Comparison of Usability between Gear Shifters with Varied Visual and Haptic Patterns and Complexities

Abstract

:1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Equipment

2.3. Experimental Conditions

2.3.1. Shifter Types

2.3.2. Visibility State

2.3.3. Complexity Level

2.4. Experimental Design

2.4.1. Gear Shifting Task

2.4.2. Distraction Task

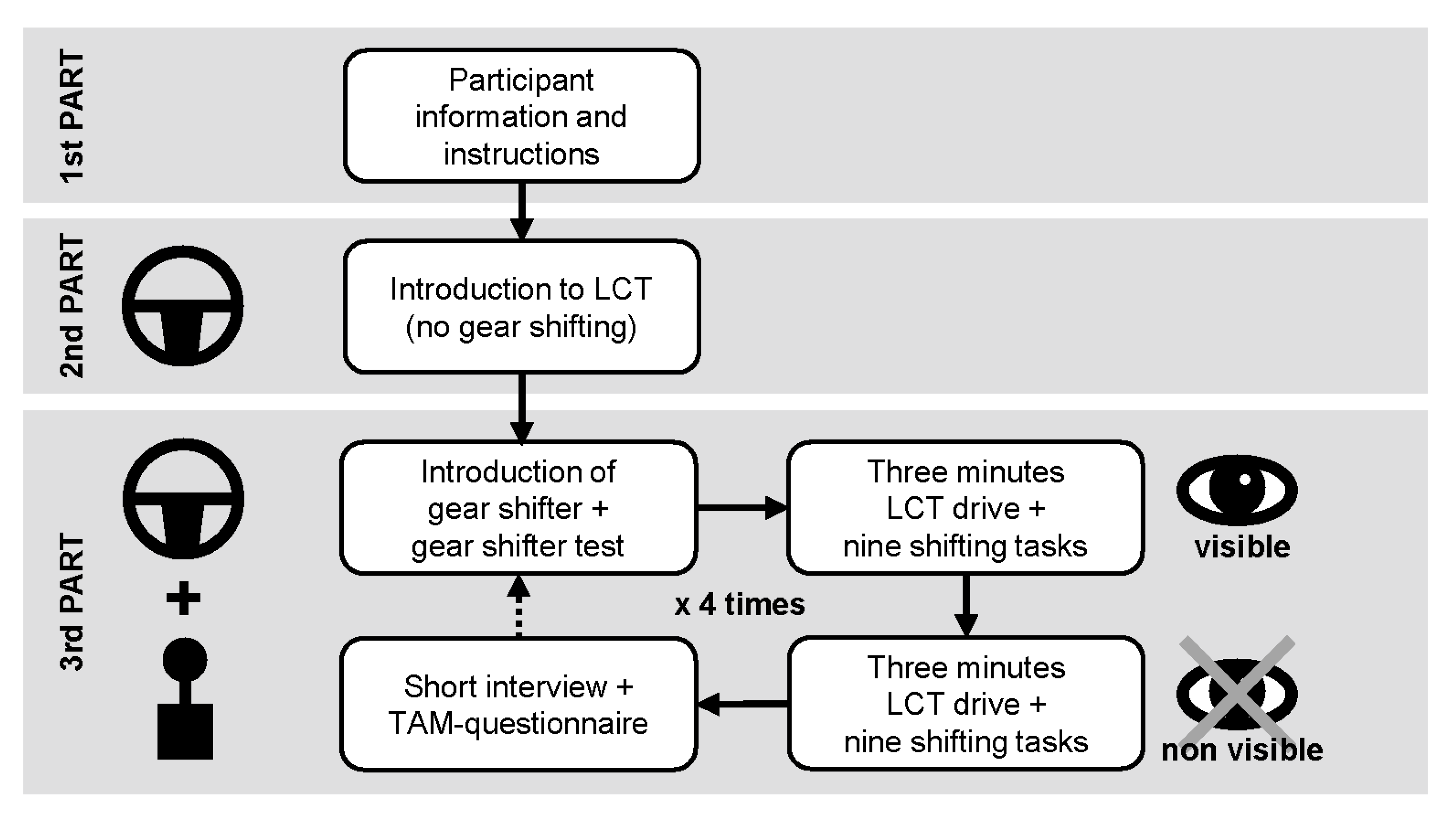

2.4.3. Procedure

2.5. Measures

2.5.1. Efficiency (Task Completion Time)

2.5.2. Subjective Ease of Use

2.6. Analysis

3. Results

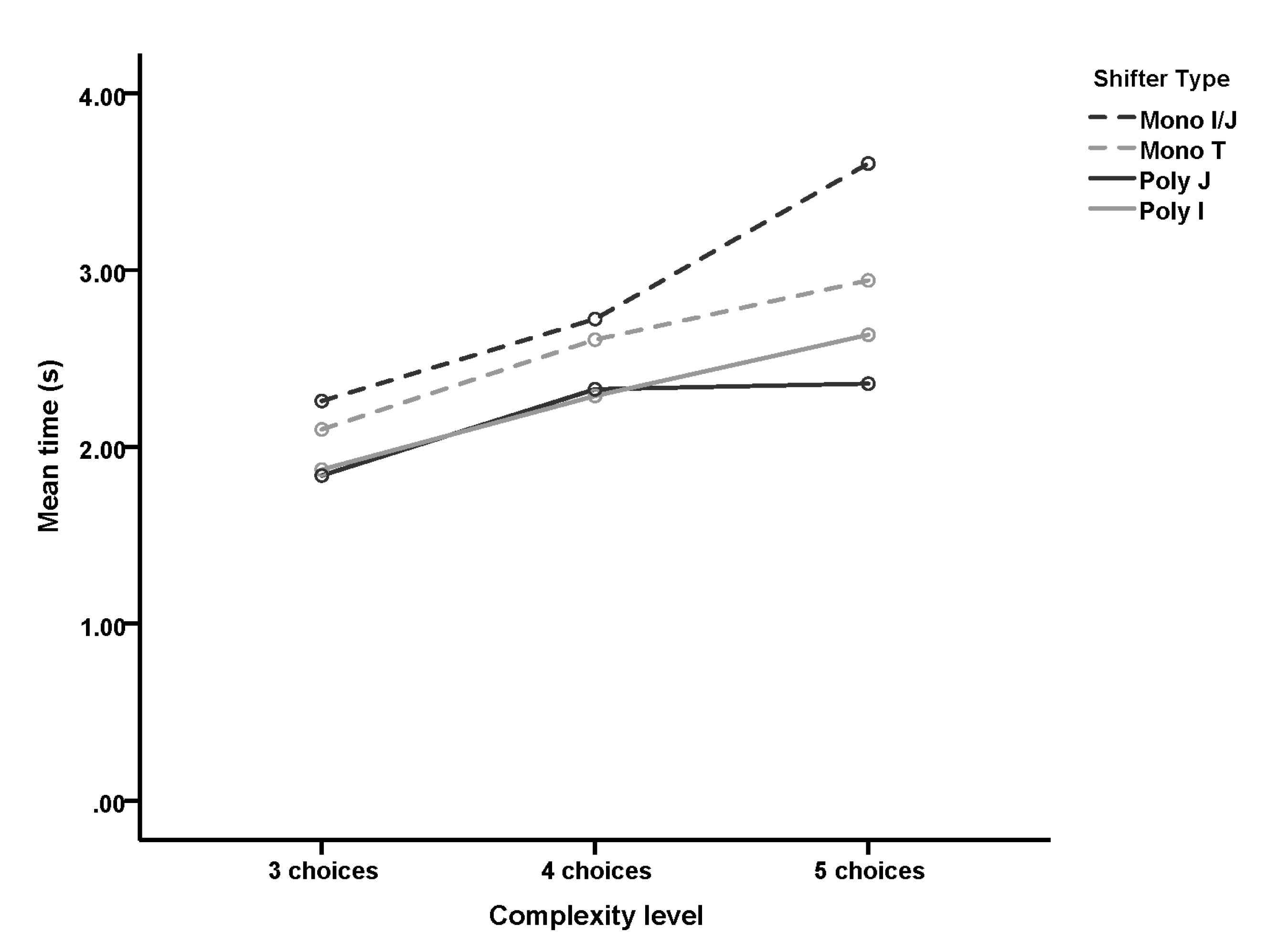

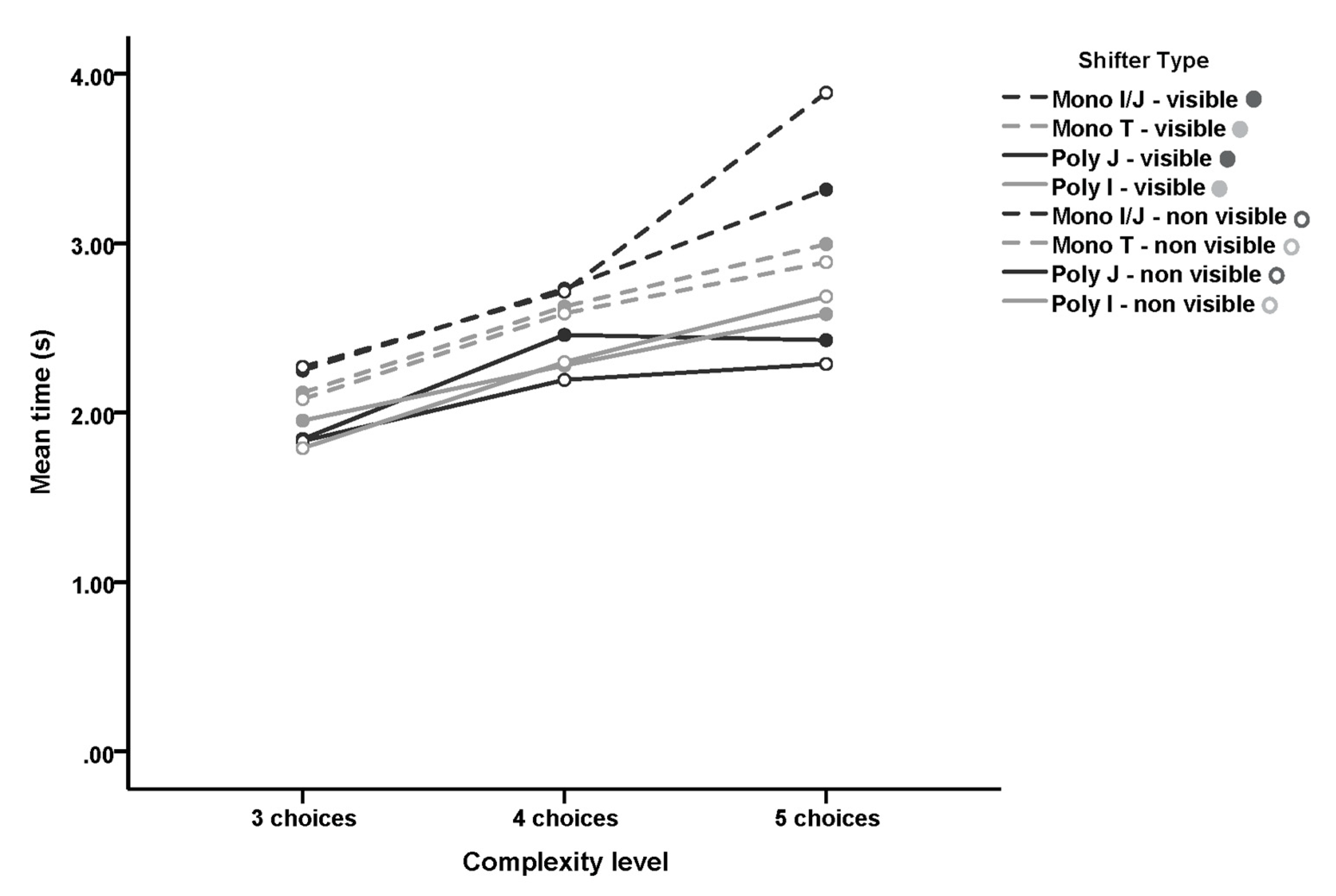

3.1. Results Regarding Efficiency (Task Completion Time)

3.1.1. Shifter Types

3.1.2. Visibility State

3.1.3. Complexity Levels

3.1.4. Interaction Effects

