Influence of Bi Content on the Temperature of the Formation of the Hard Magnetic MnBi Phase: Simultaneous Irreversible Drop of Resistance

Abstract

:1. Introduction

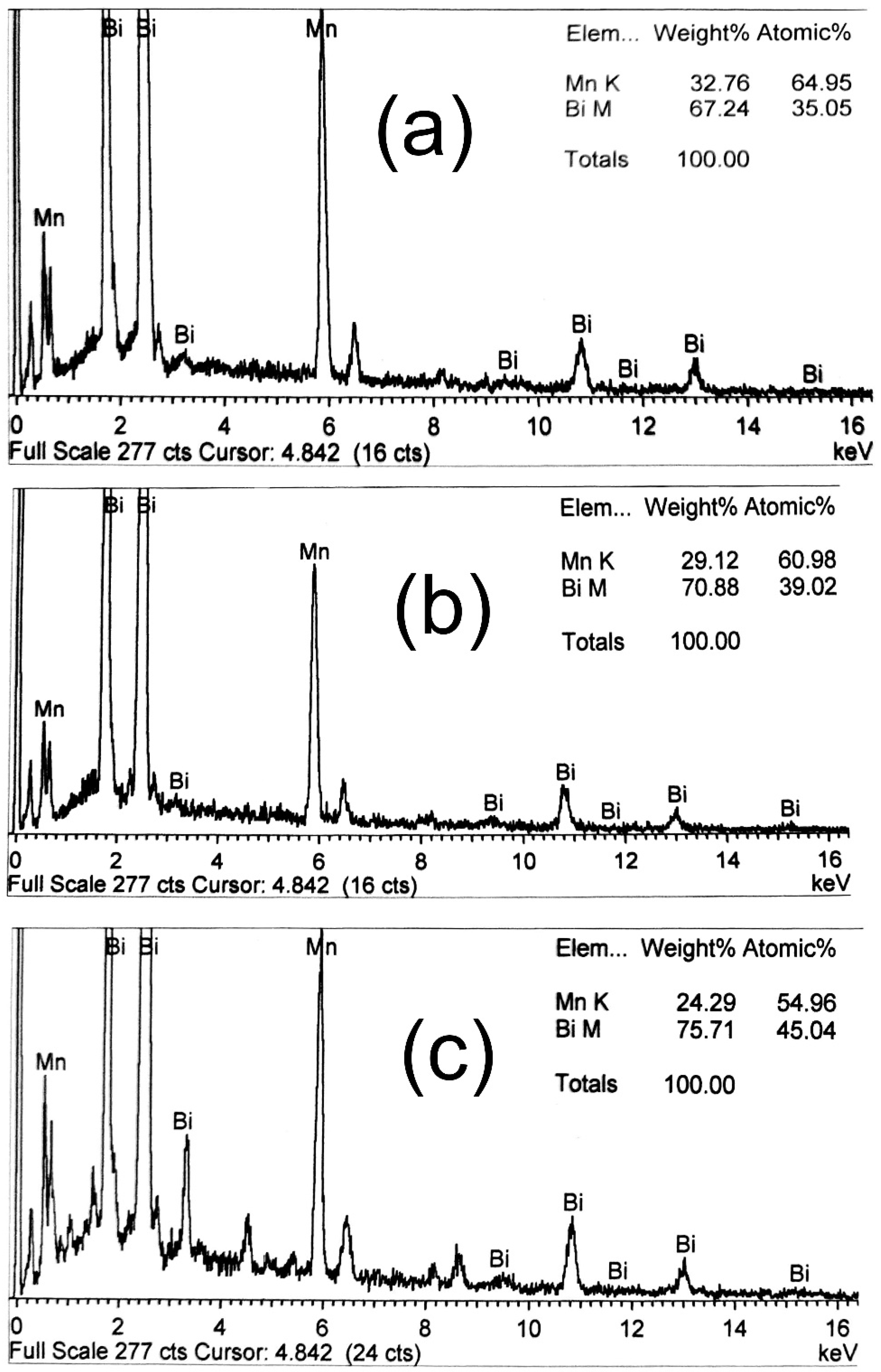

