Protein Bread Fortification with Cumin and Caraway Seeds and By-Product Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Seed Extraction

2.2. Raw Materials for Protein Bread Preparation

2.3. Protein Bread Making Technology

2.4. Sensory Evaluation of Protein Bread

2.5. Protein Bread Moisture Content

2.6. Protein Bread Crumb Hardness

2.7. Protein Bread Crumb Color

2.8. Extraction and Determination of Phenolic Compounds from Protein Bread

2.9. Determination of Trolox Equivalent Antioxidant Capacity (TEAC)

2.10. Theoretical Calculation of Protein Bread Nutritional Value

- * Carbohydrates (except polyols): 4 kcal∙g−1;

- * Protein, 4 kcal∙g−1;

- * Fat, 9 kcal∙g−1;

- * Fibre, 2 kcal∙g−1.

2.11. Statistical Analyses

3. Results and Discussion

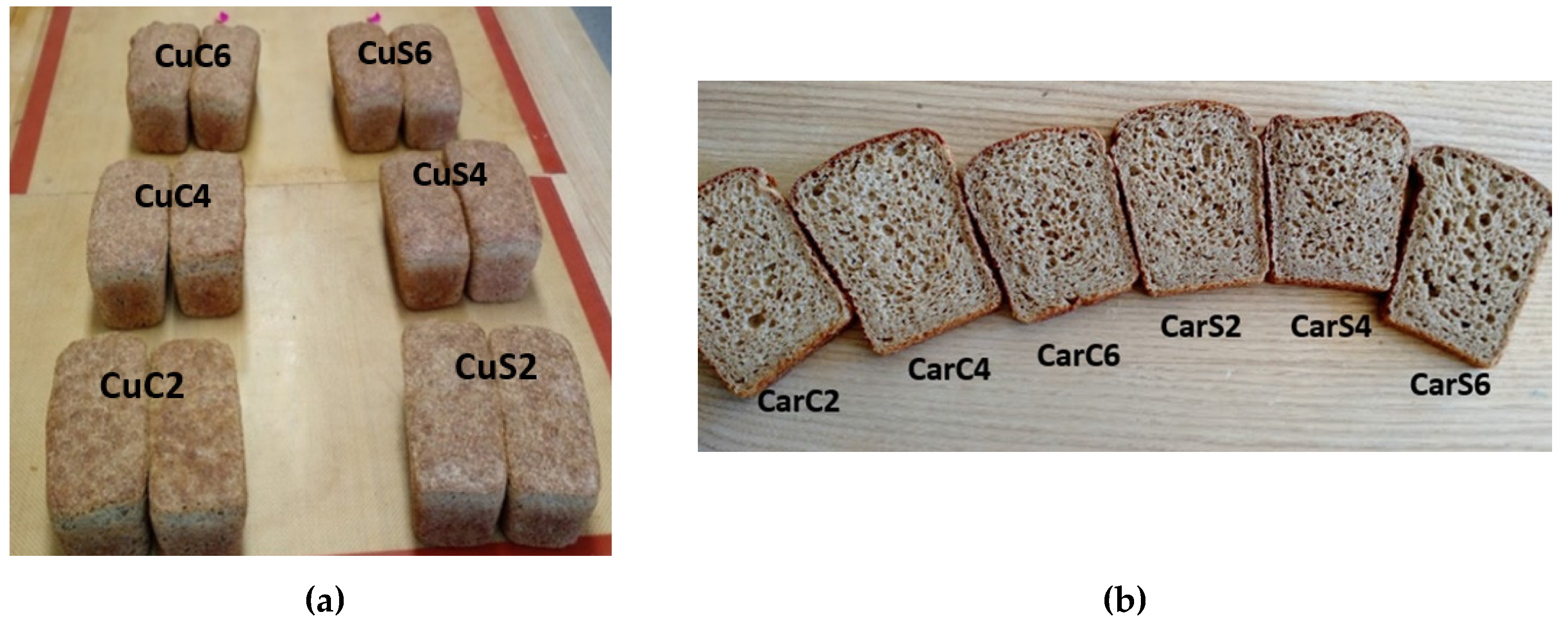

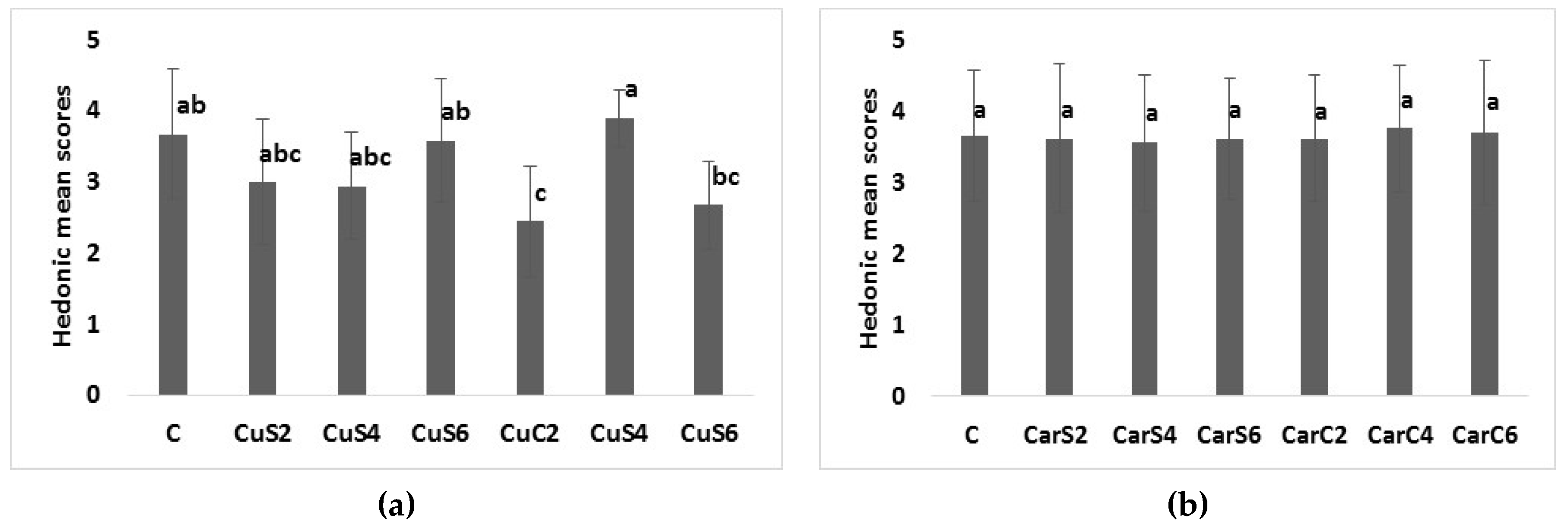

3.1. Protein Bread Sensory Analysis

3.2. Protein Bread Color Analysis

3.3. Protein Bread Moisture Content Analysis

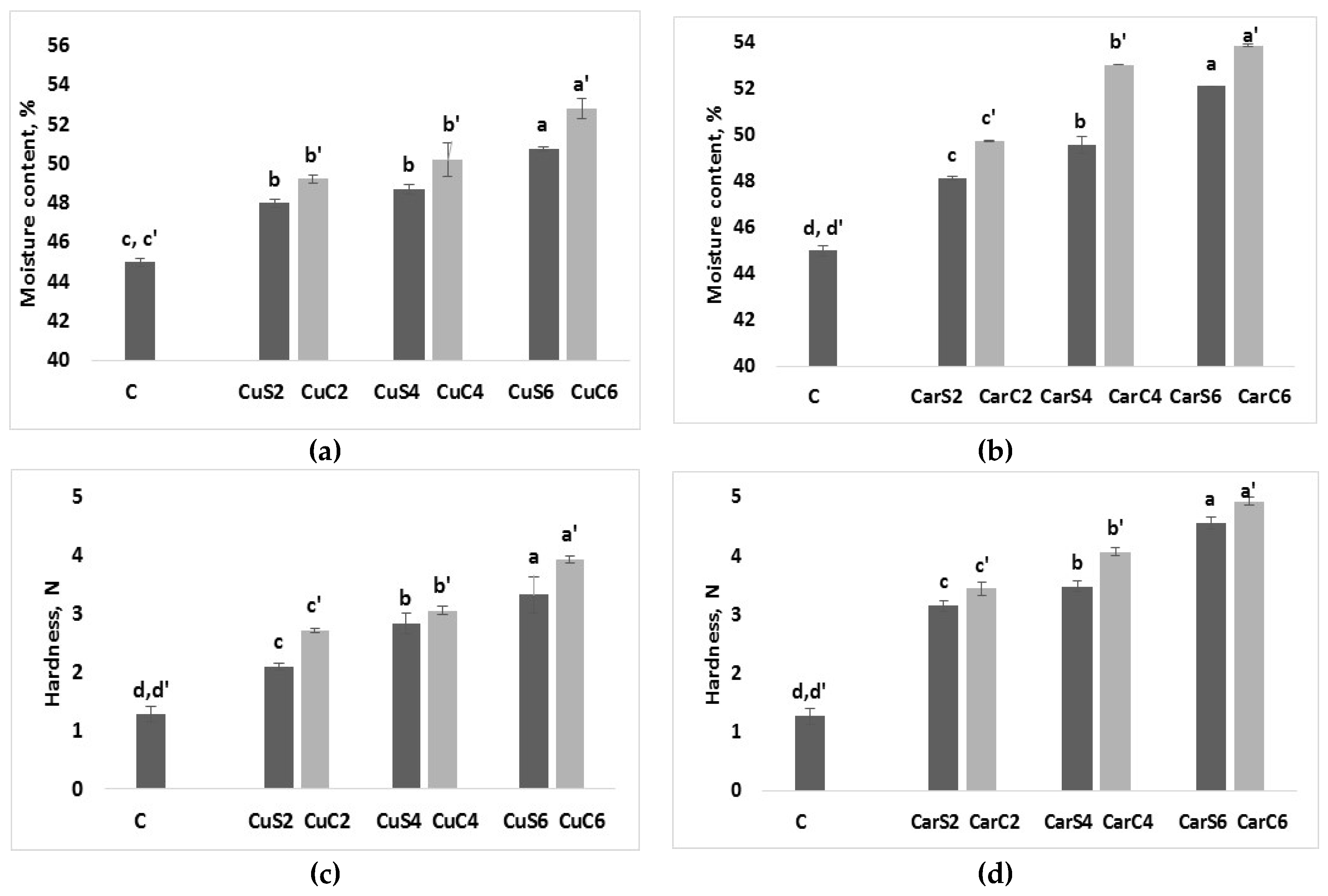

3.4. Protein Bread Hardness Analysis

