Tool Wear Monitoring with Artificial Intelligence Methods: A Review

Abstract

:1. Introduction

- (1)

- Which publications simultaneously use offline and online measurement methods to detect tool wear?

- (2)

- What are the cutting parameters used? What types of tools are used in milling, turning and drilling? What are the turning, milling and drilling machine tools used? What are the metal materials processed?

- (3)

- Which sensors can detect and interpret these signals in milling, drilling and turning processes?

- (4)

- What are the characteristics that can be extracted in the time domain, frequency domain and time-frequency domain? Are we also using raw data, or other signal signals?

- (5)

- What are the artificial intelligence algorithms that predict tool wear?

- (6)

- What are the performances that use algorithms to predict tool wear?

- (7)

- What is the value of the performances that use the algorithms to see the tool wear?

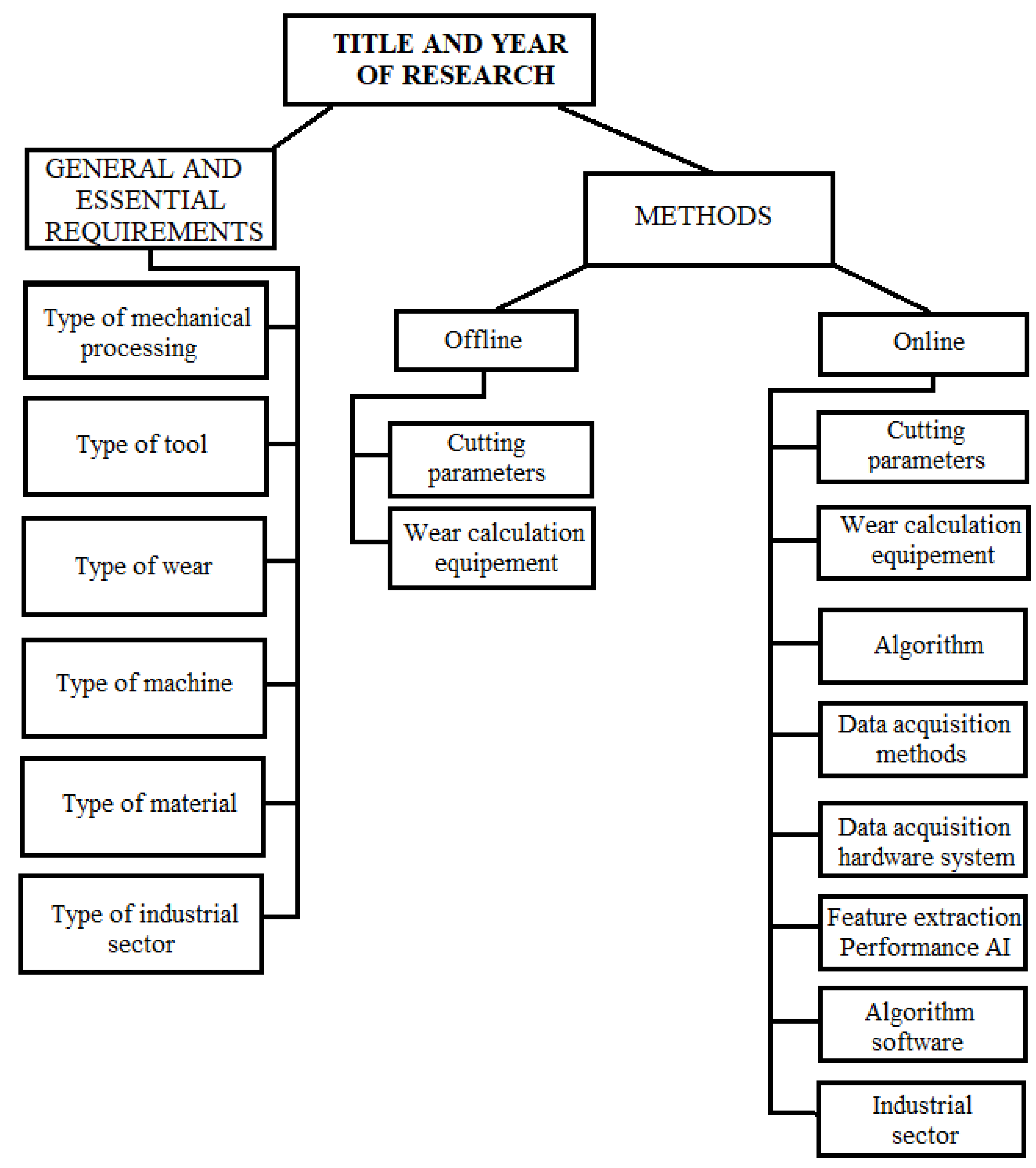

2. Methods of Research Level, Research Item and Research Number of Published Articles Found

Eligibility Criteria and Search Strategy

3. Selection of Offline and Online Publications and Related Data Extraction from the Publications

4. Results of Research

4.1. Introduction Selection and Inclusion of Publications

4.2. General and Essential Requirement of Machining Operations, Number of Articles, Type of Wear, Type of Machine and Type of Material

