Properties of Hot Mix Asphalt (HMA) with Several Contents of Recycled Concrete Aggregate (RCA) †

Abstract

:1. Introduction

2. Materials

3. Methods and Results

3.1. Mechanical Properties

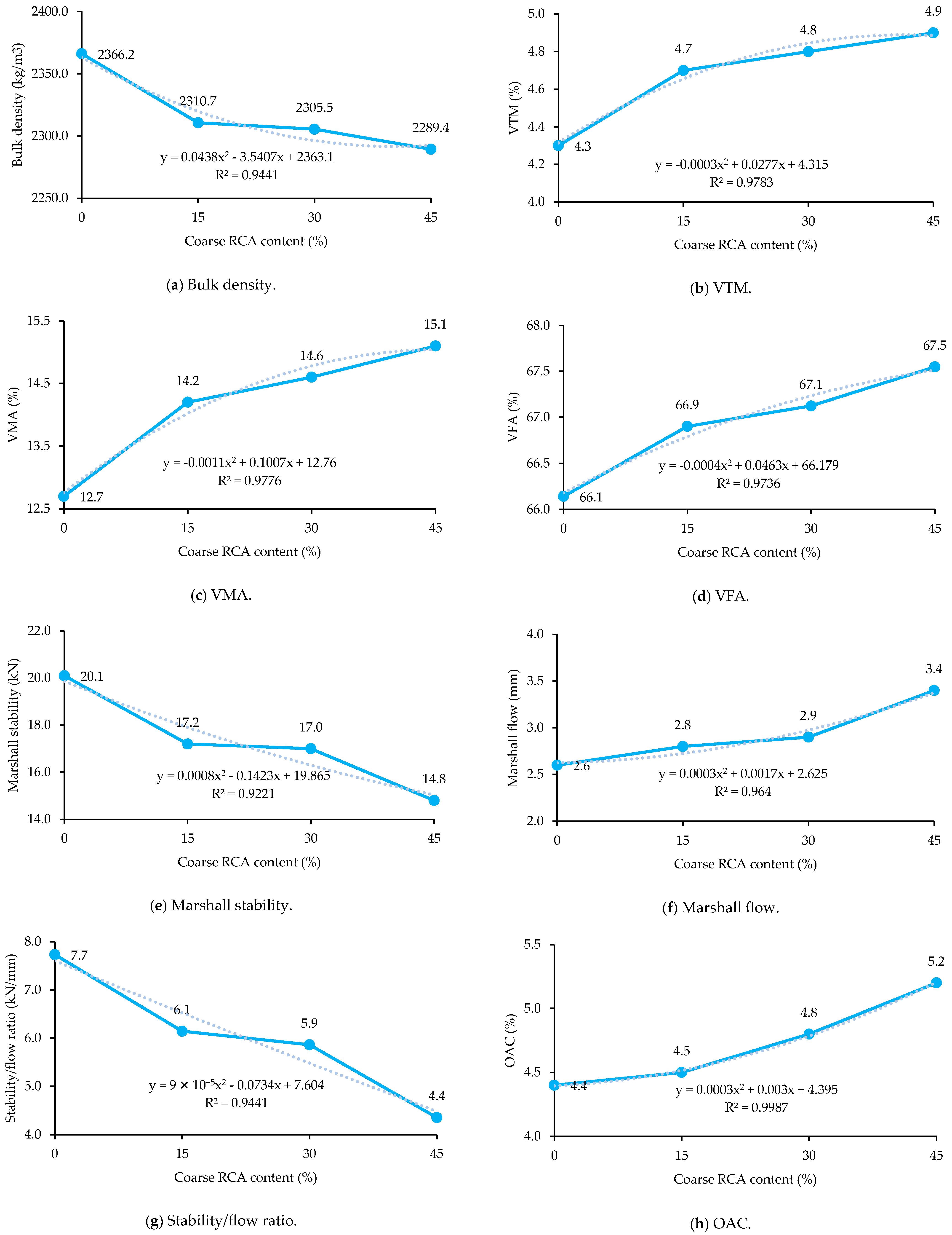

3.1.1. Marshall Parameters

- As the coarse RCA content increases, there is a decrease in bulk density, Marshall stability, and stability/flow ratio.

- The VTM, VMA, VFA, Marshall flow, and OAC progressively augment with the increment in the coarse RCA content.

- Although the increase in the RCA dosage generates a rise for all the void indicators (i.e., VTM, VMA, and VFA), it is not possible to affirm that the RCA content marks a strong correlation with these parameters. In most scenarios, these indicators are only incremented by a minuscule quantity (even less than one percentage unit), so it is not feasible to assemble definitive conclusions. Thus, it is essential for future research to evaluate a greater number of samples in order to carry out an analysis of statistical significance.

