Prognosis and Remaining Useful Life Estimation of Lithium-Ion Battery with Optimal Multi-Level Particle Filter and Genetic Algorithm

Abstract

:1. Introduction

2. Particle Filter Concept

2.1. Sequential Important Sampling (SIS)

2.2. Resampling Technique

2.3. Multi-Level Particle Filter (MPF)

- -

- for i = 1, 2, 3, …, ns samples;

- -

- ;

- -

- then set ;

- -

- estimate the importance weights using Equation (11) and normalize them;

- -

- the normalized important weights ;

- -

- randomly select a variable θ with values between 0 and 1;

- -

- find particles from such that ; NB: normalized weight is used;

- -

- the estimated particle: ;

- -

- end.

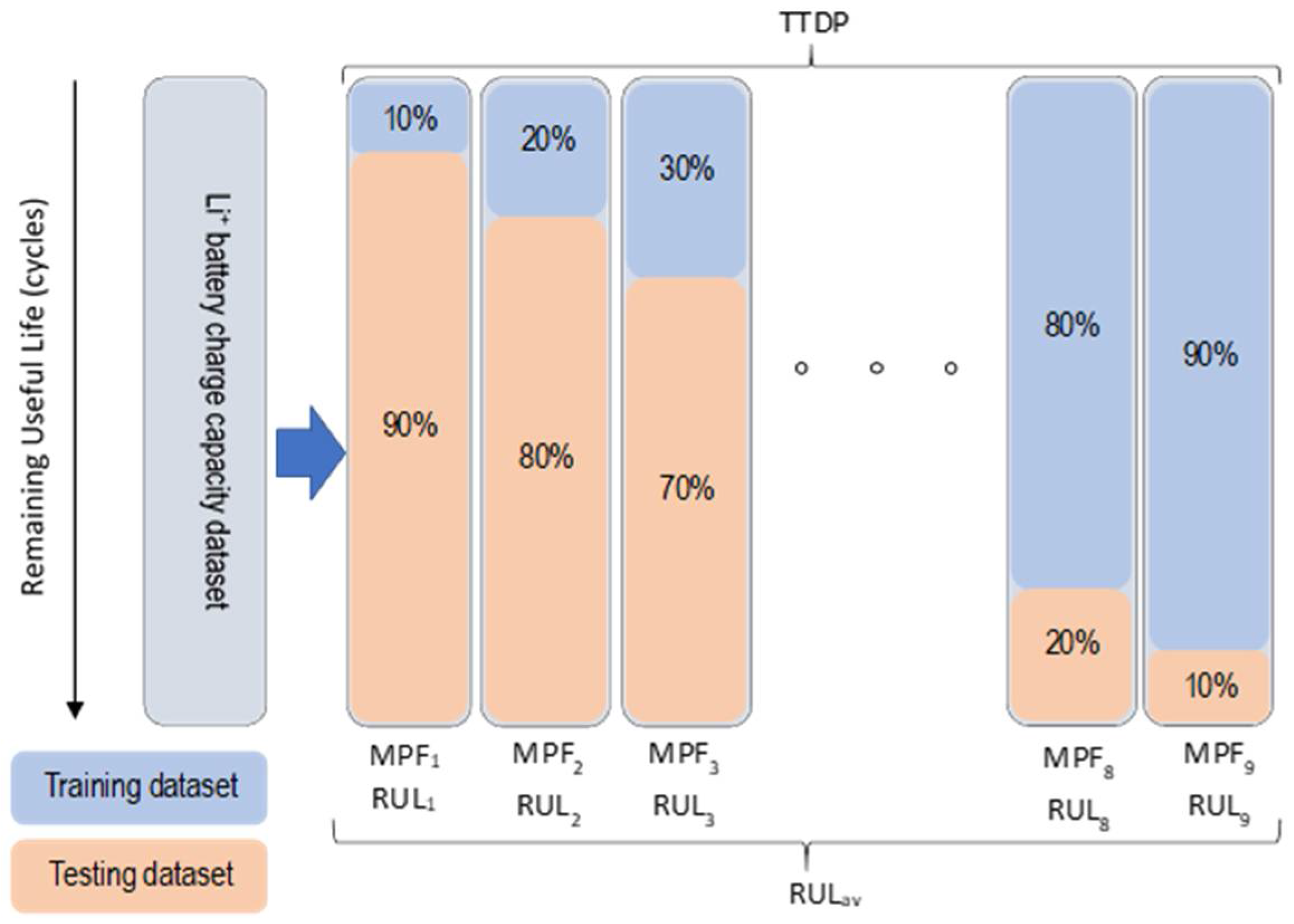

3. Framework for Optimal Multi-Level Particle Filter (OPMPF) Estimation

