Environmental and Economic Comparison of Natural and Recycled Aggregates Using LCA

Abstract

:1. Introduction

2. Methodology

2.1. System Boundaries

2.2. Type and Source of Aggregates

2.3. Processing Characteristics

2.4. Databases

2.5. Environmental Impacts and Methods

3. Results and Discussion

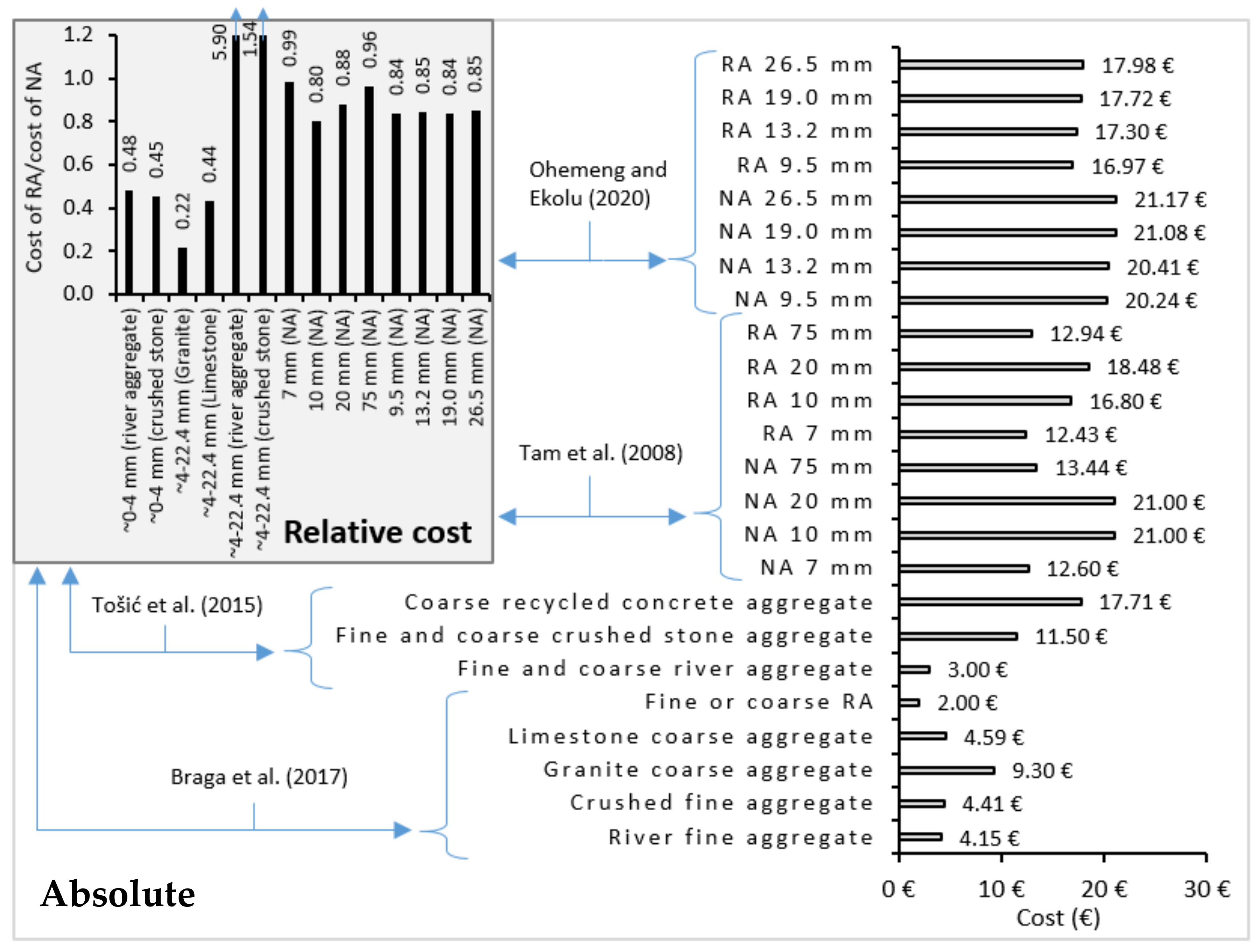

3.1. Economic Impact of Natural and Recycled Aggregates

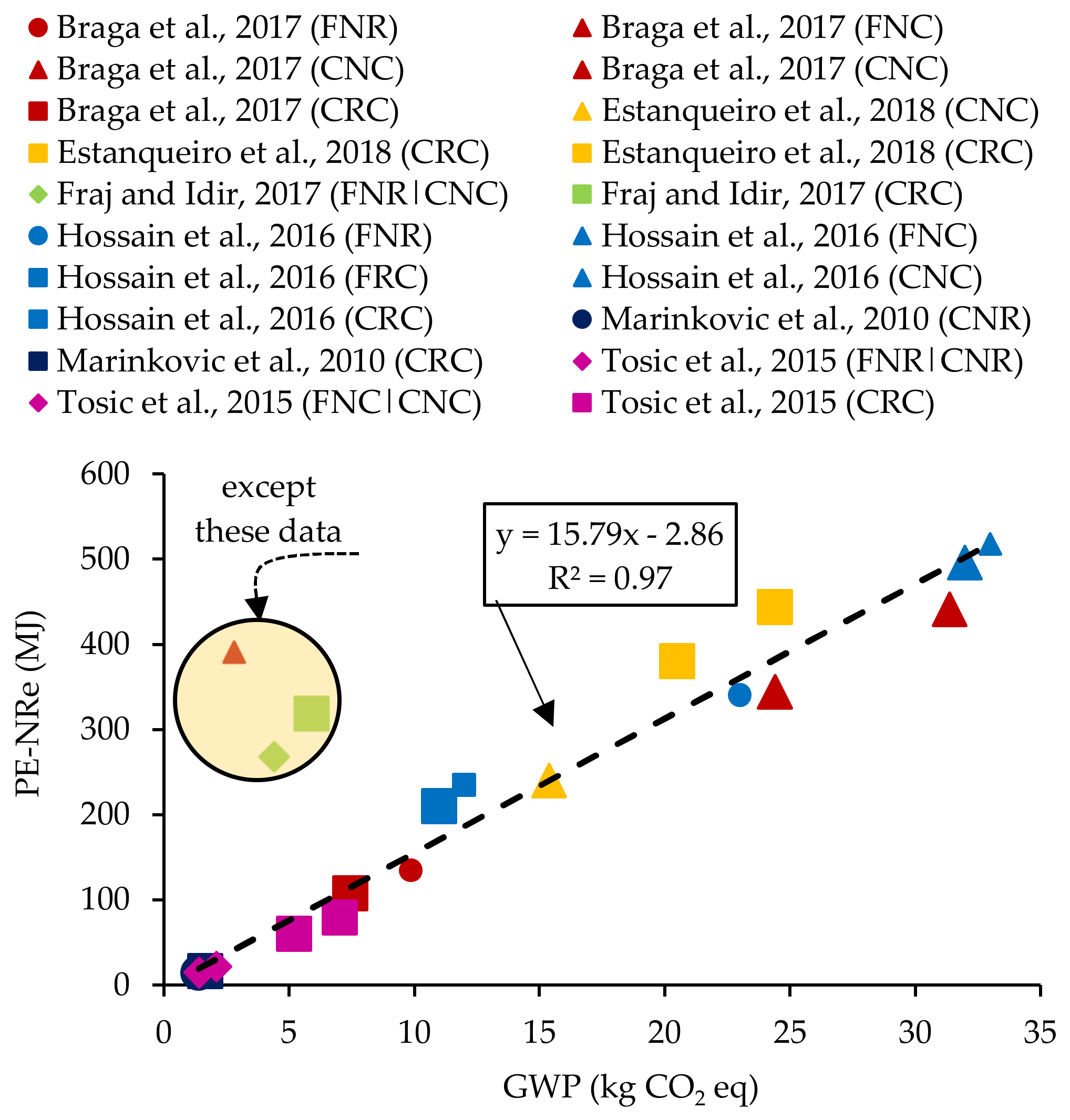

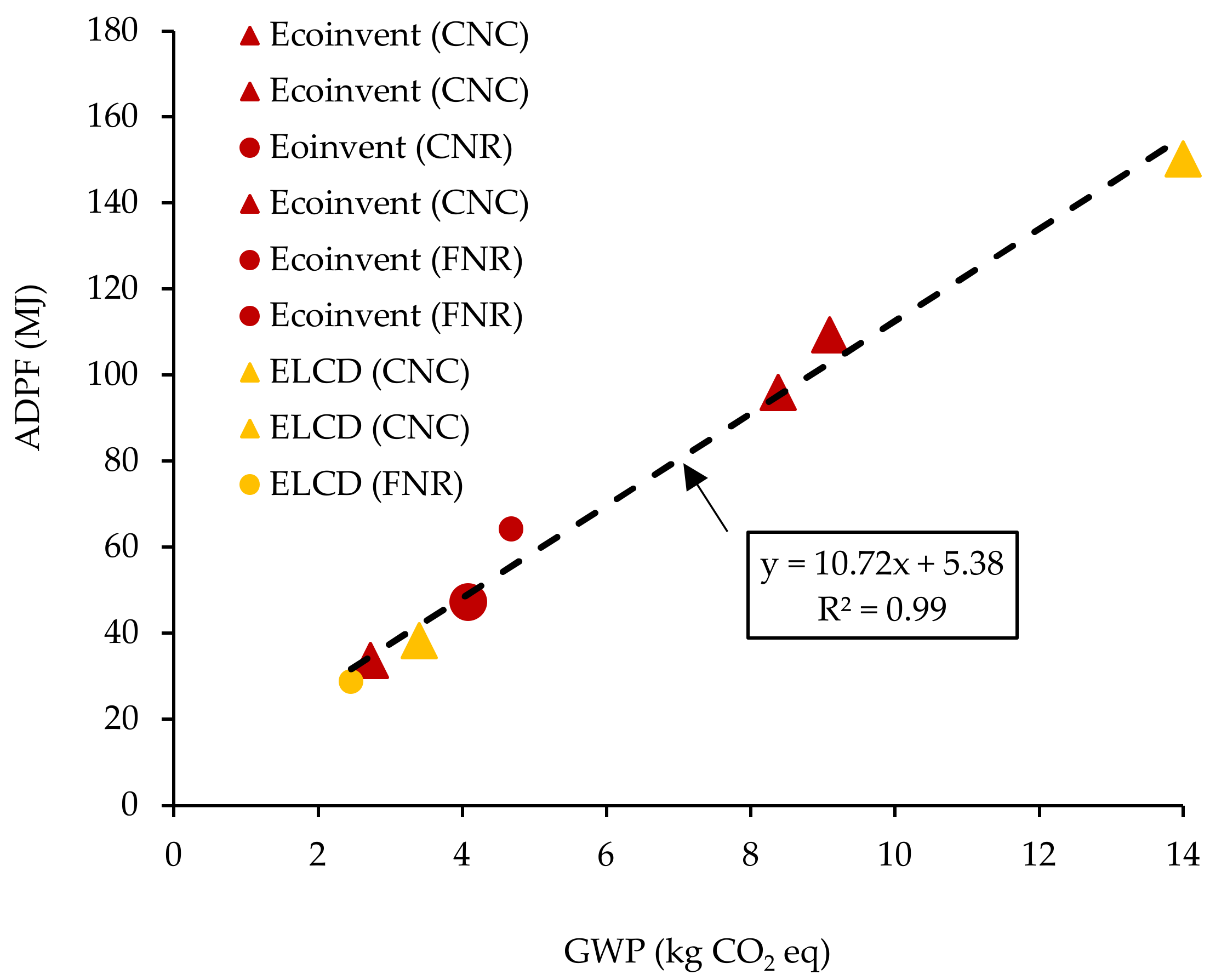

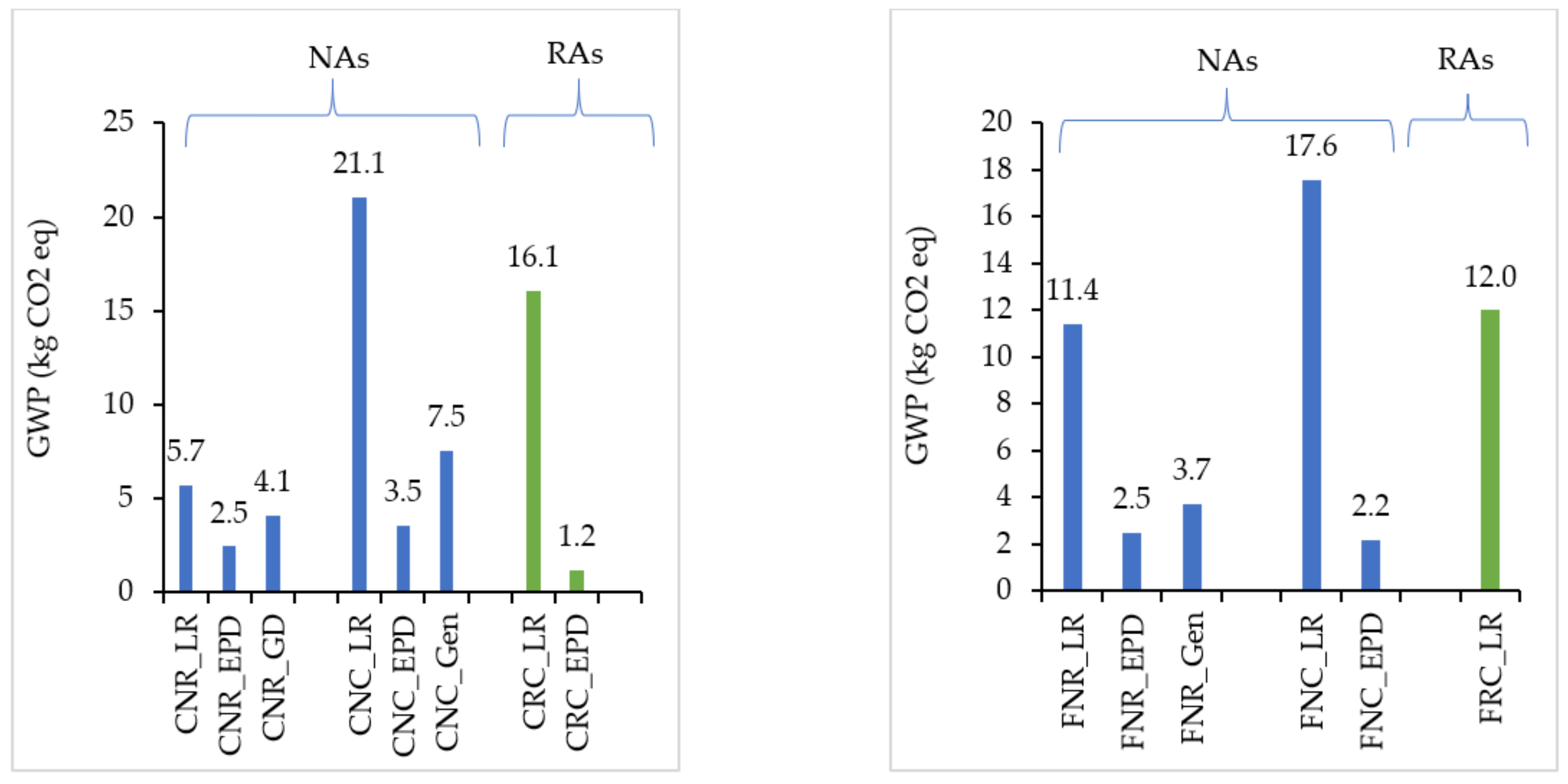

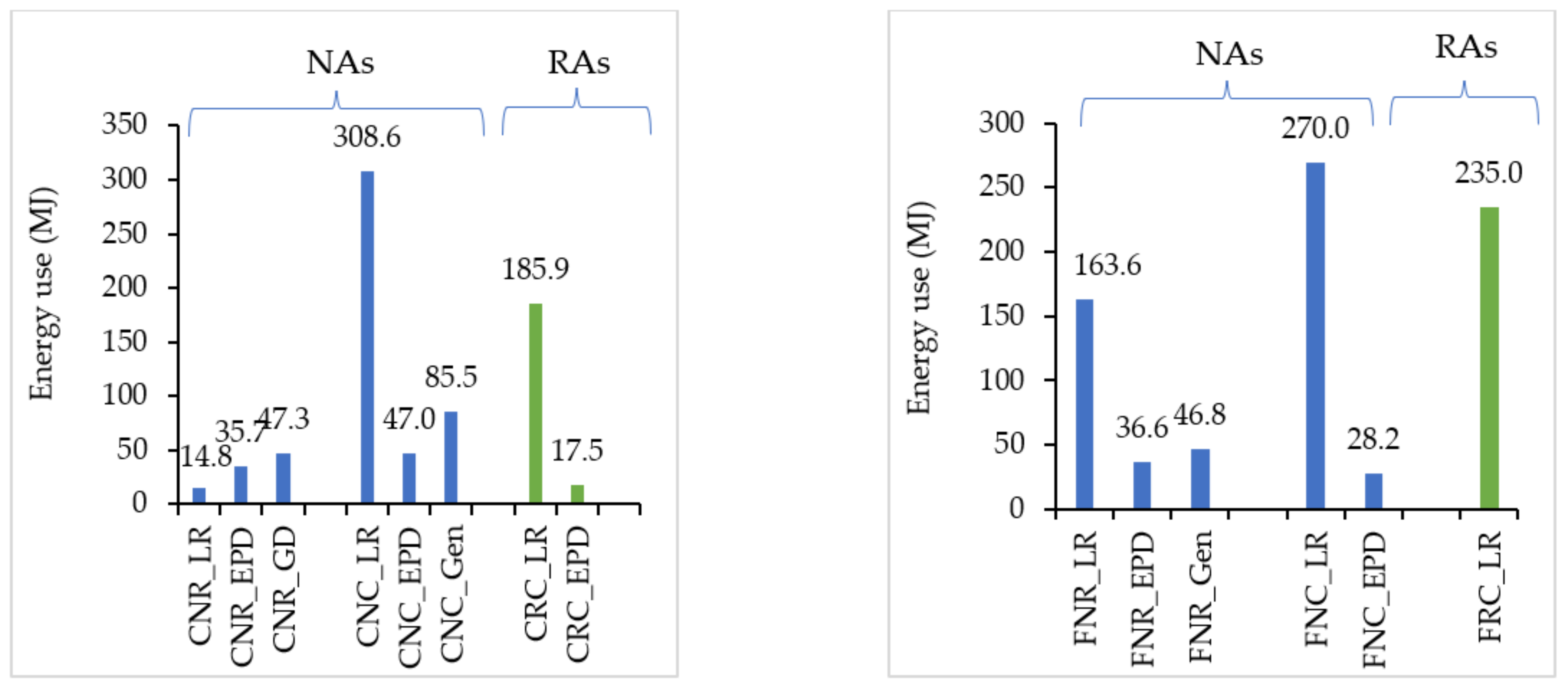

3.2. Environmental Impact of Natural and Recycled Aggregates

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Wu, H.; Tam, V.W.Y.; Zuo, J. Considering life-cycle environmental impacts and society’s willingness