| Designs | Mass Fraction Regarding the Total Mixture Weight (%) | ||||

|---|---|---|---|---|---|

| Asphalt Binder | Filler NA | Fine NA | Coarse NA | Coarse RCA | |

| HMA with 0% coarse RCA content | 4.400 | 3.920 | 44.358 | 47.322 | 0.000 |

| HMA with 15% coarse RCA content | 4.500 | 3.916 | 44.312 | 40.182 | 7.091 |

| HMA with 30% coarse RCA content | 4.800 | 3.903 | 44.173 | 32.987 | 14.137 |

| HMA with 45% coarse RCA content | 5.200 | 3.887 | 43.987 | 25.809 | 21.117 |

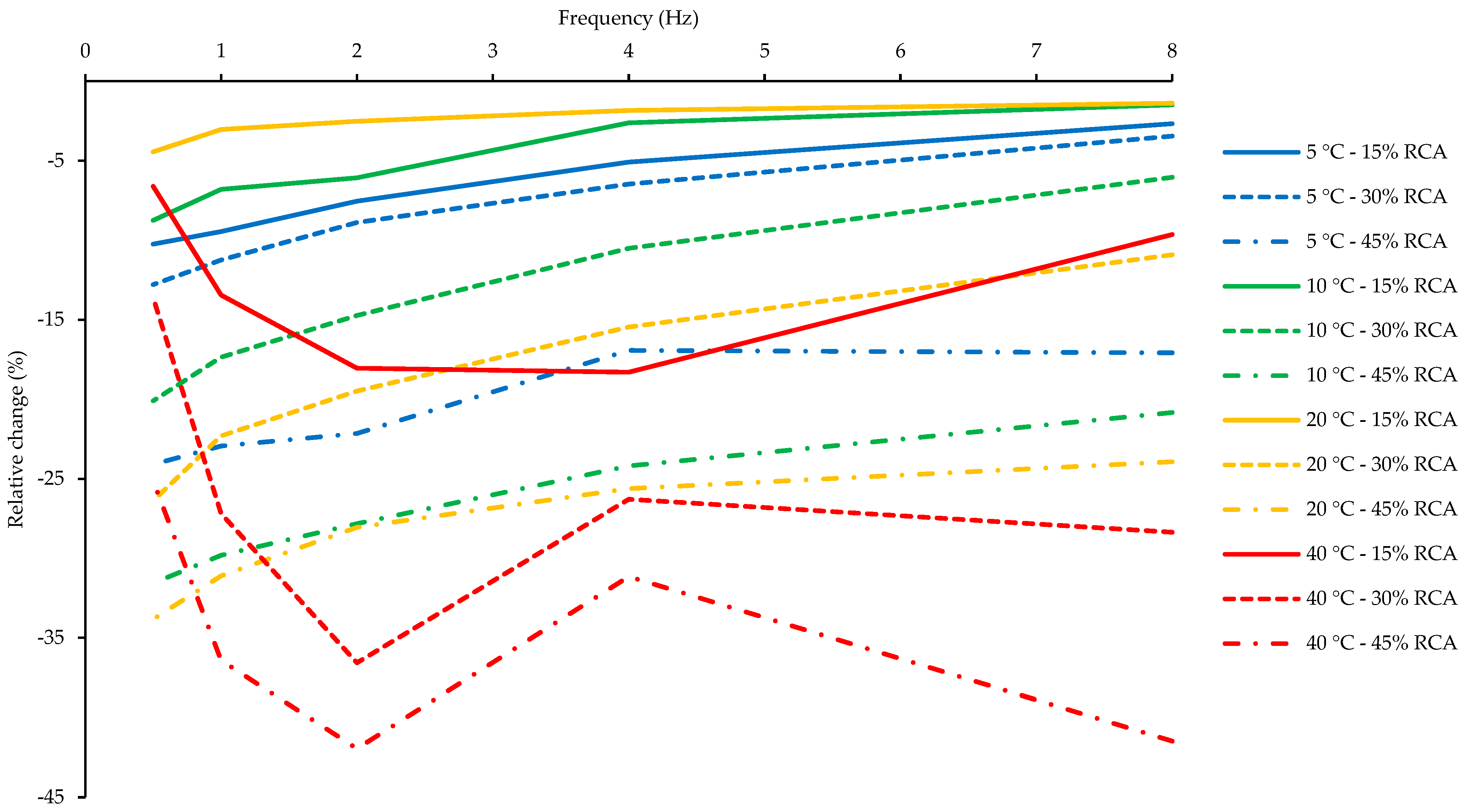

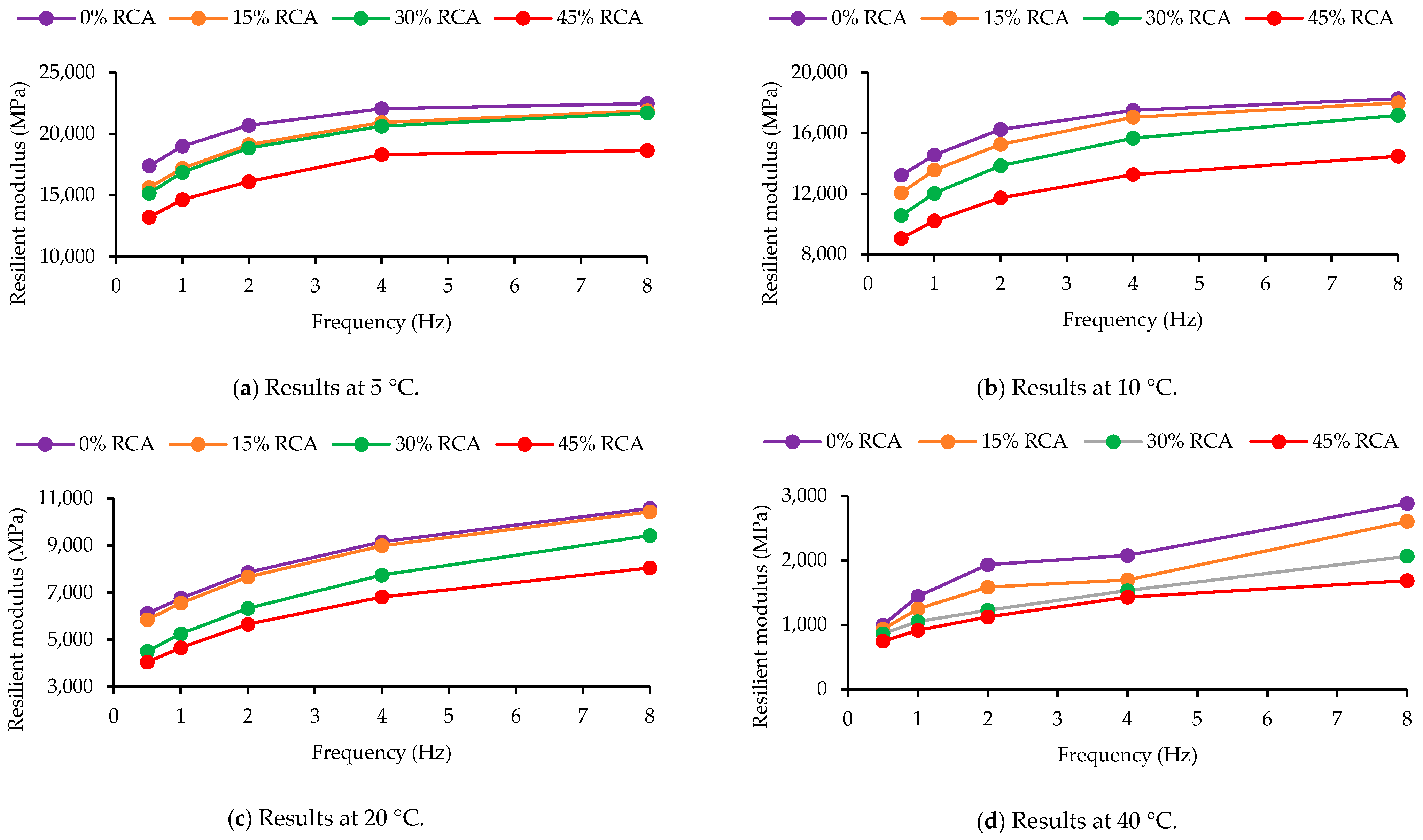

3.1.2. Resilient Modulus

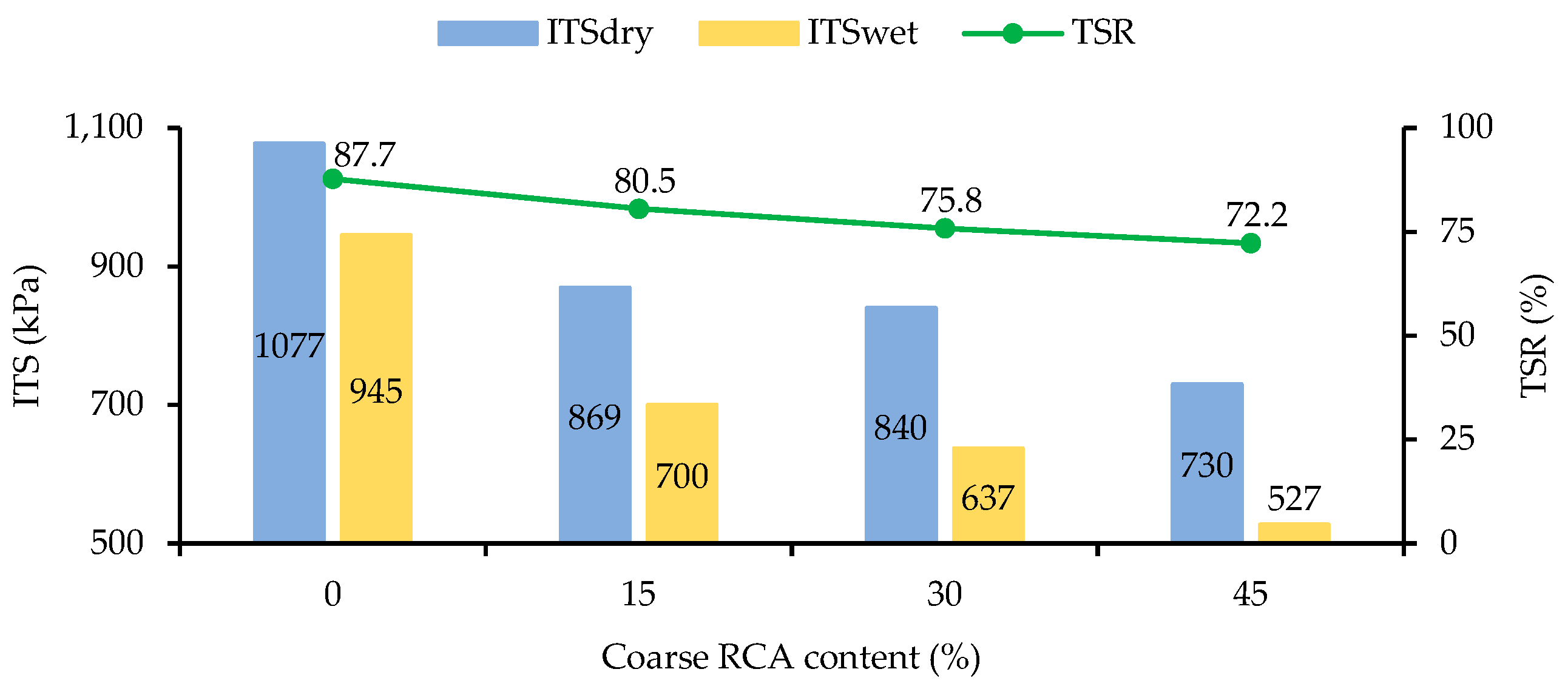

3.1.3. Moisture Susceptibility

3.1.4. Rutting Resistance

3.1.5. Fatigue Life

3.2. Sustainability Properties

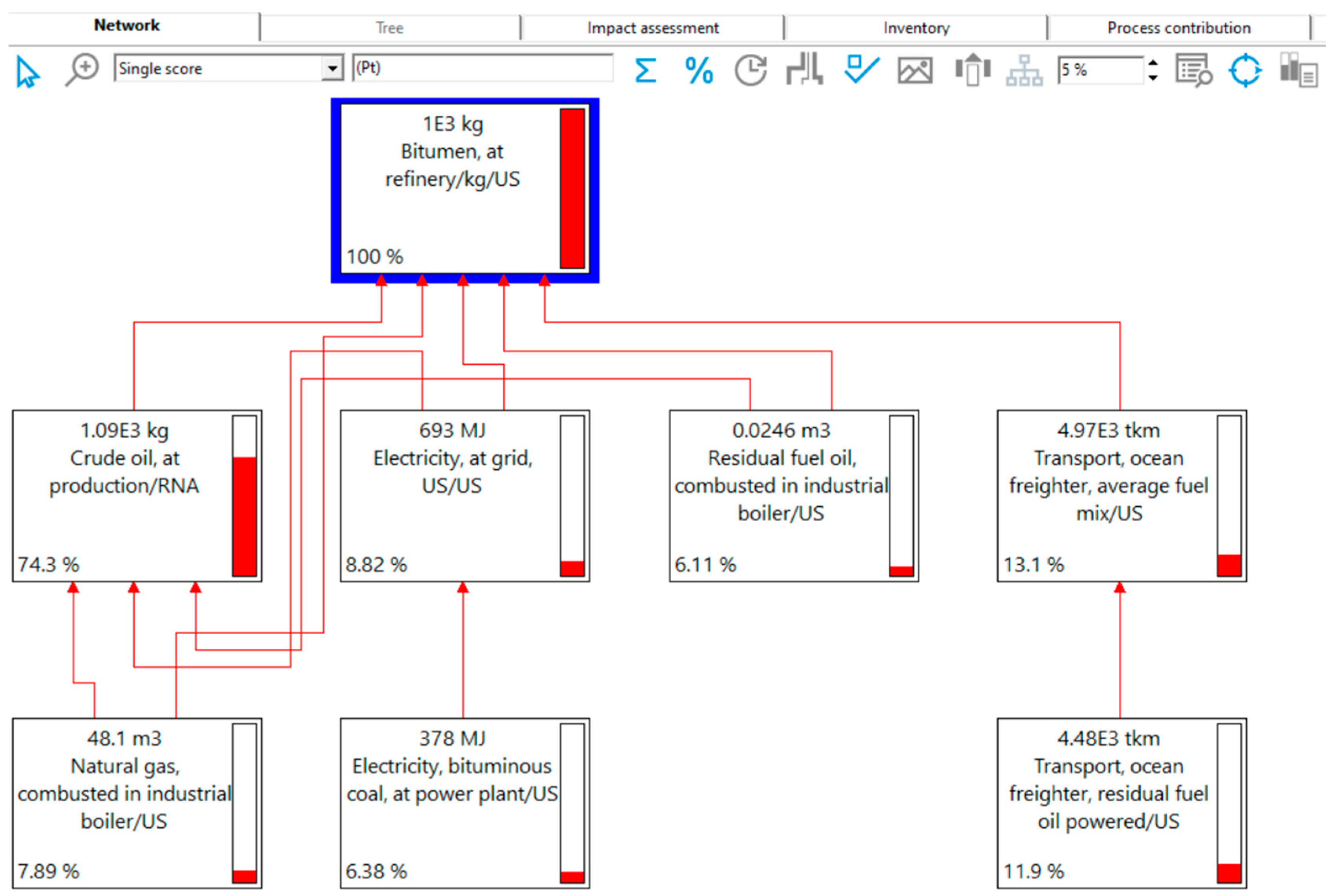

3.2.1. Environmental Impacts

3.2.2. Production Costs

4. Discussion

- The incorporation of RCA reduced the resilient modulus of the HMA by about 45%. The higher alterations were presented at higher temperatures.

