Characterizing the Digital Twin in Structural Mechanics

Abstract

:1. Introduction

2. Related Literature

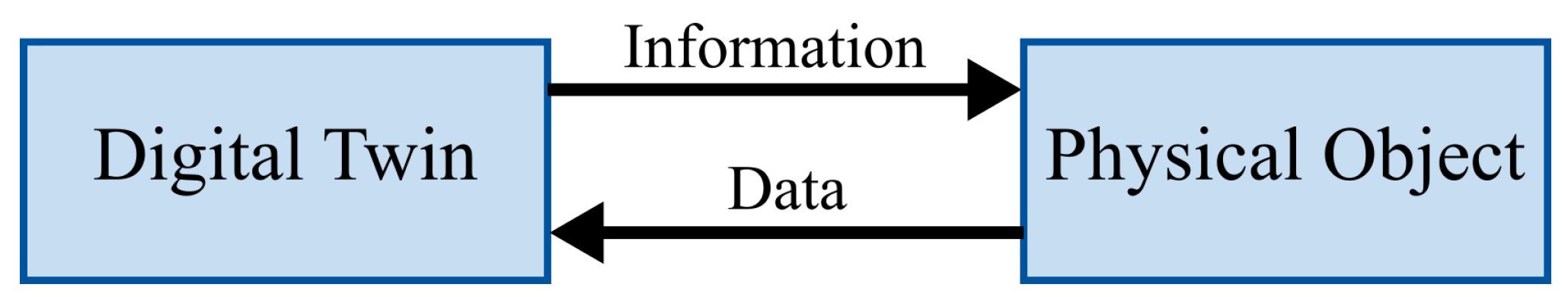

2.1. Digital Twin Definitions and Categories

2.2. Structural Design Process

2.2.1. Definition of a Structure According to Wiedemann

- Wiedemann [34] defines “topology” as the number of variables and their relationship within the function. For example, the topology of a beam consists of the variance of its cross-section over its length and that of a truss variances by the number of its rods.

- The “shape” determines the geometric characteristics of the structural system. These are, for example, the external dimensions of a beam cross-section or the nodal coordinates of a truss.

- The “dimensioning” determines the quantitative wall thicknesses of the individual cross-section parts and thus completes the geometric description of the load-bearing system.