3.5. Nutritional Values of Protein Bread

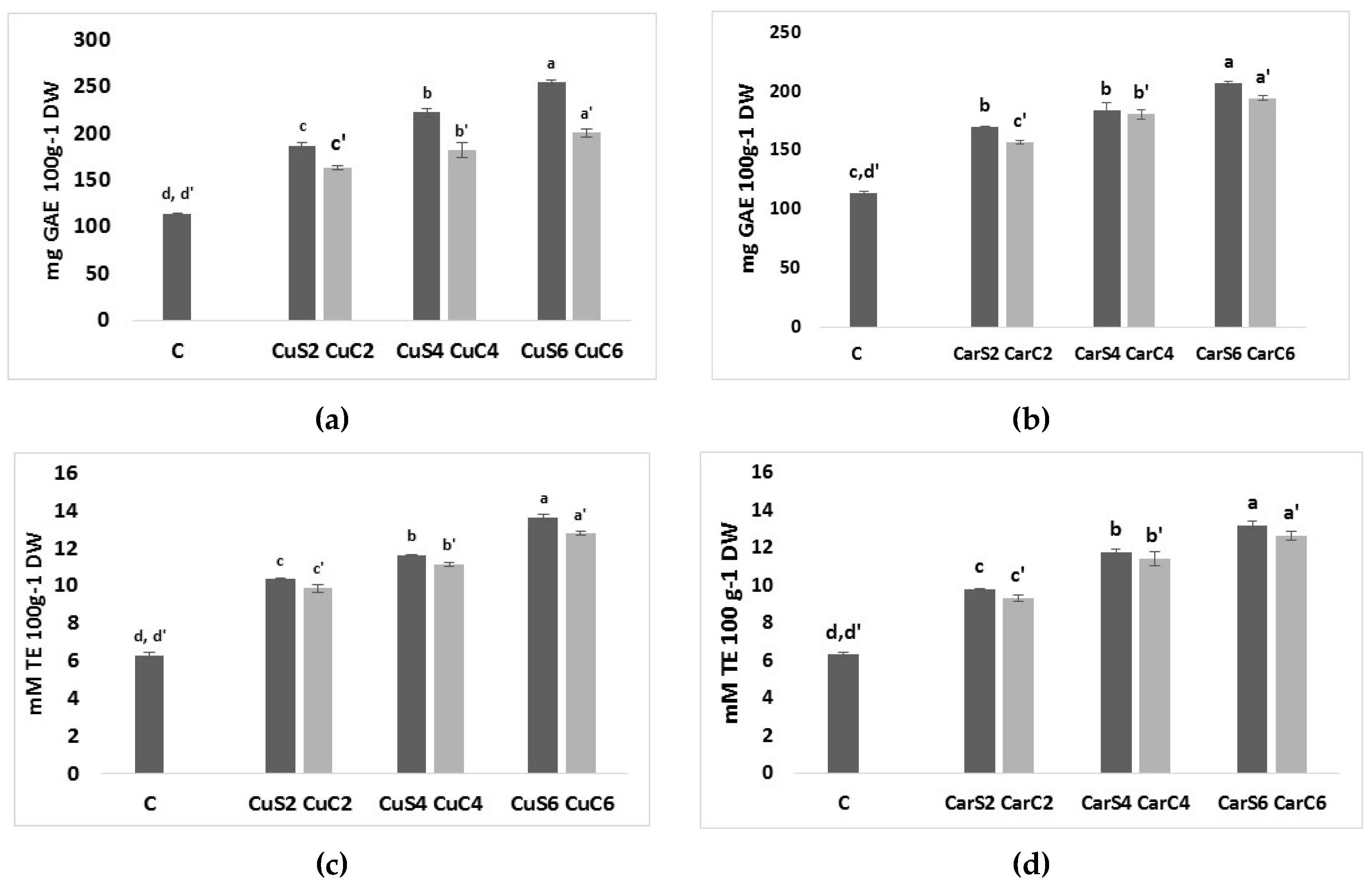

3.6. Total Phenolic Content (TPC) Analysis

3.7. Trolox Equivalent Antioxidant Capacity (TEAC) Analysis

4. Conclusion

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Ngozi, A.A. Effect of whole wheat flour on the quality of wheat-baked bread. Glob. J. Food Sci. Technol. 2014, 3, 127–133. [Google Scholar]

- Ndife, J.; Abdulraheem, L.O.; Zakari, U.M. Evaluation of the nutritional and sensory quality of functional breads produced from whole wheat and soya bean flour blends. Afr. J. Food Sci. 2011, 5, 466–472. [Google Scholar]

- Atrooz, O.M. The effects of Cuminum cyminum L. and Carum carvi L. seed extracts on human erythrocye hemolysis. Int. J. Biol. 2013, 5, 57–63. [Google Scholar] [CrossRef]

- Sultan, M.T.; Butt, M.S.; Akhtar, S.; Ahmad, A.N.; Rauf, M.; Saddique, M.S. Antioxidant and antimicrobial potential of dried cumin (Cuminum cyminum L.), caraway (Carum carvi L.) and turmeric powder (Curcuma Longa L.). J. Food. Agric. Environ. 2014, 12, 71–76. [Google Scholar]

