The Potential Biomedical Application of NiCu Magnetic Nanoparticles

Abstract

:1. Introduction

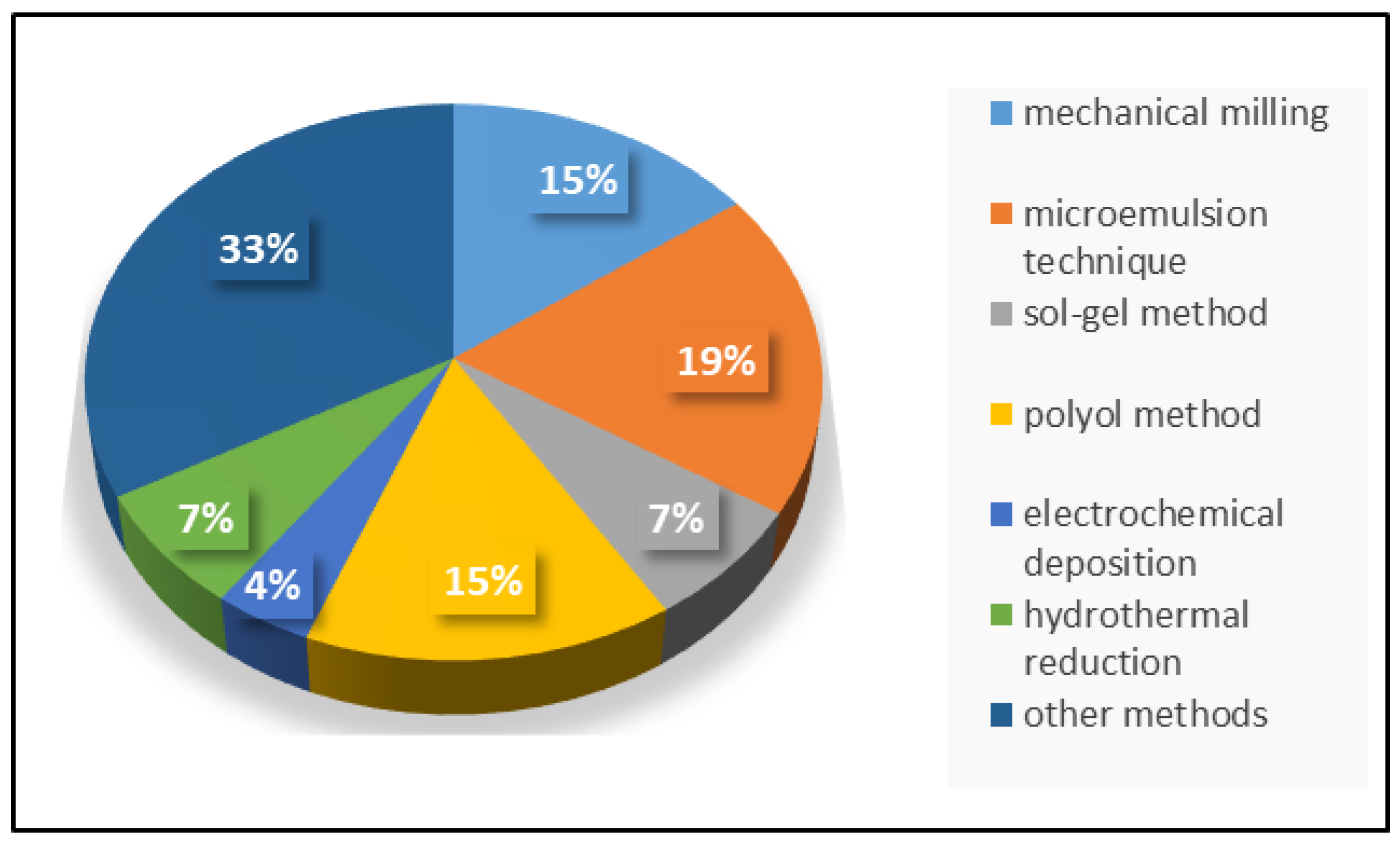

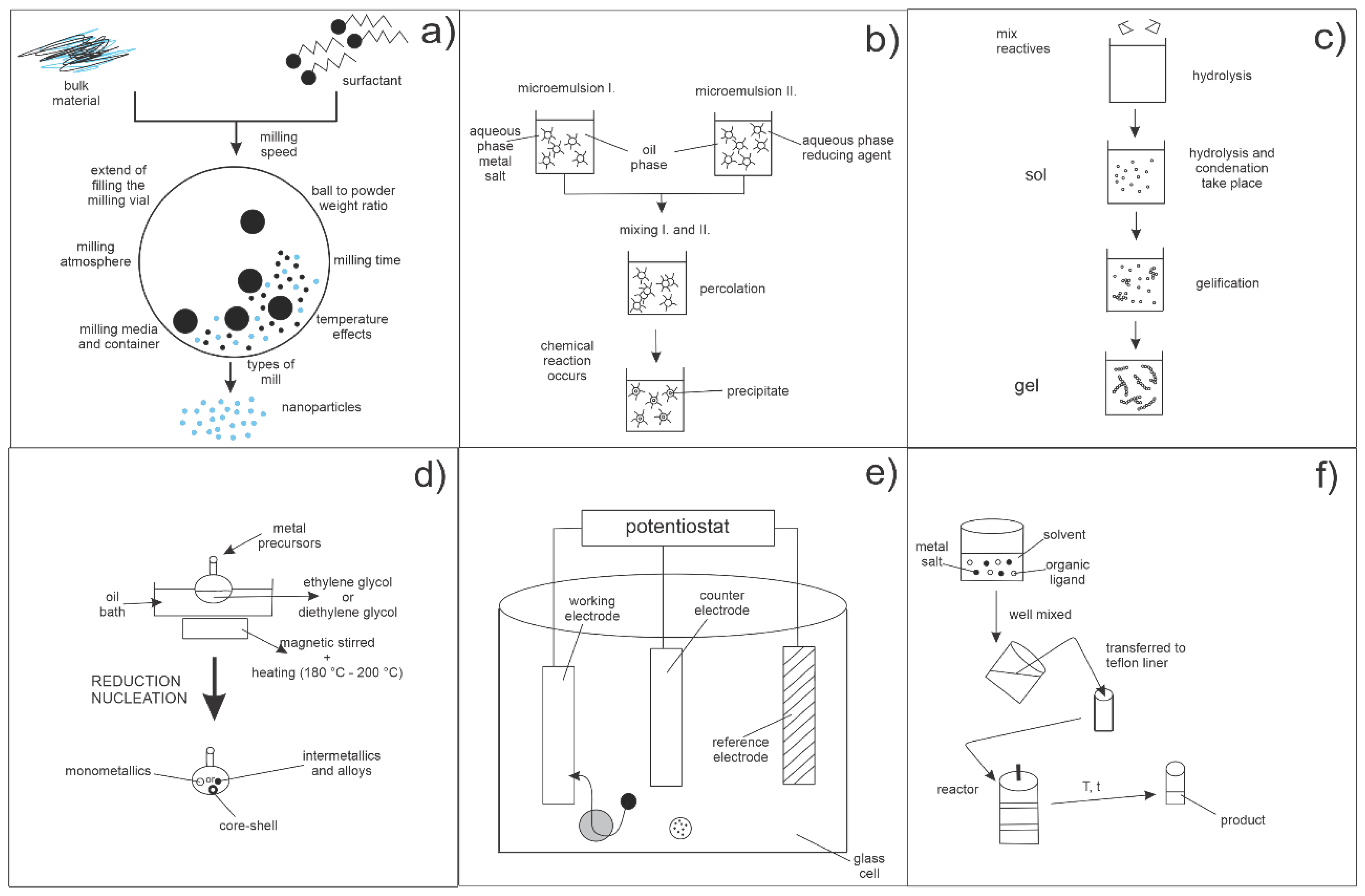

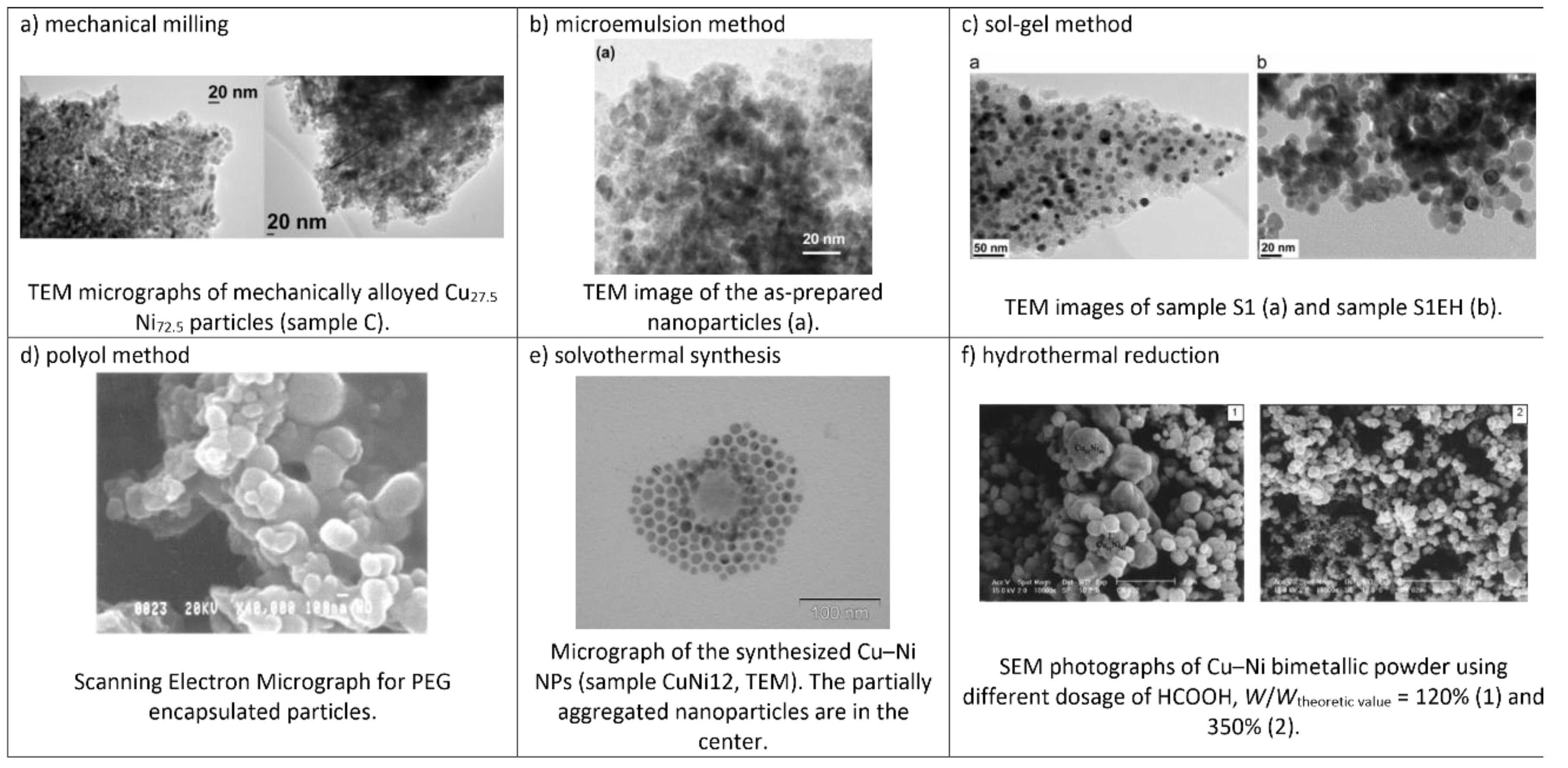

2. Synthesis of Magnetic NiCu NPs

2.1. Mechanical Milling

2.2. Microemulsion Technique

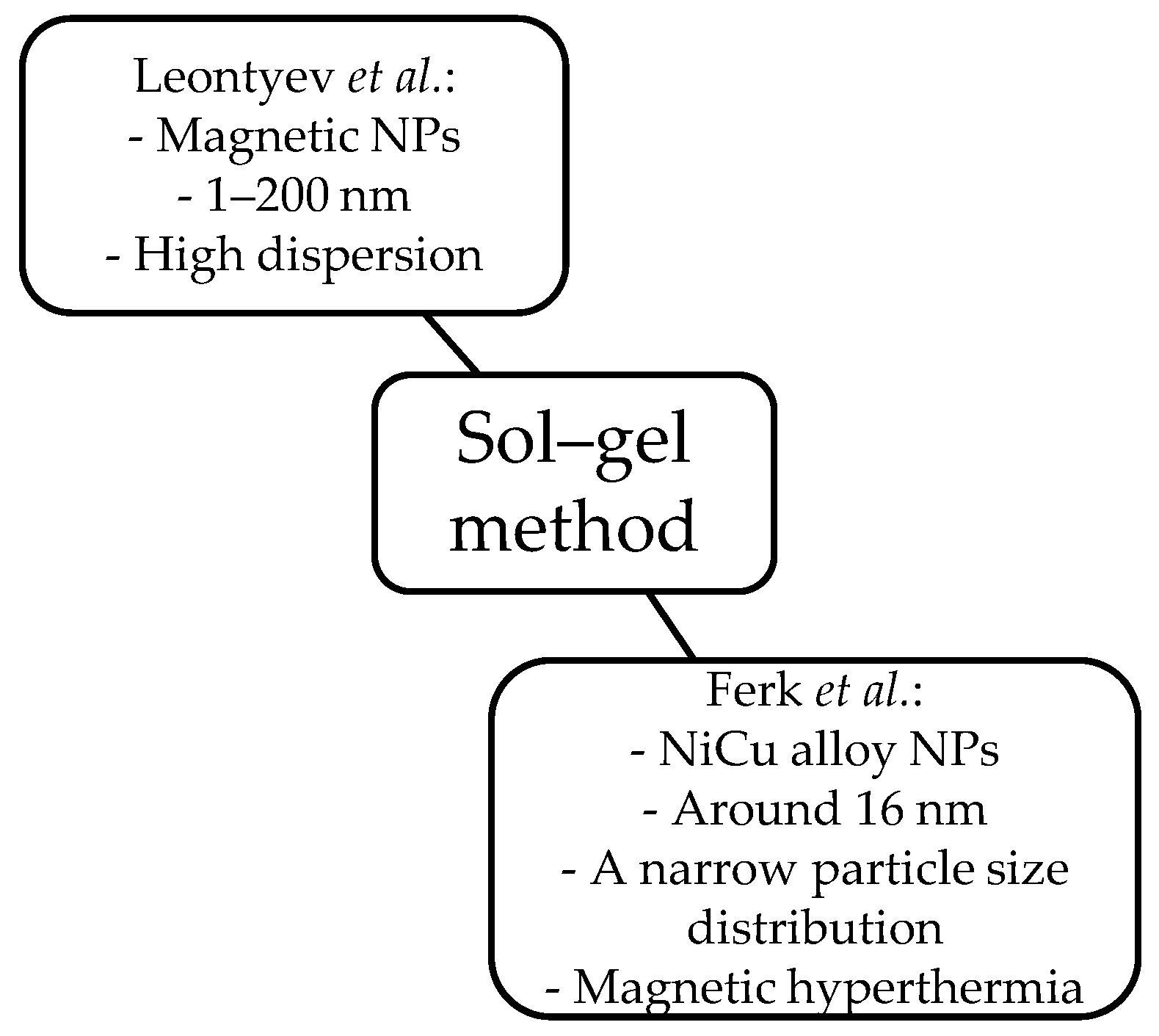

2.3. Sol–Gel Method

