DC Bus Voltage Stabilization and SOC Management Using Optimal Tuning of Controllers for Supercapacitor Based PV Hybrid Energy Storage System

Abstract

:1. Introduction

- A novel TI control scheme is proposed for the DC bus voltage stabilization of the battery and supercapacitor-based HESS.

- Its performance was compared with that of integer-order PI and fractional-order PI controllers to demonstrate the feasibility of the proposed TI controller.

- To present the robustness of the proposed controller by subjecting it to varying input (irradiance and temperature) and load conditions.

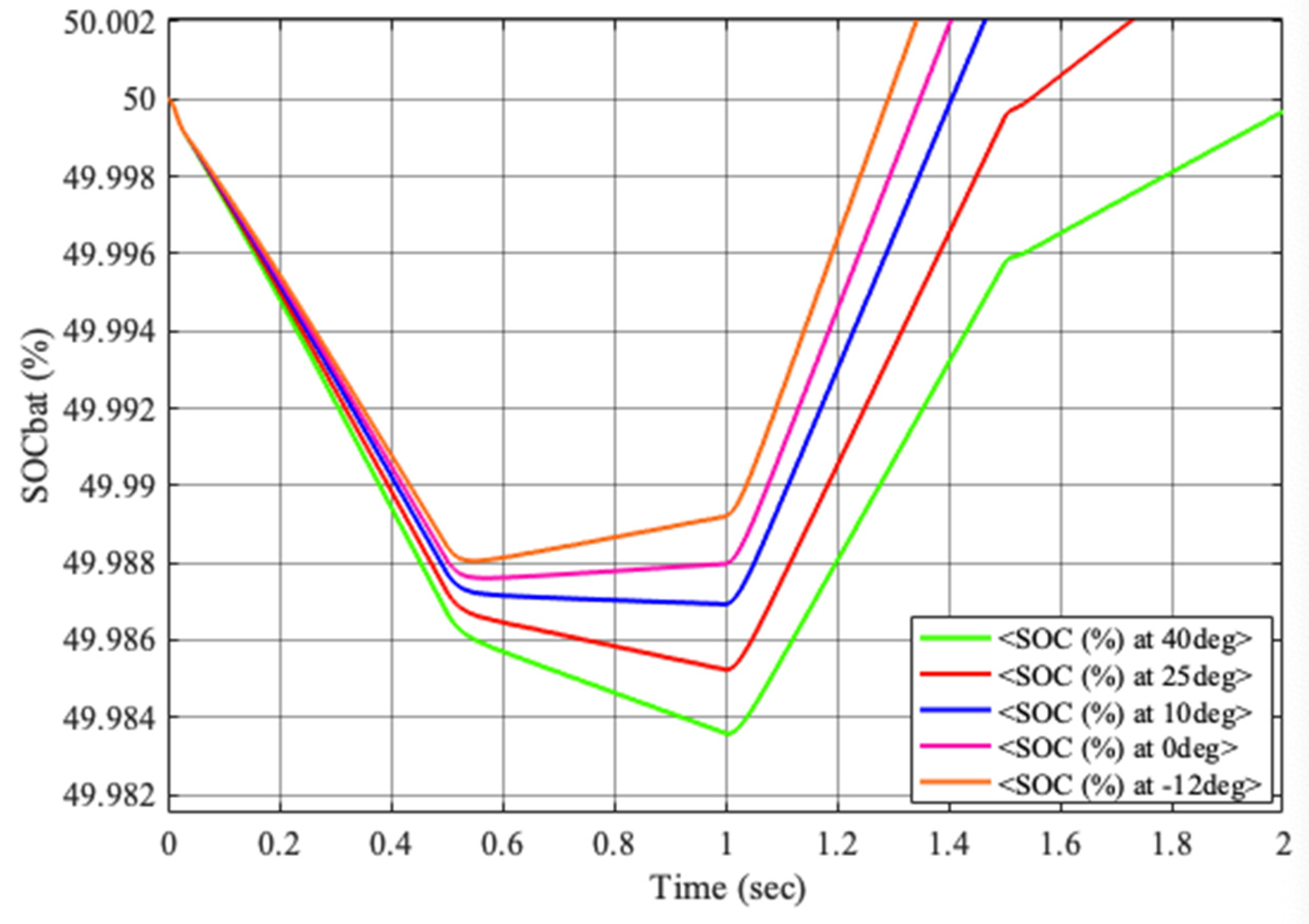

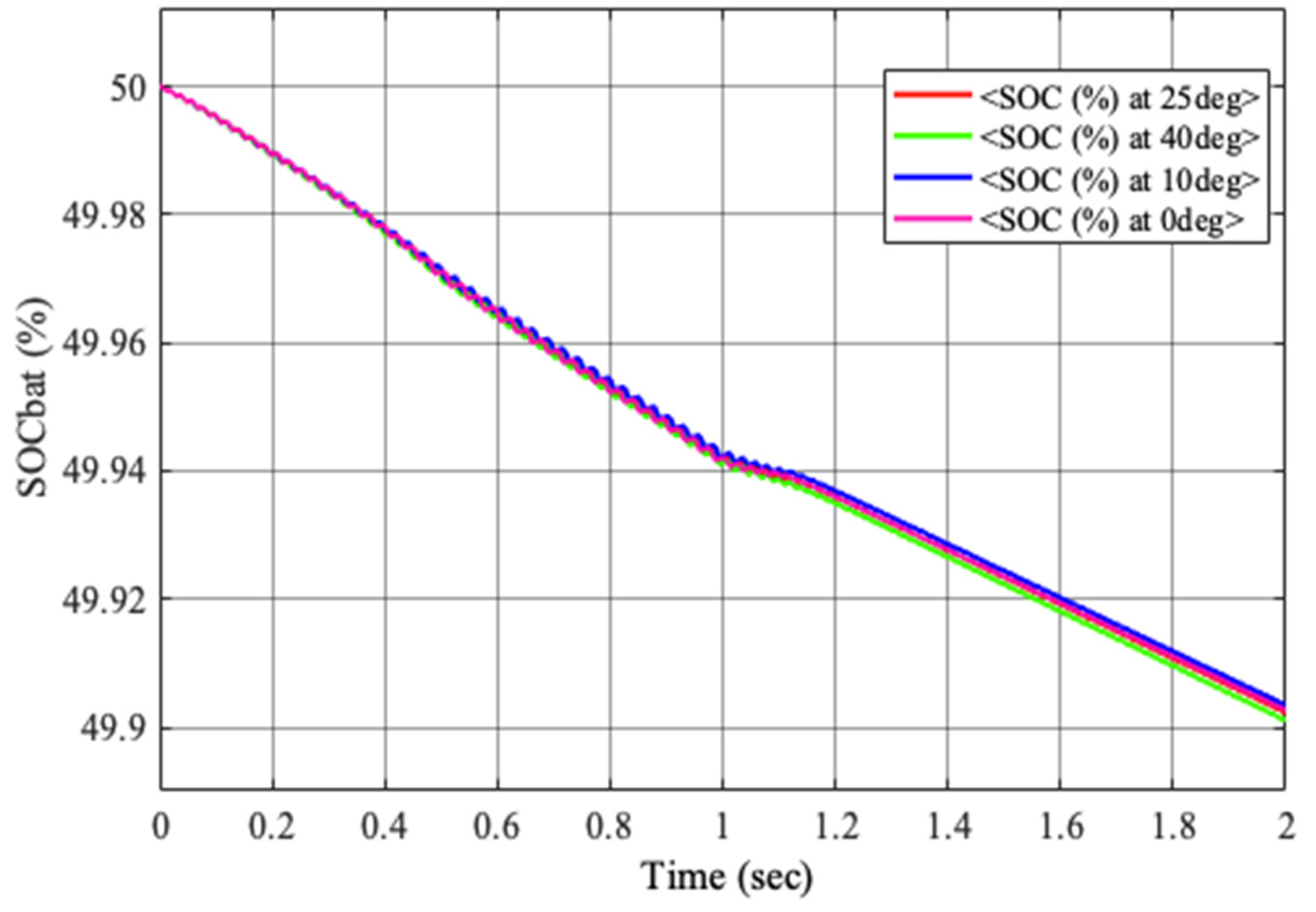

