A Data-Driven Digital Twin of Electric Vehicle Li-Ion Battery State-of-Charge Estimation Enabled by Driving Behavior Application Programming Interfaces

Abstract

:1. Introduction

- The technical aspects of backend and hardware design for cloud-based BMS DTs were seldom presented, and the system’s capabilities were not validated through field operations.

- There is a lack of cloud-compatible battery services algorithms that can support enterprise decision making and leverage a high computational power of real-time data, such as integrating the driving behavior, global positioning system (GPS) location, and weather factors in the SOC estimation for battery electric vehicles (BEVs).

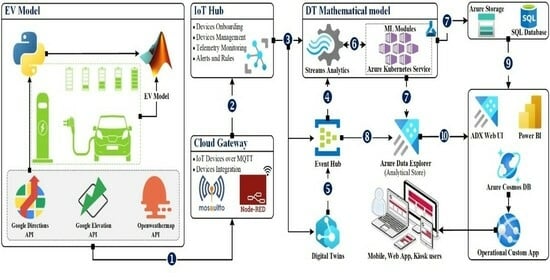

- Proposing a DT framework for SOC estimation of LIBs integrated into a cloud-based data-driven system considering different aspects affecting BEV’s SOC estimation, including driving behavior, GPS location of the EV, and weather factors.

- Developing a hybrid twin for LIB by bridging the gap between the estimations from the DT and the measurements obtained from the physical LIB module.

- The proposed method uses readily available measurements in existing LIBs (such as voltage, current, and operating temperature).

- Collection of essential data and information from three application programming interfaces (APIs), namely Google Directions API, Google Elevation API, and OpenWeatherMap API, to closely emulate real-world battery electric vehicles.

- The proposed framework provides information about the battery SOC in advance, facilitating determining the EV range.

- The effectiveness of the proposed DT model has been validated by simulation and experimental results.

2. SOC Estimation and Battery Digital Twin

2.1. SOC Estimation

2.2. Battery Digital Twin

- How can a DT model be developed and validated for accurate estimation of SOC in the battery systems?

- How can real-time data capturing, integration, and synchronization be achieved in a DT model for SOC estimation to ensure up-to-date and accurate predictions?

- What key factors and variables significantly influence the accuracy of a data-driven SOC estimation-based DT model for battery systems?

- What are the most suitable regression-based ML algorithms for accurate SOC estimation in a DT model?

3. Proposed DT Model

3.1. System Configuration

3.1.1. Numerical Simulation

- GPS location: This information is essential as different routes may have varying characteristics such as road type, traffic conditions, and elevation changes, impacting energy consumption and SOC estimation.

- Distance traveled: This is crucial as it directly affects energy consumption and the battery’s SOC. By measuring the distance covered during the trip, it is possible to estimate the energy expenditure and monitor the battery’s state [45].

- Time traveled: The duration of the trip, or the time spent on the road, is another essential factor to consider. The time traveled can impact energy consumption and SOC due to variations in driving conditions, traffic patterns, and driving speeds.

- Acceleration: The rate of velocity changes over time and plays a role in determining energy consumption. Aggressive acceleration increases power demands, leading to higher energy usage and faster SOC depletion [47].

- Driving state: Categorizes the vehicle’s movement into climbing, steady, or declining driving conditions. Each state has different energy requirements, with climbing typically demanding more energy and causing faster SOC depletion, while declining may enable regenerative braking, recovering energy, and improving SOC.

- Ambient temperature: Aggressive changes in ambient temperatures can have a significant impact on the battery’s internal resistance and capacity. At lower temperatures, the battery’s internal resistance typically increases, leading to higher losses. Conversely, at higher temperatures, these increases can accelerate chemical reactions within the battery, resulting in expedited degradation and reduced capacity. To mitigate these effects, thermal management systems are commonly employed [3,48].