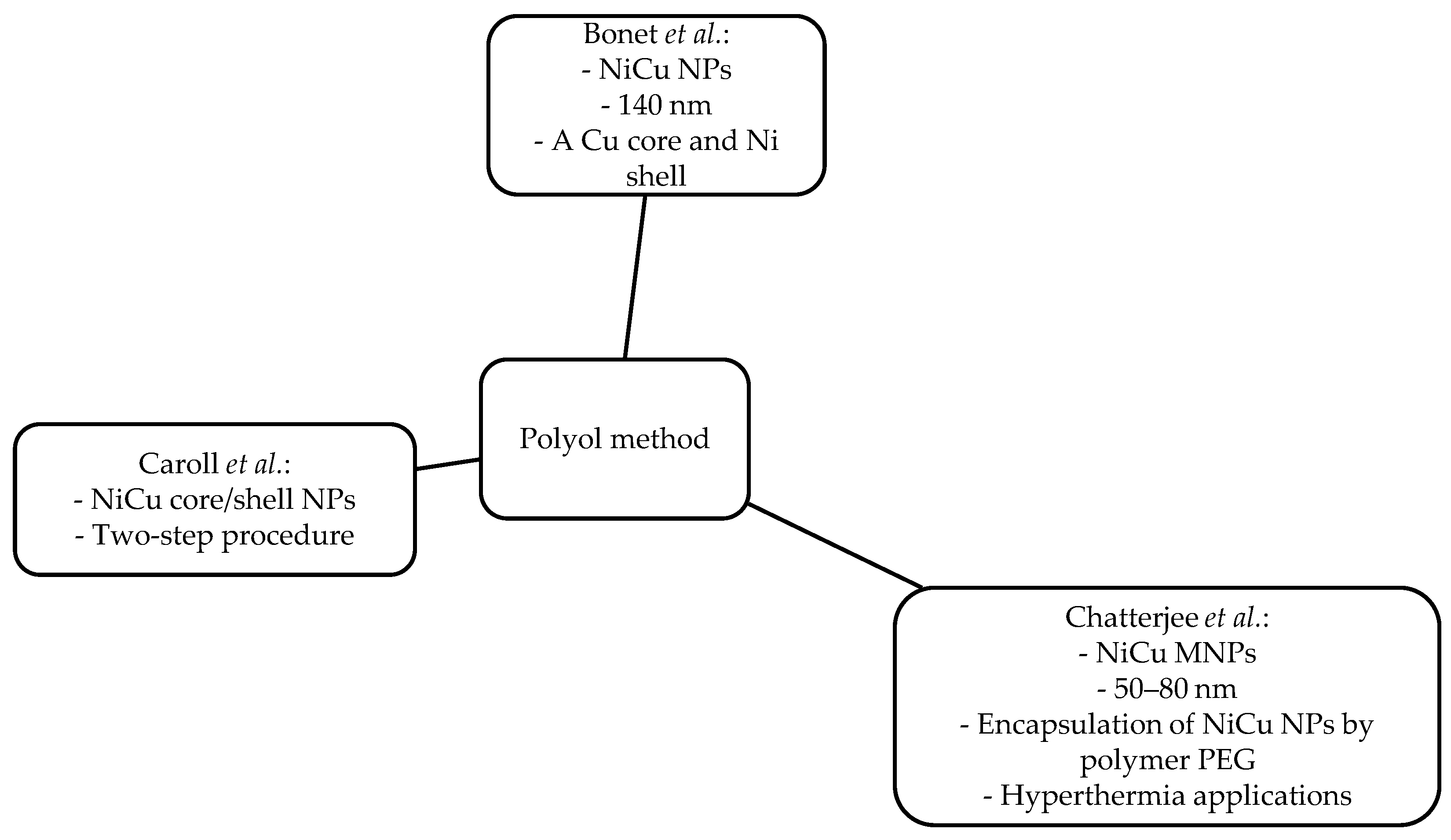

2.4. Polyol Method

2.5. Electrochemical Deposition

2.6. Hydrothermal Reduction

2.7. Other Methods

3. NiCu MNP Functionalization Methods

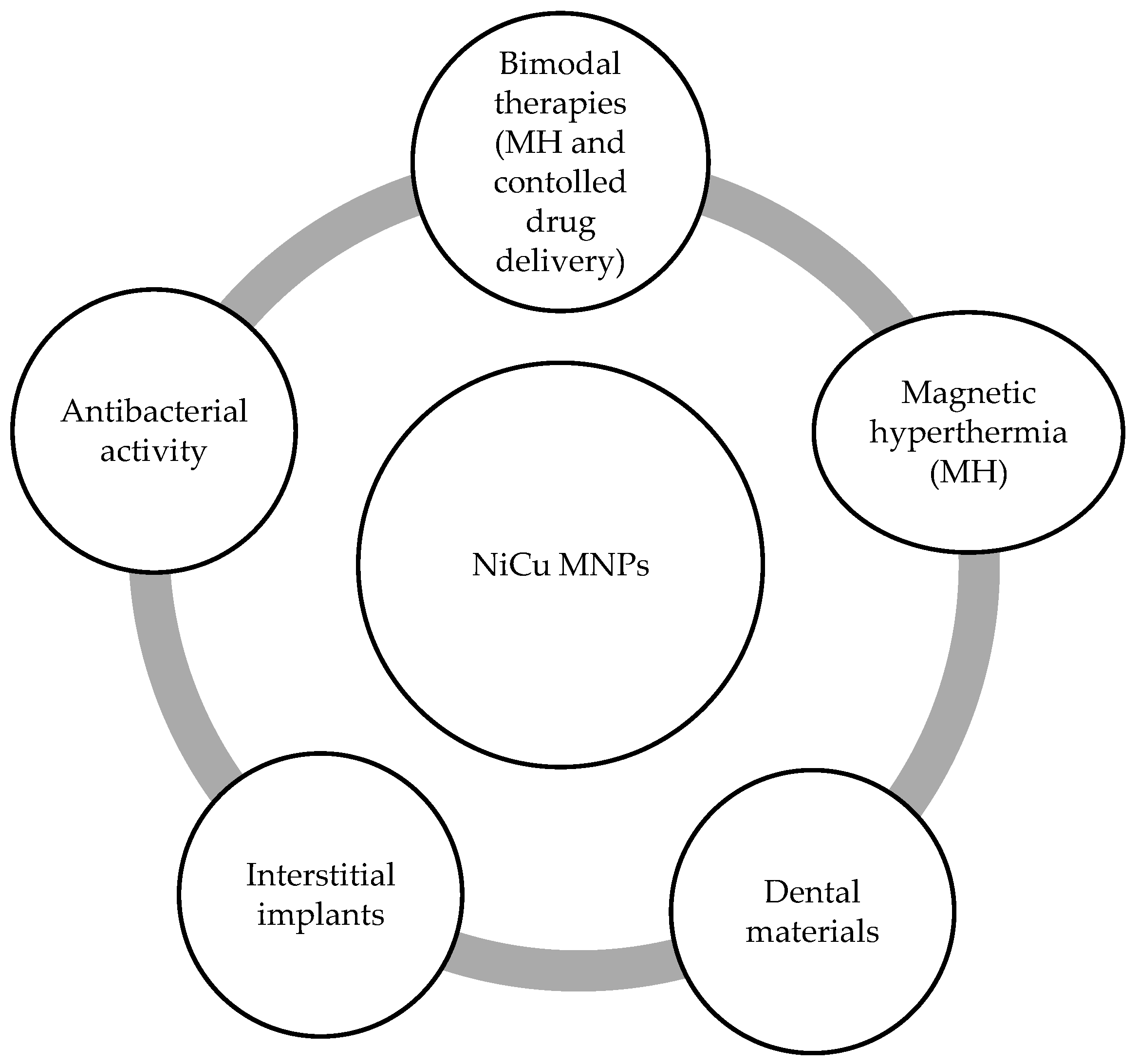

4. Application of NiCu MNPs in Biomedicine

4.1. Magnetic Hyperthermia

4.2. Bimodal Cancer Therapy (A Combination of MH and Controlled Drug Delivery)

4.3. MH Implants

4.4. Antibacterial Activity

4.5. Dental Materials

5. Biosafety Considerations

6. Conclusions

Funding

Conflicts of Interest

References

- Liu, Z.; Kiessling, F.; Gätjens, J. Advanced Nanomaterials in Multimodal Imaging: Design, Functionalization, and Biomedical Applications. J. Nanomater. 2010, 2010, 15. [Google Scholar] [CrossRef] [Green Version]