2.2.2. Product Development According to VDI Guideline 2221/2019

2.2.3. Summary of Structural Design Process

3. Analyzing the Product Life Cycle of Structures for Digital Twins

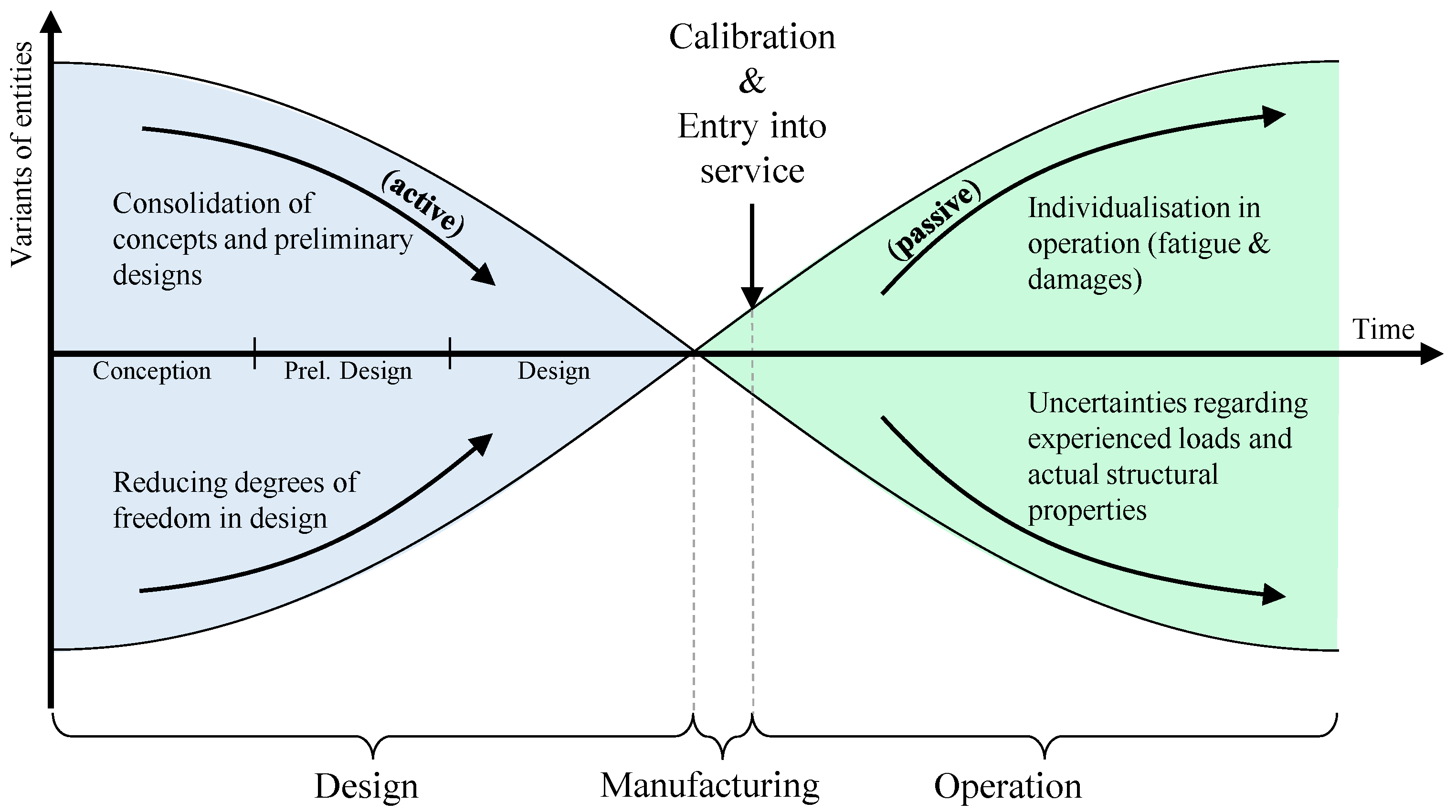

3.1. Requirements of the Design Phase

- Conception:

- –

- Clarify and specify the problem or task.

- –

- Determining functions.

- –

- Searching for solution principles.

- –

- Evaluating and selecting the solution concept.

- Preliminary Design:

- –

- Structuring into subsystems, components and interfaces.

- –

- Layout of components and interfaces.

- Design:

- –

- Integrating the entire product.

- –

- Implementing the design and usage specifications.

- –

- Ensuring the fulfillment of requirements by dimensioning and optimizing chosen components and interfaces.

- Formalized representation of the three steps of conception, preliminary design, and design.

- Providing a virtual environment that represents the boundary conditions and the associated subsystem.

- Interface to databases, e.g., for material comparisons, which provide additional information about properties, costs, availability, etc.

- Modelling approaches with an increasing level of detail depending on the design phase organized in hierarchical modelling.

- Virtual test-bed for interaction with the (virtual) environment in an early design stage and simulation-based load case development.

3.2. Requirements of the Operational Phase

- Provide a synchronization mechanism, in the form of continues re-calibration, between real components and the model;

- Automate data acquisition, processing and evaluation of an SHM system of the structure;

- Merge and store data from multiple data sources including the SHM system, environmental influences and operational data;

- Provide hierarchical coupling of suitable structural mechanical models (implicit and explicit);

- Support feedback loops to enable bi-directional coupling for individual evaluation of the structure concerning inspections like maintenance on demand or RUL [22].