- Atmospheric pressure: The pressure is closely tied to altitude, as atmospheric pressure decreases with increasing altitude, and vice versa. As the altitude changes during a trip, the air density also changes. This variation in air density can influence the aerodynamic forces acting on the EV, which, in turn, affects energy consumption and, consequently, the battery’s SOC [49].

- Wind direction “degree”: This can impact the aerodynamics of the EV. For instance, crosswinds, in particular, can introduce additional resistance and affect energy consumption and SOC depending on the EV’s heading and wind angle [50].

- Google Directions API is used to retrieve directions and route information between the initial and final destination locations; accordingly, detailed information about the trip can be provided, such as distance traveled, time traveled, and coordinates for each point along the trip route “polyline”.

- Google Elevation API calculates the road inclination during the trip “driving state”. By providing the coordinates obtained from the Google Directions API, this API can determine whether the road is climbing, steady, or declining. This information can be useful for analyzing the driving conditions and the effect on EV range.

- OpenWeatherMap API is leveraged to retrieve weather-related data at the EV’s location. It provides information such as ambient temperature, atmospheric pressure, and wind speed direction.

| Algorithm 1: Integrating data sources from the APIs |

|

3.1.2. Experimental Setup

3.2. Data-Driven SOC-Based DT Proposed Strategy

- Execution time: As the complexity of the DT increases with multiple layers and interactions, the execution time required for processing and updating the models also increases. It is crucial to manage the computational load efficiently and optimize the algorithms to ensure that the DT operates in a timely manner.

- Data exchange: In a multi-level DT architecture, data exchange between different layers is essential for information flow and synchronization. Efficient mechanisms need to be established to facilitate data exchange between layers while minimizing delays and bottlenecks. This ensures that the models at different levels are updated with the latest information from the physical entity.

- Time dependencies: The layers in a hierarchical DT may have time dependencies, meaning changes in one layer can affect the models and data in other layers. It is important to manage these dependencies to ensure consistency and accuracy throughout the system. Synchronization mechanisms need to be in place to handle these dependencies and update the models in a coordinated manner. In this study, a synchronization mechanism has been implemented at the Node-Red gateway by adding a time synchronization function to each twin device.

- Physical space: This refers to the real-world entity or system that the DT aims to replicate and monitor, specifically the LIB system in this case.

- Perception layer: The perception layer is responsible for data collection and time synchronization. It collects comprehensive data from the physical LIB system, ensuring that the data are synchronized with the DT system’s timeline. This layer is crucial in acquiring the necessary input data for subsequent processing and modeling.

- Middle layers: The middle layers are responsible for data processing tasks such as signal interpolation and data filtering. They receive the data collected by the perception layer and perform necessary pre-processing steps to prepare the data for modeling and storage. This may involve techniques like signal interpolation to fill in missing data points or data filtering to remove noise and anomalies.

- Modeling layer: The modeling layer utilizes the processed data to build and refine the DT models. Different modeling techniques can be employed in this layer, such as physics-based models, data-driven models, cybernetics “hybrid techniques” models, and/or expert system models, to create an accurate virtual replica of the LIB system. These models capture the behavior and dynamics of the physical entity, enabling simulations and predictions.

- Decision visualization layer: This facilitates human interaction with the DT system. It provides a graphical user interface (GUI) that displays the components of the EV and control features related to optimizing the LIB performance. The GUI allows users to visualize and interact with the DT models, enabling them to make informed decisions and take appropriate actions based on the insights provided by the DT.