- To estimate the amount of SOC consumed in the battery under varying temperature conditions and determine the effectiveness of the controller performance in reducing stress on the battery.

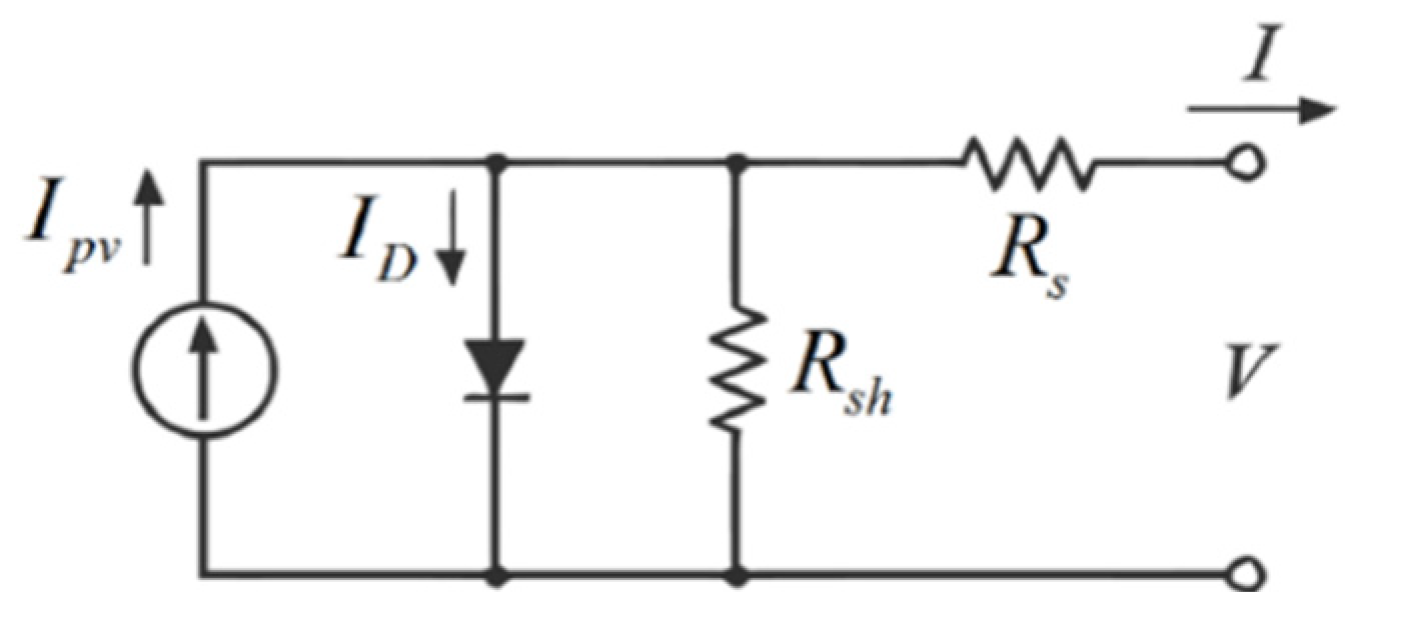

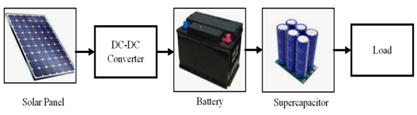

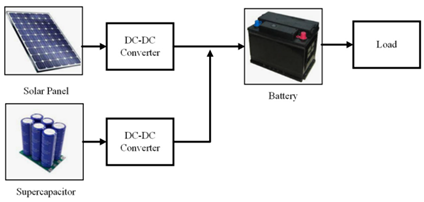

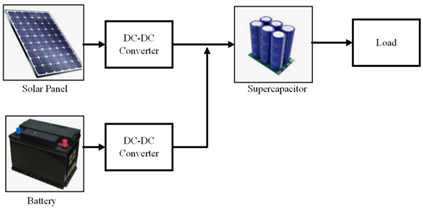

2. Modeling and System Configuration

- A PV panel is the main source of energy.

- A battery is used in the case of a surplus/deficiency of energy harvesting from the PV system.

- A supercapacitor limits the PV/load variation and assists the battery in the case of sudden fluctuations.

