1. Introduction

With an annual global production volume of 105.3 million m

3 in 2022 [

1], particleboard represents a fundamental wood-based composite material in commercial applications. Its widespread use in the furniture and construction industries highlights its importance as a cost-efficient alternative to solid wood and plywood. The production of particleboard involves a complex process, wherein the preparation of wood particles plays a substantial role and contributes significantly to the total production costs [

2]. Understanding the influence of particle dimensions is essential, as they affect board properties [

3]. Therefore, comprehending the impact of particle size on board properties is of significant importance for optimizing production processes in terms of efficiency and ensuring consistent quality.

While the variables that influence the properties of particleboard appear to have been widely investigated, there are inevitable gaps in the knowledge of the influence of particle dimensions. The primary reason for this limitation is that, to date, particle dimensions have been assessable only through undifferentiated sieve analysis to an insufficient extent using 2D image analysis or with immense personnel expenditure through manual individual measurements. In the case of 3D image analysis based on free-falling particles, different results are obtained for repetitively measured particles depending on their orientation to the cameras. Previous research approaches shared a common limitation in that their test setups did not enable an isolated examination of the effect of particle dimensions, despite a fundamental absence of appropriate particle measurements. Their results are therefore obscured by parameters that have well-known influences on board properties. These are board density [

4,

5,

6], distinctive density profile [

7], multi-layered board structure (different particle sizes in face and core layer), obvious particle-size distribution perpendicular to the board plane, adhesive content (AC) [

3] (pp. 786–789), and surface-specific adhesive amount (SSAA) [

2]. For an isolated investigation, these parameters have to be kept constant.

For example, Istek et al. [

8] investigated three-layer particleboards with varying particle dimensions in the face and core layers by using different sieve fractions. Due to the production parameters (press temperature: 180 °C; press duration: 190 s), it is likely that the boards possess distinctive density profiles that vary with the applied particle material and thus obscure the influence of the particle size. Furthermore, the inevitable change in the SSAA with variation in the particle dimensions was not taken into account. The bending properties increased with increasing face and core layer particle size. The IB increased with increasing core layer particle size, whereas changing the surface layer particle size did not lead to a significant increase in IB. Niemz and Sonderegger [

9] provide insights into the relationship between particle dimensions and board properties, although they provide no details on the chosen experimental setup. They note an increase in the MOR with increasing particle length and a decrease with particle width and thickness. The MOR and MOE increase up to a slenderness ratio (defined as the ratio of length to thickness) of approximately 100. Further, the IB decreases with increasing particle length and width and reaches a maximum at moderate (not defined in detail) particle thicknesses. Arabi et al. [

10] investigated single-layer particleboards made of three different sieve fractions of poplar particles and found an increase in the bending properties with an increasing slenderness ratio, while the opposite was found for IB. With the chosen production parameters (press temperature: 180 °C; press duration 5 min), the particleboards must have had a distinctive density profile and therefore were unsuitable for assessing the isolated influence of particle size. Arabi et al. [

11] obtained similar results for the relationship between the slenderness ratio and the mechanical properties of particleboard by applying the response surface method. Post [

12] analyzed boards made of particles with varying dimensions and a constant SSAA (but a distinctive density profile due to a press temperature of 135 °C and a press duration of 15 min) and found an increase in the bending properties with an increasing slenderness ratio of up to 300. In contrast, Kitahara and Kasagi [

13] found an increase in the bending properties with decreasing particle size while investigating boards made of particles of proportionally different sizes (uniform shape), keeping the SSAA constant. Kimoto et al. [

14] made single-layer particleboards of particles of different sizes and with a distinctive density profile (press temperature: 130 °C; press duration: 18 min) without keeping the SSAA constant. They found an increase in the MOR and a decrease in the IB when increasing the slenderness ratio up to 100.

