This section presents the experimental results, in which a first subsection is focused on the FLEHAP energy-harvester operations, while a second one is focused on the energy-harvesting circuit.

2.1. FLEHAP Device Operations

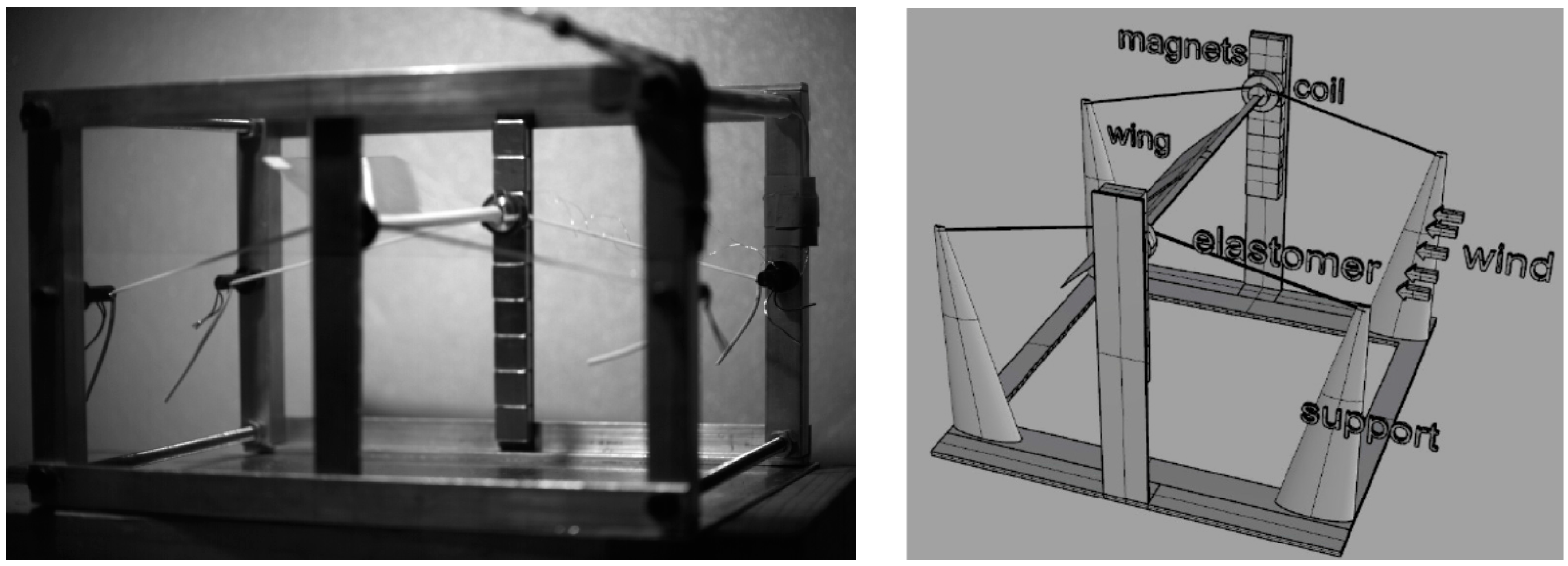

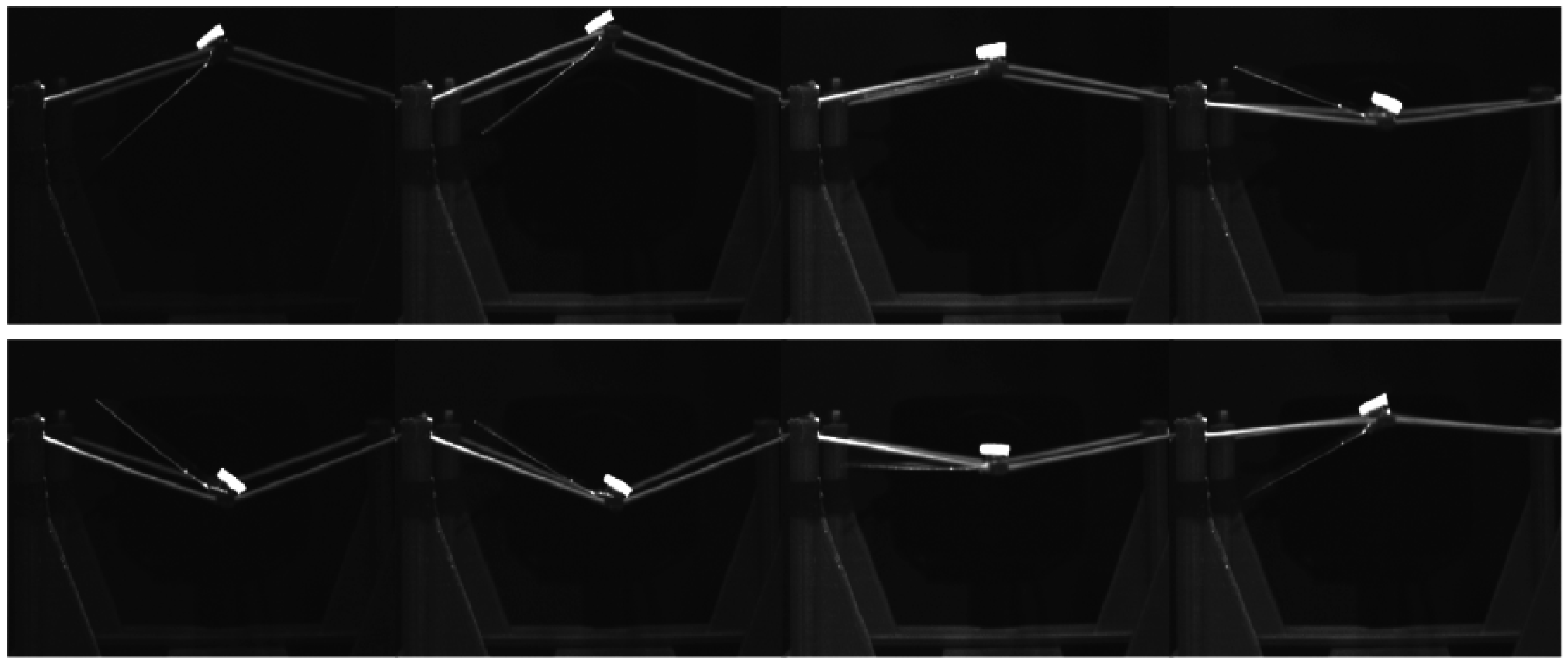

In

Figure 2 we report some images extracted from a typical movie. The wind is coming from the right. It is evident that the rigid axis (where the elastomers are fixed) moves along a periodic trajectory in the vertical direction, while the wing oscillates in angle, as Equations (1) and (2) report.

This behavior is due to the aeroelastic interaction of the wind with the system. When the wing assumes a positive angle (counter-clockwise) a lift force is generated, inducing the wing to move up. When the elastic force counterbalances this lift force, the wing rotates around the axis, the angle becomes negative, then reverts to the direction of the lift force. Computational fluid dynamics (CFD) simulations and smoke fluid visualization (not reported here) show that a vortex is created at the leading edge (LE) when the wing reaches an angle (positive or negative) larger than 30°.

These vortices are responsible of the instability that triggers the wing movement, inducing the transition to a stable LCO.

Many parameters influence the shape of LCO: mass and shape of the wing, elastomer strength, and position of the rigid axis along the wing side. Acting on these parameters, it is possible to tune the system in order to maximize LCO amplitude and frequency in a particular wind range.