- VTM, VMA, Marshall stability, Marshall flow, and Stability/flow ratio exhibit changes around 10–45% regarding the control mixture. Nonetheless, the other Marshall parameters (i.e., bulk density, VFA, and OAC) undergo the tiniest percentual influences in their magnitudes (due to the elevated coarse RCA contents). According to these findings, it is notorious that the RCA dosage significantly influences most Marshall parameters.

- Except for the fatigue resistance measured at a compressive load equal to 30% of the ITS dry value, the 15% coarse RCA generates a decrease in the mechanical performance of the HMA that may be acceptable; even this dosage improves the rutting resistance. However, higher RCA contents yield much more significant detriments.

- Most of the environmental impacts generated by HMA production are reduced by 5–10% by partially substituting 15% coarse NAs with coarse RCA. Nevertheless, higher RCA dosages increase environmental impacts by 6–17%. On the other hand, a similar behavior (but with smaller relative changes) is exhibited by production costs. Therefore, the dramatic influence of this waste material on the HMA’s sustainability properties is notorious.

- Including RCA in the HMA design causes minimal differences in production costs. Nonetheless, considering the typical high volumes of materials required for road infrastructure projects, this variation could become economically significant for the cost-effectiveness of some specific contexts.

5. Conclusions

- A coarse RCA content of 15% increases the HMA’s rutting resistance. However, higher replacement dosages cause the opposite effect. Conversely, for all other mechanical properties, any RCA content causes degradation in the HMA’s performance. Regardless, that decrease in engineering behavior may be tolerable at low dosages (i.e., 15%). Therefore, from a mechanical standpoint, it is concluded that the optimal content of coarse RCA is 15%.

- Concerning the control mixture (i.e., HMA without RCA), the HMA with 15% coarse RCA presents an improvement in its sustainability performance, comprised of a reduction in its environmental impacts and production costs. Nevertheless, higher RCA contents considerably increase both sustainability benchmarks, i.e., environmental burdens and monetary costs. Thus, at a 15% coarse RCA, the mitigation of NA depletions is more significant than the growth in the OAC. Meanwhile, at 30 and 45% of coarse RCA, the OAC is so elevated that there is no environmental or economic benefit from employing recycled aggregates.

- Overall, in terms of mechanical and sustainability properties, the optimal HMA design was achieved by incorporating coarse RCA at a 15% dosage. Accordingly, it is not recommended to use greater RCA dosages.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Acheampong, A.O.; Dzator, J.; Dzator, M.; Salim, R. Unveiling the Effect of Transport Infrastructure and Technological Innovation on Economic Growth, Energy Consumption and CO2 Emissions. Technol. Forecast. Soc. Chang. 2022, 182, 1–24. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, L. The Role of Transport Infrastructure in Economic Growth: Empirical Evidence in the UK. Transp. Policy 2023, 133, 223–233. [Google Scholar] [CrossRef]

- Munday, M.; Reynolds, L.; Roberts, A. Re-Appraising ‘in-Process’ Benefits of Strategic Infrastructure Improvements: Capturing the Unexpected Socio-Economic Impacts for Lagging Regions. Transp. Policy 2023, 134, 119–127. [Google Scholar] [CrossRef]

- Mohmand, Y.T.; Mehmood, F.; Mughal, K.S.; Aslam, F. Investigating the Causal Relationship between Transport Infrastructure, Economic Growth and Transport Emissions in Pakistan. Res. Transp. Econ. 2021, 88, 100972. [Google Scholar] [CrossRef]

- Pradhan, R.P.; Arvin, M.B.; Nair, M. Urbanization, Transportation Infrastructure, ICT, and Economic Growth: A Temporal Causal Analysis. Cities 2021, 115, 103213. [Google Scholar] [CrossRef]

- Tan, R.; Pan, L.; Xu, M.; He, X. Transportation Infrastructure, Economic Agglomeration and Non-Linearities of Green Total Factor Productivity Growth in China: Evidence from Partially Linear Functional Coefficient Model. Transp. Policy 2022, 129, 1–13. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Peñabaena-Niebles, R. A Multi-Objective Optimization Based on Genetic Algorithms for the Sustainable Design of Warm Mix Asphalt (WMA). Int. J. Pavement Eng. 2022, 1–21. [Google Scholar] [CrossRef]

- Plati, C. Sustainability Factors in Pavement Materials, Design, and Preservation Strategies: A Literature Review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Mora, O.; Duque, J.; Turbay, E.; Martinez-Arguelles, G.; Fuentes, L.; Guerrero, O.; Perez, S. Environmental and Economic Feasibility of Implementing Perpetual Pavements (PPs) against Conventional Pavements: A Case Study of Barranquilla City, Colombia. Case Stud. Constr. Mater. 2023, 18, e02112. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, M.; Yuan, H.; Sabri Sabri, M.M.; Li, X. Towards Sustainable Construction Materials: A Comparative Study of Prediction Models for Green Concrete with Metakaolin. Buildings 2022, 12, 772. [Google Scholar] [CrossRef]

- Turbay, E.; Martinez-Arguelles, G.; Navarro-Donado, T.; Sanchez-Cotte, E.; Polo-Mendoza, R.; Covilla-Valera, E. Rheological Behaviour of WMA-Modified Asphalt Binders with Crumb Rubber. Polymers 2022, 14, 4148. [Google Scholar] [CrossRef] [PubMed]

- Polo-Mendoza, R.; Navarro-Donado, T.; Ortega-Martinez, D.; Turbay, E.; Martinez-Arguelles, G.; Peñabaena-Niebles, R. Properties and Characterization Techniques of Graphene Modified Asphalt Binders. Nanomaterials 2023, 13, 955. [Google Scholar] [CrossRef]

- Sanchez-Cotte, E.; Pacheco, C.; Ana, F.; Pineda, Y.; Mercado, R.; Yepes-Martinez, J.; Lagares, R. The Chemical-Mineralogical Characterization of Recycled Concrete Aggregates from Different Sources and Their Potential Reactions in Asphalt Mixtures. Materials 2020, 13, 5592. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Cotte, E.; Fuentes, L.; Martinez-Arguelles, G.; Rondon, H.; Walubita, L.; Cantero, J. Influence of Recycled Concrete Aggregates from Different Sources in Hot Mix Asphalt Design. Constr. Build. Mater. 2020, 259, 120427. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, A.; Khan, K.; Ahmad, W.; Nazar, S.; Faraz, M.I.; Alabdullah, A.A. Split Tensile Strength Prediction of Recycled Aggregate-Based Sustainable Concrete Using Artificial Intelligence Methods. Materials 2022, 15, 4296. [Google Scholar] [CrossRef]