Genetic Algorithm (GA) for OPMPF Estimation

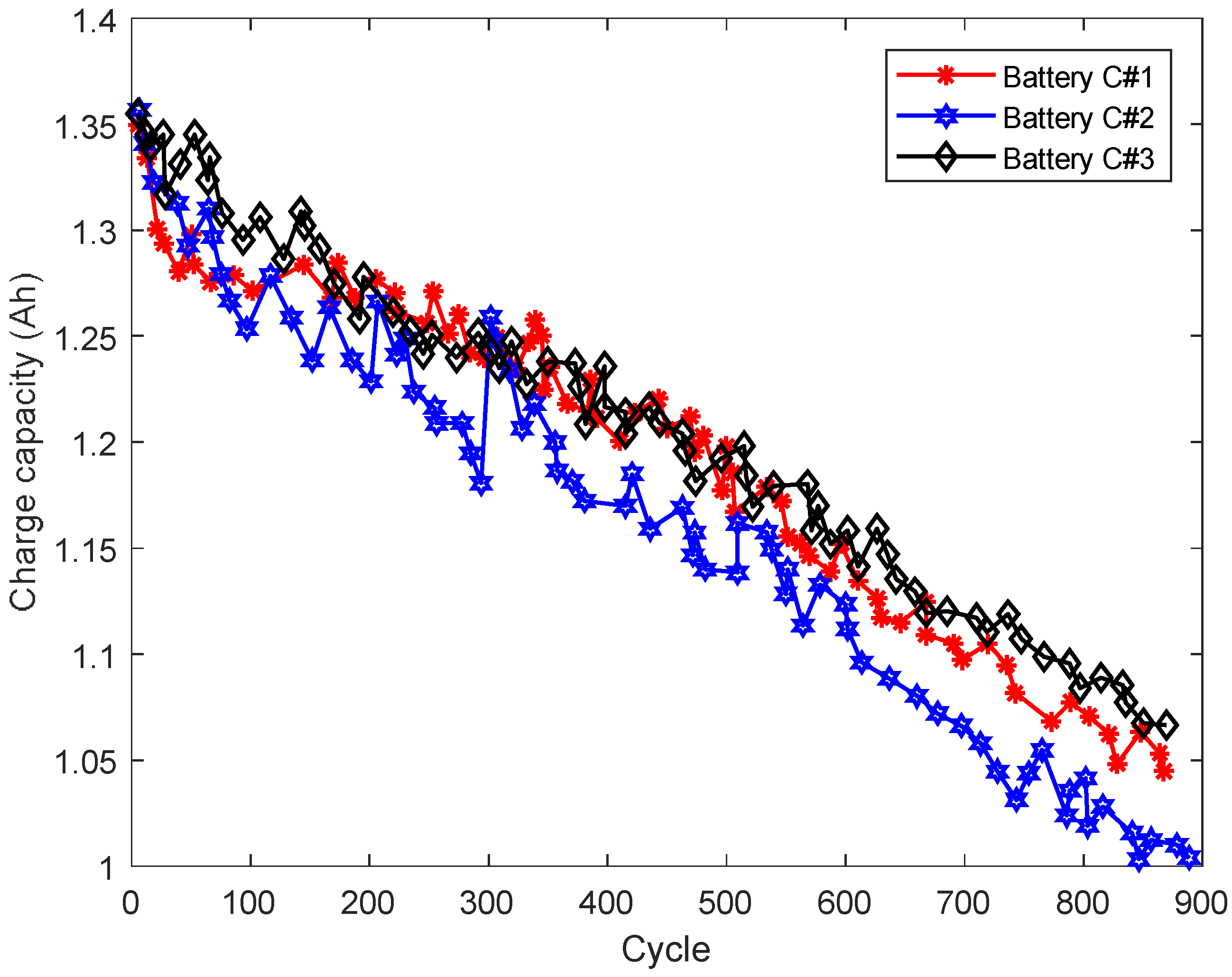

4. Illustrative Case Study of Lithium-Ion Battery Charge Capacity Decay

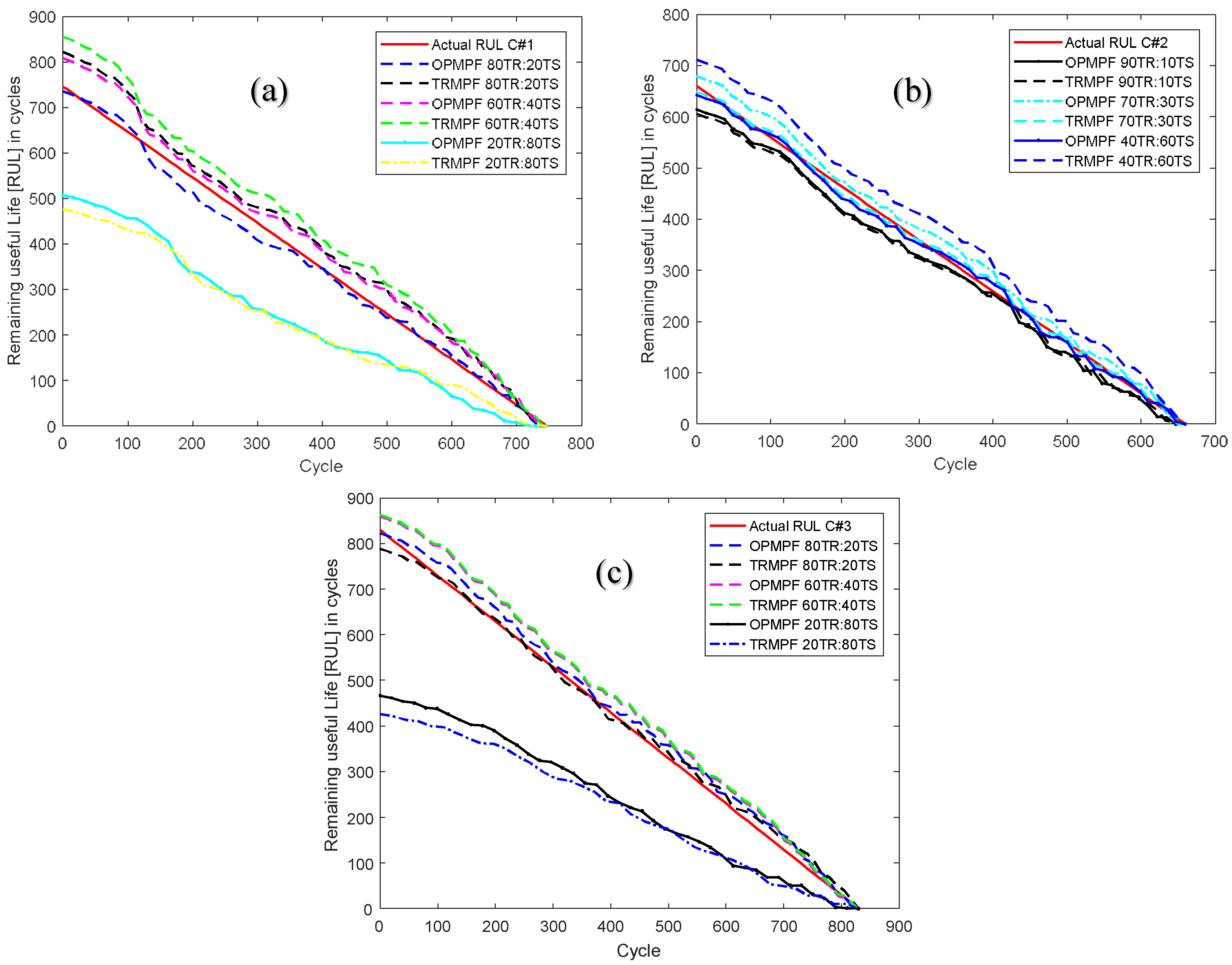

4.1. Lithium-Ion Battery Remaining Useful Life (RUL) Estimation

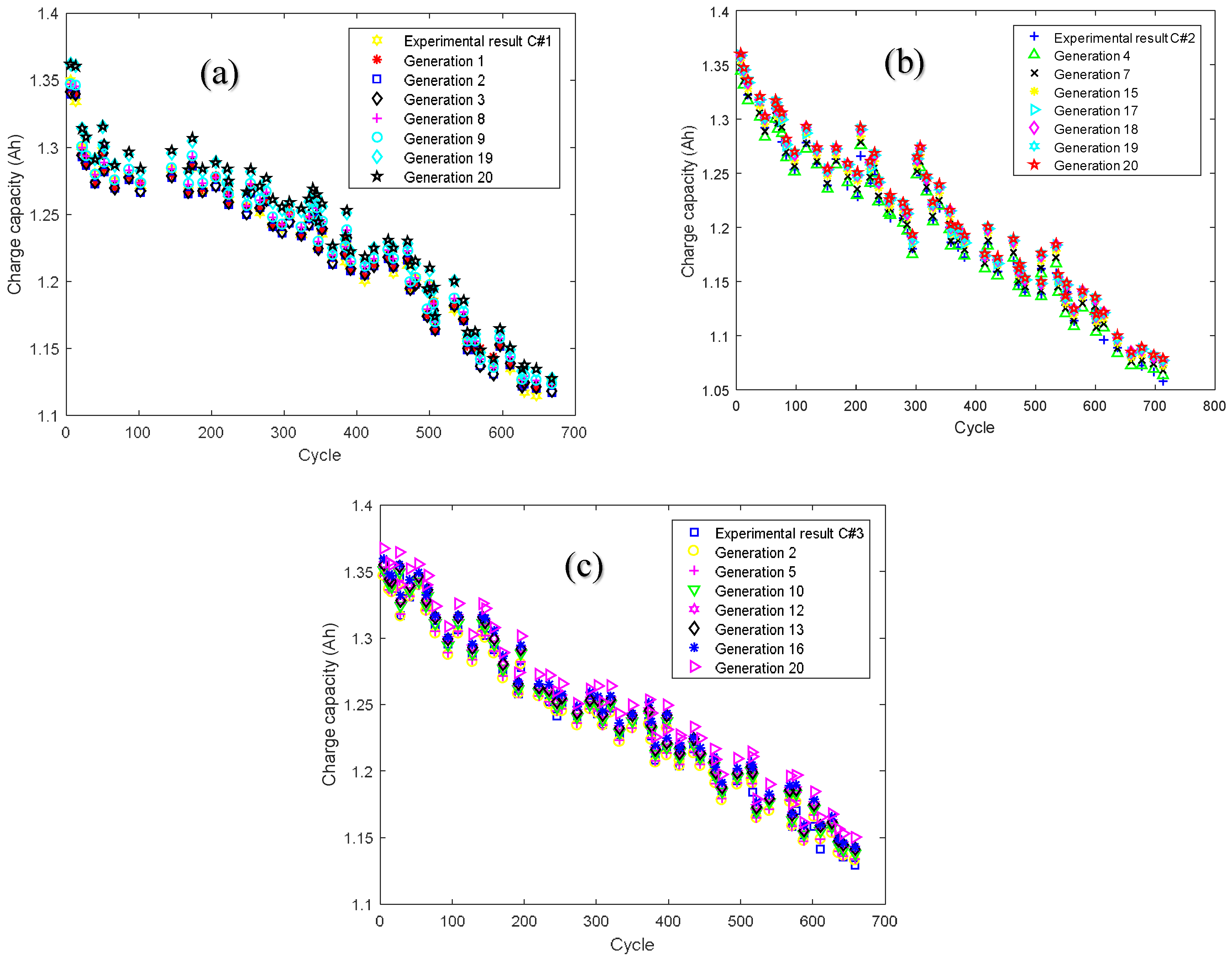

4.2. Decay Trend of GA-Estimated Lithium-Ion Battery Charge Capacity

