Recycling Perspectives of Circular Business Models: A Review

Abstract

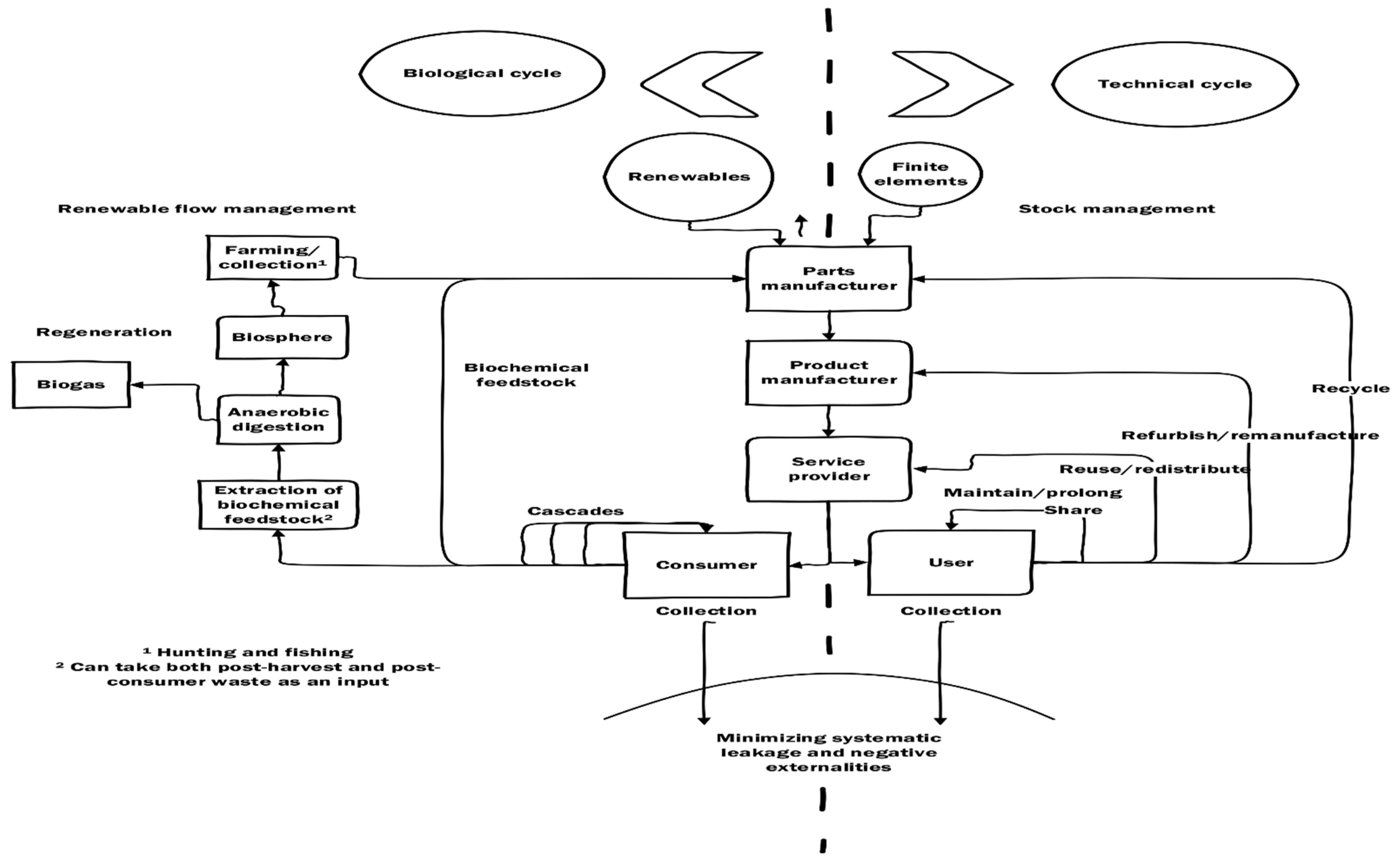

:1. Introduction

2. Research Method

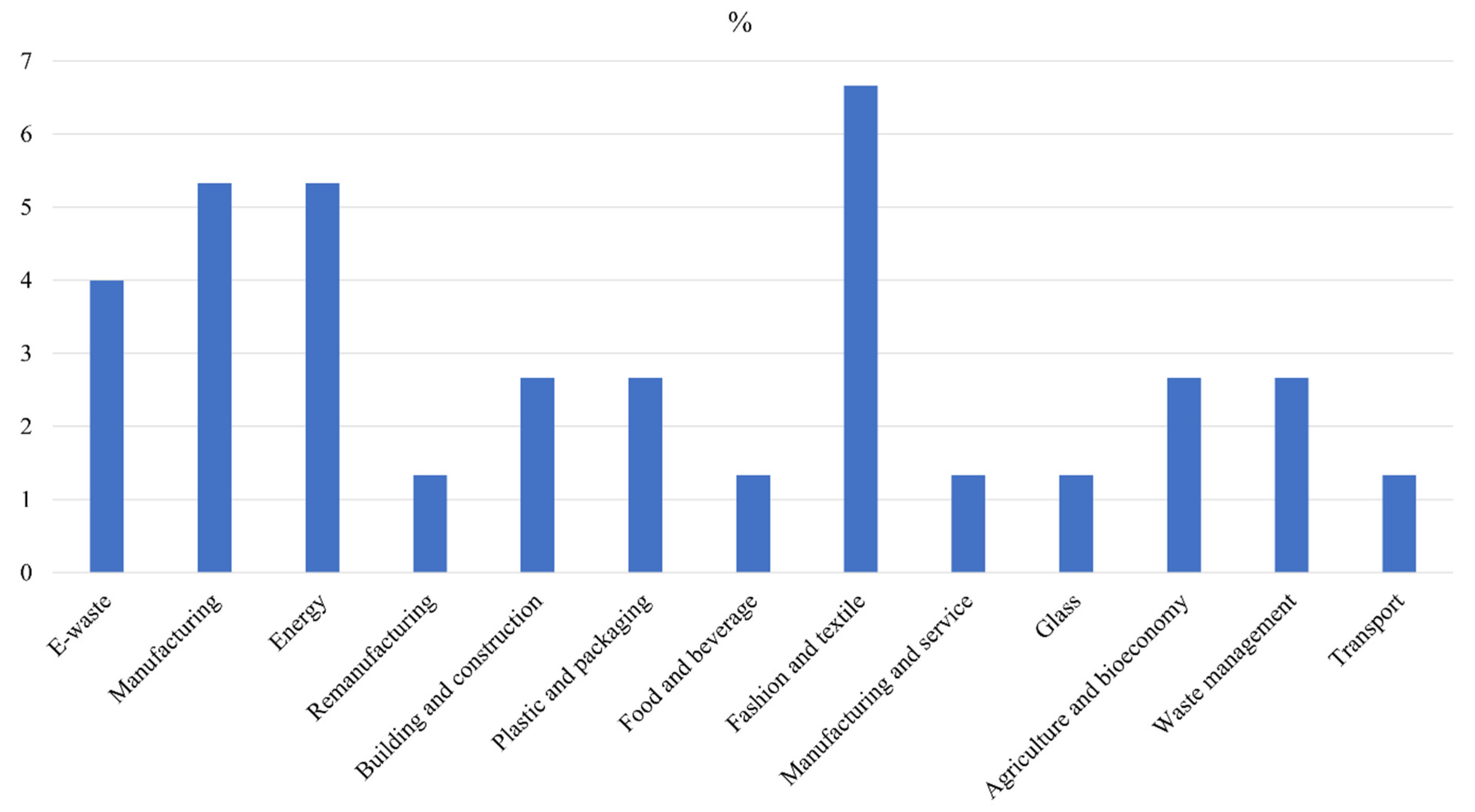

Descriptive Analysis

3. In-Depth Analysis of the Literature

3.1. Product, Material, and Sector Specific Recycling Barriers

3.1.1. E-Waste

3.1.2. Manufacturing

3.1.3. Energy Sector

3.1.4. Remanufacturing

3.1.5. Building and Construction

3.1.6. Plastics and Packaging

3.1.7. Food and Beverage

3.1.8. Fashion and Textile

3.1.9. Manufacturing and Service

3.1.10. Glass

3.1.11. Agriculture and Bioeconomy

3.1.12. Waste Management

3.1.13. Transport

3.2. Assessment, Measurement, and Matrices

3.2.1. Indicators

3.2.2. Complementary Assessment and Decision-Making Methods

3.2.3. Data and Information—Source Acquisition and Capture

3.3. Digitalization of Recycling

3.3.1. Three-Dimensional Printing

3.3.2. Sensor-Based RFID Tagging

3.3.3. Additive Manufacturing and Industry 4.0

3.3.4. Internet of Things (IoT)

3.4. Organizational Structure and Business Practice

3.4.1. Collaboration and Partnership

3.4.2. Organizational Benefits

3.5. System-Oriented Approach

3.5.1. Industrial Symbiosis

3.5.2. Material Substitution

3.5.3. Deposit-Refund System

3.6. Circularity in Supply Chain for Circular Business Models

3.6.1. Circular Supply Chain—Principles and Practices

3.6.2. Regional Focus of Recycling

3.6.3. Recycled Material Use

3.6.4. Product Design and Disassembly

3.6.5. Reverse Logistics

3.6.6. Recycling Infrastructure and Technologies

3.6.7. Schemes, Policy, and Regulations

3.6.8. Social Dimensions in CBM

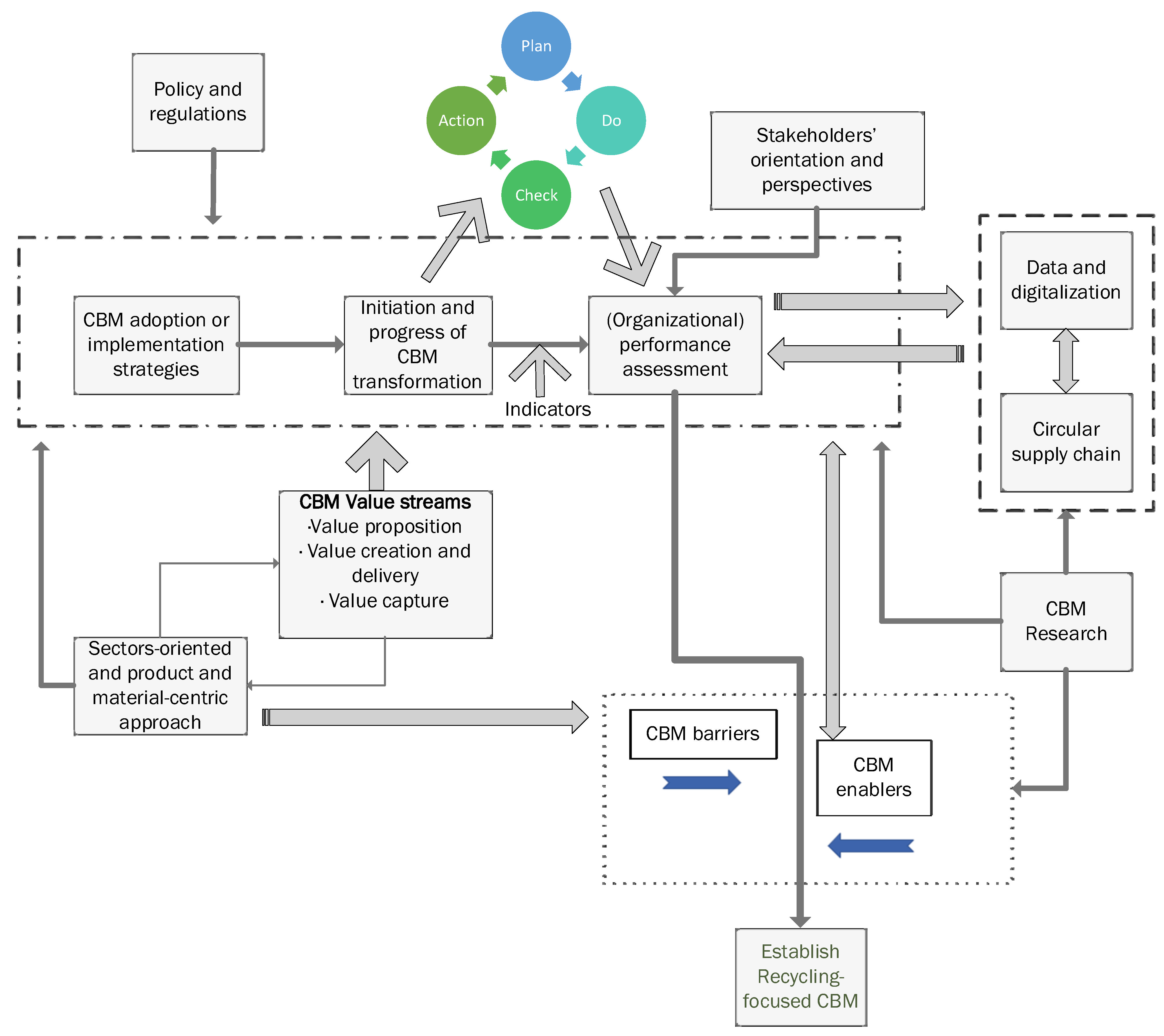

4. Conceptual Framework Development

5. Discussions and Future Research on Business Model Perspectives

5.1. Circularity Measurement and Performance Assessment Methodologies

5.2. Circular Bioeconomy

5.3. Reverse Supply Chain Management

5.4. Product Design

5.5. Consumer Behavior

5.6. Emerging Waste Streams and Technology Management

5.7. Recycling Infrastructure and Technology

5.8. Market for Recycled Material

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Buren, N.; Demmers, M.; Van der Heijden, R.; Witlox, F. Towards a Circular Economy: The Role of Dutch Logistics Industries and Governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef] [Green Version]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N.; Strupeit, L.; Whalen, K.; Nussholz, J. A Review and Evaluation of Circular Business Model Innovation Tools. Sustainability 2019, 11, 2210. [Google Scholar] [CrossRef] [Green Version]

