1. Introduction

Processing 100% green composites implies that biosourced (biodegradable) polymeric resins can be conveniently reinforced by natural materials, such as plant-based fibers, for example jute, hemp, flax and bamboo fibers [

1,

2,

3,

4,

5]. Bamboos are one of the most abundant ligno-cellulosic plants produced in the world [

6]. There are so many different species of bamboos, and some of them grow so fast (up to 120 cm per day), that no other source of vegetable fibers could be considered more renewable. On the other hand, it is not obvious how to control from a botanical point of view the supply of bamboo from tropical forests, due to their degradation, especially when classified as “ambiguous lands”, i.e., in principle state-owned yet used by low income people for harvesting, e.g., bamboo shoots [

7]. For this reason, a possibility which has been explored is for example the extraction of lignin from steam exploded bamboo for the production of epoxy resins [

8].

A more valuable yet sustainable perspective is nonetheless the possibility to produce composites by using bamboo fibers as the reinforcement for biodegradable matrices [

9]. In this regard, the use of bamboo fibers, also due to the variable quality of supply, cannot always be recommended, because the difficult predictability of their properties has an effect also on those of composites produced with them. For example, due to the variable presence of defects in the fibers, introducing longer fibers in the load direction does not always result in substantial and repeatable improvement of composite performance, as, e.g., reported in a study on bamboo fiber/starch-based composites [

10]. A further issue, which heavily contributes to the variability of bamboo fibers properties, is that, as it is the case for all ligno-cellulosic fibers, their morphology can be very variable in terms of diameter, hollow size and geometry, elliptical shape of the section, etc. [

11,

12,

13].

Polymers synthesized from naturally sourced monomers, such as poly(lactic acid) (PLA), have in contrast quite controllable properties and are therefore very suitable for the production of fully sustainable composites with vegetable fibers: a significant amount of literature does exist on these materials [

14]. A major aspect to be controlled is therefore the quality of the fiber–matrix interface, that can be measured on fiber composites by a number of possible methods, among which is pull-out testing [

15].

An early study on flax fiber pull-out from polyethylene matrix proposed that the same methods used in the case of traditional fibers, such as glass or carbon fibers, could work as well, despite the peculiar structural characteristics of lignocellulosic fibers [

16]. Following this, pull-out testing proved suitable to offer sufficiently reliable values of the apparent interface shear strength on a number of different lignocellulosic fibers [

17]. Pull-out tests of sisal fibers embedded at three-millimeter depth in polyester blocks of 10-mm side and then stretched to failure confirmed, despite a very large standard deviation, the effectiveness of mercerization in improving fiber–matrix interface strength [

18].

As for bamboo fibers, the significant influence of environmental factors on the adhesion strength between fiber and matrix has already been highlighted [

19]. However, in general, the measurement of interface strength has found so far only quite limited coverage in the literature, despite the fact that substantial issues are still perceived in the achievement of sufficient properties for PLA/bamboo fiber composites [

2,

6,

11,

20]. Recent work pointed out that information about practical adhesion of bamboo fibers with thermoplastic polymer matrices could be obtained from different parameters from pull-out tests, such as interfacial shear stress, radial tensile stress and theoretical work of adhesion: the study indicated a better interface for bamboo fibers with poly(vinylidene fluoride) (PVDF) rather than with polypropylene (PP), although much weaker than for glass fibers [

21].

The measurement of apparent shear strength can be not completely accurate, since the pull-out process may be friction-dominated in bamboo fiber systems, and friction is not considered by this parameter [

22]. Accurate measurements of interfacial adhesion in bamboo fibers are also cumbersome for other reasons, such as the variable adhesion of filaments to form bundles (which makes them easily prone to fibrillation) and the need to account also for cross-sectional complex shapes and variable sizes (which requires multiple measurements of the diameter across the same section). Notwithstanding these limitations, it is worth considering whether the application of a simple method for measuring the apparent interfacial shear strength with values of diameter obtained under reasonable assumptions would supply any suitable indication for the improvement of composite properties. This approach may be simplistic in comparison with other approaches, such as local analysis and computational predictions [

23], well adapted when both the matrix and the fibers have quite regular and predictable properties. However, when it comes to natural materials, whose supply is not subjected to a rigorous quality control from the producer as for synthetic ones, but only possibly to some selection of the most suitable samples, predictability is a real issue: for this reason, experimental approaches, which give access to the average properties of the entire population under sensible assumptions, can provide reasonably good estimates of the properties. In spite of this, the positive influence of maleinisation and silane treatment on polypropylene/bamboo composites interfacial shear strength was highlighted [

24].

