Substrates. Nano Lett. 2009, 9, 3137–3141. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Myung, S. A Flexible Approach to Mobility. Nat. Nanotechnol. 2007, 2, 207–208. [Google Scholar] [CrossRef] [PubMed]

- Koziol, K.K.; Janas, D.; Brown, E.; Hao, L. Thermal Properties of Continuously Spun Carbon Nanotube Fibres. Phys. E Low-Dimens. Syst. Nanostructures 2017, 88, 104–108. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal Conductivity of Carbon Nanotube Networks: A Review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

- Mingo, N.; Stewart, D.; Broido, D.; Srivastava, D. Phonon Transmission through Defects in Nanotubes from First Principles. Phys. Rev. B 2008, 77, 033418. [Google Scholar] [CrossRef] [Green Version]

| Applications | Principle | Detection Target | Year Ref. | |

|---|---|---|---|---|

| Sensors | Electrochemical sensors | Made of silver nanoparticles (AuNPs) + MWCNTs Mannan-Os Adducts | Dopamine | 2015 [9] |

| Made of glassy carbon electrodes modified with MWCNTs and copper microparticles (CuMPs) dispersed in polyethylenimine (PEIs) | Amino acids and glucose | 2016 [10] | ||

| Based on MWCNTs | Clostridium tetani | 2016 [11] | ||

| Based on AgNPs/bismuth (Bi)NPs/MWCNTs nafion modified | Lead and Cadmium | 2020 [12] | ||

| Based on carbon sensor fabricated with coalesced ruthenium-doped titanium dioxide (Ru–TiO2) NPs and MWCNTs | Cetrizine | 2019 [13] | ||

| Based on glassy carbon sensor modified with MWCNT in pH 9.0 phosphate-buffered solution (PBS) | Methdilazine | 2019 [14] | ||

| Based on (Ru–TiO2) NPs and MWCNTs | Flufenamic acid (FFA) Mefenamic acid (MFA) | 2019 [15] | ||

| Based on BiNPs decorated MWCNTs modified carbon paste electrode (Bi-MWCNT/MCPE) at physiological pH | Gallic Acid (GA) | 2020 [16] | ||

| Function | ||||

| Piezoelectric sensors | Based on MWCNTs on polydimethylsiloxane (PDMS) | N.R. | 2017 [17] | |

| Based on graphene, CNTs and graphene-CNTs composite | N.R. | 2018 [18] | ||

| Based on MWCNT on PDMS as substrate. | For developing robotic hands (rehabilitation) Strain detecting needle for tissue characterization | 2019 [19] | ||

| Based on MWCNTs on thermoplastic urethane as substrate. | Sensors integrated in gloves and bandages for assessing specific human functions | 2019 [20] | ||

| Based on MWCNTs on PDMS substrate | To measure pressure directly without the use of deformation materials. | 2019 [21] | ||

| Detection Target | ||||

| Gas sensors | Based on a resonant electromagnetic transducer in microstrip technology | Volatile Organic Compounds (VOCs) | 2019 [22] | |

| Based on dye functionalized matrix anchored onto MWCNTs. ammonia | Sulphur dioxide and chlorine | 2018 [23] | ||

| Based on tungsten oxide nano-bricks and MWCNTs | Ammonia gas | 2019 [24] | ||

| Transported Drugs | ||||

| Drug Targeting | Based on MWCNT and pH responsive gel consisting of chitosan coated magnetic nanocomposites | Doxorubicin (DOX) to U-87 Glioblastoma cells | 2019 [25] | |

| Based on stimuli responsive CNTs using Ag nanowires to stimulate the drug release from the core of NTs | Cisplatin | 2017 [26] | ||

| Based on electro responsive polymer-MWCNT hybrid hydrogel | Sucrose | 2013 [27] | ||

| Based on MWCNTs biodegradable, biocompatible nanocomposite hydrogel. | Diclofenac sodium | 2016 [28] | ||

| Cancer diagnosis and treatment | Based on methotrexate loaded MWCNTs releasing drugs by enzymatic cleavage | Methotrexate to in vitro breast cells | 2010 [29] | |

| Based on DOX loaded dendrimer modified MWCNTs releasing drugs at low pH | DOX | 2013 [30] | ||

| Based on cationic MWCNTs-NH3þ for direct intertumoral injections | Apoptotic siRNA against polo-like kinase (siPLK1) in calu6 tumor xenografts | 2015 [31] | ||

| Target bacteria/Applications | ||||

| Antibacterial agents | Based on chitosan/MWCNTs nanocomposites | Enterococcus faecalis Staphylococcus epidermidis Escherichia coli | [32,33,34,35,36,37,38] | |

| Based on iron oxides/SWCNTs | E. coli | 2018 [39] | ||

| Based on Ag–Fe3O4/SWCNTs | N.R. | 2018 [40] | ||

| Based on cyclodextrin/Ag/MWCNTs | N.R. | 2014 [41] | ||

| Based on MWCNTs containing carboxylic functions | N.R. | 2015 [42] | ||

| Based on polyaniline/graphene/CNTs | Staphylococcus aureus, E. coli | 2018,2012 [43,44] | ||

