Hydrometallurgical Method of Producing Lithium Perrhenate from Solutions Obtained during the Processing of Li-Ion Battery Scrap

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical Methods

3. Results

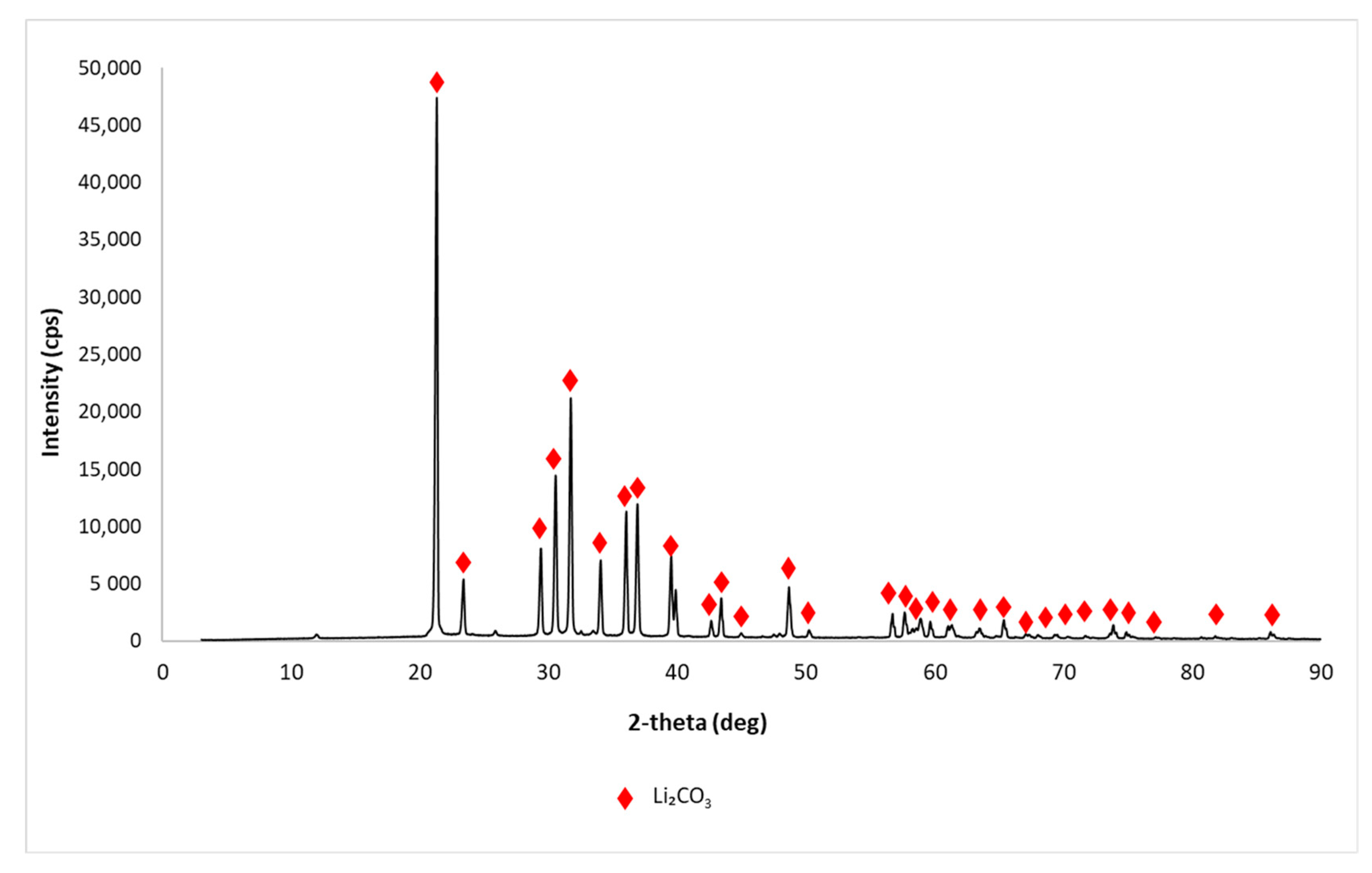