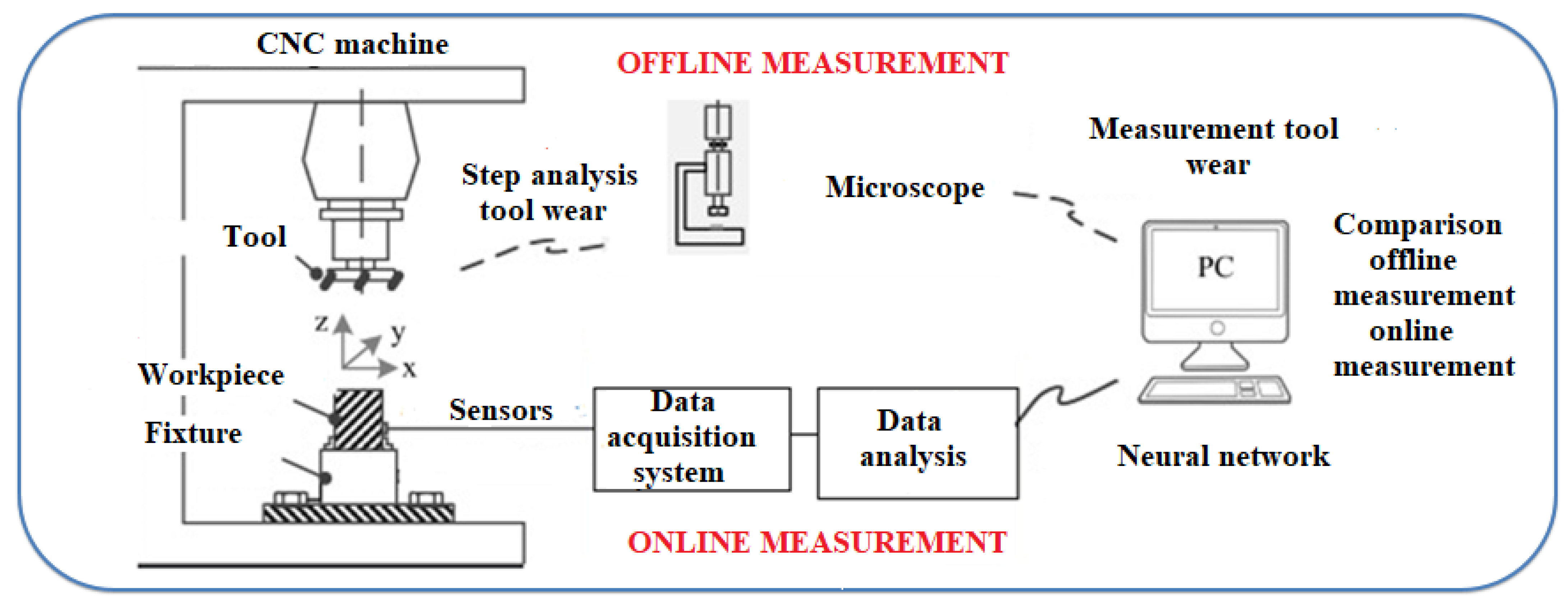

4.3. Introduction Methods of Measurement

4.3.1. Offline Measurement

4.3.2. Online Measurement

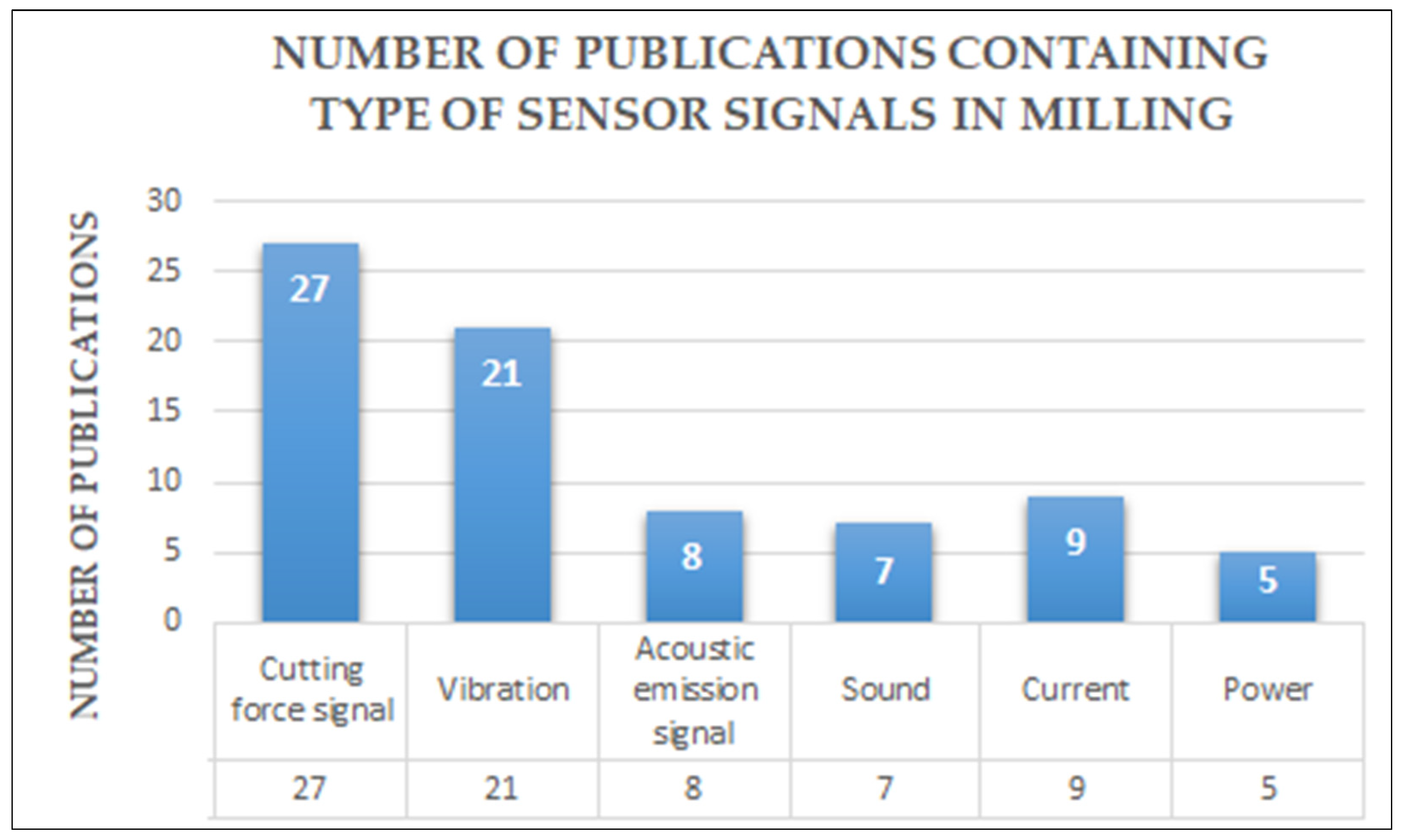

4.4. Type of Sensors and How They Are Used in Research Experiments

4.4.1. Cutting Force Sensor

4.4.2. Vibration Sensor

4.4.3. AE or Acoustic Emission Sensor

4.4.4. Sound Sensor

4.4.5. Current and Power Sensor

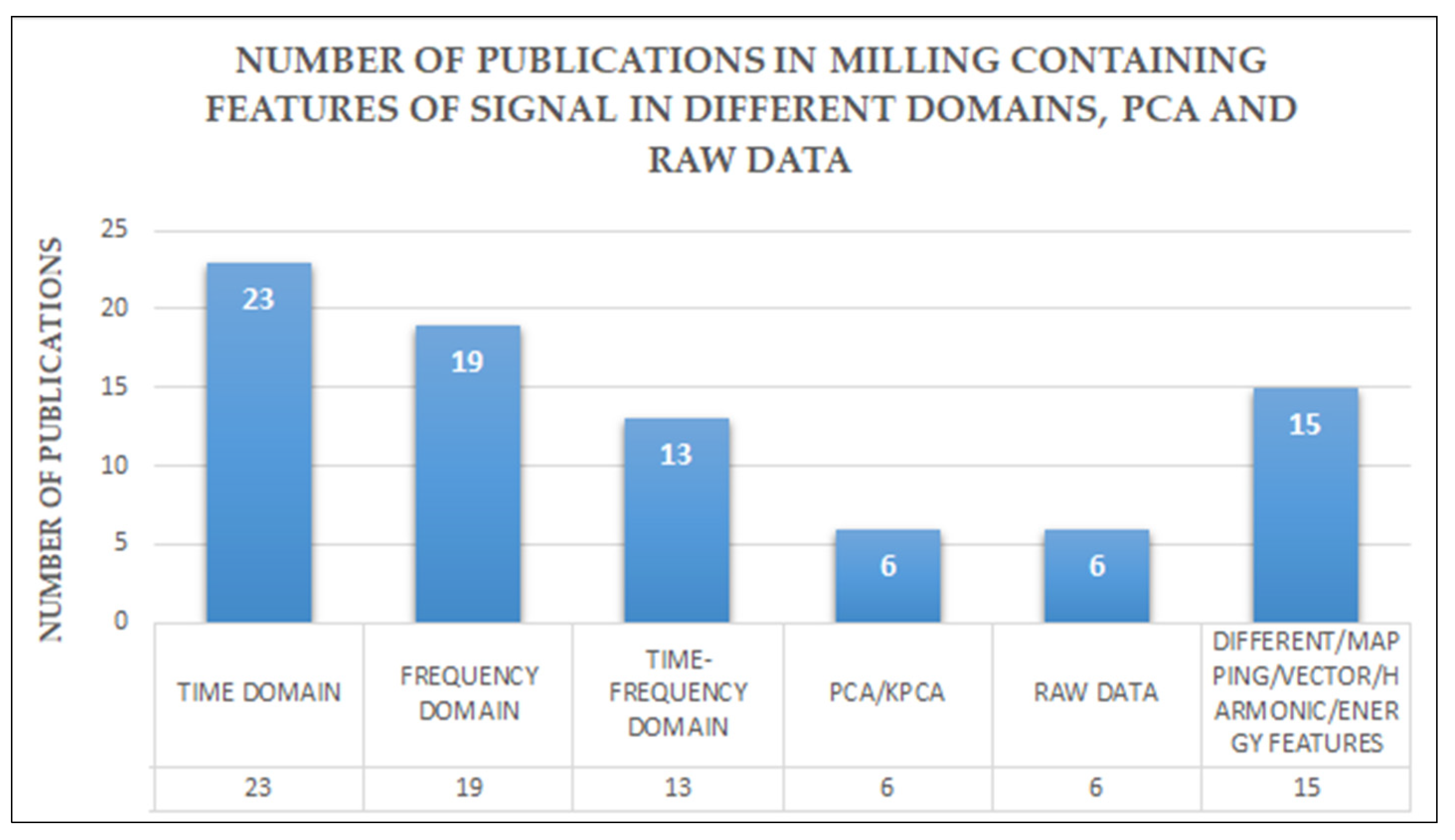

4.5. Features of Signal, AI Methods and Performances

4.5.1. Introduction of Features Sensor Signal

4.5.2. Features Sensor Signal in Different Domains: Time Domain—Frequency Domain—Time Frequency Domain—Other

4.5.3. Introduction and General Explanation of AI Methods

4.6. Methods of AI Applications: ANN, GA, FL, SVM, HMM, DT, RF, ANFIS, BN, KNN, PCA, CNN, C-Mean, RVM, ELM, SSA, KALMN FILTER, CRF