| Based on MWCNTs | Treatment of drinking water through removal and inactivation of virus and bacteria | 2011 [45] | ||

| Based on MWCNTs functionalized with mono-, di-, and tri-ethanolamine | E. coli, Klebsiella pneumonia Pseudomonas aeruginosa Salmonella typhimurium, Bacillus subtilis S. aureus, Bacillus cereus Streptococcus pneumonia | 2014 [46] | ||

| Based on dispersion SWCNTs/tetra-arylbimesityl derivative activated with carboxy groups | E. coli, S. aureus | 2019 [47] | ||

| Target fungi | ||||

| Antifungal agents | Based on chitosan/MWCNTs | Aspergillus niger, Candida trobicalis C. neoformans | 2000 [48] | |

| Based on functionalized CNTs | A. niger, C. albicans, A. fumigatus, Penicillium chrysogenum Saccharomyces cerevisiae, Fusarium culmorum Microsporum canis, Trichophyton mentagrophytes T. rubrum, P. lilacinum | 2013 [49] | ||

| Based on dispersion SWCNTs/tetra-arylbimesityl derivative activated with carboxy groups | C. albicans | 2019 [47] | ||

| Key Properties | Potential Uses | Current Hurdles |

|---|---|---|

| Size [61] | Nano-electronics [64] | Electronic heterogeneity [76] |

| Crystallographic defects | ||

| Stone–Wales defects | ||

| Ø < 100 nm Thickness = 1–2 nm Ideally infinite length | Conductors (SWCNTs) Superconductors Semi-conductors 1 Supercapacitors | Not tunable conductivity |

| Electrical and electrochemical properties | Interconnects | ⇩ Controllable orientation |

| ⇧ Electrical conductivity Constant resistively [63] Electrons emission capacity | Chips manufacture [65] Conductivity-enhancing components | ⇩ Organized configuration |

| Thermal Properties | ⇧ Variation in size and density [76] | |

| ⇧ Heat conductivity Expansion | Optics and photonics | |

| Mechanical properties | Light-emitting diodes (LEDs) [66,67] 2 | Export restrictions |

| ⇧ Tensile strength ⇧Elastic modulus | Photodetectors [68] 2 | |

| Optical Properties | Bolometers [69] 2 | |

| Absorption properties | Optoelectronic memory devices [70] 2 | |

| Photoluminescence (fluorescence) | ||

| Raman spectroscopy properties | ||

| Others | Batteries [71] | Environmental concerns [76] |

| Easily modifiable structure | ||

| Presence of functional groups | Supercapacitors production Ultra-thin flexible batteries Implantable medical devices | |

| Chemical inertness | ||

| Easily optimizable solubility and dispersion | Cleaning up polluted environments | |

| Water filtration Air filters, such as smokestacks [72] | ||

| Others | ||

| Transistors production [73,74] | ||

| Energy production | ||

| Solar cells [75] | ||

| Light weight | Energy Storage | |

| ⇧ Biocompatibility | CNT-based fibers and fabrics | |

| Capability of molecules immobilization | CNT-based ceramics | |

| Transport of protein, DNA, RNA | ||

| Large surface area | Sources of light | |

| High capability of absorbing chemicals from their surroundings | Entrenched dominance of other material |

| Nanostructure | Bacteria | Constituents | Function * Occurrence (%) ** | Ref. |

|---|---|---|---|---|

| NTs | B. subtilis | CM | Trade of cytoplasmic materials, nutrients, toxins * 70% ** | [51,56,59] |

| E. coli | ||||

| B. megaterium | ||||

| D. radiodurans | ||||

| NWs | Shewanella genus | CM | Electrically conductive appendages * | [84,85] |

| Geobacter genus | ||||

| NPs | Delfitia sp. Cs 1-4 | CM | Long-distance interactions with environment * Deployment of OM vesicles and tubes (OMV/Ts) * | [84,85,86] |

| H. archaea Thermococcus genus | ||||

| OMTs | M. xanthus F. novicida | OM | Functions in pathogenesis * | [55,57] |

| Bacterial Specie | Class of NT | Location | Function | Ref. |

|---|---|---|---|---|

| B. subtilis E. coli | ENTs | Attached to a single cell | ⇧ Surface area of cells Contribute to nutrient uptake | [51,54,56,88,89] |

| INTs | Connecting two cells | Conduits for transport of metabolites (amino acids), proteins (including toxins), and non-conjugative plasmids |

| Method | Process Type | Products Purity | Conditions Yields (%) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Arc discharge (AC) | The carbon in the negative electrode sublimates due to the high discharge temperatures (T) | SWCNTs short tubes Ø = 0.6–1.4 nm MWCNTs short tubes Inner Ø = 1–3 nm Outer Ø = 10 nm Medium purity | Argon/N2 500 torr T ≤ 4000 °C 20–100% | Few structural defects | Length ≤ 50 µm |