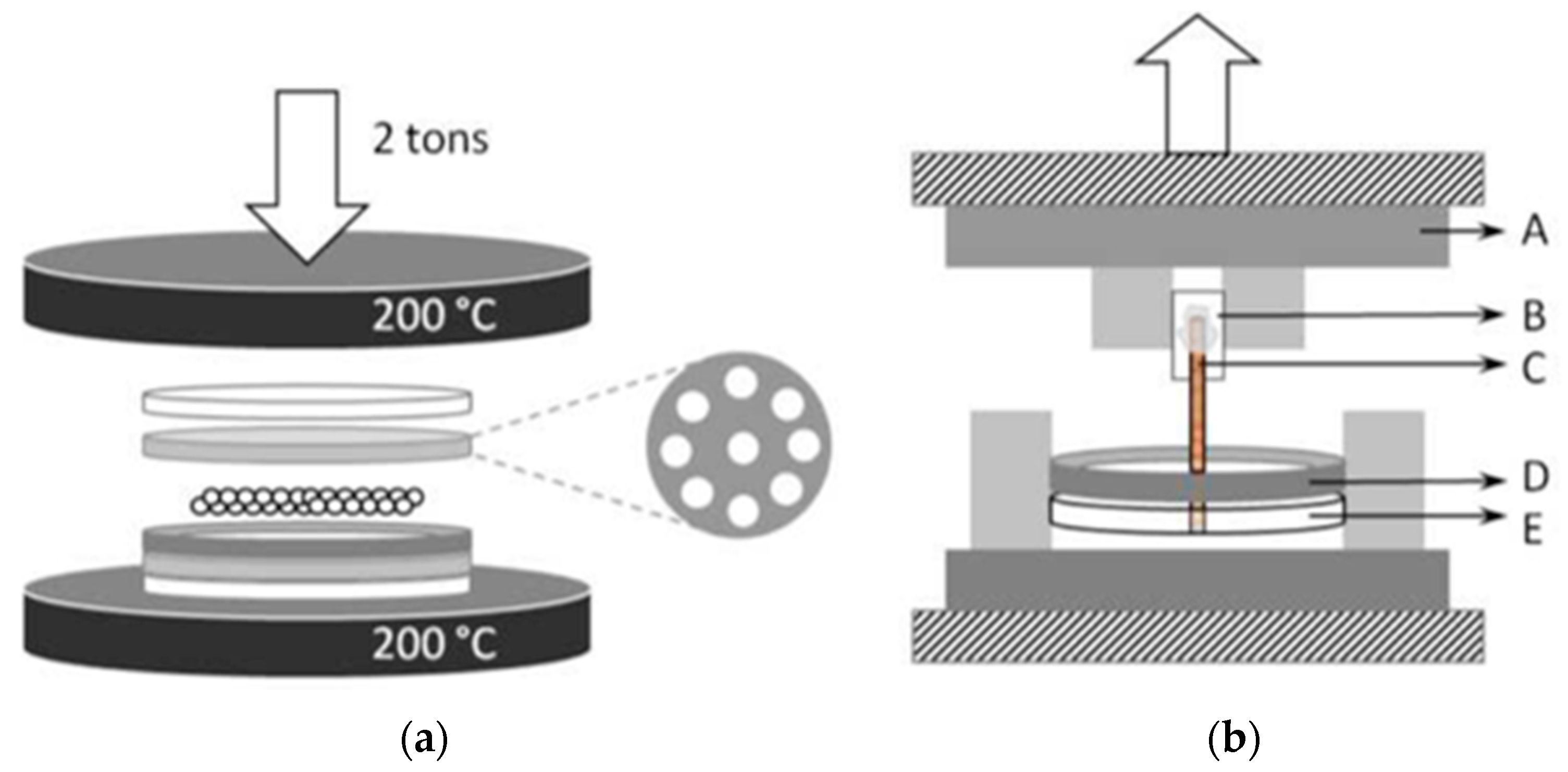

In this work, measurements of the apparent interfacial shear strength were carried out by performing pull-out tests on bamboo technical fibers embedded in thin PLA matrices. Fibers belonging to the same batch were used either as received or after mercerization, embedded in the same polymeric matrix. A procedure was used to obtain samples with an improved control over the embedded length, and a critical approach to the experimental results was used to select and interpret them.

3. Results and Discussion

Pull-out tests consist of embedding a fiber in a matrix and then performing a tensile test by gripping the free tip of the fiber (top) and the matrix (bottom) to pull them apart (

Figure 2b). The result typically expected for this kind of test is the fiber being pulled out of the matrix without breaking, meaning that adhesive failure (debonding at the fiber/polymer interface) rather than cohesive failure (either in the fiber or in the matrix) occurs. The force vs. displacement curves are used to determine the shear strength at the interface between the fiber and the matrix using the Kelly–Tyson equation, as suggested by Greszczuk (Equation (2)) [

34] that can be written as:

where

τapp (MPa) is the apparent interfacial shear strength,

Fdeb (N) is the force required to debond the fiber from the matrix,

πDf (mm) is the perimeter of the fiber as

Df (mm) is the diameter, and

Lemb (mm) is the length of fiber embedded into the matrix.