3. Proposed Control Scheme for PV Power System

3.1. PI Controller

3.2. FOPI Controller

3.3. TI Controller

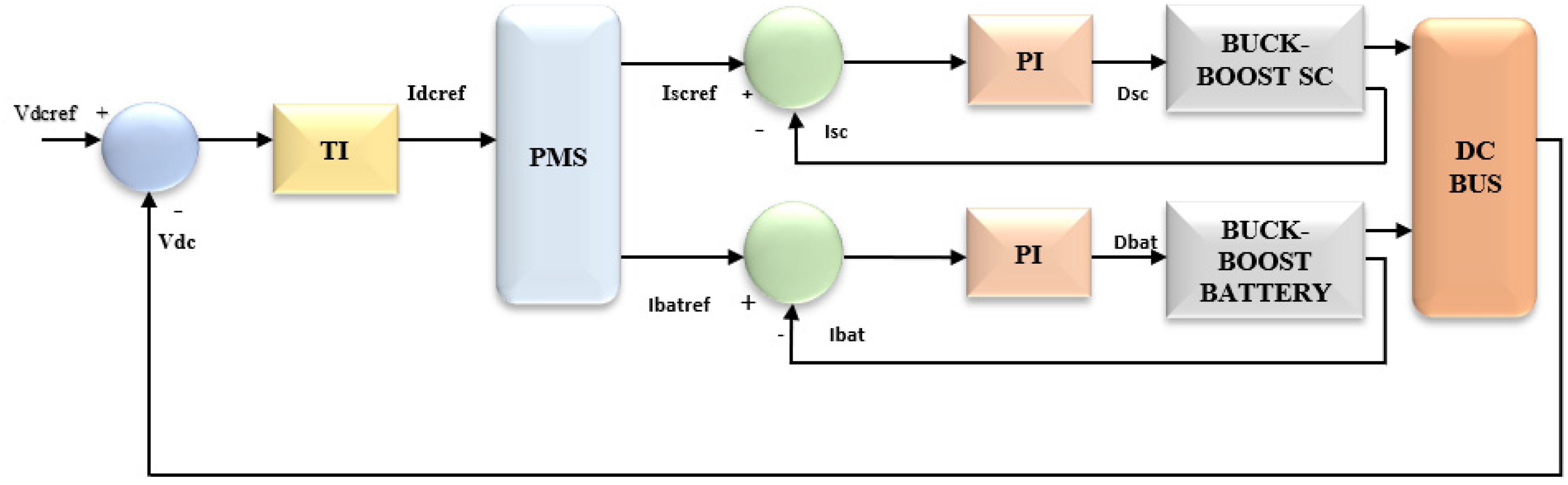

3.4. Control Strategy to Stabilize the DC Bus Voltage

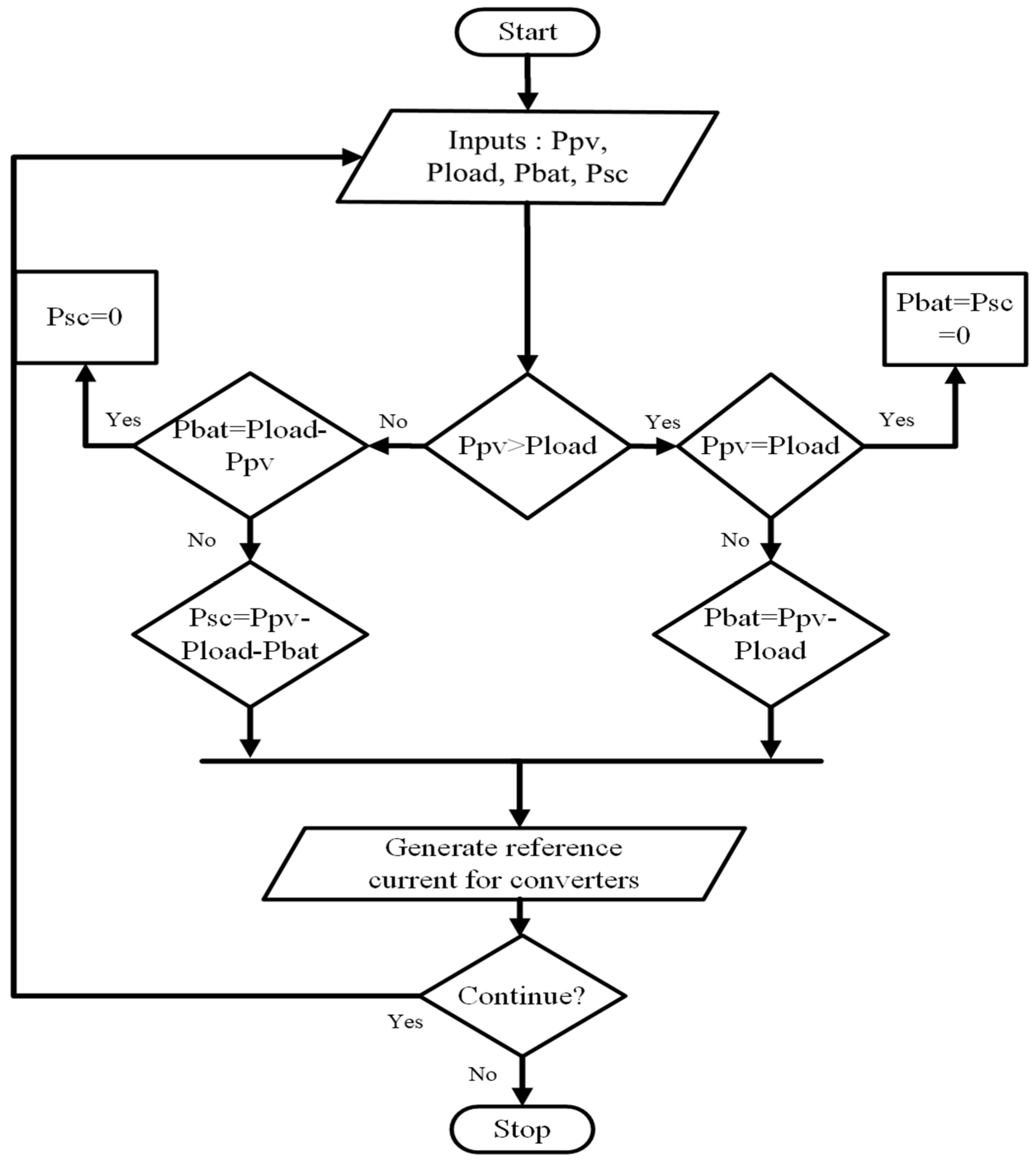

3.5. PMS and Control Scheme

3.6. Optimization Based Controller Tuning

4. Results and Discussion

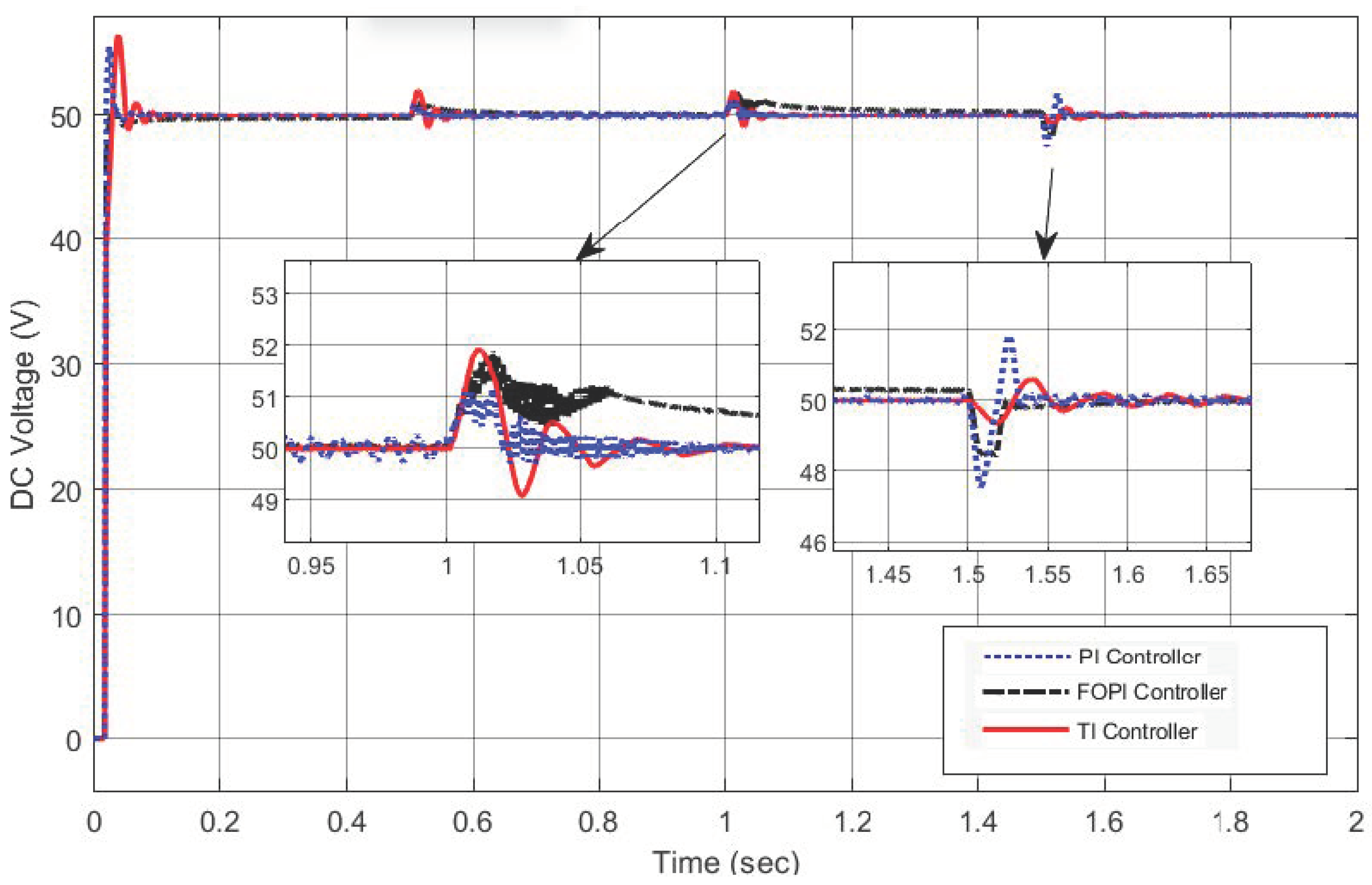

4.1. Dynamic Performance Evaluation of the Controllers

4.2. Robustness Analysis of the Proposed Controller

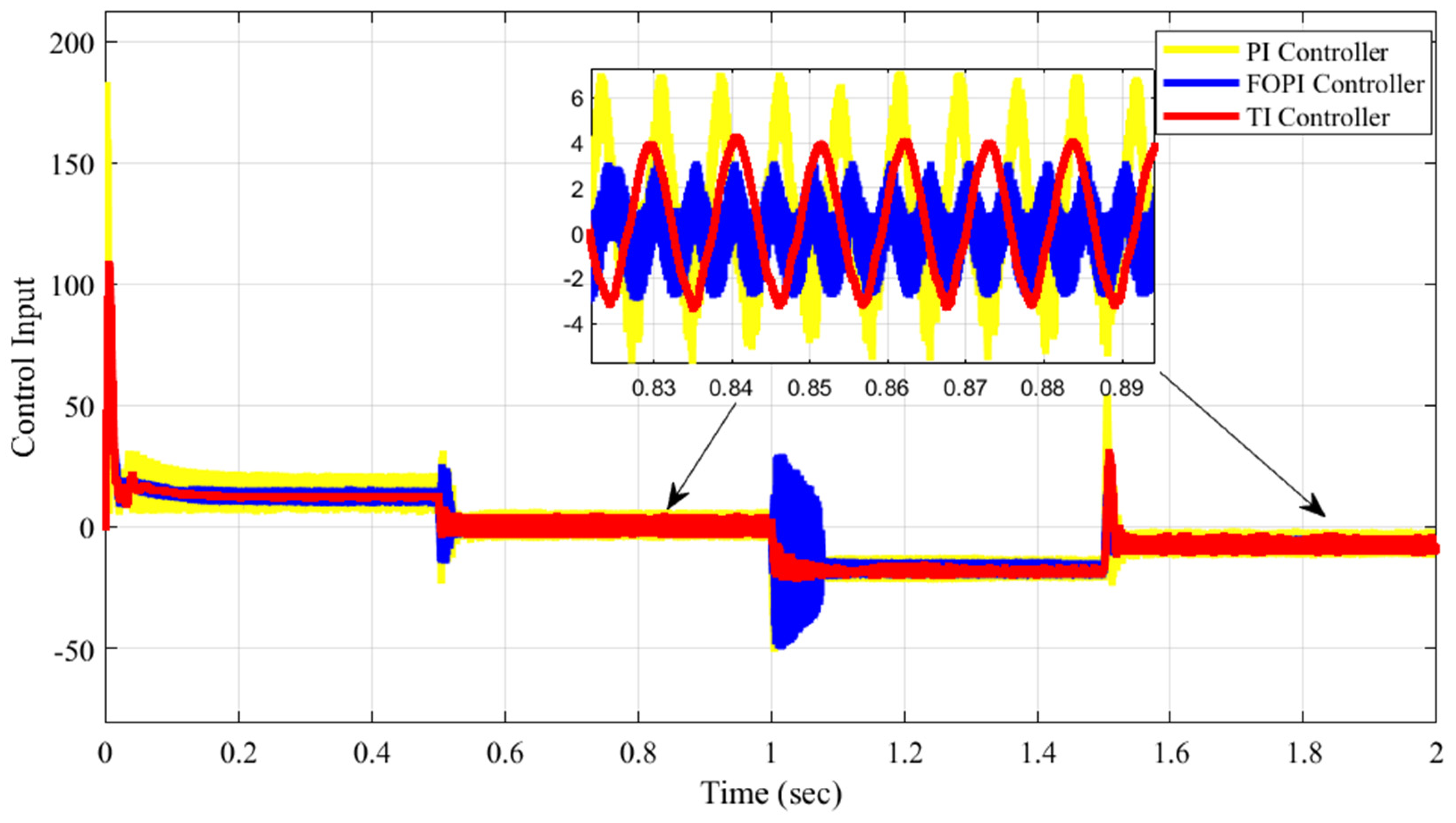

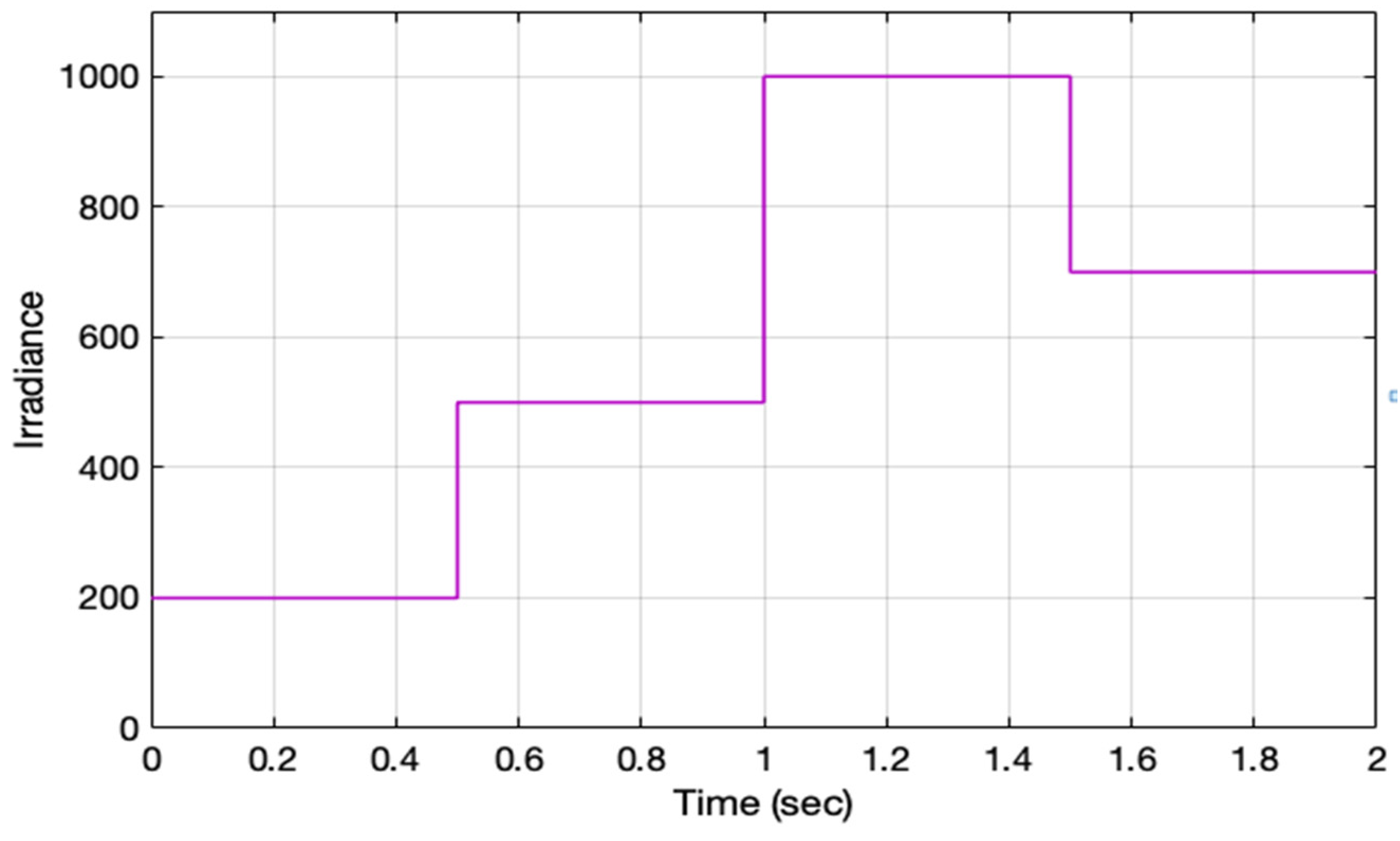

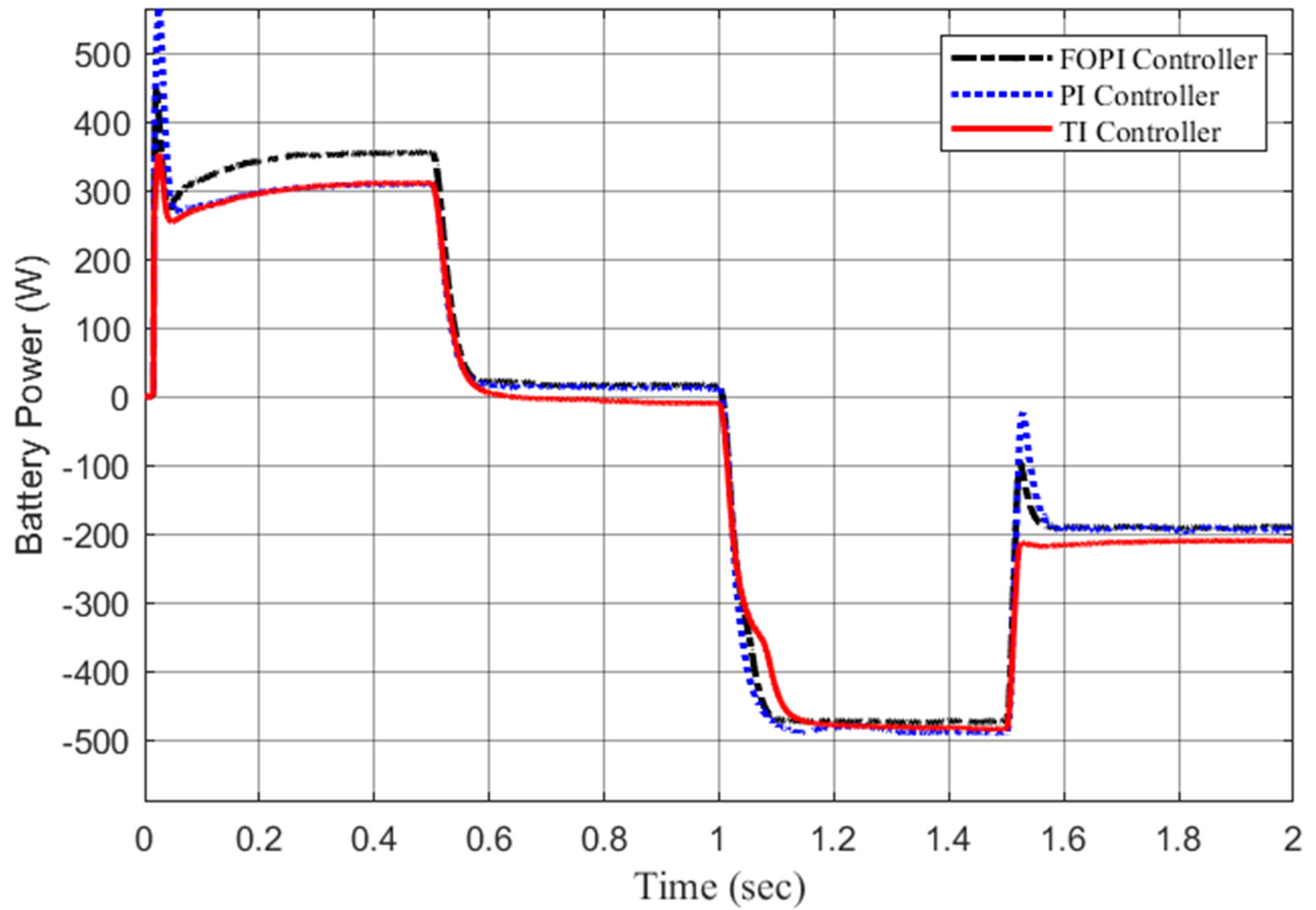

4.2.1. Analysis with Varying Solar Irradiance and Load

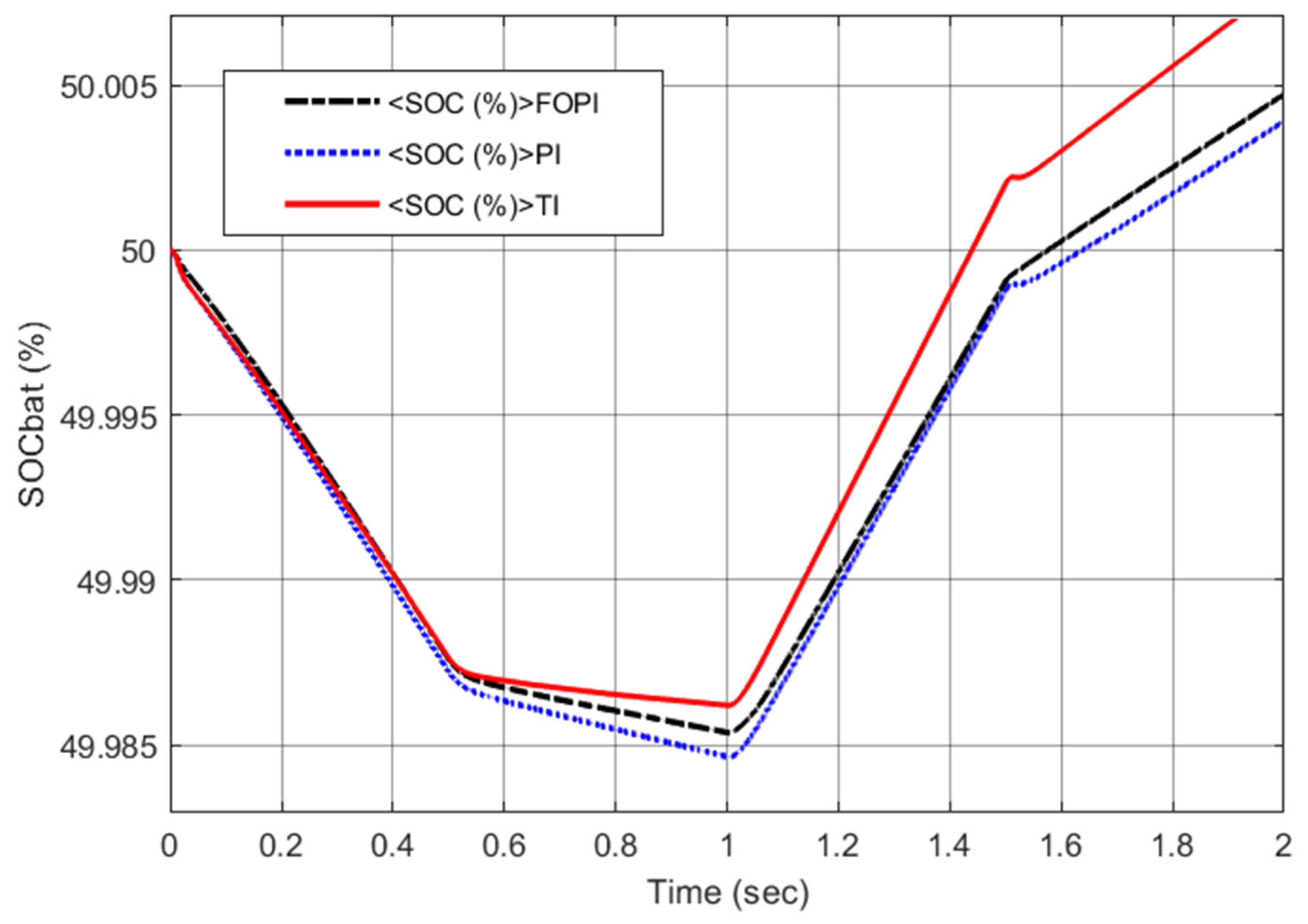

4.2.2. Analysis with Varying Temperature and Estimating the SOC Consumption