for optimizing construction and demolition waste management fee: An empirical study of China. J. Clean. Prod. 2019, 206, 1004–1014. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular economy on construction and demolition waste: A literature review on material recovery and production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef] [PubMed]

- Coelho, A.; de Brito, J. Environmental analysis of a construction and demolition waste recycling plant in Portugal-Part II: Environmental sensitivity analysis. Waste Manag. 2013, 33, 147–161. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.V. Use of Recycled Aggregate from Construction and Demolition Wastes in the Production of Structural Concrete. Ph.D. Thesis, Civil Engineering, Instituto Superior Técnico, Universidade de Lisboa, Lisbon, Portugal, 2015. [Google Scholar]

- Freire, A.C.; Neves, J.M.C.; Roque, A.J.; Martins, I.M.; Antunes, M.L. Feasibility study of milled and crushed reclaimed asphalt pavement for application in unbound granular layers. Road Mater. Pavement Des. 2021, 22, 1500–1520. [Google Scholar] [CrossRef]

- Durgaprasad, K.; Koppala, S.; Guptha, M.R.V.S.G. Experimental investigation on fully recycled coarse aggregate concrete at various atmospheric conditions. Int. J. Sci. Res. Rev. 2018, 7, 1582–1591. [Google Scholar]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared environmental and economic impact from cradle to gate of concrete with natural and recycled coarse aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Manfredi, S.; Pant, R. Supporting