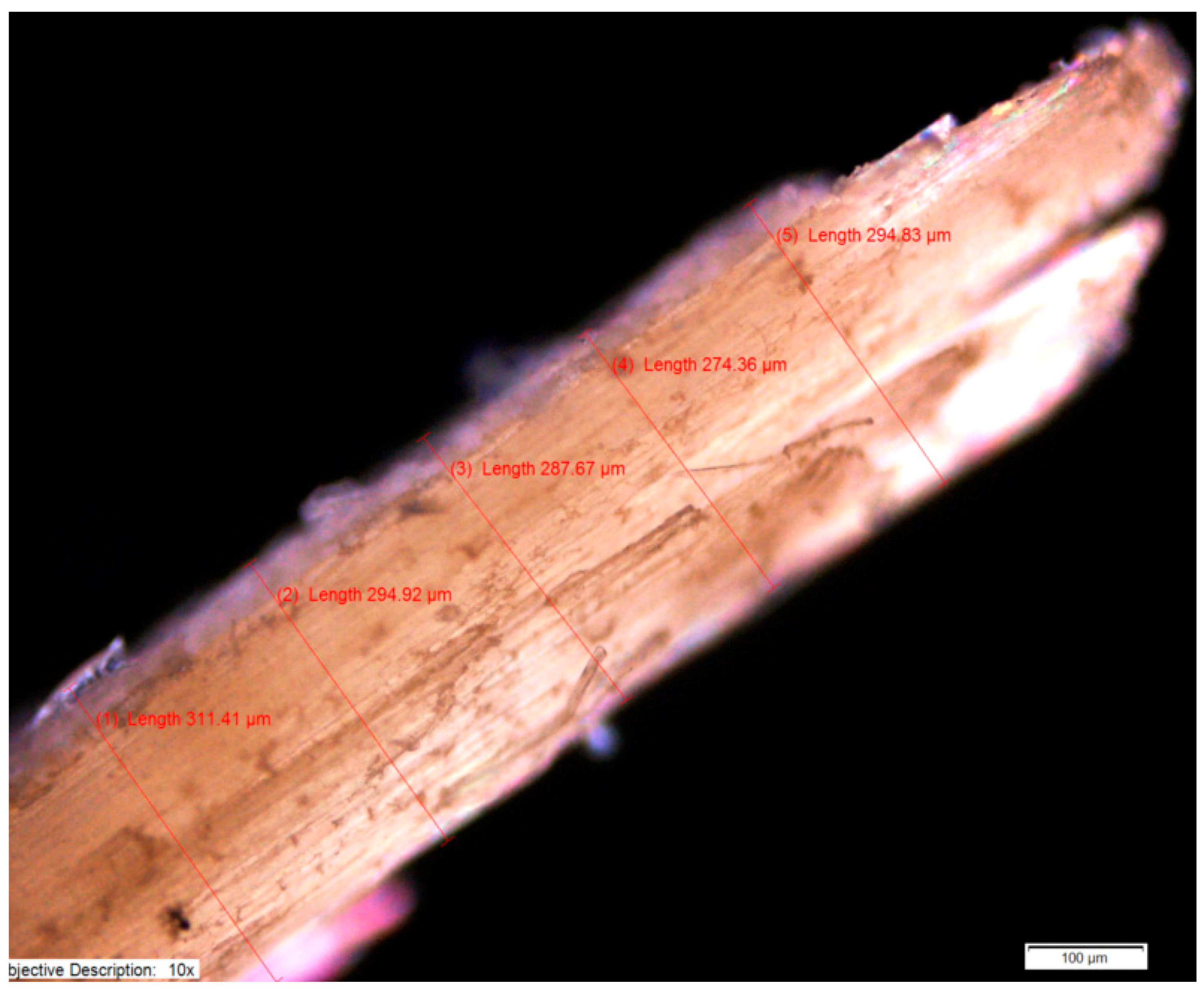

Equation (2) provides a value of interfacial shear strength that is apparent because it depends on both the embedded length and the diameter of the fiber, which are usually assumed constant. A number of issues can be seen in the application of Equation (2) to pull-out tests on vegetable fibers. Major ones would concern the fact that the section of vegetable fibers is typically non-circular, presenting at least some ellipticity if not a more complex shape, which may be not accounted for by the method of diameter measurement. In practice, considering the diameter at five different locations along the length of the fiber, as described in

Section 2.2.2, led to measuring values with a standard deviation between 0.7% and 7.5% and an average standard deviation of 3.1%. As a whole, the main concentration of diameter values measured in this work reflected those reported by Rao and Rao [

35], who found that most mechanically extracted bamboo fibers have a diameter between 200 and 350 microns.

The experimental approach suggested in this work gives a reliable value for

Lemb and the debonding force

Fdeb is measured directly: the consequence of this fact is that the fiber perimeter

πDf estimated with the assumption of a constant diameter is the parameter in Equation (2) with the highest uncertainty. Each fiber is unique and has a shape that varies over its entire embedded length; thus, estimates of fiber perimeter can be made only indirectly at best, unless the fiber is imaged while embedded in the matrix for example using X-ray microtomography (µ-CT) [

36].

At least five possibilities exist for estimating the contact perimeter, and each one of these has its own advantages and disadvantages. For example, the perimeter of the hole left in the PLA matrix by the pulled-out bamboo fiber could be estimated by SEM, but this approach lacks precision and does not account for the fact that the perimeter is not uniform over the entire embedded length. Another approach would be to cut the fiber before embedding and taking an image of the cross-section, but cutting obviously introduces damage, which may reduce the fiber strength. Some authors assume a density and estimate the total fiber length to evaluate the perimeter by weighing a group of fibers [

12], whereas others estimate the perimeter by the Wilhelmy method [

34]. Finally, assumptions about the fiber cross-sectional shape can be made, such as the projection of a virtual cross-section whose diameter could be estimated from optical microscope images at several positions along the fiber length and that would behave equivalently to the real cross-section. In this work, the final choice was made to assume a circular equivalent fiber such that the perimeter is

πDf with

Df as the equivalent diameter, obtained as the average of five values of apparent diameter measured at different places along each fiber from a side view by optical microscopy. This approach is expected to give estimates for the perimeter that are larger than reality, in a way that the final estimates for the apparent interfacial shear strength are lower than reality (conservative estimate).

In Equation (2),

τapp was interpreted as if the fiber was loaded until debonding and then completely extracted from the matrix.

Fdeb was estimated as the maximum value of the experimental force vs. displacement curves, whereas

Lemb was evaluated by measuring the thickness of the PLA thin disk.