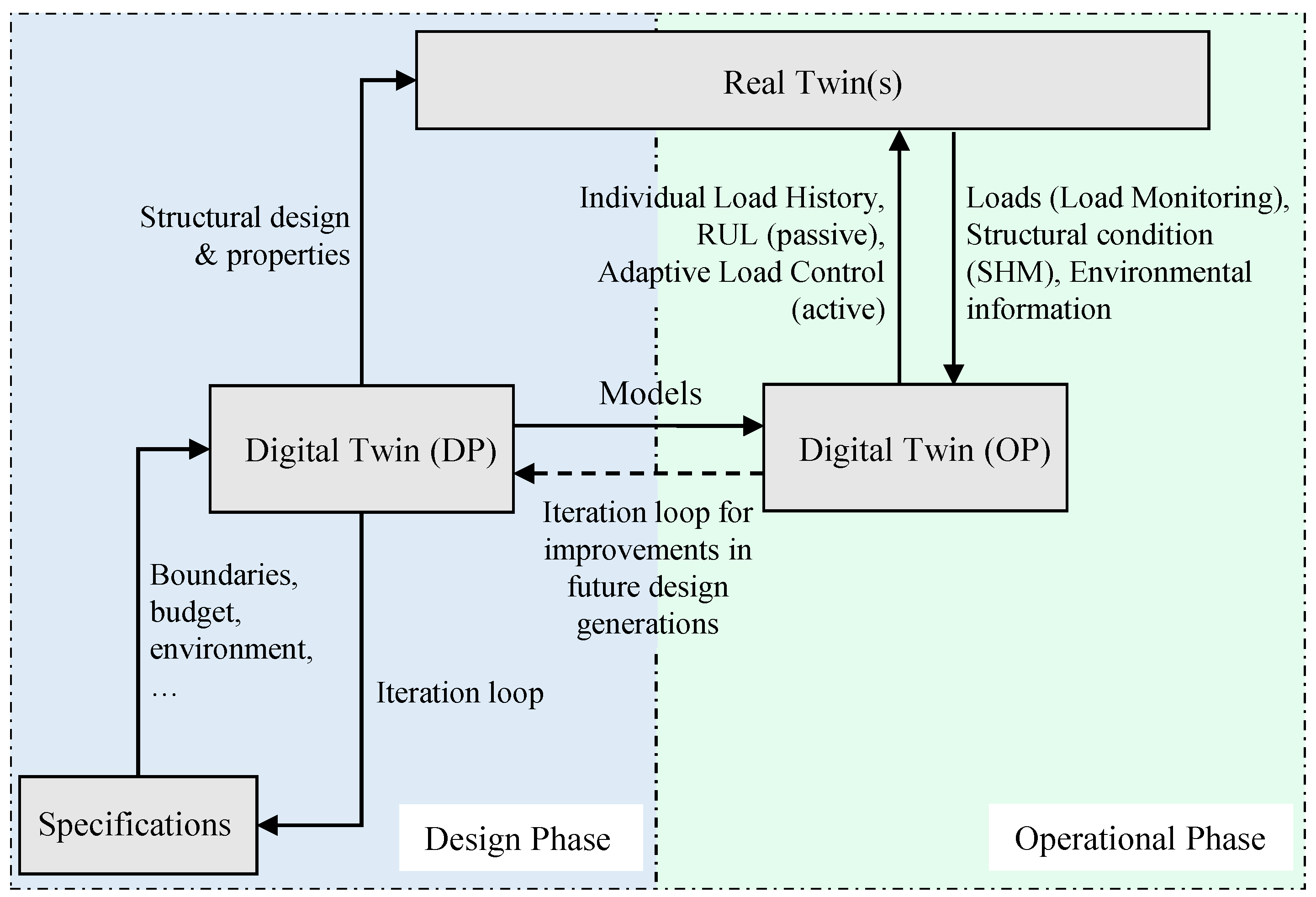

3.3. Merging the Design and Operation Phases

4. Classification of Structural Mechanics in Digital Twin Taxonomy

4.1. Data Collection

4.2. Data Handling and Distribution

- Design and optimization of (lightweight) structures.

- Monitoring of structural fatigue and damage for Predictive Maintenance Strategies.

- Coupling of intervening control units to actively influence the structure utilization during operation.

4.3. Conceptional Scope

- The Digital Twin of the structure is an explicit, detailed and identical representation of a structural component.

- The Digital Twin of the structure is a sufficiently accurate implicit and partial representation of the overall system.