In all the described research approaches, the test setups did not allow an investigation of the isolated influence of the particle size. Therefore, the main aim of the present study was to investigate the isolated influence of the particle size on the mechanical properties of particleboard without the overlapping effects of the following:

A multi-layered board structure (different particle sizes in face and core layers);

A distinctive density profile (perpendicular to the board plane);

A changing specific amount of adhesive caused by a change in surface area (SSAA).

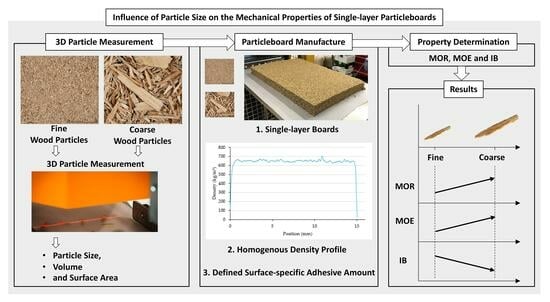

This was achieved by producing and investigating single-layer particleboards with a uniform density profile and a defined SSAA made from (fine) face layer particles (FLPs) and (coarse) core layer particles (CLPs) obtained from an industrial particleboard manufacturer.

In this paper, a comprehensive investigation into the impact of particle size on particleboard properties is presented. The recently developed 3D Particleview (Fagus-GreCon Greten GmbH & Co. KG (GreCon), Alfeld, Germany) measurement technology is used, which automatically determines the dimensions, surface, and volume of particles and enables one to calculate the material-specific surface area (mm2/g) and, thus, the SSAA (g/m2). The MOR and MOE were found to increase with increasing particle size, while the opposite applies to the IB. Such data regarding basic correlations are crucial for process optimization.

2. Materials and Methods

2.1. Wood Particles and Adhesive

The wood particles used in this study were FLPs and CLPs supplied by the particleboard manufacturer Pfleiderer Deutschland GmbH, Neumarkt, Germany. They were taken from the material flow after drying and before gluing.

The FLPs were sieved in preparation for the measurement by using an Allgaier TSM 600/3 sieve machine (Allgaier-Werke GmbH, Uhingen, Germany) with a sieve insert of 1 mm mesh size. The particles were dried in a laboratory convection dryer at 103 °C to a residual moisture content (MC) of approximately 1% and packed in airtight polyethylene bags for intermediate storage.

The adhesive used was urea formaldehyde (UF) adhesive with 66% solid content, a pH of 7.5 to 9, viscosity of 400 to 600 mPa·s (at 20 °C), and a gel time of 40 to 60 s (at 100 °C). An ammonium nitrate solution with 40% solid content was used as the hardener.

2.2. Determination of Particle Moisture Content

The particle moisture content (MC) was determined by using a thermogravimetric moisture analyzer Sartorius MA 35 (Sartorius AG, Göttingen, Germany).

2.3. Three-Dimensional Particle Measurement

To determine the particle dimensions, the particle surface and the particle volume, an automated laser scanner (3D Particleview (GreCon)) with version 1.0.0.0 of the software was used. The resolution of the measuring device is 0.1 mm in length and width and 0.02 mm in thickness. Thus, to ensure a reliable measurement, the FLPs were sieved. The chosen measurement mask was “min. area 1 mm2”, the conveyor belt speed was set to 15 m/min, the first vibratory feeder was set to 16%, and the second vibratory feeder was set to 45% of the maximum available vibration rate.

FLPs and CLPs were measured by using triple determination. Each measuring run weighed approximately 5 g for FLPs. To ensure that a similar number of particles was measured for CLPs, a weight of 24 g was selected based on the number of particles per gram.

In addition to measuring particle length, width, thickness, and surface, the slenderness ratio (length divided by thickness), width ratio (length divided by width), and flatness (width divided by thickness) were calculated for each individual particle. The mean values are provided in

Section 3.

2.4. Calculation of SSAA

The SSAA was calculated on the basis of the dry particle mass, the AC (mass of solid adhesive in relation to dry particle mass), and the surface area per gram (dry particles), following Equation (1),

while the surface area per gram was calculated as the quotient of surface area and dry particle mass.