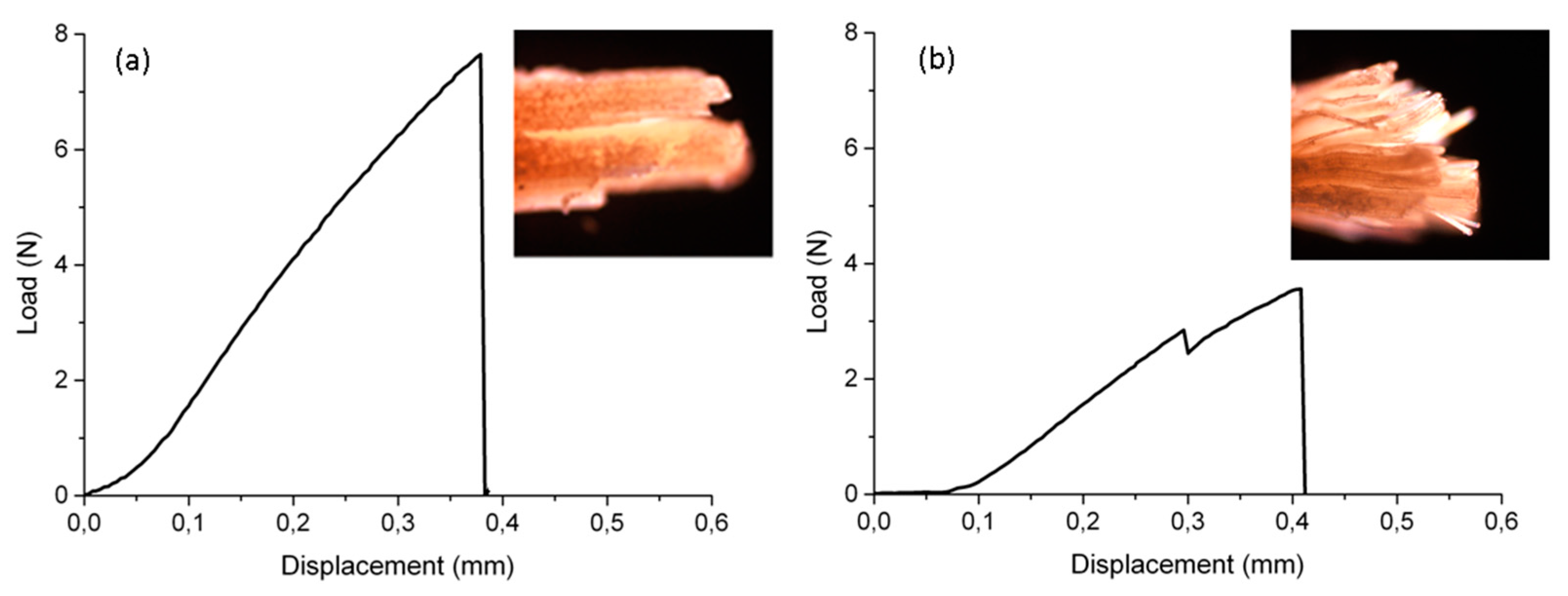

Figure 3 reports two examples of the typical load vs. displacement curves obtained in this work. In all cases the fiber was completely extracted from the polymer without clearly breaking.

Figure 3a shows the ideal outcome for the pull-out tests performed in this work (smooth load vs. displacement curve until interface failure by fiber/polymer debonding). Results like these are the most appropriate to calculate

Fdeb and

τapp because none of the elementary fibers break during the test. On the other hand, the curve in

Figure 3b reveals that some intermediate failure occurred during the tensile part of the pull-out test. In fact, whenever the test is run on a technical fiber, the internal interfaces between the elementary fibers may debond at lower loads with respect to the outer interface, and break the bundle before debonding it from the matrix. Curves like this cannot be assuredly discarded, but can neither be used to determine

τapp according to Equation (2). In this case the stressed interface is not only the one connecting the outer surface of the technical fiber to the matrix, but also the one connecting the elementary fibers to each other within the same bundle. For this reason, even when the experimental curves seemed correct, the tip of each bamboo fiber extracted from the PLA matrix was observed by optical microscopy (example pictures on the top right corner of

Figure 3a,b) to identify the failure mechanism associated with the pull-out test and to get a deeper insight in the nature of the constraints experienced by the fiber.

Regular fibers were defined as those that did not show an obvious fibrillation, i.e., separation of filaments, when being extracted from the polymer matrix (

Figure 3a). Whenever fibrillation was clearly shown during fiber failure so that the tensile load could not be regarded as exclusively applied orthogonally to the fiber section, the fibers were defined as non-regular (

Figure 3b). SEM images confirmed that successful pull-out tests were most frequently obtained from regular fibers, where the fiber tip remained aligned with the bulk of it during the whole loading event. Moreover, when the fiber behavior was non-regular, a load drop was frequently observed during loading, which can be attributed to the moment when the filaments started splitting from each other, leading to fibrillation. In general, fibrillation might be considered to improve fiber–matrix adhesion; as a matter of fact, mechanically induced fibrillation has been already used on bamboo–PLA composites to make them more suitable to processing techniques, such as extrusion, pelletizing and subsequent injection molding [

37]. However, when fibrillation occurs, pull-out tests usually overestimate the value obtained for the interfacial shear strength because mechanical interlocking could contribute to a stronger connection of the technical fiber (through its elementary fibers) to the polymeric matrix.

