Mechanical Properties of Cold Mix Asphalt (CMA) Mixed with Recycled Asphalt Pavement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Mix Design

2.3. Testing Methods

2.3.1. Indirect Tensile Strength Test

2.3.2. Resilient Modulus Test

2.3.3. Wheel Tracking Test

2.3.4. Four-Point Bending Test: Fatigue Test

3. Results

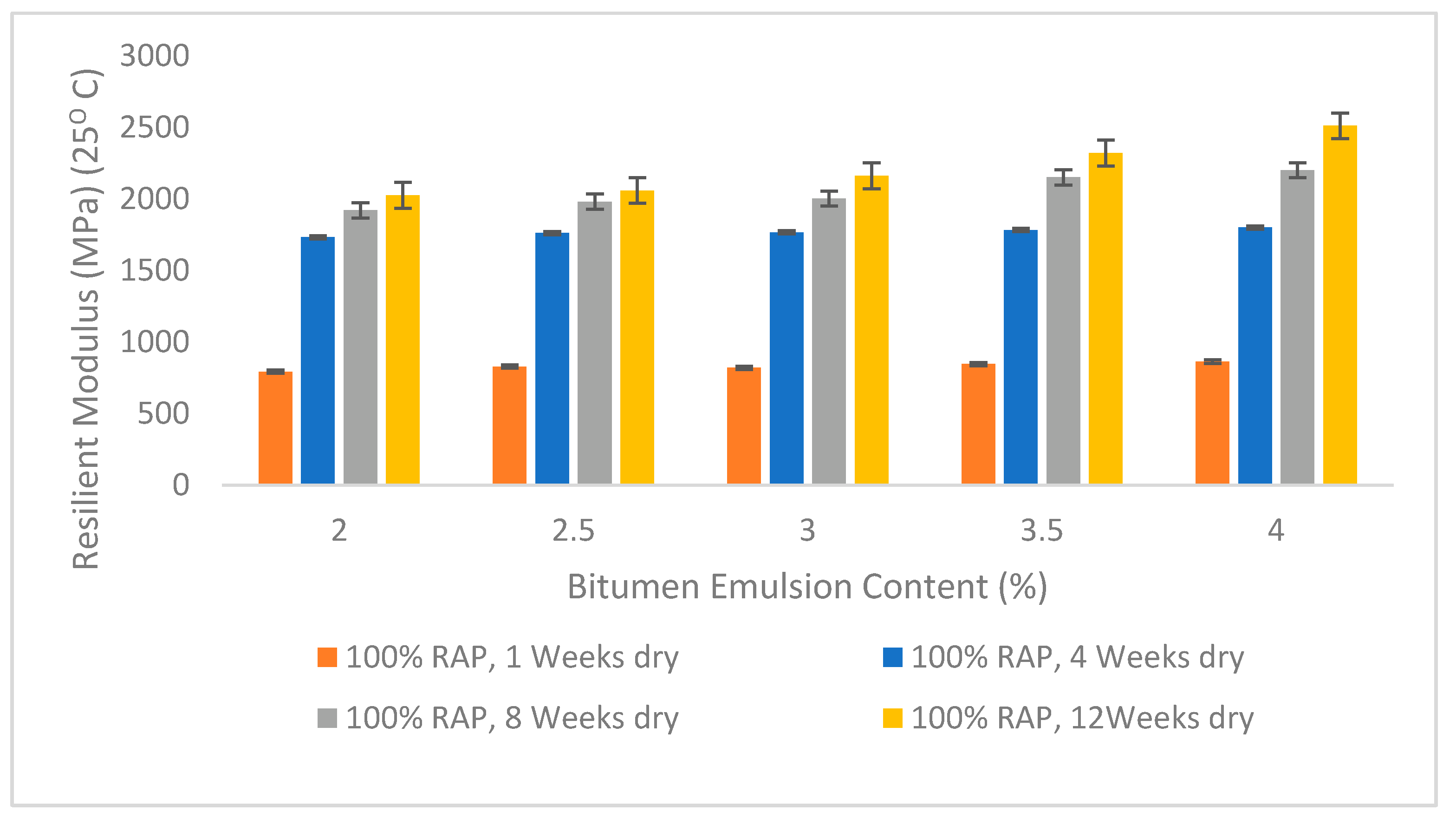

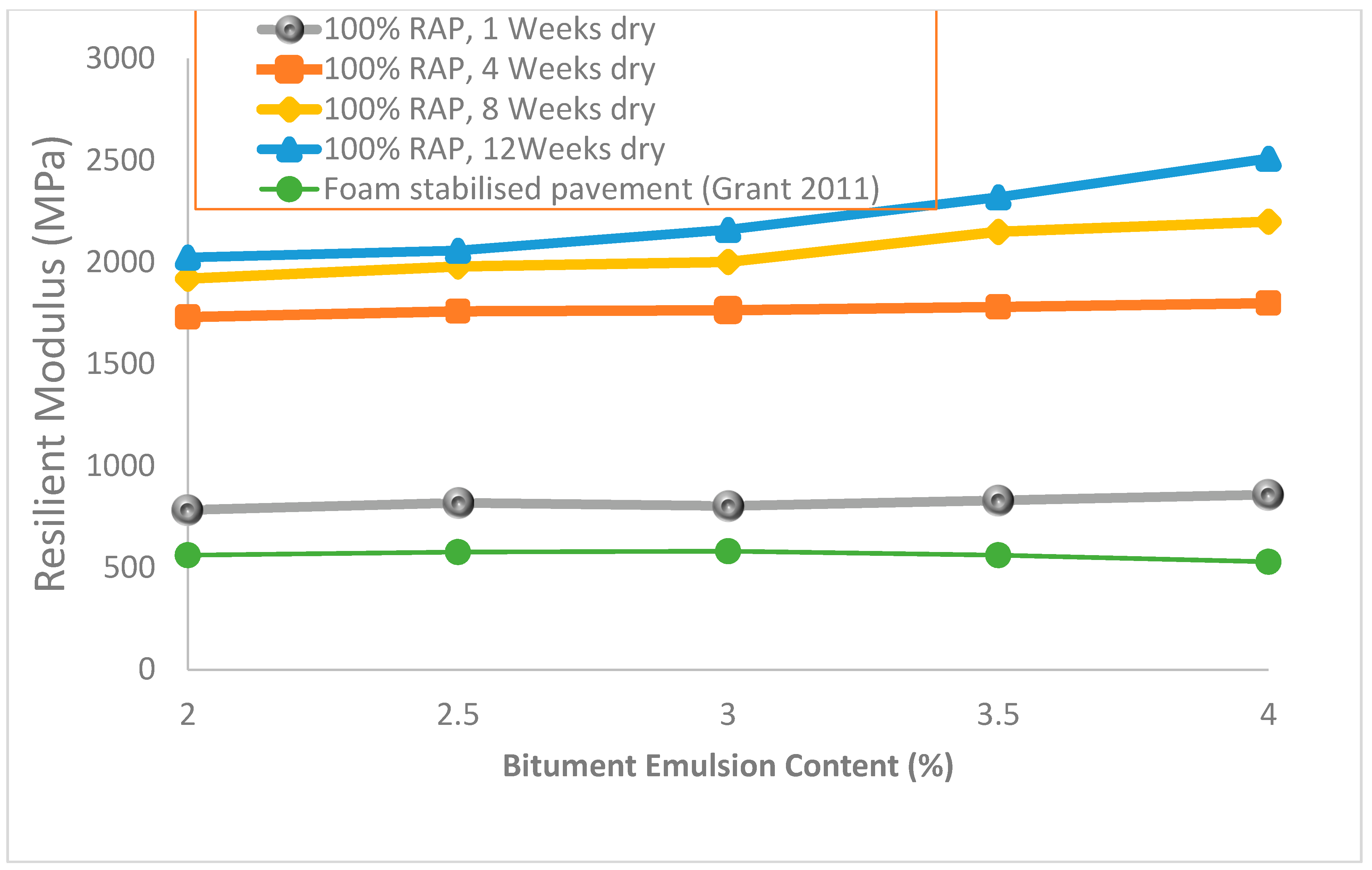