2. Materials and Methods

3. Results and Discussion

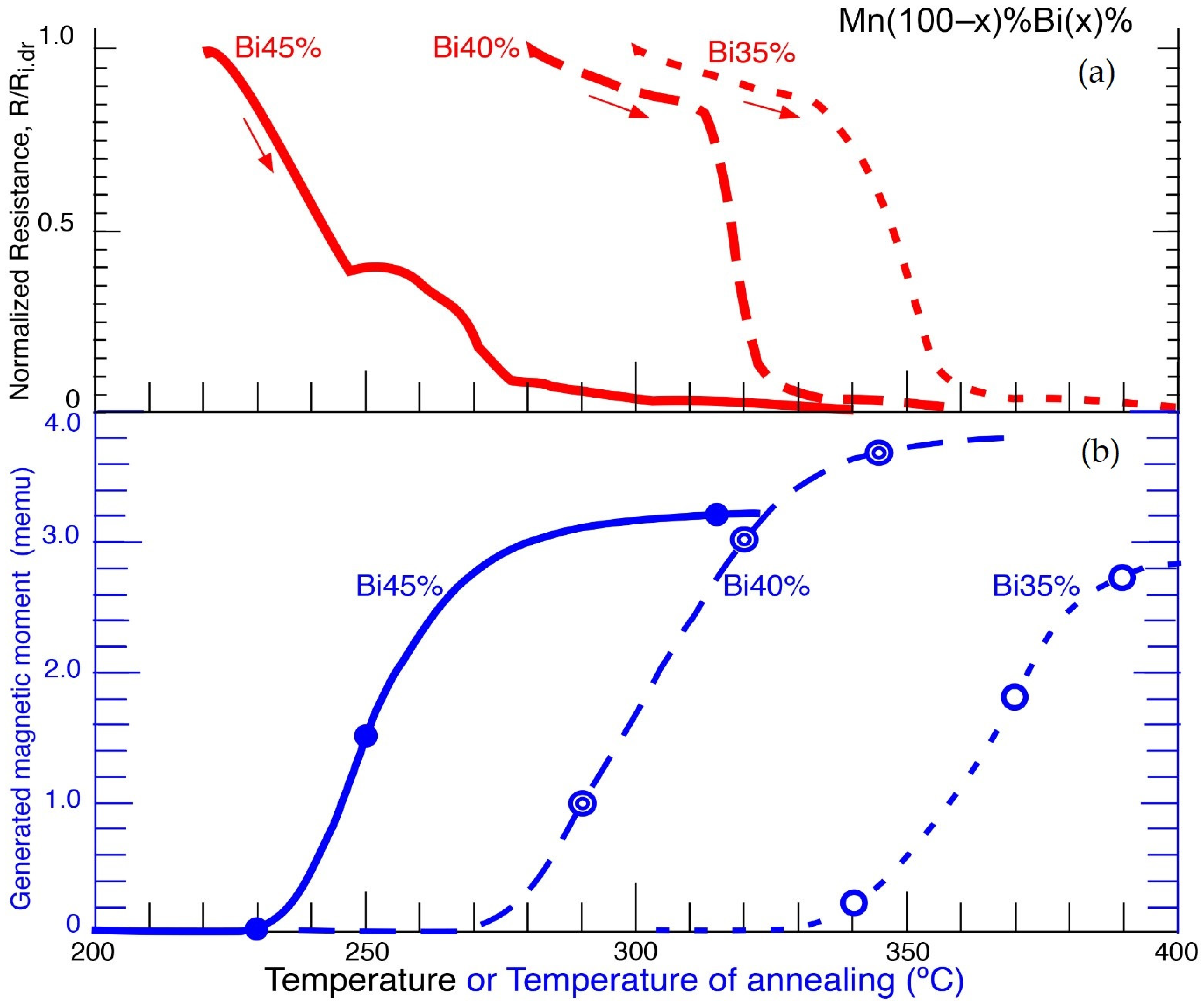

- I.

- Sample I: Mn(65%)Bi(35%) Film

- II.

- Sample II: Mn(60%)Bi(40%) Film

- III.