2.5. Mat Center Temperature Measurement

Thermocouples were used to check the temperature at the center of two additional test boards, one made from FLPs and the other made from CLPs. Three thermocouples were placed at the center of each test board during scattering. The mat temperature was documented during pressing by using the laboratory hot press’s integrated data logger. This allowed for verification that the adhesive was fully cured and the particle mat center had reached a minimum temperature of 100 °C.

2.6. Particleboard Manufacturing

Single-layer particleboards were produced using a computer-controlled laboratory hot press, Siempelkamp Typ 2 (G. Siempelkamp GmbH & Co. KG, Krefeld, Germany). The target density of the boards conditioned at 20 °C and 65% relative humidity (RH) was 650 kg/m

3. The target board thickness was 15 mm. The target MC of the particle mat (mass of water in relation to dry mass of particle mat) was 7.1%. The AC varied from 8 to 5.3 and 12.2%; the corresponding SSAAs were 8.2 and 12.5 g/m

2 (see

Table 1). Before application, 6% hardener (mass of solid content in relation to dry particle mass) was added. Gluing of the particles was conducted by using a portable concrete mixer (Atika Maschinenfabrik Wilhelm Pollmeier GmbH & Co., Ahlen, Germany) with a drum diameter of 600 mm. The adhesive was transported through a silicone hose from the beaker to the nozzle (Schlick Mod. 940/5 0.8 mm W38558 (Düsen-Schlick GmbH, Untersiemau/Coburg, Germany)) with an orifice of 1.8 mm by using a Watson-Marlow 323 peristaltic hydraulic pump (Watson-Marlow GmbH, Rommerskirchen, Germany). The glue was applied by using a pressure of approximately 5 bar onto the falling stream of particles at the center of the rotating drum. The amount of additional water was calculated with regard to particle moisture content and added with an atomizer before applying the adhesive to the particles in the rotating drum. The particle MC was unified in this manner, rather than by adding water to the adhesive beforehand, ensuring a uniform viscosity during all tests. Furthermore, by scattering the particle mat in excess, the desired density was achieved despite the mat’s lateral deflection during the pressing process.

The particles were weighed and scattered in a forming mold of 585 × 400 mm positioned on an aluminum caul plate covered with siliconized paper to prevent adherence between the board and caul plates. The finished scattered particle mat was pre-compacted before the forming mold was removed. After removing the forming mold, the particle mat was covered with a second siliconized paper and transferred to the laboratory hot press.

In order to obtain particleboards with a uniform density profile, the cold particle mat was compacted to a thickness of 15 mm with a closing time of 30 s and a pressure limited to 230 bar in the hot press. During the following 60 min, the distance was kept constant at a pressure limited to 120 bar, while the press temperature was steadily increased to 120 °C. After hot pressing, the boards were cooled at ambient conditions, edge-trimmed to 515 × 330 mm, and then stored in a climate chamber at 20 °C and 65% RH before sample cutting.

2.7. Test Specimen Preparation

According to the cutting plan shown in

Figure 1, for BT 1 to BT 4,

Between cutting and testing, the test specimens were stored in a climate chamber at 20 °C and 65% RH.

To confirm that the board preparation process yields boards with uniform density profiles, three samples measuring 50 × 50 × 15 mm were cut from each board. The samples were taken from the edges of the examined bending specimens, and density scans were performed.

2.8. Board Density Determination

The board density was determined according to [

15].

2.9. Density Profile Determination

Density profiles (density distribution perpendicular to the board plane) were determined using a Dense-Lab X laboratory density scanner (Electronic Wood Systems GmbH, Hameln, Germany) with the resolution set to 20 (0.36 mm/s).

2.10. Horizontal Density Distribution

The distribution of the density in the horizontal direction of the board was determined by calculating the bulk densities of all bending and IB test specimens for each test board. The absolute value of the deviation (AVD) from the mean value of the tested specimens per test board was set in relation to the mean value (of all test specimens per board) and given as a percentage, following Equation (2).

