In Situ X-ray Diffraction Analysis of Stresses during Deep Rolling of Steel

Abstract

1. Introduction

2. Materials and Methods

3. Theoretical Approach and Analysis

4. Results

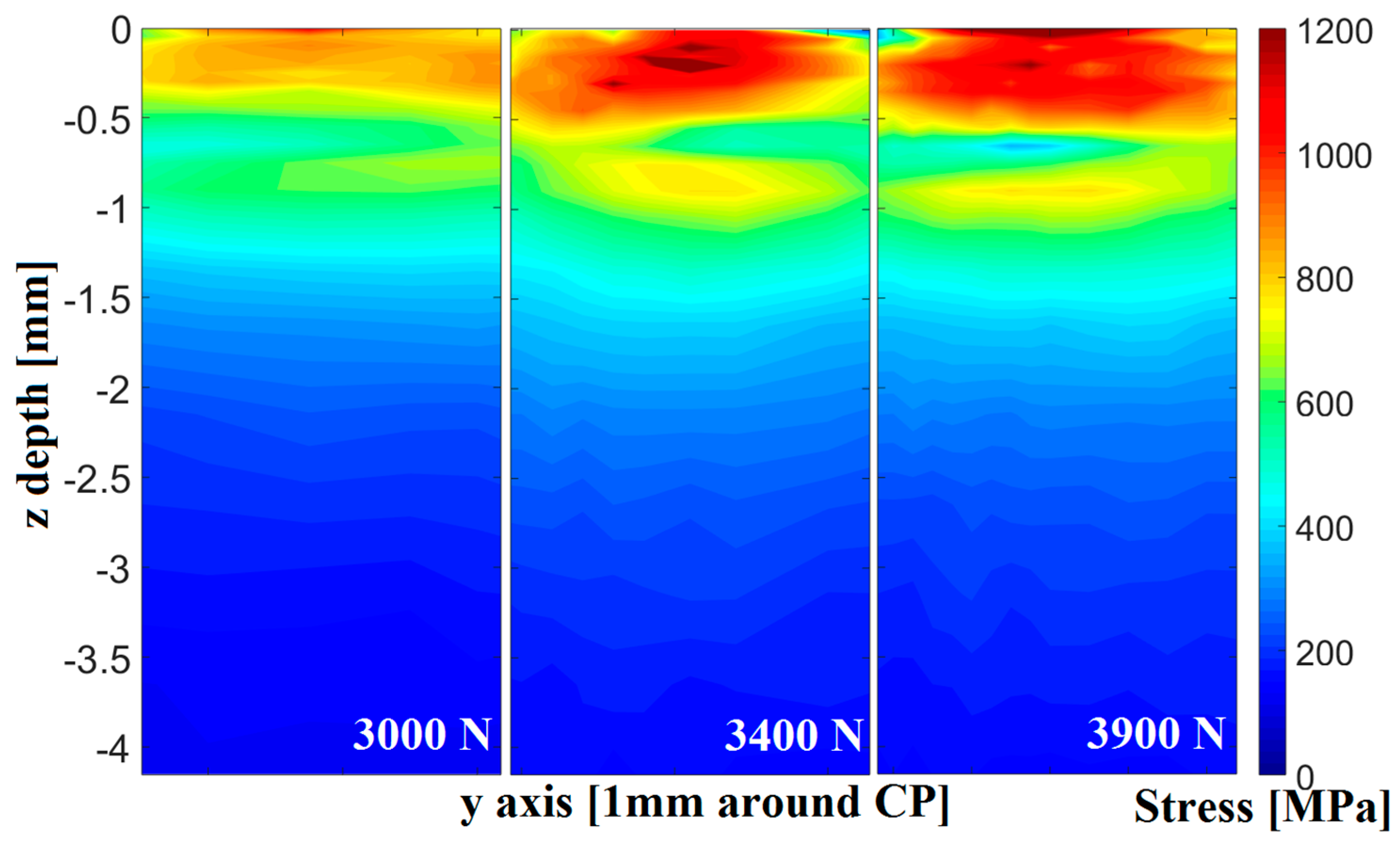

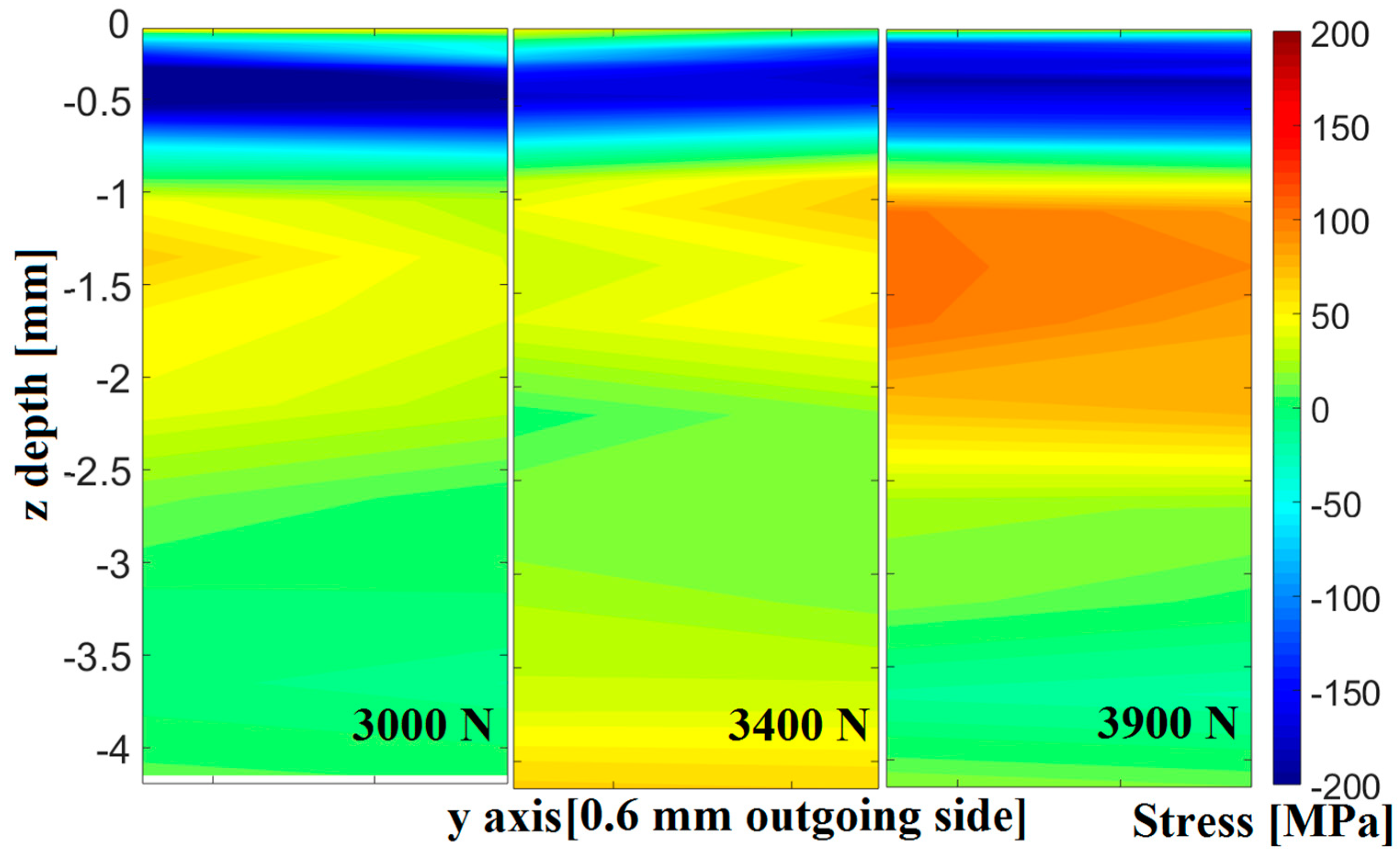

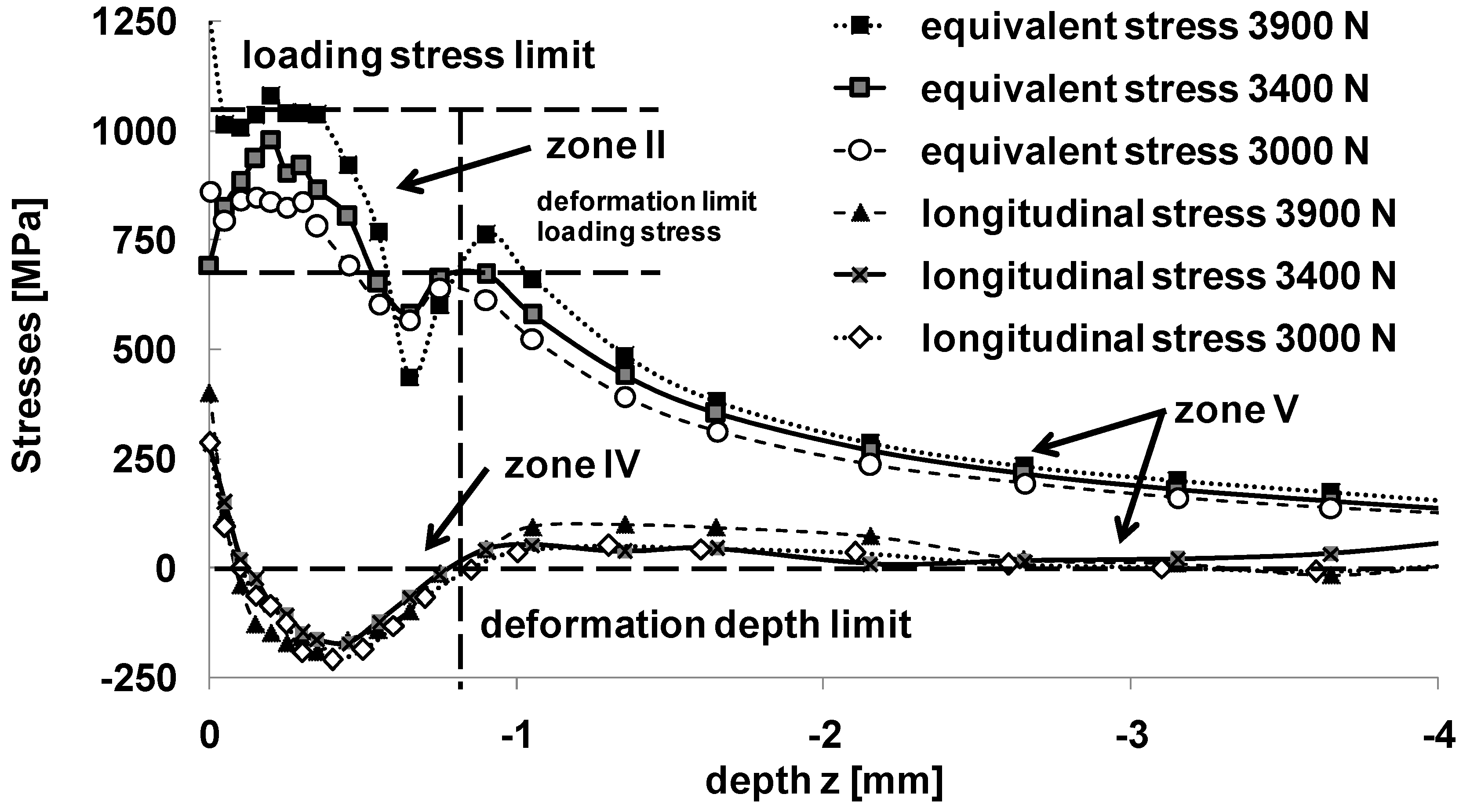