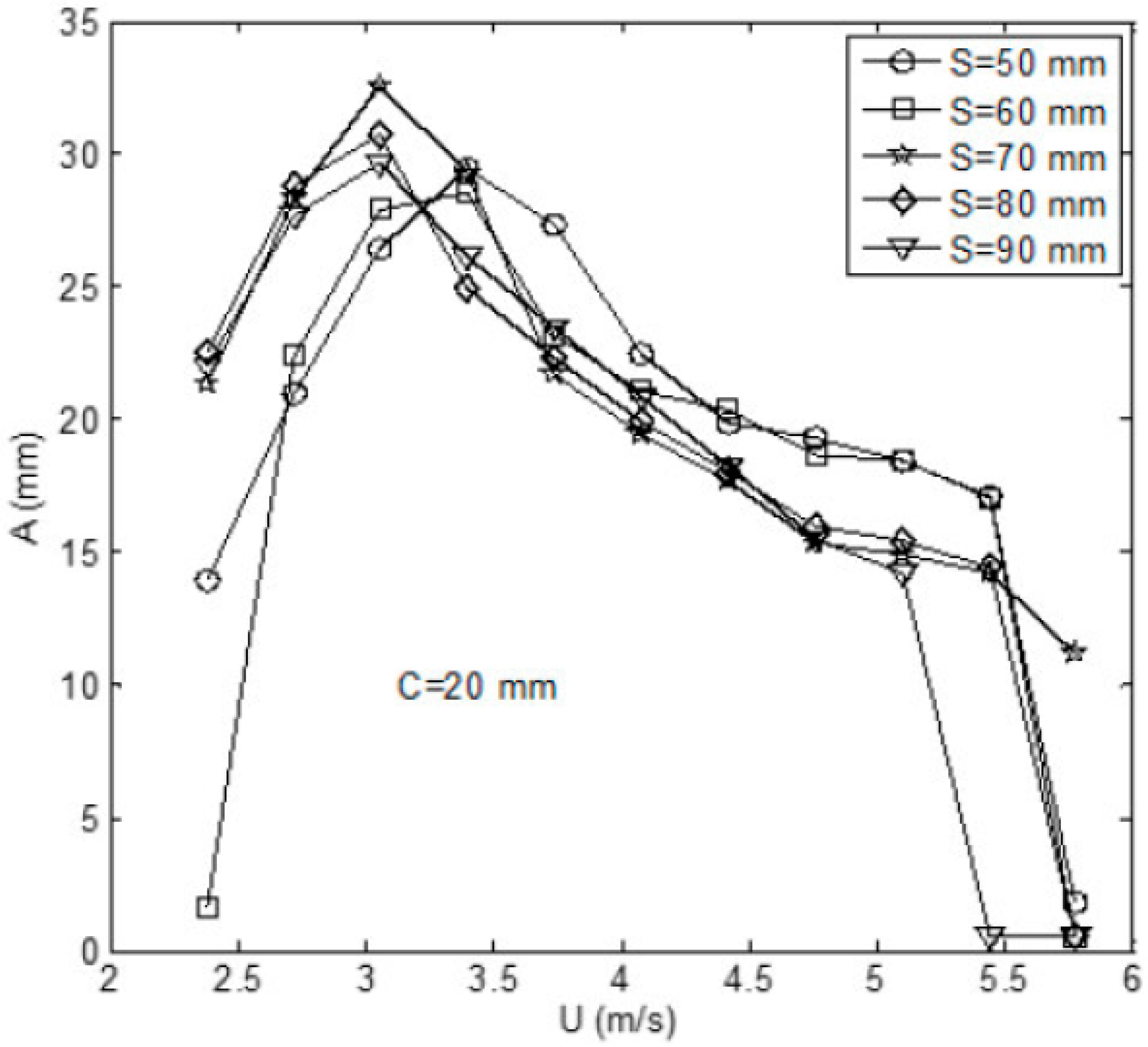

As an example, we show in

Figure 3 the

LCO amplitude vs.

U for a wing with chord = 20 mm and span in the range of 50–90 mm. The system oscillates if the wind velocity is in the range of 2–6 m/s, reaching a maximum at 3 m/s. About the wing angle, it is around 50° (in absolute value) at low velocity, reaches a maximum around 90° at a velocity of 3.5 m/s, then decreases at higher velocities.

For U > 6 m/s, the movement stops and the wing assumes a horizontal position.

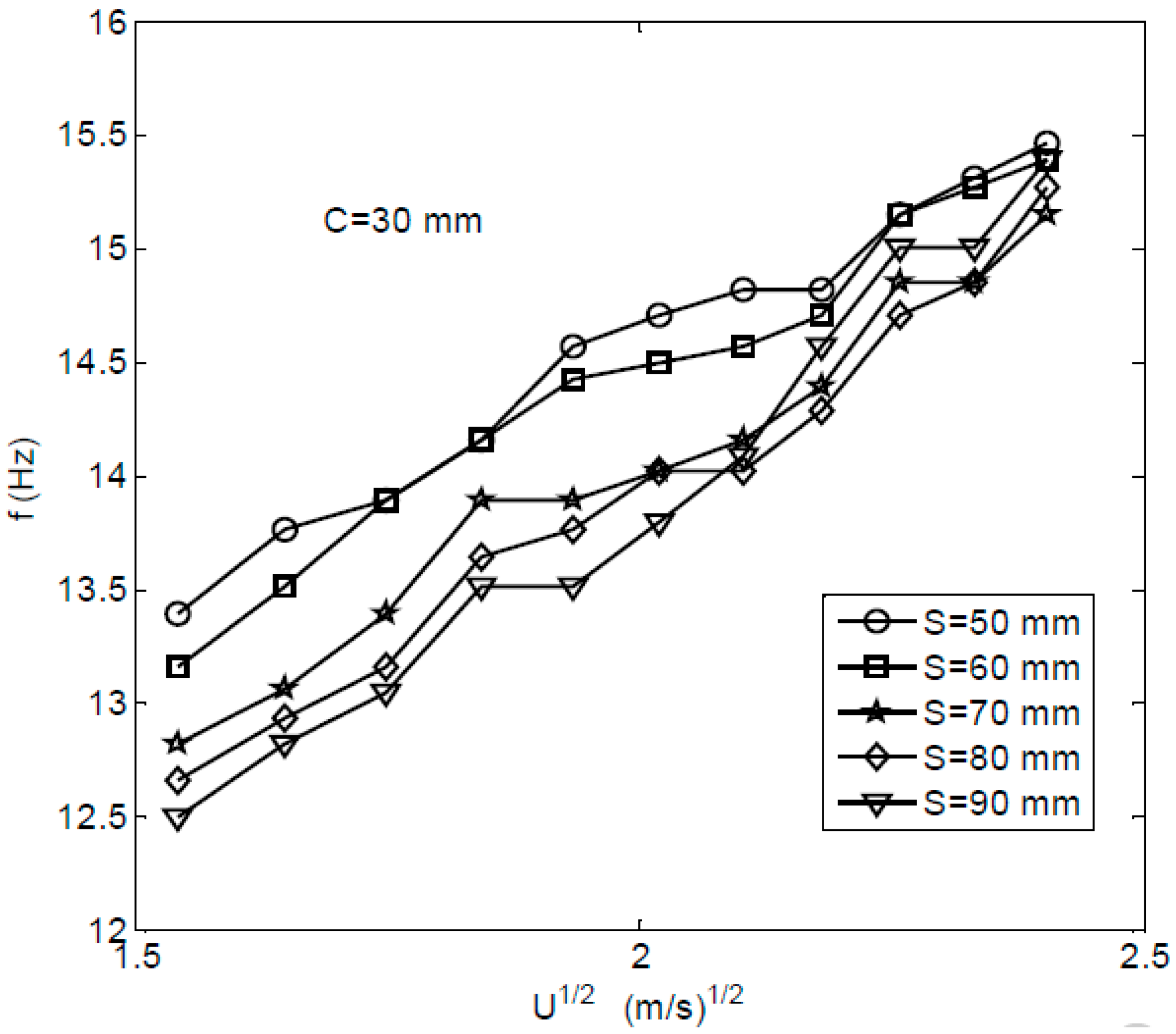

In order to efficiently extract energy from such a system with an electromagnetic coupling, the oscillation frequency needs to be maximized. The measured frequency

f is always larger than the natural frequency

fn of the system:

where

is the effective elastomer strength along the vertical direction and

m is the system translational mass.