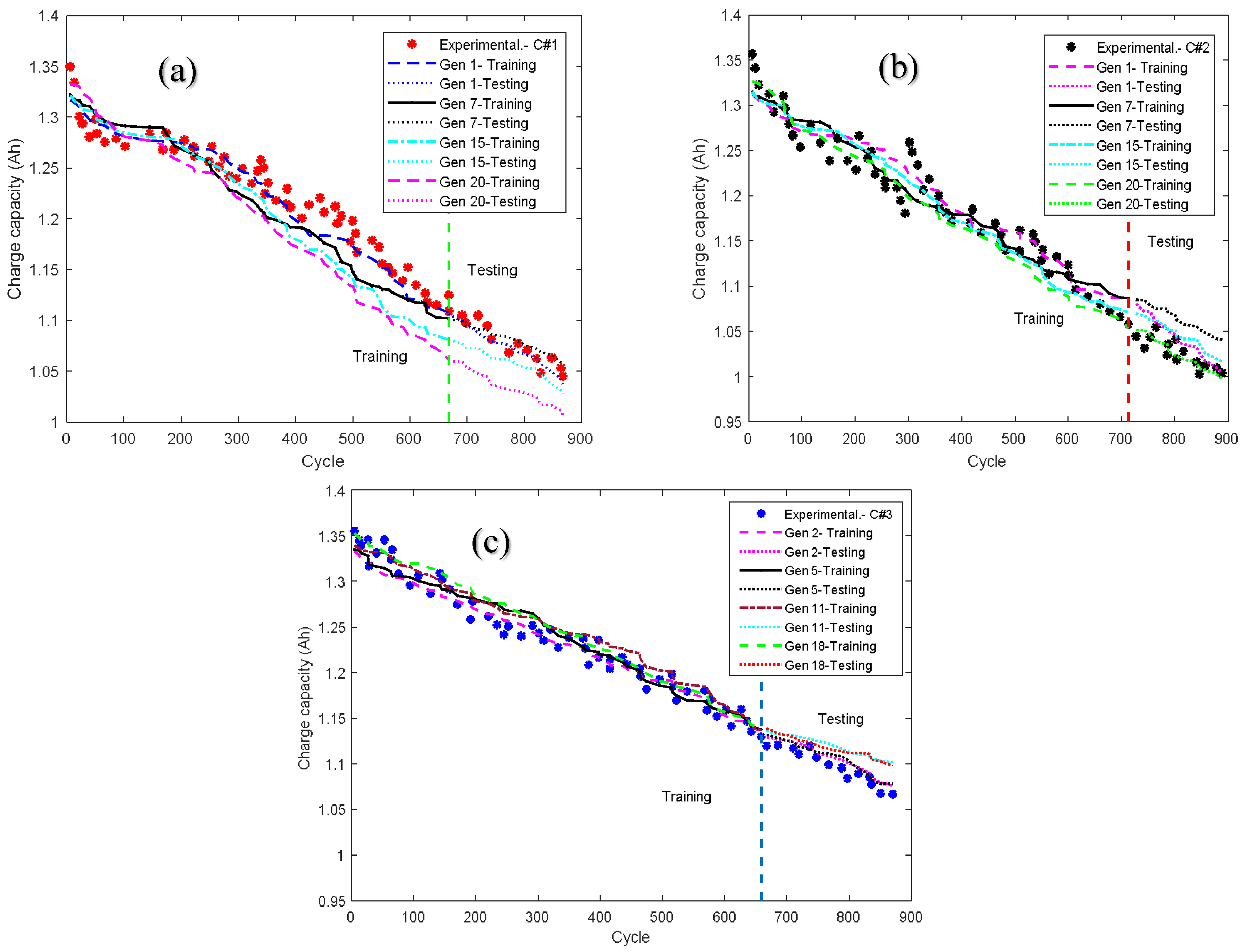

4.3. Lithium-Ion Battery RUL Estimation

5. Results and Discussion

6. Conclusions

Conflicts of Interest

References

- Tahan, M.; Tsoutsanis, E.; Muhammad, M.; Karim, Z.A. Performance-based health monitoring, diagnostics, and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy 2017, 198, 122–144. [Google Scholar] [CrossRef]