3.1. Resilient Modulus Test

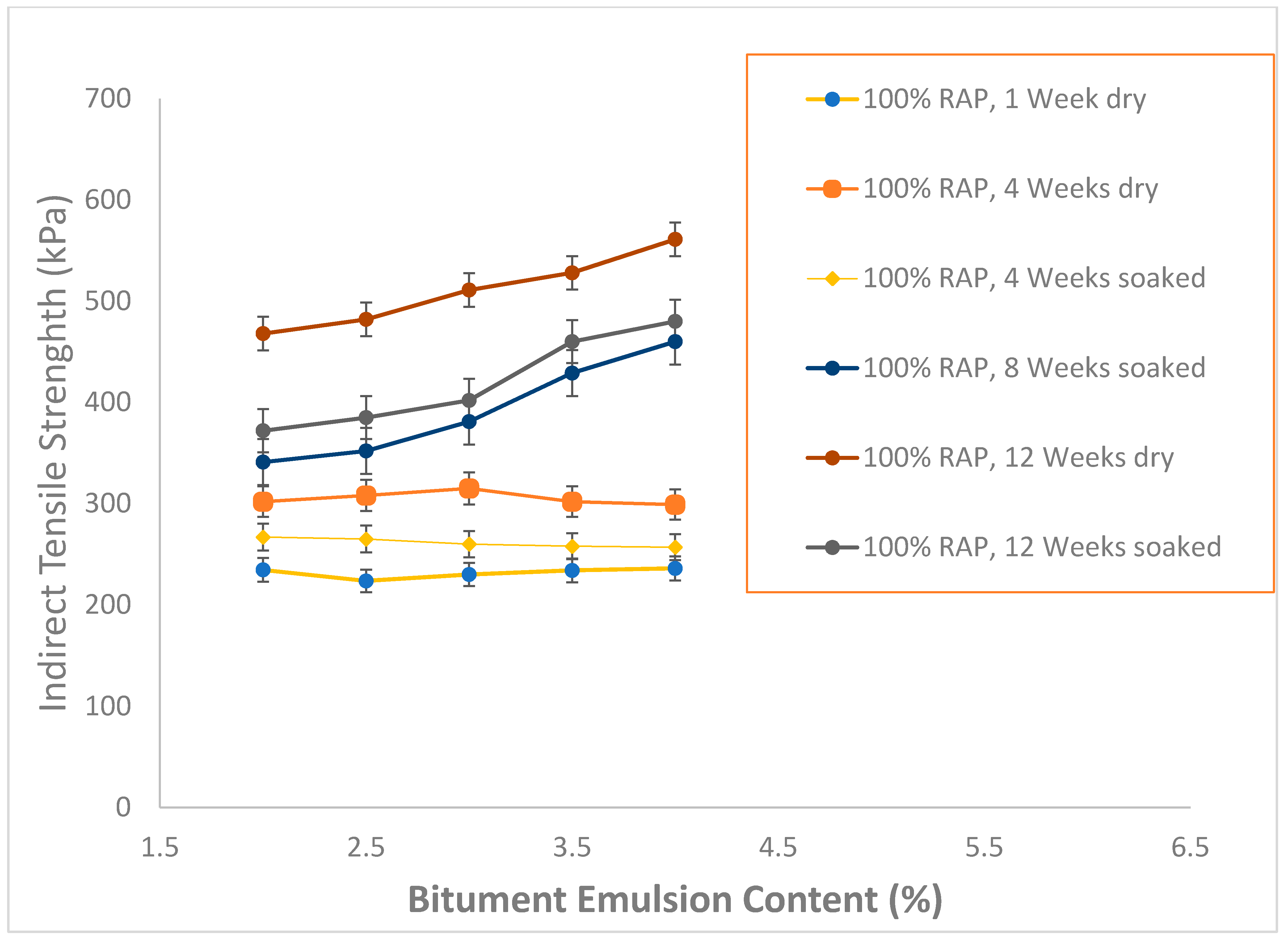

3.2. Indirect Tensile Strength Test

3.3. Rutting Resistance Test

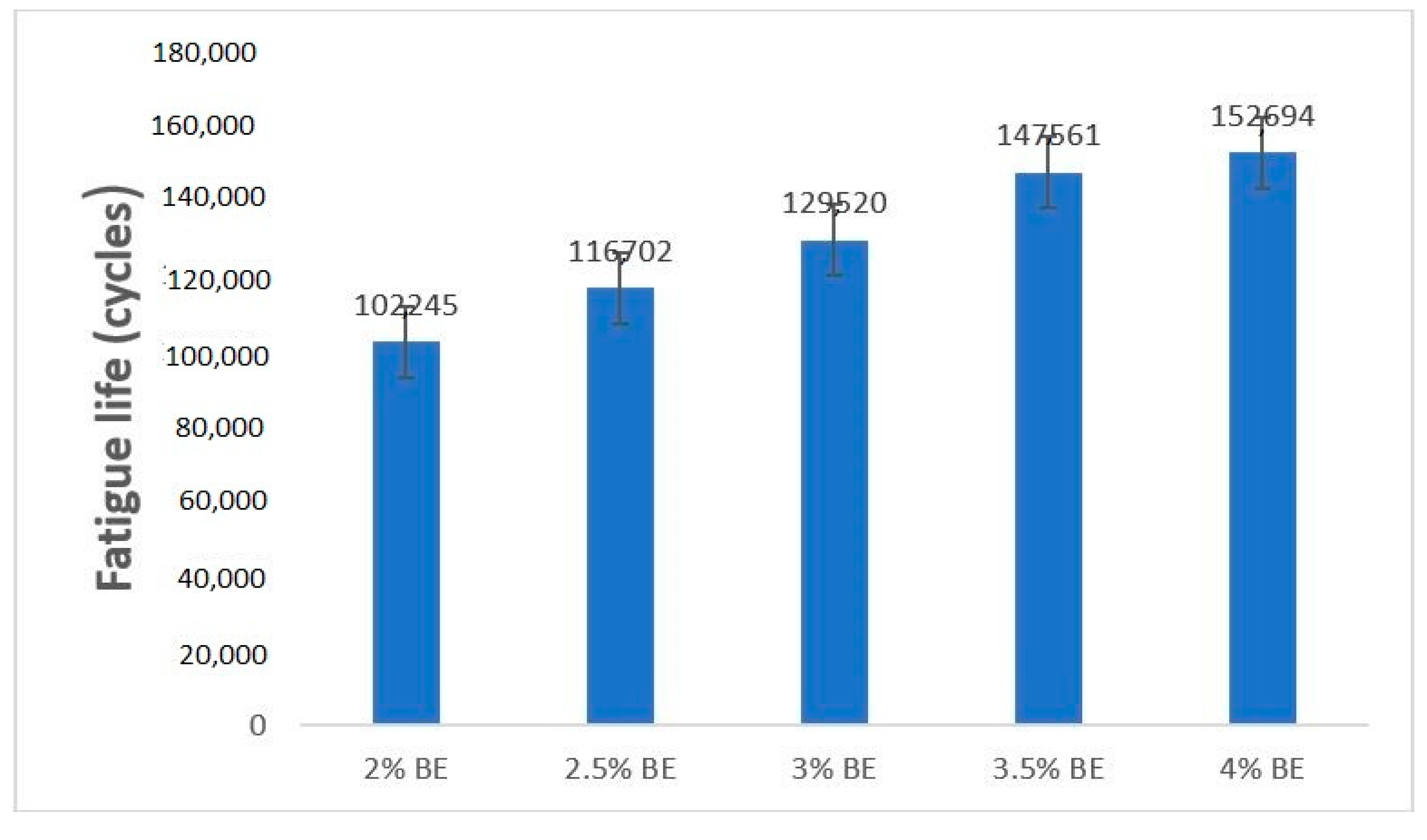

3.4. Four-Point Bending Test

4. Discussion

5. Conclusions

- (a)

- A longer curing time is suggested for the use of 100% RAP and cold mix asphalt as a reflection of long term use in real conditions.