Environmentally Sound Decisions for Construction and Demolition (C&D) Waste Management. In JRC Scientific and Technical Reports; European Commission, Joint Research Centre, Institute for Environment and Sustainability: Luxembourg, 2011. [Google Scholar]

- Silvestre, J.D.; de Brito, J.; Pinheiro, M.D. Environmental impacts and benefits of the end-of-life of building materials-calculation rules, results and contribution to a “cradle to cradle” life cycle. J. Clean. Prod. 2014, 66, 37–45. [Google Scholar] [CrossRef]

- Tecco, N.; Baudino, C.; Girgenti, V.; Peano, C. Innovation strategies in a fruit growers association impacts assessment by using combined LCA and s-LCA methodologies. Sci. Total Environ. 2016, 568, 253–262. [Google Scholar] [CrossRef]

- Pargana, N.; Pinheiro, M.D.; Silvestre, J.D.; de Brito, J. Comparative environmental life cycle assessment of thermal insulation materials of buildings. Energy Build. 2014, 82, 466–481. [Google Scholar] [CrossRef]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef] [Green Version]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Jullien, A.; Proust, C.; Martaud, T.; Rayssac, E.; Ropert, C. Variability in the environmental impacts of aggregate production. Resour. Conserv. Recycl. 2012, 62, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Simion, I.M.; Fortuna, M.E.; Bonoli, A.; Gavrilescu, M. Comparing environmental impacts of natural inert and recycled construction and demolition waste processing using LCA. J. Environ. Eng. Landsc. Manag. 2013, 21, 273–287. [Google Scholar] [CrossRef]

