Analysis of the Energy Efficiency of a Hybrid Energy Storage System for an Electric Vehicle

Abstract

:1. Introduction

2. Current Status of Hybrid Energy Storage Systems (HESSs)

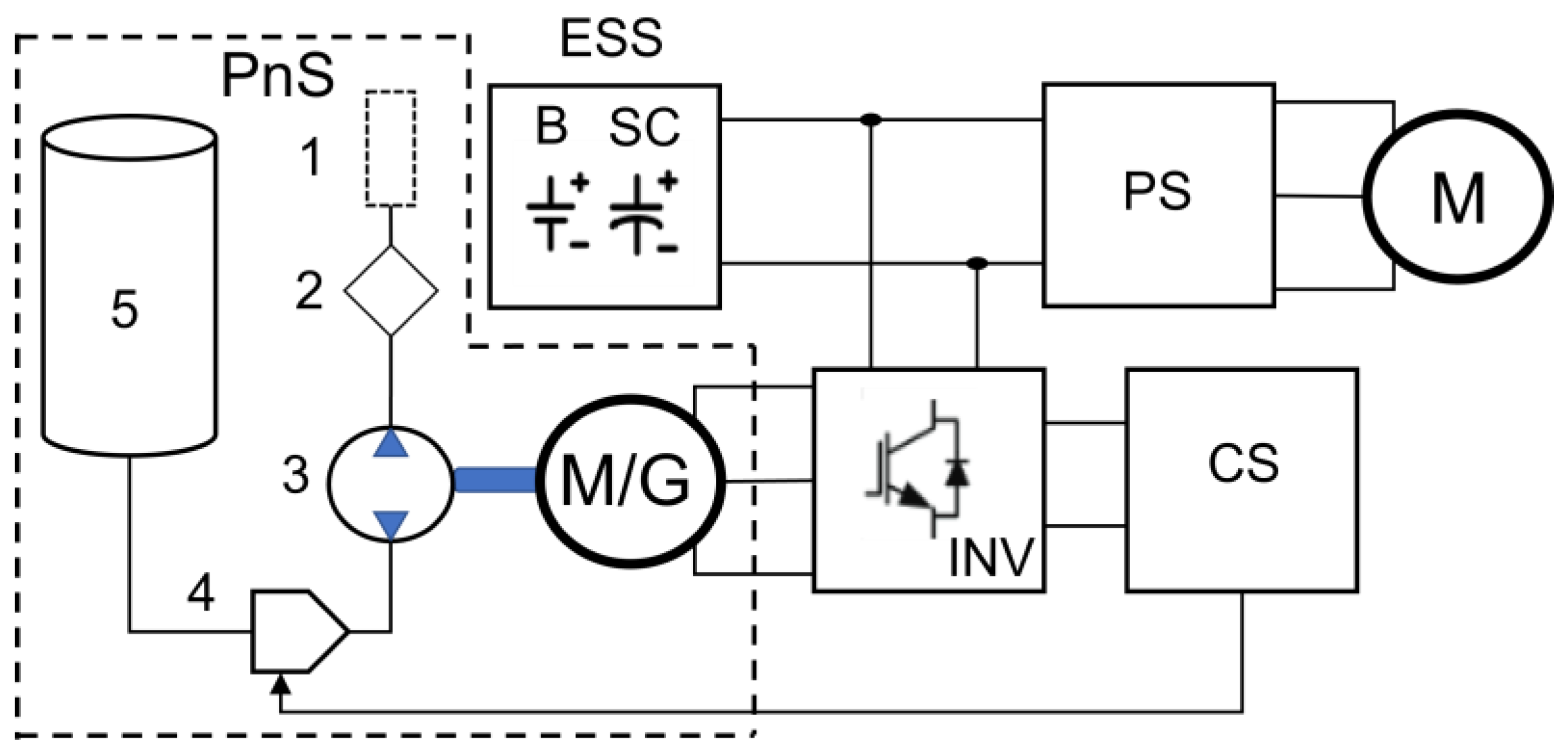

2.1. Hybrid Energy Storage System with Flywheel

2.2. Hybrid Energy Storage System with Compressed Air

2.3. Superconducting Magnetic Energy Storage Systems

2.4. Hybrid Energy Storage System with Supercapacitor