- Tartaj, P.; del Puerto Morales, M.; Veintemillas-Verdaguer, S.; González-Carreño, T.; Serna, C.J. The preparation of magnetic nanoparticles for applications in biomedicine. J. Phys. D Appl. Phys. 2003, 36, R182. [Google Scholar] [CrossRef]

- Lu, A.-H.; Salabas, E.L.; Schüth, F. Magnetic Nanoparticles: Synthesis, Protection, Functionalization, and Application. Angew. Chem. Int. Ed. 2007, 46, 1222–1244. [Google Scholar] [CrossRef] [PubMed]

- Mornet, S.; Vasseur, S.; Grasset, F.; Veverka, P.; Goglio, G.; Demourgues, A.; Portier, J.; Pollert, E.; Duguet, E. Magnetic nanoparticle design for medical applications. Progr. Solid State Chem. 2006, 34, 237–247. [Google Scholar] [CrossRef]

- Dürr, S.; Janko, C.; Lyer, S.; Tripal, P.; Schwarz, M.; Zaloga, J.; Tietze, R.; Alexiou, C. Magnetic nanoparticles for cancer therapy. Nanotechnol. Rev. 2013, 2, 395–409. [Google Scholar] [CrossRef] [Green Version]

- Ahola, S.; Salmi, J.; Johansson, L.S.; Laine, J.; Osterberg, M. Model films from native cellulose nanofibrils. Preparation, swelling, and surface interactions. Biomacromolecules 2008, 9, 1273–1282. [Google Scholar] [CrossRef]

- Park, J.W.; Lee, G.U. Properties of mixed lipid monolayers assembled on hydrophobic surfaces through vesicle adsorption. Langmuir 2006, 22, 5057–5063. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Xu, C. Magnetic Nanoparticles for Biomedical Applications: From Diagnosis to Treatment to Regeneration. In Engineering in Translational Medicine; Cai, W., Ed.; Springer: London, UK, 2014; pp. 567–583. [Google Scholar] [CrossRef]

- Tweedle, M.F. The Chemistry of Contrast Agents in Medical Magnetic Resonance Imaging Edited by André E. Merbach and Éva Tóth (University of Lausanne). J. Wiley & Sons: Chichester, New York, Weinheim, Brisbane, Singapore, Toronto. 2001. xii + 472 pp. $160.00. ISBN: 0-471-60778-9. J. Am. Chem. Soc. 2002, 124, 884–885. [Google Scholar] [CrossRef]

- Catherine, C.B.; Curtis, A.S.G. Functionalisation of magnetic nanoparticles for applications in biomedicine. J. Phys. D Appl. Phys. 2003, 36, R198. [Google Scholar]

- Le Trequesser, Q.; Seznec, H.; Delville, M.-H. Functionalized nanomaterials: Their use as contrast agents in bioimaging: Mono- and multimodal approaches. Nanotechnol. Rev. 2013, 2, 125. [Google Scholar] [CrossRef] [Green Version]

- Portet, D.; Denizot, B.; Rump, E.; Lejeune, J.-J.; Jallet, P. Nonpolymeric Coatings of Iron Oxide Colloids for Biological Use as Magnetic Resonance Imaging Contrast Agents. J. Colloid Interface Sci. 2001, 238, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Issa, B.; Obaidat, I.M.; Albiss, B.A.; Haik, Y. Magnetic nanoparticles: Surface effects and properties related to biomedicine applications. Int. J. Mol. Sci. 2013, 14, 21266–21305. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jordan, A.; Scholz, R.; Maier-Hauff, K.; Johannsen, M.; Wust, P.; Nadobny, J.; Schirra, H.; Schmidt, H.; Deger, S.; Loening, S.; et al. Presentation of a new magnetic field therapy system for the treatment of human solid tumors with magnetic fluid hyperthermia. J. Magn. Magn. Mater. 2001, 225, 118–126. [Google Scholar] [CrossRef] [Green Version]

- Wong, J.; Prout, J.; Seifalian, A. Magnetic Nanoparticles: New Perspectives in Drug Delivery. Curr. Pharm. Des. 2017, 23, 2908–2917. [Google Scholar] [CrossRef]

- Stergar, J.; Ban, I.; Gradišnik, L.; Maver, U. Novel drug delivery system based on NiCu nanoparticles for targeting various cells. J. Sol-Gel Sci. Technol. 2018, 88, 57–65. [Google Scholar] [CrossRef]

- Kumar, C.S.S.R.; Mohammad, F. Magnetic nanomaterials for hyperthermia-based therapy and controlled drug delivery. Adv. Drug Deliv. Rev. 2011, 63, 789–808. [Google Scholar] [CrossRef] [Green Version]

- Bernkop-Schnurch, A.; Walker, G. Multifunctional matrices for oral peptide delivery. Crit. Rev. Ther. Drug Carr. Syst. 2001, 18, 459–501. [Google Scholar] [CrossRef]

- Chomoucka, J.; Drbohlavova, J.; Huska, D.; Adam, V.; Kizek, R.; Hubalek, J. Magnetic nanoparticles and targeted drug delivering. Pharmacol. Res. 2010, 62, 144–149. [Google Scholar] [CrossRef]

- Salunkhe, A.B.; Khot, V.M.; Pawar, S.H. Magnetic hyperthermia with magnetic nanoparticles: A status review. Curr. Top. Med. Chem. 2014, 14, 572–594. [Google Scholar] [CrossRef]

- Laurent, S.; Dutz, S.; Häfeli, U.O.; Mahmoudi, M. Magnetic fluid hyperthermia: Focus on superparamagnetic iron oxide nanoparticles. Adv. Colloid Interface Sci. 2011, 166, 8–23. [Google Scholar] [CrossRef]

- Sun, C.; Lee, J.S.; Zhang, M. Magnetic nanoparticles in MR imaging and drug delivery. Adv. Drug Deliv. Rev. 2008, 60, 1252–1265. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stephen, Z.R.; Kievit, F.M.; Zhang, M. Magnetite Nanoparticles for Medical MR Imaging. Mater. Today 2011, 14, 330–338. [Google Scholar] [CrossRef]

- Mohammed, L.; Gomaa, H.G.; Ragab, D.; Zhu, J. Magnetic nanoparticles for environmental and biomedical applications: A review. Particuology 2017, 30, 1–14. [Google Scholar] [CrossRef]

- Hauser, A.K.; Wydra, R.J.; Stocke, N.A.; Anderson, K.W.; Hilt, J.Z. Magnetic nanoparticles and nanocomposites for remote controlled therapies. J. Control. Release Off. J. Control. Release Soc. 2015, 219, 76–94. [Google Scholar] [CrossRef] [Green Version]

- McBain, S.C.; Yiu, H.H.P.; Dobson, J. Magnetic nanoparticles for gene and drug delivery. Int. J. Nanomed. 2008, 3, 169–180. [Google Scholar]

- Majidi, S.; Sehrig, F.Z.; Samiei, M.; Milani, M.; Abbasi, E.; Dadashzadeh, K.; Akbarzadeh, A. Magnetic nanoparticles: Applications in gene delivery and gene therapy. Artif. Cells Nanomed. Biotechnol. 2016, 44, 1186–1193. [Google Scholar] [CrossRef]