- (b)

- Variations of RAP mix and cold mix asphalt could be a good point to further consider.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Al-Rkaby, A.H.J.; Chegenizadeh, A.; Nikraz, H.R. Directional-dependence in the mechanical characteristics of sand: A review. Int. J. Geotech. Eng. 2016, 10, 499–509. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. An investigation into effect of sawdust treatment on permeability and compressibility of soil-bentonite slurry cut-off wall. J. Clean. Prod. 2017, 162, 1–6. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Keramatikerman, M.; Nikraz, H. Liquefaction resistance of fibre reinforced low-plasticity silt. Soil Dyn. Earthq. Eng. 2018, 104, 372–377. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Investigation on Strength of Fiber Reinforced Clay. Adv. Mater. Res. 2011, 261, 957–963. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Composite Soil: Fiber Inclusion and Strength. Adv. Mater. Res. 2011, 308, 1646–1650. [Google Scholar] [CrossRef]

- Javilla, B.; Fang, H.; Mo, L.; Shu, B.; Wu, S. Test evaluation of rutting performance indicators of asphalt mixtures. Constr. Build. Mater. 2017, 155, 1215–1223. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Xiao, R.; Hu, W.; Jiang, X.; Huang, B. Characterization of aggregate interlocking in hot mix asphalt by mechanistic performance tests. Road Mater. Pavement Des. 2021, 22 (Suppl. 1), S498–S513. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Tokoni, L.; Nikraz, H.; Dadras, E. Effect of ethylene-vinyl acetate (EVA) on stone mastic asphalt (SMA) behaviour. Constr. Build. Mater. 2021, 272, 121628. [Google Scholar] [CrossRef]

- Al-Busaltan, S.; Al Nageim, H.; Atherton, W.; Sharples, G. Mechanical Properties of an Upgrading Cold-Mix Asphalt Using Waste Materials. J. Mater. Civ. Eng. 2012, 24, 1484–1491. [Google Scholar] [CrossRef]

- Jain, S.; Singh, B. Cold mix asphalt: An overview. J. Clean. Prod. 2021, 280, 124378. [Google Scholar] [CrossRef]

- Thanaya, I.N.A. Review and recommendation of cold asphalt emulsion mixtures CAEMS design. Civ. Eng. Dimens. 2007, 9, 49–56. [Google Scholar]

- Singh, B.; Saboo, N.; Kumar, P. Effect of Short-Term Aging on Creep and Recovery Response of Asphalt Binders. J. Transp. Eng. Part B Pavements 2017, 143, 04017017. [Google Scholar] [CrossRef]

- Monu, K.; Ransinchung, G.D.; Singh, S. Effect of long-term ageing on properties of RAP inclusive WMA mixes. Constr. Build. Mater. 2019, 206, 483–493. [Google Scholar] [CrossRef]

- Lu, S.-M.; Lu, C.; Tseng, K.-T.; Chen, F.; Chen, C.-L. Energy-saving potential of the industrial sector of Taiwan. Renew. Sustain. Energy Rev. 2013, 21, 674–683. [Google Scholar] [CrossRef]

- Valdés, G.; Pérez-Jiménez, F.; Miró, R.; Martínez, A.; Botella, R. Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2011, 25, 1289–1297. [Google Scholar] [CrossRef] [Green Version]

- Williams, B.A.; Willis, J.R.; Shacat, J. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2019; National Asphalt Pavement Association (NAPA): Greenbelt, MD, USA, 2020. [Google Scholar]

- Kamariya, U.; Zala, L.; Amin, A.A. Utilization of Reclaimed Asphalt Pavement (RAP) Materials: A Synthesis Report. IJTIMES 2018, 5, 1–7. [Google Scholar]

- Rahman, M.A.; Lmteaz, M.A.; Arulrajah, A.; Piratheepan, J.; Disfani, M.M. Recycled construction and demolition materials in permeable pavement systems: Geotechnical and hydraulic characteristics. J. Clean. Prod. 2015, 90, 183–194. [Google Scholar] [CrossRef]

- Chan, R.; Santana, M.A.; Oda, A.M.; Paniguel, R.C.; Vieira, L.B.; Figueiredo, A.D.; Galobardes, I. Analysis of potential use of fibre reinforced recycled aggregate concrete for sustainable pavements. J. Clean. Prod. 2019, 218, 183–191. [Google Scholar] [CrossRef]

- Wijayasundara, M.; Crawford, R.H.; Mendis, P. Comparative assessment of embodied energy of recycled aggregate concrete. J. Clean. Prod. 2017, 152, 406–419. [Google Scholar] [CrossRef]