- Pan, X.; Xiao, Y.; Suhail, S.A.; Ahmad, W.; Murali, G.; Salmi, A.; Mohamed, A. Use of Artificial Intelligence Methods for Predicting the Strength of Recycled Aggregate Concrete and the Influence of Raw Ingredients. Materials 2022, 15, 4194. [Google Scholar] [CrossRef]

- Vega, D.; Santos, J.; Martinez-Arguelles, G. Life Cycle Assessment of Hot Mix Asphalt with Recycled Concrete Aggregates for Road Pavements Construction. Int. J. Pavement Eng. 2020, 23, 923–936. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y.; Sreeram, A.; Wu, Q.; Chen, G.; Cheng, S.; Chen, Z.; Chen, X. Potential Use of Recycled Concrete Aggregate (RCA) for Sustainable Asphalt Pavements of the Future: A State-of-the-Art Review. J. Clean. Prod. 2022, 344, 130893. [Google Scholar] [CrossRef]

- Tang, Q.; Xiao, P.; Kou, C.; Lou, K.; Kang, A.; Wu, Z. Physical, Chemical and Interfacial Properties of Modified Recycled Concrete Aggregates for Asphalt Mixtures: A Review. Constr. Build. Mater. 2021, 312, 125357. [Google Scholar] [CrossRef]

- Qasrawi, H.; Asi, I. Effect of Bitumen Grade on Hot Asphalt Mixes Properties Prepared Using Recycled Coarse Concrete Aggregate. Constr. Build. Mater. 2016, 121, 18–24. [Google Scholar] [CrossRef]

- Sharma, A.; Rongmei Naga, G.R.; Kumar, P.; Rai, P. Mix Design, Development, Production and Policies of Recycled Hot Mix Asphalt: A Review. J. Traffic Transp. Eng. 2022, 9, 765–794. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Reyes-Lizcano, F.A.; Rondón-Quintana, H.A. Use of Recycled Concrete Aggregates in Asphalt Mixtures for Pavements: A Review. J. Traffic Transp. Eng. 2022, 9, 725–741. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Peñabaena-Niebles, R. Environmental Optimization of Warm Mix Asphalt (WMA) Design with Recycled Concrete Aggregates (RCA) Inclusion through Artificial Intelligence (AI) Techniques. Results Eng. 2023, 17, 100984. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Peñabaena-Niebles, R.; Giustozzi, F.; Martinez-Arguelles, G. Eco-Friendly Design of Warm Mix Asphalt (WMA) with Recycled Concrete Aggregate (RCA): A Case Study from a Developing Country. Constr. Build. Mater. 2022, 326, 126890. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Fatigue Performance of Bituminous Mixtures Made with Recycled Concrete Aggregates and Waste Tire Rubber. Constr. Build. Mater. 2017, 157, 26–33. [Google Scholar] [CrossRef] [Green Version]

- Hou, Y.; Ji, X.; Li, J.; Li, X. Adhesion between Asphalt and Recycled Concrete Aggregate and Its Impact on the Properties of Asphalt Mixture. Materials 2018, 11, 2528. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Sun, D.; Pang, Q.; Sun, G.; Hu, M.; Lu, T. Potential of Recycled Concrete Aggregate Pretreated with Waste Cooking Oil Residue for Hot Mix Asphalt. J. Clean. Prod. 2019, 221, 469–479. [Google Scholar] [CrossRef]

- Singh, B.; Prasad, D.; Kant, R.R. Effect of Lime Filler on RCA Incorporated Bituminous Mixture. Clean. Eng. Technol. 2021, 4, 100166. [Google Scholar] [CrossRef]

- Naser, M.; Abdel-Jaber, M.t.; Al-shamayleh, R.; Louzi, N.; Ibrahim, R. Evaluating the Effects of Using Reclaimed Asphalt Pavement and Recycled Concrete Aggregate on the Behavior of Hot Mix Asphalts. Transp. Eng. 2022, 10, 100140. [Google Scholar] [CrossRef]

- Sapkota, K.; Yaghoubi, E.; Wasantha, P.L.P.; Staden, R.V.; Fragomeni, S. Mechanical Characteristics and Durability of HMA Made of Recycled Aggregates. Sustainability 2023, 15, 5594. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Samali, B.; Yeaman, J.; Crabb, R. The Use of Glass to Optimize Bitumen Absorption of Hot Mix Asphalt Containing Recycled Construction Aggregates. Materials 2018, 11, 1053. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- D4402/D4402M-23; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing and Materials: Philadelphia, PA, USA, 2023. [CrossRef]

- D6926-20; Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus. American Society for Testing and Materials: Philadelphia, PA, USA, 2020. [CrossRef]

- INVIAS. Especificaciones Generales de Construcción de Carreteras. Inst. Nac. Vias 2022, 1–1269. [Google Scholar]

- D6927-22; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. American Society for Testing and Materials: Philadelphia, PA, USA, 2022. [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Walubita, L.F.; Moreno-Navarro, F.; Giustozzi, F.; Fuentes, L.; Navarro-Donado, T. Ultraviolet Ageing of Bituminous Materials: A Comprehensive Literature Review from 2011 to 2022. Constr. Build. Mater. 2022, 350, 128889. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory Evaluation of Warm Mix Asphalt Mixtures Containing Electric Arc Furnace (EAF) Steel Slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, S.; Choubane, B.; Upshaw, P. Construction of Dynamic Modulus Master Curves with Resilient Modulus and Creep Test Data. Transp. Res. Rec. 2012, 2296, 1–14. [Google Scholar] [CrossRef]

- Dan, H.; Yang, P.; Cao, W.; Shan, H.; Zhang, Z. The Stiffness Behavior of Asphalt Mixtures with Different Compactness under Variable Confinement. Materials 2023, 16, 771. [Google Scholar] [CrossRef]

- Kahil, N.S.; Najjar, S.S.; Chehab, G. Probabilistic Modeling of Dynamic Modulus Master Curves for Hot-Mix Asphalt Mixtures. Transp. Res. Rec. 2015, 2507, 90–99. [Google Scholar] [CrossRef]

- Kuchiishi, A.K.; dos Santos Antão, C.C.; Vasconcelos, K.; Bernucci, L.L.B. Influence of Viscoelastic Properties of Cold Recycled Asphalt Mixtures on Pavement Response by Means of Temperature Instrumentation. Road Mater. Pavement Des. 2019, 20, S710–S724. [Google Scholar] [CrossRef]

- D7369-20; Standard Test Method for Determining the Resilient Modulus of Asphalt Mixtures by Indirect Tension Test. American Society for Testing and Materials: Philadelphia, PA, USA, 2020. [CrossRef]

- Xie, J.; Wu, S.; Pang, L.; Lin, J.; Zhu, Z. Influence of Surface Treated Fly Ash with Coupling Agent on Asphalt Mixture Moisture Damage. Constr. Build. Mater. 2012, 30, 340–346. [Google Scholar] [CrossRef]