- Finn, J.; Wagner, J.; Bassily, H. Monitoring strategies for a combined cycle electric power generator. Appl. Energy 2010, 87, 2621–2627. [Google Scholar] [CrossRef]

- Dai, J.; Das, D.; Ohadi, M.; Pecht, M. Reliability risk mitigation of free air cooling through prognostics and health management. Appl. Energy 2013, 111, 104–112. [Google Scholar] [CrossRef]

- Dai, J.; Das, D.; Pecht, M. Prognostics-based risk mitigation for telecom equipment under free air cooling conditions. Appl. Energy 2012, 99, 423–429. [Google Scholar] [CrossRef]

- Lei, Y. Introduction and background. In Intelligent Fault Diagnosis and Remaining Useful Life Prediction of Rotating Machinery; Butterworth-Heinemann: Woburn, MA, USA, 2017; pp. 1–16. ISBN 9780128115343. [Google Scholar]

- Arora, P.; White, R.E.; Doyle, M. Capacity fade mechanisms and side reactions in lithium-ion batteries. J. Electrochem. Soc. 1998, 145, 3647–3667. [Google Scholar] [CrossRef]

- Yao, Y.; McDowell, M.T.; Ryu, I.; Wu, H.; Liu, N.; Hu, L.; Nix, W.D.; Cui, Y. Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett. 2011, 11, 2949–2954. [Google Scholar] [CrossRef] [PubMed]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Shai, D.; Chen, C.; Pooley, M.; D’Andrade, B.W. Prognostics for the Power Industry. In The Power Grid; Academic Press: New York, NY, USA, 2017; pp. 287–316. ISBN 9780128053218. [Google Scholar]

- Ocak, H.; Loparo, K.A.; Discenzo, F.M. Online tracking of bearing wear using wavelet packet decomposition and probabilistic modeling: A method for bearing prognostics. J. Sound Vib. 2007, 302, 951–961. [Google Scholar] [CrossRef]

- Roemer, M.J.; Ghiocel, D.M.; Rieger, N.F. A Probabilistic Approach to the Diagnosis of Gas Turbine Engine Faults. Cond. Monit. Diagn. Eng. Manag. 1998, 2, 767–776. [Google Scholar]

- Guan, X.; Liu, Y.; Jha, R.; Saxena, A.; Celaya, J.; Geobel, K. Comparison of two probabilistic fatigue damage assessment approaches using prognostic performance metrics. Int. J. Progn. Health Manag. 2011, 1, 005. [Google Scholar]

- Kacprzynski, G.J.; Roemer, M.J.; Modgil, G.; Palladino, A.; Maynard, K. Enhancement of physics-of-failure prognostic models with system level features. In Proceedings of the Aerospace Conference Proceedings, Big Sky, MT, USA, 9–16 March 2002; Volume 6, p. 6. [Google Scholar]

- Mendonça, P.L.; Bonaldi, E.L.; de Oliveira, L.E.L.; Lambert-Torres, G.; da Silva, J.G.B.; da Silva, L.E.B.; Salomon, C.P.; Santana, W.C.; Shinohara, A.H. Detection and modelling of incipient failures in internal combustion engine driven generators using Electrical Signature Analysis. Electr. Power Syst. Res. 2017, 149, 30–45. [Google Scholar] [CrossRef]

- Dong, M. A tutorial on nonlinear time-series data mining in engineering asset health and reliability prediction: Concepts, models, and algorithms. Math. Probl. Eng. 2010, 2010, 175936. [Google Scholar] [CrossRef]

- Tobon-Mejia, D.A.; Medjaher, K.; Zerhouni, N.; Tripot, G. A mixture of gaussians hidden markov model for failure diagnostic and prognostic. In Proceedings of the 2010 IEEE Conference on Automation Science and Engineering (CASE), Toronto, ON, Canada, 21–24 August 2010; pp. 338–343. [Google Scholar]

- Smyth, P. Hidden Markov models for fault detection in dynamic systems. Pattern Recognit. 1994, 27, 149–164. [Google Scholar] [CrossRef]

- Peng, Y.; Dong, M. A hybrid approach of HMM and grey model for age-dependent health prediction of engineering assets. Expert Syst. Appl. 2011, 38, 12946–12953. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- Widodo, A.; Yang, B.S. Machine health prognostics using survival probability and support vector machine. Expert Syst. Appl. 2011, 38, 8430–8437. [Google Scholar] [CrossRef]

- Kim, H.E.; Tan, A.C.; Mathew, J.; Kim, E.Y.; Choi, B.K. Machine Prognostics Based on Health State Estimation Using SVM; Springer: Berlin, Germany, 2008. [Google Scholar]

- Jiang, Y.; Wang, Y.; Wu, Y.; Sun, Q. Fault prognostic of electronics based on optimal multi-order particle filter. Microelectron. Reliab. 2016, 62, 167–177. [Google Scholar] [CrossRef]