3.1. Lithium Recovery from the Post-Leaching Solutions and Analysis of the Obtained Lithium Carbonate

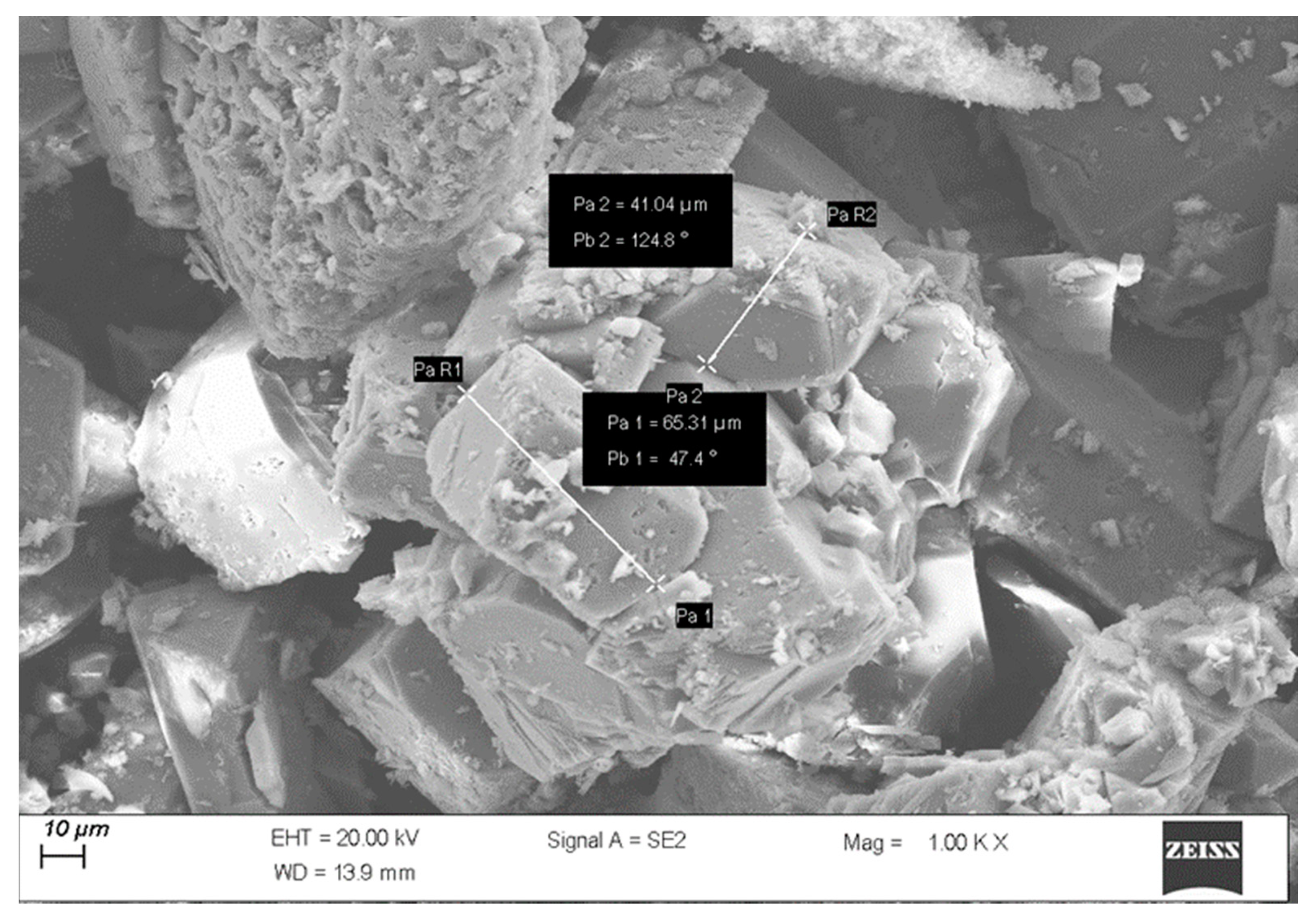

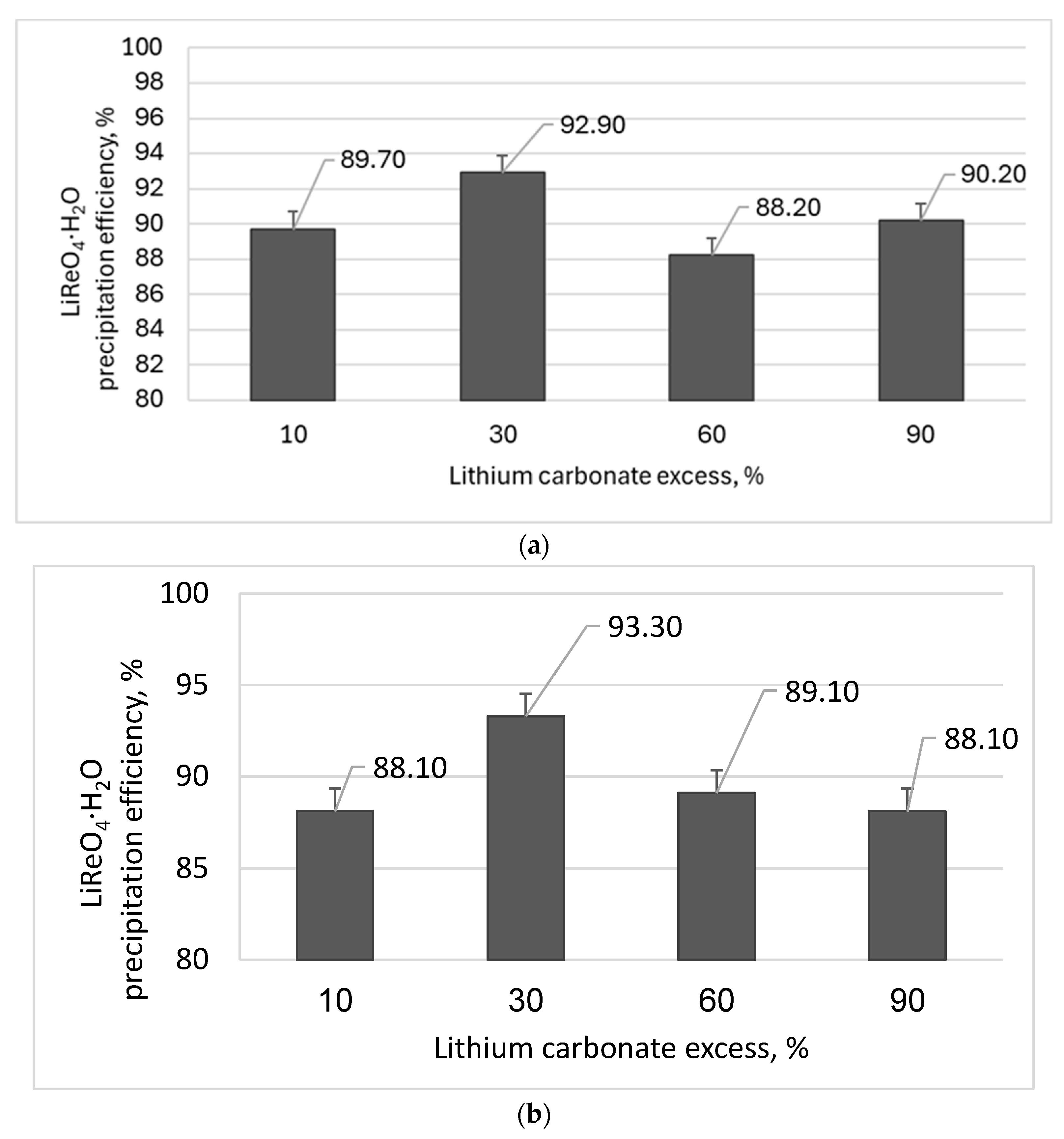

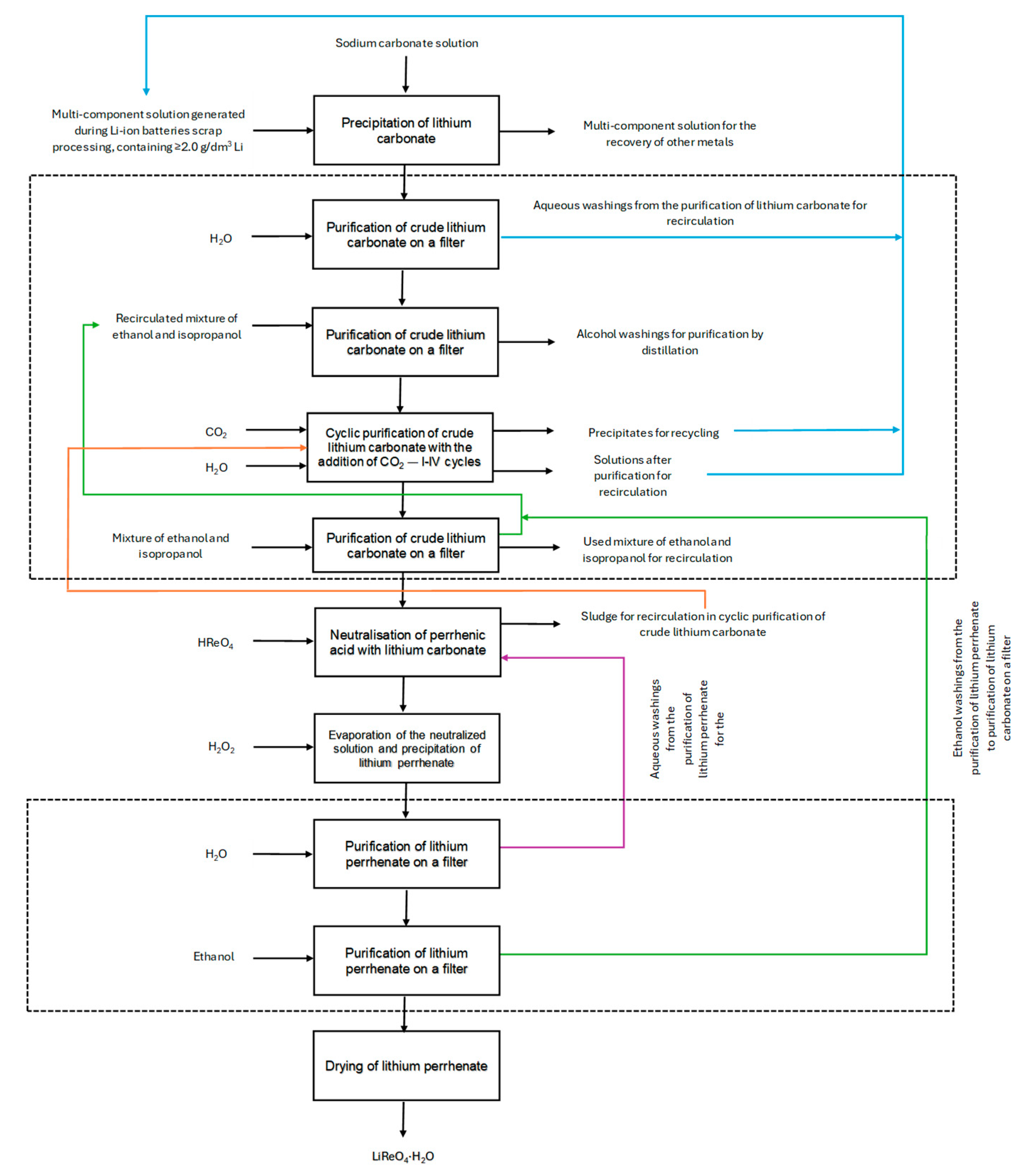

3.2. Preparation and Characterization of the Obtained LiReO4·H2O

4. Conclusions

- −

- maximizing the use of waste;

- −

- maximizing the recirculation;

- −

- minimizing the losses of valuable ingredients (rhenium and lithium);

- −

- minimizing the energy consumption;

- −

- maximizing the use of CO2.

