Study on Di-Phase Membrane Device with DZ272(DDD) for Purification Behavior of Divalent Cobalt Ions in Slops

Abstract

:1. Introduction

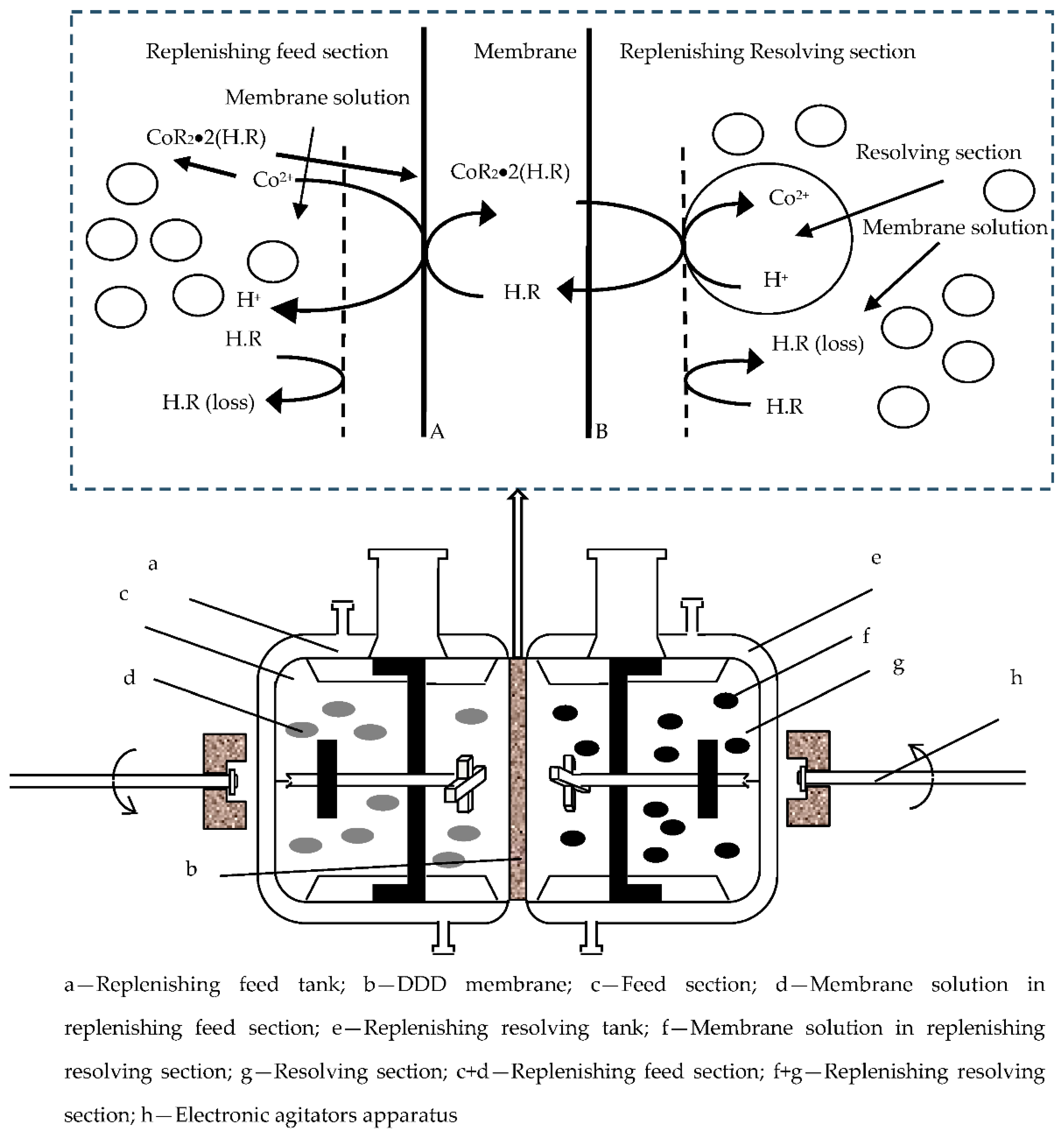

2. Materials and Methods

2.1. Theoretical Methods

2.2. Reagents and Devices

2.3. Experimental Procedure

3. Results and Discussion

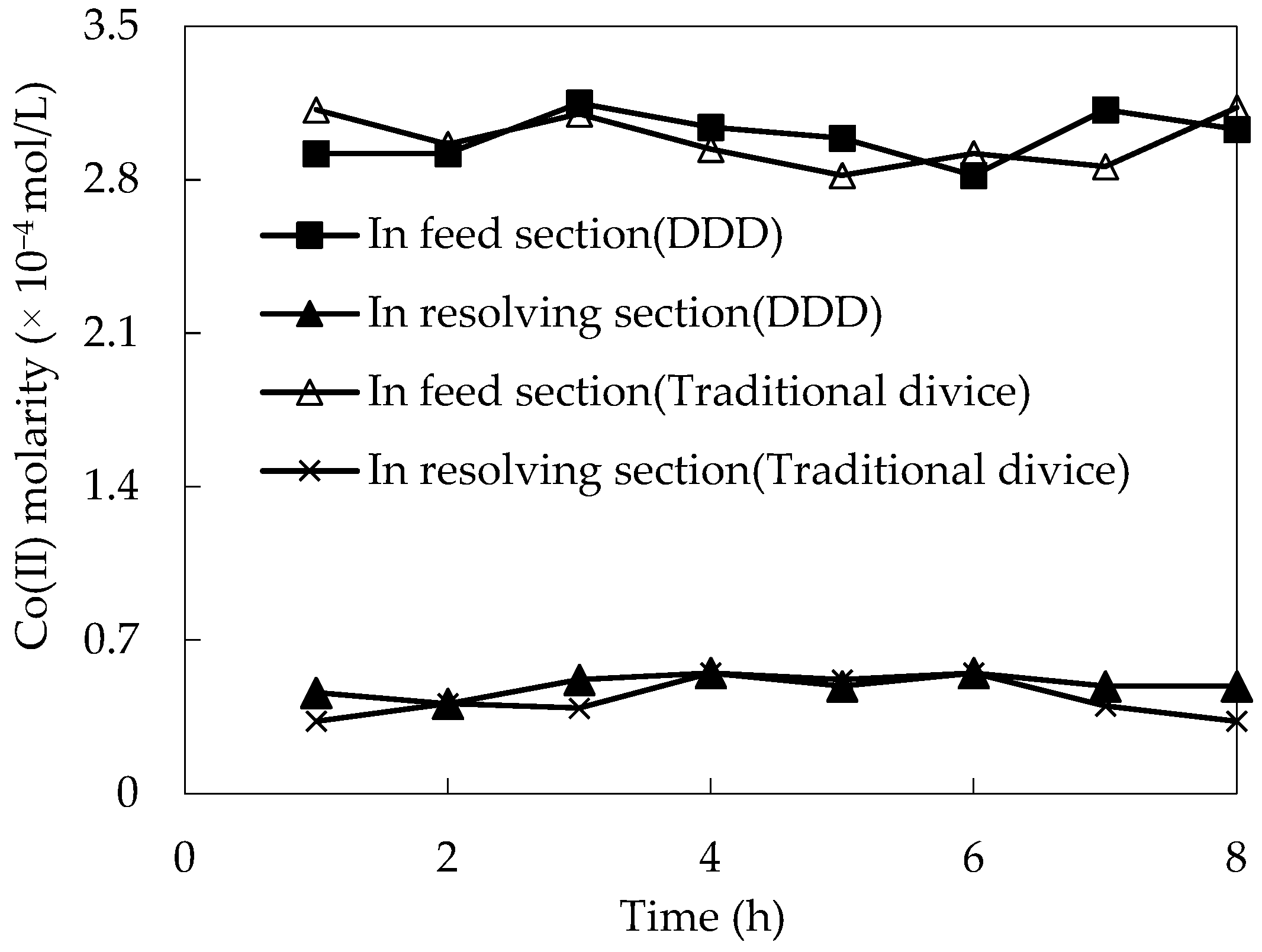

3.1. Stability of DDD

3.2. Effect of the Voluminal Ratio of the Membrane Solution and Feed Solution (O/F)

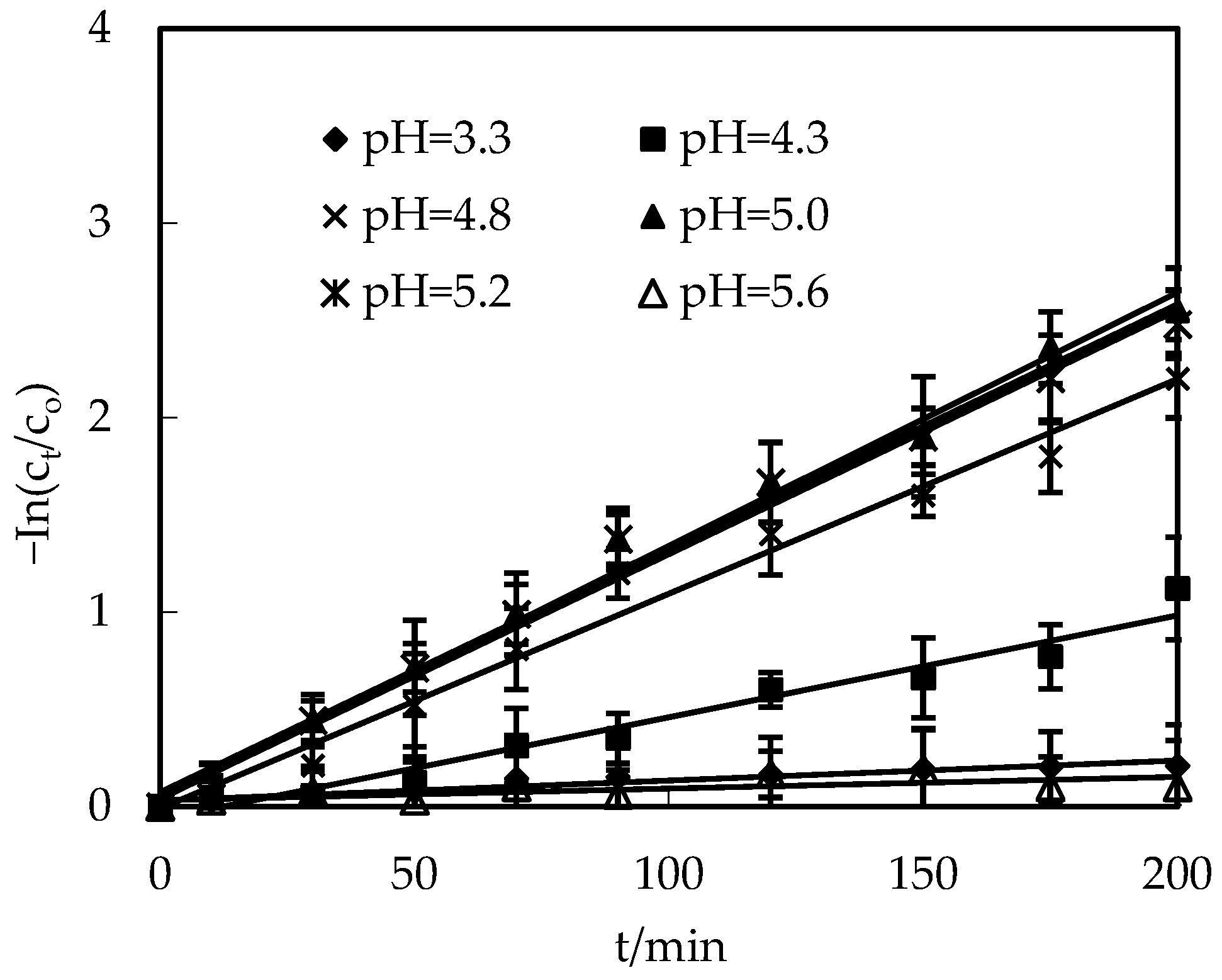

3.3. Effect of pH on the Replenishing Feed Section

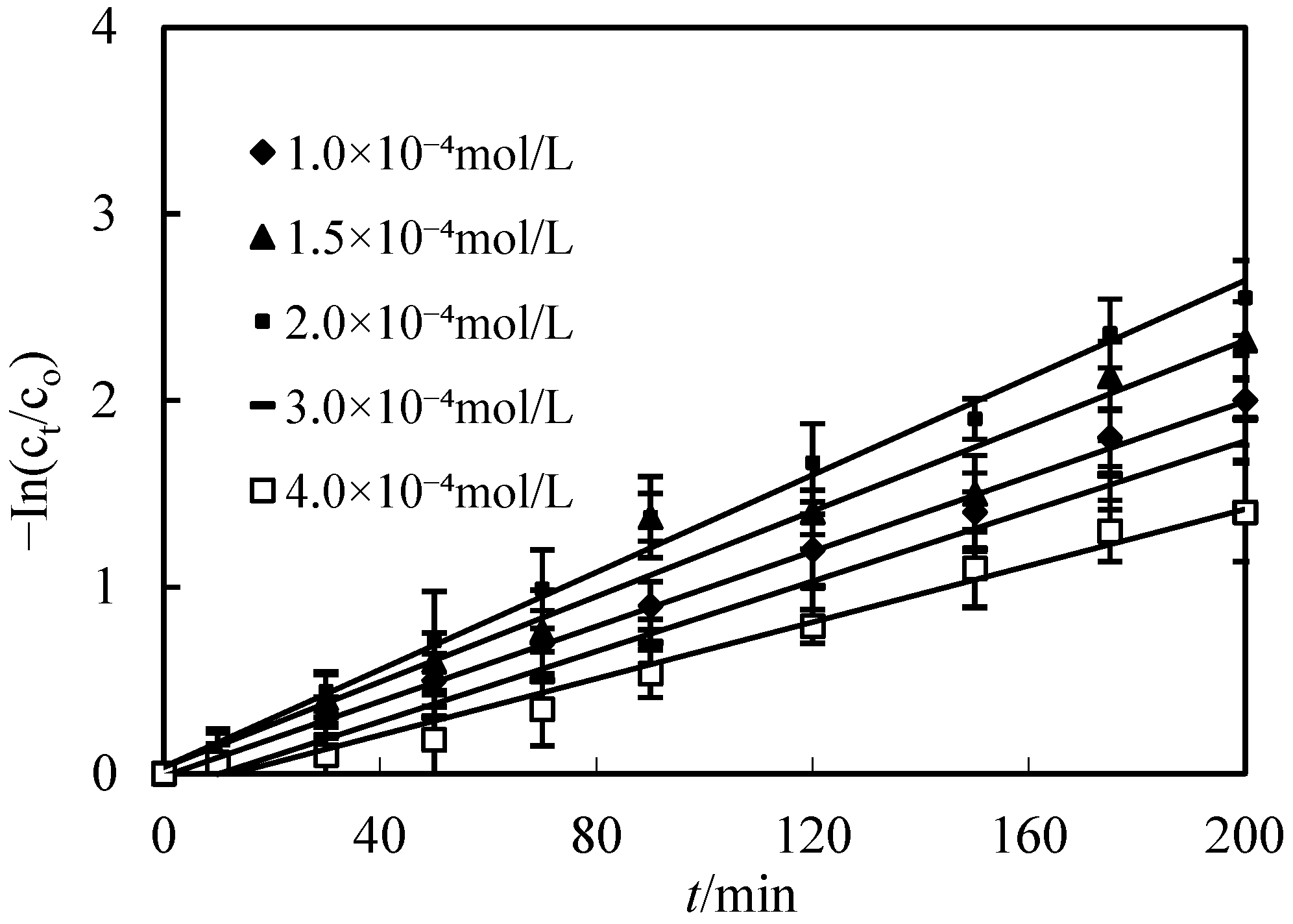