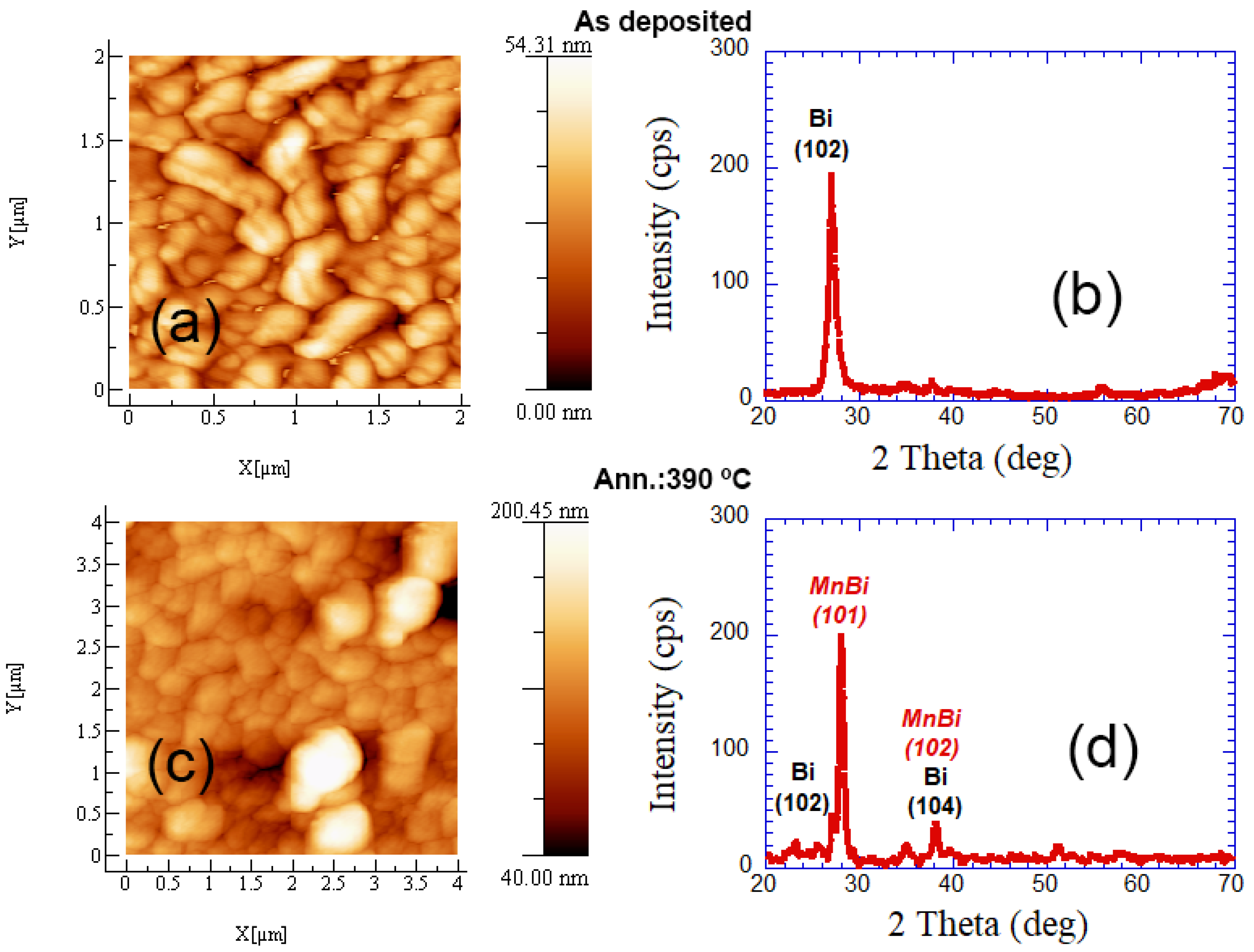

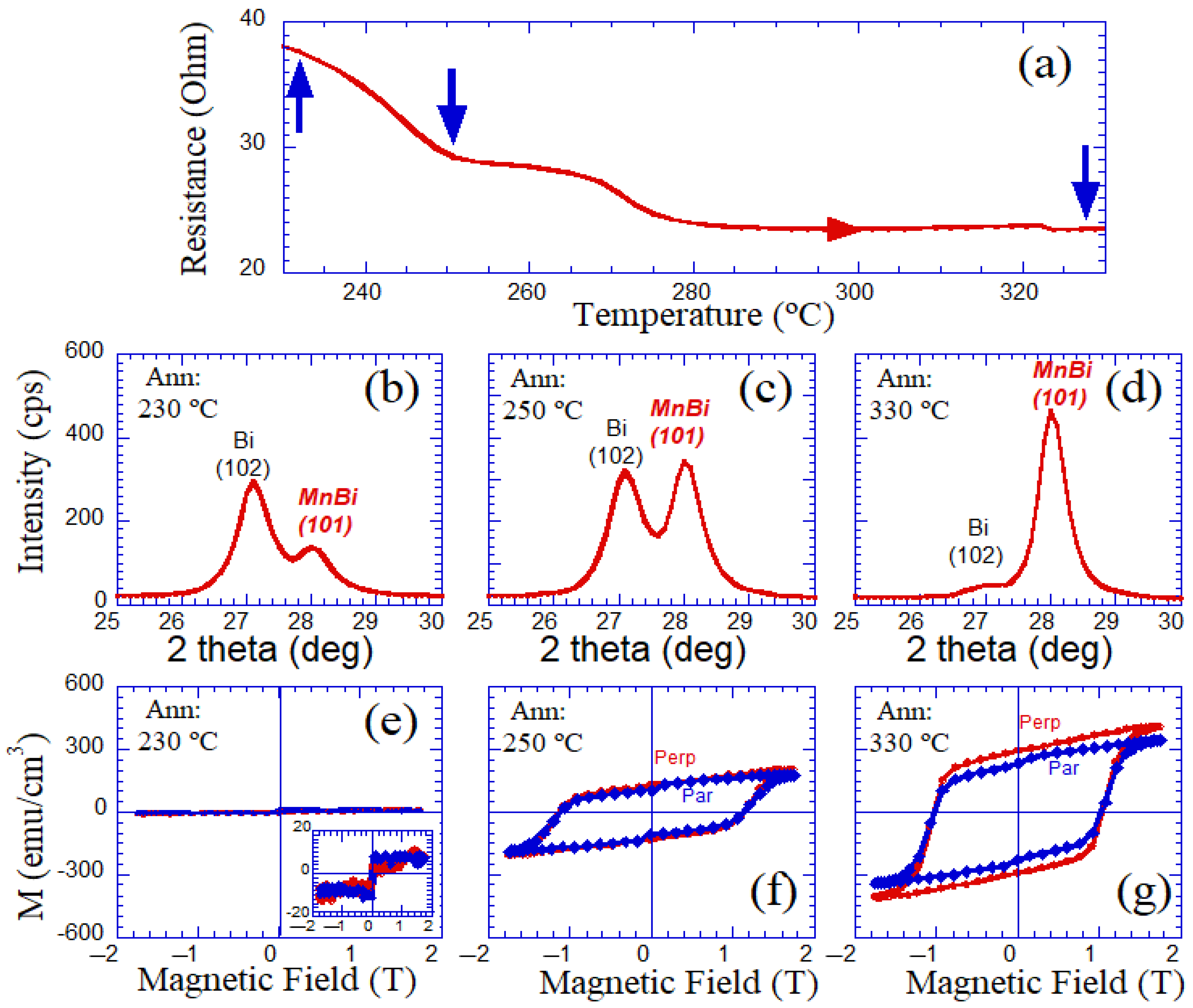

- Sample III: Mn(55%)Bi(45%) Film

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, D.; Pan, D.; Li, S.; Zhang, Z. Recent developments of rare-earth-free hard-magnetic materials. Sci. China Phys. Mech. Astron. 2016, 59, 617501. [Google Scholar] [CrossRef]

- Guo, X.; Chen, X.; Altounian, Z.; Ström-Olsen, J.O. Magnetic properties of MnBi prepared by rapid solidification. Phys. Rev. B 1992, 46, 14578–14582. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, J.; Liu, J.P. Rare-earth–free permanent magnets: The past and the future. In Handbook of Magnetic Materials; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 27, pp. 1–57. [Google Scholar] [CrossRef]