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roskill Rhenium: Outlook to 2029, 11th ed.; Roskill Information Services Ltd: London, UK, 2019; ISBN 978-1-910-92279-8.

- Sinclair, W.D.; Jonasson, I.R.; Kirkham, R.V.; Soregaroli, A.E. Rhenium in Canadian Mineral Deposits; Geological Survey of Canada: Ottawa. ON, Canada, 2016. [CrossRef]

- Barton, I.F.; Rathkopf, C.A.; Barton, M.D. Rhenium in Molybdenite: A Database Approach to Identifying Geochemical Controls on the Distribution of a Critical Element. Mining Metall. Explor. 2020, 37, 21–37. [Google Scholar] [CrossRef]

- Kesler, S.E.; Gruber, P.W.; Medina, P.A.; Keoleian, G.A.; Everson, M.P.; Wallington, T.J. Global Lithium Resources: Relative Importance of Pegmatite, Brine and Other Deposits. Ore Geol. Rev. 2012, 48, 55–69. [Google Scholar] [CrossRef]

- Gardiner, N.J.; Jowitt, S.M.; Sykes, J.P. Lithium: Critical, or Not so Critical? Geoenergy 2024, 2, geoenergy2023-045. [Google Scholar] [CrossRef]

- Mishra, B.; Anderson, C.D.; Taylor, P.R.; Anderson, C.G.; Apelian, D.; Blanpain, B. CR3 Update: Recycling of Strategic Metals. Jom 2012, 64, 441–443. [Google Scholar] [CrossRef]

- Werner, T.T.; Mudd, G.M.; Jowitt, S.M.; Huston, D. Rhenium Mineral Resources: A Global Assessment. Resour. Policy 2023, 82, 103441. [Google Scholar] [CrossRef]

- Alessia, A.; Alessandro, B.; Maria, V.G.; Carlos, V.A.; Francesca, B. Challenges for Sustainable Lithium Supply: A Critical Review. J. Clean. Prod. 2021, 300, 126954. [Google Scholar] [CrossRef]

- Available online: https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-rhenium.pdf (accessed on 8 April 2024).

- Available online: https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-lithium.pdf (accessed on 8 April 2024).

- Meng, F.; McNeice, J.; Zadeh, S.S.; Ghahreman, A. Review of Lithium Production and Recovery from Minerals, Brines, and Lithium-Ion Batteries. Miner. Process. Extr. Metall. Rev. 2021, 42, 123–141. [Google Scholar] [CrossRef]

- Sharmili, N.; Nagi, R.; Wang, P. A Review of Research in the Li-Ion Battery Production and Reverse Supply Chains. J. Energy Storage 2023, 68, 107622. [Google Scholar] [CrossRef]

- Goriparti, S.; Miele, E.; De Angelis, F.; Di Fabrizio, E.; Proietti Zaccaria, R.; Capiglia, C. Review on Recent Progress of Nanostructured Anode Materials for Li-Ion Batteries. J. Power Sources 2014, 257, 421–443. [Google Scholar] [CrossRef]

- Orda, S.; Drzazga, M.; Leszczyńska-Sejda, K.; Ciszewski, M.; Kocur, A.; Branecka, P.; Gall, K.; Słaboń, M.; Lemanowicz, M. Investigations of the Density and Solubility of Ammonium Perrhenate and Potassium Perrhenate Aqueous Solutions. Materials 2023, 16, 5481. [Google Scholar] [CrossRef]

- Kunkes, E.L.; Simonetti, D.A.; Dumesic, J.A.; Pyrz, W.D.; Murillo, L.E.; Chen, J.G.; Buttrey, D.J. The Role of Rhenium in the Conversion of Glycerol to Synthesis Gas over Carbon Supported Platinum-Rhenium Catalysts. J. Catal. 2008, 260, 164–177. [Google Scholar] [CrossRef]

- Huang, M.; Zhu, J. An Overview of Rhenium Effect in Single-Crystal Superalloys. Rare Met. 2016, 35, 127–139. [Google Scholar] [CrossRef]

- Leszczyńska-Sejda, K.; Majewski, T.; Benke, G.; Piętaszewski, J.; Anyszkiewicz, K.; Michałowski, J.; Chmielarz, A. Production of High-Purity Ammonium Perrhenate for W-Re-Ni-Fe Heavy Alloys. J. Alloys Compd. 2012, 513, 347–352. [Google Scholar] [CrossRef]

- Majewski, T.; Leszczyńska-Sejda, K. Investigation of Application Possibilities of Re-Ni Alloy Powder to Tungsten Heavy Alloys Production. Solid State Phenom. 2016, 251, 14–19. [Google Scholar] [CrossRef]

- Kopyto, D.; Leszczyńska-Sejda, K.; Benke, G.; Chmielarz, A.; Ciszewski, M. Production of Electrolytic Rhenium-Cobalt Alloys. In Proceedings of the 9th European Metallurgical Conference, Leipzig, Germany, 25–28 June 2017; pp. 521–530. [Google Scholar]