- EMF. The Butterfly Diagram: Visualising the Circular Economy. Available online: https://ellenmacarthurfoundation.org/circular-economy-diagram (accessed on 6 October 2022).

- Geissdoerfer, M.; Pieroni, M.P.P.; Pigosso, D.C.A.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 17. [Google Scholar] [CrossRef]

- Bigliardi, B.; Filippelli, S. Investigating Circular Business Model Innovation through Keywords Analysis. Sustainability 2021, 13, 5036. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Terzi, S. Towards Circular Business Models: A systematic literature review on classification frameworks and archetypes. J. Clean. Prod. 2019, 236, 117696. [Google Scholar] [CrossRef]

- MacArthur, E. Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Reuter, M.A.; Schaik, A.v.; Gutzmer, J.; Bartie, N.; Abadías-Llamas, A. Challenges of the Circular Economy: A Material, Metallurgical, and Product Design Perspective. Annu. Rev. Mater. Res. 2019, 49, 253–274. [Google Scholar] [CrossRef]

- Zhou, G.; Gu, Y.; Wu, Y.; Gong, Y.; Mu, X.; Han, H.; Chang, T. A systematic review of the deposit-refund system for beverage packaging: Operating mode, key parameter and development trend. J. Clean. Prod. 2020, 251, 119660. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Ong, B.H.Y.; Klemeš, J.J.; Tan, R.R.; Varbanov, P.S. Circular Integration of processes, industries, and economies. Renew. Sustain. Energy Rev. 2019, 107, 507–515. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Delivering the Circular Economy: A Toolkit for Policymakers; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. Available online: https://ellenmacarthurfoundation.org/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 29 September 2022).

- Brissaud, D.; Zwolinski, P. The Scientific Challenges for a Sustainable Consumption and Production Scenario: The Circular Reuse of Materials for the Upgrading and Repurposing of Components. Procedia CIRP 2017, 61, 663–666. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Modelling reverse supply chain through system dynamics for realizing the transition towards the circular economy: A case study on electric vehicle batteries. J. Clean. Prod. 2020, 254, 120025. [Google Scholar] [CrossRef]

- Hultberg, E.; Pal, R. Lessons on business model scalability for circular economy in the fashion retail value chain: Towards a conceptual model. Sustain. Prod. Consum. 2021, 28, 686–698. [Google Scholar] [CrossRef]