Frequency

f grows with the wind velocity as

U1/2, as shown in

Figure 4. We notice that because of this relationship, the

FLEHAP device can be used as an autonomous sensor to measure wind velocity.

In order to harvest energy from the wing fluttering, the part transforming the mechanical energy into electrical energy uses an electromagnetic coupling: two series of magnets are placed in front of the coils that are fixed at the ends of the rigid axis (

Figure 1).

The magnets (NdFeB) have dimensions 10 mm × 10 mm × 4 mm, a coercive field of 38 Moe, and are arranged with alternating polarity N–S–N–S–N face to the coils. The coils have L = 10 mH, R = 150 Ω, 1500 turns, and external diameter 10 mm.

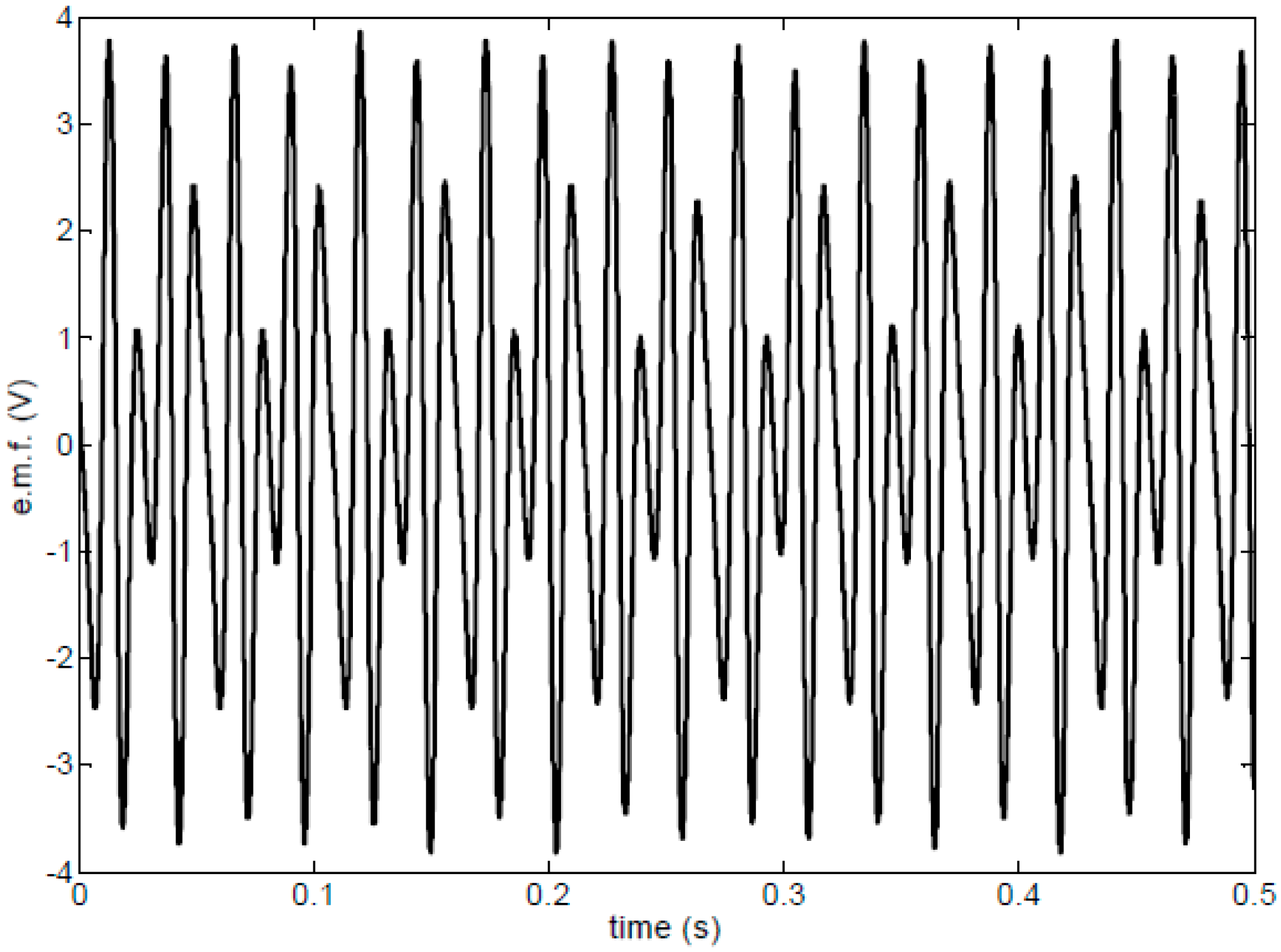

A typical e.m.f. measured during the wing oscillation is reported in

Figure 5.

The first evaluation of the FLEHAP device as an energy harvester has been done by simply connecting the coils to a resistive load

RL. Under the wind’s action, the induced current acts as an electromagnetic brake, lowering the frequency oscillation and eventually stopping the wing movement (if

RL is low enough and the wind velocity is not high). Of course, this effect also depends on the other parameters of the system, since the equations describing the system are coupled and nonlinear. A similar effect is discussed in [

11]. Then, it is necessary to tune the resistive load for a fixed wind velocity or to choose an

RL value as a compromise that is useful for a larger wind velocity range.