5. Discussion: The Two Archetypes of Structural Digital Twins

- A structure-designing Digital Twin for the design and concept phase.

- A structure-monitoring Digital Twin for the operational phase.

6. Conclusions

- Collecting and clustering design and operational requirements for the Digital Twins of structures.

- Deriving two central archetypes, which have unique characteristics due to their respective life cycle phases, but can be linked by calibration after manufacturing:

- A structure-designing Digital Twin for the design and concept phase.

- A structure-monitoring Digital Twin for the operational phase.

- Reducing the complexity of the conceptualization of Digital Twins by providing a framework and considering the Digital Twin of a structure as a holistic system over the product life cycle.

- Holistic development of structural Digital Twins: investigate how a holistic perspective can enhance the overall implementation of Digital Twins in various applications.

- Formalization of the design process: examine the potential for formalizing the design process, incorporating methodologies such as Model-Based Systems Engineering (MBSE), and assess how a formalized approach can contribute to an increased efficiency in the development of Digital Twins.

- Reusability of design process models: investigate the reusability of design process models in the context of SHM data analysis for the seamless and effective coupling of SHM with Digital Twins.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CPS | Cyber Physical System |

| DT | Digital Twin |

| DOF | Degree of Freedom |

| FE | Finite Element (Model) |

| HMI | Human–Machine Interface |

| M2M | Machine to Machine (Interface) |

| MBSE | Model-Based Systems Engineering |

| RUL | Remaining Useful Life |

| SHM | Structural Health Monitoring |

| UML | Unified Modelling Language |

| VDI | “Verein Deutscher Ingenieure”/Association of German Engineers |

References

- Gartner Identifies the Top 10 Strategic Technology Trends for 2019. Available online: https://www.gartner.com/smarterwithgartner/gartner-top-10-strategic-technology-trends-for-2019 (accessed on 4 April 2023).

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the digital twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Josifovska, K.; Yigitbas, E.; Engels, G. Reference framework for digital twins within cyber-physical systems. In Proceedings of the 2019 IEEE/ACM 5th International Workshop on Software Engineering for Smart Cyber-Physical Systems (SEsCPS), Montreal, QC, Canada, 28 May 2019. [Google Scholar]

- Semeraro, C.; Lezoche, M.; Panetto, H.; Dassisti, M. Digital twin paradigm: A systematic literature review. Comput. Ind. 2021, 130, 103469. [Google Scholar] [CrossRef]

- Van der Valk, H.; Haße, H.; Möller, F.; Otto, B. Archetypes of digital twins. Bus. Inf. Syst. Eng. 2021, 64, 1–17. [Google Scholar] [CrossRef]

- Ciminio, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Phanden, R.K.; Sharma, P.; Dubey, A. A review on simulation in digital twin for aerospace, manufacturing and robotics. Mater. Today Proc. 2021, 38, 174–178. [Google Scholar] [CrossRef]

- Erol, T.; Mendi, A.F.; Doǧan, D. The Digital Twin Revolution in Healthcare. In Proceedings of the 2020 4th International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020. [Google Scholar]

- Xia, H.; Liu, Z.; Efremochkina, M.; Liu, X.; Lin, C. Predictive maintenance using digital twins: Study on city digital twin technologies for sustainable smart city design: A review and bibliometric analysis of geographic infor-mation system and building information modeling integration. Sustain. Cities Soc. 2022, 84, 104009. [Google Scholar] [CrossRef]

- Chen, B.Q.; Guedes Soares, C.; Videiro, P.M. Review of digital twin of ships and offshore structures. In Maritime Technology and Engineering 5 Volume 1—Proceedings of the 5th International Conference on Maritime Technology and Engineering (MARTECH 2020), Lisbon, Portugal, 16–19 November 2020; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Aydemir, H.; Zengin, U.; Durak, U. The Digital Twin Paradigm for Aircraft Review and Outlook. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering aircraft structural life prediction using a digital twin. Int. J. Aerosp. Eng. 2011, 2011, 154798. [Google Scholar] [CrossRef]