- Tošic, N.; Marinković, S.; Dašić, T.; Stanić, M. Multicriteria optimization of natural and recycled aggregate concrete for structural use. J. Clean. Prod. 2015, 87, 766–776. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Pellegrino, C.; Pasinato, S. Sustainable management and supply of natural and recycled aggregates in a medium-size integrated plant. Waste Manag. 2016, 46, 146–155. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Fraj, A.B.; Idir, R. Concrete based on recycled aggregates-Recycling and environmental analysis: A case study of Paris’ region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Estanqueiro, B.; Silvestre, J.D.; de Brito, J.; Pinheiro, M.D. Environmental life cycle assessment of coarse natural and recycles aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 12, 429–449. [Google Scholar] [CrossRef]

- Colangelo, F.; Petrillo, A.; Cioffi, R.; Borrelli, C.; Forcina, A. Life cycle assessment of recycled concretes: A case study in southern Italy. Sci. Total Environ. 2018, 615, 1506–1571. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resources, Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Park, W.J.; Kim, T.; Roh, S.; Kim, R. Analysis of life cycle environmental impact of recycled aggregate. Appl. Sci. 2019, 9, 1021. [Google Scholar] [CrossRef] [Green Version]

- Pradhan, S.; Tiwari, B.R.; Kumar, S.; Barai, S. Comparative LCA of recycled and natural aggregate concrete using Particle Packing Method and conventional method of design mix. J. Clean. Prod. 2019, 228, 679–691. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O. Comparative analysis on costs and benefits of producing natural and recycled concrete aggregates: A South African case study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Kulekci, G.; Yilmaz, A.O.; Cullu, M. Experimental investigation of usability of construction waste as aggregate. J. Min. Environ. 2021, 12, 63–76. [Google Scholar]

- FSKB-2018-1-ECOINVENT; Average EPD for Aggregates. SÜGB: Bern, Switzerland, 2018.

- NEPD-1537-527-EN; Crushed Stone Construction Aggregate products, Oslo and Bærum. The Norwegian EPD Foundation: Oslo, Norway, 2018.

- S-P-02081; Environmental Product Declaration for Aggregates from Copenhagen, Terminal for Marine Aggregates–Avedøre. The International EPD System: Stockholm, Sweden, 2020.

- S-P-00843; Environmental Product Declaration for Aggregates from the Stationary Crushing Plant RamNAslätt. The International EPD System: Stockholm, Sweden, 2017.

- S-P-01640; Environmental Product Declaration for Aggregates from Uddevalla Quarry-Glimmingen. The International EPD System: Stockholm, Sweden, 2020.

- S-P-00528; EPD Average Aggregate–Holcim Romania. The International EPD System: Stockholm, Sweden, 2014.

- NEPD-2750-1447-EN; Crushed Stones and Aggregates, Produced at DC Seljestokken Aggregates AS. The Norwegian EPD Foundation: Oslo, Norway, 2021.

- BREG EN EPD No.: 000205; Granite Aggregate-Glensanda. BRE Global: Watford, UK, 2018.

- BREG EN EPD No.: 000199; Limestone Aggregate. BRE Global: Watford, UK, 2018.

- S-P-03101; Recycled Aggregate Products. EPD International AB: Stockholm, Sweden, 2021.

- EPDIE 20-22; Recycled Aggregates. Irish Green Building Council: Dublin, Ireland, 2020.

- S-P-00426; Environmental Product Declaration (EPD) of Secondary Raw Materials or Aggregates of Industrial Origin-Sand Matrix. International EPD System: Lomello, Italy, 2013.

- S-P-00427; Environmental Product Declaration (EPD) of Secondary Raw Materials or Aggregates of Industrial Origin-AGMatrix. International EPD System: Lomello, Italy, 2013.

| Author | Type of Aggregate | Source of Aggregate | |

|---|---|---|---|

| Tam (2008) [12] | NA | Produced from rocks | Quarry |

| RA | Recycled concrete waste | Recycling plant | |

| Marinković et al. (2010) [13] | NA | River aggregate | River |

| RA | Recycled coarse aggregate | Demolished reinforced concrete structure | |

| Jullien et al. (2012) [14] | NA | Site 1—amphibolites from Roselier Site 2 and 3—alluvial deposits, Fz and Fy (sand and gravel) | - |

| RA | - | - | |

| Simion et al. (2013) [15] | NA | Natural inert quarries | Quarry |

| RA | C&D inert waste | CDW recycling plant | |

| Tošić et al. (2015) [16] | NA | Fine and coarse river aggregate; fine and coarse crushed stone aggregate | - |

| RA | Coarse recycled concrete aggregate | - | |

| Faleschini et al. (2016) [17] | NA | High quality/low quality (gravel/sand) | Quarry |