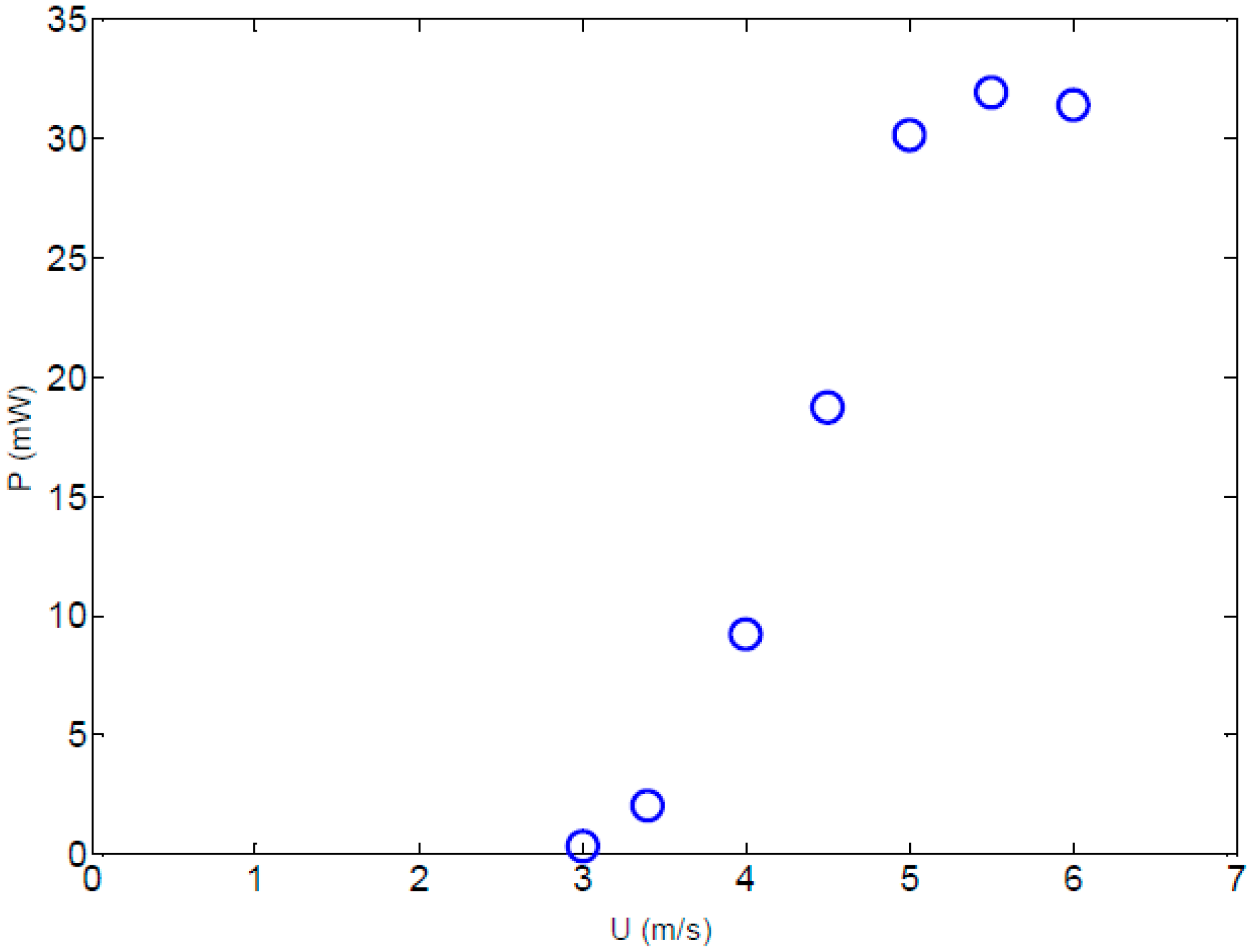

Optimizing the

RL value for each velocity, we obtain the curve reported in

Figure 6: in this case, the device starts to produce electrical energy in wind at 3 m/s and reaches a maximum of 32 mW in wind at 5.5 m/s.

Coherent with previous literature studies [

12], the efficiency of the device is calculated as the ratio of output electrical power and input wind power, estimated as

With the present device, the efficiency can reach a value greater than 8%.

2.2. Energy-Harvesting Circuit

To efficiently transform the energy harvested by a device into electrical energy, a specialized electronic circuit must be designed. Such a circuit must be adapted to the specific characteristics of the device, and many different solutions have been proposed in the literature [

15].