3.4. Effect of Initial Molarity of Co(II) on the Replenishing Resolving Section

3.5. Effect of the Voluminal Ratio of the Membrane Solution and H2SO4 Solution (O/S)

3.6. Effect of the Molarity of H2SO4 in the Replenishing Resolving Section

3.7. Effect of Ionic Intensity in the Replenishing Feed Section

3.8. Reuse of the Membrane Solution

3.9. Reuse of the Membrane Sheet

3.10. Retention in the Membrane Section

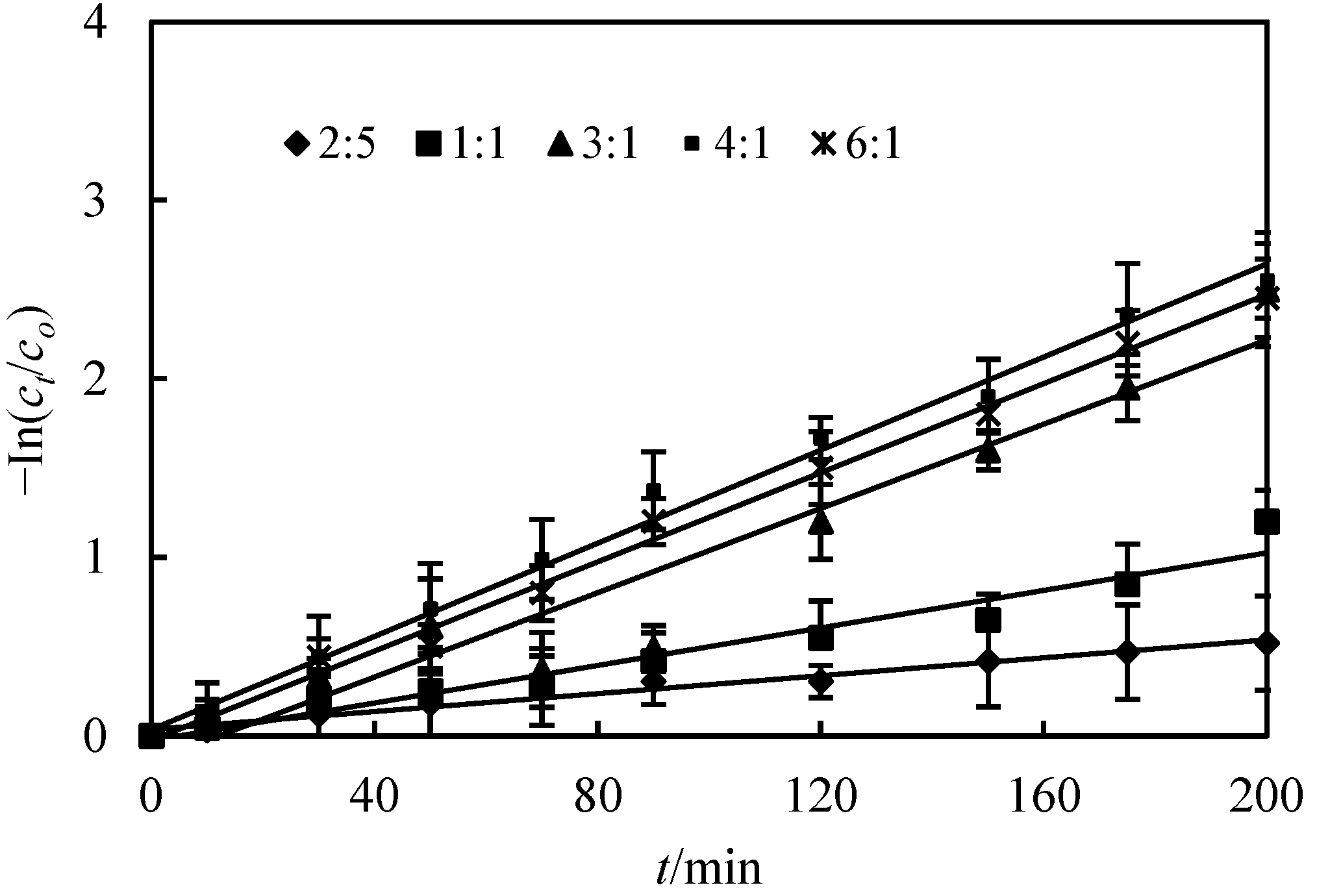

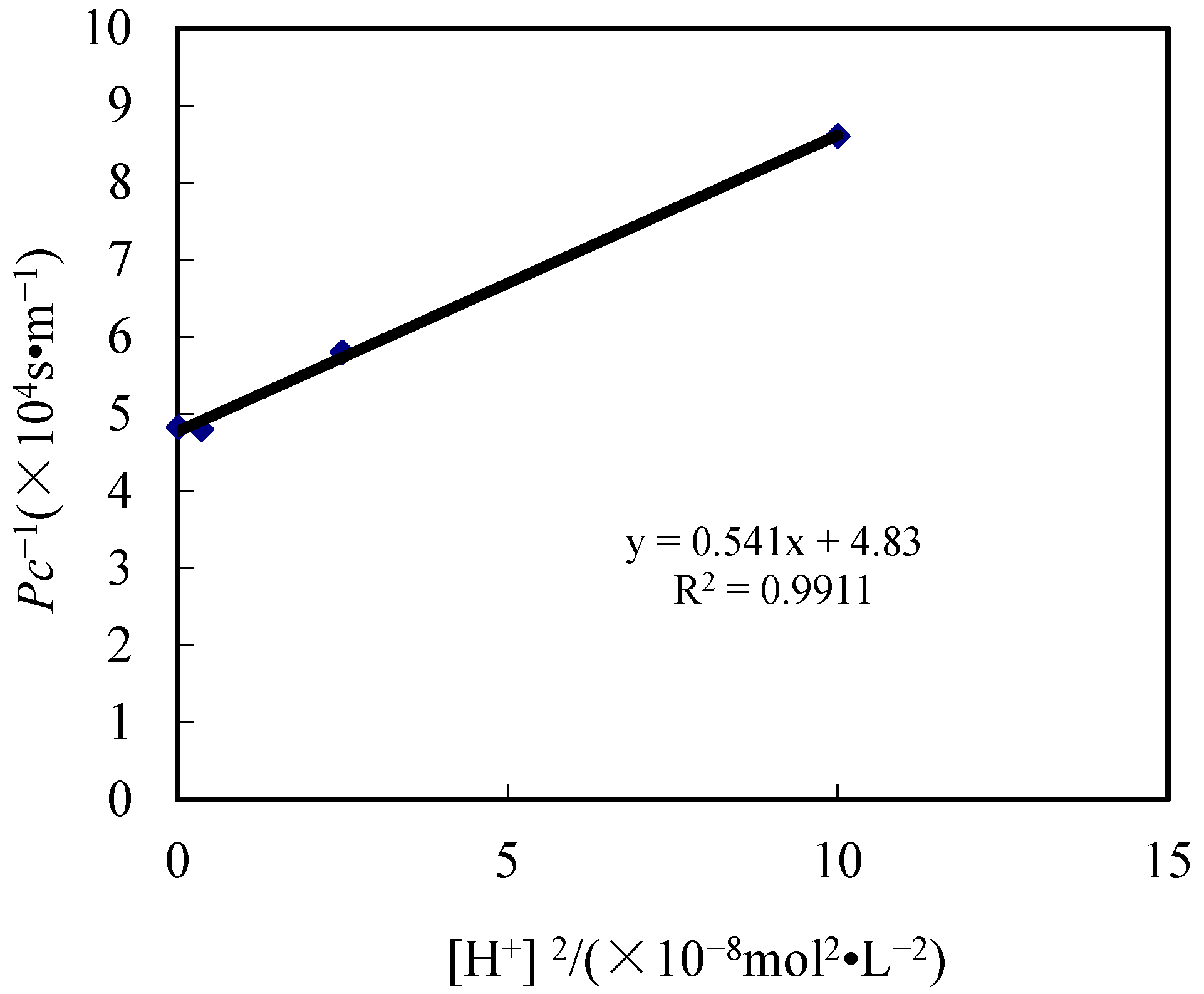

4. Kinetic Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, B.; Zhou, F.J.; Yang, F.; Lian, J.J.; Ye, T.R.; Wu, H.Y.; Wang, L.M.; Song, N.; Liu, Y.Y.; Hui, A.Y. Enhanced