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ustun, T.S.; Hashimoto, J.; Otani, K. Impact of Smart Inverters on Feeder Hosting Capacity of Distribution Networks. IEEE Access 2019, 7, 163526–163536. [Google Scholar] [CrossRef]

- Singh, N.K.; Koley, C.; Gope, S.; Dawn, S.; Ustun, T.S. An Economic Risk Analysis in Wind and Pumped Hydro Energy Storage Integrated Power System Using Meta-Heuristic Algorithm. Sustainability 2021, 13, 13542. [Google Scholar] [CrossRef]

- Zaheeruddin; Munish, M. Renewable energy management through microgrid central controller design: An approach to integrate solar, wind and biomass with battery. Energy Rep. 2015, 1, 156–163. [Google Scholar] [CrossRef] [Green Version]

- Dey, P.P.; Das, D.C.; Latif, A.; Hussain, S.M.S.; Ustun, T.S. Active Power Management of Virtual Power Plant under Penetration of Central Receiver Solar Thermal-Wind Using Butterfly Optimization Technique. Sustainability 2020, 12, 6979. [Google Scholar] [CrossRef]

- Latif, A.; Hussain, S.S.; Das, D.C.; Ustun, T.S. Double stage controller optimization for load frequency stabilization in hybrid wind-ocean wave energy based maritime microgrid system. Appl. Energy 2021, 282, 116171. [Google Scholar] [CrossRef]

- Barbour, E.; Grant Wilson, I.A.; Radcliffe, J.; Ding, Y.; Li, Y. A review of pumped hydro energy storage development in significant international electricity markets. Renew. Sustain. Energy Rev. 2016, 61, 421–432. [Google Scholar] [CrossRef] [Green Version]

- Cengiz, M.S.; Mamiş, M.S. Price-efficiency relationship for photovoltaic systems on a global basis. Int. J. Photoenergy 2015, 2015, 256101. [Google Scholar] [CrossRef] [Green Version]

- Ustun, T.S.; Aoto, Y.; Hashimoto, J.; Otani, K. Optimal PV-INV Capacity Ratio for Residential Smart Inverters Operating Under Different Control Modes. IEEE Access 2020, 8, 116078–116089. [Google Scholar] [CrossRef]

- Nadeem, F.; Hussain, S.M.S.; Tiwari, P.K.; Goswami, A.K.; Ustun, T.S. Review of Smart and Innovative Energy Storage Systems. In Proceedings of the International Conference on Vision Towards Emerging Trends in Communication and Networking (ViTECoN), Vellore, India, 30–31 March 2019; pp. 1–6. [Google Scholar]

- Diouf, B.; Pode, R. Potential of lithium-ion batteries in renewable energy. Renew. Energy 2015, 76, 375–380. [Google Scholar]

- Filomeno, M.V.; Pedro, S.M.; Aníbal, T.A. Energy storage system for self-consumption of photovoltaic energy in residential zero energy buildings. Renew. Energy 2017, 103, 308–320. [Google Scholar]

- Singh, S.; Chauhan, P.; Aftab, M.A.; Ali, I.; Hussain, S.M.S.; Ustun, T.S. Cost Optimization of a Stand-Alone Hybrid Energy System with Fuel Cell and PV. Energies 2020, 13, 1295. [Google Scholar] [CrossRef] [Green Version]