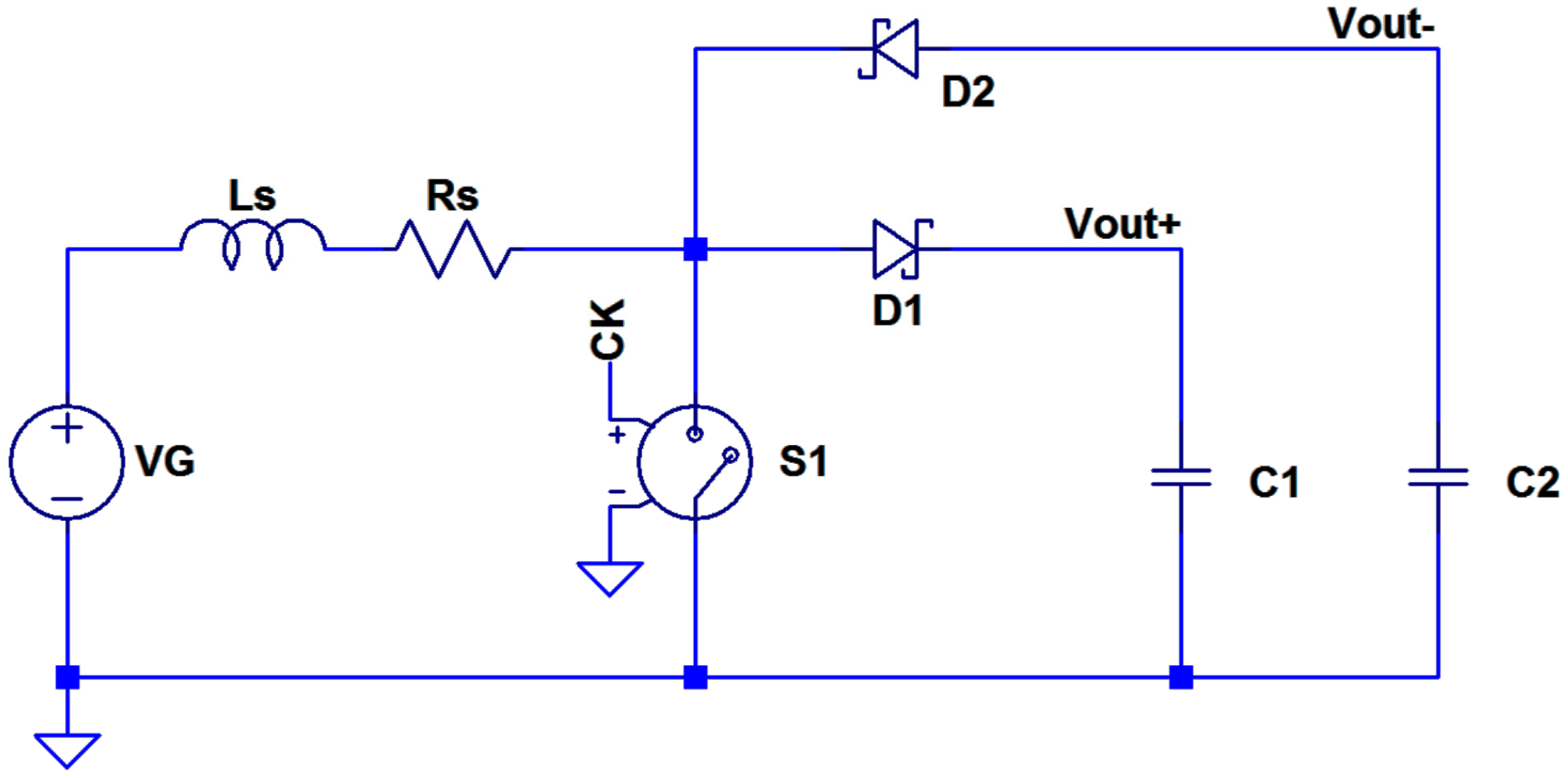

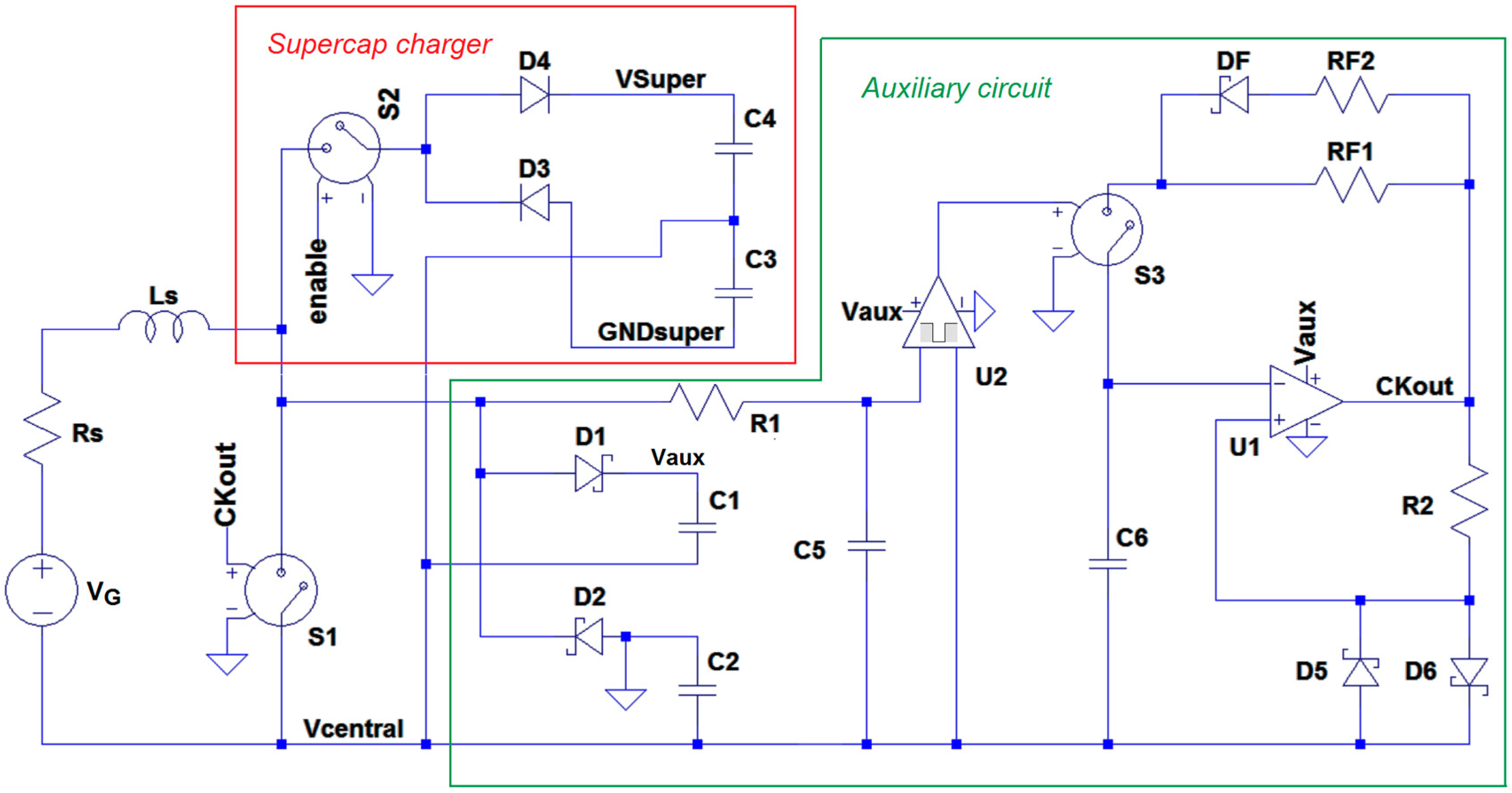

In our case, since we want to possibly obtain a voltage on the supercap higher than the peak value of the input, we chose a boost configuration [

15,

16,

17] that, in its simplest form, consists of a switched inductor converter, as depicted in

Figure 7. The red box on the left of the schematics contains the series V

G, R

S, and L

S, which represents the electromagnetic generator obtained as the series wiring of the two coils described previously.

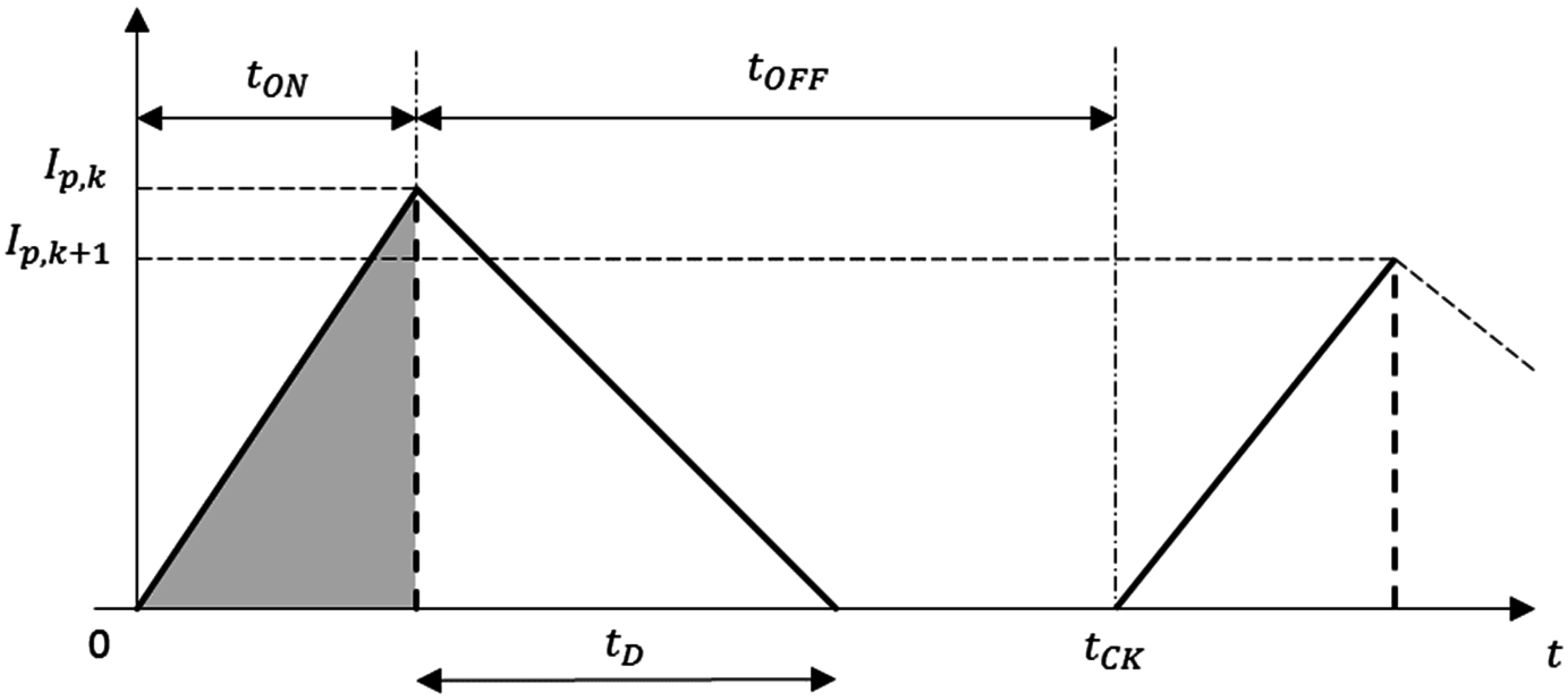

Switch S1 is controlled by a clock signal, CK, with period

, where

is the time interval during which the switch is closed, and

is the time interval it is open (

Figure 8). The frequency of the clock signal is

. We can also define a duty cycle,

.

Considering the inductive behavior of the generator coils, represented by the inductance

and resistance

in

Figure 7, we can derive a model of the circuit, as seen by the generator, as an equivalent resistive load

. To this purpose, it is worth noting that, considering an ideal switch S1 with a zero value series resistance in the closed state, and a constant input voltage

, the transient of the current flowing in the circuit follows an exponential behavior as the S1 closes, with a time constant

and an asymptotic value

. Approaching such a value, most of the power is dissipated on

. Since what we want is to efficiently extract power from the generator to supply the sensor network node circuitry, we need to reduce the power dissipation on

as much as possible, while keeping the possibility of controlling the electromagnetic brake effect on the wing motion.

This can be done keeping the current regime at much values lower than , which corresponds to adopt a sampling time .

For our discussion, let us now relax the constant input voltage condition: as soon as the switch opens, the current starts flowing through the diode and capacitor series. Let us also consider a case in which the capacitor is already charged at a voltage , greater than the sum of and the drops across and the diode.

With these assumptions, we can consider a linear increment of the current as the switch is closed, followed by a linear decrease of duration

, as represented in

Figure 8. It will be a design issue to keep

in all conditions.

Neglecting the voltage drops across both

and the switch, we can derive the current value integrating the input voltage:

To compute the equivalent resistance model of the switched inductance, consider first, as a reference, an input signal of arbitrary waveform loaded with an ideal resistor .

In that case, the average power dissipated on

over the period

is

To carry out the comparison with the switched inductance circuit of

Figure 7, let the number of clock cycles comprised in a period of the input signal be an integer number N:

.

In this perspective, in the case of large N (e.g., N > 100), it is possible to approximate the input signal, with an acceptable low error, considering its discrete time equivalent = with . This expression corresponds to a sampling occurring at the beginning of each clock cycle: different choices (e.g., sampling at the middle of the interval) would not affect our conclusions.