- Sbarufatti, C.; Corbetta, M.; Giglio, M.; Cadini, F. Adaptive prognosis of lithium-ion batteries based on the combination of particle filters and radial basis function neural networks. J. Power Sources 2017, 344, 128–140. [Google Scholar] [CrossRef]

- Pan, P.; Schonfeld, D. Visual tracking using high-order particle filtering. IEEE Signal Process. Lett. 2011, 18, 51–54. [Google Scholar] [CrossRef]

- Li, T.; Wang, S.; Shi, J.; Ma, Z. An adaptive-order particle filter for remaining useful life prediction of aviation piston pumps. Chin. J. Aeronaut. 2017. [Google Scholar] [CrossRef]

- Orchard, M.E.; Hevia-Koch, P.; Zhang, B.; Tang, L. Risk measures for particle-filtering-based state-of-charge prognosis in lithium-ion batteries. IEEE Trans. Ind. Electron. 2013, 60, 5260–5269. [Google Scholar] [CrossRef]

- Hu, C.; Jain, G.; Tamirisa, P.; Gorka, T. Method for estimating capacity and predicting remaining useful life of lithium-ion battery. Appl. Energy 2014, 126, 182–189. [Google Scholar] [CrossRef]

- Ray, A.; Tangirala, S. Stochastic modeling of fatigue crack dynamics for on-line failure prognostics. IEEE Trans. Control Syst. Technol. 1996, 4, 443–451. [Google Scholar] [CrossRef]

- Orhan, E. Particle Filtering; Center for Neural Science, University of Rochester: Rochester, NY, USA, 2012; Volume 8. [Google Scholar]

- Tokdar, S.T.; Kass, R.E. Importance sampling: A review. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 54–60. [Google Scholar] [CrossRef]

- Geweke, J. Bayesian inference in econometric models using Monte Carlo integration. Econom. J. Econom. Soc. 1986, 57, 1317–1339. [Google Scholar] [CrossRef]

- Liu, J.S.; Chen, R. Sequential Monte Carlo methods for dynamic systems. J. Am. Stat. Assoc. 1998, 93, 1032–1044. [Google Scholar] [CrossRef]

- Schon, T.; Gustafsson, F.; Nordlund, P.J. Marginalized particle filters for mixed linear/nonlinear state-space models. IEEE Trans. Signal Process. 2005, 53, 2279–2289. [Google Scholar] [CrossRef]

- Orchard, M.E.; Vachtsevanos, G.J. A particle-filtering approach for on-line fault diagnosis and failure prognosis. Trans. Inst. Meas. Control 2009, 31, 221–246. [Google Scholar] [CrossRef]

- Xiao, Q.; Fang, Y.; Liu, Q.; Zhou, S. Online machine health prognostics based on modified duration-dependent hidden semi-Markov model and high-order particle filtering. Int. J. Adv. Manuf. Technol. 2017, 94, 1283–1297. [Google Scholar] [CrossRef]

- Alcantar, V.; Ledesma, S.; Aceves, S.M.; Ledesma, E.; Saldana, A. Optimization of type III pressure vessels using genetic algorithm and simulated annealing. Int. J. Hydrogen Energy 2017, 42, 20125–20132. [Google Scholar] [CrossRef]

- Sergeeva, M.; Delahaye, D.; Mancel, C.; Vidosavljevic, A. Dynamic airspace configuration by genetic algorithm. J. Traffic Transp. Eng. 2017, 4, 300–314. [Google Scholar] [CrossRef]

- Tsai, P.W.; Pan, J.S.; Chen, S.M.; Liao, B.Y.; Hao, S.P. Parallel cat swarm optimization. In Proceedings of the 2008 International Conference on Machine Learning and Cybernetics, Kunming, China, 12–15 July 2008; Volume 6, pp. 3328–3333. [Google Scholar]

- Tsai, P.W.; Pan, J.S.; Chen, S.M.; Liao, B.Y. Enhanced parallel cat swarm optimization based on the Taguchi method. Expert Syst. Appl. 2012, 39, 6309–6319. [Google Scholar] [CrossRef]

- Chen, S.M.; Huang, C.M. Generating weighted fuzzy rules from relational database systems for estimating null values using genetic algorithms. IEEE Trans. Fuzzy Syst. 2003, 11, 495–506. [Google Scholar] [CrossRef]

- Chen, S.M.; Kao, P.Y. TAIEX forecasting based on fuzzy time series, particle swarm optimization techniques and support vector machines. Inf. Sci. 2013, 247, 62–71. [Google Scholar] [CrossRef]

- Wang, H. Texture analysis method based on fractional Fourier entropy and fitness-scaling adaptive genetic algorithm for detecting left-sided and right-sided sensorineural hearing loss. Fundam. Inform. 2017, 151, 505–552. [Google Scholar] [CrossRef]

- Lu, S. A note on the weight of inverse complexity in improved hybrid genetic algorithm. J. Med. Syst. 2016, 40, 150. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Williard, N.; Osterman, M.; Pecht, M. Prognostics of lithium-ion batteries based on Dempster–Shafer theory and the Bayesian Monte Carlo method. J. Power Sources 2011, 196, 10314–10321. [Google Scholar] [CrossRef]