- Moghadas Nejad, F.; Azarhoosh, A.R.; Hamedi, G.H.; Azarhoosh, M.J. Influence of Using Nonmaterial to Reduce the Moisture Susceptibility of Hot Mix Asphalt. Constr. Build. Mater. 2012, 31, 384–388. [Google Scholar] [CrossRef]

- Xu, S.; Xiao, F.; Amirkhanian, S.; Singh, D. Moisture Characteristics of Mixtures with Warm Mix Asphalt Technologies—A Review. Constr. Build. Mater. 2017, 142, 148–161. [Google Scholar] [CrossRef]

- D4867/D4867M-22; Standard Test Method for Effect of Moisture on Asphalt Mixtures. American Society for Testing and Materials: Philadelphia, PA, USA, 2022. [CrossRef]

- Brondani, C.; Menezes Vestena, P.; Faccin, C.; Lisboa Schuster, S.; Pivoto Specht, L.; da Silva Pereira, D. Moisture Susceptibility of Asphalt Mixtures: 2S2P1D Rheological Model Approach and New Index Based on Dynamic Modulus Master Curve Changes. Constr. Build. Mater. 2022, 331, 127316. [Google Scholar] [CrossRef]

- BS-EN-12697-25; Bituminous Mixtures—Test Methods for Hot Mix Asphalt. Part 25: Cyclic Compression Test. British Standards Institution: London, UK, 2005.

- Cao, Y.; Liu, Z.; Song, W. Performance and Overall Evaluation of Nano-Alumina-Modified Asphalt Mixture. Nanotechnol. Rev. 2022, 11, 2891–2902. [Google Scholar] [CrossRef]

- Wasfi Al-Mistarehi, B.; Khadaywi, T.S.; Khaled Hussein, A. Investigating the Effects on Creep and Fatigue Behavior of Asphalt Mixtures with Recycled Materials as Fillers. J. King Saud Univ.—Eng. Sci. 2021, 33, 355–363. [Google Scholar] [CrossRef]

- Ye, Y.; Hao, Y.; Zhuang, C.; Shu, S.; Lv, F. Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite-Asphalt Mixture. Materials 2022, 15, 915. [Google Scholar] [CrossRef]

- Pszczola, M.; Jaczewski, M.; Szydlowski, C. Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test. Appl. Sci. 2019, 9, 846. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.T.T.; Do, T.-T.; Tran, V.-T.; Phan, T.-N.; Pham, T.-A.; Nguyen, M.L. Determination of Creep Compliance of Asphalt Mixtures at Intermediate and High Temperature Using Creep-Recovery Test. Road Mater. Pavement Des. 2021, 22, S514–S535. [Google Scholar] [CrossRef]

- BS EN 12697-24; Bituminous Mixtures—Test Methods for Hot Mix Asphalt. Part 24: Resistance to Fatigue. British Standards Institution: London, UK, 2018. [CrossRef]

- Nunes Lopes, L.; Muniz de Farias, M.; Rodrigues de Mello, L.G. Fatigue Tests and Damage Analyses in Modified Binders and Gap-Graded Asphalt Mixtures with Reacted and Activated Rubber–RAR. Road Mater. Pavement Des. 2021, 22, 1616–1636. [Google Scholar] [CrossRef]

- Júnior, J.L.O.L.; Babadopulos, L.F.A.L.; Soares, J.B.; Souza, L.T. Evaluating the Effect of Amine-Based Anti-Stripping Agent on the Fatigue Life of Asphalt Pavements. Int. J. Pavement Eng. 2022, 23, 2785–2795. [Google Scholar] [CrossRef]

- Diab, A.; You, Z.; Othman, A.M.; Ahmed, H.Y. Effect of Hydrated Lime Application Method on Mechanical and Fatigue Properties of HMA. In Proceedings of the 12th International Conference of Transportation Professionals (CICTP), Beijing, China, 3–6 August 2012; pp. 3327–3334. [Google Scholar]

- Walubita, L.F.; Martinez-Arguelles, G.; Polo-Mendoza, R.; Ick-Lee, S.; Fuentes, L. Comparative Environmental Assessment of Rigid, Flexible, and Perpetual Pavement: A Case Study of Texas. Sustainability 2022, 14, 9983. [Google Scholar] [CrossRef]

- Wang, T.; Wang, J.; Wu, P.; Wang, J.; He, Q.; Wang, X. Estimating the Environmental Costs and Benefits of Demolition Waste Using Life Cycle Assessment and Willingness-to-Pay: A Case Study in Shenzhen. J. Clean. Prod. 2018, 172, 14–26. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006; pp. 1–20.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006; pp. 1–46.

- FHWA-HIF-16-014; Pavement Life Cycle Assessment Framework. Federal Highway Administration: Washington, DC, USA, 2016; pp. 1–244.

- Vega, D.; Santos, J.; Martinez-Arguelles, G. Carbon Footprint of Asphalt Road Pavements Using Warm Mix Asphalt with Recycled Concrete Aggregates: A Colombian Case Study. Pavement Roadway Bridg. Life Cycle Assess. 2020, 2020, 333–342. [Google Scholar]

- Schrijvers, D.; Loubet, P.; Sonnemann, G. Archetypes of Goal and Scope Definitions for Consistent Allocation in LCA. Sustainability 2020, 12, 5587. [Google Scholar] [CrossRef]

- Dubois-Iorgulescu, A.-M.; Bernstad Saraiva, A.K.E.; Valle, R.; Rodrigues, L.M. How to Define the System in Social Life Cycle Assessments? A Critical Review of the State of the Art and Identification of Needed Developments. Int. J. Life Cycle Assess. 2018, 23, 507–518. [Google Scholar] [CrossRef]

- Kim, R.; Lim, M.-K.; Roh, S.; Park, W.-J. Analysis of the Characteristics of Environmental Impacts According to the Cut-Off Criteria Applicable to the Streamlined Life Cycle Assessment (S-LCA) of Apartment Buildings in South Korea. Sustainability 2021, 13, 2898. [Google Scholar] [CrossRef]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Developing a Systematic Framework for Consistent Allocation in LCA. Int. J. Life Cycle Assess. 2016, 21, 976–993. [Google Scholar] [CrossRef]

- Oele, M.; Dolfing, R.; Grace, V. SimaPro 9.4: Full Update Instructions. PRéSustainability 2022, 1–16. [Google Scholar]

- Polo-Mendoza, R.; Turbay, E.; Martinez-Arguelles, G.; Peñabaena-Niebles, R. Environmental Efficiency Assessment of RCA Inclusion as Partial Replacement of Virgin Aggregates in HMA and WMA. In Roads and Airports Pavement Surface Characteristics; Crispino, M., Toraldo, E., Eds.; CRC Press: Milan, Italy, 2023; pp. 778–787. [Google Scholar] [CrossRef]