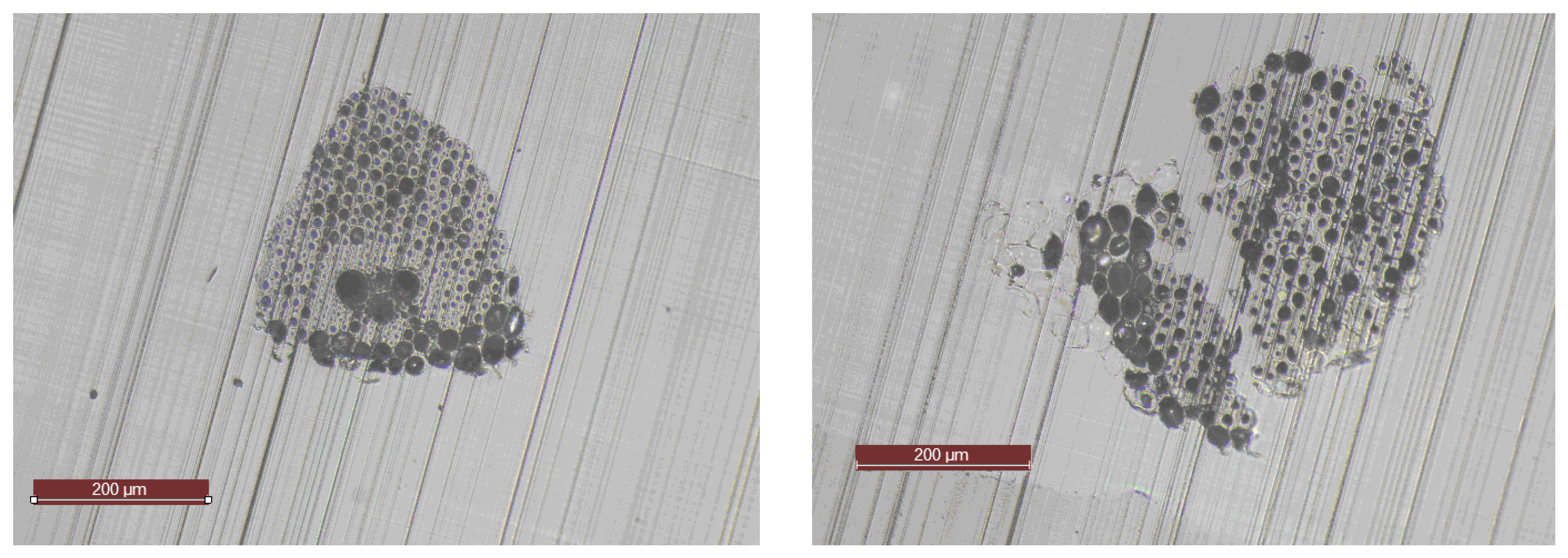

Figure 4a shows the failure mode associated with non-regular pull-out-test curves; in this case, the technical fiber partially broke instead of getting pulled out of the matrix, meaning that the bamboo/PLA interface was not necessarily stressed to failure. In contrast,

Figure 4b shows the hole left in the matrix by a fiber pulled out during a regular pull-out test; here, only a few elementary fibers broke, proving that the interface actually stressed by the pulling action was essentially the one connecting the outer surface of the technical fiber to the polymer. It is worth noticing that the bamboo fiber shown in

Figure 4a has an apparent diameter of about 200 μm, whereas the one shown in

Figure 4b is much thicker (about 500 μm). This is quite typical and indicates that, to avoid fibrillation, fibers should not only be regularly-sized and possibly defect-free, but also rather thick. In fact, a balance should be found between the cross-section resisting the uniaxial tensile stress (which depends exactly on the cross-sectional shape and size of the technical fiber) and the extent of the outer surface in connection with the matrix (which depends essentially on the equivalent diameter of the fiber and on the length of it actually embedded in the polymeric matrix,

Lemb). Considering only regular samples (12 values out of the 39 tests reported in this work), a value

τapp = 7.0 ± 3.1 MPa was obtained.

Tokoro et al. [

20] used short bamboo fiber bundles (diameter 39.2 µm and length 215 µm before fabrication) to obtain PLA composites by injection molding. They performed micro-droplet tests to evaluate

τapp according to Equation (2) and found an average value of about 4.3 MPa (estimating that processing reduced both the diameter and the length to 21.3 µm and 86.3 µm respectively), but no statistical variations were given about these values. A clear comparison is difficult to make, because the samples used for this study have larger

Df (200–480 µm) and

Lemb (423–790 µm) and the results obtained for regular samples spread over a range going from 2.1 to 13.6 MPa. Fuentes et al. [

38] performed fiber pull-out tests on technical bamboo fibers embedded in poly(vinylidene fluoride) (PVDF) and polypropylene (PP). The diameter of the fibers was not given, but their perimeter was estimated by the Wilhelmy equation applied to dynamic contact-angle measurements. They considered different

Lemb (0.6 to 5 mm) and fit the experimental data with Greszczuk’s model [

35], finding a value of ultimate interfacial shear strength of about 7.5 MPa for PVDF (polar) and 3.4 MPa for PP (non polar). As a comparison, the value obtained here is quite close to the value obtained for PVDF, which is consistent considering that PLA is a fairly polar polymer. Le Duigou et al. [

39] performed microbond tests on flax fibers and poly (L-lactic acid) (PLLA), and reported a value of interfacial shear strength of 15.3 ± 3.3 MPa calculated according to Equation (2) for fibers having an aspect ratio (

Lemb/

Df) of 1.3 ± 0.1. Wong et al. [

40] also used Equation (2) to evaluate the interfacial strength between flax fibers and PLLA. They obtained values in the range 8–17 MPa by pulling out fibers having

Df in the range 100–160 µm and

Lemb in the range 200–500 µm. The comparison of all these values, especially when it comes to

Df, would be even more difficult if the ellipticity (or even higher geometrical complexity) of bamboo fiber sections were, as it should be, taken into account. In fact, this would require the measurement of the exact diameter of the fractured section, an example of which is reported in

Figure 5. Such a procedure was not systematically pursued due to the difficulty of getting a section with obvious edges and as flat as possible, and may be the object of dedicated work in the future.