- Mo, B.; Yu, J.; Tang, D.; Liu, H. A remaining useful life prediction approach for lithium-ion batteries using Kalman filter and an improved particle filter. In Proceedings of the 2016 IEEE International Conference on Prognostics and Health Management (ICPHM), Ottawa, ON, Canada, 20–22 June 2016; pp. 1–5. [Google Scholar]

- Xing, Y.; Ma, E.W.; Tsui, K.L.; Pecht, M. An ensemble model for predicting the remaining useful performance of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 811–820. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. Modeling Li-ion battery capacity depletion in a particle filtering framework. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September–1 October 2009; pp. 2909–2924. [Google Scholar]

- Miao, Q.; Xie, L.; Cui, H.; Liang, W.; Pecht, M. Remaining useful life prediction of lithium-ion battery with unscented particle filter technique. Microelectron. Reliab. 2013, 53, 805–810. [Google Scholar] [CrossRef]

| Genetic Algorithm Generations | Battery C#1 | Battery C#2 | Battery C#3 | |||

|---|---|---|---|---|---|---|

| MAE | MAPE (%) | MAE | MAPE (%) | MAE | MAPE (%) | |

| 1 | 0.012542 | 1.0262 | 0.014126 | 1.1692 | 0.009827 | 0.7885 |

| 2 | 0.012780 | 1.0494 | 0.013663 | 1.1326 | 0.009964 | 0.8084 |

| 3 | 0.012692 | 1.0426 | 0.013521 | 1.1211 | 0.010006 | 0.8123 |

| 4 | 0.012692 | 1.0426 | 0.013590 | 1.1267 | 0.009875 | 0.8022 |

| 5 | 0.012693 | 1.0427 | 0.013614 | 1.1290 | 0.009932 | 0.8066 |

| 6 | 0.012472 | 1.0240 | 0.013190 | 1.0919 | 0.010561 | 0.8568 |

| 7 | 0.012583 | 1.0327 | 0.013432 | 1.1102 | 0.010215 | 0.8281 |

| 8 | 0.012591 | 1.0334 | 0.013410 | 1.1083 | 0.010224 | 0.8287 |

| 9 | 0.012512 | 1.0268 | 0.013429 | 1.1091 | 0.010210 | 0.8275 |

| 10 | 0.012539 | 1.0287 | 0.013446 | 1.1114 | 0.010172 | 0.8243 |

| 11 | 0.012437 | 1.0201 | 0.013350 | 1.1032 | 0.010081 | 0.8158 |

| 12 | 0.012690 | 1.0398 | 0.013484 | 1.1112 | 0.009742 | 0.7879 |

| 13 | 0.012690 | 1.0398 | 0.013478 | 1.1107 | 0.009742 | 0.7879 |

| 14 | 0.012648 | 1.0357 | 0.013847 | 1.1398 | 0.009795 | 0.7907 |

| 15 | 0.012585 | 1.0306 | 0.013723 | 1.1292 | 0.009771 | 0.7888 |

| 16 | 0.012454 | 1.0194 | 0.013779 | 1.1333 | 0.009680 | 0.7812 |

| 17 | 0.012967 | 1.0583 | 0.013960 | 1.1443 | 0.010447 | 0.8396 |

| 18 | 0.013049 | 1.0647 | 0.013625 | 1.1170 | 0.010437 | 0.8389 |

| 19 | 0.013126 | 1.0714 | 0.013863 | 1.1355 | 0.010392 | 0.8352 |

| 20 | 0.013250 | 1.0810 | 0.013605 | 1.1133 | 0.010576 | 0.8499 |

| Generations | Battery C#1 | Battery C#2 | Battery C#3 | |||

|---|---|---|---|---|---|---|

| Training | Testing | Training | Testing | Training | Testing | |

| RMPSE (%) | RMPSE (%) | RMPSE (%) | RMPSE (%) | RMPSE (%) | RMPSE (%) | |

| 1 | 1.0119 | 1.4345 | 1.6339 | 2.0210 | 1.2979 | 0.9196 |

| 2 | 2.2817 | 1.7134 | 1.7442 | 1.1866 | 0.9316 | 0.8407 |

| 3 | 2.1552 | 1.0190 * | 1.6275 | 2.9504 | 1.0506 | 2.5433 |

| 4 | 2.9195 | 3.0299 | 1.8242 | 0.9584 * | 0.9463 | 0.7707 |

| 5 | 2.3627 | 2.4592 | 1.6717 | 1.3328 | 1.0331 | 0.9112 |

| 6 | 2.4744 | 2.4617 | 1.6797 | 3.4521 | 1.0659 | 1.8295 |

| 7 | 2.7419 | 1.1883 | 1.6813 | 3.7837 | 0.8799 | 2.8126 |

| 8 | 2.4283 | 2.0409 | 1.5439 | 2.6058 | 1.0385 | 1.8660 |

| 9 | 2.3687 | 1.5284 | 1.5756 | 3.5130 | 1.0959 | 2.7003 |

| 10 | 4.8160 | 5.3376 | 2.7919 | 1.1718 | 1.7588 | 1.0078 |