3.2.1. Supervised Voting Ensemble Regression ML

3.2.2. Evaluation Metrics

4. Verification and Discussion

4.1. Data Collection

4.2. DT Model for Battery’s SOC Estimation

4.3. Digital Twin Model Validation

4.4. Proposed Dashboard

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| AIBM | Artificial Intelligence-Based Method |

| API | Application Programming Interface |

| AutoML | Automated Machine Learning |

| AWS | Amazon Web Service |

| BEV | Battery Electric Vehicle |

| BMS | Battery Management System |

| BP | Battery Pack |

| C.G. | Centre of Gravity |

| CCM | Coulomb Counting Method |

| DC | Direct Current |

| DCS | Drive Cycle Source |

| DSEM | Direct SOC Estimation Method |

| DT | Digital Twin |

| ENT | Environment |

| EV | Electric vehicle |

| FTP | Federal Test Procedure |

| GCP | Google Cloud Platform |

| GPS | Global Positioning System |

| GUI | Graphical User Interface |

| HSEM | Hybrid SOC Estimation Method |

| IIoT | Industrial Internet-of-Things |

| IoT | Internet-of-Things |

| JSON | JavaScript Object Notation |

| LIB | Lithium-Ion Battery |

| LightGBM | Light Gradient Boosting Machine |

| MaxAbsScaler | Maximum Absolute Scaler |

| MBSEM | Model-Based SOC Estimation Method |

| MinMaxScaler | Minimum-Maximum Scaler |

| ML | Machine Learning |

| NRMSE | Normalized Root Mean Square Error |

| RMSE | Root Mean Square Error |

| SOC | State-Of-Charge |

| SOH | State-Of-Health |

| XGBoostRegressor | eXtreme Gradient Boosting Regressor |

References

- Habib, A.A.; Hasan, M.K.; Mahmud, M.; Motakabber, S.M.; Ibrahimya, M.I.; Islam, S. A review: Energy storage system and balancing circuits for electric vehicle application. IET Power Electron. 2021, 14, 1–13. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Hussain, A.; Yusof, Y.; Ker, P.J. State-of-the-art and energy management system of lithium-ion batteries in electric vehicle applications: Issues and recommendations. IEEE Access 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- Liu, W.; Placke, T.; Chau, K.T. Overview of batteries and battery management for electric vehicles. Energy Rep. 2022, 8, 4058–4084. [Google Scholar] [CrossRef]

- Ouyang, D.; Weng, J.; Chen, M.; Wang, J.; Wang, Z. Sensitivities of lithium-ion batteries with different capacities to overcharge/over-discharge. J. Energy Storage 2022, 52, 104997. [Google Scholar] [CrossRef]

- Zhou, L.; Lai, X.; Li, B.; Yao, Y.; Yuan, M.; Weng, J.; Zheng, Y. State Estimation Models of Lithium-Ion Batteries for Battery Management System: Status, Challenges, and Future Trends. Batteries 2023, 9, 131. [Google Scholar] [CrossRef]

- Xu, J.; Cao, B.; Chen, Z.; Zou, Z. An online state of charge estimation method with reduced prior battery testing information. Int. J. Electr. Power Energy Syst. 2014, 63, 178–184. [Google Scholar] [CrossRef]

- Shen, J.N.; He, Y.J.; Ma, Z.F.; Luo, H.B.; Zhang, Z.F. Online state of charge estimation of lithium-ion batteries: A moving horizon estimation approach. Chem. Eng. Sci. 2016, 154, 42–53. [Google Scholar] [CrossRef]

- Yang, F.; Li, W.; Li, C.; Miao, Q. State-of-charge estimation of lithium-ion batteries based on gated recurrent neural network. Energy 2019, 175, 66–75. [Google Scholar] [CrossRef]

- T, G.; C, D. A Review on Different State of Battery Charge Estimation Techniques and Management Systems for EV Applications. Electronics 2022, 11, 1795. [Google Scholar] [CrossRef]

- Biller, B.; Biller, S. Implementing Digital Twins That Learn: AI and Simulation Are at the Core. Machines 2023, 11, 425. [Google Scholar] [CrossRef]

- Wang, Z.; Liao, X.; Zhao, X.; Han, K.; Tiwari, P.; Barth, M.J.; Wu, G. A digital twin paradigm: Vehicle-to-cloud based advanced driver assistance systems. In Proceedings of the 2020 IEEE 91st Vehicular Technology Conference (VTC2020-Spring), Antwerp, Belgium, 30 June 2020. [Google Scholar] [CrossRef]

- Hanelt, A.; Piccinini, E.; Gregory, R.W.; Hildebrandt, B.; Kolbe, L.M. Digital transformation of primarily physical industries-exploring the impact of digital trends on business models of automobile manufacturers. Wirtsch. Proc. 2015. Available online: https://aisel.aisnet.org/wi2015/88 (accessed on 9 October 2023).