- Leszczyńska-Sejda, K.; Benke, G.; Kopyto, D.; Drzazga, M.; Ciszewski, M. Application of Ion Exchange for Preparation of Selected Metal Perrhenates—Precursors for Superalloy Production. Metals 2019, 9, 201. [Google Scholar] [CrossRef]

- Leszczyńska-Sejda, K.; Benke, G.; Kopyto, D.; Malarz, J.; Ciszewski, M.; Goc, K. A New Method of Obtaining High Purity Nickel(II) Perrhenate from Waste. Crystals 2023, 13, 1465. [Google Scholar] [CrossRef]

- Leszczyńska-Sejda, K.; Benke, G.; Chmielarz, A.; Anyszkiewicz, K.; Satora, W.; Kozub, K. Hydrometallurgical Methods for Production of Ni(ReO4)2 and Co(ReO4)2. In Proceedings of the Conference Papers and Proceedings, Congresses European Metallurgical Conference, EMC, Hydrometallurgy, Weimar, Germany, 23–26 June 2013; pp. 885–898. [Google Scholar]

- Leszczyńska-Sejda, K.; Benke, G.; Ciszewski, M.; Malarz, J.; Drzazga, M. Method of Preparation for High-Purity Nanocrystalline Anhydrous Cesium Perrhenate. Metals 2017, 7, 96. [Google Scholar] [CrossRef]

- Benke, G.; Leszczyńska-Sejda, K.; Anyszkiewicz, K.; Chmielarz, A.; Machelska, G.; Witman, K. Sposób Produkcji Bezwodnego Renianu(VII) Żelaza(III)—PL 221891 B1 2010. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/68e950abb9a3e8ca4695b16a91c567be (accessed on 26 January 2024).

- Leszczynska-Sejda, K.; Benke, G.; Malarz, J.; Ciszewski, M.; Kopyto, D.; Piatek, J.; Drzazga, M.; Kowalik, P.; Zemlak, K.; Kula, B. Rhenium(VII) Compounds as Inorganic Precursors for the Synthesis of Organic Reaction Catalysts. Molecules 2019, 24, 1451. [Google Scholar] [CrossRef]

- Leszczyńska-Sejda, K.; Benke, G.; Kopyto, D.; Ciszewski, M.; Malarz, J.; Drzazga, M.; Kowalik, P.; Piątek, J.; Śmieszek, J.; Grabowski, T.; et al. Rhenium Recovery from Recycling-Based Materials. In Proceedings of the 10th European Metallurgical Conference, Düsseldorf, Germany, 24–26 June 2019; pp. 327–340. [Google Scholar]

- Naumov, D.Y.; Virovets, A.V.; Korenev, S.V.; Gubanov, A.I. Silver Perrhenate, AgReO4. Acta Crystallogr. Sect. C Cryst. Struct. Commun. 1999, 55, IUC9900097. [Google Scholar] [CrossRef]

- Ciszewski, M.; Koszorek, A.; Osadnik, M.; Szleper, K.; Drzazga, M.; Leszczyńska-Sejda, K. Lithium Perrhenate Catalyst for Carbon Aerogel-Based Supercapacitor. SN Appl. Sci. 2020, 2, 786. [Google Scholar] [CrossRef]

- Leszczyńska-Sejda, K.; Benke, G.; Kopyto, D.; Majewski, T.; Drzazga, M. Production of High-Purity Anhydrous Nickel(II) Perrhenate for Tungsten-Based Sintered Heavy Alloys. Materials 2017, 10, 448. [Google Scholar] [CrossRef] [PubMed]

- Smith, W.T.; Long, S.H. The Salts of Perrhenic Acid. I. The Alkali Metals and Ammonium. J. Am. Chem. Soc. 1948, 70, 354–356. [Google Scholar] [CrossRef]

- Tawonezvi, T.; Nomnqa, M.; Petrik, L.; Bladergroen, B.J. Recovery and Recycling of Valuable Metals from Spent Lithium-Ion Batteries: A Comprehensive Review and Analysis. Energies 2023, 16, 1365. [Google Scholar] [CrossRef]

- Sonoc, A.; Jeswiet, J. A Review of Lithium Supply and Demand and a Preliminary Investigation of a Room Temperature Method to Recycle Lithium Ion Batteries to Recover Lithium and Other Materials. Procedia CIRP 2014, 15, 289–293. [Google Scholar] [CrossRef]

- Ordoñez, J.; Gago, E.J.; Girard, A. Processes and Technologies for the Recycling and Recovery of Spent Lithium-Ion Batteries. Renew. Sustain. Energy Rev. 2016, 60, 195–205. [Google Scholar] [CrossRef]

- Liu, X.; Wang, R.; Liu, S.; Pu, J.; Xie, H.; Wu, M.; Liu, D.; Li, Y.; Liu, J. Organic Eutectic Salts-Assisted Direct Lithium Regeneration for Extremely Low State of Health Ni-Rich Cathodes. Adv. Energy Mater. 2023, 13, 2302987. [Google Scholar] [CrossRef]

- Liang, Z.; Cai, C.; Peng, G.; Hu, J.; Hou, H.; Liu, B.; Liang, S.; Xiao, K.; Yuan, S.; Yang, J. Hydrometallurgical Recovery of Spent Lithium Ion Batteries: Environmental Strategies and Sustainability Evaluation. ACS Sustain. Chem. Eng. 2021, 9, 5750–5767. [Google Scholar] [CrossRef]