- Upadhyay, A.; Akter, S.; Adams, L.; Kumar, V.; Varma, N. Investigating “circular business models” in the manufacturing and service sectors. J. Manuf. Technol. Manag. 2019, 30, 590–606. [Google Scholar] [CrossRef] [Green Version]

- Lewandowski, M. Designing the Business Models for Circular Economy-Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Suárez-Eiroa, B.; Fernández, E.; Méndez, G. Integration of the circular economy paradigm under the just and safe operating space narrative: Twelve operational principles based on circularity, sustainability and resilience. J. Clean. Prod. 2021, 322, 129071. [Google Scholar] [CrossRef]

- Suchek, N.; Fernandes, C.I.; Kraus, S.; Filser, M.; Sjögrén, H. Innovation and the circular economy: A systematic literature review. Bus. Strateg. Environ. 2021, 30, 3686–3702. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N.; Baumber, A.; Shumon, R.; Zaman, A.; Ali, F.; Hossain, R.; Sahajwalla, V. A global review of consumer behavior towards e-waste and implications for the circular economy. J. Clean. Prod. 2021, 316, 128297. [Google Scholar] [CrossRef]

- Lahti, T.; Wincent, J.; Parida, V. A Definition and Theoretical Review of the Circular Economy, Value Creation, and Sustainable Business Models: Where Are We Now and Where Should Research Move in the Future? Sustainability 2018, 10, 2799. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, J.J.; Fernandes, C.I.; Veiga, P.M.; Hughes, M. Prevailing theoretical approaches predicting sustainable business models: A systematic review. Int. J. Product. Perform. Manag. 2021, 71, 790–813. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Chiaroni, D.; Del Vecchio, P.; Urbinati, A. Designing business models in circular economy: A systematic literature review and research agenda. Bus. Strateg. Environ. 2020, 29, 1734–1749. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Diaz Lopez, F.J.; Bastein, T.; Tukker, A. Business Model Innovation for Resource-efficiency, Circularity and Cleaner Production: What 143 Cases Tell Us. Ecol. Econ. 2019, 155, 20–35. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; vanderGrinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Mayring, P. Qualitative content analysis: Theoretical foundation, basic procedures and software solution. GESIS–Leibniz Inst Soc. Sci. 2014. Available online: https://www.ssoar.info/ssoar/handle/document/39517 (accessed on 1 April 2022).