- Šafařík, I.; Šafaříková, M. Magnetic Nanoparticles and Biosciences. Monatshefte Chem. Chem. Mon. 2002, 133, 737–759. [Google Scholar] [CrossRef]

- Ludwig, F.; Heim, E.; Mäuselein, S.; Eberbeck, D.; Schilling, M. Magnetorelaxometry of magnetic nanoparticles with fluxgate magnetometers for the analysis of biological targets. J. Magn. Magn. Mater. 2005, 293, 690–695. [Google Scholar] [CrossRef]

- Wiekhorst, F.; Steinhoff, U.; Eberbeck, D.; Trahms, L. Magnetorelaxometry assisting biomedical applications of magnetic nanoparticles. Pharm. Res. 2012, 29, 1189–1202. [Google Scholar] [CrossRef] [Green Version]

- Ismail, R.A.; Sulaiman, G.M.; Abdulrahman, S.A.; Marzoog, T.R. Antibacterial activity of magnetic iron oxide nanoparticles synthesized by laser ablation in liquid. Mater. Sci. Eng. C 2015, 53, 286–297. [Google Scholar] [CrossRef]

- Thukkaram, M.; Sitaram, S.; Kannaiyan, S.K.; Subbiahdoss, G. Antibacterial Efficacy of Iron-Oxide Nanoparticles against Biofilms on Different Biomaterial Surfaces. Int. J. Biomater. 2014, 2014, 716080. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ito, A.; Shinkai, M.; Honda, H.; Kobayashi, T. Medical application of functionalized magnetic nanoparticles. J. Biosci. Bioeng. 2005, 100, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mok, H.; Zhang, M. Superparamagnetic iron oxide nanoparticle-based delivery systems for biotherapeutics. Expert Opin. Drug Deliv. 2013, 10, 73–87. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Williams, H.M. The application of magnetic nanoparticles in the treatment and monitoring of cancer and infectious diseases. Biosci. Horiz. Int. J. Stud. Res. 2017, 10, hzx009. [Google Scholar] [CrossRef] [Green Version]

- Ban, I.; Stergar, J.; Drofenik, M.; Ferk, G.; Makovec, D. Synthesis of copper–nickel nanoparticles prepared by mechanical milling for use in magnetic hyperthermia. J. Magn. Magn. Mater. 2011, 323, 2254–2258. [Google Scholar] [CrossRef]

- Ferk, G.; Stergar, J.; Makovec, D.; Hamler, A.; Jagličić, Z.; Drofenik, M.; Ban, I. Synthesis and characterization of Ni–Cu alloy nanoparticles with a tunable Curie temperature. J. Alloys Compd. 2015, 648, 53–58. [Google Scholar] [CrossRef]

- Kuznetsov, A.A.; Leontiev, V.G.; Brukvin, V.A.; Vorozhtsov, G.N.; Kogan, B.Y.; Shlyakhtin, O.A.; Yunin, A.M.; Tsybin, O.I.; Kuznetsov, O.A. Local radiofrequency-induced hyperthermia using CuNi nanoparticles with therapeutically suitable Curie temperature. J. Magn. Magn. Mater. 2007, 311, 197–203. [Google Scholar] [CrossRef]

- Amrollahi, P.; Ataie, A.; Nozari, A.; Seyedjafari, E.; Shafiee, A. Cytotoxicity Evaluation and Magnetic Characteristics of Mechano-thermally Synthesized CuNi Nanoparticles for Hyperthermia. J. Mater. Eng. Perform. 2015, 24, 1220–1225. [Google Scholar] [CrossRef]

- Ferk, G.; Stergar, J.; Drofenik, M.; Makovec, D.; Hamler, A.; Jagličić, Z.; Ban, I. The synthesis and characterization of nickel–copper alloy nanoparticles with a narrow size distribution using sol–gel synthesis. Mater. Lett. 2014, 124, 39–42. [Google Scholar] [CrossRef]

- Songping, W.; Jing, N.; Li, J.; Zhenou, Z. Preparation of ultra-fine copper–nickel bimetallic powders with hydrothermal–reduction method. Mater. Chem. Phys. 2007, 105, 71–75. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, C.-P. Preparation of Cu–Ni alloy nanocrystallites in water-in-oil microemulsions. J. Colloid Interface Sci. 2006, 293, 414–420. [Google Scholar] [CrossRef] [PubMed]

- Hergt, R.; Andra, W.; d’Ambly, C.G.; Hilger, I.; Kaiser, W.A.; Richter, U.; Schmidt, H.G. Physical limits of hyperthermia using magnetite fine particles. IEEE Trans. Magn. 1998, 34, 3745–3754. [Google Scholar] [CrossRef]

- Jordan, A.; Scholz, R.; Wust, P.; Fähling, H.; Roland, F. Magnetic fluid hyperthermia (MFH): Cancer treatment with AC magnetic field induced excitation of biocompatible superparamagnetic nanoparticles. J. Magn. Magn. Mater. 1999, 201, 413–419. [Google Scholar] [CrossRef]

- Chang, D.; Lim, M.; Goos, J.; Qiao, R.; Ng, Y.Y.; Mansfeld, F.M.; Jackson, M.; Davis, T.P.; Kavallaris, M. Biologically Targeted Magnetic Hyperthermia: Potential and Limitations. Front. Pharmacol. 2018, 9, 831. [Google Scholar] [CrossRef] [Green Version]

- Andra, W.; Nowak, H. Magnetism in Medicine: A Handbook, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2007; 629p. [Google Scholar]

- Chatterjee, J.; Bettge, M.; Haik, Y.; Jen Chen, C. Synthesis and characterization of polymer encapsulated Cu–Ni magnetic nanoparticles for hyperthermia applications. J. Magn. Magn. Mater. 2005, 293, 303–309. [Google Scholar] [CrossRef]

- Bettge, M.; Chatterjee, J.; Haik, Y. Physically synthesized Ni-Cu nanoparticles for magnetic hyperthermia. Biomagn. Res. Technol. 2004, 2, 4. [Google Scholar] [CrossRef] [Green Version]

- Paulus, J.A.; Parida, G.R.; Tucker, R.D.; Park, J.B. Corrosion analysis of NiCu and PdCo thermal seed alloys used as interstitial hyperthermia implants. Biomaterials 1997, 18, 1609–1614. [Google Scholar] [CrossRef]

- Abenojar, E.C.; Wickramasinghe, S.; Bas-Concepcion, J.; Samia, A.C.S. Structural effects on the magnetic hyperthermia properties of iron oxide nanoparticles. Prog. Nat. Sci. Mater. 2016, 26, 440–448. [Google Scholar] [CrossRef] [Green Version]

- Engelmann, U.M.; Roeth, A.A.; Eberbeck, D.; Buhl, E.M.; Neumann, U.P.; Schmitz-Rode, T.; Slabu, I. Combining Bulk Temperature and Nanoheating Enables Advanced Magnetic Fluid Hyperthermia Efficacy on Pancreatic Tumor Cells. Sci. Rep. 2018, 8, 13210. [Google Scholar] [CrossRef]

- Soetaert, F.; Kandala, S.K.; Bakuzis, A.; Ivkov, R. Experimental estimation and analysis of variance of the measured loss power of magnetic nanoparticles. Sci. Rep. 2017, 7, 6661. [Google Scholar] [CrossRef] [Green Version]

- Allia, P.; Barrera, G.; Tiberto, P. Nonharmonic Driving Fields for Enhancement of Nanoparticle Heating Efficiency in Magnetic Hyperthermia. Phys. Rev. Appl. 2019, 12, 034041. [Google Scholar] [CrossRef]

- Sue, K.; Tanaka, S.; Hiaki, T. Synthesis of Ni–Cu Particles by Hydrogen Reduction in Hot-compressed Water. Chem. Lett. 2006, 35, 50–51. [Google Scholar] [CrossRef]