- Makuza, B.; Tian, Q.; Guo, X.; Chattopadhyay, K.; Yu, D. Pyrometallurgical Options for Recycling Spent Lithium-Ion Batteries: A Comprehensive Review. J. Power Sources 2021, 491, 229622. [Google Scholar] [CrossRef]

- Zhou, M.; Li, B.; Li, J.; Xu, Z. Pyrometallurgical Technology in the Recycling of a Spent Lithium Ion Battery: Evolution and the Challenge. ACS ES T Eng. 2021, 1, 1369–1382. [Google Scholar] [CrossRef]

- Windisch-Kern, S.; Holzer, A.; Ponak, C.; Raupenstrauch, H. Pyrometallurgical Lithium-Ion-Battery Recycling: Approach to Limiting Lithium Slagging with the Indured Reactor Concept. Processes 2021, 9, 84. [Google Scholar] [CrossRef]

- Klimko, J.; Oráč, D.; Miškufová, A.; Vonderstein, C.; Dertmann, C.; Sommerfeld, M.; Friedrich, B.; Havlík, T. A Combined Pyro-and Hydrometallurgical Approach to Recycle Pyrolyzed Lithium-Ion Battery Black Mass Part 2: Lithium Recovery from Li Enriched Slag— Thermodynamic Study, Kinetic Study, and Dry Digestion. Metals 2020, 10, 1558. [Google Scholar] [CrossRef]

- He, M.; Jin, X.; Zhang, X.; Duan, X.; Zhang, P.; Teng, L.; Liu, Q.; Liu, W. Combined Pyro-Hydrometallurgical Technology for Recovering Valuable Metal Elements from Spent Lithium-Ion Batteries: A Review of Recent Developments. Green Chem. 2023, 25, 6561–6580. [Google Scholar] [CrossRef]

- Holzer, A.; Zimmermann, J.; Wiszniewski, L.; Necke, T.; Gatschlhofer, C.; Öfner, W.; Raupenstrauch, H. A Combined Hydro-Mechanical and Pyrometallurgical Recycling Approach to Recover Valuable Metals from Lithium-Ion Batteries Avoiding Lithium Slagging. Batteries 2023, 9, 15. [Google Scholar] [CrossRef]

- Grosse, A.V. The Isolation of Lithium Rhenide. Z. Naturforsch.-Sect. B J. Chem. Sci. 1953, 8, 533–536. [Google Scholar] [CrossRef]

- Weaver, J.; Soderquist, C.Z.; Washton, N.M.; Lipton, A.S.; Gassman, P.L.; Lukens, W.W.; Kruger, A.A.; Wall, N.A.; McCloy, J.S. Chemical Trends in Solid Alkali Pertechnetates. Inorg. Chem. 2017, 56, 2533–2544. [Google Scholar] [CrossRef] [PubMed]

- Burkert, P.K.; Hutter, F.M. Spectroscopic Investigations in the Solid State Chemistry, X * Re-NQ R Investigations on TlRe0 4 and LiReO42H2O. Z. Naturforsch. B 1976, 31, 145–148. [Google Scholar] [CrossRef]

- Shklovskaya, R.M.; Arkhipov, S.M.; Kidyarov, B.I. No LiIO3-LiReO4-H2O System at 25 Deg C. Zhurnal Neorg. Khimii 1979, 24, 2287–2288. [Google Scholar]

- von Scholder, R.; Huppert, K.L. Uber Alkali- Und Erdalkali-Oxorhenate(VII). Z. Anorg. Und Allg. Chem. 1964, 334, 209–224. [Google Scholar] [CrossRef]

- Boguslavskii, A.; Shcherbakova, S. Temperature-Dependece of Re-187 Nuclear-Quadrupole Resonance Frequencies in Lithium Perrhenate and Lithium and Yttrium Perrhenate Crystal Hydrates. Izv. Akad. Nauk SSSR Seriya Fiz. 1978, 42, 2142–2145. [Google Scholar]

- Sequoia, E.; Skudlarski, K.; Lukas, W.; April, R. Studies on the Vaporization. 1973, 33, 171–176. Available online: https://www.mindat.org/reference.php?id=2740281 (accessed on 26 January 2024).

- Zaytseva, L.L.; Konarev, M.I.; Velichko, A. V Lithium Pertechnetate and Perrhenate. Zhurnal Neorg. Khimii 1977, 22, 2348–2353. [Google Scholar]

- Lukas, W.; Chatillon, C.; Allibert, M. The Termodynamic Activity Od LiReO4, in the LiReO4-CsReO4 System as Determined by Mass Spectrometry. J. Less-Common Met. 1979, 66, 211–217. [Google Scholar] [CrossRef]

- Betz, T.; Hoppe, R. Über Perrhenate. 1. Zur Kenntnis von LiReO4. Z. Anorg. Und Allg. Chem. 1983, 500, 23–30. [Google Scholar] [CrossRef]

- Betz, T.; Hoppe, R. Zur Kenntnis von Li5ReO6 Und Na5ReO6—Mit Einer Bemerkung Uber Na5lO6. Z. Anorg. Und Allg. Chem. 1984, 512, 19–33. [Google Scholar] [CrossRef]

