Investigation on Strengthening Approaches Adopted for Poorly Detailed RC Corbels

Abstract

:1. Introduction

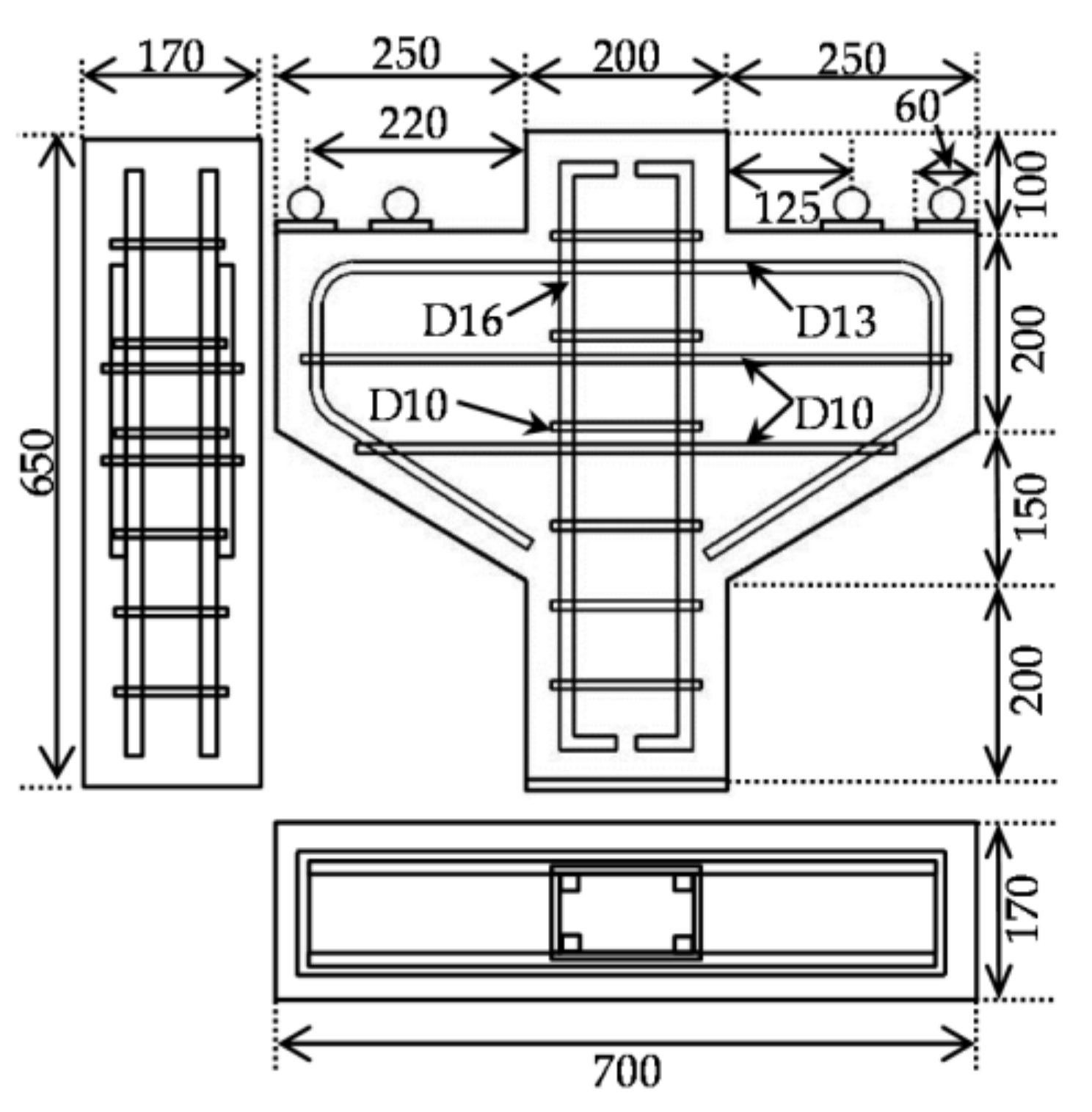

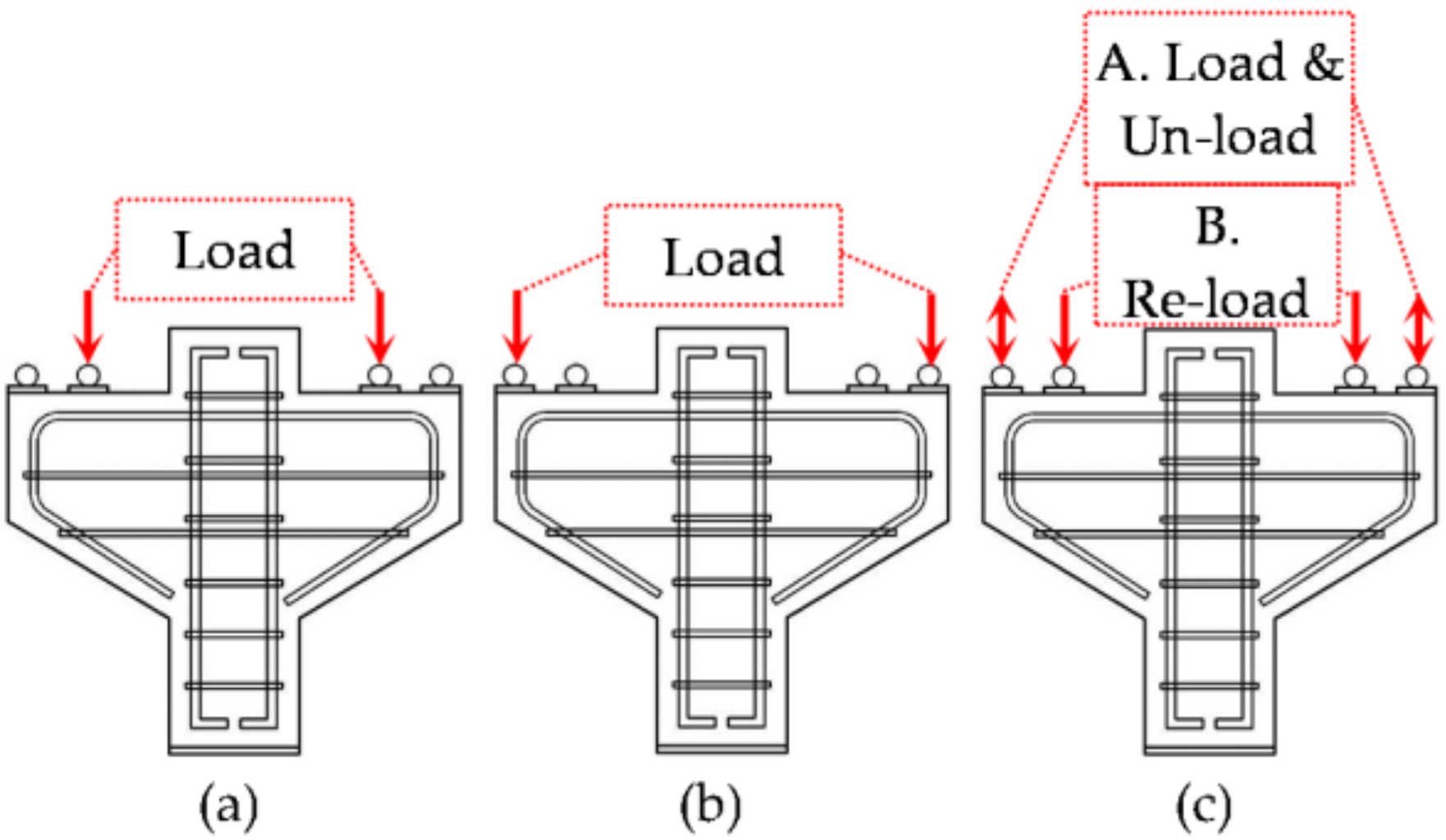

2. Experimental Program

2.1. Overview

2.2. Material Properties

2.3. Application of CFRP

- The bonding area was scrapped using a disk sander to completely remove the outer bleeding layer and crumbling surface or dirt, revealing the tough aggregates. All four sharp edges were rounded approximately 20 mm in radius. Tentative reference for rounding radius was taken from Sadeghian et al. 2010 [12]. Surface and voids were made free of grind dust using a high pressure air blower.

- Prescribed proportion of primer (FP-NS) was mixed by hand and applied at room temperature over the roughened dry surface, as per manufacturer’s guidelines, at the rate of 200 g/m2. It was allowed to set hard for a minimum of three hours at the room temperature.

- Levelling putty (FE-Z) was applied at the rate of 1500 g/m2 to smoothen uneven surfaces and sharp corners. All voids were filled properly with putty. It was allowed to set hard for a minimum of 24 h at room temperature.

- The CFRP tow sheet was laid after applying one layer resin (FP-E3P) at the rate of 500 g/m2. Another cover layer resin was also applied at the same rate and rolled with a roller so that the resin connected to each fiber properly. For multiple layers of CRFP tow sheet, a layer of resin was applied below and above the sheet.

- The test was performed seven days after the complete application of CFRP.