- Islam, M.T.; Huda, N. Reverse logistics and closed-loop supply chain of Waste Electrical and Electronic Equipment (WEEE)/E-waste: A comprehensive literature review. Resour. Conserv. Recycl. 2018, 137, 48–75. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational resources: A literature review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar] [CrossRef]

- Franco, M.A.; Groesser, S.N. A Systematic Literature Review of the Solar Photovoltaic Value Chain for a Circular Economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Kleinhans, K.; Demets, R.; Dewulf, J.; Ragaert, K.; De Meester, S. Non-household end-use plastics: The ‘forgotten’ plastics for the circular economy. Curr. Opin. Chem. Eng. 2021, 32, 100680. [Google Scholar] [CrossRef]

- Spooren, J.; Binnemans, K.; Björkmalm, J.; Breemersch, K.; Dams, Y.; Folens, K.; González-Moya, M.; Horckmans, L.; Komnitsas, K.; Kurylak, W. Near-zero-waste processing of low-grade, complex primary ores and secondary raw materials in Europe: Technology development trends. Resour. Conserv. Recycl. 2020, 160, 104919. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy–moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F. Materials passport’s review: Challenges and opportunities toward a circular economy building sector. Built Environ. Proj. Asset Manag. 2021, 11, 767–782. [Google Scholar] [CrossRef]

- Mies, A.; Gold, S. Mapping the social dimension of the circular economy. J. Clean. Prod. 2021, 321, 128960. [Google Scholar] [CrossRef]

- Islam, M.M.; Perry, P.; Gill, S. Mapping environmentally sustainable practices in textiles, apparel and fashion industries: A systematic literature review. J. Fash. Mark. Manag. Int. J. 2021, 25, 331–353. [Google Scholar] [CrossRef]

- González-Sánchez, R.; Settembre-Blundo, D.; Ferrari, A.M.; García-Muiña, F.E. Main Dimensions in the Building of the Circular Supply Chain: A Literature Review. Sustainability 2020, 12, 2459. [Google Scholar] [CrossRef] [Green Version]

- Testa, M.; Malandrino, O.; Sessa, M.R.; Supino, S.; Sica, D. Long-Term Sustainability from the Perspective of Cullet Recycling in the Container Glass Industry: Evidence from Italy. Sustainability 2017, 9, 1752. [Google Scholar] [CrossRef] [Green Version]

- Abideen, A.Z.; Pyeman, J.; Sundram, V.P.K.; Tseng, M.-L.; Sorooshian, S. Leveraging Capabilities of Technology into a Circular Supply Chain to Build Circular Business Models: A State-of-the-Art Systematic Review. Sustainability 2021, 13, 8997. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T. A review of emerging industry 4.0 technologies in remanufacturing. J. Clean. Prod. 2019, 237, 117805. [Google Scholar] [CrossRef]

- Herrador, M.; Cho, Y.; Park, P.-H. Latest circular economy policy and direction in the Republic of Korea: Room for enhancements. J. Clean. Prod. 2020, 269, 122336. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, J.; Osmani, M. Integration of Digital Economy and Circular Economy: Current Status and Future Directions. Sustainability 2021, 13, 7217. [Google Scholar] [CrossRef]

- Kühl, C.; Bourlakis, M.; Aktas, E.; Skipworth, H. How does servitisation affect supply chain circularity?–A systematic literature review. J. Enterp. Inf. Manag. 2020, 33, 703–728. [Google Scholar] [CrossRef] [Green Version]

- Savolainen, J.; Collan, M. How Additive Manufacturing Technology Changes Business Models?—Review of Literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Trapp, C.T.C.; Kanbach, D.K. Green entrepreneurship and business models: Deriving green technology business model archetypes. J. Clean. Prod. 2021, 297, 126694. [Google Scholar] [CrossRef]

- Salim, H.K.; Stewart, R.A.; Sahin, O.; Dudley, M. Drivers, barriers and enablers to end-of-life management of solar photovoltaic and battery energy storage systems: A systematic literature review. J. Clean. Prod. 2019, 211, 537–554. [Google Scholar] [CrossRef]

- Walden, J.; Steinbrecher, A.; Marinkovic, M. Digital Product Passports as Enabler of the Circular Economy. Chem. Ing. Tech. 2021, 93, 1717–1727. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R. Circular supply chain management: A state-of-art review and future opportunities. J. Clean. Prod. 2020, 258, 120859. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar] [CrossRef] [Green Version]

- de Aguiar Hugo, A.; de Nadae, J.; da Silva Lima, R. Can Fashion Be Circular? A Literature Review on Circular Economy Barriers, Drivers, and Practices in the Fashion Industry’s Productive Chain. Sustainability 2021, 13, 12246. [Google Scholar] [CrossRef]

- Parajuly, K.; Fitzpatrick, C.; Muldoon, O.; Kuehr, R. Behavioral change for the circular economy: A review with focus on electronic waste management in the EU. Resour. Conserv. Recycl. X 2020, 6, 100035. [Google Scholar] [CrossRef]

- Bansal, S.; Jain, M.; Garg, I.; Srivastava, M. Attaining circular economy through business sustainability approach: An integrative review and research agenda. J. Public Aff. 2020, 22, e2319. [Google Scholar] [CrossRef]

- Ada, N.; Kazancoglu, Y.; Sezer, M.D.; Ede-Senturk, C.; Ozer, I.; Ram, M. Analyzing Barriers of Circular Food Supply Chains and Proposing Industry 4.0 Solutions. Sustainability 2021, 13, 6812. [Google Scholar] [CrossRef]