| 11 | 1.8373 | 1.5030 | 1.7296 | 3.3415 | 1.1747 | 2.1394 |

| 12 | 3.9640 | 4.7354 | 2.0801 | 1.1794 | 1.2603 | 0.6644 |

| 13 | 2.6407 | 1.8496 | 1.7156 | 2.8668 | 1.1547 | 2.1764 |

| 14 | 1.6035 | 1.6166 | 1.8933 | 2.7728 | 1.7223 | 2.2987 |

| 15 | 2.7887 | 2.0031 | 1.6621 | 2.1270 | 1.0690 | 1.6782 |

| 16 | 2.9095 | 4.0364 | 1.6345 | 1.2570 | 1.1555 | 0.4609 |

| 17 | 2.2468 | 2.4977 | 1.6312 | 1.2087 | 1.4299 | 1.1629 |

| 18 | 2.1851 | 1.3490 | 1.6992 | 3.3097 | 1.1238 | 2.0182 |

| 19 | 2.4045 | 2.6096 | 1.7789 | 1.5067 | 1.3861 | 0.7031 * |

| 20 | 3.5188 | 3.9359 | 1.8373 | 0.9990 | 1.3124 | 1.2113 |

| Training/Testing Dataset Partitions (TTDP) | Battery C#1 | Battery C#2 | Battery C#3 | |||

|---|---|---|---|---|---|---|

| OPMPF | TRMPF | OPMPF | TRMPF | OPMPF | TRMPF | |

| 90:10 | 0.4798 | 9.028 | 1.0752 | 2.3793 | 0.5422 | 9.4759 |

| 80:20 | 1.0191 | 7.4073 | 0.9756 | 2.1281 | 0.4413 | 8.2846 |

| 70:30 | 1.159 | 11.0494 | 1.0518 | 5.7559 | 0.7156 | 11.8412 |

| 60:40 | 1.0437 | 11.8767 | 1.1141 | 9.3161 | 0.652 | 12.6843 |

| 50:50 | 1.2067 | 13.2404 | 1.219 | 8.7671 | 0.8023 | 12.1215 |

| 40:60 | 0.9692 | 13.4266 | 0.9435 | 10.8667 | 1.0859 | 15.5847 |

| 30:70 | 0.8164 | 12.7947 | 1.6497 | 11.3206 | 1.5076 | 17.0099 |

| 20:80 | 7.5976 | 27.6519 | 7.3983 | 12.0204 | 11.8386 | 31.4732 |

| 10:90 | 7.855 | 33.1341 | 9.6566 | 14.6807 | 1.4086 | 20.922 |

| RMSPEav (%) | 2.4607 | 15.5121 | 2.7871 | 8.5817 | 2.1105 | 15.4886 |

| Standard deviation | 2.8224 | 8.2709 | 3.1203 | 4.0882 | 3.4572 | 6.7322 |

| Experimental Result | ||||||

|---|---|---|---|---|---|---|

| Battery | C#1 | C#2 | C#3 | |||

| 80% EOL failure cycle | 746 | 660 | 830 | |||

| OPMPF and TRMPF predictions RUL at different Training (TR) and Testing (TS) datasets partitions | ||||||

| Training/Testing Dataset Partition (TTDP):TR:TS | C#1 | C#2 | C#3 | |||

| OPMPF | TRMPF | OPMPF | TRMPF | OPMPF | TRMPF | |

| 90:10 | 738 | 630 | 614 | 606 | 822 | 788 |

| 80:20 | 736 | 821 | 626 | 746 | 834 | n/a |

| 70:30 | 824 | 737 | 679 | 649 | 860 | 863 |

| 60:40 | 808 | 856 | 694 | 666 | 835 | n/a |

| 50:50 | 790 | n/a | 700 | 783 | 815 | n/a |

| 40:60 | 789 | n/a | 642 | 711 | 823 | 854 |

| 30:70 | 767 | n/a | 714 | n/a | 830 | n/a |

| 20:80 | 508 | 476 | n/a | n/a | 466 | 426 |

| 10:90 | 539 | 345 | 500 | n/a | n/a | n/a |

| RULav (cycle) | 722 | 644 | 646 | 694 | 786 | 733 |

| Standard deviation | 110 | 184 | 65 | 60 | 121 | 179 |

| Difference | 24 | 102 | 14 | −34 | 44 | 97 |

| % variation | 3.20% | 13.65% | 2.10% | −5.08% | 5.35% | 11.72% |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ossai, C.I. Prognosis and Remaining Useful Life Estimation of Lithium-Ion Battery with Optimal Multi-Level Particle Filter and Genetic Algorithm. Batteries 2018, 4, 15. https://doi.org/10.3390/batteries4020015

Ossai CI. Prognosis and Remaining Useful Life Estimation of Lithium-Ion Battery with Optimal Multi-Level Particle Filter and Genetic Algorithm. Batteries. 2018; 4(2):15. https://doi.org/10.3390/batteries4020015

Chicago/Turabian StyleOssai, Chinedu I. 2018. "Prognosis and Remaining Useful Life Estimation of Lithium-Ion Battery with Optimal Multi-Level Particle Filter and Genetic Algorithm" Batteries 4, no. 2: 15. https://doi.org/10.3390/batteries4020015