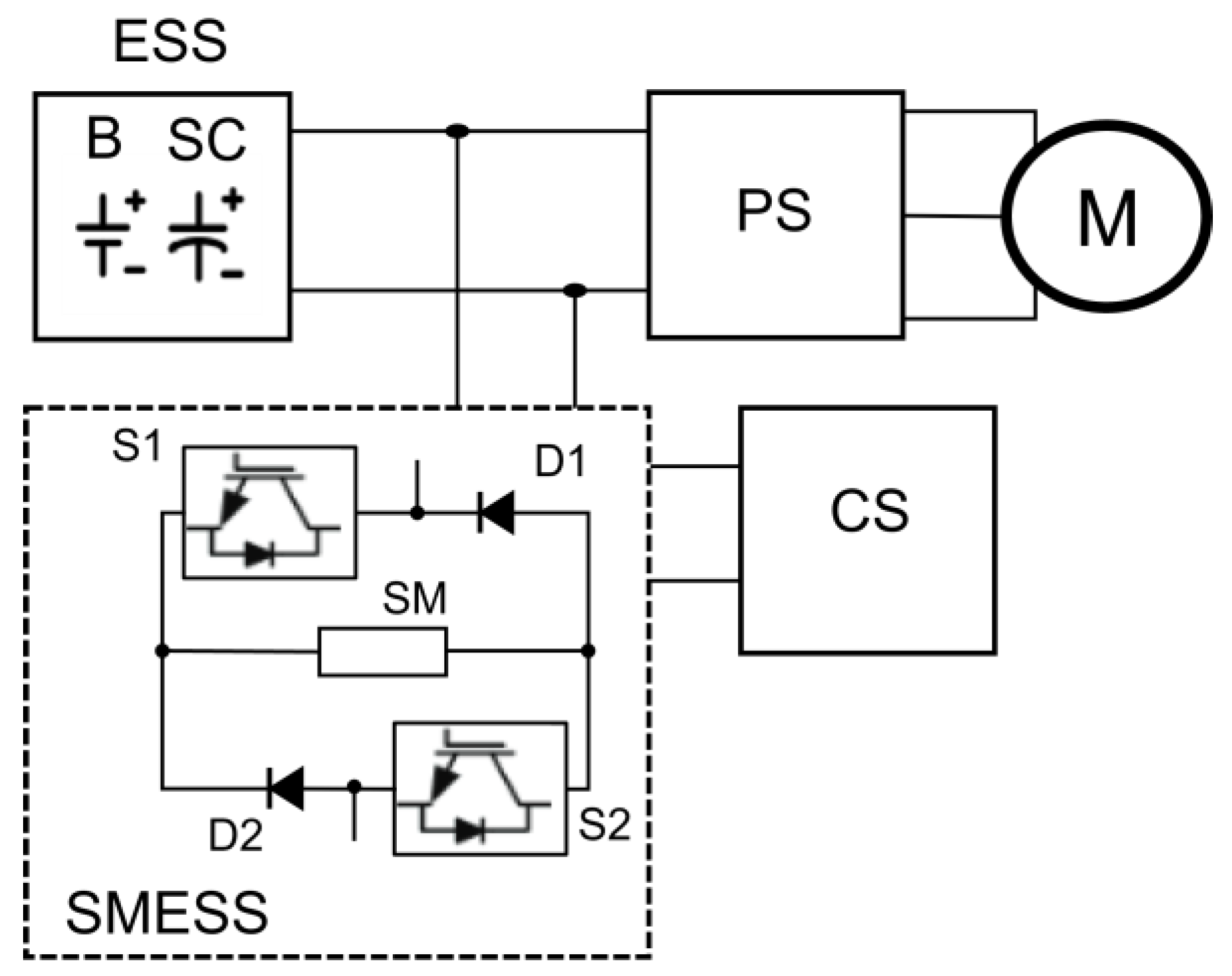

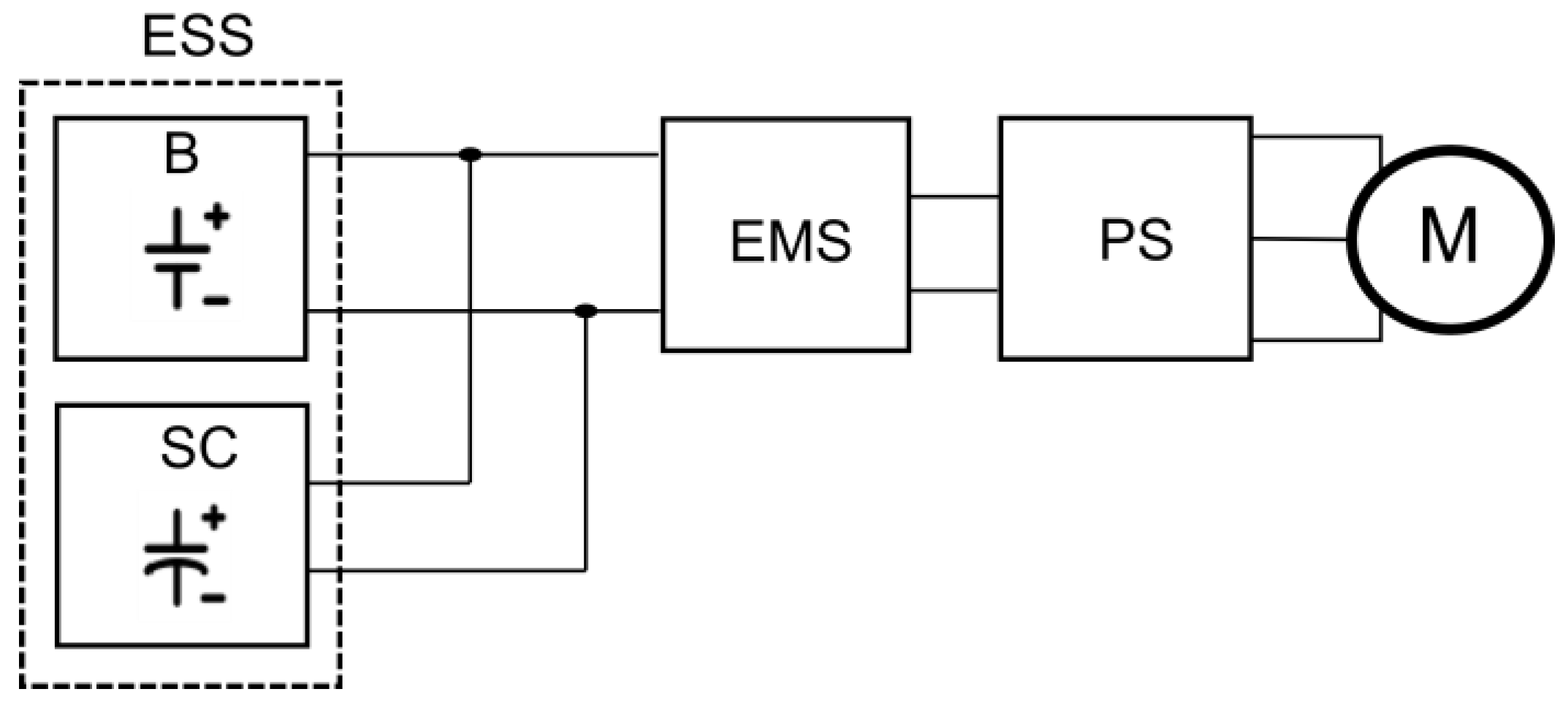

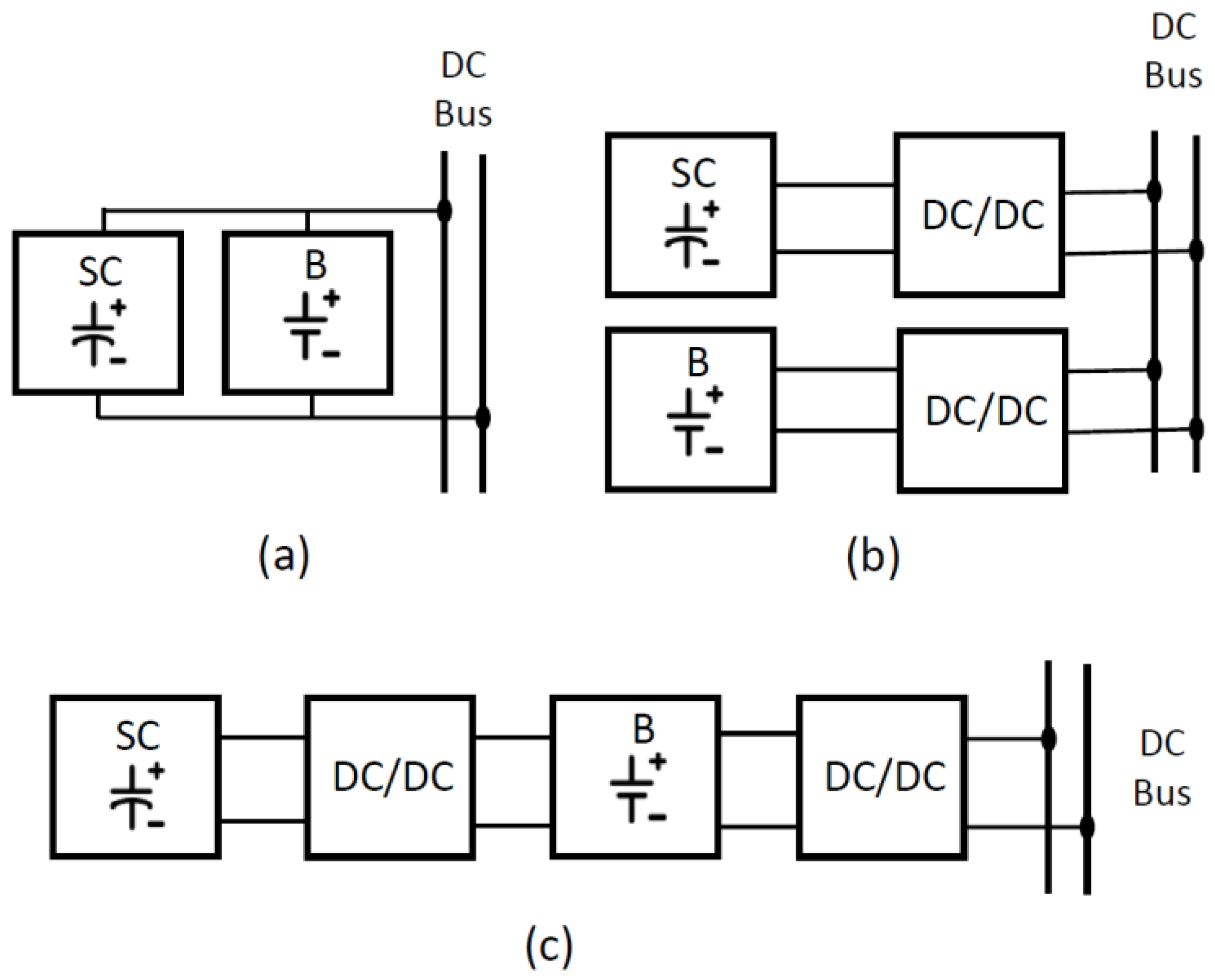

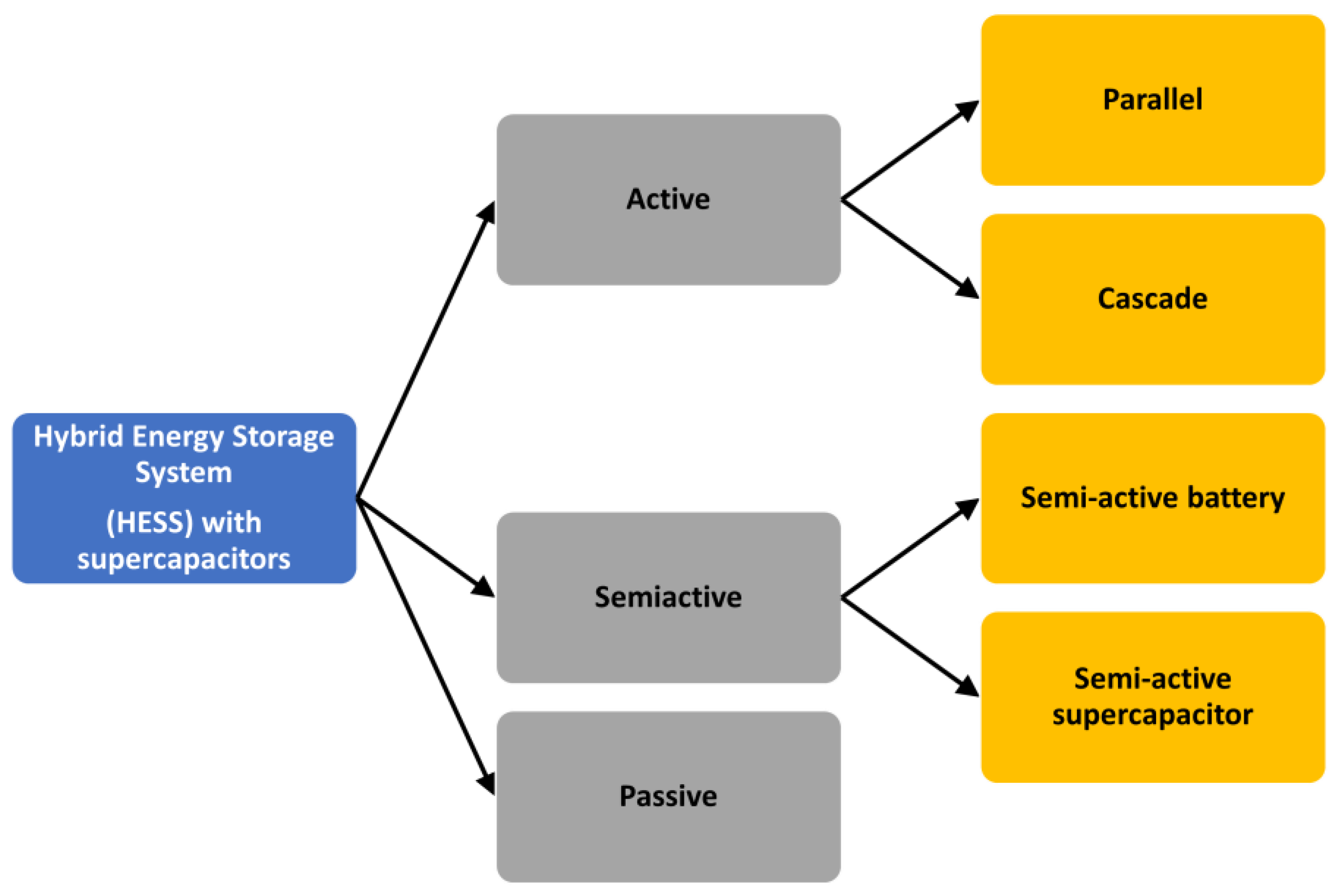

2.5. Classification of Battery–Supercapacitor Hybrid Energy Storage Systems

3. Materials and Methods

3.1. Theoretical Considerations on Supercapacitors

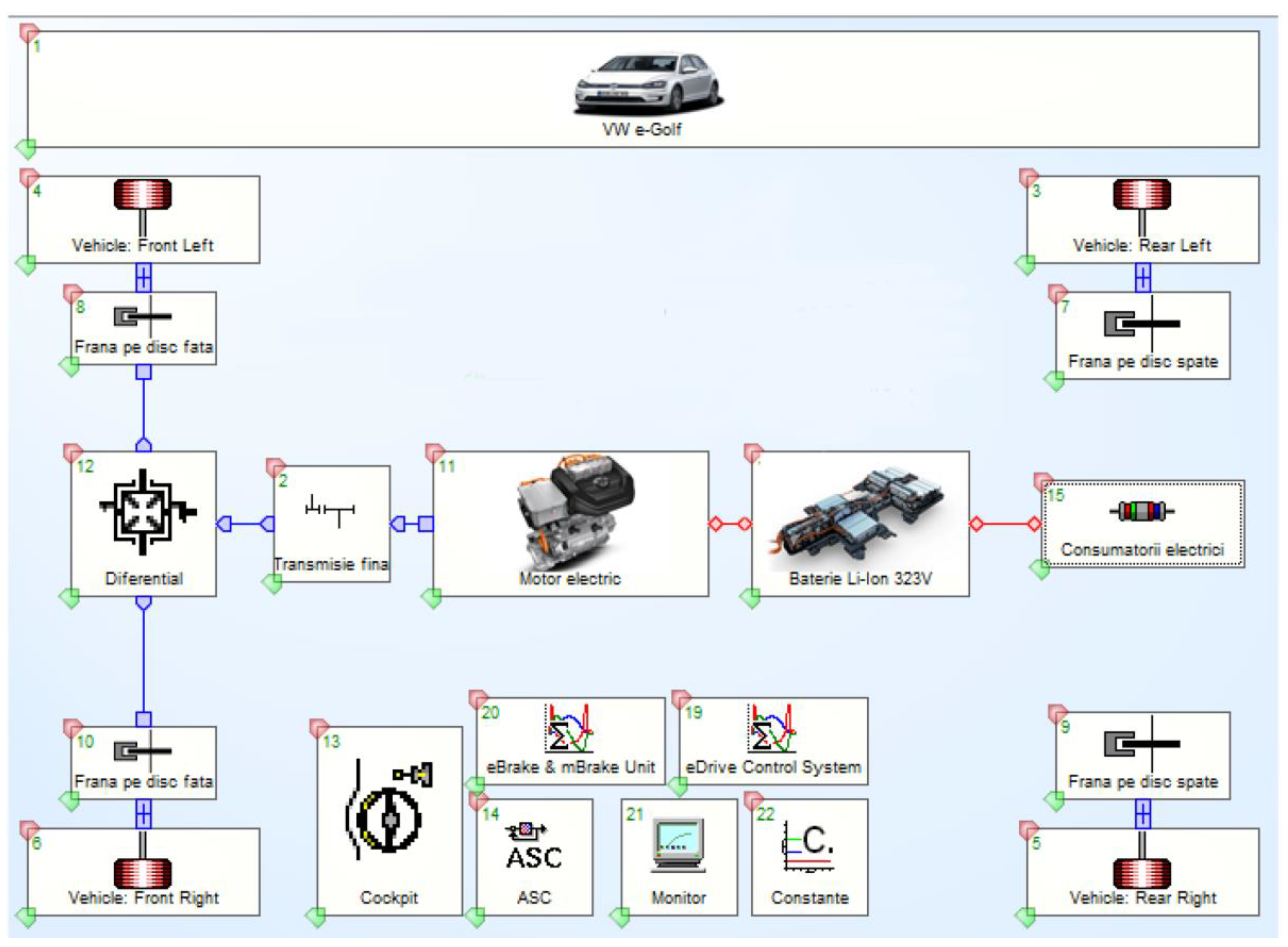

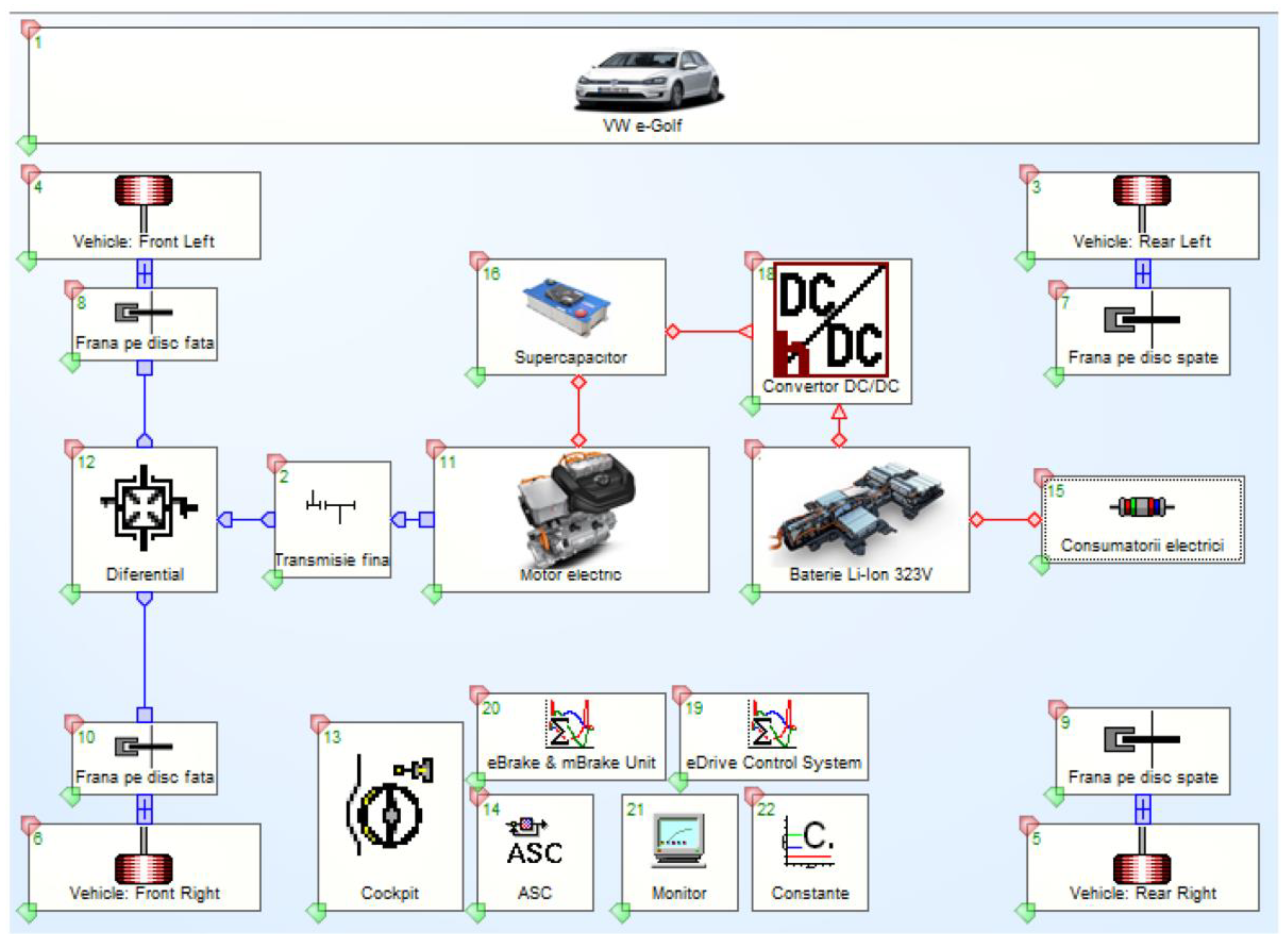

3.2. Modeling and Simulation of the Electric Vehicle

- Creating a new project/version;

- Development of the vehicle model;

- Realization of energy connections;

- Making informational connections;

- Entering the initial technical data into the model;

- Establishing tasks and simulation criteria;

- Establishing the characteristics of the simulation process;

- Running computer simulations;

- Visualization and evaluation of results.