- Ryll, T.; Kuhtz, M.; Quirin, L.; Nguyen, M.; Gude, M.; Filippatos, A. Design approach for the development of a digital twin of a generic hybrid lightweight structure. MATEC Web Conf. 2021, 349, 03004. [Google Scholar] [CrossRef]

- Kokkonen, P.; Hemming, B.; Mikkola, E.; Teir, L.; Lämsä, V.; Junttila, J. Robust lightweight design and digital twins considering manufacturing quality variation and sustainability requirements. Raken. Mek. 2022, 55, 66–80. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, Y. Intelligent Analysis for Safety-Influencing Factors of Prestressed Steel Structures Based on Digital Twins and Random Forest. Metals 2022, 12, 646. [Google Scholar] [CrossRef]

- Van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive maintenance using digital twins: A systematic literature review. Inf. Softw. Technol. 2022, 151, 107008. [Google Scholar] [CrossRef]

- Tygesen, U.T.; Jepsen, M.S.; Vestermark, J.; Dollerup, N.; Pedersen, A. The true digital twin concept for fatigue re-assessment of marine structures. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018. [Google Scholar]

- Cheng, Z.; Tan, E.; Cai, M.; Allan, R.M. Concept design of a digital twin architecture for ship structural health management. J. Phys. Conf. Ser. 2022, 2311, 012010. [Google Scholar] [CrossRef]

- Richstein, R.; Schmid, S.; Schröder, K.U. Using SHM for the representation of structural components over their service life within digital twins. In Proceedings of the European Workshop On Structural Health Monitoring: EWSHM 2022, Palermo, Italy, 4–7 June 2022. [Google Scholar]

- Schmid, S.; Richstein, R.; Schröder, K.U. Integration of Fatigue Estimation into Experimentable Digital Twins for Structural Applications. In Proceedings of the European Workshop On Structural Health Monitoring: EWSHM 2022, Palermo, Italy, 4–7 June 2022. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Hartmann, D.; Herz, M.; Wever, U. Model Order Reduction a Key Technology for Digital Twins. In Reduced-Order Modeling (ROM) for Simulation and Optimization; Keiper, W., Milde, A., Volkwein, S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 167–179. [Google Scholar]

- Sadeghi, A.R.; Wachsmann, C.; Waidner, M. Security and privacy challenges in industrial internet of things. In Proceedings of the 52nd Annual Design Automation Conference, San Francisco, CA, USA, 7 June 2015. [Google Scholar]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2019, 13, 534–556. [Google Scholar] [CrossRef]

- Chen, Y. Integrated and intelligent manufacturing: Perspectives and enablers. Engineering 2017, 3, 588–595. [Google Scholar] [CrossRef]

- Yun, S.; Park, J.H.; Kim, W.T. Data-centric middleware based digital twin platform for dependable cyber-physical systems. In Proceedings of the 2017 Ninth International Conference on Ubiquitous and Future Networks (ICUFN), Milan, Italy, 4–7 July 2017. [Google Scholar]

- Roßmann, J.; Schluse, M. Experimentierbare Digitale Zwillinge im Lebenszyklus technischer Systeme. In Handbuch Industrie 4.0: Recht, Technik, Gesellschaft; Frenz, W., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 837–859. [Google Scholar]

- Bauernhansl, T.; Krüger, J.; Reinhart, G.; Schuh, G. WGP-Standpunkt Industrie 4.0; Abele, E., Ed.; Scientific Society for Production Engineering: Darmstadt, Germany, 2016; Available online: https://www.google.co.th/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwiMm-y49t6DAxUE2TgGHcIzDAkQFnoECAsQAQ&url=https%3A%2F%2Fwww.ipa.fraunhofer.de%2Fcontent%2Fdam%2Fipa%2Fde%2Fdocuments%2FPresse%2FPresseinformationen%2F2016%2FJuni%2FWGP_Standpunkt_Industrie_40.pdf&usg=AOvVaw0dWTcKleEnFAt84WuBQlCA&opi=89978449 (accessed on 30 March 2023).