Following this approach, we can write the approximate expression of the average power

, adapting Equation (3) to the sampled case:

To make a comprehensive comparison of the continuous and sampled case, it is necessary to adapt the latter to manage both signs of the input signal. This can be accomplished via a complementary rectifier as depicted in

Figure 9. Positive voltages at the input will produce a charge increment in C1, while negative values will charge C2.

Considering a generic sample

k, we can obtain

The energy available in the inductance for each clock cycle is:

Such energy is transferred to the capacitors during the

interval:

As an example, with

,

with

, the peak current becomes

. Considering an average voltage drop across the diode of

(e.g., in the case of a BAT54 low-cost Schottky barrier diode), it follows that

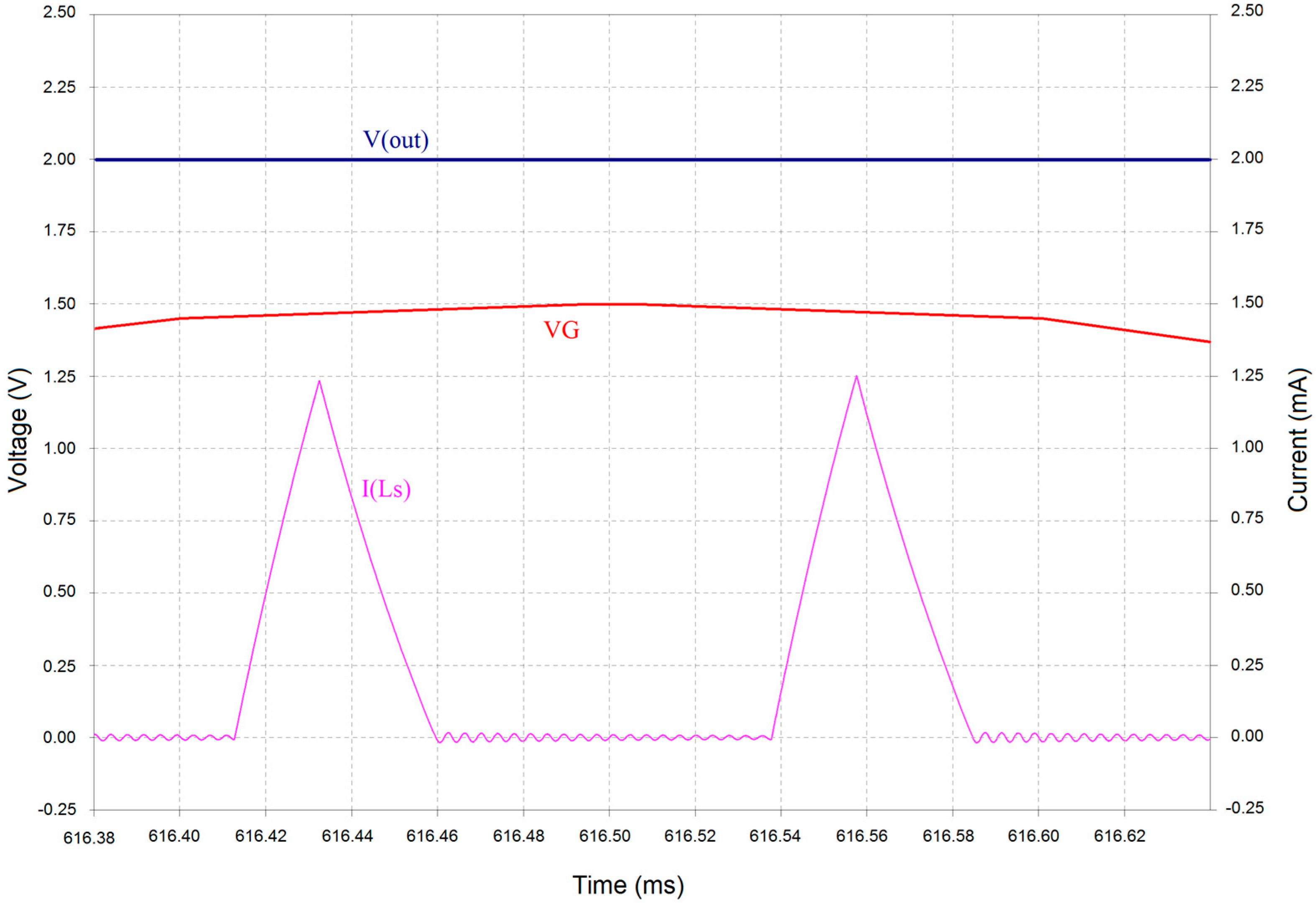

. This is confirmed by the simulation reported in

Figure 10. Better results could be achieved using active rectifiers instead of diodes.

Being the original circuit able to manage both signs of the input signal, we can consider that the energy transferred during a period T of the source is:

From this equation, we can write the average power obtainable in a period as:

Comparing Equations (3) and (9), and defining

as the equivalent value to obtain the same amount of energy transfer in the two cases, we can write

and consequently:

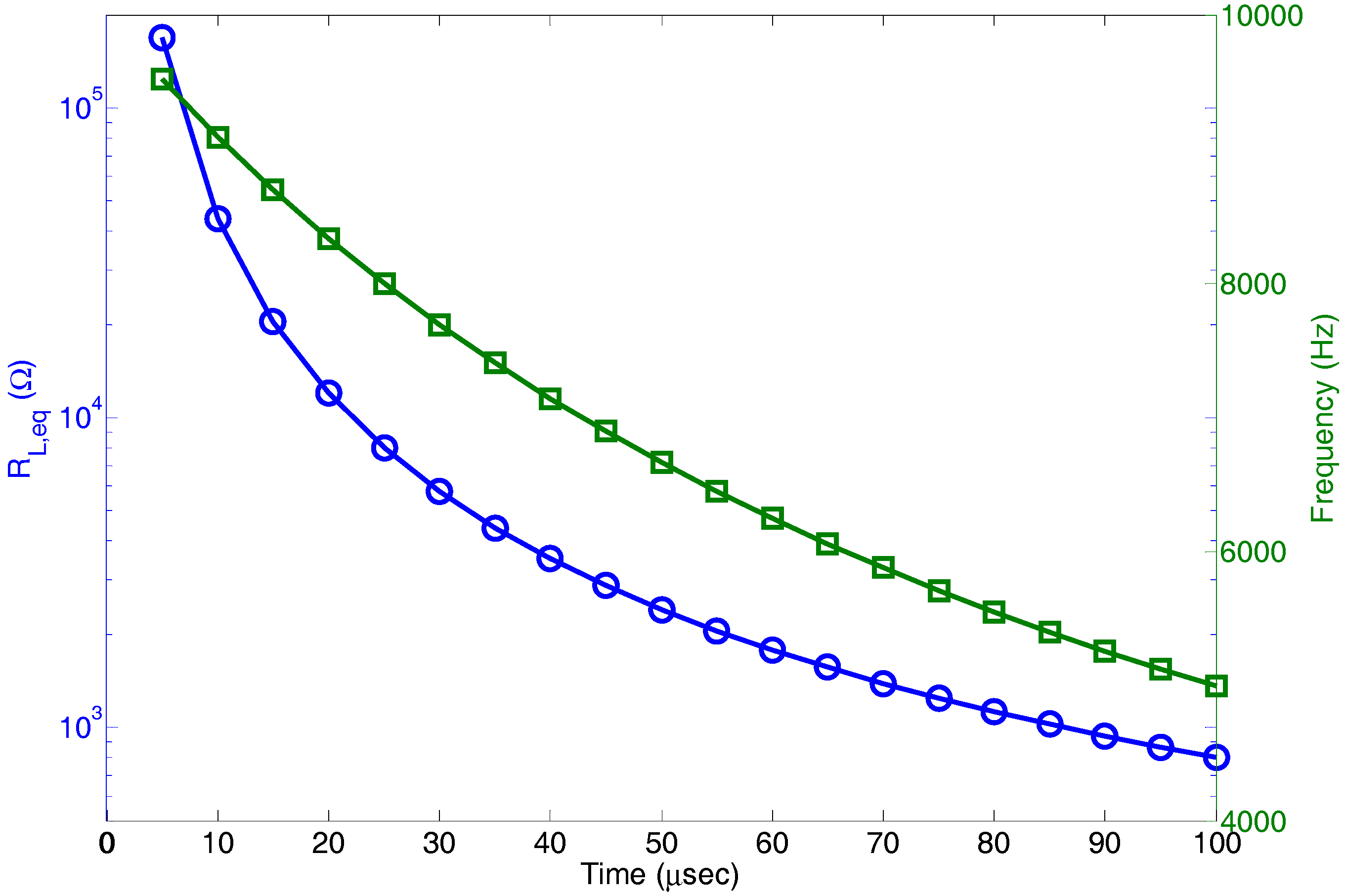

This expression is plotted in

Figure 10. This model can be used to optimize the equivalent load and its electromagnetic brake effect to obtain the maximum power transfer.