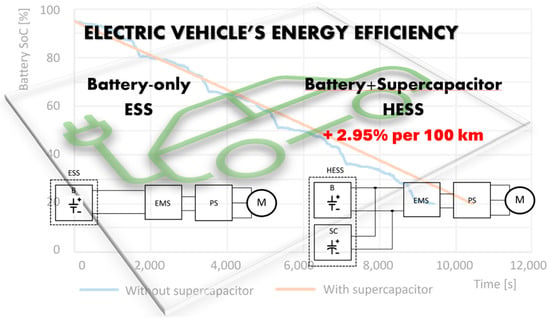

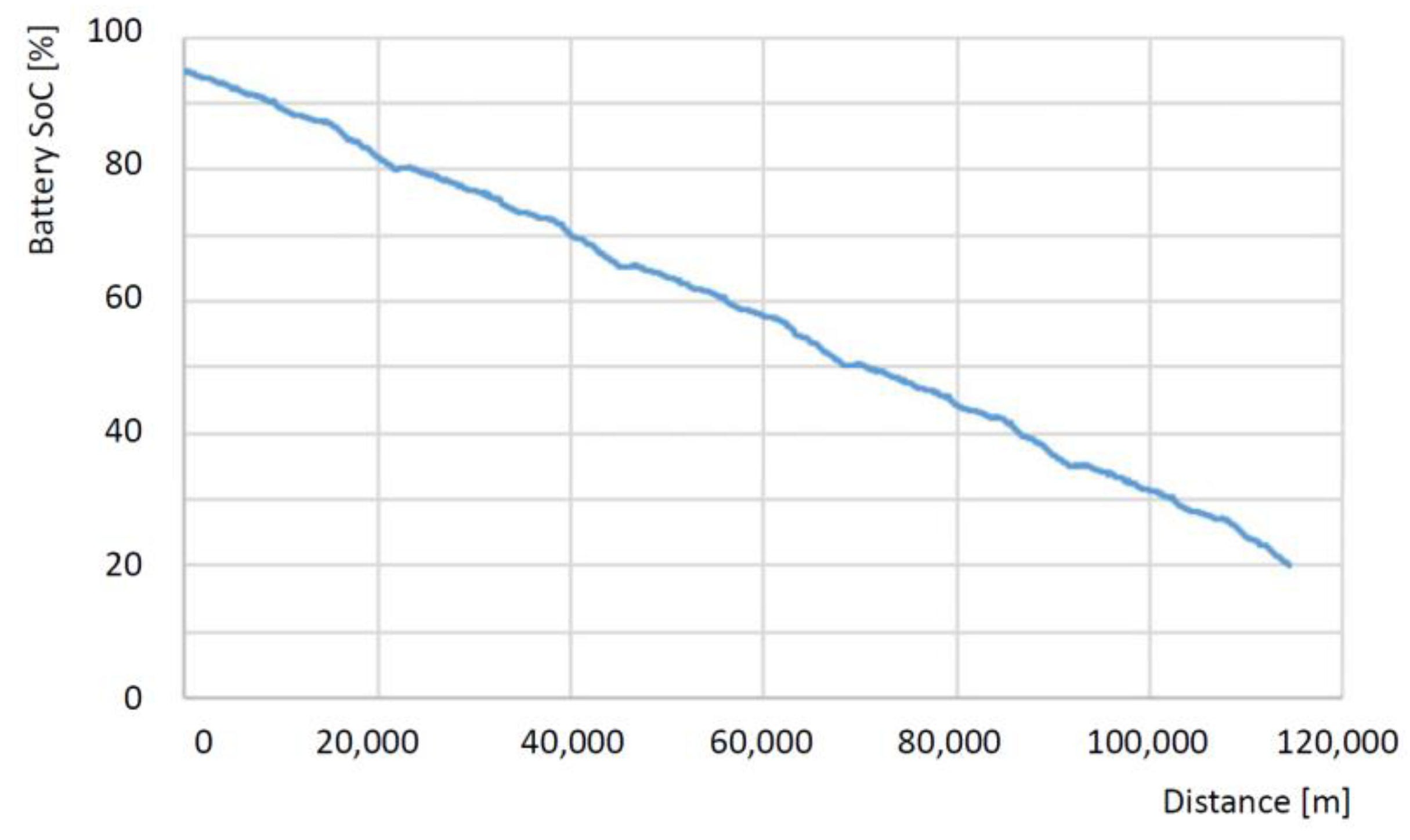

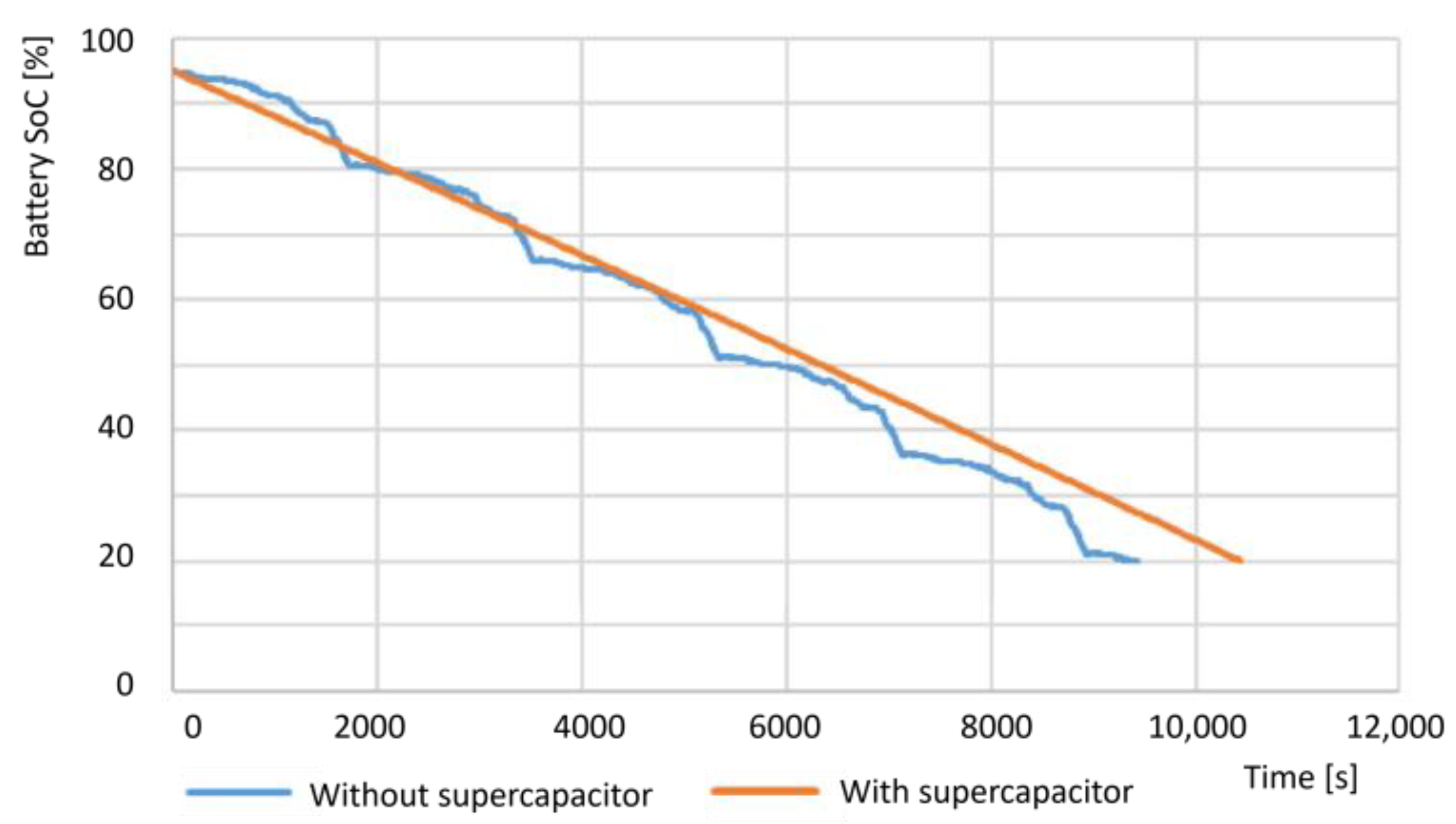

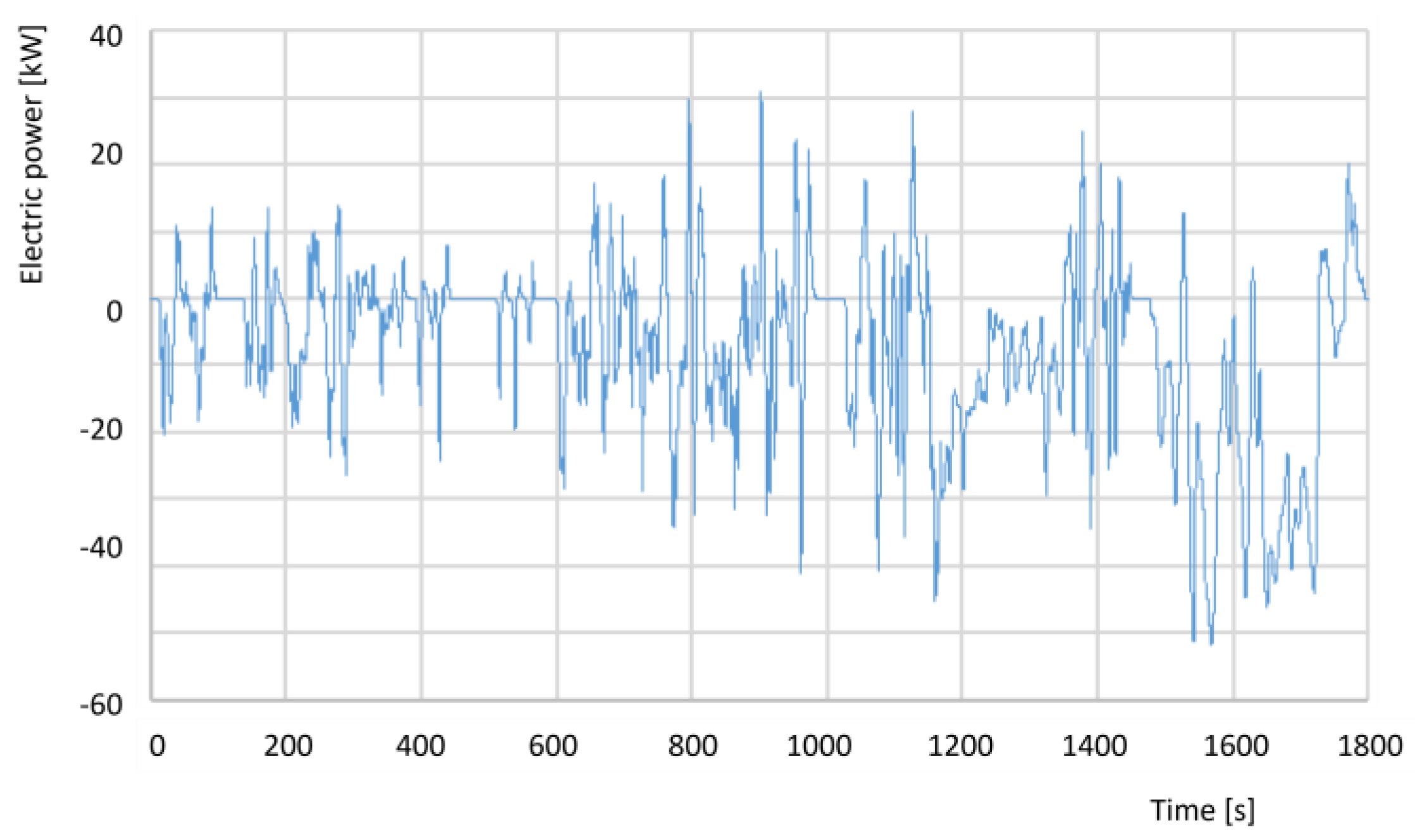

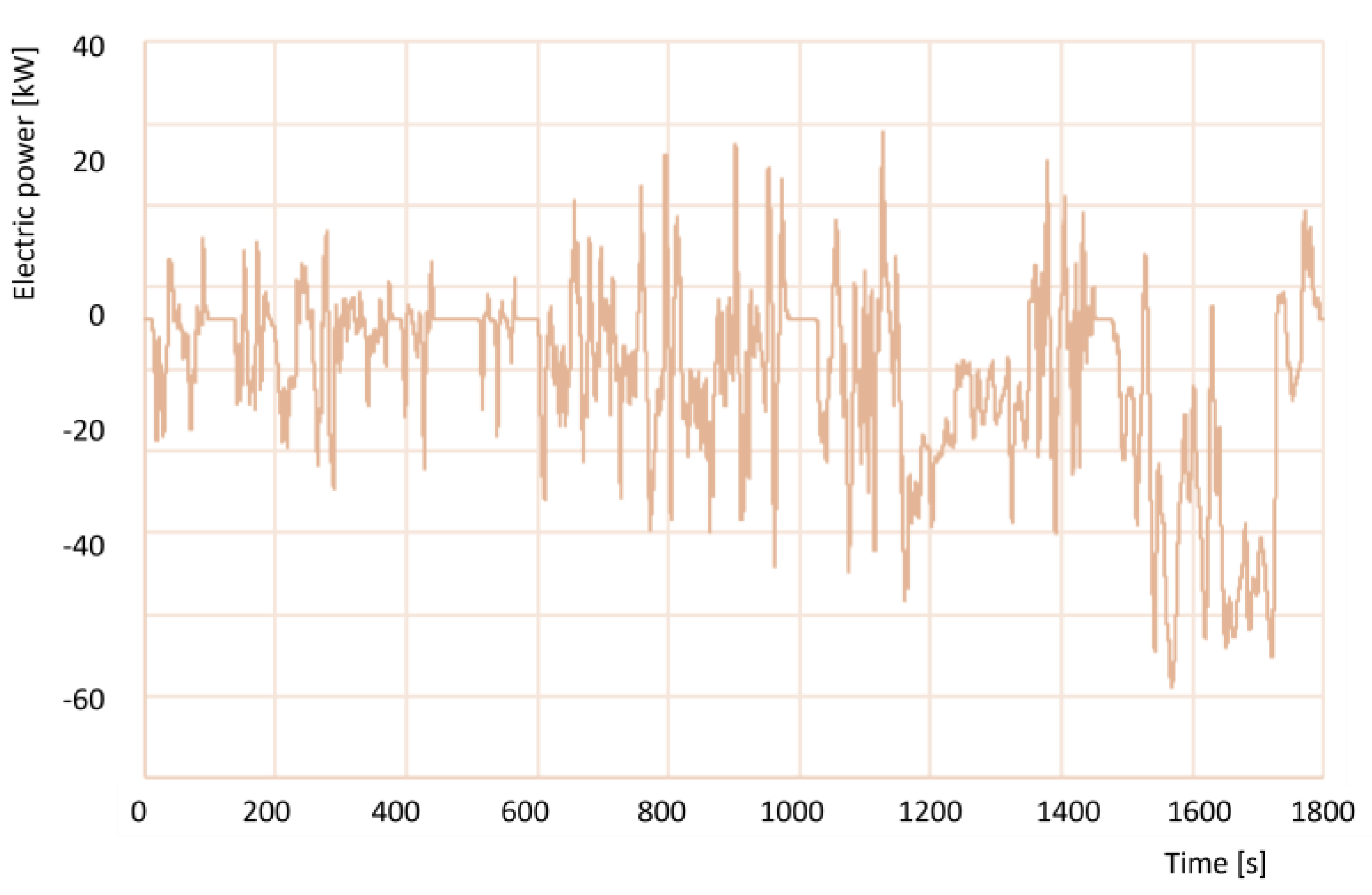

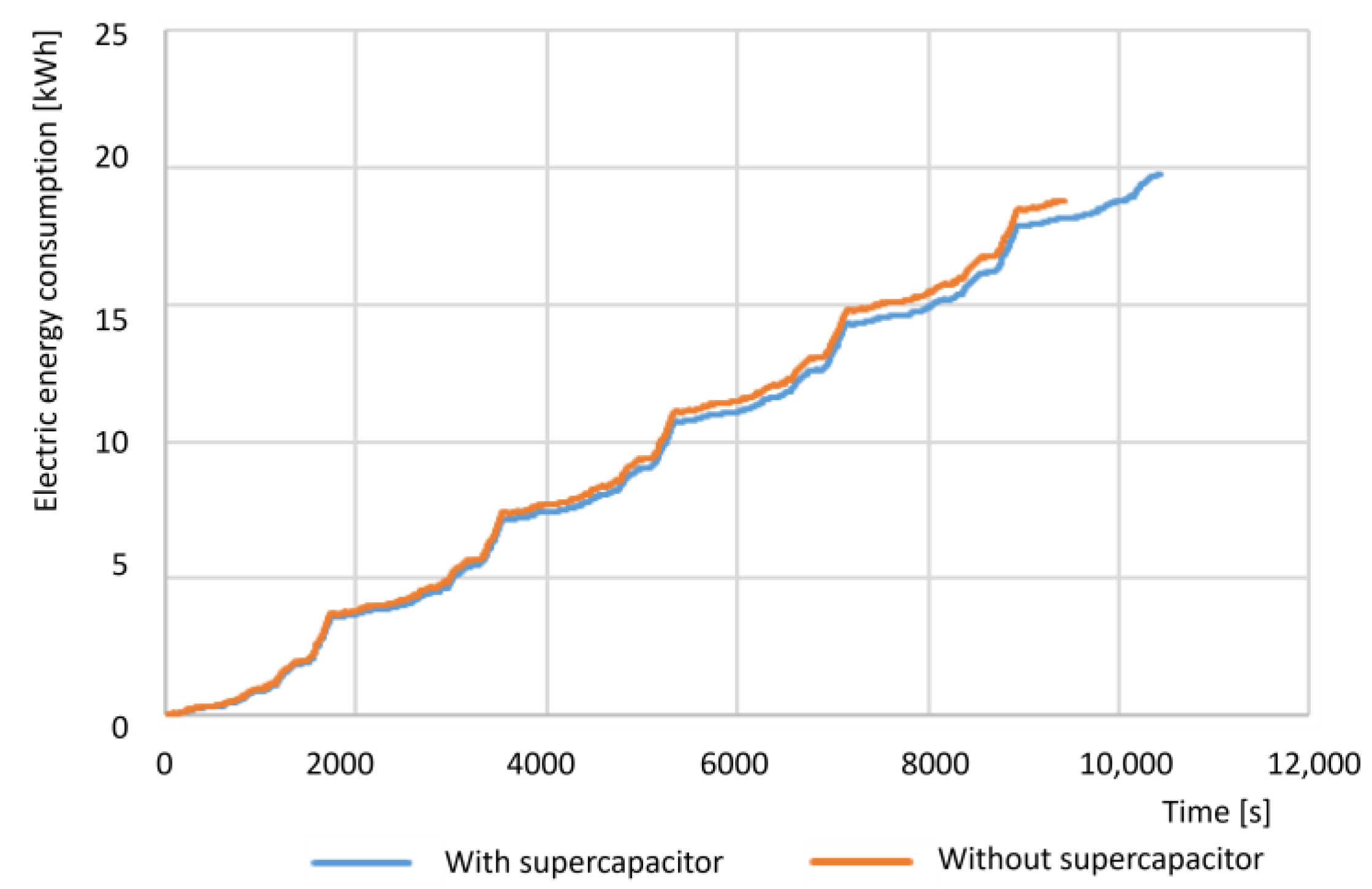

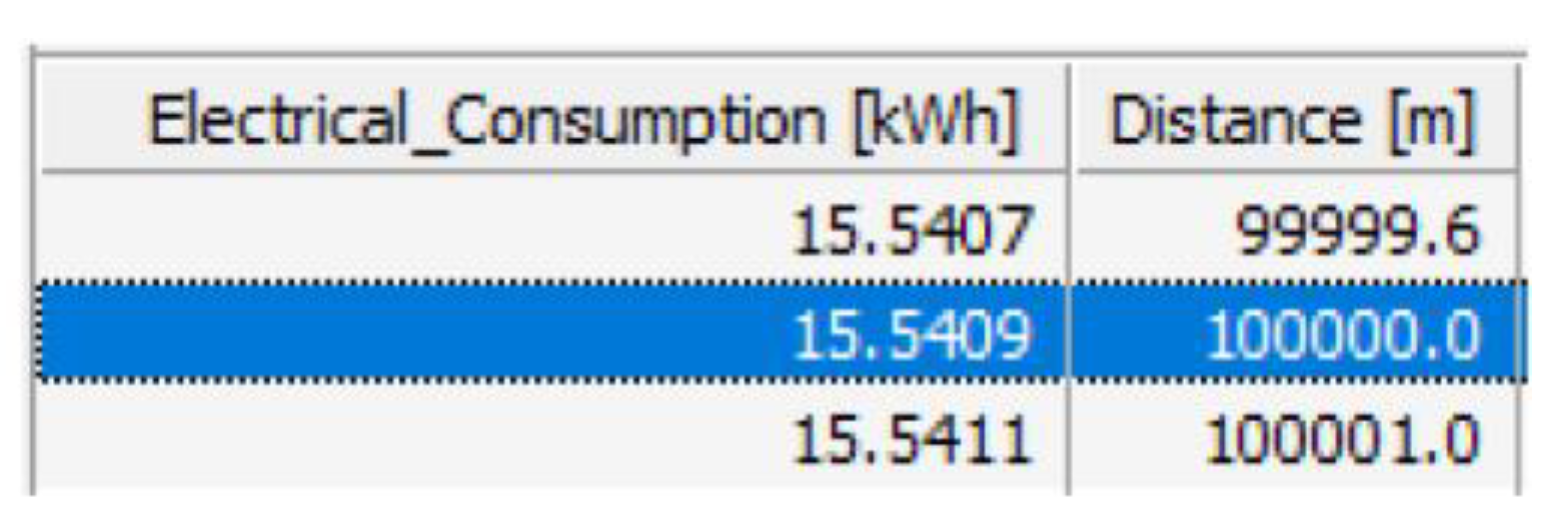

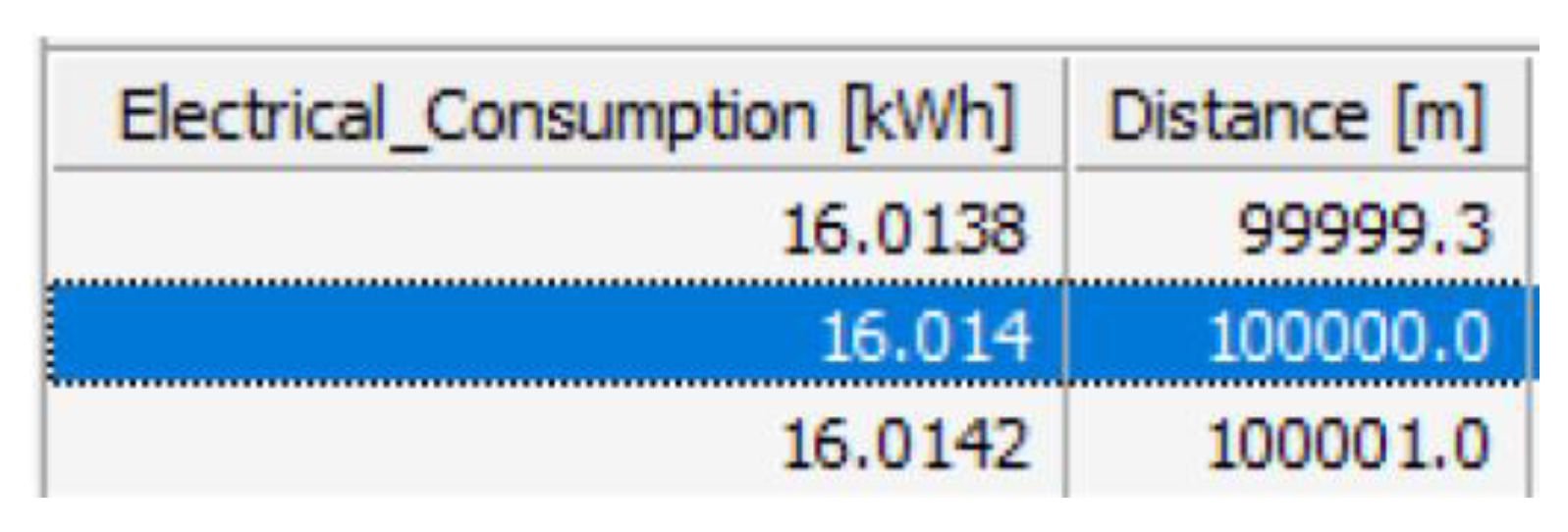

4. Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sepasi, S.; Ghorbani, R.; Liaw, B.Y. A novel on-board state-of-charge estimation method for aged Li-ion batteries based on model adaptive extended Kalman filter. J. Power Sources 2014, 245, 337–344. [Google Scholar] [CrossRef]

- Sepasi, S.; Roose, L.R.; Matsuura, M.M. Extended Kalman Filter with a fuzzy Method for Accurate Battery Pack State of Charge Estimation. Energies 2015, 8, 5217–5223. [Google Scholar] [CrossRef]

- Siang, F.T.; Chee, W.T. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar]

- Şahin, M.E.; Blaabjerg, F.; Sangwongwanich, A. A Comprehensive Review on Supercapacitor Applications and Developments. Energies 2022, 15, 674. [Google Scholar] [CrossRef]

- Horn, M.; MacLeod, J.; Liu, M.; Webb, J.; Motta, N. Supercapacitors: A new source of power for electric cars? Econ. Anal. Policy 2019, 61, 93–103. [Google Scholar] [CrossRef] [Green Version]

- Roy, P.K.S.; Bora Karayaka, H.; Yan, Y.; Alqudah, Y. Investigations into best cost battery-supercapacitor hybrid energy storage system for a utility scale PV array. J. Energy Storage 2019, 22, 50–59. [Google Scholar] [CrossRef]

- He, X.; Zhang, X. A comprehensive review of supercapacitors: Properties, electrodes, electrolytes and thermal management systems based on phase change materials. J. Energy Storage 2022, 56, 106023. [Google Scholar] [CrossRef]