sequestration of molybdenum(VI) using composite constructed wetlands and responses of microbial communities. Water Sci. Technol. 2022, 85, 1065–1078. [Google Scholar] [CrossRef]

- Pei, L.; Wang, C.; Sun, L. Effects of Unconventional Water Agricultural Utilization on the Heavy Metals Accumulation in Typical Black Clay Soil around the Metallic Ore. Toxics 2022, 10, 476. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, G.; Zeng, L.; Zhou, Q.; Li, Z.; Zhang, D.; Cao, Z.; Guan, W.; Li, Q.; Xiao, L. Study on removal of molybdenum from ammonium tungstate solutions using solvent extraction with quaternary ammonium salt extractant. Hydrometallurgy 2019, 186, 218–225. [Google Scholar] [CrossRef]

- Pei, L.; Wang, L.; Ma, Z. Modeling of Ce(IV) transport through a dispersion flat combined liquid membrane with carrier P507. Front. Environ. Sci. Eng. 2013, 8, 503–509. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, G.; Zeng, L.; Guan, W.; Wu, S.; Li, Z.; Zhou, Q.; Zhang, D.; Qing, J.; Long, Y.; et al. Continuous solvent extraction operations for the removal of molybdenum from am-monium tungstate solution with quaternary ammonium salt extractant. Hydrometallugy 2020, 195, 105401. [Google Scholar] [CrossRef]