4.6.1. AI Applications in Milling

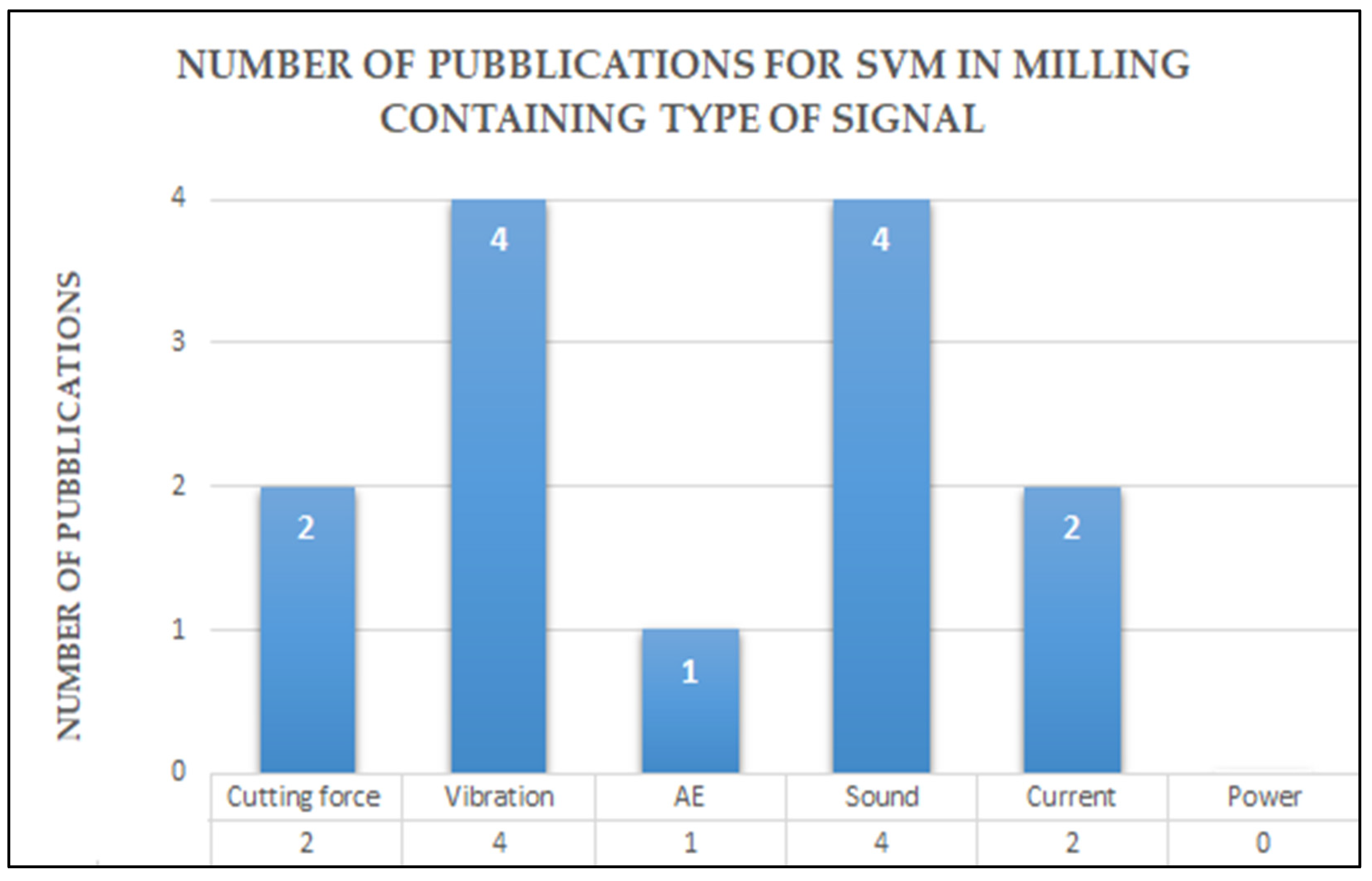

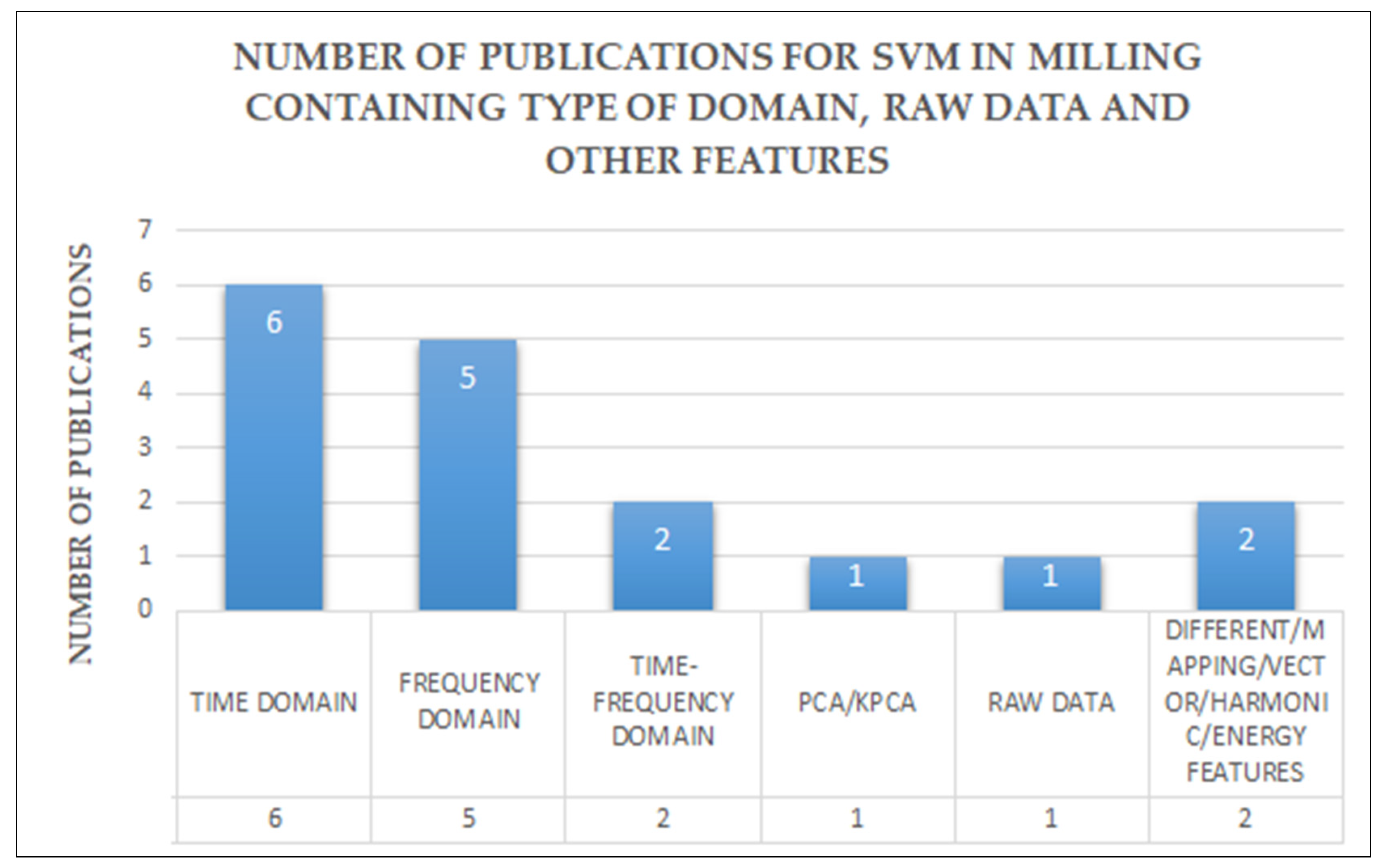

- Analysis SVM in milling

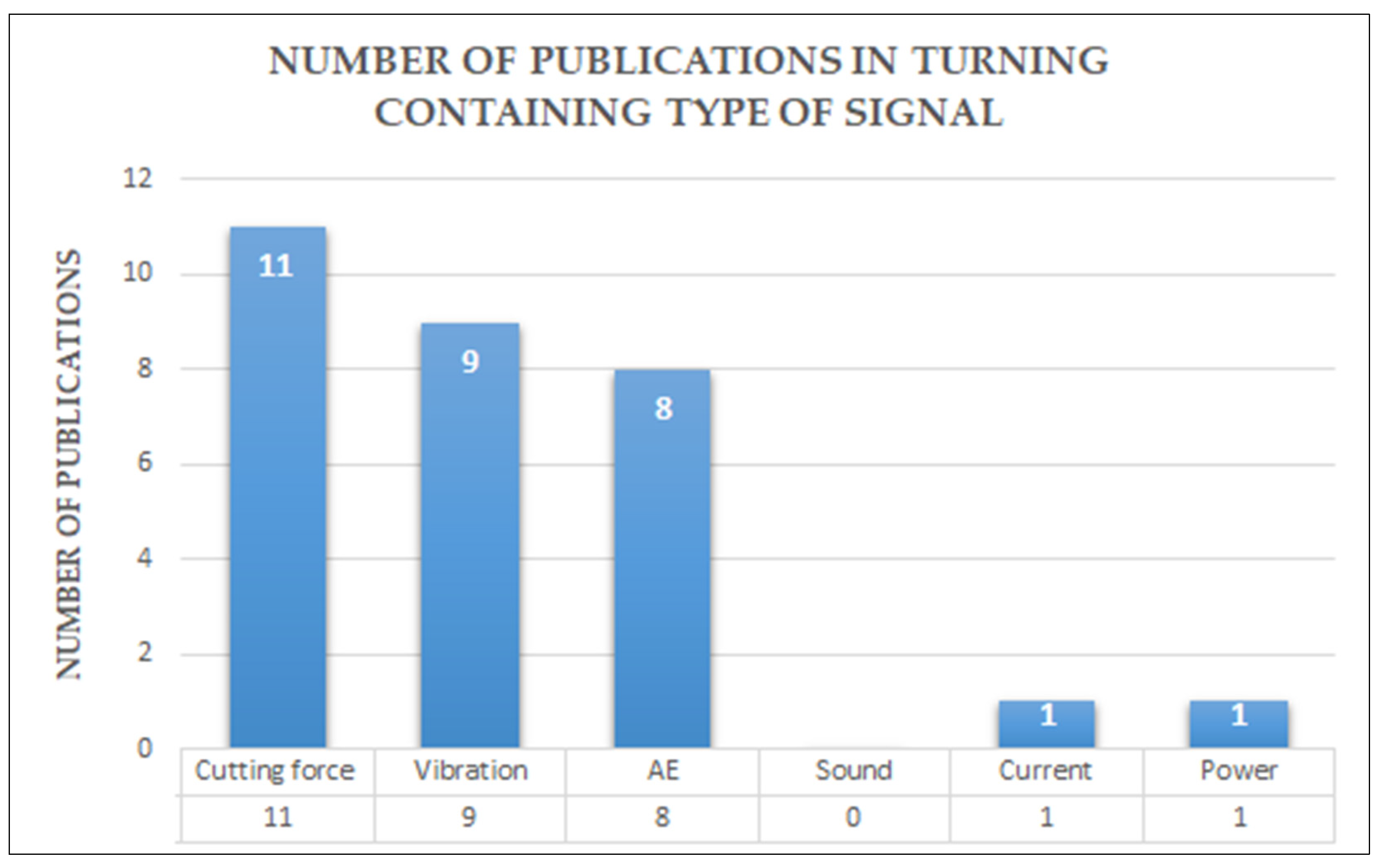

4.6.2. AI Applications in Turning

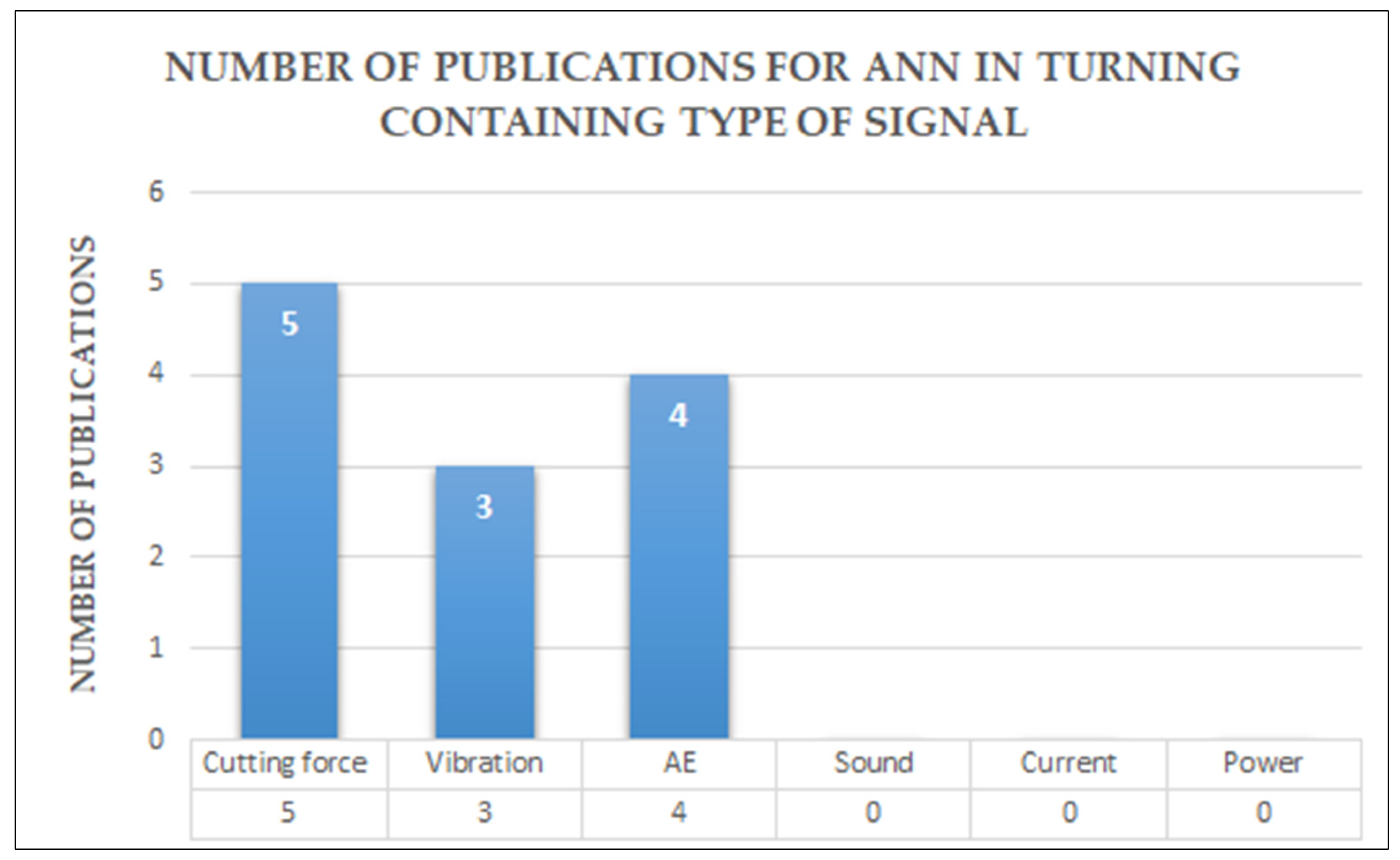

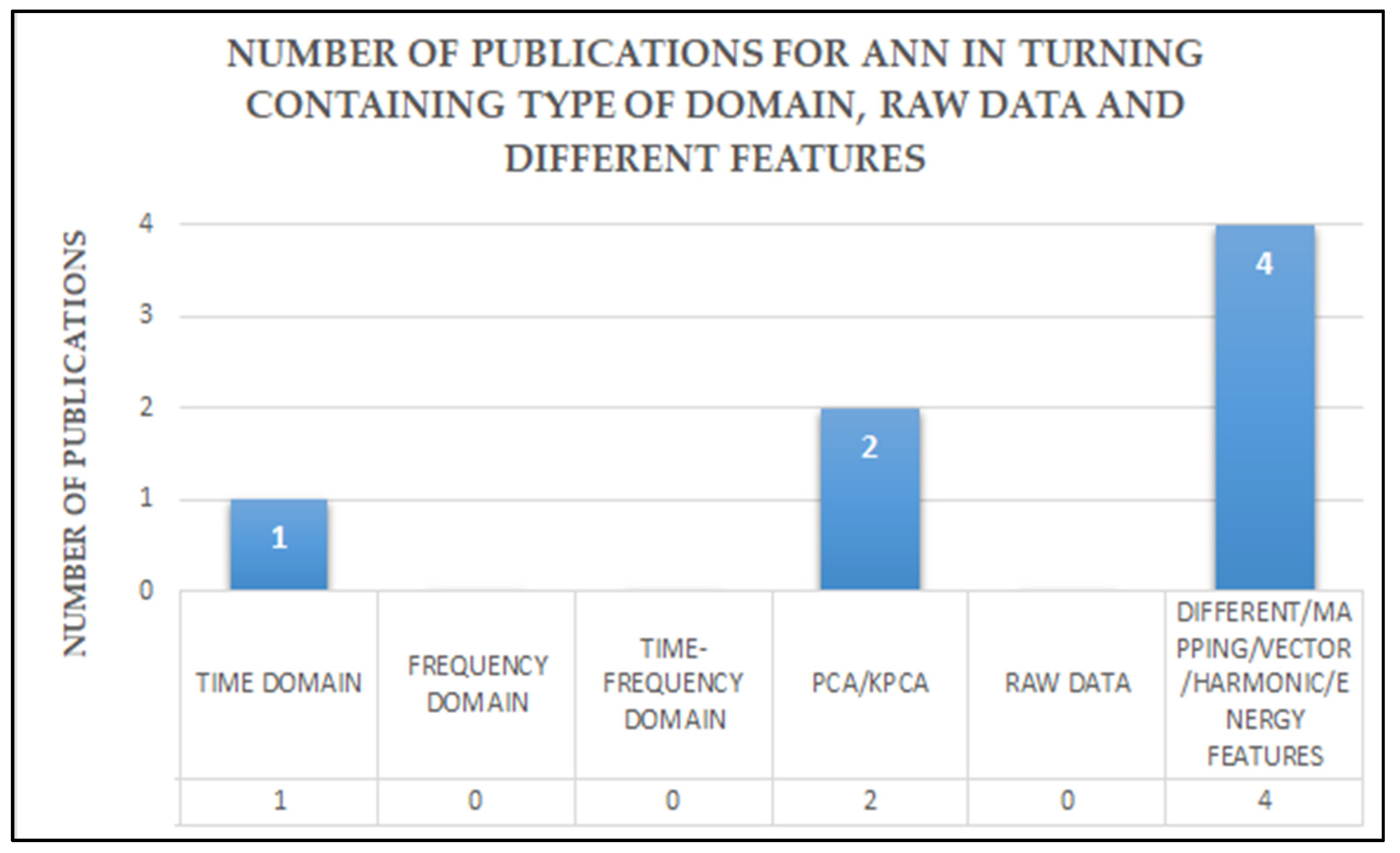

- Analysis ANN in turning

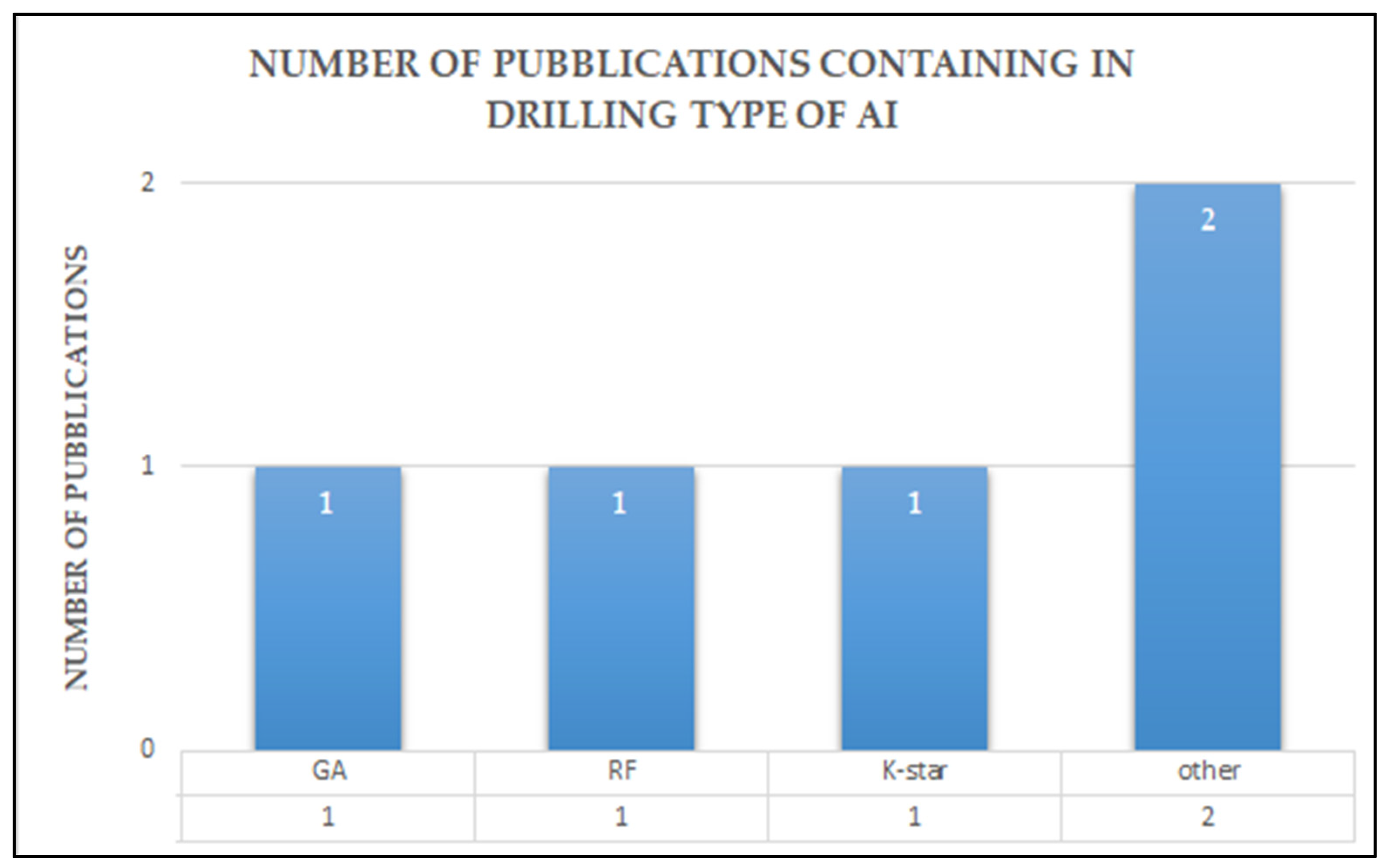

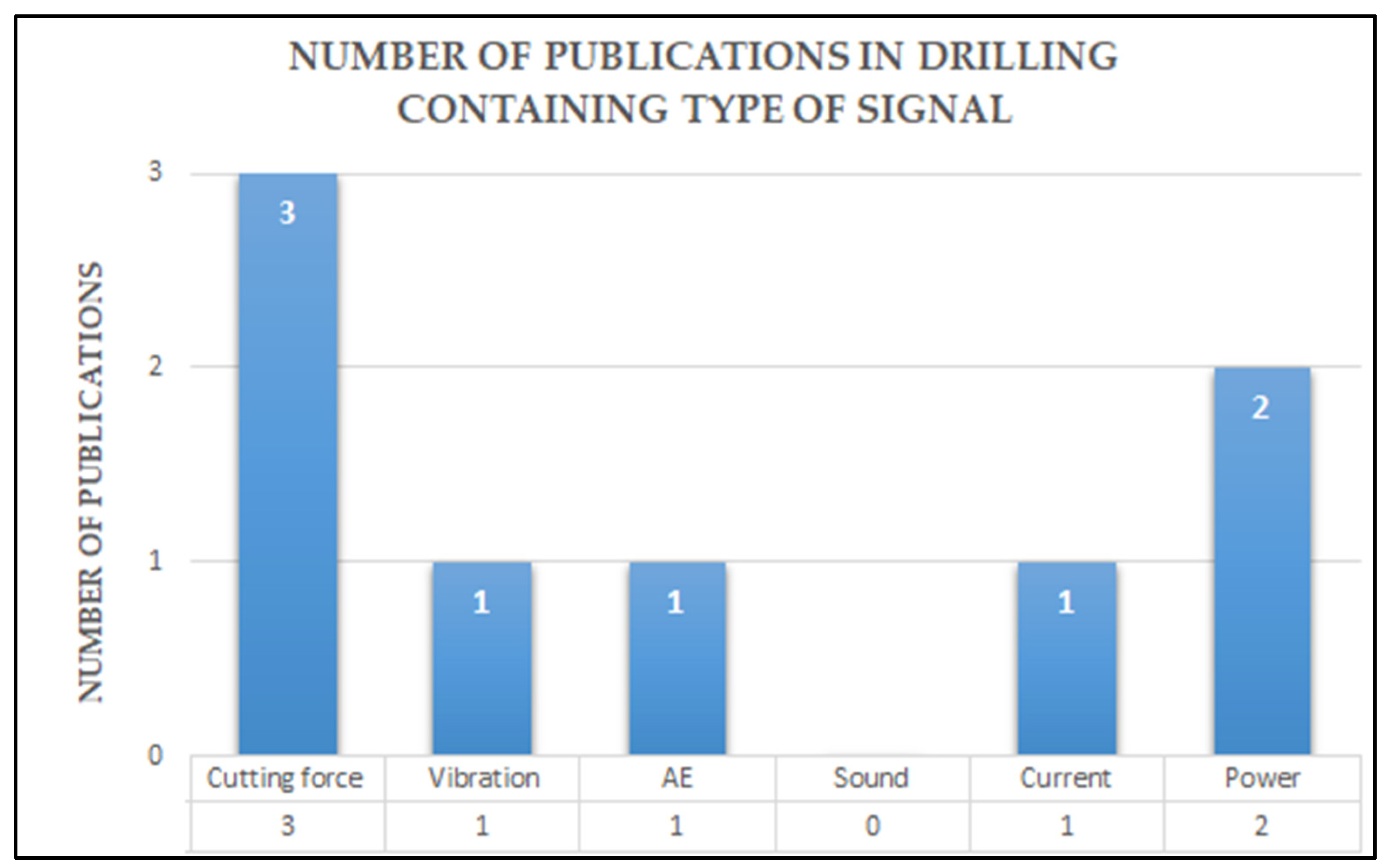

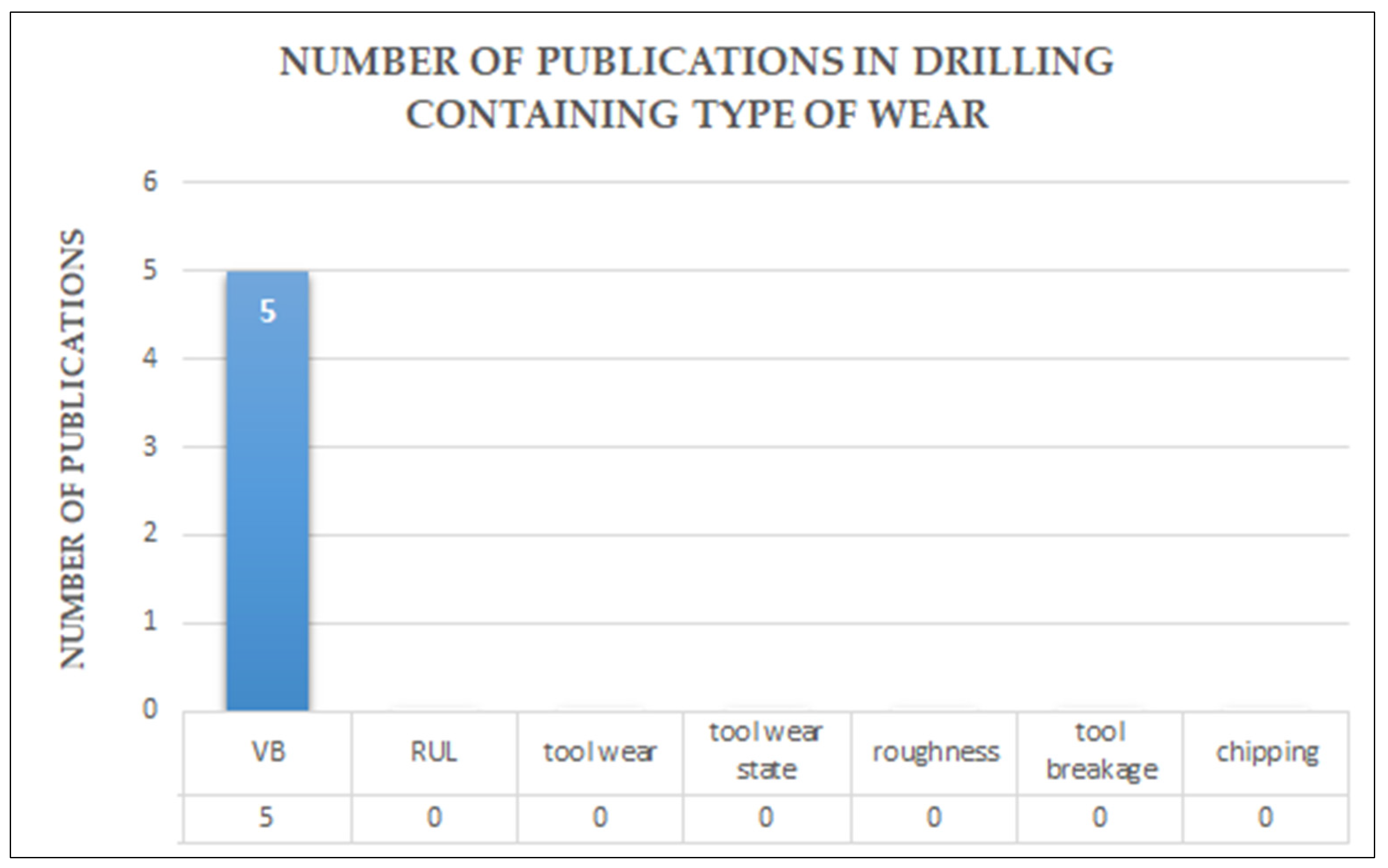

4.6.3. AI Applications in Drilling

4.6.4. Introduction of the Performance of an AI Algorithm

Performance of an AI Algorithm in Milling, Turning and Drilling

5. Industrial Application and Future Trends of Research

- -

- economical, reliable and robust sensors because machines are obsolete after 20 years, the sensors will therefore be used to increase the useful life of machine tools, which may be incorporated into machine tools;