- Huang, S.; Zhu, X.; Sarkar, S.; Zhao, Y. Challenges and opportunities for supercapacitors. APL Mater. 2019, 7, 100901. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.; An, J.; Park, K.; Roh, G.; Chun, K. Analysis of a Supercapacitor/Battery Hybrid Power System for a Bulk Carrier. Appl. Sci. 2019, 9, 1547. [Google Scholar] [CrossRef] [Green Version]

- Vukajlović, N.; Milićević, D.; Dumnić, B.; Popadić, B. Comparative analysis of the supercapacitor influence on lithium battery cycle life in electric vehicle energy storage. J. Energy Storage 2020, 31, 101603. [Google Scholar] [CrossRef]

- Xiao, G.; Chen, Q.; Xiao, P.; Zhang, L.; Rong, Q. Multiobjective Optimization for a Li-Ion Battery and Supercapacitor Hybrid Energy Storage Electric Vehicle. Energies 2022, 15, 2821. [Google Scholar] [CrossRef]

- Muralee Gopi, C.V.V.; Vinodh, R.; Sambasivam, S.; Obaidat, I.M.; Kim, H.-J. Recent progress of advanced energy storage materials for flexible and wearable supercapacitor: From design and development to applications. J. Energy Storage 2020, 27, 101035. [Google Scholar] [CrossRef]

- Thakur, A.K.; Choudhary, R.B. High-performance supercapacitors based on polymeric binary composites of polythiophene (PTP)-titanium dioxide (TiO2). Synth. Met. 2016, 220, 25–33. [Google Scholar] [CrossRef]

- Saravanakumar, B.; Purushothaman, K.K.; Muralidharan, G. Interconnected V2O5 nanoporous network for high-performance supercapacitors. ACS Appl. Mater. Interfaces 2012, 4, 4484–4490. [Google Scholar] [CrossRef]

- Thakur, A.K.; Deshmukh, A.B.; Choudhary, R.B.; Karbhal, I.; Majumder, M.; Shelke, M.V. Facile synthesis and electrochemical evaluation of PANI/CNT/MoS2 ternary composite as an electrode material for high performance supercapacitor. Mater. Sci. Eng. B 2017, 223, 24–34. [Google Scholar] [CrossRef]

- Tantawy, N.S.; El-Taib Heakal, F.; Ahmed, S.Y. Synthesis of worm-like binary metallic active material by electroless deposition approach for high-performance supercapacitor. J. Energy Storage 2020, 31, 101625. [Google Scholar] [CrossRef]