- Kasra-Kermanshahi, R.; Tajer-Mohammad-Ghazvini, P.; Bahrami-Bavani, M. A biotechnological strategy for molybdenum extraction using acidithiobacillusferrooxidans. Appl. Biochem. Biotechnol. 2020, 193, 884–895. [Google Scholar] [CrossRef]

- Pei, L.; Sun, L. Impact Factors on Migration of Molybdenum(VI) from the Simulated Trade Effluent Using Membrane Chemical Reactor Combined with Carrier in the Mixed Renewal Solutions. Toxics 2022, 10, 438. [Google Scholar] [CrossRef]

- Valenzuela, F.; Fonseca, C.; Basualto, C.; Correa, O.; Tapia, C.; Sapag, J. Removal of copper ions from a wastewater by a liquid emulsion membrane method. Miner. Eng. 2015, 18, 33–40. [Google Scholar] [CrossRef]

- Albaraka, Z. Carrier-mediated liquid membrane systems for lead (II) ion separations. Chem. Pap. 2020, 74, 77–88. [Google Scholar] [CrossRef]

- Shen, L.; Li, X.; Lindberg, D.; Taskinen, P. Tungsten extractive metallurgy: A review of processes and their challenges for sustainability. Miner. Eng. 2019, 142, 105934. [Google Scholar] [CrossRef]

- Pei, L.; Wang, L. Migration of Trivalent Praseodymium from Tombarthite Sewage by Microtubule Ultrafiltration Reactor with Organophosphorus in Fuel Oil. Int. J. Environ. Res. Public Health 2022, 19, 9364. [Google Scholar] [CrossRef] [PubMed]