- Piromalis, D.; Kantaros, A. Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence. Appl. Syst. Innov. 2022, 5, 65. [Google Scholar] [CrossRef]

- Bhatti, G.; Mohan, H.; Singh, R.R. Towards the future of smart electric vehicles: Digital twin technology. Renew. Sustain. Energy Rev. 2021, 141, 110801. [Google Scholar] [CrossRef]

- Biesinger, F.; Weyrich, M. The facets of digital twins in production and the automotive industry. In Proceedings of the 2019 23rd International Conference on Mechatronics Technology (ICMT), Salerno, Italy, 23–26 October 2019. [Google Scholar] [CrossRef]

- Li, W.; Rentemeister, M.; Badeda, J.; Jöst, D.; Schulte, D.; Sauer, D.U. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557. [Google Scholar] [CrossRef]

- Francisco, A.; Mohammadi, N.; Taylor, J.E. Smart city digital twin–enabled energy management: Toward real-time urban building energy benchmarking. J. Manag. Eng. 2020, 36, 04019045. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, Y.; Ming, W.; Zhou, Y.; Wu, J. Digital twin-driven estimation of state of charge for Li-ion battery. In Proceedings of the 2022 IEEE 7th International Energy Conference (ENERGYCON), Riga, Latvia, 9–12 May 2022. [Google Scholar] [CrossRef]

- Tang, H.; Wu, Y.; Cai, Y.; Wang, F.; Lin, Z.; Pei, Y. Design of power lithium battery management system based on digital twin. J. Energy Storage 2022, 47, 103679. [Google Scholar] [CrossRef]

- Shrivastava, P.; Soon, T.K.; Idris, M.Y.; Mekhilef, S. Overview of model-based online state-of-charge estimation using Kalman filter family for lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 113, 109233. [Google Scholar] [CrossRef]

- Xu, J.; Gao, M.; He, Z.; Han, Q.; Wang, X. State of charge estimation online based on EKF-Ah method for lithium-ion power battery. In Proceedings of the 2009 2nd International Congress on Image and Signal Processing, Tianjin, China, 17–19 October 2009. [Google Scholar] [CrossRef]

- Roscher, M.A.; Sauer, D.U. Dynamic electric behavior and open-circuit-voltage modeling of LiFePO4-based lithium ion secondary batteries. J. Power Sources 2011, 196, 331–336. [Google Scholar] [CrossRef]

- Movassagh, K.; Raihan, S.A.; Balasingam, B. Performance analysis of coulomb counting approach for state of charge estimation. In Proceedings of the 2019 IEEE Electrical Power and Energy Conference (EPEC), Montreal, QC, Canada, 16–18 October 2019. [Google Scholar] [CrossRef]

- Leng, F.; Tan, C.M.; Yazami, R.; Le, M.D. A practical framework of electrical based online state-of-charge estimation of lithium ion batteries. J. Power Sources 2014, 255, 423–430. [Google Scholar] [CrossRef]

- Bouchareb, H.; Saqli, K.; M’sirdi, N.K.; Bentaie, M.O.; Naamane, A. Sliding mode observer design for battery state of charge estimation. In Proceedings of the 2020 5th International Conference on Renewable Energies for Developing Countries, Marrakech, Morocco, 29–30 June 2020. [Google Scholar] [CrossRef]

- Ipek, E.; Yilmaz, M. A novel method for SOC estimation of Li-ion batteries using a hybrid machine learning technique. Turk. J. Electr. Eng. Comput. Sci. 2021, 29, 18–31. [Google Scholar] [CrossRef]