- Müller, K.-H.; Sawatzki, S.; Gauss, R.; Gutfleisch, O. Permanent magnet materials and applications. In Handbook of Magnetism and Magnetic Materials; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Park, J.; Hong, Y.-K.; Lee, J.; Lee, W.; Kim, S.-G.; Choi, C.-J. Electronic Structure and Maximum Energy Product of MnBi. Metals 2014, 4, 455–464. [Google Scholar] [CrossRef] [Green Version]

- Rao, N.V.R.; Gabay, A.M.; Li, W.F.; Hadjipanayis, G.C. Nanostructured bulk MnBi magnets fabricated by hot compaction of cryomilled powders. J. Phys. D Appl. Phys. 2013, 46, 265001. [Google Scholar] [CrossRef]

- Marker, M.C.; Terzieff, P.; Kainzbauer, P.; Bobnar, M.; Richter, K.W.; Ipser, H. BiMn: Synthesis, separation by centrifugation, and characterization. J. Alloys Compd. 2018, 741, 682–688. [Google Scholar] [CrossRef]

- Mitsui, Y.; Umetsu, R.Y.; Takahashi, K.; Koyama, K. Reactive sintering process of ferromagnetic MnBi under high magnetic fields. J. Magn. Magn. Mater. 2018, 453, 231–235. [Google Scholar] [CrossRef]

- Xiang, Z.; Wang, T.; Ma, S.; Qian, L.; Luo, Z.; Song, Y.; Yang, H.; Lu, W. Microstructural evolution and phase transformation kinetics of MnBi alloys. J. Alloys Compd. 2018, 741, 951–956. [Google Scholar] [CrossRef]

- Cui, J.; Choi, J.-P.; Polikarpov, E.; Bowden, M.E.; Xie, W.; Li, G.; Nie, Z.; Zarkevich, N.A.; Kramer, M.J.; Johnson, D. Effect of composition and heat treatment on MnBi magnetic materials. Acta Mater. 2014, 79, 374–381. [Google Scholar] [CrossRef] [Green Version]

- Mitsui, Y.; Umetsu, R.Y.; Koyama, K.; Watanabe, K. Magnetic-field-induced enhancement for synthesizing ferromagnetic MnBi phase by solid-state reaction sintering. J. Alloys Compd. 2014, 615, 131–134. [Google Scholar] [CrossRef]

- Gabay, A.M.; Hadjipanayis, G.C.; Cui, J. Preparation of highly pure α-MnBi phase via melt-spinning. AIP Adv. 2018, 8, 056702. [Google Scholar] [CrossRef]

- Poudyal, N.; Liu, X.; Wang, W.; Nguyen, V.V.; Ma, Y.; Gandha, K.; Elkins, K.; Liu, J.P.; Sun, K.; Kramer, M.J.; et al. Processing of MnBi bulk magnets with enhanced energy product. AIP Adv. 2016, 6, 056004. [Google Scholar] [CrossRef] [Green Version]

- Xiang, Z.; Song, Y.; Pan, D.; Shen, Y.; Qian, L.; Luo, Z.; Liu, Y.; Yang, H.; Yan, H.; Lu, W. Coercivity enhancement and magnetization process in Mn55Bi45 alloys with refined particle size. J. Alloys Compd. 2018, 744, 432–437. [Google Scholar] [CrossRef]

- Zhang, D.; Geng, W.; Yue, M.; Liu, W.; Zhang, J.; Sundararajan, J.; Qiang, Y. Crystal structure and magnetic properties of MnxBi100−x (x=48, 50, 55 and 60) compounds. J. Magn. Magn. Mater. 2012, 324, 1887–1890. [Google Scholar] [CrossRef]