| Laser ablation (LA) | Graphite samples are vaporized in a reactor at ⇧ T by a pulsed laser in presence of an inert gas CNTs grow up on the cooler reactor’s surfaces as the vaporized carbon condenses | SWCNTs 5–20 µm Ø = 1–2 nm MWCNTs Low purity | 500–1000 °C at ⇧ energy laser beam 25–1000 °C≤ 70% | Controllable Ø by the reaction temperature | ⇧ Expensive than AC, CVD |

| Chemical Vapor Deposition(CVD) | Layered metal catalyst particles are heated in a reactor where a process gas and a carbon-containing gas are bled into | SWCNTs long tubes Ø = 0.6–4 nm MWCNTs long tubes Ø = 10–240 nm Medium-High purity | Low pressure inner gas (argon) 500–1200 °C 60–90% | ⇧ Economic and simple than AD and LA Synthesis at ⇩ temperature and ambient pressure ⇧ Yield and purity than AD and LA. Versatile in the control of CNTs structure/architecture Suitable for scale up | ⇩ Crystallinity than that by AD and LA Removal of the catalyst support |

| Cells | Species | Tubular Structure Type | Constituents | Inducing Stress | Physiological Role |

|---|---|---|---|---|---|

| Prokaryotic | B. subtilis | NTs | CM proteins CM lipids | Poly-L-lysine Pressure Different antibiotics | Hallmark of dying cells or cell death and cell disintegration |

| B. megaterium | NTs | CM proteins CM lipids | N.R. | To be better investigated | |

| D. radiodurans | NTs | CM proteins CM lipids | Mitomycin C | Cytoplasmic constituents exchange To be better investigated | |

| E. coli | NTs | CM proteins CM lipids | Amino-acid deprivation | Cytoplasmic constituents exchange To be better investigated | |

| M. xanthus | OMTs | OM protein OM lipids | Lack of oxygen Metabolic inhibitors | Hallmark of ghost cells | |

| F. novidica | OMTs | OM protein OM lipids | Amino-acid deprivation Macrophage infection | Hallmark of ghost cells | |

| F. tularensis | OMTs | OM protein M lipids | Amino-acid deprivation Macrophage infection | Hallmark of ghost cells | |

| Eukaryotic | Macrophages | TNTs | F-actin Proteins | HIV-1 Mycobacterium tuberculosis | Channels for cell-to-cell communication |

| Physical Property | Largest | Smallest | Ref. |

|---|---|---|---|

| Diameter | N.R. | 0.30 nm (MWCNT) 1 0.43 nm (SWCNT) | [148] |

| Length | 0.5 m 2 | Cycloparaphenylenes (2.49 Å) 3 | [149] [150] |

| Density | 1.6 g/cm * | N.R. | [151,152] |

| Associations Morphologies | Type of Interaction Arrangement | Possible products | Applications/Properties | Ref. |

|---|---|---|---|---|

| CNTs/CNTs * | Junctions s | Metallic CNTs/semiconducting CNTs | Component of NTs-based electronic circuits | [153,154,157] |

| CNTs/graphene * | Junctions | Pillared graphene (3D-CNTs) | Energy storage Supercapacitors Field emission Transistors High-performance catalysis Photovoltaics Biomedical devices Implants Sensors | [158,159,160,161] |

| 2 CNTs/fullerenes * | Covalent Bond | Fullerene-like nanobuds | Field emitters | [162] |

| CNT/fullarene * | Entrapment | Carbon peapods (CPPs) | Heating devices Irradiating devices Oscillators | [163,164,165,166] |

| Doughnut shape ** | CNTs twisted into a toroid (Annulus shape). | Nanotori (NTRs) | ⇧ magnetic moment ⇧ stability | [167,168] |

| GFs/MWCNTs * | GFs integrated MWCNTs | Graphenated carbon nanotubes (GCNTs) | ⇧ surface area 3D-framework ⇧ total charge capacity per unit of nominal area | [169,170] |

| quasi-1D carbon structures ** | Stacking microstructure of graphene layers | Cup-stacked carbon nanotubes (CSCNTs) | Semiconductors | [171] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfei, S.; Schito, G.C. Nanotubes: Carbon-Based Fibers and Bacterial Nano-Conduits Both Arousing a Global Interest and Conflicting Opinions. Fibers 2022, 10, 75. https://doi.org/10.3390/fib10090075

Alfei S, Schito GC. Nanotubes: Carbon-Based Fibers and Bacterial Nano-Conduits Both Arousing a Global Interest and Conflicting Opinions. Fibers. 2022; 10(9):75. https://doi.org/10.3390/fib10090075

Chicago/Turabian StyleAlfei, Silvana, and Gian Carlo Schito. 2022. "Nanotubes: Carbon-Based Fibers and Bacterial Nano-Conduits Both Arousing a Global Interest and Conflicting Opinions" Fibers 10, no. 9: 75. https://doi.org/10.3390/fib10090075