- Ahmad, B.S.; Talou, T.; Saad, Z.; Hijazi, A.; Cerny, M.; Kanaan, H.; Chokr, A.; Merah, O. Fennel oil and by-products seed characterization and their potential applications. Ind. Crops Prod. 2018, 111, 92–98. [Google Scholar] [CrossRef]

- Venturi, F.; Sanmartin, C.; Taglieri, I.; Nari, A.; Andrich, G.; Terzuoli, E.; Donnini, S.; Nicolella, C.; Zinnai, A. Development of phenol-enriched olive oil with phenolic compounds extracted from wastewater produced by physical refining. Nutrients 2017, 9, 916. [Google Scholar] [CrossRef] [PubMed]

- Das, R.; Biswas, S.; Banerjee, E.R. Nutraceutical-prophylactic and therapeutic role of functional food in health. J. Nutr. Food Sci. 2016, 6, 527. [Google Scholar] [CrossRef]

- El-Soukkary, F.A.H. Evaluation of pumpkin seed products for bread fortification. Plant Foods Hum. Nutr. 2001, 56, 365–384. [Google Scholar] [CrossRef] [PubMed]

- Majzoobi, M.; Azadmard-Damrichi, S.; Peighambardoust, S.H.; Aghamirzaei, M. Effects of grape seed powder as a functional ingredient on flour physicochemical characteristics and dough rheological properties. J. Agric. Sci. Technol. 2015, 17, 365–373. [Google Scholar]

- Ahmad, B.S.; Straumite, E.; Sabovics, M.; Kruma, Z.; Merah, O.; Saad, Z.; Hijazi, A.; Talou, T. Effect of addition of fennel (Foeniculum vulgare L.) on the quality of protein bread. Nutr. Health 2017, 71, 509–514. [Google Scholar]

- Tarek-Tilistyák, J.; Tarek, M.; Juhász-Román, M.; Jekő, J. Effect of oil-seed pressing residue on bread colour and texture. Acta. Univ. Sapientiae Alimentaria 2015, 8, 118–124. [Google Scholar] [CrossRef]

- Sánchez-Pardo, M.E.; Blancas-Nápoles, A.; Vázquez-Landaverde, P.A.; Nari, A.; Taglieri, I.; Ortiz-Moreno, A.; Mayorga-Reyes, L.; Sanmartin, C.; Bermúdez-Humarán, L.G.; Torres-Maravilla, E. The use of mexican xaxtle as leavening agent in Italian straight dough bread making to produce pulque bread. Agrochimica 2016, 60, 329–342. [Google Scholar]

- Sgherri, C.; Micaelli, F.; Andreoni, N.; Baldanzi, M.; Ranieri, A. Retention of phenolic compounds and antioxidant properties in potato bread obtained from a dough enriched with a powder from the purple cv. Vitelotte. Agrochimica 2016, 60, 312–328. [Google Scholar]

- Chandrasekara, A.; Rasek, O.A.; John, J.A.; Chandrasekara, N.; Shahidi, F. Solvent and extraction conditions control the assayable phenolic content and antioxidant activities of seeds of black beans, canola and millet. J. Am. Oil Chem. Soc. 2016, 93, 275–283. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar]

- Yu, L.; Nanguet, A.L.; Beta, T. Comparison of antioxidant properties of refined and whole wheat flour and bread. Antioxidants 2013, 2, 370–383. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EU) No. 1169/2011 of the European Parliament and of the Council. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011R1169 (accessed on 16 January 2018).

- Capuano, E.; Ferrigno, A.; Acampa, I.; Serpen, A.; Açar, Ö.Ç.; Gökmen, V. Effect of flour type on maillard reaction and acrylamide formation during toasting of bread crisp model systems and mitigation strategies. Food Res. Int. 2009, 42, 1295–1302. [Google Scholar] [CrossRef]

- Bansal, R.; Kapoor, K. Physiochemical analysis of bread fortified with different levels of soya flour blends. Int. J. Pure Appl. Biosci. 2015, 3, 52–64. [Google Scholar]

- Amir, I.; Hanida, H.S.; Syafiq, A. Development and physical analysis of high fiber bread incorporated with cocoa (Theobroma cacao sp.) pod husk powder. Int. Food Res. J. 2013, 20, 1301–1305. [Google Scholar]