- Latif, A.; Hussain, S.M.S.; Das, D.C.; Ustun, T.S. Design and Implementation of Maiden Dual-Level Controller for Ameliorating Frequency Control in a Hybrid Microgrid. Energies 2021, 14, 2418. [Google Scholar] [CrossRef]

- Latif, A.; Hussain, S.M.S.; Das, D.C.; Ustun, T.S. Optimization of Two-Stage IPD-(1+I) Controllers for Frequency Regulation of Sustainable Energy Based Hybrid Microgrid Network. Electronics 2021, 10, 919. [Google Scholar] [CrossRef]

- Kollimalla, S.K.; Mishra, M.K.; Narasamma, N.L. Design and analysis of novel control strategy for battery and supercapacitor storage system. IEEE Trans. Sustain. Energy 2014, 5, 1137–1144. [Google Scholar] [CrossRef]

- Pattnaik, S.; Kumar, M.R.; Mishra, S.K. Supercapacitor-based automated fast charging system for electric vehicles. In Symposium on Communication and Control for Robotic System; Springer: Berlin, Germany, 2021; Volume 229, pp. 377–393. [Google Scholar]

- Pattnaik, S.; Kumar, M.R.; Mishra, S.K.; Gautam, S.P. A review on characterization of supercapacitors and its efficiency analysis for different charging methods and applications. Energy Storage 2022, e398. [Google Scholar] [CrossRef]

- Niyigena, D.; Habineza, C.; Ustun, T.S. Computer-based smart energy management system for rural health centers. In Proceedings of the 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December 2015; pp. 1–5. [Google Scholar]

- Latif, A.; Hussain, S.M.S.; Das, D.C.; Ustun, T.S. Optimum Synthesis of a BOA Optimized Novel Dual-Stage PI − (1 + ID) Controller for Frequency Response of a Microgrid. Energies 2020, 13, 3446. [Google Scholar] [CrossRef]

- Ulutas, A.; Altas, I.H.; Onen, A.; Ustun, T.S. Neuro-Fuzzy-Based Model Predictive Energy Management for Grid Connected Microgrids. Electronics 2020, 9, 900. [Google Scholar] [CrossRef]

- Javed, K.; Ashfaq, H.; Singh, R.; Hussain, S.M.S.; Ustun, T.S. Design and Performance Analysis of a Stand-alone PV System with Hybrid Energy Storage for Rural India. Electronics 2019, 8, 952. [Google Scholar] [CrossRef] [Green Version]

- Guentri, H.; Allaoui, T.; Mekki, M.; Denai, M. Power management and control of a photovoltaic system with hybrid battery-supercapacitor energy storage based on heuristics methods. J. Energy Storage 2021, 39, 102578. [Google Scholar] [CrossRef]

- Abdolrasol, M.G.M.; Hussain, S.M.S.; Ustun, T.S.; Sarker, M.R.; Hannan, M.A.; Mohamed, R.; Ali, J.A.; Mekhilef, S.; Milad, A. Artificial Neural Networks Based Optimization Techniques: A Review. Electronics 2021, 10, 2689. [Google Scholar] [CrossRef]

- Zou, C.; Zhang, L.; Hu, X.; Wang, Z.; Wik, T.; Pecht, M. A review of fractional-order techniques applied to lithium-ion batteries, lead-acid batteries, and supercapacitors. J. Power Sources 2018, 390, 286–296. [Google Scholar] [CrossRef] [Green Version]

- Rao, K.D.; Ghosh, S.; Das, S.; Kumar, M.R. Transient behavior modeling-based hysteresis-dependent energy estimation of ultracapacitor. IEEE Trans. Instrum. Meas. 2020, 69, 6455–6464. [Google Scholar]

- Latif, A.; Hussain, S.S.; Das, D.C.; Ustun, T.S.; Iqbal, A. A review on fractional order (FO) controllers’ optimization for load frequency stabilization in power networks. Energy Rep. 2021, 7, 4009–4021. [Google Scholar] [CrossRef]

- Freeborn, T.J.; Maundy, B.; Elwakil, A.S. Fractional-order models of supercapacitors, batteries and fuel cells: A survey. Mater. Renew. Sustain. Energy 2015, 4, 9. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Petras, I.; Xue, D. Fractional order control—A tutorial. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; Volume 8, pp. 1397–1411. [Google Scholar]

- Khokhar, B.; Dahiya, S.; Parmar, K.P.S. A novel hybrid fuzzy PD-TID controller for load frequency control of a standalone microgrid. Arab. J. Sci. Eng. 2021, 46, 1053–1065. [Google Scholar]

- Guha, D.; Roy, P.; Banerjee, S. A maiden application of salp swarm algorithm optimized cascade tilt-integral-derivative controller for load frequency control of power systems. IET Gener. Transm. Distrib. 2019, 13, 1110–1120. [Google Scholar] [CrossRef]

- Ahmed, B.; Abdelkrim, T.; Mordjaoui, M.; Mohcene, B.; Moussa, S. An optimal tilt integral derivative applied to the regulation of DC link voltage in a stand-alone hybrid energy system. J. Eur. Syst. Autom. 2021, 54, 607–616. [Google Scholar]

- Mussadiq, U.; Kausar, T.; Ahmed, S.; Kim, S.M. A hybrid storage system for energy sharing and management within prosumers’ community. In Proceedings of the 2022 5th International Conference on Energy Conservation and Efficiency, Lahore, Pakistan, 16–17 March 2022; pp. 1–6. [Google Scholar]

- Keshan, H.; Thornburg, J.; Ustun, T.S. Comparison of lead-acid and lithium ion batteries for stationary storage in off-grid energy systems. In Proceedings of the 4th IET Clean Energy and Technology Conference (CEAT 2016), Kuala Lumpur, Malaysia, 14–15 November 2016. [Google Scholar]

- Elgendy, M.A.; Zahawi, B.; Atkinson, D.J. Assessment of Perturb and Observe MPPT algorithm implementation techniques for PV pumping applications. IEEE Trans. Sustain. Energy 2012, 3, 21–33. [Google Scholar] [CrossRef]

- Ustun, T.S.; Nakamura, Y.; Hashimoto, J.; Otani, K. Performance analysis of PV panels based on different technologies after two years of outdoor exposure in Fukushima, Japan. Renew. Energy 2019, 136, 159–178. [Google Scholar] [CrossRef]

- Cabrane, Z.; Ouassaid, M.; Maaroufi, M. Management and control of storage photovoltaic energy using battery-supercapacitor combination. In Proceedings of the Second World Conference on Complex Systems (WCCS), Agadir, Morocco, 10–12 November 2014; pp. 380–385. [Google Scholar]

- Bhatti, S.A.; Malik, S.A.; Daraz, A. Comparison of P-I and I-P controller by using Ziegler-Nichols tuning method for speed control of DC motor. In Proceedings of the 2016 International Conference on Intelligent Systems Engineering (ICISE), Islamabad, Pakistan, 15–17 January 2016; pp. 330–334. [Google Scholar] [CrossRef]