On the basis of such consideration we designed the final circuit shown in

Figure 11.

It is worth noting that the circuit has been used for extensive circuital simulation with LTSpice IV [

18], modeling the input signal with a simplified piecewise linear generator.

Such circuits consist of two blocks: an auxiliary circuit, and the main rectifier circuit for supercap charging. Both are equipped with a peak-to-peak rectifier (respectively equipped with low-drop diodes D1 and D2 for the first one, and low-leakage diodes D3 and D4 for the latter), for the purpose of maximizing the output voltage available for the user, also in the case of slow wind condition.

The purpose of the auxiliary circuit is to quickly provide power for controlling switches, as soon as it becomes available from the environment. It consists of: (1) an oscillator circuit which generates a clock signal as soon as the

voltage reaches the 1.5 V level necessary to bias the comparator U1; and (2) a window comparator (U2) to detect time intervals with no power coming from the generator. The respective functions are:

- S1

the main switch is used to clamp the inductor current in the time interval during which the oscillator output CKout is at high level.

- S2

when sufficient energy has been stored in the auxiliary capacitors C1 and C2, this switch is turned on to allow supercap charging.

- S3

it stops the oscillation when no power is available, to save as much as possible the auxiliary charge stored in C1 and C2.

The circuit has been designed to operate according to the following algorithm:

Starting from a completely zero voltage situation, as soon as some power comes from the generator, the auxiliary rectifier starts charging C1 and C2. As soon as the voltage reaches about 1.5 V, S3 being closed by the window comparator, the oscillator starts working, clamping the intrinsic source inductance Ls.

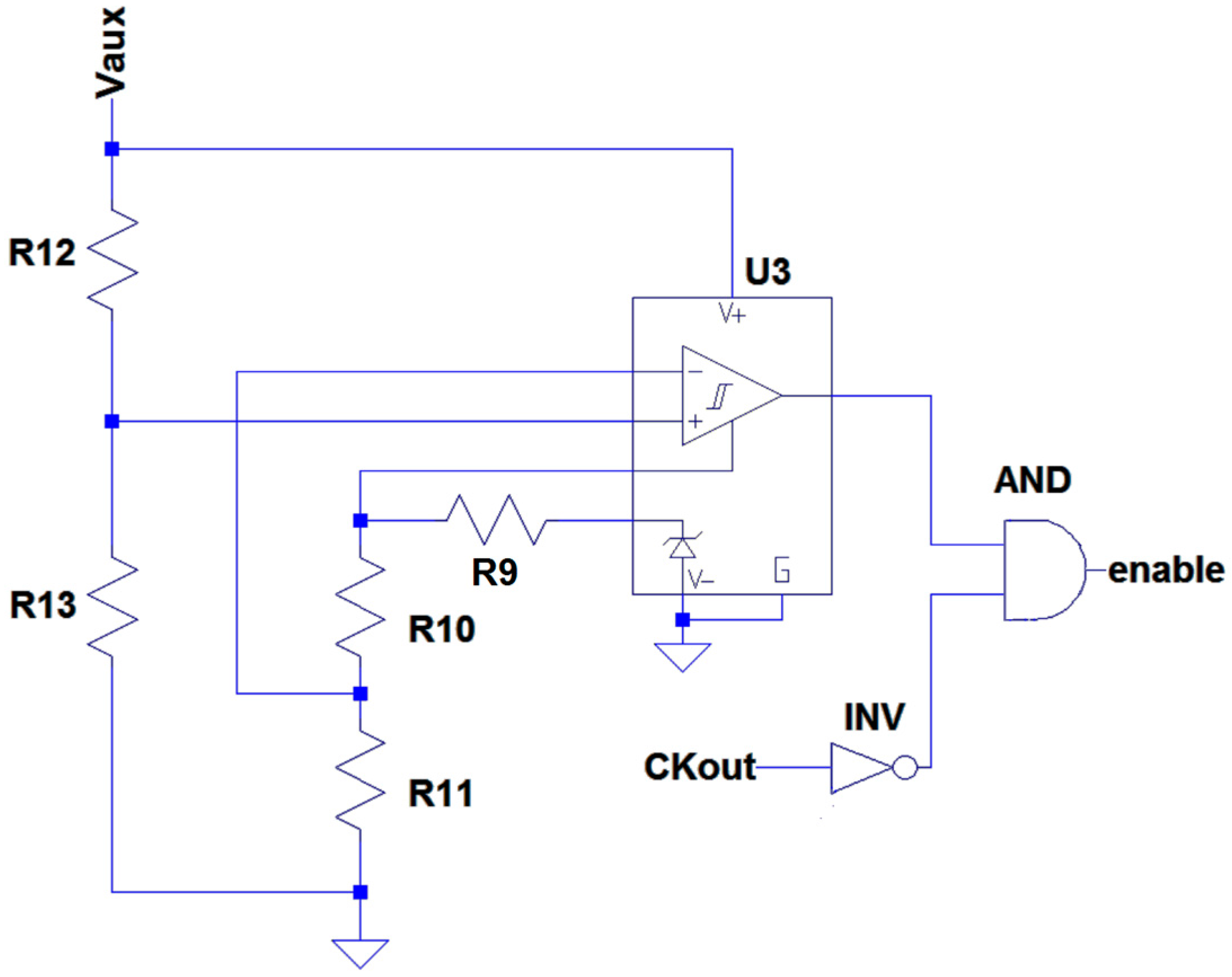

The U3-based Schmidt trigger shown in

Figure 12 monitors the

level: the auxiliary charging phase continues since an upper limit

is reached. As soon as this occurs, the S2 switch is enabled, and consequently, the supercap charging phase starts. Since, at least at the beginning, the supercap voltage is lower than

, the D1 and D2 diodes do not conduct any longer, and C1 and C2 capacitors start discharging. This continues since a lower limit

is reached on

: at that threshold, U3 disconnects the supercap leaving C1 and C2 to charge again. Resistances R9–R13 (see

Figure 12) define

and

.

This cycle repeats until the maximum voltage of 10 V is reached on both branches. A Zener diode (not shown) is used to protect active circuits.