- Das, L.; Raychaudhuri, U.; Chakraborty, R. Herbal fortification of common bread by fennel seeds. Food Technol. Biotechnol. 2013, 52, 434–440. [Google Scholar]

- Srivastava, Y.; Semwal, A.D. Effect of virgin coconut meal (VCM) on the rheological, micro-structure and baking properties of cake and batter. J. Food Sci. Technol. 2015, 52, 8122–8130. [Google Scholar] [CrossRef] [PubMed]

- Scheuer, P.M.; Mattioni, B.; Barreto, P.L.M.; Montenegro, F.M.; Gomes-Ruffi, C.R.; Biondi, S. Effects of fat replacement on properties of whole wheat bread. Braz. J. Pharm. Sci. 2014, 50, 703–712. [Google Scholar] [CrossRef]

- El-Demery, M.; Mahmoud, K.F.; Bareh, G.F.; Albadawy, W. Effect of fortification by full fat and defatted flaxseed flour sensory properties of wheat bread and lipid profile laste. Int. J. Curr. Microbiol. App. Sci. 2015, 4, 581–598. [Google Scholar]

- Oliveira, L.; Carvalho, M.V.; Melo, L. Health promoting and sensory properties of phenolic compounds in food. Rev. Ceres 2014, 61, 764–779. [Google Scholar] [CrossRef]

- Villarino, C.B.; Jayasena, V.; Coorey, R.; Chakrabarti-Bell, S.; Johnson, S. The effects of bread-making process factors on Australian sweet lupin-wheat bread quality characteristics. Int. J. Food Sci. Technol. 2014, 49, 2373–2381. [Google Scholar] [CrossRef]

- Irakli, M.; Katsantonis, D.; Kleisiaris, F. Evaluation of quality attributes, nutraceutical components and antioxidant potential of wheat bread substituted with rice bran. J. Cereal. Sci. 2015, 65, 74–80. [Google Scholar] [CrossRef]

- Szawara-Nowak, D.; Bączek, N.; Zieliński, H. Antioxidant capacity and bioaccessibility of buckwheat-enhanced wheat bread phenolics. J. Food Sci. Technol. 2016, 53, 621–630. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Ma, J.; Cheng, K.W.; Jiang, Y.; Chen, F.; Wang, M. The effects of grape seed extract fortification on the antioxidant activity and quality attributes of bread. Food Chem. 2010, 119, 49–53. [Google Scholar] [CrossRef]

- Nsimba, R.Y.; Kikuzaki, H.; Konishi, Y. Antioxidant activity of various extracts and fractions of Chenopodium quinoa and Amaranthus spp. seeds. Food Chem. 2008, 106, 760–766. [Google Scholar] [CrossRef]

- Moldovana, B.; Iasko, B.; David, L. Antioxidant activity and total phenolic content of some commercial fruit-flavored yogurts. Stud. Univ. Babes-Bolyai Chem. 2016, 61, 101–108. [Google Scholar]

| Bread Samples | Abbreviations | L* | a* | b* | ΔE Values |

|---|---|---|---|---|---|

| C | Control | 61.08 ± 2.06 a | 0.47 ± 0.69 d | 20.32 ± 1.96 c | - |

| CuS2 | 2% of cumin powder seed | 55.79 ± 0.52 cd | 1.21 ± 0.04 cd | 20.56 ± 0.01 c | 5.35 |

| CuS4 | 4% of cumin powder seed | 53.77 ± 0.75 d | 3.59 ± 0.03 b | 21.19 ± 0.09 bc | 8.01 |

| CuS6 | 6% of cumin powder seed | 50.86 ± 0.89 e | 5.48 ± 0.65 a | 22.56 ± 0.46 ab | 11.62 |

| CuC2 | 2% of cumin by-product | 58.90 ± 1.18 ab | 0.90 ± 0.01 cd | 20.16 ± 0.79 c | 2.22 |