- Reinhardt, R.; Christodoulou, I.; Gassó-Domingo, S.; Amante García, B. Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Wang, B.; Lewis, K.; Duarte, F.; Ratti, C.; Behdad, S. The future of waste management in smart and sustainable cities: A review and concept paper. Waste Manag. 2018, 81, 177–195. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Stegmann, P.; Londo, M.; Junginger, M. The circular bioeconomy: Its elements and role in European bioeconomy clusters. Resour. Conserv. Recycl. X 2020, 6, 100029. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, Z.; Chen, C.-H.; Pheng Khoo, L. A survey of smart product-service systems: Key aspects, challenges and future perspectives. Adv. Eng. Inform. 2019, 42, 100973. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply chain configurations in the circular economy: A systematic literature review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef] [Green Version]

- Antwi-Afari, P.; Ng, S.T.; Hossain, M.U. A review of the circularity gap in the construction industry through scientometric analysis. J. Clean. Prod. 2021, 298, 126870. [Google Scholar] [CrossRef]

- Bressanelli, G.; Saccani, N.; Pigosso, D.C.A.; Perona, M. Circular Economy in the WEEE industry: A systematic literature review and a research agenda. Sustain. Prod. Consum. 2020, 23, 174–188. [Google Scholar] [CrossRef]

- Acerbi, F.; Taisch, M. A literature review on circular economy adoption in the manufacturing sector. J. Clean. Prod. 2020, 273, 123086. [Google Scholar] [CrossRef]

- Florén, H.; Barth, H.; Gullbrand, J.; Holmén, M. Additive manufacturing technologies and business models–A systematic literature review. J. Manuf. Technol. Manag. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Hernandez Korner, M.E.; Lambán, M.P.; Albajez, J.A.; Santolaria, J.; Ng Corrales, L.D.C.; Royo, J. Systematic Literature Review: Integration of Additive Manufacturing and Industry 4.0. Metals 2020, 10, 1061. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Action Plan. Available online: https://ec.europa.eu/environment/strategy/circular-economy-action-plan_en (accessed on 21 February 2022).

- Mutezo, G.; Mulopo, J. A review of Africa’s transition from fossil fuels to renewable energy using circular economy principles. Renew. Sustain. Energy Rev. 2021, 137, 110609. [Google Scholar] [CrossRef]

- Gwara, S.; Wale, E.; Odindo, A.; Buckley, C. Why do We Know So Much and Yet So Little? A Scoping Review of Willingness to Pay for Human Excreta Derived Material in Agriculture. Sustainability 2020, 12, 6490. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; van der Heide, A.; Radavičius, T.; Denafas, J.; Lemaire, E.; Wang, K.; Poortmans, J.; Voroshazi, E. Towards a circular supply chain for PV modules: Review of today’s challenges in PV recycling, refurbishment and re-certification. Prog. Photovolt. Res. Appl. 2020, 28, 454–464. [Google Scholar] [CrossRef]

- The Ellen MacArthur Foundation. Material Circularity Indicator (MCI). Available online: https://ellenmacarthurfoundation.org/material-circularity-indicator (accessed on 1 April 2022).

- Mesa, J.; Esparragoza, I.; Maury, H. Developing a set of sustainability indicators for product families based on the circular economy model. J. Clean. Prod. 2018, 196, 1429–1442. [Google Scholar] [CrossRef]

- Figge, F.; Thorpe, A.S.; Givry, P.; Canning, L.; Franklin-Johnson, E. Longevity and Circularity as Indicators of Eco-Efficient Resource Use in the Circular Economy. Ecol. Econ. 2018, 150, 297–306. [Google Scholar] [CrossRef]

- IDEAL&CO Explore. The Circularity Calculator. Available online: http://www.circularitycalculator.com/ (accessed on 1 April 2022).

- Palafox-Alcantar, P.G.; Hunt, D.V.L.; Rogers, C.D.F. The complementary use of game theory for the circular economy: A review of waste management decision-making methods in civil engineering. Waste Manag. 2020, 102, 598–612. [Google Scholar] [CrossRef] [PubMed]

- iFixit. Laptop Repairability Scores. Available online: https://www.ifixit.com/laptop-repairability (accessed on 1 April 2022).

- Greenpeace. Guide to Greener Electronics. Available online: https://www.greenpeace.org/usa/wp-content/uploads/2017/10/Guide-to-Greener-Electronics-2017.pdf (accessed on 1 April 2022).

- Alcayaga, A.; Wiener, M.; Hansen, E.G. Towards a framework of smart-circular systems: An integrative literature review. J. Clean. Prod. 2019, 221, 622–634. [Google Scholar] [CrossRef]

- Blüher, T.; Riedelsheimer, T.; Gogineni, S.; Klemichen, A.; Stark, R. Systematic Literature Review—Effects of PSS on Sustainability Based on Use Case Assessments. Sustainability 2020, 12, 6989. [Google Scholar] [CrossRef]

- Baldassarre, B.; Keskin, D.; Diehl, J.C.; Bocken, N.; Calabretta, G. Implementing sustainable design theory in business practice: A call to action. J. Clean. Prod. 2020, 273, 123113. [Google Scholar] [CrossRef]

- Trevisan, A.H.; Castro, C.G.; Gomes, L.A.V.; Mascarenhas, J. Unlocking the circular ecosystem concept: Evolution, current research, and future directions. Sustain. Prod. Consum. 2022, 29, 286–298. [Google Scholar] [CrossRef]

- Hjorth, S.; Chrysostomou, D. Human–robot collaboration in industrial environments: A literature review on non-destructive disassembly. Robot. Comput. -Integr. Manuf. 2022, 73, 102208. [Google Scholar] [CrossRef]

- Pinheiro, M.A.P.; Seles, B.M.R.P.; Fiorini, P.D.C.; Jugend, D.; de Sousa Jabbour, A.B.L.; da Silva, H.M.R.; Latan, H. The role of new product development in underpinning the circular economy: A systematic review and integrative framework. Manag. Decis. 2019, 57, 840–862. [Google Scholar] [CrossRef]