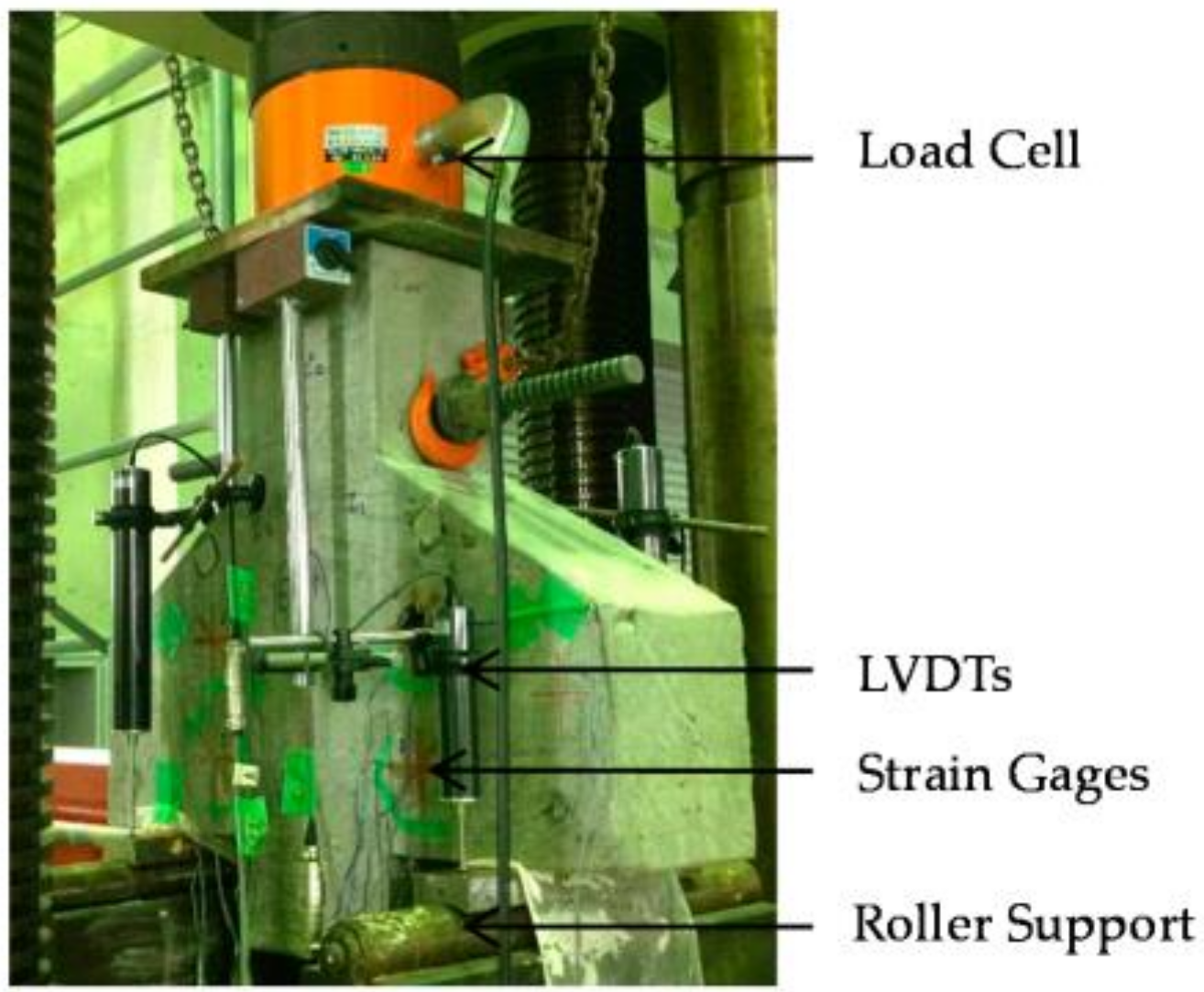

2.4. Test Setup and Measurements

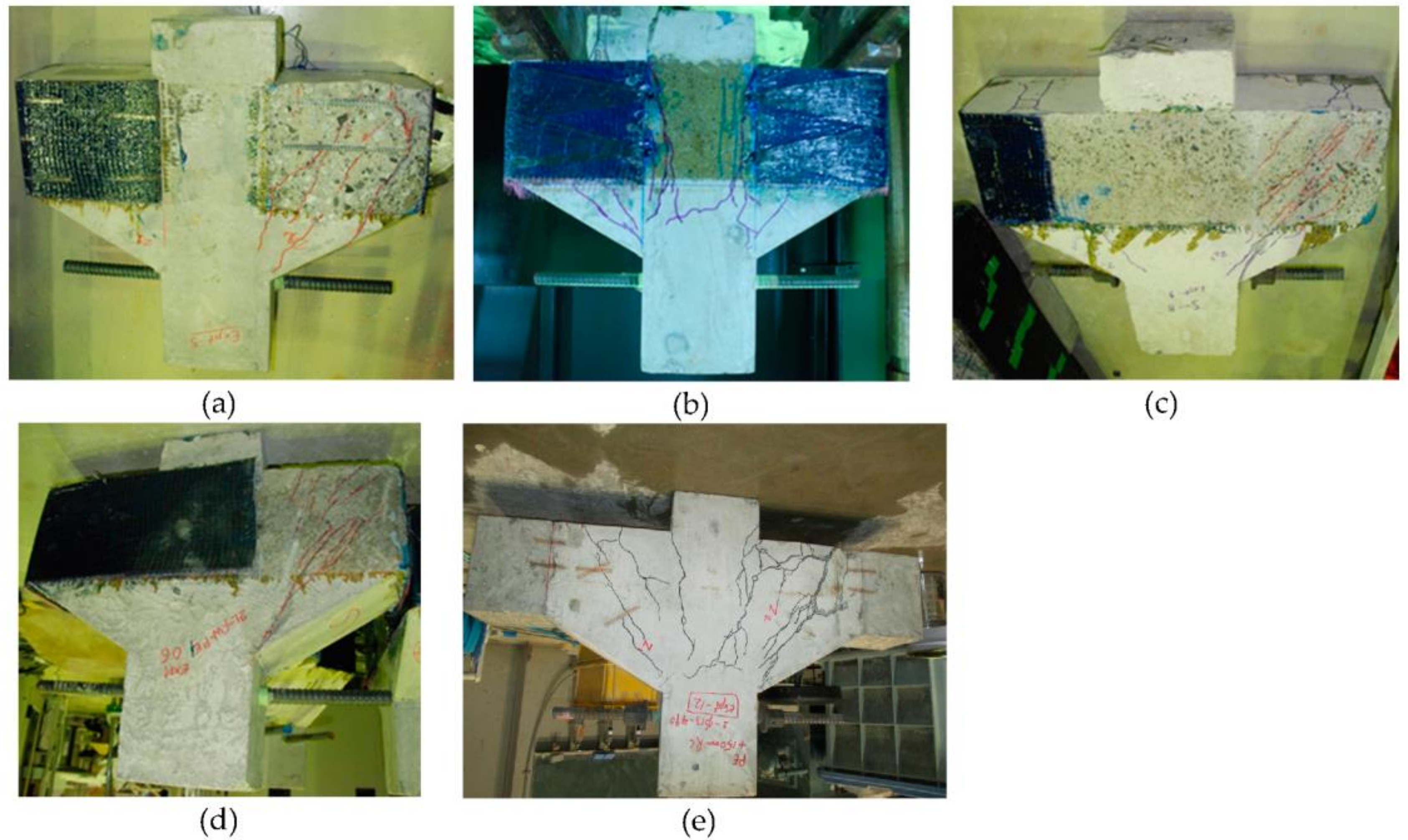

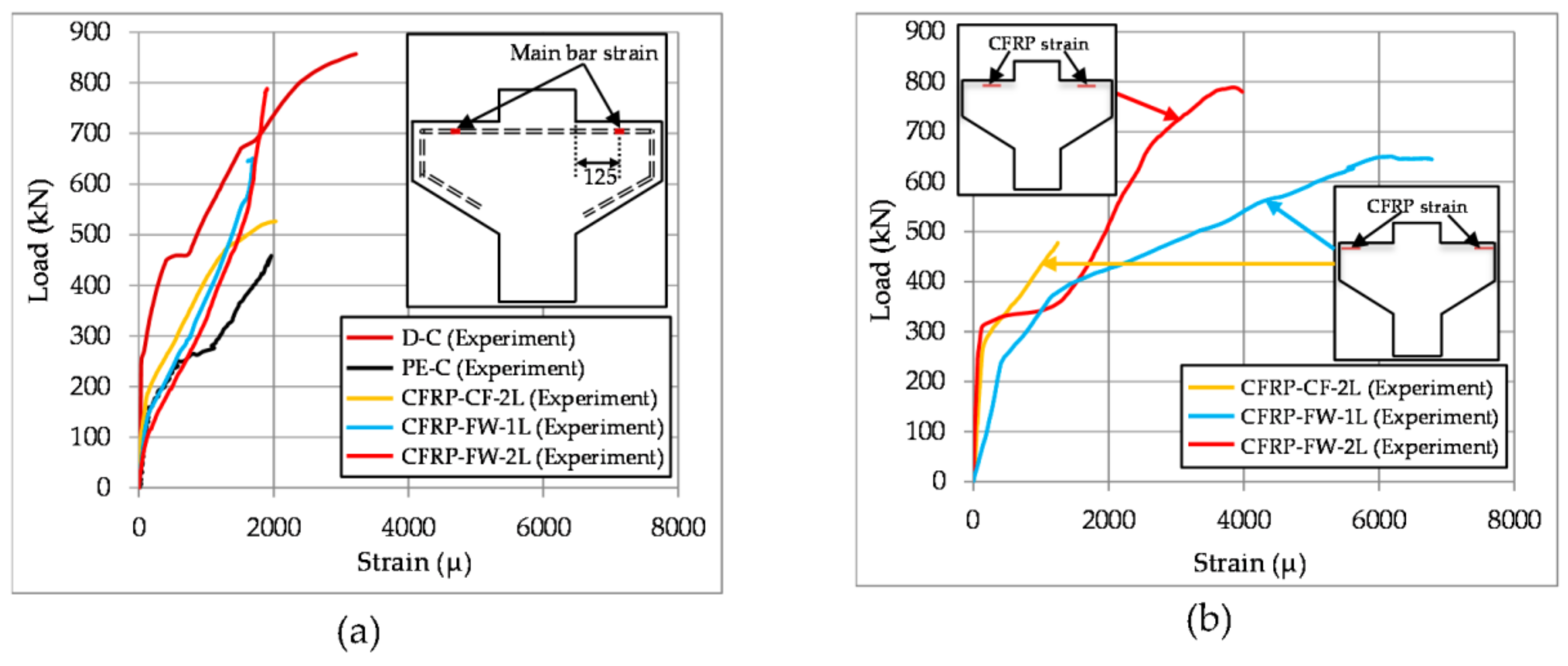

3. Experimental Results

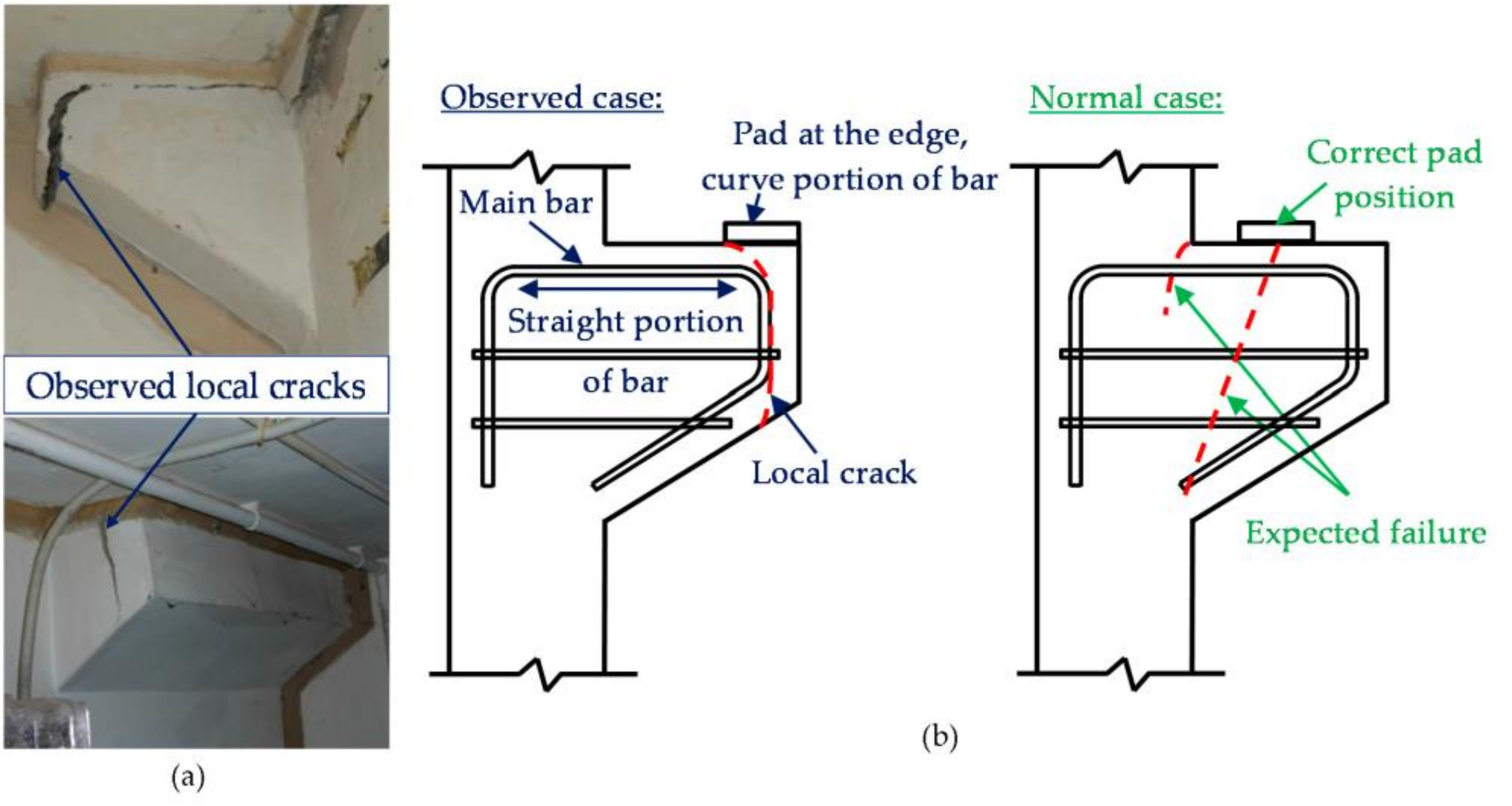

3.1. Premature Failure and Residual Capacity

3.2. Retrofitting of Corbels Subjected to Local Failure Criterion

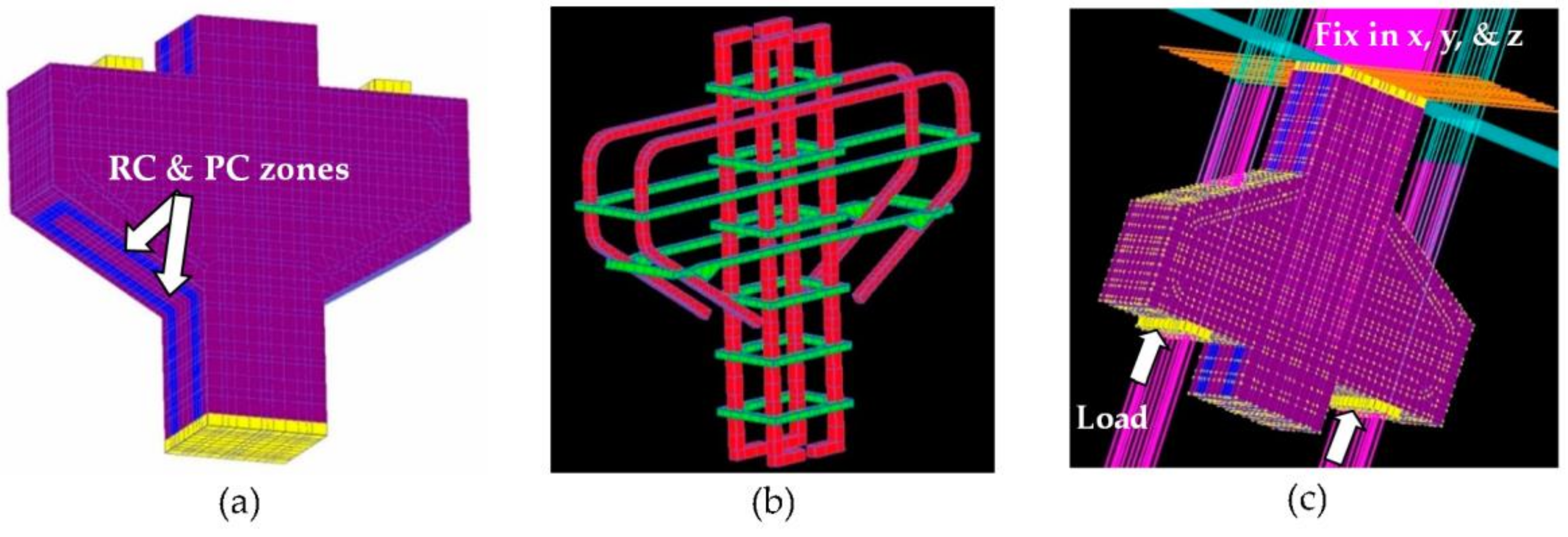

4. Numerical Analysis

4.1. Introduction and Constitutive Model

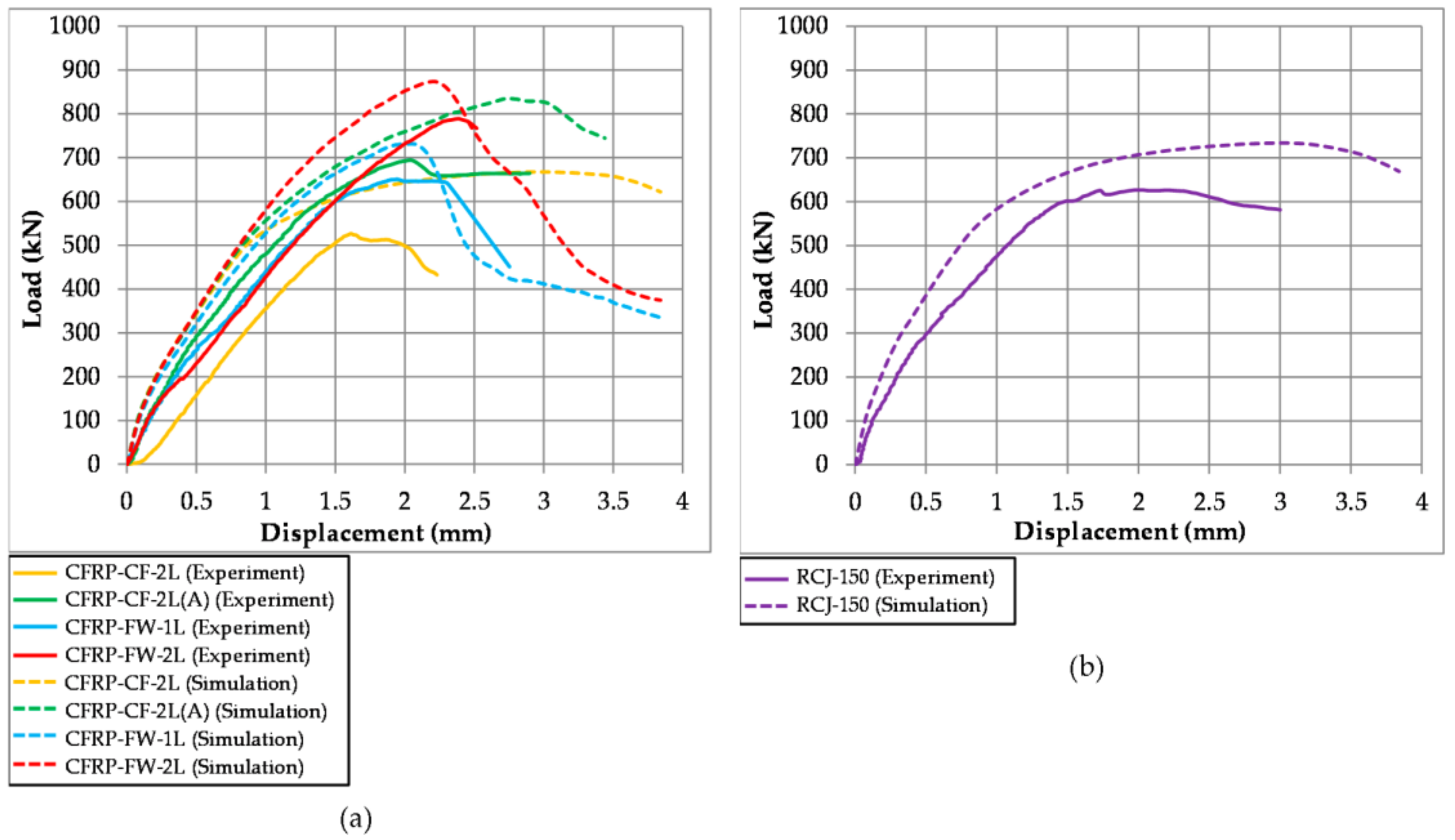

4.2. Validation of Experimental Works

4.3. Parametric Studies

4.3.1. Higher CFRP Stiffness and Lower Tensile Strength in CFRP-FW-2L

4.3.2. Flexibility of Application Range of RC Jacketing

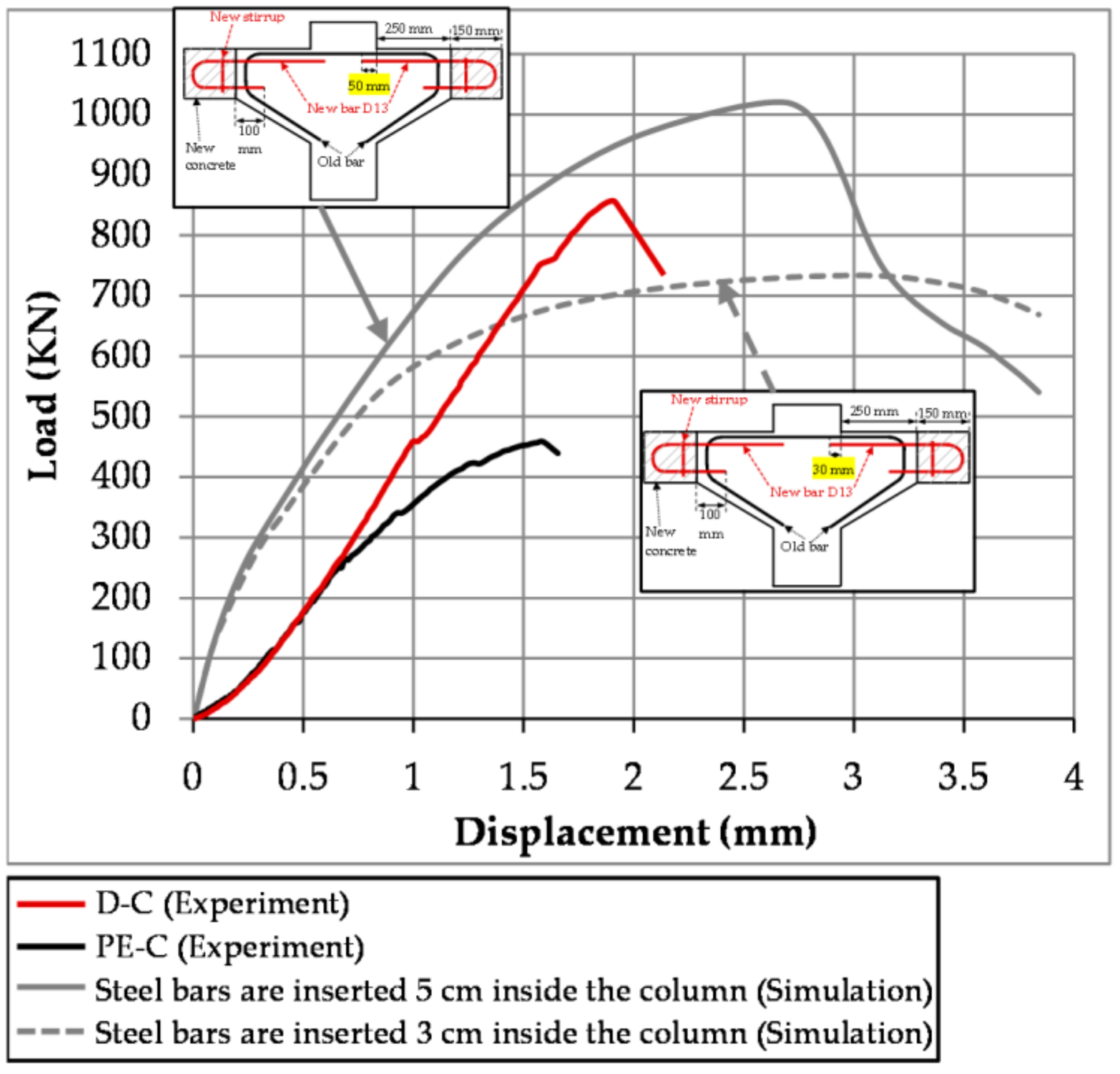