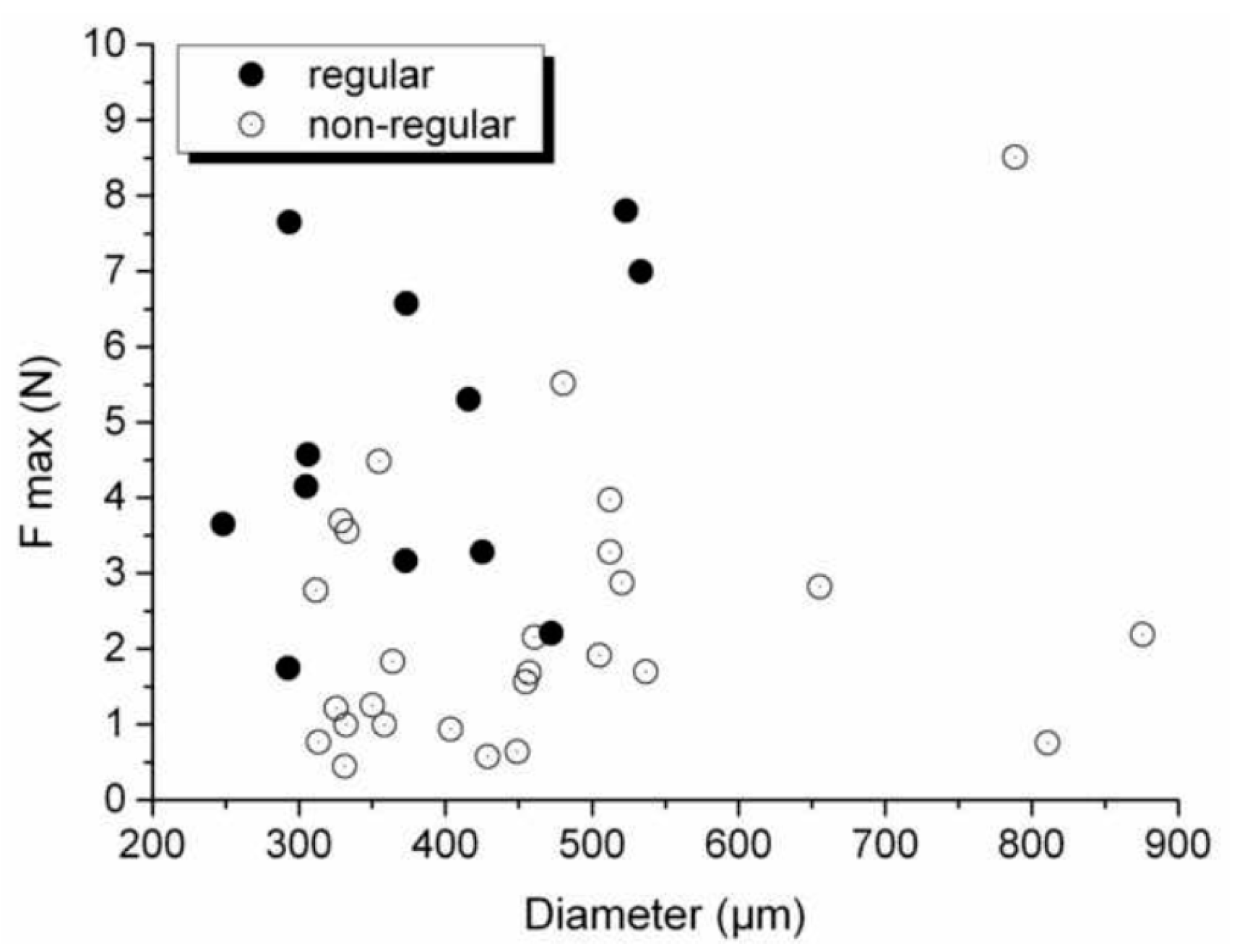

The values of maximum load (

Fmax) recorded during the pull-out tests of untreated bamboo fibers are shown in

Figure 6 as a function of

Df (39 values, 12 regular plus 27 non-regular).

Figure 6 provides an additional criterion for the initial selection of the fibers: they should not only be regularly-sized, defect-free and thick enough to resist the tensile stress applied to pull them out, but on the other side also thin enough to minimize the proportion of internal interfaces (connecting the elementary fibers and the fibrils to each other) with respect to the outer interface (connecting the fiber to the polymer). Thicker technical fibers have more extended outer surfaces, but also many more internal interfaces, which increases the probability of extraction by structural telescoping. The

Fmax values in

Figure 6 are spread over a range of equivalent diameters from about 250 μm to almost one millimeter, but regular tests were obtained only for samples processed with fibers having a diameter less than 500 μm, whatever the value of

Lemb. As a matter of fact, Da Costa et al. [

41] already observed that, when performing tensile tests on bamboo fibers with the aim of Weibull analysis, thinner fibers showed a more uniform fracture associated with lesser fibrils, while fibers with larger diameters would display a relatively non-uniform fracture with participation of more fibrils. Statistically, the probability that one of the many fibrils of the thicker bamboo fiber would prematurely break and then act as a flaw to cause the fiber rupture at a lower stress is higher, when compared to the thinner fiber. As a consequence, it is more likely that larger diameter fibers have lower interfacial shear strength than the opposite.

Pull-out tests were also performed on mercerized bamboo fibers from the same batch.

Figure 4c shows the surface of an untreated bamboo fiber. Mercerization modified the surface of the fibers both topographically and chemically.

Figure 4d shows that roughness changed and

Figure 4e proves that the removal of the lignin loosened the bundles. The literature reports that NaOH solutions make the fibers swell by attacking and destroying their non-cellulosic structure [

42]. Having the elementary fibers loosened is good when the objective is dispersing the bamboo fibers within a matrix to obtain the final green composite; however, in terms of pull-out tests, this condition is probably the most complicated to interpret. Unless the elementary fibers are completely isolated from each other, it is hard to quantify the extent of fiber surface actually interacting with the polymer and efficiently stressed during the pull-out test. In addition,

Figure 4f shows that mercerization, if not followed by a thorough washing procedure, leaves residual salts on the surface of the fibers, which is a drawback of the treatment.