2.11. MOR, MOE, and IB Determination

The MOR and MOE were determined according to [

16]. IB was determined according to [

17].

2.12. Experimental Design

Four types of board, each produced in triplicate, were manufactured. The boards were composed of varying particle materials (FLPs, CLPs) and SSAAs (8.2 g/m

2, 12.5 g/m

2) (see

Table 1). For board type (BT) 1, the SSAA calculation was based on the surface area of the CLPs along with an AC of 8%. Similarly, for BT 2, the SSAA calculation was based on the surface area of FLPs and an AC of 8%. The AC for BT 3 was calculated by using the SSAA of BT 1, in combination with the surface area of FLPs. Similarly, the AC for BT 4 was calculated by using the SSAA of BT 2, along with the surface area of CLPs, in accordance with Equation (3):

The FLPs served as a particle material with a small particle size, and the CLPs served as a particle material with a large particle size.

In order to investigate the influence of particle size on the board properties, the SSAA of BT 1 (CLP) selected was the same as that of BT 3 (FLP), and that of BT 4 (CLP) was the same as that of BT 2 (FLP). The different surface areas of the particle materials resulted in different ACs.

From the combined consideration of the board properties of BT 1 and BT 3, as well as BT 2 and BT 4, the influence of particle size on the board properties can be deduced since, in addition to the density, the SSAA was kept constant.

From the consideration of BT 1 and BT 4, as well as BT 2 and BT 3, the influence of the SSAA can be derived since the particle size was kept constant.

2.13. Statistical Analysis

Statistical analysis and graphical representation of the experiments were carried out by using the JMP 16 analysis tool (SAS, Cary, NC, USA) and Microsoft Excel 2021 (Microsoft Corporation, Redmond, DC, USA), respectively.

Each dataset was checked for extreme outliers by applying the interquartile range (IQR) method, with the IQR being the difference between the third quartile (Q3 or 75% quantile) and the first quartile (Q1 or 25% quantile). As the lower criterion for defining an extreme outlier, the first quartile minus the triple IQR (Q1 − 3 IQR) was used; as the upper criterion for defining an extreme outlier, the third quartile plus the triple IQR (Q3 + 3 IQR) was used. In the case of a detected extreme outlier, all data available for this test specimen were excluded from the evaluation.

The selection of appropriate tests for statistical data analysis was carried out according to a statistical decision path given by Benthien et al. [

18], which is shown in

Figure 2. All statistical tests were carried out at a significance level of α = 0.05.

2.14. Shift of Data to Targeted Board Density

Between excluding extreme outliers and conducting further statistical evaluation, the values for the mechanical board properties were adjusted to match the target density. This was achieved by calculating a linear regression between specimen density and strength, which was then applied to each board type to bring the corresponding strength to the level matching the board’s target density (Equation (4)).

3. Results

3.1. Three-Dimensional Particle Measurement

Table 2 presents the results of the 3D particle measurement. Regarding FLPs, in total, 52,306 particles were measured, while there were 59,024 CLPs. For the FLPs, the mean length, width, and thickness are 2.0, 0.9, and 0.23 mm; for the coarser CLPs, they are 3.6, 1.1, and 0.33 mm. The mean slenderness ratio, width ratio, and flatness are 10.1, 2.4, and 4.4 for the FLPs and 12.9, 3.4, and 4.0 for the CLPs. Compared to the CLPs, the FLPs have a higher surface area per gram (9734 versus 6389 mm

2/g).

3.2. Verification of Press Program Suitability and Board Characteristic Achievement

Both the FLPs and the CLPs required a maximum of 53 min for the mat center temperature to reach 100 °C (the maximum value recorded by the six thermocouples).