- Santa-Maria, T.; Vermeulen, W.J.V.; Baumgartner, R.J. Framing and assessing the emergent field of business model innovation for the circular economy: A combined literature review and multiple case study approach. Sustain. Prod. Consum. 2021, 26, 872–891. [Google Scholar] [CrossRef]

- Aloini, D.; Dulmin, R.; Mininno, V.; Stefanini, A.; Zerbino, P. Driving the transition to a circular economic model: A systematic review on drivers and critical success factors in circular economy. Sustainability 2020, 12, 10672. [Google Scholar] [CrossRef]

- Babbitt, C.W.; Althaf, S.; Cruz Rios, F.; Bilec, M.M.; Graedel, T.E. The role of design in circular economy solutions for critical materials. One Earth 2021, 4, 353–362. [Google Scholar] [CrossRef]

- Nosratabadi, S.; Mosavi, A.; Shamshirband, S.; Kazimieras Zavadskas, E.; Rakotonirainy, A.; Chau, K.W. Sustainable Business Models: A Review. Sustainability 2019, 11, 1663. [Google Scholar] [CrossRef]

- Betancourt Morales, C.M.; Zartha Sossa, J.W. Circular economy in Latin America: A systematic literature review. Bus. Strateg. Environ. 2020, 29, 2479–2497. [Google Scholar] [CrossRef]

- Moran, C.A.; Eichelmann, E.; Buggy, C.J. The challenge of “Depeche Mode” in the fashion industry–Does the industry have the capacity to become sustainable through circular economic principles, a scoping review. Sustain. Environ. 2021, 7, 1975916. [Google Scholar] [CrossRef]

- Cramer, J. The raw materials transition in the Amsterdam metropolitan area: Added value for the Economy, Well-Being, and the Environment. Environ. Sci. Policy Sustain. Dev. 2017, 59, 14–21. [Google Scholar] [CrossRef] [Green Version]

- Böckel, A.; Nuzum, A.-K.; Weissbrod, I. Blockchain for the Circular Economy: Analysis of the Research-Practice Gap. Sustain. Prod. Consum. 2021, 25, 525–539. [Google Scholar] [CrossRef]

- Sarja, M.; Onkila, T.; Mäkelä, M. A systematic literature review of the transition to the circular economy in business organizations: Obstacles, catalysts and ambivalences. J. Clean. Prod. 2021, 286, 125492. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; De Meester, S.; Dewulf, J. Resource efficiency indicators to assess circular economy strategies: A case study on four materials in laptops. Resour. Conserv. Recycl. 2022, 178, 106099. [Google Scholar] [CrossRef]

- Makarichi, L.; Techato, K.-a.; Jutidamrongphan, W. Material flow analysis as a support tool for multi-criteria analysis in solid waste management decision-making. Resour. Conserv. Recycl. 2018, 139, 351–365. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. Material flow analysis (MFA) as a strategic tool in E-waste management: Applications, trends and future directions. J. Environ. Manag. 2019, 244, 344–361. [Google Scholar] [CrossRef]

- De Meester, S.; Nachtergaele, P.; Debaveye, S.; Vos, P.; Dewulf, J. Using material flow analysis and life cycle assessment in decision support: A case study on WEEE valorization in Belgium. Resour. Conserv. Recycl. 2019, 142, 1–9. [Google Scholar] [CrossRef]

- Beigl, P.; Lebersorger, S.; Salhofer, S. Modelling municipal solid waste generation: A review. Waste Manag. 2008, 28, 200–214. [Google Scholar] [CrossRef] [PubMed]

- Bandara, N.J.; Hettiaratchi, J.P.A.; Wirasinghe, S.; Pilapiiya, S. Relation of waste generation and composition to socio-economic factors: A case study. Environ. Monit. Assess. 2007, 135, 31–39. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.T.; Huda, N. Reshaping WEEE management in Australia: An investigation on the untapped WEEE products. J. Clean. Prod. 2020, 250, 119496. [Google Scholar] [CrossRef]

- Nagalli, A. Estimation of construction waste generation using machine learning. Proc. Inst. Civ. Eng.-Waste Resour. Manag. 2021, 174, 22–31. [Google Scholar] [CrossRef]

- Lu, W.; Lou, J.; Webster, C.; Xue, F.; Bao, Z.; Chi, B. Estimating construction waste generation in the Greater Bay Area, China using machine learning. Waste Manag. 2021, 134, 78–88. [Google Scholar] [CrossRef]

- Nußholz, J.L.K. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef] [Green Version]

- Barros, M.V.; Salvador, R.; de Francisco, A.C.; Piekarski, C.M. Mapping of research lines on circular economy practices in agriculture: From waste to energy. Renew. Sustain. Energy Rev. 2020, 131, 109958. [Google Scholar] [CrossRef]

- Toop, T.A.; Ward, S.; Oldfield, T.; Hull, M.; Kirby, M.E.; Theodorou, M.K. AgroCycle–developing a circular economy in agriculture. Energy Procedia 2017, 123, 76–80. [Google Scholar] [CrossRef]

- Achillas, C.; Aidonis, D.; Vlachokostas, C.; Moussiopoulos, N.; Banias, G.; Triantafillou, D. A multi-objective decision-making model to select waste electrical and electronic equipment transportation media. Resour. Conserv. Recycl. 2012, 66, 76–84. [Google Scholar] [CrossRef]

- Sohag, M.U.; Podder, A.K. Smart garbage management system for a sustainable urban life: An IoT based application. Internet Things 2020, 11, 100255. [Google Scholar] [CrossRef]

- Shojaei, A.; Ketabi, R.; Razkenari, M.; Hakim, H.; Wang, J. Enabling a circular economy in the built environment sector through blockchain technology. J. Clean. Prod. 2021, 294, 126352. [Google Scholar] [CrossRef]

- Kahhat, R.; Kim, J.; Xu, M.; Allenby, B.; Williams, E.; Zhang, P. Exploring e-waste management systems in the United States. Resour. Conserv. Recycl. 2008, 52, 955–964. [Google Scholar] [CrossRef]

- Climate Council. Powerful Potential: Battery Storage for Renewable Energy and Electric Cars. Available online: https://www.climatecouncil.org.au/resources/batterystoragereport2015/ (accessed on 18 February 2022).