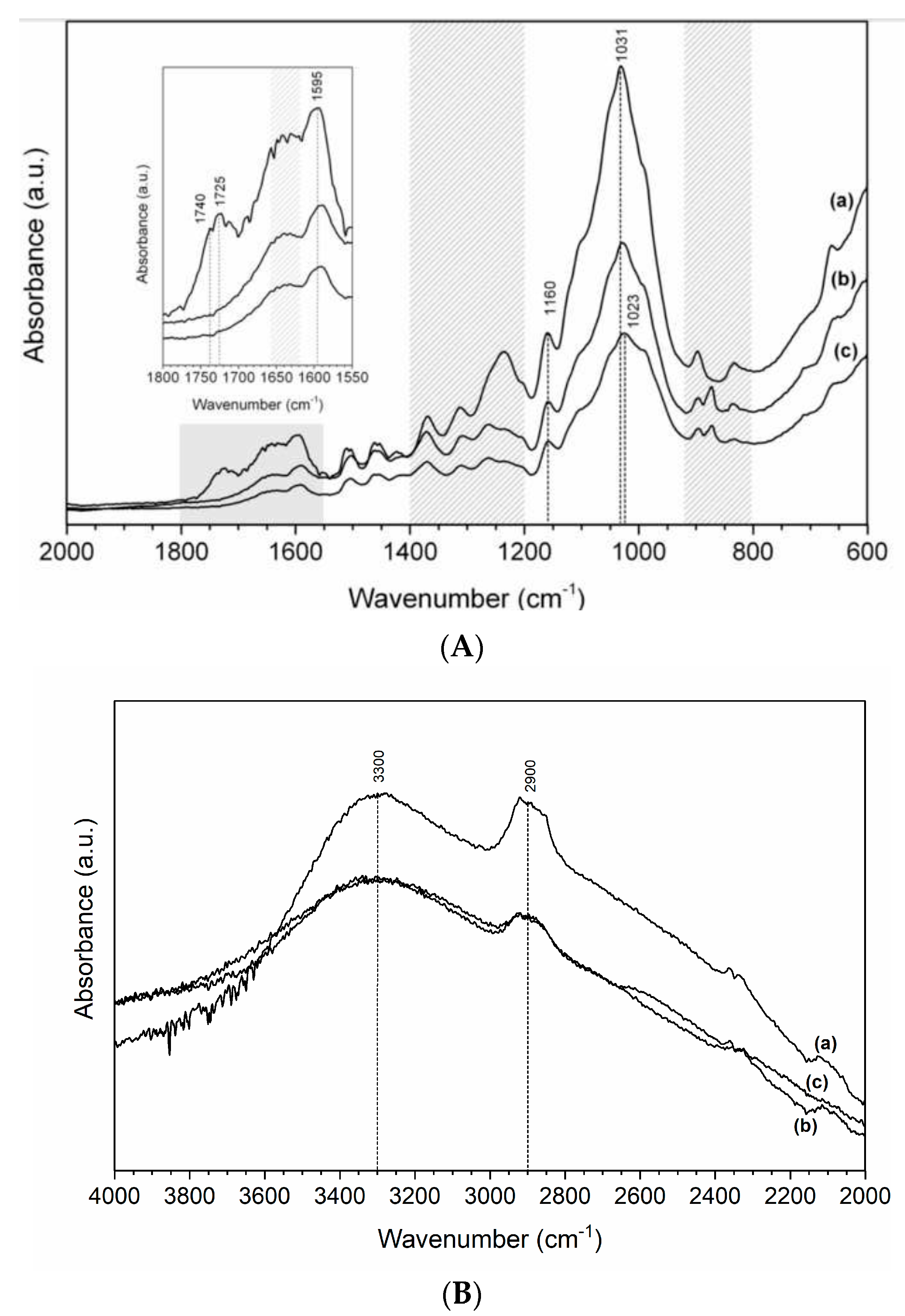

The chemical effects of mercerization were investigated by FTIR spectroscopy.

Figure 7A shows the FTIR spectra of bamboo fibers between 2000 and 600 cm

−1: (a) before the treatment; (b) right after the treatment (without washing); and (c) when the treatment was followed by careful washing and filtering.

Figure 7B reports the relative FTIR spectra between 4000 and 2000 cm

−1, where only stretching vibration peaks of =C-H and –C-H are observed around 3300 and 2900 cm

−1.

The absorption bands were assigned on the basis of the data reported in the literature about different ligno-cellulosic materials (hemp hurds [

43] and fibers [

44], wheat straw nanofibers [

45], oil palm fibers [

46], bamboo fibers [

47], wood [

48,

49]). In the range between 1800 cm

−1 and 800 cm

−1 it is possible to find evidence of the chemical modification of the fibers, mostly consisting of the removal of lignin and hemicellulose and the purification of crystalline cellulose. The inset zooms in a range showing a reduction of the bands typically assigned to hemicellulose (1740 cm

−1) and lignin (1725 and 1595 cm

−1, vibrations of the carbonyl groups and of the aromatic rings of phenyl propane, respectively). The hatched area on the inset identifies the absorption bands assigned to the bending vibration of the hydroxyl groups of water absorbed by holocellulose. The first hatched area on the main graph includes the stretching vibrations of the hydroxyl groups of water absorbed by holocellulose, but also the bending and stretching vibrations of CH and CO bonds in the aromatic rings of crystalline cellulose. The second hatched area contains the out-of-plane stretching vibrations of CH bonds in the aromatic rings of crystalline cellulose, as well as the stretching vibrations of CH and COC bonds in the β-(1,4)-glycosidic linkages between the anhydroglucose units. Polymorphism has already been documented for NaOH-treated cellulose [

50]. The absorption band at 1160 cm

−1 is due to crystalline cellulose (COC asymmetrical stretching). The peak between 1150 cm

−1 and 950 cm

−1 contains many contributions: it is particularly noteworthy the slight shift of the main peak from 1031 cm

−1 (in-plane deformation of CH bonds from lignin) to 1023 cm

−1 (stretching vibration of CO bonds in crystalline cellulose), which could be a further sign of successful mercerization. Additionally, the smoothest FTIR spectra were recorded on the fibers that were carefully washed and filtered (

Figure 7Ac), which is in agreement with the comment about

Figure 4f.