| RA | High quality/low quality | CDW recycling plant | |

| Hossain et al. (2016) [18] | NA | River sand/crushed stone | - |

| RA | CDW/waste glass | - | |

| Braga et al. (2017) [7] | NA | River/crushed (fine aggregate); Granitic/limestone (coarse aggregate) | River/quarry |

| RA | Precast/demolished/cast in laboratory elements | Recycling plant | |

| Fraj and Idir (2017) [19] | NA | Calcareous (Boulonnais landfill) | Boulonnais landfill |

| RA | Low grade and high grade | Recycled concrete aggregate, demolished buildings | |

| Rosado et al. (2017) [20] | NA | Basalt mineral | Basalt quarry |

| RA | Mix CDW generation | CDW recycling plant facility | |

| Estanqueiro et al. (2018) [21] | NA | Limestone | Quarry |

| RA | CDW | Demolition site | |

| Colangelo et al. (2018) [22] | NA | Natural sand and gravel Natural stone | - |

| RA | CDW from concrete industry and marble sludge Cement kiln dust | - | |

| Kurda et al. (2018) [23] | NA | Limestone; river sand | River/quarry |

| RA | CDW | Recycling plant | |

| Park et al. (2019) [24] | NA | Gravel (25 mm, 45 mm, 75 mm) | Sea, land and mountains |

| RA | Waste concrete | Demolition and deconstruction of structures | |

| Pradhan et al. (2019) [25] | NA | Basalt | Mine |

| RA | CDW | Demolition site/recycling plant | |

| Ohemeng and Ekolu (2020) [26] | NA | Fine NA | Quarry |

| RA | Fine recycled concrete aggregate | Recycling plant | |

| Kulekci et al. (2021) [27] | NA | - | - |

| RA | Construction wastes | 3 provinces in Turkey | |

| Aggregates | LCA Databases | |||

|---|---|---|---|---|

| Portugal | International | |||

| Literature Review | Literature Review | EPD | Generic Databases | |

| Coarse natural rolled | 0 | 3 | 2 | 1 |

| Coarse natural crushed | 2 | 3 | 9 | 3 |

| Coarse recycled crushed | 2 | 5 | 4 | 0 |

| Fine natural rolled | 1 | 3 | 2 | 2 |

| Fine natural crushed | 1 | 2 | 2 | 0 |

| Fine recycled crushed | 0 | 1 | 0 | 0 |

| System Process | Database |

|---|---|

| Basalt {RoW}| quarry operation | Cut-off, S | Ecoinvent 3 |

| Gravel, crushed {RoW}| production | Cut-off, S | Ecoinvent 3 |

| Gravel, round {RoW}| gravel and sand quarry operation | Cut-off, S | Ecoinvent 3 |

| Limestone, crushed, for mill {RoW}| production | Cut-off, S | Ecoinvent 3 |

| Sand {RoW}| gravel and quarry operation | Cut-off, S | Ecoinvent 3 |

| Sand {RoW}| sand quarry operation, extraction from riverbed | Cut-off, S | Ecoinvent 3 |

| Crushed stone 16/32 mm, open-pit mining, production mix, at the plant, undried RER S | ELCD |

| Gravel 2/32 mm, wet and dry quarry, production mix, at the plant, undried RER S | ELCD |

| Sand 0/2 mm, wet and dry quarry, production mix, at the plant, undried RER S | ELCD |

| CML Baseline | Cumulative Energy Demand | Eco-Indicator 99 | Mat France | IMPACT 2002+ | |

|---|---|---|---|---|---|

| Number of studies | 4 | 2 | 1 | 1 | 1 |

| Abiotic depletion | X | X | |||

| Abiotic depletion (fossil fuels) | X | ||||

| Acidification | X | X | X | ||

| Air pollution | X | ||||

| Aquatic acidification | X | ||||

| Aquatic ecotoxicity | X | ||||

| Aquatic eutrophication | X | ||||

| Carcinogens | X | X | |||

| Climate change | X | ||||

| Ecotoxicity | X | ||||

| Energy consumption | X | ||||

| Eutrophication | X | X | X | ||

| Freshwater aquatic ecotoxicity | X | ||||

| Fossil fuels | X | ||||

| Global warming | X | X | X | ||

| Human toxicity | X | ||||

| Ionizing radiation | X | ||||

| Land use | X | X | |||

| Marine aquatic ecotoxicity | X | ||||

| Minerals | X | X | |||

| Non-carcinogens | X | ||||

| Non-renewable | X | X | |||

| Ozone layer depletion (ODP) | X | X | X | X | |

| Photochemical oxidation | X | X | |||

| Radiation | |||||

| Renewable | X | ||||

| Resp. inorganics | X | X | |||

| Resp. organics | X | X | |||

| Terrestrial acidification/nutrification | X | ||||

| Terrestrial ecotoxicity | X | X | |||

| Water pollution | X | ||||

| Water usage | X | ||||

| Wastes | X |

| Author | Coarse/Fine | Natural/ Recycled | Crushed/ Rolled | Origin | GWP (kg CO2 eq) | PE-NRe (MJ) |