- Silva, H.M.; Oliveira, J.R.; Jesus, C.M. Are totally recycled hot mix asphalts a sustainable alternative for road paving? Resour. Conserv. Recycl. 2012, 60, 38–48. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef] [Green Version]

- Biswas, W.K. Carbon footprint and embodied energy assessment of a civil works program in a residential estate of Western Australia. Int. J. Life Cycle Assess. 2014, 19, 732–744. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Jia, X.; Woods, M. Laboratory Performance Evaluation of Warm-Mix Asphalt Containing High Percentages of Reclaimed Asphalt Pavement. Transp. Res. Rec. 2012, 2294, 98–105. [Google Scholar] [CrossRef]

- Lopes, M.; Gabet, T.; Bernucci, L.; Mouillet, V. Durability of hot and warm asphalt mixtures containing high rates of reclaimed asphalt at laboratory scale. Mater. Struct. 2014, 48, 3937–3948. [Google Scholar] [CrossRef]

- Bocci, E.; Graziani, A.; Bocci, M. Cold In-place Recycling for a Base Layer of an Italian High-Traffic Highway. In Lecture Notes in Civil Engineering; Springer Science and Business Media LLC: New York, NY, USA, 2020; pp. 313–322. [Google Scholar]

- Godenzoni, C.; Graziani, A.; Perraton, D. Complex modulus characterisation of cold-recycled mixtures with foamed bitumen and different contents of reclaimed asphalt. Road Mater. Pavement Des. 2017, 18, 130–150. [Google Scholar] [CrossRef]

- Graziani, A.; Raschia, S.; Mignini, C.; Carter, A.; Perraton, D. Use of fine aggregate matrix to analyze the rheological behavior of cold recycled materials. Mater. Struct. 2020, 53, 1–16. [Google Scholar] [CrossRef]

- Meijide, B.G. How Long of the Curing Time Is Suitable for Asphalt Mixture in the Lab; European Asphalt Pavement Association (EAPA): Brussels, Belgium, 2016. [Google Scholar]

- Keramatikerman, M.; Chegenizadeh, A. Effect of Particle Shape on Monotonic Liquefaction: Natural and Crushed Sand. Exp. Mech. 2017, 57, 1341–1348. [Google Scholar] [CrossRef]

- As/Nzs 2891.5:2015; Methods of Sampling and Testing Asphalt Compaction of Asphalt by Marshall Method and Determination of Stability and Flow—Marshall Procedure. The Exchange Centre: Sydney, NSW, Australia, 2015.

- Australia, M.R.W. Bitumen Content and Particle Size Distribution of Asphalt and Stabilised Soil: Centrifuge Method 730.1; Department of Transport: East Perth, Australia, 2011. [Google Scholar]

- Australia, M.R.W. Stability and Flow of Asphalt: Marshall Method 731.1; Department of Transport: East Perth, Australia, 2017. [Google Scholar]

- Austroads. Sample Preparation—Compaction of Asphalt Slabs; Austroads: Sydney, Australia, 2005. [Google Scholar]

- Australia, M.R.W. Western Australian Confined Compression Test 142.1; Department of Transport: East Perth, Australia, 2012. [Google Scholar]

- Huan, Y. Effects of Aggregate Properties on Strength Characteristics of the Foamed Bitumen Mixture with Relation to Western Australian Roadway Construction. Master’s Thesis, Curtin University, Singapore, 2014. [Google Scholar]

- As/Nzs 2891.13.1:2013; Methods of Sampling and Testing Asphalt Determination of the Resilient Modulus of Asphalt—Indirect Tensile Method. The Exchange Centre: Sydney, NSW, Australia, 2013.