- Khrustalev, V.N.; Varfolomeev, M.B.; Shamrai, N.B.; Lindeman, S.V.; Struchkov, Y.T. Crystal Structure of Lithium Perrhenate Sesquihydrate. Zhurnal Neorg. Khimii 1995, 40, 208–213. [Google Scholar] [CrossRef]

- Abakumov, A.M.; Rozova, M.G.; Shpanchenko, R.V.; Mironov, A.V.; Antipov, E.V.; Bramnik, K.G. Synthesis and Crystal Structure of the Lithium Perrhenate Monohydrate LiReO4·H2O. Solid State Sci. 2001, 3, 581–586. [Google Scholar] [CrossRef]

- Marenich, A.V.; Solomonik, V.G. Nonempirical Study of Nuclear Dynamics in Nonrigid LiReO4 and K2SO4 Molecules. Zhurnal Strukt. Khimii 2002, 43, 899–907. [Google Scholar] [CrossRef]

- Burenin, A.V. Symmetry of Internal Dynamics and Separation of Motions in the Major Isomer of the LiReO4 Molecule. Opt. Spectrosc. 2004, 97, 176–183. [Google Scholar] [CrossRef]

- Ulbricht, V.K.; Kriegsmann, H. Spektroskopische Untersuchungen an Einigen Wasserfreien Perrhenaten. Z. Anorg. Und Allg. Chem. 1968, 358, 193–304. [Google Scholar] [CrossRef]

- Gaphurov, M.M.; Aliev, A.R. Spectroscopic Study of the Melting Features of Crystals with Molecular Anions. Raman Scatt. 2000, 4069, 43. [Google Scholar] [CrossRef]

- Vanderhevden, J.-L.E.; Su, F.-M.; Ehrhardt, G.J. Soluble Irradiation Targets and Methods for the Production of Radiorhenium—US5145636A 1991. Available online: https://worldwide.espacenet.com/patent/search/family/027023285/publication/US5145636A?q=US5145636A (accessed on 26 January 2024).

- Leszczyńska-Sejda, K.; Benke, G.; Anyszkiewicz, K. Use of Ion-Exchange Resins for Sorption of Ammonium Ions from Aqueous Solutions of Ammonium Perrhenate. Przem. Chem. 2008, 87, 289–295. [Google Scholar]

- Leszczyńska-Sejda, K.; Benke, G.; Ciszewski, M.; Drzazga, M. Technology to Produce High-Purity Anhydrous Rubidium Perrhenate on an Industrial Scale. Materials 2019, 12, 1130. [Google Scholar] [CrossRef] [PubMed]

- Leszczyńska-Sejda, K.; Benke, G.; Chmielarz, A.; Krompiec, S.; Michalik, S.; Krompiec, M. Synthesis of Perrhenic Acid Using Ion Exchange Method. Hydrometallurgy 2007, 89, 289–296. [Google Scholar] [CrossRef]

- Leszczyńska-Sejda, K.; Benke, G.; Chmielarz, A. Hydrometallurgical Methods for Production of Nickel(II) and Cobalt(II) Perrhenates—Semi-Products for Manufacture of Re-Ni, Re-Co Alloy Powders. Erzmetall 2013, 66, 267–273. [Google Scholar]

- Leszczyńska-Sejda, K.; Benke, G.; Krompiec, S.; Chmielarz, A.; Anyszkiewicz, K.; Gotfryd, L. Synthesis of Perrhenic Acid Using Solvent Extraction. Hydrometallurgy 2009, 95, 325–332. [Google Scholar] [CrossRef]

- Lewandowski, D.; Kozłowski, J.; Mikłasz, W. Sposób Recyklingu Baterii Wtórnych—PL 240110 B1 2017. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/a3b307c0e296f35de335e8a84244064b (accessed on 26 January 2024).

| Compound | Melting Point, °C | Solubility in Water, % | Density, g/cm3 | ||

|---|---|---|---|---|---|

| 0 °C | 30 °C | 50 °C | |||

| AgReO4 | 455.0 | 0.40 | 1.30 | 2.60 | 6.96 |

| Ni(ReO4)2 | - | - | 75.60 | - | - |

| Co(ReO4)2 | 816.0 | - | 74.90 | - | 5.33 |

| Fe(ReO4)3 | - | - | 73.00 | - | - |

| RbReO4 | 598.0 | 0.38 | 1.57 | 3.40 | 4.73 |

| CsReO4 | 616.0 | 0.41 | 1.38 | 2.95 | 4.76 |

| NH4ReO4 | - | 2.81 | 7.50 | 12.50 | - |

| LiReO4 | 426.0 | 74.50 | 80.30 | 80.30 | 4.61 |

| LiReO4·2H2O | 87.5 | 275.15 | 385.21 | 385.21 | 3.69 |

| Solution | pH | Concentration, g/dm3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Li | Ni | Co | Fe | Al | Cu | Mn | F | ||