- Kumar, M.R.; Ghosh, S. Hybrid Optimization Based FOPI Controller Design with Real-Time Validation. IFAC Pap. Line 2018, 51, 78–83. [Google Scholar] [CrossRef]

- Kumar, M.R.; Deepak, V.; Ghosh, S. Fractional-order controller design in frequency domain using an improved nonlinear adaptive seeker optimization algorithm. Turk. J. Electr. Eng. Comput. Sci. 2017, 25, 4299–4310. [Google Scholar] [CrossRef]

- Das, S. Functional Fractional Calculus; Springer Science and Business Media: Berlin, Germany, 2011. [Google Scholar]

- Maria, C.A.; Christos, C.M.; Soteris, A.K.; Paul, C. A novel power management algorithm for a residential grid-connected PV system with battery-supercapacitor storage for increased self-consumption and self-sufficiency. Energy Convers. Manag. 2021, 246, 11467. [Google Scholar]

- Pankaj, D.; Mukhija, P.; Saxena, A.R.; Yogendra, A. Comparative performance investigation of optimal controller for AGC of electric power generating systems. Automatika 2017, 57, 902–921. [Google Scholar]

- Özdemir, M.; Öztürk, D. Comparative performance analysis of optimal PID parameters tuning based on the optics inspired optimization methods for automatic generation control. Energies 2017, 10, 2134. [Google Scholar] [CrossRef] [Green Version]

- Mouayad, A.S.; Bestoun, S.A. A new multiobjective performance criterion used in PID tuning optimization algorithms. J. Adv. Res. 2016, 7, 125–134. [Google Scholar]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence properties of the Nelder--Mead simplex method in low dimensions. SIAM J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, Z.; Atlas, M. Optimal solution of integro-differential Equation of Suspension Bridge Model using Genetic Algorithm and Nelder-Mead method. J. Assoc. Arab. Univ. Basic Appl. Sci. 2017, 24, 310–314. [Google Scholar]

- Chen, P.L.; Yang, M.C.; Sun, T.Y. PSO-based on-line tuning PID controller for setpoint changes and load disturbance. In Proceedings of the 2011 IEEE Congress of Evolutionary Computation (CEC), New Orleans, LA, USA, 5–8 June 2011; pp. 1887–1894. [Google Scholar] [CrossRef]

| Configuration | Topology | Features | Drawback |

|---|---|---|---|

| Basic passive parallel Hybrid configuration |  | Supercapacitor and battery are directly connected with load. Hence it is easy to implement with good reliability | Power sharing between battery and supercapacitor is uncontrolled. Hence the DC bus voltage is not regulated |

| Supercapacitor/battery parallel configuration |  | Supercapacitor energy is used more efficiently to maintain constant DC bus voltage that changes w.r.t SOC of battery | DC Bus voltage regulation is difficult to obtain and there are chances of load imbalance |

| Battery/supercapacitor parallel configuration |  | Battery voltage can be higher and lower than the supercapacitor voltage. It costs less with a reduction in complexity due to a single converter used. | Improper DC bus voltage regulation due to the supercapacitor variable voltage |

| Multiple converter |  | Most efficient configuration is a separate converter for the battery and a supercapacitor is used, which provides the easy control of power | High cost due to complex circuitry and a large number of components |

| Devices/Components | Parameters | Value |

|---|---|---|

| PV module | Maximum power | 120.7 W |

| Short circuit current | 8 A | |

| Open circuit voltage | 21 V | |

| PV array sizing | 2 series and 4 parallel strings | |

| Battery | Nominal voltage | 24 V |

| Rated capacity | 14 Ah | |

| Initial SOC | 50% | |

| Supercapacitor | Rated capacitance | 29 F |

| Rated voltage | 32 V | |

| Initial voltage | 32 V | |

| No. of series and parallel capacitors | 1.1 | |

| DC bus parameters | DC link capacitance | 300 μF |

| Power load | 500 W | |

| DC bus voltage | 50 V |

| Controller | Kp | KI | N | λ | ITAE |

|---|---|---|---|---|---|

| PI | 1.424 ± 0.3424 | 3037.9 ± 0.255 | - | - | 0.4881 ± 0.00649 |

| FOPI | 1.913 ± 0.098 | 50.908 ± 0.227 | - | 0.504 ± 0.0314 | 0.4203 ± 0.00239 |

| TI | 1.015 ± 0.173 | 1039.55 ± 0.358 | 2.558 ± 0.3155 | - | 0.3839 ± 0.00161 |

| Controller | Risetime | Undershoot (%) | Settling Time (ms) | Slew Rate |

|---|---|---|---|---|

| PI | 9.410 ns | 1.340 | 9.149 | 4.229 |

| FOPI | 228.427 µs | 1.999 | 5.691 | 173.759 |

| TI | 41.071 ps | 0.563 | 5.013 | 966.580 |

| Case Study | Temp | Consumption of SOC | % Consumption of SOC in 1 h |

|---|---|---|---|

| PI | 40 °C | 0.0164 | 29.52 |

| 25 °C | 0.0146 | 26.28 | |

| 10 °C | 0.0130 | 22.40 | |

| 0 °C | 0.0122 | 21.96 | |

| −12 °C | 0.0118 | 21.24 | |

| FOPI | 40 °C | 0.0158 | 28.44 |

| 25 °C | 0.0131 | 23.58 | |

| 10 °C | 0.0130 | 23.4 | |

| 0 °C | 0.0092 | 16.56 | |

| −12 °C | 0.009 | 16.38 | |

| TI | 40 °C | 0.0149 | 26.82 |

| 25 °C | 0.0120 | 21.60 | |

| 10 °C | 0.0109 | 19.76 | |

| 0 °C | 0.0091 | 16.38 | |

| −12 °C | 0.0088 | 15.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pattnaik, S.; Kumar, M.R.; Mishra, S.K.; Gautam, S.P.; Appasani, B.; Ustun, T.S. DC Bus Voltage Stabilization and SOC Management Using Optimal Tuning of Controllers for Supercapacitor Based PV Hybrid Energy Storage System. Batteries 2022, 8, 186. https://doi.org/10.3390/batteries8100186

Pattnaik S, Kumar MR, Mishra SK, Gautam SP, Appasani B, Ustun TS. DC Bus Voltage Stabilization and SOC Management Using Optimal Tuning of Controllers for Supercapacitor Based PV Hybrid Energy Storage System. Batteries. 2022; 8(10):186. https://doi.org/10.3390/batteries8100186

Chicago/Turabian StylePattnaik, Saswati, Mano Ranjan Kumar, Sunil Kumar Mishra, Shivam Prakash Gautam, Bhargav Appasani, and Taha Selim Ustun. 2022. "DC Bus Voltage Stabilization and SOC Management Using Optimal Tuning of Controllers for Supercapacitor Based PV Hybrid Energy Storage System" Batteries 8, no. 10: 186. https://doi.org/10.3390/batteries8100186