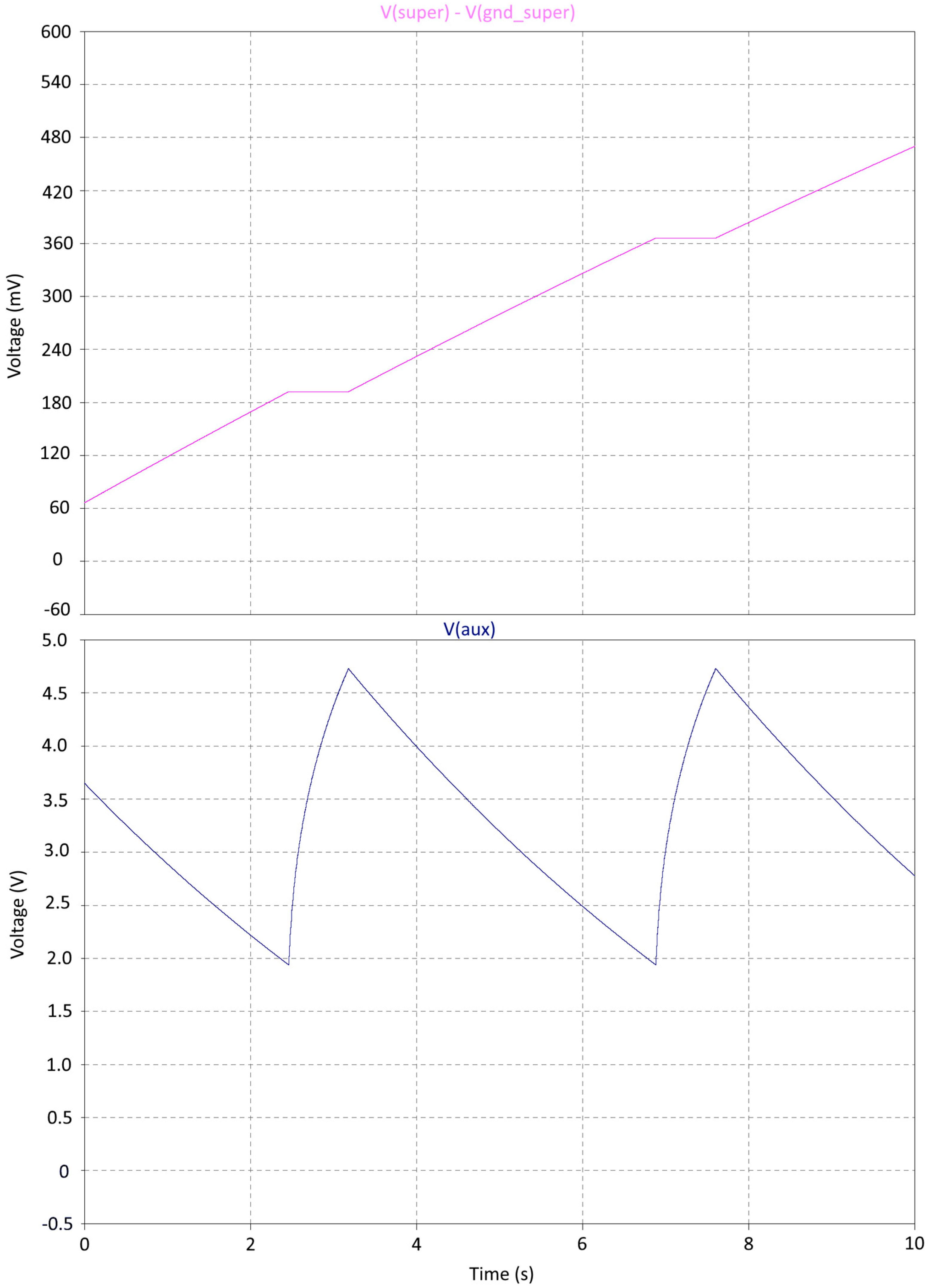

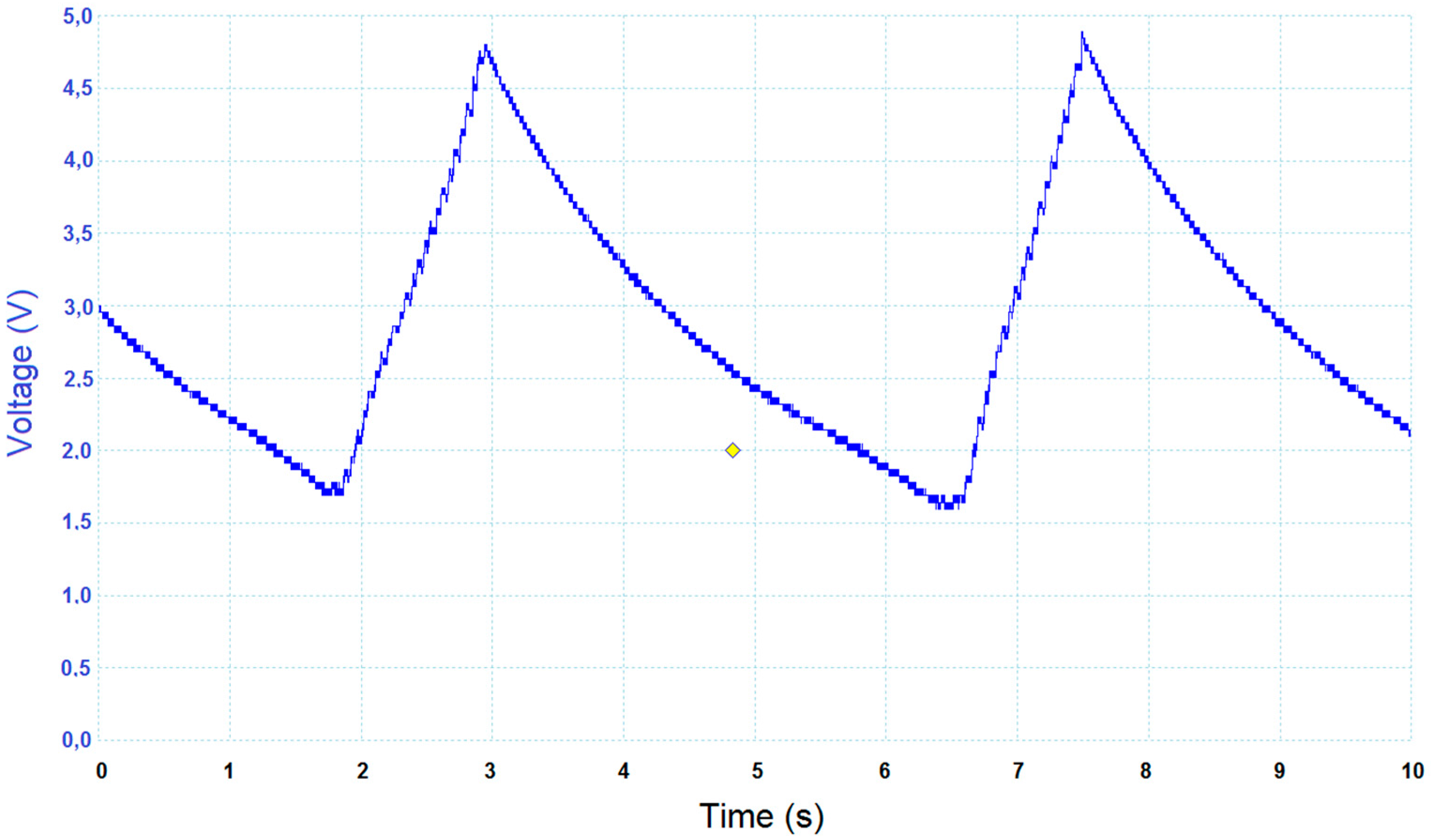

The result of a circuit simulation is show in

Figure 13, for a time interval of 10 s. In the example, the following thresholds have been used:

;

. The bottom trace represents the behavior of the auxiliary supply voltage

, while the upper trace represents the supercap voltage, illustrating the sequence described above. The LTC1540 ultralow power comparator [

19] from Linear Technology has been used as U1 and U3, while U2 has been implemented with two open drain comparators contained in a TLV3402 chip from Texas Instruments [

20].

The same experiment of

Figure 14 has been replicated in the real case with a wind speed of 3.5 m/s, as depicted in

Figure 15. When the switch S2 is closed, the

signal decreases.

The correspondence with the simulated case reported so far is encouraging.

At the moment, the overall efficiency of the circuit is limited to around 60%: this value is due to the component used and to the correct tuning of the dynamic resistance seen by the generator, which changes with the wind speed. A new version of the circuit is currently under construction.