- Xu, L.; Wu, J.; Zhou, W.; Jiang, F.; Xu, J. Binder-free hierarchical porous N-doped graphene directly anchored on carbon fiber cloth for high-performance electrochemical energy storage. J. Energy Storage 2020, 31, 101682. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Hou, J.; Han, X.; Ouyang, M. Energy management strategies comparison for electric vehicles with hybrid energy storage system. Appl. Energy 2014, 134, 321–331. [Google Scholar] [CrossRef]

- Hu, J.; Liu, D.; Du, C.; Yan, F.; Lv, C. Intelligent energy management strategy of hybrid energy storage system for electric vehicle based on driving pattern recognition. Energy 2020, 198, 117298. [Google Scholar] [CrossRef]

- Xu, H.; Shen, M. The control of lithium-ion batteries and supercapacitors in hybrid energy storage systems for electric vehicles: A review. Int. J. Energy Res. 2021, 45, 20524–20544. [Google Scholar] [CrossRef]

- Yang, B.; Wang, J.; Zhang, X.; Wang, J.; Shu, H.; Li, S.; He, T.; Lan, C.; Yu, T. Applications of battery/supercapacitor hybrid energy storage systems for electric vehicles using perturbation observer based robust control. J. Power Sources 2020, 448, 227444. [Google Scholar] [CrossRef]

- Kouchachvili, L.; Yaïci, W.; Entchev, E. Hybrid battery/supercapacitor energy storage system for the electric vehicles. J. Power Sources 2018, 374, 237–248. [Google Scholar] [CrossRef]

- Hung, K.; Masarapu, C.; Ko, T.; Wei, B. Wide-temperature range operation supercapacitors from nanostructured activated carbon fabric. J. Power Sources 2009, 193, 944–949. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Durganjali, C.S.; Chawla, V.; Raghavan, H.; Radhika, S. Design, development, and techno-economic analysis of extreme fast charging topologies using Super Capacitor and Li-Ion Battery combinations. J. Energy Storage 2022, 56, 106140. [Google Scholar] [CrossRef]