5. Conclusions

- It was confirmed through the experimental observation and numerical simulation that the wrong position of bearing pad (PE-C) where the bearing pad is placed at the edge of the RC corbel causes a significant drop in the loading capacity due to of local splitting failure. It was observed in the experiment that the capacity of the corbel was reduced by 46.5%, while in the simulation, it was predicted that the capacity was reduced by 46.1%. In order to investigate the residual capacity of the damaged corbel, the locally failed PE-C was reloaded by moving the bearing pad to the designed position. Residual capacity of the damaged corbel (ResCap-PE-C) was almost 95.5% of the corbel designed and detailed according to the codes (D-C).

- Different retrofitting methods show different behaviors in terms of loading capacity and failure behavior. CFRP full wrap case (CFRP-FW-2L) was more effective than CFRP wrap terminated at the column face cases (CFRP-CF-2L and CFRP-CF-2L(A)). CFRP-FW-2L showed a 92.02% capacity improvement, while CFRP-CF-2L and CFFRP-CF-2L(A) showed 61.44% and 81% capacity improvements, respectively. The main reason was the absence of the early delamination of CFRP in CFRP-FW-2L. Meanwhile, the retrofitting method using CFRP wrap was superior to RC jacketing because of the occurrence of concrete cover splitting above the post-installed steel bars. The capacity improvement in RCJ-150 was 73%. The same tendencies were predicted by the numerical simulation. However, none of the retrofitting methods could fully recover the capacity of the corbel to the capacity level of the corbel designed and detailed according to codes (DC).

- Based on the parametric studies using numerical simulation, the modulus of elasticity of CFRP had higher influence than its ultimate tensile strength. It is recommended that if the initial stiffness and the ultimate tensile strength of CFRP are 540,000 MPa and 1900 MPa, respectively, four layers of CFRP, 0.13 mm in thickness, are effective to recover the designed strength of the corbel.

- Numerical simulation showed that RC jacketing is a more flexible method for retrofitting the damaged corbel because increasing the reinforcement ratio or anchorage length has a direct influence on its loading capacity. Inadequate anchorage of the inserted reinforcing bars will reduce the strengthening ability for the corbel-column interface.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- ACI (American Concrete Institute). Building Code Requirements for Structural Concrete; ACI 318-11; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- CEN. Eurocode 2: Design of Concrete Structures-Part 1-1: General Rules and Rules for Buildings. EN1992-1-1. Comité Europeen de Normalisation: Brussels, Belgium, 2004. Available online: https://law.resource.org/pub/eu/eurocode/en.1992.1.1.2004.pdf (accessed on 7 April 2017).