- -

- data processing units should extract their own data with more accurate and precise information, and thus, make algorithm prediction much more accurate;

- -

- develop automatic procedures for extracting relevant information from data processing units. These procedures should also consider CNC units for machine tools.

- -

- it is necessary to identify the most appropriate AI algorithms to predict the wear of turning, milling and drilling tools, particularly in industrial environments. These environments are characterized by noise; real data is very complicated to filter and, in many cases, for reasons pertaining to production time, the training and wear forecast datasets are very small. This is why the algorithms to be developed need to automatically adapt to industrial contexts;

- -

- significantly faster, simpler and cheaper offline measurement techniques;

- -

- outlier detection techniques, which are often carried out in industrial environments;

- -

- new methodologies or algorithms for optimising parameter adjustment without the assistance of cutting process experts.

6. Results and Conclusions Compared with Recent Reviews

6.1. Result Review

- 1.

- A total of 77 online and offline measurement publications were identified, as shown in Table 1. The common purpose of the publications was to compare the offline tool wear data obtained with the online tool wear data. Comparison between the two methods of measurement was the essential requirement. Without this, other publications were not considered. The most widely used measurement methods to compare online measurement forecasts were digital microscopes, optical microscopes, laser scanning microscopes, 3D digital microscopes, video measuring systems, profile projectors and electron scanning microscopes (SEM). The most commonly used online measurement methods in research were ANN, GA, FL, SVM, HMM, DT, RF and ANFIS, with the use of other algorithms such as BN, KNN, PCA, CNN, C-mean, RVM, ELM, SSA, KALMN FILTER and CRF. Specifying the algorithms mentioned in the milling and turning processes, they were all used in a heterogeneous way, while in the drilling processes, the algorithms K-means, K-star, RF and GA were used;

- 2.

- The most used cutting parameters in milling machining were the spindle speed, cutting depth and feed; in turning machining, the cutting speed, cutting depth and feed; in drilling machining, all cutting parameters are considered; i.e., cutting speed, spindle speed, depth of cut, feed and cutting diameter. Lubrication was only identified in one publication;

- 3.

- For the most commonly used tools for milling, they were insert and hard metal cutters; for turning, the CNMG insert; and for drilling, high-speed steel bits;

- 4.

- The most common sensors were dynamometers, used to obtain the cutting force signal, and then accelerometers or vibration sensors, and finally, acoustic emission sensors. As previously described, research needs to focus on low-cost, wireless and reliable sensors to better detect signals and ensure the reliability of the data acquisition process. For example, machine signals such as power and current are less used, but should be the most commercially attractive because they are far less expensive;

- 5.