- Green, S.A.; Billinghurst, M.; Chen, X.; Chase, J.G. Human-robot collaboration: A literature review and augmented reality approach in design. Int. J. Adv. Robot. Syst. 2008, 5, 1. [Google Scholar] [CrossRef]

- Gupta, P.K.; Shree, V.; Hiremath, L.; Rajendran, S. The use of modern technology in smart waste management and recycling: Artificial intelligence and machine learning. In Recent Advances in Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2019; pp. 173–188. [Google Scholar]

- Sitra. Mobile Facilities on a Lease. Available online: https://www.sitra.fi/en/cases/mobile-facilities-on-a-lease/ (accessed on 21 February 2022).

- Knowledge Hub. Giotex Is a Company that Offers Recycled Cotton Yarns and Fabrics from Pre Consumer Feedstock. Available online: https://knowledge-hub.circle-lab.com/article/9450?n=Giotex-is-a-company-that-offers-recycled-cotton-yarns-and-fabrics-from-pre-consumer-feedstock (accessed on 18 February 2022).

- Knowledge Hub. Recover (TM) Offers Handcrafted Recycled Cotton Fibre. Available online: https://knowledge-hub.circle-lab.com/article/9469?n=Recover(TM)-offers-handcrafted-recycled-cotton-fibre (accessed on 18 February 2022).

- Henry, M.; Bauwens, T.; Hekkert, M.; Kirchherr, J. A typology of circular start-ups: An Analysis of 128 circular business models. J. Clean. Prod. 2020, 245, 118528. [Google Scholar] [CrossRef]

| Reference | Aspects | Sector | Barriers | Enablers | Description |

|---|---|---|---|---|---|

| Kleinhans, et al. [34] | Non-household plastic recycling rate | Plastics and packaging | ✓ | Introduction of clear terminology, structured data collection, state of the art waste management solutions, circular business cases creation, and behavioural changes of businesses | |

| Ferreira, Fernandes, Veiga and Hughes [24] | Assessment and efficiency measurement of recycling system | Not applicable | ✓ | LCA for analyzing environmental impacts of product and service | |

| Spooren, et al. [35] | Efficient recovery of metals from low-grade material streams under near-zero-waste processing concept | Metal | ✓ | Development of technologies and processes, processing flexibility (inputs of various compositions and properties), research on mineral waste treatment, and primary ore extractive metallurgy | |

| Kristensen and Mosgaard [36] | Indicators representing measurement of recycling (micro indicators at company level) | Not applicable | ✓ | Trade-off between CE coverage and practical usability | |

| Munaro and Tavares [37] | Material passport for resource recovery | Building | ✓ | Competitive price and quality assurance for by-products and/or recycled materials | |

| Mies and Gold [38] | Factors affecting consumers’ behavioral dimensions on recycling | Not applicable | ✓ | Rewards to return products for recycling, availability, and accessibility of information, strong government policy and regulations, adequate recycling infrastructure, quality, and performance of recycled products | |

| Islam, et al. [39] | Sustainable waste recycling | Textiles, apparel, and fashion | ✓ | Technological innovation and (recycled material), collaboration among textile manufacturers, sustainable designers, and fashion retailers | |

| González-Sánchez, et al. [40] | Circularity in supply chain | General | ✓ | New or recycled materials, cleaner technologies, and new organizational and logistical practices | |

| Testa, et al. [41] | Regional recycling for sustainability | Glass manufacturing | ✓ | Municipal waste collection systems, waste management supply chain, refinement of legislation | |

| Abideen, et al. [42] | Technological capabilities for circular supply chain, focusing on polystyrene | Plastics and packaging | ✓ | Lack of polystyrene recycling knowledge, strategic reverse logistic decision, and effective recycling policy for waste management | |

| Hultberg and Pal [17] | Business model scalability and strategies for value chain | Textile | ✓ | Share of recycled content in new product manufacturing | |

| Kerin and Pham [43] | Industry 4.0 and circular supply chain | Remanufacturing in general | ✓ | Internet connected monitoring and reporting system for recycling data and availability of disassembled parts for recycling | |

| Herrador, et al. [44] | Policy for recycling in South Korea | Not applicable | ✓ | Social cost of recycling (obligatory payment made by individuals and companies), culture of recycling, waste recycling equipment, investment in recycling-focus SMEs, improved recycling techniques, and establishment of business-specific resource circulation targets for enhanced recycling performance. | |

| Upadhyay, Akter, Adams, Kumar and Varma [18] | Role of CBM, with a focus on food industry (FI) | Manufacturing and service | ✓ | Product modification and renovation using recycling technologies, organizational capability identifying recyclable material available in the supply chain, | |

| Liu, et al. [45] | Innovation in integrated CE and digital economy | General | ✓ | Integrated design and production, product design, recycling product license (for recyclers’ ownership and issuance of maximum service life), recycling product management, Digital twin, product-service system, servitization | |

| Suchek, Fernandes, Kraus, Filser and Sjögrén [21] | Innovation (eco-innovations)-related framework development | General | ✓ | 3D printing application in recycling system, institutional support for fostering eco-innovations, associated factors with recycling are (for German case): efficient regulatory structure, technological innovations, producer responsibilities for waste packaging, and reduction of greenhouse gases | |

| Kühl, et al. [46] | Impact of servitization on supply chain circularity | General | ✓ | Product take-back schemes, supporting practice through tax benefits, and recycling requirements | |

| Savolainen and Collan [47] | Business model impact on closed and open market | Additive manufacturing | ✓ | Due to high AM metal powder price, cost of new product price will remain high despite using recycled (plastic) materials | |

| Trapp and Kanbach [48] | Green entrepreneurship and green technology | General | ✓ | Development of technology that establish profit model based on the creation of resource loops | |

| Lüdeke-Freund, Gold and Bocken [2] | Business model pattern | Not applicable | ✓ | Deposit added to a product (e.g., plastic bottles or glass) incentivize return and facilitate recycling | |