- Wang, L.-L.; Jiang, J.-S. Preparation of α-Fe2O3 nanoparticles by high-energy ball milling. Phys. B Condens. Matter 2007, 390, 23–27. [Google Scholar] [CrossRef]

- Ali, M.E.; Ullah, M.; Maamor, A.; Hamid, S.B.A. Surfactant Assisted Ball Milling: A Simple Top down Approach for the Synthesis of Controlled Structure Nanoparticle. Adv. Mater. Res. 2014, 832, 356–361. [Google Scholar] [CrossRef]

- Durivault, L.; Brylev, O.; Reyter, D.; Sarrazin, M.; Bélanger, D.; Roué, L. Cu–Ni materials prepared by mechanical milling: Their properties and electrocatalytic activity towards nitrate reduction in alkaline medium. J. Alloys Compd. 2007, 432, 323–332. [Google Scholar] [CrossRef]

- Ge, Y.; Gao, T.; Wang, C.; Shah, Z.H.; Lu, R.; Zhang, S. Highly efficient silica coated CuNi bimetallic nanocatalyst from reverse microemulsion. J. Colloid Interface Sci. 2017, 491, 123–132. [Google Scholar] [CrossRef]

- Ahmed, J.; Ramanujachary, K.V.; Lofland, S.E.; Furiato, A.; Gupta, G.; Shivaprasad, S.M.; Ganguli, A.K. Bimetallic Cu–Ni nanoparticles of varying composition (CuNi3, CuNi, Cu3Ni). Colloids Surf. A Physicochem. Eng. Asp. 2008, 331, 206–212. [Google Scholar] [CrossRef]

- Stergar, J.; Ban, I.; Drofenik, M.; Ferk, G.; Makovec, D. Synthesis and Characterization of Silica-Coated Cu1−xNix Nanoparticles; Institute of Electrical and Electronics Engineers: New York, NY, USA, 2012; p. 4. [Google Scholar]

- Wen, M.; Liu, Q.-Y.; Wang, Y.-F.; Zhu, Y.-Z.; Wu, Q.-S. Positive microemulsion synthesis and magnetic property of amorphous multicomponent Co-, Ni- and Cu-based alloy nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2008, 318, 238–244. [Google Scholar] [CrossRef]

- Wang, X.L.; Ben Ahmed, N.; Alvarez, G.S.; Tuttolomondo, M.V.; Helary, C.; Desimone, M.F.; Coradin, T. Sol-gel Encapsulation of Biomolecules and Cells for Medicinal Applications. Curr. Top. Med. Chem. 2015, 15, 223–244. [Google Scholar] [CrossRef]

- Brinker, C.J.; Scherer, G.W. Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing; Academic Press: Boston, MA, USA, 1990. [Google Scholar]

- Leontyev, V. Magnetic properties of Ni and Ni–Cu nanoparticles. Phys. Status Solidi (b) 2013, 250, 103–107. [Google Scholar] [CrossRef]

- Hachani, R.; Lowdell, M.; Birchall, M.; Hervault, A.; Mertz, D.; Begin-Colin, S.; Thanh, N.T. Polyol synthesis, functionalisation, and biocompatibility studies of superparamagnetic iron oxide nanoparticles as potential MRI contrast agents. Nanoscale 2016, 8, 3278–3287. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Songvorawit, N.; Tuitemwong, K.; Tuitemwong, P. Single Step Synthesis of Amino-Functionalized Magnetic Nanoparticles with Polyol Technique at Low Temperature. ISRN Nanotechnol. 2011, 2011, 6. [Google Scholar] [CrossRef] [Green Version]

- Carroll, K.J.; Calvin, S.; Ekiert, T.F.; Unruh, K.M.; Carpenter, E.E. Selective Nucleation and Growth of Cu and Ni Core/Shell Nanoparticles. Chem. Mater. 2010, 22, 2175–2177. [Google Scholar] [CrossRef]

- Bonet, F.; Grugeon, S.; Dupont, L.; Urbina, R.H.; Guéry, C.; Tarascon, J.M. Synthesis and characterization of bimetallic Ni–Cu particles. J. Solid State Chem. 2003, 172, 111–115. [Google Scholar] [CrossRef]

- Jayakrishnan, D.S. 5—Electrodeposition: The versatile technique for nanomaterials. In Corrosion Protection and Control Using Nanomaterials; Saji, V.S., Cook, R., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 86–125. [Google Scholar] [CrossRef]

- Foyet, A.; Hauser, A.; Schäfer, W. Double template electrochemical deposition and characterization of NiCo and NiCu alloys nanoparticles and nanofilms. J. Solid State Electrochem. 2007, 12, 47–55. [Google Scholar] [CrossRef]

- Feng, S.H.; Li, G.H. Chapter 4—Hydrothermal and Solvothermal Syntheses. In Modern Inorganic Synthetic Chemistry, 2nd ed.; Xu, R., Xu, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 73–104. [Google Scholar] [CrossRef]

- Songping, W.; Li, J.; Jing, N.; Zhenou, Z.; Song, L. Preparation of ultra fine copper–nickel bimetallic powders for conductive thick film. Intermetallics 2007, 15, 1316–1321. [Google Scholar] [CrossRef]

- Kwon, Y.S.; An, V.V.; Ilyin, A.P.; Tikhonov, D.V. Properties of powders produced by electrical explosions of copper–nickel alloy wires. Mater. Lett. 2007, 61, 3247–3250. [Google Scholar] [CrossRef]

- Bahlawane, N.; Premkumar, P.A.; Tian, Z.; Hong, X.; Qi, F.; Kohse-Höinghaus, K. Nickel and Nickel-Based Nanoalloy Thin Films from Alcohol-Assisted Chemical Vapor Deposition. Chem. Mater. 2010, 22, 92–100. [Google Scholar] [CrossRef]

- Pál, E.; Kun, R.; Schulze, C.; Zöllmer, V.; Lehmhus, D.; Bäumer, M.; Busse, M. Composition-dependent sintering behaviour of chemically synthesised CuNi nanoparticles and their application in aerosol printing for preparation of conductive microstructures. Colloid Polym. Sci. 2012, 290, 941–952. [Google Scholar] [CrossRef]

- Zin, V.; Brunelli, K.; Dabalà, M. Characterization of Cu–Ni alloy electrodeposition and synthesis of nanoparticles by pulsed sonoelectrochemistry. Mater. Chem. Phys. 2014, 144, 272–279. [Google Scholar] [CrossRef]

- Sopousek, J.; Vrestal, J.; Pinkas, J.; Broz, P.; Bursik, J.; Styskalik, A.; Skoda, D.; Zobac, O.; Lee, J. Cu–Ni nanoalloy phase diagram—Prediction and experiment. Calphad 2014, 45, 33–39. [Google Scholar] [CrossRef] [Green Version]

- de León-Quiroz, E.L.; Puente-Urbina, B.A.; Vázquez-Obregón, D.; García-Cerda, L.A. Preparation and structural characterization of CuNi nanoalloys obtained by polymeric precursor method. Mater. Lett. 2013, 91, 67–70. [Google Scholar] [CrossRef]

- Stergar, J.; Ferk, G.; Ban, I.; Drofenik, M.; Hamler, A.; Jagodič, M.; Makovec, D. The synthesis and characterization of copper–nickel alloy nanoparticles with a therapeutic Curie point using the microemulsion method. J. Alloys Compd. 2013, 576, 220–226. [Google Scholar] [CrossRef]

- Ban, I.; Stergar, J.; Maver, U. NiCu magnetic nanoparticles: Review of synthesis methods, surface functionalization approaches, and biomedical applications. Nanotechnol. Rev. 2018, 7, 187. [Google Scholar] [CrossRef]