- Brenner, B.; Hummel, V. Digital Twin as Enabler for an Innovative Digital Shopfloor Management System in the ESB Logistics Learning Factory at Reutlingen-University. Procedia Manuf. 2017, 9, 198–205. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Enders, M.R.; Hoßbach, N. The Digital Twin Revolution in Healthcare—A Literature Review. In Proceedings of the 25th Americas Conference on Information Systems, Cancun, Mexico, 15–17 August 2019. [Google Scholar]

- Wiedemann, J. Leichtbau: Elemente und Konstruktion, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- VDI 2221—Part 1 (2019), Design of Technical Products and Systems—Model of Product Design; Verein Deutscher Ingenieure: Dusseldorf, Germany, 2019.

- Rocchetta, R.; Broggi, M.; Huchet, Q.; Patelli, E. On-line Bayesian model updating for structural health monitoring. Mech. Syst. Signal Process. 2018, 103, 174–195. [Google Scholar] [CrossRef]

| Meta-Dimension | Dimension | Characteristics | ||

|---|---|---|---|---|

| Data Collection | Data Aquisition | Automated | Semi-manual | |

| Data Source | Multiple Source | Single Source | ||

| Synchronization | With | Without | ||

| Data Input | Raw Data | Preprocessed Data | ||

| Data Handling | Data Gouvern. | Rules Applied | Rules Not Applied | |

| Data Link | Bi-Directional | One-Directional | ||

| Interface | HMI | M2M | ||

| Interoperability | None | Via Translator | Fully | |

| Purpose | Processing | Transfer | Repository | |

| Conceptual Scope | Accuracy | Identical | Partial | |

| Conceptual Elem. | Independent | Bound | ||

| Time of Creation | Digital First | Physical First | Simultaneously |

| Phase | Information Type | Data | DT Requirements |

|---|---|---|---|

| Conception | Principal Solution | - | Concept database |

| Conceptual load-bearing system | - | ||

| Material | Characteristics | Material database | |

| Cost | |||

| Boundaries | Positions | Virtual environment | |

| DOF | |||

| Bearing | |||

| Installation space | |||

| Loads | Type | Virtual test-bed for generating and testing simulation-based load cases | |

| Direction | |||

| Size | |||

| Position | |||

| Preliminary Design | Subsystem | - | Models with a low detail level (implicit) for identifying and testing influencing parameters |

| Interface | Position | ||

| DOF | |||

| Component | Length | ||

| Cross-section | |||

| Orientation | |||

| DOF | |||

| Design | Component Shape | Dimensions | Models with a high detail level (explicit) for verification |

| Dimensioning | (Wall) Thickness | ||

| Safety factors | |||

| Joints | Typ | ||

| Positions | |||

| Number | |||

| Dimensions |

| Design Phase | Operation Phase | |

|---|---|---|

| mandatory | semi-manual data acquisition | automated data acquisition |

| multiple data sources | multiple data sources | |

| without synchronization | with synchronization | |

| pre-processed data input | raw data input | |

| one-directional data link | bi-directional data link | |

| processing and repository purpose | processing and repository purpose | |

| partial and identical accuracy | partial accuracy | |

| digital first | physical first | |

| optional | automated data acquisition | |

| with synchronization | ||

| raw data input | pre-processed data input | |

| bi-directional data link | ||

| transfer purpose | transfer purpose | |

| identical accuracy | ||

| physical first | digital first | |

| not discussed | Data Governance | |

| Interoperability | ||

| Interface | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richstein, R.; Schröder, K.-U. Characterizing the Digital Twin in Structural Mechanics. Designs 2024, 8, 8. https://doi.org/10.3390/designs8010008

Richstein R, Schröder K-U. Characterizing the Digital Twin in Structural Mechanics. Designs. 2024; 8(1):8. https://doi.org/10.3390/designs8010008

Chicago/Turabian StyleRichstein, Rebecca, and Kai-Uwe Schröder. 2024. "Characterizing the Digital Twin in Structural Mechanics" Designs 8, no. 1: 8. https://doi.org/10.3390/designs8010008