| CuC4 | 4% of cumin by-product | 57.69 ± 0.14 bc | 1.70 ± 0.39 c | 22.44 ± 0.55 ab | 4.18 |

| CuC6 | 6% of cumin by-product | 56.35 ± 0.12 bcd | 3.09 ± 0.05 b | 23.59 ± 0.46 a | 6.13 |

| CarS2 | 2% of caraway powder seed | 58.21 ± 0.07 b | 1.32 ± 0.11 d | 20.37 ± 0.43 d | 2.04 |

| CarS4 | 4% of caraway powder seed | 57.72 ± 0.27 b | 3.20 ± 0.09 b | 22.66 ± 0.82 c | 3.84 |

| CarS6 | 6% of caraway powder seed | 56.34 ± 0.30 b | 4.94 ± 0.77 a | 26.98 ± 1.03 a | 9.31 |

| CarC2 | 2% of caraway by-product | 59.03 ± 0.13 ab | 1.28 ±0.31 d | 22.43 ±0.24 bc | 3.05 |

| CarC4 | 4% of caraway by-product | 58.33 ± 0.81 b | 2.19 ±0.08 c | 24.09 ±0.54 bc | 4.97 |

| CarC6 | 6% of caraway by-product | 57.70 ± 0.38 b | 3.49 ±0.04 b | 25.83±0.58 ab | 7.13 |

| Bread Samples | Nutrients (g∙100 g−1) | Energy Value (kcal∙100 g−1) | |||

|---|---|---|---|---|---|

| Carbohydrates | Protein | Fiber | Fat | ||

| Whole wheat | 59.70 | 11.90 | 11.20 | 2.30 | 340 |

| Cumin seed | 44.24 | 17.81 | 10.50 | 22.27 | 375 |

| Caraway seed | 49.90 | 19.77 | 38.00 | 14.59 | 333 |

| C | 25.59 | 22.37 | 4.96 | 0.97 | 210.49 |

| CuS2 | 25.77 | 22.4 | 5.01 | 1.2 | 213.50 |

| CuS4 | 25.95 | 22.42 | 5.06 | 1.42 | 216.38 |

| CuS6 | 26.13 | 22.45 | 5.11 | 1.65 | 219.39 |

| CuC2 | 25.93 | 22.48 | 5.05 | 1.09 | 213.55 |

| CuC4 | 26.27 | 22.58 | 5.14 | 1.22 | 216.66 |

| CuC6 | 26.60 | 22.69 | 5.22 | 1.34 | 219.66 |

| CarS2 | 25.82 | 22.42 | 5.24 | 1.14 | 213.70 |

| CarS4 | 26.04 | 22.47 | 5.51 | 1.31 | 216.85 |

| CarS6 | 26.26 | 22.52 | 5.78 | 1.48 | 220.00 |

| CarC2 | 26.00 | 22.51 | 5.38 | 1.06 | 214.34 |

| CarC4 | 26.41 | 22.65 | 5.78 | 1.15 | 218.15 |

| CarC6 | 26.81 | 22.79 | 6.19 | 1.24 | 221.94 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayed Ahmad, B.; Talou, T.; Straumite, E.; Sabovics, M.; Kruma, Z.; Saad, Z.; Hijazi, A.; Merah, O. Protein Bread Fortification with Cumin and Caraway Seeds and By-Product Flour. Foods 2018, 7, 28. https://doi.org/10.3390/foods7030028

Sayed Ahmad B, Talou T, Straumite E, Sabovics M, Kruma Z, Saad Z, Hijazi A, Merah O. Protein Bread Fortification with Cumin and Caraway Seeds and By-Product Flour. Foods. 2018; 7(3):28. https://doi.org/10.3390/foods7030028

Chicago/Turabian StyleSayed Ahmad, Bouchra, Thierry Talou, Evita Straumite, Martins Sabovics, Zanda Kruma, Zeinab Saad, Akram Hijazi, and Othmane Merah. 2018. "Protein Bread Fortification with Cumin and Caraway Seeds and By-Product Flour" Foods 7, no. 3: 28. https://doi.org/10.3390/foods7030028