- Cui, J.; Choi, J.P.; Li, G.; Polikarpov, E.; Darsell, J.; Overman, N.; Olszta, M.; Schreiber, D.; Bowden, M.; Droubay, T.; et al. Thermal stability of MnBi magnetic materials. J. Phys. Condens. Matter 2014, 26, 064212. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, Y.-F.; Ma, X.-B.; Liu, S.-Q.; Chang-Sheng, W.; Zhu, M.-G.; Wang, C.-S.; Yang, J.-B. Preparation of Highly Textured Bi and MnBi Films by the Pulsed Laser Deposition Method. Chin. Phys. Lett. 2015, 32, 127502. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, J.; Liu, S.; Tian, H.; Zhao, H.; Du, H.; Yang, Y.; Fang, Y.; Li, W.; Yang, J. Structural modification and ultra-high coercivity of nanostructural anisotropic MnBi/Bi films. Acta Mater. 2017, 128, 96–102. [Google Scholar] [CrossRef]

- Zhang, W.; Kharel, P.; Valloppilly, S.; Yue, L.; Sellmyer, D.J. High-energy-product MnBi films with controllable anisotropy. Phys. Status Solidi (B) 2015, 252, 1934–1939. [Google Scholar] [CrossRef]

- Kharel, P.; Li, X.Z.; Shah, V.R.; Al-Aqtash, N.; Tarawneh, K.; Sabirianov, R.F.; Skomski, R.; Sellmyer, D.J. Structural, magnetic, and electron transport properties of MnBi:Fe thin films. J. Appl. Phys. 2012, 111, 07E326. [Google Scholar] [CrossRef] [Green Version]

- Myagkov, V.G.; Bykova, L.E.; Yakovchuk, V.Y.; Zhigalov, V.S.; Volochaev, M.N.; Matsynin, A.A.; Tambasov, I.A.; Seredkin, V.A.; Patrin, G.S.; Bondarenko, G.N. Structural and magnetic features of solid-phase transformations in Mn/Bi and Bi/Mn films. J. Exp. Theor. Phys. Lett. 2016, 103, 254–259. [Google Scholar] [CrossRef]

- Sellmyer, D.J.; Kirby, R.D.; Chen, J.; Wierman, K.W.; Shen, J.X.; Liu, Y.; Robertson, B.W.; Jaswal, S.S. Magneto-optical and structural properties of nanocrystalline MnBi-based films. J. Phys. Chem. Solids 1995, 56, 1549–1555. [Google Scholar] [CrossRef]

- Hozumi, T.; LeClair, P.; Mankey, G.; Mewes, C.; Sepehri-Amin, H.; Hono, K.; Suzuki, T. Magnetic and structural properties of MnBi multilayered thin films. J. Appl. Phys. 2014, 115, 17A737. [Google Scholar] [CrossRef]

- Ito, M.; Tanaka, Y.; Satoh, T.; Mankey, G.; Schad, R.; Suzuki, T. Magnetic properties and structure of low temperature phase MnBi with island structure. AIP Adv. 2017, 7, 056226. [Google Scholar] [CrossRef]

- Sabet, S.; Hildebrandt, E.; Romer, F.; Radulov, I.; Zhang, H.; Farle, M.; Alff, L. Low-Temperature Phase c-axis Oriented Manganese Bismuth Thin Films With High Anisotropy Grown From an Alloy Mn55Bi45Target. IEEE Trans. Magn. 2016, 53, 2100306. [Google Scholar] [CrossRef]

- Moon, H.; Kim, S.; Jung, H.; Lee, H.-S.; Lee, W. Layer-number dependence of the magnetic properties of MnBi films. Appl. Surf. Sci. 2017, 420, 618–624. [Google Scholar] [CrossRef]

- Céspedes, E.; Villanueva, M.; Navío, C.; Mompeán, F.; García-Hernández, M.; Inchausti, A.; Pedraz, P.; Osorio, M.; Camarero, J.; Bollero, A. High coercive LTP-MnBi for high temperature applications: From isolated particles to film-like structures. J. Alloys Compd. 2017, 729, 1156–1164. [Google Scholar] [CrossRef]

- Quarterman, P.; Zhang, D.; Schliep, K.B.; Peterson, T.J.; Lv, Y.; Wang, J.-P. Effect of capping layer on formation and magnetic properties of MnBi thin films. J. Appl. Phys. 2017, 122, 213904. [Google Scholar] [CrossRef]