- Solongo, T.; Fukushi, K.; Altansukh, O.; Yoshio, T.; Akitoshi, A.; Gankhurel, B.; Yunden, A.; Odgerel, E.; Boldbaatar, D.; Davaasuren, D.; et al. Distribution and chemical speciation of molybdenum in river and pond sediments affected by mining activity in Erdenet City, Mongolia. Minerals 2018, 8, 288. [Google Scholar] [CrossRef]

- Han, Z.; Wan, D.; Tian, H.; He, W.; Wang, Z.; Liu, Q. Pollution Assessment of Heavy Metals in Soils and Plants around a Molybdenum Mine in Central China. Pol. J. Environ. Stud. 2018, 28, 123–133. [Google Scholar] [CrossRef]

- Song, Z.; Song, G.; Tang, W.; Yan, D.; Zhao, Y.; Zhu, Y.; Wang, J.; Ma, Y. Molybdenum contamination dispersion from mining site to a reservoir. Ecotoxicol. Environ. Saf. 2021, 208, 111631. [Google Scholar] [CrossRef]

- Li, F.P.; Wang, Y.; Mao, L.C.; Chen, M. Molybdenum background and pollution levels in the TaipuRiver, China. Environ. Chem. Lett. 2022, 20, 1009–1015. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M.; Yu, W.; Li, J.; Kong, D. Ecotoxicological risk ranking of 19 metals in the lower Yangtze River of China based on their threats to aquatic wildlife. Sci. Total Environ. 2021, 812, 152370. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Z.; Zhan, K.; Sun, R.; Sheng, Z.; Wang, M.; Wang, S.; Hou, X. Two dimensional nanomaterial-based separation membranes. Electrophoresis 2019, 40, 2029–2040. [Google Scholar] [CrossRef]

- Mal’tseva, E.E.; Blokhin, A.A.; Murashkin Yu, V. Sorptiveparation of molybdenum(VI) from rhenium-containing solutions. Russ. J. Appl. Chem. 2017, 90, 528–532. [Google Scholar] [CrossRef]

- Ahmad, A.; Tariq, S.; Zaman, J.U.; Perales, A.I.M.; Mubashir, M.; Luque, R. Recent trends and challenges with the syn-thesis of membranes: Industrial opportunities towards environmental remediation. Chemosphere 2022, 135, 634. [Google Scholar]

- Pei, L.; Wang, L.-M. Transport Behavior of Divalent Lead Ions through Disphase Supplying Supported Liquid Membrane with PC-88A as Mobile Carrier. Int. J. Chem. React. Eng. 2012, 10, 1–24. [Google Scholar] [CrossRef]

- Pei, L.; Wang, L.; Guo, W.; Zhao, N. Study on a Novel Disphase Supplying Supported Liquid Membrane for Transport Behavior of Divalent Nickel Ions. Chin. J. Chem. Eng. 2012, 20, 633–640. [Google Scholar] [CrossRef]

- Bhatluri, K.K.; Manna, M.S.; Ghoshal, A.K.; Saha, P. Separation of cadmium and lead from wastewater using supported liquid membrane integrated with in-situ electrodeposition. Electrochimica Acta 2017, 229, 1–7. [Google Scholar] [CrossRef]

- Foong, C.Y.; Wirzal, M.D.H.; Bustam, M.A. A review on nanofibers membrane with amino-based ionic liquid for heavy metal removal. J. Mol. Liq. 2020, 297, 111793. [Google Scholar] [CrossRef]

- Pichler, T.; Koopmann, S. Should monitoring of molybdenum (Mo) in groundwater, drinking water and well permitting made mandatory? Environ. Sci. Technol. 2020, 54, 1–2. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Qiu, Z.; Yang, J.; Cao, L.; Zhang, W. Recovery of Mo and Ni from spent acrylonitrile catalysts using an oxidation leaching-chemical precipitation technique. Hydrometallurgy 2016, 164, 64–70. [Google Scholar] [CrossRef]

- Davies, T.D.; Pickard, J.; Hall, K.J. Acute molybdenum toxicity to rainbow trout and other fish. J. Environ. Eng. Sci. 2005, 4, 481–485. [Google Scholar] [CrossRef]

- Zeng, L.; Zhao, Z.; Huo, G.; Wang, X.; Pu, H. Mechanism of Selective Precipitation of Molybdenum from Tungstate Solution. JOM 2020, 72, 800–805. [Google Scholar] [CrossRef]