| Salim, et al. [49] | End of life solar PV and battery storage system | Energy | ✓ | Logistics costs, number of collection and recycling infrastructures, and profitability | |

| Walden, et al. [50] | Digital product passport | General | ✓ | Dedicated program and business unit for recycling with an emphasis on public share holding company | |

| Lewandowski [19] | Business model design | Not applicable | ✓ | Collaboration, data management system, and recycled material use for profit and material value maximization | |

| Kirchherr, Reike and Hekkert [26] | Definition of circular economy | Not applicable | ✓ | System thinking for production and consumption pattern | |

| Lahane, et al. [51] | Barriers to circular supply chain management (CSCM) | General | ✓ | Ineffective recycling policies, lack of recycling policies, and lack of recycling material availability | |

| Farooque, et al. [52] | Circular supply chain | General | ✓ | Technology-related barriers in recycling value chains | |

| Walmsley, Ong, Klemeš, Tan and Varbanov [11] | Industry and economies | General | ✓ | Dimensions of recycling at process-level, industrial, and regional level | |

| Sassanelli, et al. [53] | Performance assessment method | General | ✓ | DEA model for solid waste recycling and energy analysis for recycling benefits in industrial parks | |

| Geissdoerfer, Pieroni, Pigosso and Soufani [5] | CBM Archetypes | Not applicable | ✓ | “Product recycling/Recycling 2.0” | |

| Reuter, Schaik, Gutzmer, Bartie and Abadías-Llamas [9] | Product design and metallurgical challenges | Manufacturing and metallurgical | ✓ | Product-centric view of closed loop recycling and lack of exergy and metallurgical detail are largely neglected in CE research | |

| Bressanelli, et al. [54] | Supply chain redesign | Manufacturing | ✓ | Growth of product complexity and proliferation of new materials has critical impacts on recycling process | |

| de Aguiar Hugo, et al. [55] | Ease of recycling | Fashion and textile | ✓ | Use of mono-material | |

| Parajuly, et al. [56] | EPR implementation issues | E-waste | ✓ | Lack of incentives for resource recovery, product design, and business model redevelopment under the EPR scheme | |

| Bansal, et al. [57] | Elements of CBM development mechanism and value creation | General | ✓ | Co-creation, recycled material use in supply chain, product design | |

| Ada, et al. [58] | Government’s role in circular supply chain | Food and beverage | ✓ | Innovation policies and public procurement of recycled material | |

| Zhou, Gu, Wu, Gong, Mu, Han and Chang [10] | Problems of deposit-refund system | Plastics and packaging | ✓ | intelligent collection system development using IoT and internet communication, lack of ecological design promotion and lack of initiatives of developing multi-profitable CBM | |

| Reinhardt, et al. [59] | Requirements of battery recycling facilities | Transport (vehicles and batteries) | ✓ | Economically feasible recycling framework, high fixed cost, supply of large volume of retired batteries, | |

| Franco and Groesser [33] | Solar PV recycling barriers | Energy (solar PV) | ✓ | Current PV panel designs lead to ineffective material separation and incentivize for low-value recycling | |

| Esmaeilian, et al. [60] | Driver behind consumers recycling behavior | Waste management | ✓ | Monetary incentive, social influence, regulations, psychological factors, demographic, convenience of recycling, personal values, awareness, ethnicity, and attitude | |

| Jia, et al. [61] | Barriers in textile recycling | Fashion and textile | ✓ | Lack of innovative recycling and remanufacturing technologies | |

| Stegmann, et al. [62] | CBM enabler | Agriculture and bioeconomy | ✓ | Policies and regulations related to public procurement, prevent contamination of products that hampers recycling, and taxing GHG-emissions | |

| Zheng, et al. [63] | Factors for efficient and effective product recycling process by Smart recycling | Manufacturing and service | ✓ | Advanced IoT technologies and the product lifecycle data management | |

| Masi, et al. [64] | Barriers to recycled material use | General | ✓ | Comparatively higher prices than virgin materials of similar quality, technical challenge of separating the bio- from the techno-cycle | |

| Antwi-Afari, et al. [65] | Efficient building material lifecycle management | Building and construction | ✓ | Value co-creation and eco-effectiveness design strategies, material banks, and material passport (indicating life cycle, reuse strategies and recycling outlets) |

| Indicator | Description as per [36] | Reference |

|---|---|---|

| Material Circularity Indicator (MCI) | “The recycled content in a product along with waste (linear flow) and utility of a product (expressed through lifetime)” | The Ellen MacArthur Foundation [74] |

| Sustainability Indicators for CE (SICE) | “It contains a potential recycle index that considers the fraction of recyclable mass in the product, number of components, the efficiency of the recycling process etc.” | Mesa, et al. [75] |

| Product-level Circularity Metric (PLCM) | “It uses the economic value of recirculated parts (recycled and refurbished) and the economic value of all parts to calculate product circularity, which is defined as the fraction of a product that comes from used products” | Mesa, Esparragoza and Maury [75] |

| Combination Matrix (CM) | “It considers recycling as the contribution of material recycling to the overall circularity of a product/material, and the circularity is expressed as a number between one and infinity” | Figge, et al. [76] |

| Circularity Calculator (CC) | “It calculates (among others) the recycled content of a product, which includes recycled content in the original product and recycled content through closed-loop recycling.” | IDEAL&CO Explore [77] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, M.T.; Iyer-Raniga, U.; Trewick, S. Recycling Perspectives of Circular Business Models: A Review. Recycling 2022, 7, 79. https://doi.org/10.3390/recycling7050079

Islam MT, Iyer-Raniga U, Trewick S. Recycling Perspectives of Circular Business Models: A Review. Recycling. 2022; 7(5):79. https://doi.org/10.3390/recycling7050079

Chicago/Turabian StyleIslam, Md Tasbirul, Usha Iyer-Raniga, and Sean Trewick. 2022. "Recycling Perspectives of Circular Business Models: A Review" Recycling 7, no. 5: 79. https://doi.org/10.3390/recycling7050079