- Suh, S.; Lippiatt, B.C. Framework for Hybrid Life Cycle Inventory Databases: A Case Study on the Building for Environmental and Economic Sustainability (BEES) Database. Int. J. Life Cycle Assess. 2012, 17, 604–612. [Google Scholar] [CrossRef]

- Sackey, S.; Kim, B.-S. Environmental and Economic Performance of Asphalt Shingle and Clay Tile Roofing Sheets Using Life Cycle Assessment Approach and TOPSIS. J. Constr. Eng. Manag. 2018, 144, 04018104. [Google Scholar] [CrossRef]

- Gradin, K.T.; Björklund, A. The Common Understanding of Simplification Approaches in Published LCA Studies—A Review and Mapping. Int. J. Life Cycle Assess. 2021, 26, 50–63. [Google Scholar] [CrossRef]

- Llorach-Massana, P.; Farreny, R.; Oliver-Solà, J. Are Cradle to Cradle Certified Products Environmentally Preferable? Analysis from an LCA Approach. J. Clean. Prod. 2015, 93, 243–250. [Google Scholar] [CrossRef] [Green Version]

- Quintana-Pedraza, G.A.; Vieira-Agudelo, S.C.; Muñoz-Galeano, N. A Cradle-to-Grave Multi-Pronged Methodology to Obtain the Carbon Footprint of Electro-Intensive Power Electronic Products. Energies 2019, 12, 3347. [Google Scholar] [CrossRef] [Green Version]

- Bessou, C.; Basset-Mens, C.; Latunussa, C.; Vélu, A.; Heitz, H.; Vannière, H.; Caliman, J.-P. Partial Modelling of the Perennial Crop Cycle Misleads LCA Results in Two Contrasted Case Studies. Int. J. Life Cycle Assess. 2016, 21, 297–310. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental Impact and Life Cycle Assessment (LCA) of Traditional and “green” Concretes: Literature Review and Theoretical Calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Huang, M.; Dong, Q.; Ni, F.; Wang, L. LCA and LCCA Based Multi-Objective Optimization of Pavement Maintenance. J. Clean. Prod. 2021, 283, 124583. [Google Scholar] [CrossRef]

- ISO 15686-5; Buildings and Constructed Assets—Service Life Planning—Part 5: Life-Cycle Costing. International Organization for Standardization: Geneva, Switzerland, 2017; pp. 1–43.

- Vasishta, T.; Mehany, M.H.; Killingsworth, J. Comparative Life Cycle Assesment (LCA) and Life Cycle Cost Analysis (LCCA) of Precast and Cast-in-Place Buildings in United States. J. Build. Eng. 2023, 67, 105921. [Google Scholar] [CrossRef]

- Zhao, M.; Dong, Y.; Guo, H. Comparative Life Cycle Assessment of Composite Structures Incorporating Uncertainty and Global Sensitivity Analysis. Eng. Struct. 2021, 242, 112394. [Google Scholar] [CrossRef]

- INVIAS Análisis de Precios Unitarios (APUS) Para Atlántico-Colombia. Inst. Nac. Vias 2022, 1–7.

- Nwakaire, C.M.; Onn, C.C.; Yap, S.P.; Yuen, C.W.; Koting, S.; Mo, K.H.; Othman, F. The Strength and Environmental Performance of Asphalt Mixtures with Recycled Concrete Aggregates. Transp. Res. Part D Transp. Environ. 2021, 100, 103065. [Google Scholar] [CrossRef]

- Zou, G.; Sun, X.; Liu, X.; Zhang, J. Influence Factors on Using Recycled Concrete Aggregate in Foamed Asphalt Mixtures Based on Tensile Strength and Moisture Resistance. Constr. Build. Mater. 2020, 265, 120363. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Samali, B. Laboratory Investigations on the Utilization of RCA in Asphalt Mixtures. Int. J. Pavement Res. Technol. 2018, 11, 627–638. [Google Scholar] [CrossRef]

- Gul, W.A.; Guler, M. Rutting Susceptibility of Asphalt Concrete with Recycled Concrete Aggregate Using Revised Marshall Procedure. Constr. Build. Mater. 2014, 55, 341–349. [Google Scholar] [CrossRef]

- Arabani, M.; Azarhoosh, A.R. The Effect of Recycled Concrete Aggregate and Steel Slag on the Dynamic Properties of Asphalt Mixtures. Constr. Build. Mater. 2012, 35, 1–7. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Rafiq Kakar, M.; Piao, Z.; Bueno, M.; Poulikakos, L. Incorporation of Recycled Concrete Aggregate (RCA) Fractions in Semi-Dense Asphalt (SDA) Pavements: Volumetrics, Durability and Mechanical Properties. Constr. Build. Mater. 2020, 264, 120166. [Google Scholar] [CrossRef]

- Radević, A.; Đureković, A.; Zakić, D.; Mladenović, G. Effects of Recycled Concrete Aggregate on Stiffness and Rutting Resistance of Asphalt Concrete. Constr. Build. Mater. 2017, 136, 386–393. [Google Scholar] [CrossRef]

- Monu, K.; Ransinchung, G.; Pandey, G.S.; Singh, S. Performance Evaluation of Recycled-Concrete Aggregates and Reclaimed-Asphalt Pavements for Foam-Mix Asphalt Mixes. J. Mater. Civ. Eng. 2020, 32, 04020295. [Google Scholar] [CrossRef]

- Pérez, I.; Pasandín, A.R.; Medina, L. Hot Mix Asphalt Using C&D Waste as Coarse Aggregates. Mater. Des. 2012, 36, 840–846. [Google Scholar] [CrossRef] [Green Version]

- Martinho, F.; Picado-Santos, L.; Capitão, S. Influence of Recycled Concrete and Steel Slag Aggregates on Warm-Mix Asphalt Properties. Constr. Build. Mater. 2018, 185, 684–696. [Google Scholar] [CrossRef]

- Berthelot, C.; Haichert, R.; Podborochynski, D.; Wandzura, C.; Taylor, B.; Guenther, D. Mechanistic Laboratory Evaluation and Field Construction of Recycled Concrete Materials for Use in Road Substructures. Transp. Res. Rec. 2010, 2167, 41–52. [Google Scholar] [CrossRef]

| Properties | Unit | Results |

|---|---|---|

| Absolute viscosity (60 °C) | P | 2290 |

| Ductility at 25 °C | cm | >100 |

| Ignition point through the open Cleveland cup | °C | 286 |

| Kerosene content | % | 1.3 |

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 60.7 |

| Penetration index | - | −1.0 |

| Softening point | °C | 49 |

| Specific gravity 25 °C | kg/m3 | 1030 |

| Trichloroethylene solubility | % | 99.99 |

| Water content | % | 0.0 |

| Parameters | Unit | Fine NA | Coarse NA | Coarse RCA |

|---|---|---|---|---|

| Dry density | kg/m3 | 2597 | 2555 | 2304 |

| Saturated surface dry density | kg/m3 | 2627 | 2604 | 2426 |

| Water absorption | % | 1.91 | 1.14 | 5.31 |

| Los Angeles abrasion at 100 revs | % loss | - | 4.8 | 5.3 |

| Los Angeles abrasion at 500 revs | % loss | - | 21.5 | 27.3 |

| Micro-Deval | % | - | 17 | 26 |

| Wet/dry ratio of ten percent fines value | % | - | 89.7 | 83.6 |

| Sieve | Colombian Requirements for Passing Percentage | Granulometry Used (%) | ||