- Antón, J.Á.; Nieto, P.G.; de Cos Juez, F.J.; Lasheras, F.S.; Vega, M.G.; Gutiérrez, M.R. Battery state-of-charge estimator using the SVM technique. Appl. Math. Model. 2013, 37, 6244–6253. [Google Scholar] [CrossRef]

- Jiani, D.; Zhitao, L.; Youyi, W.; Changyun, W. A fuzzy logic-based model for Li-ion battery with SOC and temperature effect. In Proceedings of the 11th IEEE International Conference on Control & Automation (ICCA), Taichung, Taiwan, 18–20 June 2014. [Google Scholar] [CrossRef]

- Saji, D.; Babu, P.S.; Ilango, K. SoC estimation of lithium-ion battery using combined coulomb counting and fuzzy logic method. In Proceedings of the 2019 4th International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bangalore, India, 17–18 May 2019. [Google Scholar] [CrossRef]

- Shabarish, P.R.; Aditya, D.S.; Pavan, V.S.; Manitha, P.V. SOC estimation of battery in hybrid vehicle using adaptive neuro-fuzzy technique. In Proceedings of the 2020 International Conference on Smart Electronics and Communication (ICOSEC), Trichy, Tamilnadu, India, 10–12 September 2020. [Google Scholar] [CrossRef]

- Song, X.; Yang, F.; Wang, D.; Tsui, K.L. Combined CNN-LSTM network for state-of-charge estimation of lithium-ion batteries. IEEE Access 2019, 8, 88894–88902. [Google Scholar] [CrossRef]

- Khalid, A.; Sarwat, A.I. Unified univariate-neural network models for lithium-ion battery state-of-charge forecasting using minimized akaike information criterion algorithm. IEEE Access 2021, 9, 39154–39170. [Google Scholar] [CrossRef]

- Rae, C.; Bradley, F. Energy autonomy in sustainable communities—A review of key issues. Renew. Sustain. Energy Rev. 2012, 16, 9. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Semeraro, C.; Aljaghoub, H.; Abdelkareem, M.A.; Alami, A.H.; Olabi, A.G. Digital twin in battery energy storage systems: Trends and gaps detection through association rule mining. Energy 2023, 273, 127086. [Google Scholar] [CrossRef]

- Li, H.; Kaleem, M.B.; Chiu, I.J.; Gao, D.; Peng, J. A digital twin model for the battery management systems of electric vehicles. In Proceedings of the 2021 IEEE 23rd Int Conf on High Performance Computing & Communications; 7th Int Conf on Data Science & Systems; 19th Int Conf on Smart City; 7th Int Conf on Dependability in Sensor, Cloud & Big Data Systems & Application (HPCC/DSS/SmartCity/DependSys), Haikou, China, 20–22 December 2021. [Google Scholar] [CrossRef]

- Sancarlos, A.; Cameron, M.; Abel, A.; Cueto, E.; Duval, J.L.; Chinesta, F. From ROM of electrochemistry to AI-based battery digital and hybrid twin. Arch. Comput. Methods Eng. 2021, 28, 979–1015. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, X.; Song, Y.; Liu, D. A low cost flexible digital twin platform for spacecraft lithium-ion battery pack degradation assessment. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference, Auckland, New Zealand, 20–23 May 2019. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital twins: State of the art theory and practice, challenges, and open research questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Rathore, M.M.; Shah, S.A.; Shukla, D.; Bentafat, E.; Bakiras, S. The role of ai, machine learning, and big data in digital twinning: A systematic literature review, challenges, and opportunities. IEEE Access 2021, 9, 32030–32052. [Google Scholar] [CrossRef]

- Pierleoni, P.; Concetti, R.; Belli, A.; Palma, L. Amazon, Google and Microsoft solutions for IoT: Architectures and a performance comparison. IEEE Access 2019, 8, 5455–5470. [Google Scholar] [CrossRef]

- Gupta, N.M.; Singh, R.; Das, S.S.; Choudhary, S.K. AWS VS Azure VS GCP: Leaders of the Cloud Race. Int. Res. J. Mod. Eng. Technol. Sci. 2022, 7. Available online: https://www.irjmets.com/uploadedfiles/paper/issue_7_july_2022/28711/final/fin_irjmets1658671480.pdf (accessed on 13 July 2023).