The greatest percentage density deviation was located in an IB test specimen at the very edge of board 1 of BT 1 with a deviation of 13.7%. The mean density deviation for each test board varied from 1.6% (board 2 of BT 3) to 4.6% (board 2 of BT 1).

Figure 3 shows an exemplary density profile of an FLP board. In all cases, the intended uniform density profile was achieved.

3.3. Main Experiments

No extreme outliers were detected in any of the considered datasets following IQR outlier detection. Since density-compensated mean values were considered for further evaluation, density data are given in the

Supplementary Materials.

Table 3 presents the outcomes of the bending and internal bond tests conducted on BT 1, BT 2, BT 3, and BT 4. For the properties shown, a comparative assessment of the mean values between the individual boards for each board type is provided in capital letters. Statistically significant differences exist between the mean values annotated with different letters.

A comparison of the mean MOR of individual boards of the same board type showed no statistically significant differences. The mean MOEs showed statistically significant differences between the individual boards of BT 1 and BT 4, while the mean IBs are statistically different between the individual boards of BT 1, BT 2, BT 3, and BT 4. To be able to make a more reliable statement about the influence of particle size and SSAA on the mechanical properties, the mean values for each board type are used as follows.

In addition to the mean values for the mechanical properties of each board type,

Table 4 presents the results of pairwise mean value comparisons on the influence of particle size and SSAA on MOR, MOE, and IB. The mean values for MOR, MOE, and IB vary significantly between the different board types depending on the particle material and SSAA.

A comparison between BT 3 and BT 1 shows the influence of particle size, as both have an identical SSAA of 12.5 g/m2 but are made from fine and coarse particles, respectively. The fine FLP board BT 3 shows a significantly lower MOR and MOE than the coarse CLP board BT 1. The opposite was observed for the IB. For BT 3, the values for MOR, MOE, and IB are 7.2 (±4%), 1212 (±2%), and 1.30 (±6%) N/mm2, respectively. In contrast, for BT 1, the values are 10.0 (±5%), 1635 (±3%), and 0.85 (±5%) N/mm2. The same coherences are found by comparing BT 2 and BT 4, both of which were produced with a constant SSAA of 8.2 g/m² while varying the material from FLPs to CLPs.

A comparison of BT 2 and BT 3, which are both FLP boards but were produced with SSAAs of 8.2 g/m2 and 12.5 g/m2, respectively, shows the influence of the SSAA on the mechanical properties. BT 2, produced with an SSAA of 8.2 g/m2, has a statistically significantly lower MOR, MOE, and IB compared to BT 3, produced with an SSAA of 12.5 g/m2. For BT 2, the MOR, MOE, and IB are 6.9 (±3%), 1162 (±2%), and 1.01 (±5%) N/mm2, while for BT 3, they are 7.2 (±4%), 1212 (±2%), and 1.30 (±6%) N/mm2. The same statistically significant coherences were found when comparing BT 4 and BT 1, both made of CLPs, when changing the SSAA from 8.2 to 12.5 g/m3.

4. Discussion

The main aim of this study was to investigate the isolated influence of particle size on the mechanical properties of particleboards by excluding confounding effects of other influencing variables.

For both a low (8.2 g/m2) and high (12.5 g/m2) SSAA, the MOR and MOE increased with a change in particle size from fine to coarse. The opposite applies for the IB, even if the (mass-specific) AC is kept at a constant level of 8%, which even equates to a higher SSAA for CLPs. Consequently, it appears that coarse particles are beneficial for a high MOR and MOE, while fine particles are advantageous for a high IB.

The correlation between particle size and bending properties seems plausible, as can be easily understood by comparing the particle sizes and bending properties of oriented strand board (OSB) and particleboard. The results of the IB are less easy to interpret, considering that Sackey et al. [

19] found that the admixture of coarse particles in the core layer leads to an increased IB. It is, therefore, possible that the relationship between particle size and IB is influenced by another variable, for example, the particle shape and presumably, in consequence, particle orientation.