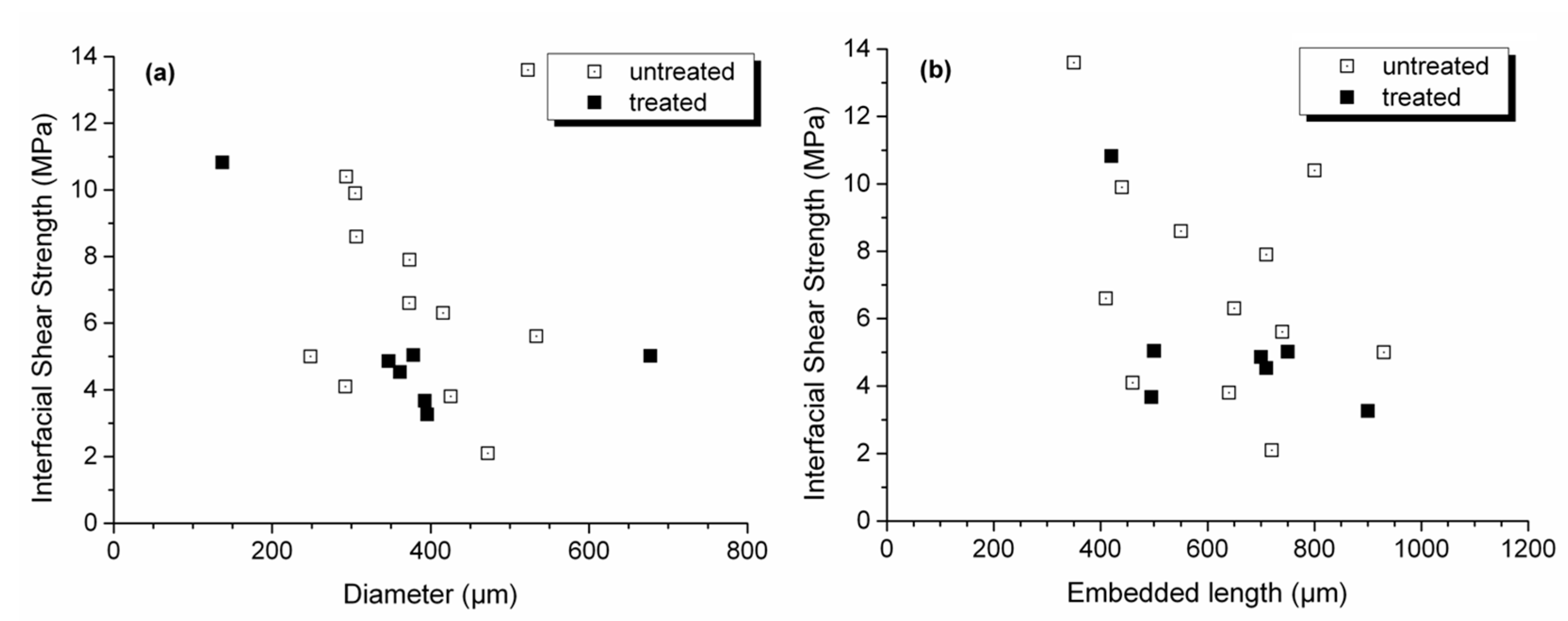

A total of 17 pull-out tests were performed on mercerized bamboo fibers; seven of them were considered as regular and interpreted, resulting in a value of

τapp = 5.3 ± 3.3 MPa (lower than the value obtained for the untreated fibers). It appears that mercerization does not necessarily improve the interface between ligno-cellulosic fibers and polymers, even though previous literature suggests the opposite. An attempt to evaluate the influence of mercerization on the quality of the interface was made by interpreting the statistics of the two populations of data via the student’s

t-test. The test gave a value of

p = 0.22, meaning that in this case mercerization has no significant impact on the results (the limit being at 0.05). Scatter plots of the values of the apparent interfacial shear strength

τapp as a function of the equivalent diameter

Df and the embedded length

Lemb are provided in

Figure 8 for both untreated and treated bamboo fibers. No obvious mathematical relationships can be pointed out.

Figure 8a shows that, except for two points, the alkali treatment limits data dispersion by restraining the values of both the apparent diameters (350 to 400 μm) and the obtained apparent interfacial shear strength (3 to 5 MPa) to narrower ranges. As for the embedded length (

Figure 8b), the alkali treatment had no statistical effect because

Lemb depends only on sample processing, and the experimental procedure used in this work was designed with the purpose of controlling it. In conclusion, definite indications that mercerization is actually improving the interface between bamboo fibers and PLA matrix were not obtained in this work. The opposite result had been obtained on traditional oil-based polyester matrices despite the fact that the alkali treatment reduces the ductility of bamboo fibers [

51]. It is proposed that the decreased ductility, together with the inherent brittleness of PLA, could have led to an early pull-out of the fibers, resulting in a weaker interface; but this would need to be confirmed in further studies.