- IoT & Edge Developer Survey Report. Eclipse Foundation 2022. Available online: https://outreach.eclipse.foundation/iot-edge-developer-survey-2022 (accessed on 4 November 2022).

- Awasthi, N. Designing of electric vehicle using Matlab and Simulink. In Proceedings of the International Conference on Recent Advances in Computational Techniques (IC-RACT) 2020, Navi Mumbai, India, 27–28 March 2020. [Google Scholar]

- Hitesh, S.; Sunanda, C. Modeling and Performance Analysis of an Electric Vehicle with MATLAB/Simulink. Int. Res. J. Eng. Technol. (IRJET) 2020, 7, 1098–1104. [Google Scholar]

- Sharmila, B.; Srinivasan, K.; Devasena, D.; Suresh, M.; Panchal, H.; Ashokkumar, R.; Meenakumari, R.; Kumar sadasivuni, K.; Shah, R.R. Modelling and performance analysis of electric vehicle. Int. J. Ambient. Energy 2022, 43, 5034–5040. [Google Scholar] [CrossRef]

- Tomar, V.; Chitra, A.; Krishnachaitanya, D.; Rao, N.R.; Indragandhi, V.; Raziasultana, W. Design of Powertrain Model for an Electric Vehicle using MATLAB/Simulink. In Proceedings of the 2021 Innovations in Power and Advanced Computing Technologies (i-PACT), Kuala Lumpur, Malaysia, 27–29 November 2021. [Google Scholar] [CrossRef]

- Tripathy, Y.; McGordon, A.; Barai, A. Improving Accessible Capacity Tracking at Low Ambient Temperatures for Range Estimation of Battery Electric Vehicles. Energies 2020, 13, 2021. [Google Scholar] [CrossRef]

- C Soares, S.M.; Sodre, J.R. Effects of atmospheric temperature and pressure on the performance of a vehicle. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2002, 216, 473–477. [Google Scholar] [CrossRef]

- Askerdal, M.; Fredriksson, J.; Laine, L. Development of simplified air drag models including crosswinds for commercial heavy vehicle combinations. Veh. Syst. Dyn. 2023, 1–18. [Google Scholar] [CrossRef]

- Varga, B.O.; Sagoian, A.; Mariasiu, F. Prediction of Electric Vehicle Range: A Comprehensive Review of Current Issues and Challenges. Energies 2019, 12, 946. [Google Scholar] [CrossRef]

- Abu-Seif, M.A.; Abdel-Khalik, A.S.; Hamad, M.S.; Hamdan, E.; Elmalhy, N.A. Data-Driven modeling for Li-ion battery using dynamic mode decomposition. Alex. Eng. J. 2022, 61, 11277–11290. [Google Scholar] [CrossRef]

- Naseri, F.; Gil, S.; Barbu, C.; Cetkin, E.; Yarimca, G.; Jensen, A.C.; Larsen, P.G.; Gomes, C. Digital twin of electric vehicle battery systems: Comprehensive review of the use cases, requirements, and platforms. Renew. Sustain. Energy Rev. 2023, 179, 113280. [Google Scholar] [CrossRef]

- Ademujimi, T.; Prabhu, V. Digital Twin for Training Bayesian Networks for Fault Diagnostics of Manufacturing Systems. Sensors 2022, 22, 1430. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Issa, R.; Hamad, M.S.; Abdel-Geliel, M. Digital Twin of Wind Turbine Based on Microsoft® Azure IoT Platform. In Proceedings of the 2023 IEEE Conference on Power Electronics and Renewable Energy (CPERE), Luxor, Egypt, 19–21 February 2023. [Google Scholar] [CrossRef]