3.2. Results Regarding Subjective Ease of Use

3.2.1. Shifter Types

3.2.2. Complexity Level

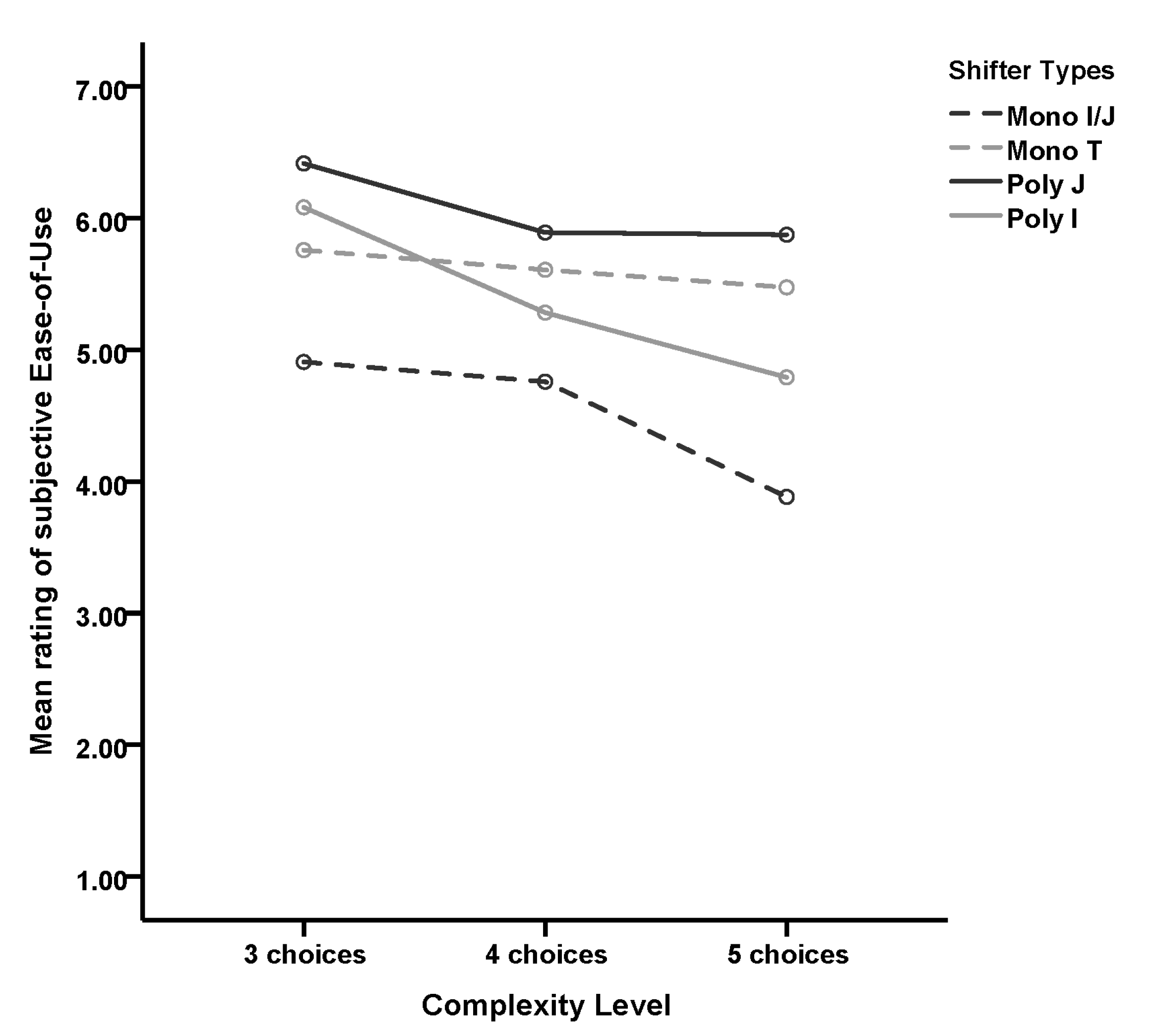

3.2.3. Interaction Effects

4. Discussion

- When drivers select the desired positon, there is only one operation target. The operation start position and operation method are always the same. Therefore, the driver can operate the shift lever without being aware of the current shift position. The shift operation destination is always a dead-end, and there is no need to stop the shift lever in the middle of a shift. This means the driver can make a shift without concern of moving the shift lever too far. This helps to prevent mis-shifts. [30]

Limitations