- Hao, R.; Xing, R.; Xu, Z.; Hou, Y.; Gao, S.; Sun, S. Synthesis, Functionalization, and Biomedical Applications of Multifunctional Magnetic Nanoparticles. Adv. Mater. 2010, 22, 2729–2742. [Google Scholar] [CrossRef]

- An, L.; Li, Z.; Wang, Y.; Yang, B. Synthesis of Fe3O4/PMMA Nanocomposite Particles by Surface-Initiated ATRP and Characterization. Chem. J. Chin. Univ. 2006, 27, 1372–1375. [Google Scholar]

- Morales, M.A.; Finotelli, P.; Coaquira, J.A.H.; Rocha-Leão, M.H.; Diaz-Aguila, C.; Baggio-Saitovitch, E.; Rossi, A.M. In situ synthesis and magnetic studies of iron oxide nanoparticles in calcium-alginate matrix for biomedical applications. Mater. Sci. Eng. C 2008, 28, 253–257. [Google Scholar] [CrossRef]

- Yallapu, M.M.; Foy, S.P.; Jain, T.K.; Labhasetwar, V. PEG-functionalized magnetic nanoparticles for drug delivery and magnetic resonance imaging applications. Pharmaceut. Res. 2010, 27, 2283–2295. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.K.; Mikhaylova, M.; Wang, F.H.; Kehr, J.; Bjelke, B.; Zhang, Y.; Tsakalakos, T.; Muhammed, M. Starch-Coated Superparamagnetic Nanoparticles as MR Contrast Agents. Chem. Mater. 2003, 15, 4343–4351. [Google Scholar] [CrossRef]

- Li, G.-Y.; Jiang, Y.-R.; Huang, K.-L.; Ding, P.; Yao, L.-L. Kinetics of adsorption of Saccharomyces cerevisiae mandelated dehydrogenase on magnetic Fe3O4–chitosan nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2008, 320, 11–18. [Google Scholar] [CrossRef]

- Saranya, D.; Rajan, R.; Suganthan, V.; Murugeswari, A.; Raj, N.A.N. Synthesis and Characterization of Pullulan Acetate Coated Magnetic Nanoparticle for Hyperthermic Therapy. Procedia Mater. Sci. 2015, 10, 2–9. [Google Scholar] [CrossRef] [Green Version]

- Berry, C.C.; Wells, S.; Charles, S.; Curtis, A.S. Dextran and albumin derivatised iron oxide nanoparticles: Influence on fibroblasts in vitro. Biomaterials 2003, 24, 4551–4557. [Google Scholar] [CrossRef]

- Gaihre, B.; Aryal, S.; Khil, M.S.; Kim, H.Y. Encapsulation of Fe3O4 in gelatin nanoparticles: Effect of different parameters on size and stability of the colloidal dispersion. J. Microencapsul. 2008, 25, 21–30. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.K.; Gupta, M. Synthesis and surface engineering of iron oxide nanoparticles for biomedical applications. Biomaterials 2005, 26, 3995–4021. [Google Scholar] [CrossRef] [PubMed]

- Shete, P.B.; Patil, R.M.; Tiwale, B.M.; Pawar, S.H. Water dispersible oleic acid-coated Fe3O4 nanoparticles for biomedical applications. J. Magn. Magn. Mater. 2015, 377, 406–410. [Google Scholar] [CrossRef]

- Silva, S.M.; Tavallaie, R.; Sandiford, L.; Tilley, R.D.; Gooding, J.J. Gold coated magnetic nanoparticles: From preparation to surface modification for analytical and biomedical applications. Chem. Commun. 2016, 52, 7528–7540. [Google Scholar] [CrossRef] [Green Version]

- Martínez-González, R.; Estelrich, J.; Busquets, M.A. Liposomes Loaded with Hydrophobic Iron Oxide Nanoparticles: Suitable T2 Contrast Agents for MRI. Int. J. Mol. Sci. 2016, 17, 1209. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.; Zhang, X.; Miao, Y.; Li, J.; Gan, Y. Lipid-coated iron oxide nanoparticles for dual-modal imaging of hepatocellular carcinoma. Int. J. Nanomed. 2017, 12, 2033–2044. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.-C.; Chang, P.-Y.; Chang, K.; Chen, C.-Y.; Lin, C.-W.; Chen, J.-H.; Mou, C.-Y.; Chang, Z.-F.; Chang, F.-H. Formulation of novel lipid-coated magnetic nanoparticles as the probe for in vivo imaging. J. Biomed. Sci. 2009, 16, 86. [Google Scholar] [CrossRef] [Green Version]

- Hauser, A.K.; Anderson, K.W.; Hilt, J.Z. Peptide conjugated magnetic nanoparticles for magnetically mediated energy delivery to lung cancer cells. Nanomedicine 2016, 11, 1769–1785. [Google Scholar] [CrossRef] [Green Version]

- Scarberry, K.E.; Dickerson, E.B.; McDonald, J.F.; Zhang, Z.J. Magnetic Nanoparticle−Peptide Conjugates for in Vitro and in Vivo Targeting and Extraction of Cancer Cells. J. Am. Chem. Soc. 2008, 130, 10258–10262. [Google Scholar] [CrossRef] [PubMed]

- Biswas, M.; Saha, A.; Dule, M.; Mandal, T.K. Polymer-Assisted Chain-like Organization of CuNi Alloy Nanoparticles: Solvent-Adoptable Pseudohomogeneous Catalysts for Alkyne–Azide Click Reactions with Magnetic Recyclability. J. Phys. Chem. C 2014, 118, 22156–22165. [Google Scholar] [CrossRef]

- Araújo-Barbosa, S.; Morales, M.A. Nanoparticles of Ni1−xCux alloys for enhanced heating in magnetic hyperthermia. J. Alloys Compd. 2019, 787, 935–943. [Google Scholar] [CrossRef]

- Pramanik, S.; Pal, S.; Bysakh, S.; De, G. CuxNi1−x alloy nanoparticles embedded SiO2 films: Synthesis and structure. J. Nanopart. Res. 2010, 13, 321–329. [Google Scholar] [CrossRef]

- El-Sayed, A.H.; Aly, A.A.; Ei-Sayed, N.I.; Mekawy, M.M.; Ei-Gendy, A.A. Calculation of heating power generated from ferromagnetic thermal seed (PdCo-PdNi-CuNi) alloys used as interstitial hyperthermia implants. J. Mater. Sci. Mater. Med. 2007, 18, 523–528. [Google Scholar] [CrossRef]

- Parimaladevi, R.; Parvathi, V.P.; Lakshmi, S.S.; Umadevi, M. Synergistic effects of copper and nickel bimetallic nanoparticles for enhanced bacterial inhibition. Mater. Lett. 2018, 211, 82–86. [Google Scholar] [CrossRef]

- Argueta-Figueroa, L.; Morales-Luckie, R.A.; Scougall-Vilchis, R.J.; Olea-Mejía, O.F. Synthesis, characterization and antibacterial activity of copper, nickel and bimetallic Cu–Ni nanoparticles for potential use in dental materials. Progr. Nat. Sci. Mater. Int. 2014, 24, 321–328. [Google Scholar] [CrossRef] [Green Version]

- Pankhurst, Q.A.; Connolly, J.; Jones, S.K.; Dobson, J. Applications of magnetic nanoparticles in biomedicine. J. Phys. D Appl. Phys. 2003, 36, R167. [Google Scholar] [CrossRef] [Green Version]

- Shimizu, T.; Matsui, M. New magnetic implant material for interstitial hyperthermia. Sci. Technol. Adv. Mat. 2003, 4, 469–473. [Google Scholar] [CrossRef]

- Arokiyaraj, S.; Saravanan, M.; Udaya Prakash, N.K.; Valan Arasu, M.; Vijayakumar, B.; Vincent, S. Enhanced antibacterial activity of iron oxide magnetic nanoparticles treated with Argemone mexicana L. leaf extract: An in vitro study. Mater. Res. Bull. 2013, 48, 3323–3327. [Google Scholar] [CrossRef]