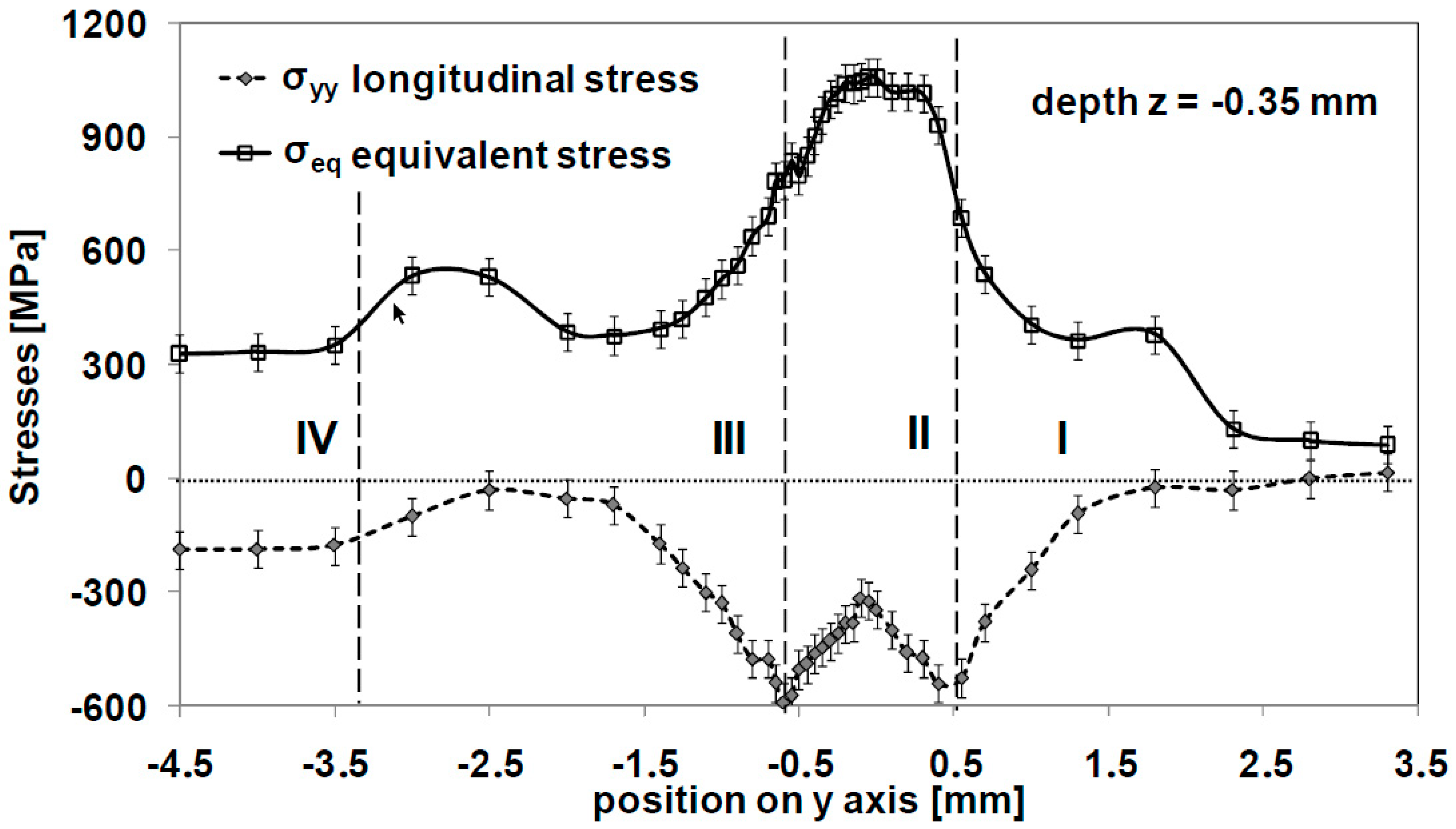

Stress Distribution during Deep Rolling

5. Discussion

5.1. Influence of Contact Parameters on Loading Stress and Residual Stress Distribution

5.2. Discussion on the Origin of Residual Stresses and Contact Sequence

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- M’saoubi, R.; Outeiro, J.C.; Changeux, B.; Lebrun, J.L.; Dias, A.M. Residual stress analysis in orthogonal machining of standard and resulfurized AISI 316L steels. J. Mater. Process. Technol. 1999, 96, 225–233. [Google Scholar] [CrossRef]

- Meyer, D.; Kämmler, J. Surface integrity of AISI 4140 after deep rolling with varied external and internal loads. Procedia CIRP 2016, 45, 363–366. [Google Scholar] [CrossRef]

- Weisser, M.A.; Evans, A.D.; Van Petegem, S.; Holdsworth, S.R.; Van Swygenhoven, H. In situ room temperature tensile deformation of a 1% CrMoV bainitic steel using synchrotron and neutron diffraction. Acta Mater. 2011, 59, 4448–4457. [Google Scholar] [CrossRef]