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tarbet, M. Cost and Weight Added by the FMVSS for Model Years 1968–2001 in Passenger Cars and Light Trucks; NHTSA Technical Report; National Highway Traffic Safety Administration: Washington, DC, USA, 2004. Available online: https://searchworks.stanford.edu/view/7701501 (accessed on 27 May 2020).

- Harvey, C.; Stanton, N.A.; Pickering, C.A.; McDonald, M.; Zheng, P. Context of use as a factor in determining the usability of in-vehicle devices. Theor. Issues Ergon. Sci. 2011, 12, 318–338. [Google Scholar] [CrossRef]

- Lindner, M.; Tille, T. Design of highly integrated mechatronic gear selector levers for automotive shift-by-wire systems. IEEE/ASME Trans. Mechatroncs 2010, 15, 961–968. [Google Scholar]

- Sanew, M. More Vehicles Move to Shift-by-Wire. The Drive. 2017. Available online: http://www.thedrive.com/sheetmetal/10274/more-vehicles-move-to-shift-by-wire (accessed on 28 May 2020).

- Mchenry, S. ODI Resume–Investigation EA 16-002; Office of Defects Investigation. National Highway Traffic Safety Administration: Washington, DC, USA, 2016. Available online: https://www-odi.nhtsa.dot.gov/acms/cs/jaxrs/download/doc/ucm528576/incla-ea16002-8352.pdf (accessed on 28 May 2020).

- Shinar, D.; Meir, M.; Ben-Shoham, I. How automatic is manual gear shifting? Hum. Factors 1998, 40, 647–654. [Google Scholar] [CrossRef] [PubMed]

- Harley, E.M.; Trachtman, D.; Heckman, G.M.; Young, D.E. Driver Gear-Shifting Behaviors and Errors. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, New York, NY, USA, 22–26 September 2008; Sage Publications: Thousand Oaks, CA, USA, 2008; Volume 52, pp. 1898–1902. [Google Scholar]

- Donohue, P. SUV’s gearshift design eyed in Metro-North tragedy. New York Daily News. 2015. Available online: http://www.nydailynews.com/new-york/donohue-suv-gearshift-design-eyed-metro-north-tragedy-article-1.2125193 (accessed on 27 May 2020).

- NHTSA. Safety Recall, NHTSA ID 10875772; Office of Defects Investigation. National Highway Traffic Safety Administration: Washington, DC, USA, 2015. Available online: https://www.nhtsa.gov/recalls#vehicle (accessed on 27 May 2020).

- NHTSA. Safety Recall, NHTSA ID 10863787; Office of Defects Investigation. National Highway Traffic Safety Administration: Washington, DC, USA, 2015. Available online: https://www.nhtsa.gov/recalls#vehicle (accessed on 27 May 2020).