- Waring, J.; Lindvall, C.; Umeton, R. Automated machine learning: Review of the state-of-the-art and opportunities for healthcare. Artif. Intell. Med. 2020, 104, 101822. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.; Choi, T.; Heo, S. A Comparative Study of Automated Machine Learning Platforms for Exercise Anthropometry-Based Typology Analysis: Performance Evaluation of AWS SageMaker, GCP VertexAI, and MS Azure. Bioengineering 2023, 10, 891. [Google Scholar] [CrossRef]

- Sherafat, E.; Force, J.; Măndoiu, I.I. Semi-supervised learning for somatic variant calling and peptide identification in personalized cancer immunotherapy. BMC Bioinform. 2020, 21, 498. [Google Scholar] [CrossRef]

- Rebbouj, M.; Said, L. Students’ Physical Education Performance Analysis Using Regression Model in Machine Learning. In The International Conference of Advanced Computing and Informatics; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Moleda, M.; Momot, A.; Mrozek, D. Predictive Maintenance of Boiler Feed Water Pumps Using SCADA Data. Sensors 2020, 20, 571. [Google Scholar] [CrossRef] [PubMed]

- Sawant, M.; Patil, R.; Shikhare, T.; Nagle, S.; Chavan, S.; Negi, S.; Bokde, N.D. A Selective Review on Recent Advancements in Long, Short and Ultra-Short-Term Wind Power Prediction. Energies 2022, 15, 8107. [Google Scholar] [CrossRef]

| Technical Specification | Value | Unit |

|---|---|---|

| Vehicle mass | 1500 | kg |

| BP size (series × parallel) | 96 × 31 | - |

| BP voltage (nominal) | 400 | V |

| Drive type | Front wheel drive | - |

| Horizontal distance from C.G. to front axle | 1.188 | m |

| Horizontal distance from C.G. to rear axle | 1.512 | m |

| C.G. above axles | 0.5 | m |

| Wheel radius | 0.336 | m |

| Drag coefficient | 0.28 | m |

| Static friction coefficient “Brake” | 0.45 | - |

| Kinetic friction coefficient “Brake” | 0.35 | - |

| Number of brake pads | 2 | - |

| Carrier to driveshaft ratio | 7.94 | - |

| Transmission | Single speed | - |

| Motor torque | 450 | N·m |

| Motor power | 211 | kW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Issa, R.; Badr, M.M.; Shalash, O.; Othman, A.A.; Hamdan, E.; Hamad, M.S.; Abdel-Khalik, A.S.; Ahmed, S.; Imam, S.M. A Data-Driven Digital Twin of Electric Vehicle Li-Ion Battery State-of-Charge Estimation Enabled by Driving Behavior Application Programming Interfaces. Batteries 2023, 9, 521. https://doi.org/10.3390/batteries9100521

Issa R, Badr MM, Shalash O, Othman AA, Hamdan E, Hamad MS, Abdel-Khalik AS, Ahmed S, Imam SM. A Data-Driven Digital Twin of Electric Vehicle Li-Ion Battery State-of-Charge Estimation Enabled by Driving Behavior Application Programming Interfaces. Batteries. 2023; 9(10):521. https://doi.org/10.3390/batteries9100521

Chicago/Turabian StyleIssa, Reda, Mohamed M. Badr, Omar Shalash, Ali A. Othman, Eman Hamdan, Mostafa S. Hamad, Ayman S. Abdel-Khalik, Shehab Ahmed, and Sherif M. Imam. 2023. "A Data-Driven Digital Twin of Electric Vehicle Li-Ion Battery State-of-Charge Estimation Enabled by Driving Behavior Application Programming Interfaces" Batteries 9, no. 10: 521. https://doi.org/10.3390/batteries9100521