- Voicu, I.; Louahlia, H.; Gualous, H.; Gallay, R. Thermal management and forced air-cooling of supercapacitors stack. Appl. Therm. Eng. 2015, 85, 89–99. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, Z.; Chen, W.; Sun, X.; Luo, M.; Zhang, X.; Li, C.; An, Y.; Song, S.; Wang, K.; et al. A Review on Thermal Behaviors and Thermal Management Systems for Supercapacitors. Batteries 2023, 9, 128. [Google Scholar] [CrossRef]

- Wieczorek, M.; Lewandowski, M.; Jefimowski, W. Cost comparison of different configurations of a hybrid energy storage system with battery-only and supercapacitor-only storage in an electric city bus. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 1095–1106. [Google Scholar]

- Qi, J.; Su, M. Analysis of Micro-Electric Vehicle with Super Capacitor/Battery Hybrid Energy Storage System. J. Phys. Conf. Ser. 2023, 2459, 012091. [Google Scholar] [CrossRef]

- Lahyani, A.; Sari, A.; Lahbib, I.; Venet, P. Optimal hybridization and amortized cost study of battery/supercapacitors system under pulsed loads. J. Energy Storage 2016, 6, 222–231. [Google Scholar] [CrossRef]

- Hebner, R.; Beno, J.; Walls, A. Flywheel batteries come around again. IEEE Spectr. 2002, 39, 46–51. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.W.; Wang, Y.H.; Liu, G.C.; Tian, G.Z. A review of control strategies for flywheel energy storage system and a case study with matrix converter. Energy Rep. 2022, 8, 3948–3963. [Google Scholar] [CrossRef]

- Jaafar, A.; Akli, C.R.; Sareni, B.; Roboam, X.; Jeunesse, A. Sizing and energy management of a hybrid locomotive based on flywheel and accumulators. IEEE Trans. Veh. Technol. 2009, 58, 3947–3958. [Google Scholar] [CrossRef] [Green Version]

- Talebi, S.; Nikbakhtian, B.; Toliyat, H. A novel algorithm for designing the PID controllers of high-speed flywheels for traction applications. In Proceedings of the Vehicle Power and Propulsion Conference (VPPC), Arlington, TX, USA, 9–12 September 2007; pp. 574–579. [Google Scholar]

- Shen, S.; Veldpaus, F.E. Analysis and control of a flywheel hybrid vehicular powertrain. IEEE Trans. Control Syst. 2004, 12, 645–660. [Google Scholar] [CrossRef]

- Lemofouet, S.; Rufer, A. A hybrid energy storage system based on compressed air and supercapacitors with maximum efficiency point tracking (MEPT). IEEE Trans. Ind. Electron. 2006, 53, 1105–1115. [Google Scholar] [CrossRef]

- Ribeiro, P.F.; Johnson, B.K.; Crow, M.L.; Arsoy, A.; Liu, Y. Energy storage systems for advanced power applications. Proc. IEEE 2001, 89, 1744–1756. [Google Scholar] [CrossRef]

- Ali, M.H.; Wu, B.; Dougal, R.A. An overview of SMES applications in power and energy systems. IEEE Trans. Sustain. Energy 2010, 1, 38–47. [Google Scholar] [CrossRef]

- Ise, T.; Kita, M.; Taguchi, A. A hybrid energy storage with a SMES and secondary battery. IEEE Trans. Appl. Supercond. 2005, 15, 1915–1918. [Google Scholar] [CrossRef]

- Zhang, H.; Ren, J.; Zhong, Y.; Chen, J. Design and test of controller in power conditioning system for superconducting magnetic energy storage. In Proceedings of the International Conference on Power Electronics (ICPE), Daegu, Republic of Korea, 22–26 October 2007; pp. 966–972. [Google Scholar]

- Trevisani, L.; Morandi, A.; Negrini, F.; Ribani, P.L.; Fabbri, M. Cryogenic fuel-cooled SMES for hybrid vehicle application. IEEE Trans. Appl. Supercond. 2009, 19, 2008–2011. [Google Scholar] [CrossRef]

- Mukherjee, P.; Rao, V.V. Superconducting magnetic energy storage for stabilizing grid integrated with wind power generation systems. J. Mod. Power Syst. Clean Energy 2019, 7, 400–411. [Google Scholar] [CrossRef] [Green Version]

- Boicea, V.A. Energy storage technologies: The past and the present. Proc. IEEE 2014, 102, 1777–1794. [Google Scholar] [CrossRef]

- Malozemoff, A.P.; Maguire, J.; Gamble, B.; Kalsi, S. Power applications of high-temperature superconductors: Status and perspective. IEEE Trans. Appl. Supercond. 2002, 12, 778–781. [Google Scholar] [CrossRef]

- Maxwell Technologies. 160 Volt Module. Available online: https://maxwell.com/products/ultracapacitors/160v-module/ (accessed on 22 April 2023).

- Ostadi, A.; Kazerani, M. A comparative analysis of optimal sizing of battery-only, ultracapacitor-only, and battery–ultracapacitor hybrid energy storage systems for a city bus. IEEE Trans. Veh. Technol. 2015, 64, 4449–4460. [Google Scholar] [CrossRef]

- Zhang, C.; Min, H.; Yu, Y.; Wang, D.; Luke, J.; Opila, D.; Saxena, S. Using CPE function to size capacitor storage for electric vehicles and quantifying battery degradation during different driving cycles. Energies 2016, 9, 903. [Google Scholar] [CrossRef] [Green Version]

- Chong, L.W.; Wong, Y.W.; Rajkumar, R.K.; Isa, D. An adaptive learning control strategy for standalone PV system with battery supercapacitor hybrid energy storage system. J. Power Sources 2018, 394, 35–49. [Google Scholar] [CrossRef]

- Rimpas, D.; Kaminaris, S.D.; Aldarraji, I.; Piromalis, D.; Vokas, G.; Papageorgas, P.G.; Tsaramirsis, G. Energy management and storage systems on electric vehicles: A comprehensive review. Mater. Today Proc. 2022, 61, 813–819. [Google Scholar] [CrossRef]

- Yan, X.; Patterson, D. Improvement of drive range, acceleration and deceleration performances in an electric vehicle propulsion system. In Proceedings of the 30th Annual IEEE Power Electronics Specialists Conference, Charleston, SC, USA, 1 July 1999; Volume 2, pp. 638–643. [Google Scholar]

- Chau, K.; Wong, Y. Hybridization of energy sources in electric vehicles. Energy Convers. Manag. 2001, 42, 1059–1069. [Google Scholar] [CrossRef]

- Miller, J.R. Engineering electrochemical capacitor applications. J. Power Sources 2016, 326, 726–735. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Han, X.; Zhang, X.; Ouyang, M. A comparison study of different semi active hybrid energy storage system topologies for electric vehicles. J. Power Sources 2015, 274, 400411. [Google Scholar] [CrossRef]

- Seaman, A.; Dao, T.S.; McPhee, J. A survey of mathematics-based equivalent-circuit and electrochemical battery models for hybrid and electric vehicle simulation. J. Power Sources 2014, 256, 410–423. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yang, D.; Ruan, X. A systematic method for generating multiple-input dc/dc converters. In Proceedings of the Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar]

- Dixon, J.W.; Ortuzar, M.E. Battery, Ultracapacitor, Fuel Cell, and Hybrid Energy Storage Systems for Electric, Hybrid Electric, Fuel Cell, and Plug-In Hybrid Electric Vehicles: State of the Art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar]

- Sibiceanu, A.R.; Iorga, A.; Nicolae, V.; Ivan, F. Consideration on the Implications of the WLTC (Worldwide Harmonized Light-Duty Test Cycle) for a Middle-Class Car, CONAT Brașov; Transilvania University Press: Braşov, Romania, 2016; pp. 203–211. ISSN 2069-0401. [Google Scholar]

- EUROCOC. WLTP Cycle Replaces NEDC. Available online: https://www.eurococ.eu/en/blog/wltp-cycle-replaces-nedc/ (accessed on 22 April 2023).

- Russo, A.; Cavallo, A. Stability and Control for Buck–Boost Converter for Aeronautic Power Management. Energies 2023, 16, 988. [Google Scholar] [CrossRef]