| A | 6.0 | 14.0 | 0.2 | 0.5 | <0.01 | <0.01 | <0.01 | 0.2 | 2.4 |

| B | 3.2 | 3.2 | 15.8 | 30.2 | <0.01 | <0.01 | <0.01 | 4.5 | 1.1 |

| C | 3.3 | 2.8 | 7.5 | 8.5 | <0.01 | <0.01 | <0.01 | 6.4 | 1.2 |

| D | 1.3 | 2.9 | 15.2 | 30.5 | 1.2 | 2.1 | 2.5 | 6.5 | 0.9 |

| Type of Solution | Type of Lithium Carbonate | Concentration, g/dm3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Li | Ni | Co | Fe | Al | Cu | Mg | Ca | Mn | F | ||

| Solution A | Crude Li2CO3 | 18.6 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 2.00 | 0.05 | <0.01 | 0.1 |

| Li2CO3 after the 1st cycle | 18.7 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 0.28 | 0.02 | <0.01 | <0.01 | |

| Li2CO3 after the 2nd cycle | 18.7 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 0.18 | 0.01 | <0.01 | <0.01 | |

| Li2CO3 after the 3rd cycle | 18.7 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 0.20 | 0.01 | <0.01 | <0.01 | |

| Li2CO3 after the 4th cycle | 18.7 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 0.18 | 0.01 | <0.01 | <0.01 | |

| Li2CO3 after purification | 18.7 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | 0.10 | <0.01 | <0.01 | <0.01 | |

| Solution D | Crude Li2CO3 | 18.7 | 0.13 | 0.60 | 0.05 | <0.01 | 0.13 | 0.10 | <0.01 | 0.12 | 0.05 |

| Li2CO3 after the 1st cycle | 18.7 | <0.01 | 0.20 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | |

| Li2CO3 after the 2nd cycle | 18.7 | <0.01 | 0.15 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | |

| Li2CO3 after the 3rd cycle | 18.7 | <0.01 | 0.10 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | |

| Li2CO3 after the 4th cycle | 18.7 | <0.01 | 0.06 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | |

| Li2CO3 after purification | 18.7 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | |

| Concentration of Re in HReO4, g/dm3 | Volume of HReO4, cm3 | Final pH | Mass of Li2CO3, g | Mass of LiReO4, g | Precipitate Mass after Neutralization, g | Precipitation Efficiency of LiReO4·H2O, % |

|---|---|---|---|---|---|---|

| 18.4 | 1000 | 7.7 | 4.75 | 25.27 | 0.35 | 92.9 |

| 50.0 | 500 | 8.3 | 6.45 | 34.20 | 0.55 | 92.6 |

| 295.0 | 50 | 7.8 | 3.80 | 20.34 | 0.60 | 93.3 |

| Excess of Li2CO3, % | Final pH | Mass of Li2CO3, g | Mass of LiReO4·H2O, g | Precipitate Mass after Neutralization, g | Precipitation Efficiency of LiReO4·H2O, % |

|---|---|---|---|---|---|

| 0 | 7.7 | 4.02 | 24.40 | 0.22 | 89.70 |

| 30 | 7.7 | 4.75 | 25.27 | 0.35 | 92.90 |

| 40 | 8.5 | 5.11 | 23.98 | 0.40 | 88.20 |

| 90 | 9.3 | 6.94 | 24.52 | 0.60 | 90.20 |

| Excess of Li2CO3, % | Final pH | Mass of Li2CO3, g | Mass of LiReO4·H2O, g | Precipitate Mass after Neutralization, g | Precipitation Efficiency of LiReO4·H2O, % |

|---|---|---|---|---|---|

| 0 | 7.7 | 3.22 | 19.20 | 0.40 | 88.10 |

| 30 | 7.8 | 3.80 | 20.34 | 0.60 | 93.30 |

| 40 | 8.5 | 4.10 | 19.43 | 1.20 | 89.10 |

| 90 | 9.4 | 5.56 | 19.20 | 1.70 | 88.10 |

| Conditions for the Precipitation of LiReO4·H2O | Composition, % | |||||

|---|---|---|---|---|---|---|

| Re | Li | Ni | Co | Fe | Mg | |

| 30%, 295 g/dm3 Re, pH = 7.7 | 67.5 | 2.57 | <0.02 | <0.02 | <0.03 | <0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leszczyńska-Sejda, K.; Ochmański, M.; Palmowski, A.; Benke, G.; Grzybek, A.; Orda, S.; Goc, K.; Malarz, J.; Kopyto, D. Hydrometallurgical Method of Producing Lithium Perrhenate from Solutions Obtained during the Processing of Li-Ion Battery Scrap. Batteries 2024, 10, 151. https://doi.org/10.3390/batteries10050151

Leszczyńska-Sejda K, Ochmański M, Palmowski A, Benke G, Grzybek A, Orda S, Goc K, Malarz J, Kopyto D. Hydrometallurgical Method of Producing Lithium Perrhenate from Solutions Obtained during the Processing of Li-Ion Battery Scrap. Batteries. 2024; 10(5):151. https://doi.org/10.3390/batteries10050151

Chicago/Turabian StyleLeszczyńska-Sejda, Katarzyna, Michał Ochmański, Arkadiusz Palmowski, Grzegorz Benke, Alicja Grzybek, Szymon Orda, Karolina Goc, Joanna Malarz, and Dorota Kopyto. 2024. "Hydrometallurgical Method of Producing Lithium Perrhenate from Solutions Obtained during the Processing of Li-Ion Battery Scrap" Batteries 10, no. 5: 151. https://doi.org/10.3390/batteries10050151