|---|---|---|---|---|

| # | mm | Upper Limit (%) | Lower Limit (%) | |

| 1″ | 25.400 | 100 | 100 | 100.0 |

| 3/4″ | 19.000 | 95 | 80 | 86.0 |

| 1/2″ | 12.500 | 85 | 67 | 69.0 |

| 3/8″ | 9.500 | 77 | 60 | 60.5 |

| No. 4 | 4.750 | 59 | 43 | 50.5 |

| No. 10 | 2.000 | 45 | 29 | 34.6 |

| No. 40 | 0.475 | 25 | 14 | 15.5 |

| No. 80 | 0.180 | 17 | 8 | 8.2 |

| No. 200 | 0.075 | 8 | 4 | 4.1 |

| LCA Stage | Activities | Unit Processes | Source Database |

|---|---|---|---|

| Raw Material extraction | Coarse NAs extraction | Gravel, crushed {RoW}|production|Cut-off, U | Ecoinvent v.3.8 |

| Fine NAs extraction | Sand {RoW}|gravel and quarry operation|Cut-off, U | Ecoinvent v.3.8 | |

| Aggregate loading onto the truck | Loader operation, large, INW/RNA | USLCI v.1.6 | |

| RCA crushing | Diesel, burned in building machine {GLO}|processing|Cut-off, U | Ecoinvent v.3.8 | |

| Asphalt binder production | Bitumen, at refinery/kg/US | USLCI v.1.6 | |

| Material transport to the asphalt mixing plant | Aggregates transportation (One-way distance: 73 km) | Transport, freight, lorry 16–32 metric ton, EURO4 {RoW}| transport, freight, lorry 16–32 metric ton, EURO4|Cut-off, U | Ecoinvent v.3.8 |

| Asphalt binder transportation (One-way distance: 592 km) | |||

| Asphalt Mixture production | NAs processing | Diesel, burned in building machine {GLO}|processing|Cut-off, U | Ecoinvent v.3.8 |

| Mixing aggregates with the asphalt binder (Required thermal energy) | Heat, district or industrial, other than natural gas {RoW}|heat production, heavy fuel oil, at an industrial furnace 1MW|Cut-off, U | Ecoinvent v.3.8 |

| Designs | TE (MJ) |

|---|---|

| HMA with 0% coarse RCA content | 245.7 |

| HMA with 0% coarse RCA content | 231.4 |

| HMA with 0% coarse RCA content | 217.8 |

| HMA with 0% coarse RCA content | 205.3 |

| Impact Categories | Unit | HMA with Coarse RCA Content of | |||

|---|---|---|---|---|---|

| 0% | 15% | 30% | 45% | ||

| Acidification | H+ mmole eq | 1,535,043 | 1,425,980 | 1,643,686 | 1,750,170 |

| Ecotoxicity | g 2.4-D eq | 20,131 | 18,740 | 21,534 | 22,943 |

| Eutrophication | g N eq | 8559 | 7897 | 9225 | 9892 |

| Global warming | g CO2 eq | 3,301,236 | 3,090,272 | 3,510,922 | 3,715,522 |

| Habitat alteration | T&E count | 0 | 0 | 0 | 0 |

| Human health cancer | g C6H6 eq | 16,772 | 15,505 | 18,048 | 19,327 |

| Human health criteria air pollutants | microDALYs | 554 | 517 | 592 | 630 |

| Human health noncancer | g C7H7 eq | 17,768,728 | 16,327,503 | 19,221,289 | 20,678,241 |

| Indoor air quality | g TVOC eq | 0 | 0 | 0 | 0 |

| Natural resource depletion | MJ surplus | 38,544 | 35,550 | 41,564 | 44,599 |

| Ozone depletion | g CFC-11 eq | 1,222,781,085 | 1,217,817,608 | 1,226,503,694 | 1,227,744,563 |

| Smog | g NOx eq | 15,885 | 14,771 | 17,009 | 18,140 |

| Water intake | liters | 3303 | 3042 | 3562 | 3814 |

| Variable | Unit | Description |

|---|---|---|

| PC | USD | Production costs of 1 t of asphalt mixture. |

| PCOSTi | USD/t | Production/processing costs of each raw material. |

| TCOSTi | USD/t/km | Hauling costs for each raw material. |

| mi | t | Mass of each material required to produce 1 t of asphalt mixture. |

| di | km | One-way transport distance for each raw material. |

| TE | MJ | TE required to produce 1 t of asphalt mixture. |

| HFOprice | USD/kg | Price of heavy fuel oil (typical fuel for asphalt mixing plants). |

| LHV | MJ/kg | Lower heating value of heavy fuel oil, i.e., 42.18 MJ/kg. |

| n | - | Number of raw materials considered. |

| Materials | Unit | Price (USD) | |

|---|---|---|---|

| Acquisition costs | Heavy fuel oil | 1 kg | $ 0.88 |

| Asphalt binder | 1 ton | $ 530.88 | |

| Filler NA | $ 6.81 | ||

| Fine NA | $ 6.81 | ||

| Coarse NA | $ 6.75 | ||

| Coarse RCA | $ 1.67 | ||

| Hauling costs | Asphalt binder | 1 ton*km | $ 0.21 |

| Filler NA | $ 0.11 | ||

| Fine NA | $ 0.11 | ||

| Coarse NA | $ 0.11 | ||

| Coarse RCA | $ 0.11 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cantero-Durango, J.; Polo-Mendoza, R.; Martinez-Arguelles, G.; Fuentes, L. Properties of Hot Mix Asphalt (HMA) with Several Contents of Recycled Concrete Aggregate (RCA). Infrastructures 2023, 8, 109. https://doi.org/10.3390/infrastructures8070109

Cantero-Durango J, Polo-Mendoza R, Martinez-Arguelles G, Fuentes L. Properties of Hot Mix Asphalt (HMA) with Several Contents of Recycled Concrete Aggregate (RCA). Infrastructures. 2023; 8(7):109. https://doi.org/10.3390/infrastructures8070109

Chicago/Turabian StyleCantero-Durango, Julio, Rodrigo Polo-Mendoza, Gilberto Martinez-Arguelles, and Luis Fuentes. 2023. "Properties of Hot Mix Asphalt (HMA) with Several Contents of Recycled Concrete Aggregate (RCA)" Infrastructures 8, no. 7: 109. https://doi.org/10.3390/infrastructures8070109