- Hamza, M.F.; Roux, J.-C.; Guibal, E. Metal valorization from the waste produced in the manufacturing of Co/Mo catalysts: Leaching and selective precipitation. J. Mater. Cycles Waste Manag. 2018, 21, 525–538. [Google Scholar] [CrossRef]

| Time (min) | Purification Percentage (%) | ||||

|---|---|---|---|---|---|

| 0 | 0.1 | 0.25 | 0.5 | 1.0 | |

| 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 23.3 ± 2.1 | 32.7 ± 1.9 | 29.8 ± 1.1 | 27.8 ± 2.8 | 19.7 ± 1.2 |

| 50 | 39.8 ± 1.7 | 54.6 ± 3.6 | 47.1 ± 1.9 | 46.1 ± 4.6 | 31.8 ± 2.3 |

| 140 | 515 ± 3.3 | 63.7 ± 2.5 | 52.3 ± 3.9 | 51.2 ± 1.5 | 49.4 ± 1.8 |

| 170 | 61.9 ± 3.2 | 76.2 ± 4.3 | 62.4 ± 4.2 | 65.3 ± 5.1 | 59.5 ± 4.2 |

| 200 | 77.3 ± 2.4 | 82.3 ± 3.1 | 78.3 ± 3.5 | 74.9 ± 4.9 | 67.0 ± 2.1 |

| Time (min) | Purification Percentage (%) | ||||

|---|---|---|---|---|---|

| 0.5 | 1.1 | 1.75 | 2.0 | 2.5 | |

| 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 29.2 ± 2.1 | 32.7 ± 1.9 | 33.1 ± 1.9 | 32.6 ± 4.0 | 29.8 ± 0.4 |

| 50 | 40.8 ± 1.6 | 54.6 ± 3.6 | 47.1 ± 3.9 | 46.1 ± 4.6 | 35.2 ± 3.0 |

| 140 | 59.9 ± 3.1 | 63.7 ± 2.5 | 53.4 ± 1.8 | 51.2 ± 1.5 | 47.4 ± 3.9 |

| 170 | 70.5 ± 3.4 | 76.2 ± 4.3 | 69.8 ± 2.5 | 65.3 ± 5.1 | 60.2 ± 1.2 |

| 200 | 82.3 ± 1.6 | 82.3 ± 3.1 | 81.3 ± 6.3 | 84.9 ± 4.9 | 79.8 ± 2.5 |

| Time (min) | Purification Percentage (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 33.4 | 35.7 | 39.2 | 32.6 | 36.7 | 39.2 | 39.2 | 31.1 |

| 50 | 49.8 | 47.7 | 54.0 | 50.2 | 52.1 | 51.7 | 54.0 | 43.7 |

| 140 | 63.9 | 69.0 | 63.2 | 60.7 | 64.6 | 62.2 | 60.7 | 59.2 |

| 170 | 78.5 | 79.8 | 74.5 | 77.8 | 75.6 | 79.1 | 77.7 | 71.3 |

| 200 | 89.3 ± 1.9 | 91.0 ± 4.8 | 89.4 ± 5.8 | 91.2 ± 2.7 | 89.3 ± 4.7 | 92.3 ± 4.5 | 90.2 ± 4.9 | 85.1 ± 5.3 |

| Technology Type | Purification Percentage (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| DDD | 91.2 ± 3.8 | 93.1 ± 5.8 | 92.7 ± 6.1 | 90.6 ± 4.2 | 90.4 ± 2.8 | 91.3 ± 3.9 | 88.7 ± 5.2 | 85.4 ± 3.7 |

| Traditional liquid membrane | 83.4 | 85.2 | 79.5 | 82.7 | 76.3 | 75.8 | 69.7 | 61.7 |

| Emulsion membrane | 79.9 | 77.2 | 74.4 | 70.6 | 62.3 | 61.9 | 44.7 | 43.1 |

| Ion exchange membrane | 81.5 | 81.8 | 79.5 | 61.4 | 69.3 | 52.9 | 40.9 | 35.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, L.; Sun, L. Study on Di-Phase Membrane Device with DZ272(DDD) for Purification Behavior of Divalent Cobalt Ions in Slops. Toxics 2022, 10, 546. https://doi.org/10.3390/toxics10090546

Pei L, Sun L. Study on Di-Phase Membrane Device with DZ272(DDD) for Purification Behavior of Divalent Cobalt Ions in Slops. Toxics. 2022; 10(9):546. https://doi.org/10.3390/toxics10090546

Chicago/Turabian StylePei, Liang, and Liying Sun. 2022. "Study on Di-Phase Membrane Device with DZ272(DDD) for Purification Behavior of Divalent Cobalt Ions in Slops" Toxics 10, no. 9: 546. https://doi.org/10.3390/toxics10090546