- Russo, A.; Cavallo, A. Supercapacitor stability and control for More Electric Aircraft application. In Proceedings of the 2020 European Control Conference, ECC 2020, Saint Petersburg, Russia, 12–15 May 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1909–1914. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Wheelbase | 2629 | mm |

| Curb weight | 1615 | kg |

| Total weight | 2000 | kg |

| Frontal area | 2.5 | m2 |

| Parameter | Value | Unit |

|---|---|---|

| Transmission ratio | 6.058 | - |

| Input moment of inertia | 0.010 | kg∙m2 |

| Output moment of inertia | 0.015 | kg∙m2 |

| Efficiency | 96 | % |

| Parameter | Value | Unit |

|---|---|---|

| Moment of inertia | 0.1431 | kg∙m2 |

| Tire friction coefficient | 1 | - |

| Load on wheel | 4037.5 | N |

| Static rolling radius/circumference | 306.055/1923 | mm |

| Dynamic rolling radius/circumference | 308.283/1937 | mm |

| Parameter | Value | Unit |

|---|---|---|

| Brake piston surface | 1800 | mm2 |

| Friction coefficient | 0.25 | - |

| Specific brake factor | 1 | - |

| Efficiency | 99 | % |

| Moment of inertia | 0.02 | kg∙m2 |

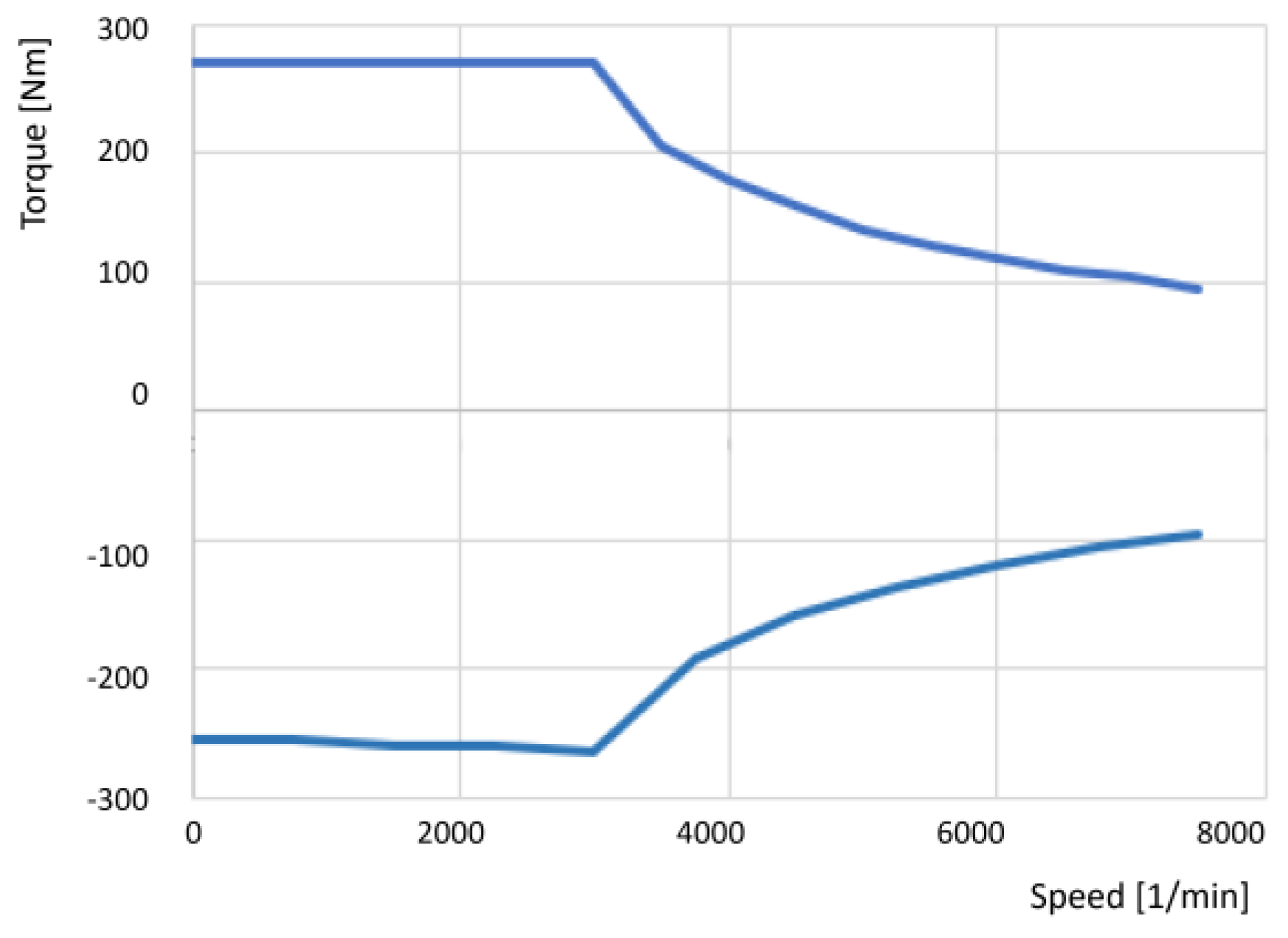

| Parameter | Value | Unit |

|---|---|---|

| Type | PSM | - |

| Nominal voltage | 323 | V |

| Moment of inertia | 1.0 × 10−4 | kg∙m2 |

| Maximum speed (engine) | 12,000 | 1/min |

| Maximum power (engine) | 85 | kW |

| Maximum torque (engine) | 270 | Nm |

| Maximum speed (generator) | 7000 | 1/min |

| Maximum power (generator) | 84 | kW |

| Maximum torque (generator) | 264 | Nm |

| Efficiency | 92.5 | % |

| Initial temperature | 20 | °C |

| Parameter | Value | Unit |

|---|---|---|

| Maximum charge | 75 | Ah |

| Nominal voltage | 323 | V |

| Energy capacity | 24.2 | kWh |

| Maximum voltage | 339 | V |

| Minimum voltage | 308 | V |

| Initial SoC | 95 | % |

| Number of cell/rows | 88 | - |

| Number of rows | 3 | - |

| Internal resistance (charging/discharging) | 0.001 | Ω |

| Operating temperature | 33 | °C |

| Specific heat transition | 0.4 | W/K |

| Specific heat capacity | 795 | J/kg∙K |

| Total weight | 318 | kg |

| Parameter | Value | Unit |

|---|---|---|

| Maximum charge | 25 | Ah |

| Nominal voltage | 3.667 | V |

| Maximum voltage | 4.2 | V |

| Minimum voltage | 3.2 | V |

| Weight | 0.724 | kg |

| Parameter | Value | Unit |

|---|---|---|

| Time | 1800 | sec |

| Distance | 23.27 | km |

| Average speed | 46.5 | km/h |

| Maximum speed | 131.3 | km/h |

| Stationary time | 12.6 | % |

| Constant functioning | 3.7 | % |

| Acceleration | 43.8 | % |

| Deceleration | 39.9 | % |

| Average positive acceleration | 0.41 | m/s2 |

| Maximum positive acceleration | 1.67 | m/s2 |

| Average deceleration | −0.45 | m/s2 |

| Minimum deceleration | −1.50 | m/s2 |

| Parameter | Value | Unit |

|---|---|---|

| Capacitance | 165 | F |

| Nominal voltage | 48.6 | V |

| Maximum current | 1970 | A |

| Maximum voltage | 51 | V |

| Minimum voltage | 46 | V |

| Parameter | Value | Unit |

|---|---|---|

| Maximum power | 2 | kW |

| Nominal voltage | 336.6 | V |

| Maximum voltage | 367.2 | V |

| Minimum voltage | 255 | V |

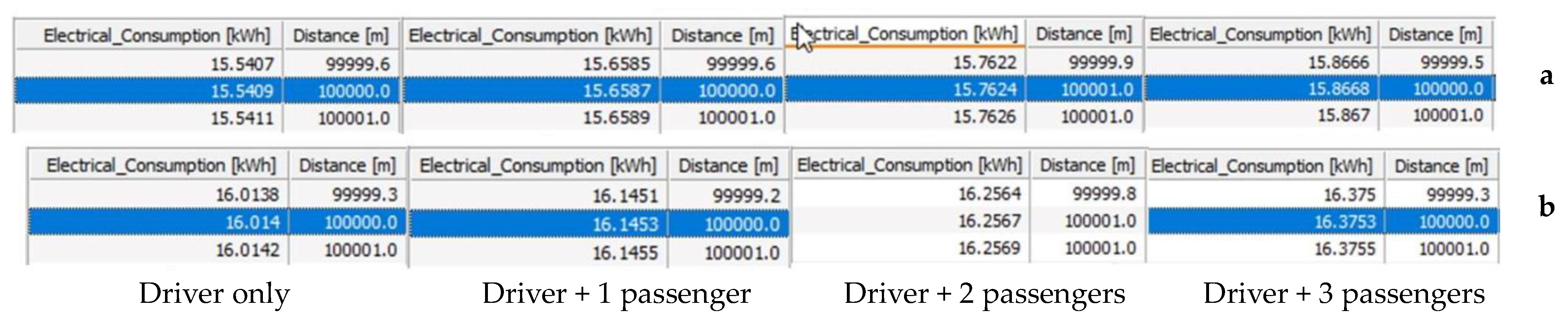

| Number of Passengers | Energy Consumption (kWh) | Autonomy (km) | ||||||

|---|---|---|---|---|---|---|---|---|

| With SC * | % | Without SC | % | With SC | % | Without SC | % | |

| 1 | 15.5409 | - | 16.0140 | - | 131.310 | - | 114.504 | - |

| 2 | 15.6587 | +0.75 | 16.1453 | +0.81 | 130.719 | −0.45 s | 113.859 | −0.56 |

| 3 | 15.7624 | +1.43 | 16.2567 | +1.52 | 130.128 | −0.90 | 113.352 | −1.00 |

| 4 | 15.8668 | +2.09 | 16.3753 | +2.26 | 129.542 | −1.34 | 112.758 | −1.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mariasiu, F.; Kelemen, E.A. Analysis of the Energy Efficiency of a Hybrid Energy Storage System for an Electric Vehicle. Batteries 2023, 9, 419. https://doi.org/10.3390/batteries9080419

Mariasiu F, Kelemen EA. Analysis of the Energy Efficiency of a Hybrid Energy Storage System for an Electric Vehicle. Batteries. 2023; 9(8):419. https://doi.org/10.3390/batteries9080419

Chicago/Turabian StyleMariasiu, Florin, and Edmond A. Kelemen. 2023. "Analysis of the Energy Efficiency of a Hybrid Energy Storage System for an Electric Vehicle" Batteries 9, no. 8: 419. https://doi.org/10.3390/batteries9080419

APA StyleMariasiu, F., & Kelemen, E. A. (2023). Analysis of the Energy Efficiency of a Hybrid Energy Storage System for an Electric Vehicle. Batteries, 9(8), 419. https://doi.org/10.3390/batteries9080419