- Austroads. Deformation Resistance of Asphalt Mixtures by the Wheel Tracking Test; Austroads: Sydney, Australia, 2006. [Google Scholar]

- Grant, R. Mechanical Characteristics of Foamed Bitumen Treated Pavement Materials in Western Australian, in Civil Engineering; Curtin University of Technology: Perth, Australia, 2011. [Google Scholar]

- Karami, M.; Nikraz, H.; Sebayang, S.; Irianti, L. Laboratory experiment on resilient modulus of BRA modified asphalt mixtures. Int. J. Pavement Res. Technol. 2018, 11, 38–46. [Google Scholar] [CrossRef]

- Venudharan, V.; Biligiri, K.P. Estimation of phase angles of asphalt mixtures using resilient modulus test. Constr. Build. Mater. 2015, 82, 274–286. [Google Scholar] [CrossRef]

- Mokhtari, A.; Nejad, F.M. Mechanistic approach for fiber and polymer modified SMA mixtures. Constr. Build. Mater. 2012, 36, 381–390. [Google Scholar] [CrossRef]

- Nwakaire, C.M.; Yap, S.P.; Yuen, C.W.; Onn, C.C.; Koting, S.; Babalghaith, A.M. Laboratory study on recycled concrete aggregate based asphalt mixtures for sustainable flexible pavement sur-facing. J. Clean. Prod. 2020, 262, 121462. [Google Scholar] [CrossRef]

| % Passing | Sieve (mm) |

|---|---|

| (Air Dry) | |

| 100 | 13.20 |

| 97.0 | 9.50 |

| 81.0 | 6.70 |

| 64.0 | 4.75 |

| 43.0 | 2.36 |

| 28.9 | 1.18 |

| 18.5 | 0.60 |

| 8.1 | 0.30 |

| 2.9 | 0.15 |

| 1.4 | 0.075 |

| Parameter | Unit | Value |

|---|---|---|

| Particle Density | (g/cm3) | 2.32 |

| Bitumen Content | (%) | 4.4 |

| Penetration | (10−1 mm) | 8 |

| Moisture Content | (%) | 0.60 |

| Emulsion | Binder | ||||

|---|---|---|---|---|---|

| pH | Setting Time | Density Conversion | Melting Point of Bitumen | Boiling Point | Colour |

| 2.5 | >8 min | 985 (L/te) | >100 °C | >250 °C | Black |

| Contents | |||||

|---|---|---|---|---|---|

| Bitumen emulsion added | 2.00% | 2.50% | 3.00% | 3.50% | 4.00% |

| Bitumen from emulsion | 1.20% | 1.50% | 1.80% | 2.10% | 2.40% |

| Total bitumen | 5.60% | 5.90% | 6.20% | 6.50% | 6.80% |

| Moisture from emulsion | 0.80% | 1.00% | 1.20% | 1.40% | 1.60% |

| Total moisture | 1.40% | 1.60% | 1.80% | 2.00% | 2.20% |

| Moisture to be added for OMC | 3.70% | 3.50% | 3.30% | 3.10% | 2.90% |

| Marshall sample (kg) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Cooper tracker sample (kg) | 10 | 10 | 10 | 10 | 10 |