- NHTSA. Safety Recall, NHTSA ID 10824042; Office of Defects Investigation. National Highway Traffic Safety Administration: Washington, DC, USA, 2016. Available online: https://www.nhtsa.gov/recalls#vehicle (accessed on 27 May 2020).

- NHTSA. Safety Recall, NHTSA ID 11150938; Office of Defects Investigation. National Highway Traffic Safety Administration: Washington, DC, USA, 2018. Available online: https://www.nhtsa.gov/recalls#vehicle (accessed on 27 May 2020).

- CBS News. Fiat Chrysler Recalls 1.1 Million Cars for Gear Shifters. 2016. Available online: https://www.cbsnews.com/news/fiat-chrysler-recalls-1-1-million-cars-for-gear-shifters/ (accessed on 27 May 2020).

- Payette, J.; Hayward, V.; Ramstein, C.; Bergeron, D. Evaluation of a force feedback (haptic) computer pointing device in zero gravity. Proc. ASME Dyn. Syst. Control Division 1996, 58, 547–553. [Google Scholar]

- Hayward, V.; Astley, O.R.; Cruz-Hernandez, M.; Grant, D.; Robles-De-La-Torre, G. Haptic interfaces and devices. Sens. Rev. 2004, 24, 16–29. [Google Scholar]

- Rydstrom, A.; Brostrom, R.; Bengtsson, P. Can haptics facilitate interaction with an in-vehicle multifunctional interface? IEEE Trans. Haptics 2009, 2, 141–147. [Google Scholar] [PubMed]

- Grane, C.; Bengtsson, P. Driving performance during visual and haptic menu selection with in-vehicle rotary device. Transp. Res. Part F Traffic Psychol. Behav. 2013, 18, 123–135. [Google Scholar] [CrossRef]

- Turner, A.; Ramsay, K.; Clark, R.; Howe, D. Direct-drive electromechanical linear actuator for shift-by-wire control of an automated transmission. In Proceedings of the 2006 IEEE Vehicle Power and Propulsion Conference, Windsor, UK, 6–8 September 2006; IEEE: Piscataway Township, NJ, USA, 2006; pp. 1–6. [Google Scholar]

- García-Canseco, E.; Ayemlong-Fokem, A.; Serrarens, A.; Steinbuch, M. A haptic gearshift interface for cars. In Proceedings of the International Conference on Human Haptic Sensing and Touch Enabled Computer Applications, Amsterdam, The Netherlands, 8–10 July 2010; Springer: Berlin/Heidelberg, Germany, 2010; pp. 315–320. [Google Scholar]

- Baronti, F.; Lazzeri, A.; Roncella, R.; Saletti, R.; Saponara, S. Design and characterization of a robotized gearbox system based on voice coil actuators for a Formula SAE Race Car. IEEE/ASME Trans. Mechatronics 2011, 18, 53–61. [Google Scholar] [CrossRef]

- Bladfält, S.L.; Grane, C.; Friström, J. Field Study Investigating Gear Shifter Usability in Car Rental Scenario. In Reports and Studies in Health Sciences; University Eastern Finland: Kuopio, Finland, 2016. [Google Scholar]

- Bladfält, S.L.; Grane, C.; Bengtsson, P. Gear Shifter Design–Lack of Dedicated Positions and the Contribution to Cognitive Load and Inattention. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, Washington, DC, USA, 24–28 July 2019; Springer: Cham, Switzerland, 2019; pp. 487–498. [Google Scholar]

- Salthouse, T.A. Aging and measures of processing speed. Biol. Psychol. 2000, 54, 35–54. [Google Scholar] [CrossRef]

- Salthouse, T.A. Mental exercise and mental aging: Evaluating the validity of the “use it or lose it” hypothesis. Perspect. Psychol. Sci. 2006, 1, 68–87. [Google Scholar] [CrossRef] [PubMed]

- Författningssamling, S. Lag (2003: 460) om Etikprövning av Forskning som avser människor [The Act Concerning the Ethical Review of Research Involving Humans]; Utbildningsdepartementet: Stockholm, Sweden, 2003. Available online: https://www.riksdagen.se/sv/dokument-lagar/dokument/svensk-forfattningssamling/lag-2003460-om-etikprovning-av-forskning-som_sfs-2003-460 (accessed on 27 May 2020).