|---|---|---|---|---|---|---|

| Braga et al. [7] | Coarse | Natural | Crushed | Granite | 24.4 | 344 |

| Braga et al. [7] | Coarse | Natural | Crushed | Limestone | 31.4 | 441 |

| Estanqueiro et al. [21] | Coarse | Natural | Crushed | Limestone | 15.4 | 240 |

| Fraj and Idir [19] | Coarse | Natural | Crushed | Limestone | 4.39 | 320 |

| Tošić et al. [16] | Coarse | Natural | Crushed | Limestone | 2.12 | 21.9 |

| Hossain et al. [18] | Coarse | Natural | Crushed | Limestone | 32.0 | 496 |

| Marinković et al. [13] | Coarse | Natural | Rolled | Undefined | 1.39 | 14.8 |

| Tošić et al. [16] | Coarse | Natural | Rolled | Undefined | 1.34 | 11.2 |

| Park et al. [24] | Coarse | Natural | Rolled | Undefined | 14.3 | - |

| Estanqueiro et al. [21] | Coarse | Recycled | Crushed | Concrete | 24.4 a | 444 a |

| Estanqueiro et al. [21] | Coarse | Recycled | Crushed | Concrete | 20.5 b | 381 b |

| Braga et al. [7] | Coarse | Recycled | Crushed | Concrete | 7.44 | 108 |

| Marinković et al. [13] | Coarse | Recycled | Crushed | Concrete | 1.64 | 17.0 |

| Fraj and Idir [19] | Coarse | Recycled | Crushed | Concrete | 5.87 | 320 |

| Hossain et al. [18] | Coarse | Recycled | Crushed | Concrete | 11.0 | 211 |

| Park et al. [24] | Coarse | Recycled | Crushed | Concrete | 29.4 c | - |

| Park et al. [24] | Coarse | Recycled | Crushed | Concrete | 38.1 d | - |

| Tošić et al. [16] | Coarse | Recycled | Crushed | Concrete | 7.02 e | 79.7 e |

| Tošić et al. [16] | Coarse | Recycled | Crushed | Concrete | 5.19 f | 60.8 f |

| Fraj and Idir [19] | Fine | Natural | Rolled | Limestone | 4.39 | 320 |

| Tošić et al. [16] | Fine | Natural | Rolled | Limestone | 2.12 | 21.9 |

| Braga et al. [7] | Fine | Natural | Rolled | Undefined | 9.87 | 135 |

| Hossain et al. [18] | Fine | Natural | Rolled | Undefined | 23.0 | 341 |

| Tošić et al. [16] | Fine | Natural | Rolled | Undefined | 1.43 | 11.2 |

| Braga et al. [7] | Fine | Natural | Crushed | Undefined | 2.79 | 392 |

| Hossain et al. [18] | Fine | Natural | Crushed | Undefined | 33.0 | 518 |

| Tošić et al. [16] | Fine | Natural | Crushed | Undefined | 2.12 | 21.9 |

| Hossain et al. [18] | Fine | Recycled | Crushed | Concrete | 12.0 | 235 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, A.; Nezami, S.; Silvestre, J.; Kurda, R.; Silva, R.; Martins, I.; de Brito, J. Environmental and Economic Comparison of Natural and Recycled Aggregates Using LCA. Recycling 2022, 7, 43. https://doi.org/10.3390/recycling7040043

Dias A, Nezami S, Silvestre J, Kurda R, Silva R, Martins I, de Brito J. Environmental and Economic Comparison of Natural and Recycled Aggregates Using LCA. Recycling. 2022; 7(4):43. https://doi.org/10.3390/recycling7040043

Chicago/Turabian StyleDias, Adriana, Salem Nezami, José Silvestre, Rawaz Kurda, Rui Silva, Isabel Martins, and Jorge de Brito. 2022. "Environmental and Economic Comparison of Natural and Recycled Aggregates Using LCA" Recycling 7, no. 4: 43. https://doi.org/10.3390/recycling7040043