- Prabhu, Y.T.; Rao, K.V.; Kumari, B.S.; Kumar, V.S.S.; Pavani, T. Synthesis of Fe3O4 nanoparticles and its antibacterial application. Int. Nano Lett. 2015, 5, 85–92. [Google Scholar] [CrossRef]

- Wang, L.; Hu, C.; Shao, L. The antimicrobial activity of nanoparticles: Present situation and prospects for the future. Int. J. Nanomed. 2017, 12, 1227–1249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramalingam, B.; Parandhaman, T.; Das, S.K. Antibacterial Effects of Biosynthesized Silver Nanoparticles on Surface Ultrastructure and Nanomechanical Properties of Gram-Negative Bacteria viz. Escherichia coli and Pseudomonas aeruginosa. ACS Appl. Mater. Interfaces 2016, 8, 4963–4976. [Google Scholar] [CrossRef] [PubMed]

- Priyadarsini, S.; Mukherjee, S.; Mishra, M. Nanoparticles used in dentistry: A review. J. Oral Biol. Craniofac. Res. 2018, 8, 58–67. [Google Scholar] [CrossRef] [Green Version]

- Besinis, A.; De Peralta, T.; Tredwin, C.J.; Handy, R.D. Review of Nanomaterials in Dentistry: Interactions with the Oral Microenvironment, Clinical Applications, Hazards, and Benefits. ACS Nano 2015, 9, 2255–2289. [Google Scholar] [CrossRef] [Green Version]

- Minocha, S.; Mumper, R.J. Effect of carbon coating on the physico-chemical properties and toxicity of copper and nickel nanoparticles. Small 2012, 8, 3289–3299. [Google Scholar] [CrossRef]

- Shih, K.; Tang, Y. Prolonged toxicity characteristic leaching procedure for nickel and copper aluminates. J. Environ. Monit. JEM 2011, 13, 829–835. [Google Scholar] [CrossRef]

- Milojević, M.; Gradišnik, L.; Stergar, J.; Klemen, M.S.; Stožer, A.; Vesenjak, M.; Dobnik Dubrovski, P.; Maver, T.; Mohan, T.; Kleinschek, K.S.; et al. Development of multifunctional 3D printed bioscaffolds from polysaccharides and NiCu nanoparticles and their application. Appl. Surf. Sci. 2019, 488, 836–852. [Google Scholar] [CrossRef]

| Method | Types of Material | MNP Size | Advantages | Disadvantages | Biomedical Applications | References |

|---|---|---|---|---|---|---|

| Mechanical milling | - Nanocrystalline NixCu1−x alloys - NiCu nanoparticles | 10–436 nm | - A good milling yield (>95%) - Broad NP size distribution - Biocompatibility - TC = 46–47 °C | - Fe contamination - TC of 45 °C - Agglomeration - Agglomeration without a liquid medium | - Controlled MH applications | [36,39,48,57] |

| Microemulsion technique | - NiCu alloy nanoparticles | 4–30 nm | - Spherical, uniform NPs - Monodispersed, spherical NPs - Crystallization behavior - Fast synthesis procedure | - A core/shell structure - Additional step (reduction) | - MH | [42,58,59,60,61] |

| Sol–gel method | - NiCu alloy nanoparticles | 1–200 nm | - Spherical shape - Narrow NP size distribution, spherical shape | - High dispersion - The silica matrix influences magnetic behavior | - MH | [40,64] |

| Polyol method | - NiCu magnetic nanoparticles - NiCu core/shell nanoparticles | 40–140 nm | - A uniform shape - TC = ~77 °C - Simple procedure | - A Cu core and a Ni shell - Two-step procedure | - MH | [47,67,68] |

| Electrochemical deposition | - Magnetic alloy nanofilms | / | - Nanostructured films | - Two peaks in the polarization curve | / | [70] |

| Hydrothermal technique | - Ultra-fine NiCu bimetallic powders - Ultra-fine NiCu bimetallic powders with a core/shell structure | 0.5 ± 0.2 μm | - Excellent dispersibility, a uniform size - Finest dispersibility | - Agglomeration | / | [41,72] |

| Other methods | - NiCu alloy nanoparticles - NiCu alloy thin films - NiCu alloy NPs | 5–1000 nm | - The composition of the alloy could be controlled by changing the Ni/Cu molar ratio in the starting solution - Applying a magnetic field (44 kHz) on the liver resulted in temperature stabilization (42 °C) - Superparamagnetic behavior - Irregular shapes of NPs | - Polydispersed particles - Additional thermal treatment - Heterogeneously distributed particle size - Broad size distribution - Oxidized surface in air | - MH | [38,48,54,73,74,75,76,77,78] |

| Types of Materials | Synthesis Methods | Surface Modification | w (atm. %) | dx (nm) | TC (°C) | MS (emu/g) | SAR (W/g) | References |

|---|---|---|---|---|---|---|---|---|

| CuNi alloy NPs | Polyol reduction method -------and---------- physical melting process | PEG | Cu30Ni70 | 50–80 ----------- 300–400 | 43–46 | 45 ---------------- 6–8 | / | Chatterjee et al. [47] |

| NiCu alloy NPs | Sol–gel method | Silica matrix | Ni67.5Cu32.5 Ni62.5Cu37.5 Ni60Cu40 | 15–20 | 51–63 | 3–9 | 0.12–0.60 | Ferk et al. [37] |

| NiCu alloy NPs | Sol–gel method | Silica matrix | Ni67.5Cu32.5 | 16 | 65 | 8 | / | Ferk et al. [40] |

| Cu1−xNix NPs | Cationic water-in-oil (W/O) microemulsions | Silica | Ni70Cu30 Ni72.5Cu27.5 Ni60Cu40 | / | 45–88 | 22 (uncoated) 7 (coated) | / | Stergar et al. [60] |

| Ni1−xCux alloys | Modified sol–gel method | Chitosan matrix | Ni70Cu30 Ni75Cu25 Ni81Cu19 Ni95Cu5 | 11–20 | 77–277 | 21–50 | 0.289–0.576 | Araújo-Barbosa et al. [99] |

| CuNi NPs | Mechano-thermal method | / | Cu50Ni50 | 20 | 44 | 18 | 260.44 | Amrollahi et al. [39] |

| CuNi alloy NPs | Co-precipitation of salts from solution followed by reduction in hydrogen and thermal treatment (sol–gel method) | NaCl matrix | 25–30 atm.% of Cu | 30 | 40–60 | / | / | Kuznetsov et al. [38] |

| NiCu NPs | Melting and ball milling | / | Ni70Cu30 | 436 | 46–47 | / | / | Bettge et al. [48] |

| CuxNi1−x alloys | Mechanical milling | / | Cu40Ni60 Cu30Ni70 Cu27.5Ni72.5 Cu27Ni73 Cu25Ni75 Cu20Ni80 | 10–12 | 24–174 | 4.4–32.9 | / | Ban et al. [36] |

| CuNi alloy NPs | Microemulsion method | / | Cu27.5Ni72.5 | 28 | 43 | 2.5–20 | 4.3–41.6 | Stergar et al. [79] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stergar, J.; Ban, I.; Maver, U. The Potential Biomedical Application of NiCu Magnetic Nanoparticles. Magnetochemistry 2019, 5, 66. https://doi.org/10.3390/magnetochemistry5040066

Stergar J, Ban I, Maver U. The Potential Biomedical Application of NiCu Magnetic Nanoparticles. Magnetochemistry. 2019; 5(4):66. https://doi.org/10.3390/magnetochemistry5040066

Chicago/Turabian StyleStergar, Janja, Irena Ban, and Uroš Maver. 2019. "The Potential Biomedical Application of NiCu Magnetic Nanoparticles" Magnetochemistry 5, no. 4: 66. https://doi.org/10.3390/magnetochemistry5040066