- Sun, M.; Xu, X.; Liang, X.; Sun, X.; Zheng, Y. Effect of oxidation on perpendicular magnetic behavior of MnBi thin films. J. Alloys Compd. 2016, 672, 59–63. [Google Scholar] [CrossRef]

- Chen, D.; Ready, J.F.; Bernal, G.E. MnBi Thin Films: Physical Properties and Memory Applications. J. Appl. Phys. 1968, 39, 3916–3927. [Google Scholar] [CrossRef]

- Chen, D. Preparation and Stability of MnBi Thin Films. J. Appl. Phys. 1971, 42, 3625–3628. [Google Scholar] [CrossRef]

- Vergara, J.; Favieres, C.; Madurga, V. MnBi hard magnetic films optimised through the correlation between resistivity, morphology and magnetic properties. J. Magn. Magn. Mater. 2019, 491, 165525. [Google Scholar] [CrossRef]

- Madurga, V.; Vergara, J.; Favieres, C. Influence of nature of the substrate on the soft magnetic properties of pulsed laser ablated-deposited amorphous Co. J. Magn. Magn. Mater. 2003, 254–255, 140–142. [Google Scholar] [CrossRef]

- Horcas, I.; Fernández, R.; Gómez-Rodriguez, J.M.; Colchero, J.; Gomez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 13705. [Google Scholar] [CrossRef] [PubMed]

- Shekhawat, R.; Pamuluri, H.; Erkkara Madhavan, V.; Ramesh, K. Structural transformation and phase change properties of Se substituted GeTe. Nat. Sci. Rep. 2021, 11, 7604. [Google Scholar] [CrossRef] [PubMed]

- Favieres, C.; Vergara, J.; Madurga, V. Tailoring Magnetic and Transport Anisotropies in Co100−x–Cux Thin Films through Obliquely Grown Nano-Sheets. Magnetochemistry 2021, 8, 4. [Google Scholar] [CrossRef]

- Angadi, M.A.; Thanigaimani, V. Thickness dependence of temperature coefficient of resistance of MnBi films. Appl. Phys. A 1987, 44, 261–264. [Google Scholar] [CrossRef]

- Vergara, J.; Favieres, C.; Madurga, V. Magnetic domain configurations of pulsed laser deposited MnBi hard magnetic films. J. Magn. Magn. Mater. 2022, 554, 169316. [Google Scholar] [CrossRef]

- Mehrer, H. Diffusion in Solids; Springer Series in Solid-State Sciences; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar] [CrossRef]