- Vetenskapsrådet, C. Regler och Riktlinjer för Forskning. 2019. Available online: http://www.codex.vr.se/en/index.shtml (accessed on 27 May 2020).

- Mattes, S. The lane-change-task as a tool for driver distraction evaluation. Qualit. Work Prod. Enterp. Future 2003, 2003, 57. [Google Scholar]

- Davis, F.D. User acceptance of information technology: System characteristics, user perceptions and behavioral impacts. Int. J. Man-Mach. Stud. 1993, 38, 475–487. [Google Scholar] [CrossRef] [Green Version]

- International Standard Organization (ISO). ISO 9241-11 Ergonomics of Human-System Interaction—Part 11: Usability: Definitions and Concepts (ISO 9241-11:2018); ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Nakade, Y.; Kamada, A.; Ueno, K.; Kume, M.; Sakaguchi, K. Shift-by-Wire System for Lexus RWD Vehicles. SAE Int. J. Engines 2017, 10, 689–694. [Google Scholar] [CrossRef]

| Time (Visible) | Time (Non-Visible) | Ease of Use | |||||

|---|---|---|---|---|---|---|---|

| Shifter Type | Complexity Level | M | SD | M | SD | M | SD |

| Mono I/J | 3 choices | 2.25 | 0.40 | 2.27 | 0.56 | 4.91 | 0.99 |

| 4 choices | 2.73 | 0.79 | 2.71 | 0.73 | 4.76 | 0.89 | |

| 5 choices | 3.32 | 0.76 | 3.89 | 0.93 | 3.88 | 1.28 | |

| Mono T | 3 choices | 2.12 | 0.38 | 2.08 | 0.38 | 5.76 | 1.04 |

| 4 choices | 2.63 | 0.77 | 2.59 | 0.72 | 5.61 | 0.81 | |

| 5 choices | 3.00 | 0.81 | 2.90 | 0.55 | 5.48 | 1.23 | |

| Poly J | 3 choices | 1.84 | 0.39 | 1.83 | 0.39 | 6.42 | 0.52 |

| 4 choices | 2.46 | 0.79 | 2.19 | 0.58 | 5.89 | 0.89 | |

| 5 choices | 2.43 | 0.54 | 2.29 | 0.53 | 5.88 | 0.83 | |

| Poly I | 3 choices | 1.95 | 0.47 | 1.79 | 0.36 | 6.08 | 1.05 |

| 4 choices | 2.28 | 0.49 | 2.30 | 0.51 | 5.28 | 1.23 | |

| 5 choices | 2.58 | 0.58 | 2.69 | 0.50 | 4.79 | 1.16 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lohilahti Bladfält, S.; Grane, C.; Bengtsson, P. Comparison of Usability between Gear Shifters with Varied Visual and Haptic Patterns and Complexities. Multimodal Technol. Interact. 2020, 4, 24. https://doi.org/10.3390/mti4020024

Lohilahti Bladfält S, Grane C, Bengtsson P. Comparison of Usability between Gear Shifters with Varied Visual and Haptic Patterns and Complexities. Multimodal Technologies and Interaction. 2020; 4(2):24. https://doi.org/10.3390/mti4020024

Chicago/Turabian StyleLohilahti Bladfält, Sanna, Camilla Grane, and Peter Bengtsson. 2020. "Comparison of Usability between Gear Shifters with Varied Visual and Haptic Patterns and Complexities" Multimodal Technologies and Interaction 4, no. 2: 24. https://doi.org/10.3390/mti4020024