- Kriz, L.B.; Raths, C.H. Connections in Precast Concrete Structures: Strength of Corbels. J. PCA Res. Dev. Lab. 1965, 10, 16–61. [Google Scholar] [CrossRef]

- Limam, O.; Foret, G.; Ehrlacher, A. RC Two-ways Slabs Strengthened with CFRP Strips: Experimental Study and A Limit Analysis Approach. Compos. Struct. 2003, 60, 467–471. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Smith, S.T.; Lu, D. CFRP-Confined Square RC Columns. I: Experimental Investigation. J. Compos. Constr. 2012, 16, 150–160. [Google Scholar] [CrossRef]

- Zhang, Z.; Hsu, C.T.; Moren, J. Shear Strengthening of Reinforced Concrete Deep Beams Using Carbon Fiber Reinforced Polymer Laminates. J. Compos. Constr. 2004, 8, 403–414. [Google Scholar] [CrossRef]

- Campione, G.; La Mendola, L.; Papia, M. Flexural Behavior of Concrete Corbels Containing Steel Fibers or Wrapped with FRP Sheets. Mater. Struct. 2005, 38, 617–625. [Google Scholar] [CrossRef]

- Elgwady, M.A.; Rabie, M.; Mostafa, M.T. Strengthening of Corbels Using CFRP an Experimental Program. Cairo University: Giza, Egypt, 2005. Available online: http://www.quakewrap.com/frp%20papers/Strengthening-Of-Corbels-Using-CFRP-An-Experimental-Program.pdf (accessed on 7 April 2017).

- Shadhan, K.K.; Kadhim, M.M. Use of CFRP laminates for strengthening of reinforced concrete corbels. Int. J. Civ. Eng. Technol. 2015, 6, 11–20. [Google Scholar]

- ACI (American Concrete Institute). Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI 440.2R-08; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Kalfat, R.; Al-Mahaidi, R.; Smith, S.T. Anchorage Devices Used to Improve the Performance of Reinforced Concrete Beams Retrofitted with CFRP Composites: State-of-the-art Review. J. Compos. Constr. 2013, 17, 14–33. [Google Scholar] [CrossRef]

- Sadeghian, P.; Rahai, A.R.; Ehsani, M.R. Experimental Study of Rectangular RC Columns Strengthened with CFRP Composites under Eccentric Loading. J. Compos. Constr. 2010, 14, 443–450. [Google Scholar] [CrossRef]

- Maekawa, K.; Pimanmas, A.; Okamura, H. Nonlinear Mechanics of Reinforced Concrete, 1st ed.; Spon Press: London, UK; New York, NY, USA, 2003. [Google Scholar]

- Neupane, R.C.; Nagai, K.; Eddy, L. Governing Parameters of Various Strengthening Approaches Applied for RC Corbels Subjected to Local Failure Criterion. In Proceedings of the 1st International Conference on Infrastructure Failure and Consequences, Melbourne, Australia, 16–18 July 2014. [Google Scholar]

| Series | Specimen Number | Specimen Name | Parameter | Shear Span av (mm) | Comp. Strength of Concrete f’c (MPa) |

|---|---|---|---|---|---|

| Series 1 | 1 | D-C | Bearing pad at the middle of the corbel | 125 | 46.59 |

| 2 | PE-C | Bearing pad at the edge of the corbel | 220 | 45.52 | |

| 3 | ResCap-PE-C | Residual capacity | 125 | 45.52 | |

| Series 2 | 4 | CFRP-CF-2L | 2 layers CFRP wrap terminated at the column face | 220 | 46.77 |

| 5 | CFRP-CF-2L(A) | 2 layers CFRP wrap terminated at the column face with fiber anchor | 220 | 48.26 | |

| 6 | CFRP-FW-1L | 1 layer CFRP full wrap with 200 mm overlay | 220 | 42.49 | |

| 7 | CFRP-FW-2L | 2 layers CFRP full wrap with 200 mm overlay | 220 | 43.15 | |

| Series 3 | 8 | RCJ-150 | RC jacketing | 220 | 47.52 |

| Material | Modulus of Elasticity Es or EFRP (MPa) | Yield Strength fy (MPa) | Ultimite Strength FFRP,u (MPa) |

|---|---|---|---|

| Steel bar D10 | 190,000 | 390 | - |

| Steel bar D13 and D16 | 190,000 | 490 | - |

| CFRP | 245,000 | - | 3400 |

| Case | Maximum Load (kN) | |

|---|---|---|

| Experiment | Simulation | |

| D-C | 857.0 | 938.1 |

| PE-C | 458.4 | 515.4 |

| ResCap-PE-C | 818.9 | 845.1 |

| CFRP-CF-2L | 526.6 | 667.5 |

| CFRP-CF-2L(A) | 694.5 | 834.5 |

| CFRP-FW-1L | 650.5 | 730.9 |

| CFRP-FW-2L | 788.7 | 872.1 |

| RCJ-150 | 626.5 | 733.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neupane, R.C.; Eddy, L.; Nagai, K. Investigation on Strengthening Approaches Adopted for Poorly Detailed RC Corbels. Fibers 2017, 5, 16. https://doi.org/10.3390/fib5020016

Neupane RC, Eddy L, Nagai K. Investigation on Strengthening Approaches Adopted for Poorly Detailed RC Corbels. Fibers. 2017; 5(2):16. https://doi.org/10.3390/fib5020016

Chicago/Turabian StyleNeupane, Ram Chandra, Liyanto Eddy, and Kohei Nagai. 2017. "Investigation on Strengthening Approaches Adopted for Poorly Detailed RC Corbels" Fibers 5, no. 2: 16. https://doi.org/10.3390/fib5020016

APA StyleNeupane, R. C., Eddy, L., & Nagai, K. (2017). Investigation on Strengthening Approaches Adopted for Poorly Detailed RC Corbels. Fibers, 5(2), 16. https://doi.org/10.3390/fib5020016