| Sample | Deposition Time | Thickness | Composition (at %) |

|---|---|---|---|

| Sample I | (Bi7sMn20s)40 | (Bi2.2nmMn1.4nm)40 | Mn(65%)Bi(35%) |

| Sample II | (Bi8.5sMn20s)40 | (Bi2.7nmMn1.4nm)40 | Mn(60%)Bi(40%) |

| Sample III | (Bi10sMn20s)40 | (Bi3.2nmMn1.4nm)40 | Mn(55%)Bi(45%) |

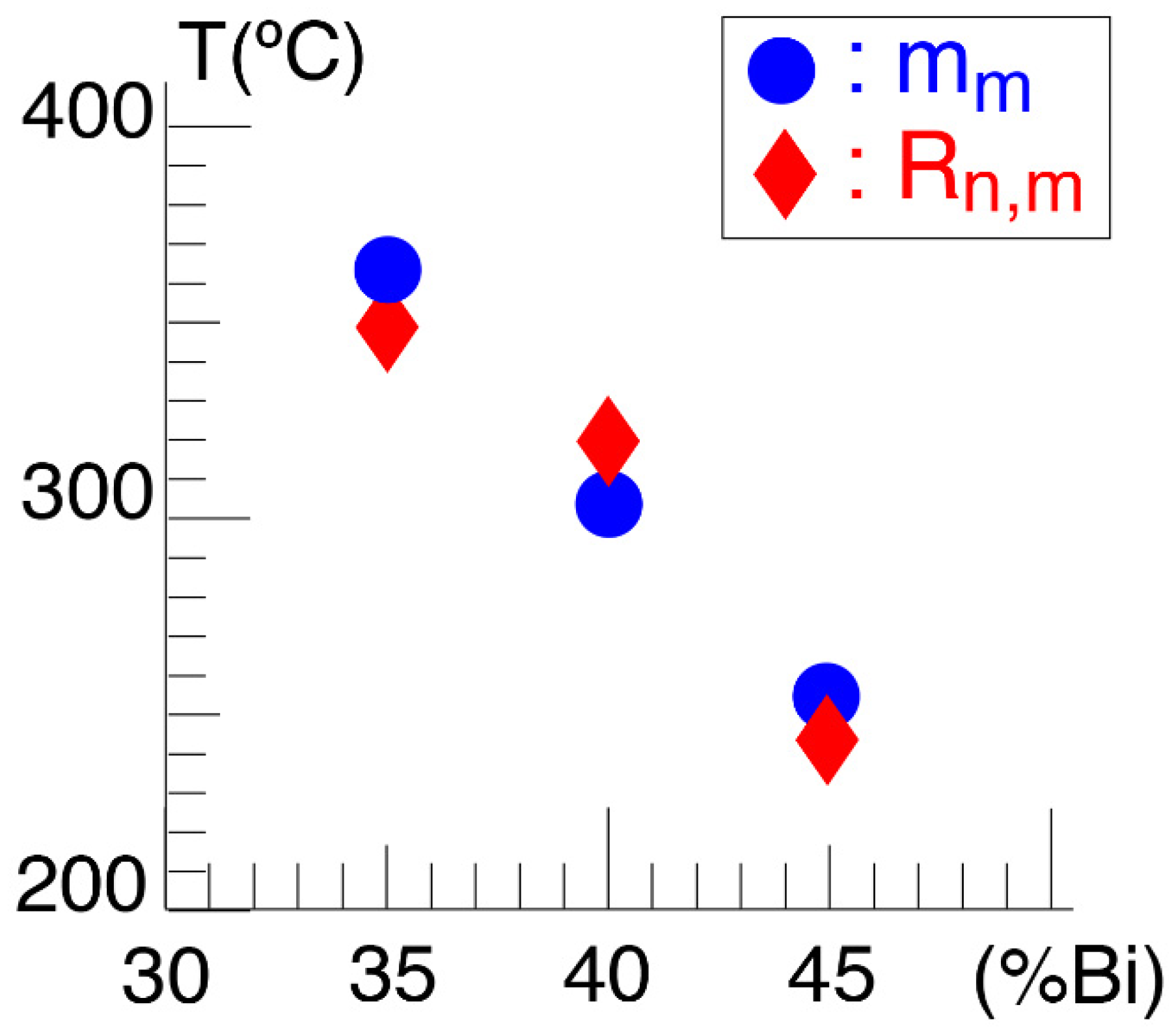

| Sample Composition | Tann < Tform | Tform | Tann > Tform |

|---|---|---|---|

| Mn(65%)Bi(35%) | 340 (°C) | 370 (°C) | 390 (°C) |

| Mn(60%)Bi(40%) | 290 (°C) | 320 (°C) | 360 (°C) |

| Mn(55%)Bi(45%) | 230 (°C) | 250 (°C) | 330 (°C) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vergara, J.; Favieres, C.; Madurga, V. Influence of Bi Content on the Temperature of the Formation of the Hard Magnetic MnBi Phase: Simultaneous Irreversible Drop of Resistance. Magnetochemistry 2022, 8, 82. https://doi.org/10.3390/magnetochemistry8080082

Vergara J, Favieres C, Madurga V. Influence of Bi Content on the Temperature of the Formation of the Hard Magnetic MnBi Phase: Simultaneous Irreversible Drop of Resistance. Magnetochemistry. 2022; 8(8):82. https://doi.org/10.3390/magnetochemistry8080082

Chicago/Turabian StyleVergara, José, Cristina Favieres, and Vicente Madurga. 2022. "Influence of Bi Content on the Temperature of the Formation of the Hard Magnetic MnBi Phase: Simultaneous Irreversible Drop of Resistance" Magnetochemistry 8, no. 8: 82. https://doi.org/10.3390/magnetochemistry8080082