- Uhlmann, E.; Henze, S.; Gerstenberger, R.; Brömmelhoff, K.; Reimers, W.; Fischer, T.; Schell, N. An extended shear angle model derived from in situ strain measurements during orthogonal cutting. Prod. Eng. 2013, 7, 401–408. [Google Scholar] [CrossRef]

- Staron, P.; Fischer, T.; Lippmann, T.; Stark, A.; Daneshpour, S.; Schnubel, D.; Eidenberger, E. In Situ Experiments with Synchrotron High-Energy X-rays and Neutrons. Adv. Eng. Mater. 2011, 13, 658–663. [Google Scholar] [CrossRef]

- Meyer, H.; Epp, J.; Zoch, H.W. In situ X-Ray Diffraction Investigation of Surface Modifications in a Deep Rolling Process under Static Condition. Mater. Res. Proc. 2017, 2, 431–436. [Google Scholar]

- Brinksmeier, E.; Klocke, F.; Lucca, D.A.; Sölter, J.; Meyer, D. Process Signatures–A new approach to solve the inverse surface integrity problem in machining processes. Procedia CIRP 2014, 13, 429–434. [Google Scholar] [CrossRef]

- Ashiotis, G.; Deschildre, A.; Nawaz, Z.; Wright, J.P.; Karkoulis, D.; Picca, F.E.; Kieffer, J. The fast azimuthal integration Python library: pyFAI. J. Appl. Crystallogr. 2015, 48, 510–519. [Google Scholar] [CrossRef] [PubMed]

- Noyan, I.C.; Cohen, J.B. Residual Stress: Measurement by Diffraction and Interpretation; Springer: New York, NY, USA, 2013. [Google Scholar]

- Zeilinger, A.; Todt, J.; Krywka, C.; Müller, M.; Ecker, W.; Sartory, B.; Keckes, J. In-situ observation of cross-sectional microstructural changes and stress distributions in fracturing TiN thin film during nanoindentation. Sci. Rep. 2016, 6, 22670. [Google Scholar] [CrossRef] [PubMed]

- Kuznetsov, V.P.; Smolin, I.Y.; Dmitriev, A.I.; Konovalov, D.A.; Makarov, A.V.; Kiryakov, A.E.; Yurovskikh, A.S. Finite element simulation of nanostructuring burnishing. Phys. Mesomech. 2013, 16, 62–72. [Google Scholar] [CrossRef]

- Kloos, K.H.; Fuchsbauer, B.; Adelmann, J. Fatigue properties of specimens similar to components deep rolled under optimized conditions. Int. J. Fatigue 1987, 9, 35–42. [Google Scholar] [CrossRef]

- Shet, C.; Deng, X. Residual stresses and strains in orthogonal metal cutting. Int. J. Mach. Tools Manuf. 2003, 43, 573–587. [Google Scholar] [CrossRef]

- Sayahi, M.; Sghaier, S.; Belhadjsalah, H. Finite element analysis of ball burnishing process: Comparisons between numerical results and experiments. Int. J. Adv. Manuf. Technol. 2013, 67, 1665–1673. [Google Scholar] [CrossRef]

| Steel | AISI | C (%) | Si (%) | Mn (%) | P (%) | S (%) | Cr (%) | Mo (%) |

|---|---|---|---|---|---|---|---|---|

| 42CrMo4 | 4140 | 0.43 | 0.26 | 0.74 | 0.01 | <0.001 | 1.09 | 0.25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyer, H.; Epp, J. In Situ X-ray Diffraction Analysis of Stresses during Deep Rolling of Steel. Quantum Beam Sci. 2018, 2, 20. https://doi.org/10.3390/qubs2040020

Meyer H, Epp J. In Situ X-ray Diffraction Analysis of Stresses during Deep Rolling of Steel. Quantum Beam Science. 2018; 2(4):20. https://doi.org/10.3390/qubs2040020

Chicago/Turabian StyleMeyer, Heiner, and Jérémy Epp. 2018. "In Situ X-ray Diffraction Analysis of Stresses during Deep Rolling of Steel" Quantum Beam Science 2, no. 4: 20. https://doi.org/10.3390/qubs2040020

APA StyleMeyer, H., & Epp, J. (2018). In Situ X-ray Diffraction Analysis of Stresses during Deep Rolling of Steel. Quantum Beam Science, 2(4), 20. https://doi.org/10.3390/qubs2040020