From the particle measurements, one can determine to what extent the dimensions of the surface and core layer particles differ from each other (see

Table 2). Based on these data, the ratios of dimensions to each other (length to width to thickness) can be calculated and specified as follows:

FLPs: 1 to 0.5 to 0.1;

CLPs: 1 to 0.3 to 0.1.

The following values of slenderness ratios, width ratios, and flatness, respectively, were obtained:

FLPs: 10.1, 2.4 and 4.4;

CLPs: 12.9, 3.4 and 4.0.

It can be seen that the particle sizes in the present study were not varied with a constant particle shape, as was the case in [

13], but the dimensions were varied disproportionately to each other. It is conceivable that this leads to a different orientation of the particles in the board and obscures the effects of the particle size.

It can be further assumed that coarse particles, due to their higher slenderness ratio, tend to be oriented parallel to the board plane during scattering. Fine, more cubic particles with a lower slenderness ratio tend to be oriented more randomly and are also perpendicular to the board plane. According to Niemz and Wenk [

20], the longitudinal wood anatomical direction is predominantly oriented parallel to the longitudinal axis of the particles, which leads to the highest strength properties in the axial direction. This fact, together with the aforementioned shape-dependent orientation of the particles during scattering, could explain the increase in bending properties with increasing particle size and also the increase in the IB with decreasing particle size. In both cases, the particles are predominantly strained in the axial direction. However, this theory is only valid if the break occurs in the wood and not in the adhesive joint, which has not been investigated in the present study. The aforementioned approach could be substantiated by May [

21], who found increased IB values when particles are oriented vertically in the core layer.

Further, an increase in all investigated board properties (MOR, MOE, IB) was found when increasing the SSAA from 8.2 g/m2 to 12.5 g/m2 within one material type (FLPs or CLPs, respectively). This reflects the well-known (positive) correlation between AC and board properties. The increase in MOE, MOR, and IB with increasing SSAA can be attributed to the availability of more adhesive in relation to the particle surface, resulting in better interconnection between the particles.

Many existing studies have (unwittingly) investigated not the influence of particle size, but rather the influence of the SSAA. This is because the AC was kept constant for particles of different sizes; hence, the SSAA was unintentionally changed. If, for example, the particle size is increased while the AC is kept constant, the total particle surface decreases and the SSAA increases, which—as shown by the presented results—leads to an increase in all considered board properties.

A comparison of this study’s results with prior studies has proven challenging due to this fact. However, if the different methodologies are disregarded, similarities can be observed. For example, various studies have shown a correlation between an increase in bending properties and either an increase in particle size [

8] or an increase in slenderness ratio [

9,

10,

11,

12,

14]. Other studies similarly found an increase in the IB with a decrease in the slenderness ratio [

10,

11,

14]. In contrast, a study on the effect of particle size on bending properties [

13] produced results that contradict the results of this study. The partly contradictory results of other studies are presumably due to the different methodologies, which attenuate the comparability.

The basic relationships presented here represent an important basis for the optimization of particleboard processes with regard to cost- and material-efficient production. If, for example, particles with high slenderness ratios are used, boards with conventional properties can be produced with a lower wood input and a lower density. Furthermore, by integrating 3D particle measurements into the process, it may be possible, for example, to counteract poor mechanical board properties because of an unintentional decrease in particle size (e.g., through wear of the knife ring flakers) by increasing the specific amount of adhesive.

Nevertheless, it should be noted that the results presented in this study are valid only for two different particle sizes. Further investigations with multiple fractions would be useful to substantiate the fundamental relationships discussed here. The method presented offers significant benefits, not only in terms of enhancing efficiency but also in predicting board properties. This prediction is possible once the causal link between individual influences and resultant properties is well understood. The approach should be viewed as a significant shift in how the outcomes of property analyses have been historically attributed to numerous overlapping factors. Further research should therefore focus on the impact of particle dimensions, rather than only the impact of particle size, on particleboard properties, given the availability of data from 3D particle measurement techniques.