| Weight of RAP (kg) | 23.5 | 23.5 | 23.5 | 23.5 | 23.5 |

| Bitumen emulsion required (kg) | 0.47 | 0.5875 | 0.705 | 0.8225 | 0.94 |

| Water required (kg) | 0.87 | 0.82 | 0.78 | 0.73 | 0.68 |

| Superior | Good | Medium | Low |

|---|---|---|---|

| <3.5 mm | 3.5–8 mm | 8–13 mm | >13 mm |

| Parameter | 2% BE | 2.5% BE | 3% BE | 3.5% BE | 4% BE |

|---|---|---|---|---|---|

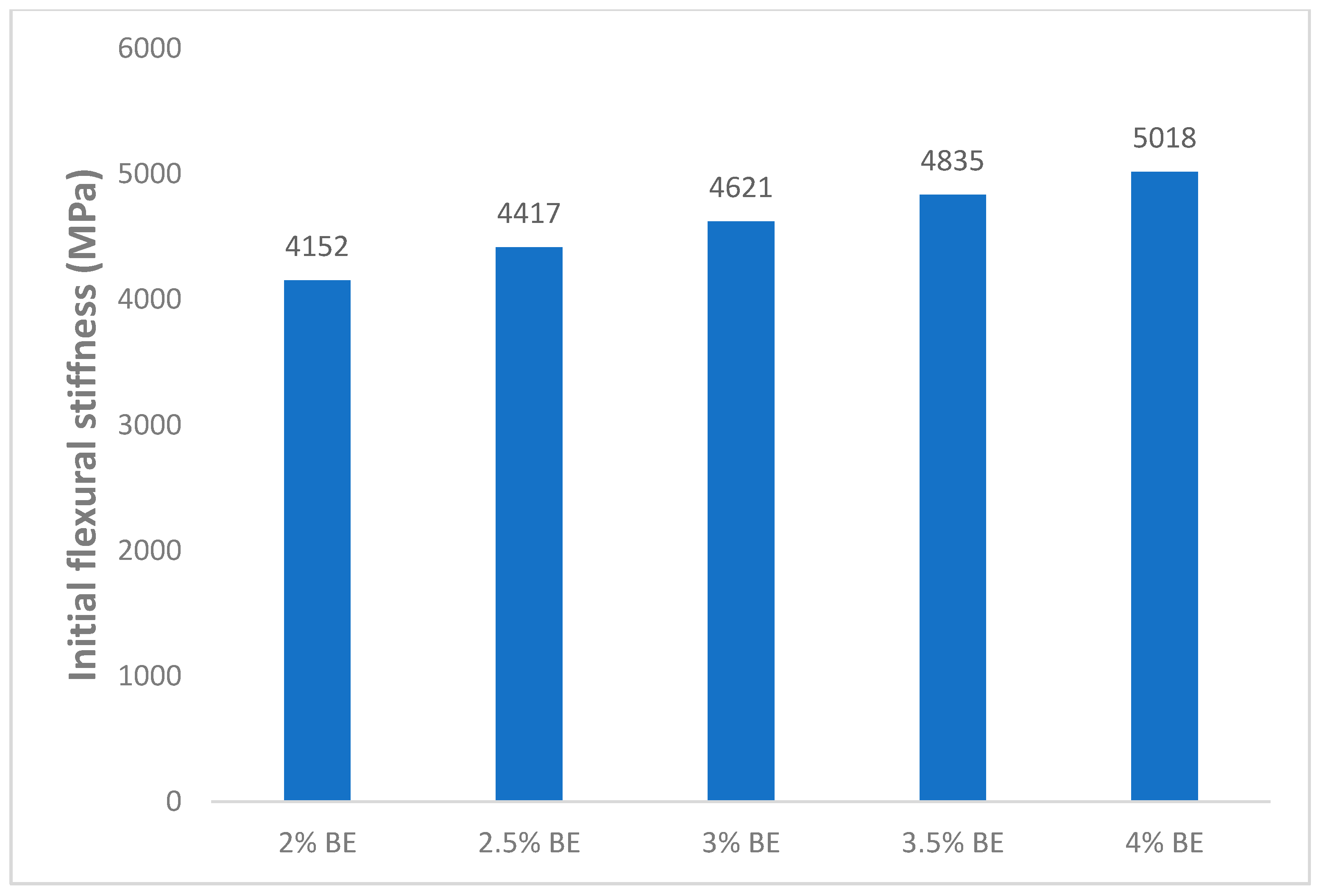

| Initial flexural stiffness (MPa) | 4152 | 4417 | 4621 | 4835 | 5018 |

| Fatigue life (cycles) | 102,245 | 116,702 | 129,520 | 147,561 | 152,694 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chegenizadeh, A.; Tufilli, A.; Arumdani, I.S.; Budihardjo, M.A.; Dadras, E.; Nikraz, H. Mechanical Properties of Cold Mix Asphalt (CMA) Mixed with Recycled Asphalt Pavement. Infrastructures 2022, 7, 45. https://doi.org/10.3390/infrastructures7040045

Chegenizadeh A, Tufilli A, Arumdani IS, Budihardjo MA, Dadras E, Nikraz H. Mechanical Properties of Cold Mix Asphalt (CMA) Mixed with Recycled Asphalt Pavement. Infrastructures. 2022; 7(4):45. https://doi.org/10.3390/infrastructures7040045

Chicago/Turabian StyleChegenizadeh, Amin, Anthony Tufilli, Indah Sekar Arumdani, Mochamad Arief Budihardjo, Ethan Dadras, and Hamid Nikraz. 2022. "Mechanical Properties of Cold Mix Asphalt (CMA) Mixed with Recycled Asphalt Pavement" Infrastructures 7, no. 4: 45. https://doi.org/10.3390/infrastructures7040045