- Most of the extracted features were in the time and frequency domain. The main characteristics extracted were: mean in the time domain, standard deviation in the time domain, kurtosis in the time domain, the root mean square (RMS) in the time domain, Fast Fourier Transform (FFT) in the time domain, variance in the time domain, skewness in the time domain, peak in the time domain, maximum in the time domain, mean in the frequency domain, skewness in the frequency domain, peak value in the frequency domain, variance value in the frequency domain, kurtosis in the frequency domain, the root mean square ratio in the frequency domain and centroid in the frequency domain. The time-frequency domain was the least used but might ensure better results. When multiple sensors were used, the data processing of the sensor fusion signal was performed through principal component analysis (PCA) to reduce the high dimensionality of the sensor data and the extraction of meaningful characteristics of the signal to be used for the recognition of models aimed at the decision-making process on the state of wear of the tool;

- 6.

- The intelligence techniques used to forecast tool wear were numerous and varied. Each identified tool wear with great accuracy and precision. The key was that the intelligence training dataset was as complete as possible. Even leaving data considered uninteresting might distort the forecast result. The performance of artificial intelligence determined whether the predictive algorithm used properly works. Analysing the publications, the most common performance indicators were covariance (R), mean relative error (MRE), variance (R2), mean absolute error (MAE), mean squared error (RMSE), the Mean Absolute Percentage Error (MAPE), Pearson’s Correlation Coefficient (PCC), and Confidence Interval of Expected Results (CI). There were also very specific ones, such as the spectrogram of the “Failure” tool, the salience map of the “Failure” tool, the positivity rate (TP rate) and the false positive rate (FP rate).

- 7.

- A very important fact is that the accuracy of the algorithms used in the identified publications varied from 84% to 100% when it came to a tool the wear of which is already known. On the other hand, when the wear was unknown because the tool was new, the precision dropped to around 73%.

6.2. Conclusions Compared with Recent Reviews

- -

- Tool wear. The reviewed articles almost exclusively studied VB wear. ISO 3685 indicates that the VB value is 0.3 mm. In industrial environments, every process is different and is made using different types of tools. Some tools have a maximum wear of 0.1 mm, while others have a maximum wear of 0.4 mm. ISO 3685 should be restated or adapted. Numerous experiments should be carried out in industrial environments. They will need to be classified on a common basis in order to be compared. Mapping will have to be constructed that will have the tools, the machine tools, the cutting parameters, the materials processed and the machining operations as input parameters and the measurement in millimetres of the tool wear as output parameters; Types of tool wear. Other techniques for evaluating wear should be studied, such as RUL, surface roughness, dimensional tolerances and residual stresses [84,85,86];

- -

- Data. The amount of data extracted from sensors used in the industrial environment is extremely large. This refers specifically to big data. Researchers will have to use continuously storing and analyzing data, using the cloud the cloud. Introducing a big data shopfloor was suggested in one publication. The data obtained in industrial environments are very noisy with different characteristics, such as very worn tools and broken tools, and with small datasets for the short duration of the machining operation. The data is thus highly skewed and dispersed. Balancing techniques such as SMOTE (Synthetic Minority Oversampling Technique) will be examined and analysed. To reduce the amount of data obtained from industrial sensors, the technique of regression to granular labelled data has been introduced with deep learning, obtaining synthetic data on a smaller time scale. Then, through second-order regression on the wear curve, the synthetic data can be segmented into smaller partitions [84,85,86];

- -

- Sensors. The dynamometer was the most common sensor in the search. The measured signal is the cutting force and related quantities such as power, torque, distance/displacement, and strain. Problems pertaining to the force sensor include the cost and the pervasive presence in the machine tool. To solve the cost problem, increasingly less expensive and high-performance sensors must be built. To resolve the issue of invasive presence, the cutting force data could be obtained from the spindle motor current. This solution is highly relevant for small businesses where costs have a larger impact on choices. Other sensors such as accelerometers, acoustic emission sensors and microphones were also used. The solution for better tool wear calculation is to use several sensors together. However, this implies an increase in costs and an invasive presence [84,85,86].

- -

- Artificial intelligence algorithms. The AI algorithms employed, analysed in the articles, were very different. Their characteristics were different. There are still too many unknowns in the nature and use of algorithms to determine a perfect result. However, the performance of the algorithms was very good, with maximum accuracy values of 96–97%. Identifying a perfect algorithm for a machining operation is impossible. The research will have to identify the best algorithms for industrial environments according to the machining operation, the tools, the machine tools, the cutting parameters, the sensors and the types and characteristics of the data. A mapping of the algorithms should be created that will have the features described as input and the performance as output. The most used algorithms in milling are: ANNs, with limitations in the extensive optimization procedure of their parameters; SVM, limited to digesting huge datasets; the DP, with accurate labelling of big data collected under different operating conditions with supervised and unsupervised learning. The DP also uses the transfer learning (TL) approach, i.e., the adaptation of knowledge for one task to another related task, and the CNN with supervised learning [84]. In drilling and turning, FL, such as decision trees, are simple techniques that are well suited to the dispersive nature of tool wear [84,85,86].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Abstract | ||

| Introduction | 1 | |

| Objectives | Provide an answer to your research | |

| Research Question | Provide an explicit statement of the question(s) the review will address | |

| Methods Of Research Level, Research’s Item And Research’s Number Of Published Articles Found | 2 | |

| Eligibility Criteria Search Strategy | 2.1 | Specify the study characteristics (study design, setting, time frame) and report characteristics (such as years considered, language, publication status) to be used as criteria for eligibility for the review. Present draft of search strategy to be used for at least one electronic database, including planned limits, such that it could be repeated |

| Selection Of Offline And Online Publications And Related Data Extraction From The Publications | 3 | |

| Results Of Research | 4 | |

| Introduction Selection and Inclusion of Publications | 4.1 | It describes which articles were included |

| General And Essential Requirement Of Machining Operations, Number Of Articles, Type Of Wear, Type Of Machine And Type Of Material | 4.2 | It describes the essential and general requirements of the articles identified and selected |

| Introduction Methods of Measurement | 4.3 | Describes in general the online and offline measurement systems. 4.3.1 Offline measurement 4.3.2 Measurement online |

| Type of Sensors and How They are used in research Experiments | 4.4 | Describes the signal that the dedicated sensor detects. 4.4.1 Cutting Force sensors 4.4.2 Vibration sensors 4.4.3 AE Emission Acoustic sensors 4.4.4 Sound sensors 4.4.5 Current and power sensors |

| Features Of Signal, AI Methods And Performances | 4.5 | It describes the features extracted from the signals, the AI methods to predict the tool wear and the performances of the algorithms. 4.5.1 Introduction of Features Sensor Signal 4.5.2 Features sensor signal in different domani: Time domain—Frequency domain—Time Frequency domain—Other 4.5.3 Introduction and General Explanation of AI methods Methods of AI applications: ANN, GA, FL, SVM, HMM, DT, RF, ANFIS, BN, KNN, PCA, CNN, C-mean, RVM, ELM, SSA, KALMN FILTER, CRF AI applications in milling. Analyse SVM in milling. AI applications in turning Analysis ANN in turning AI applications in drilling 4.5.4 Performances 4.5.4 Introduction of the Performance of an AI algorithm Performance of an AI algorithm in milling, turning and drilling |

| Industrial Application And Future Trends Of Research | 5 | |

| Results And Conclusion Compared With Recent Reviews | 6 | 6.1 Result review 6.2 Conclusions compared with recent reviews |

Appendix B

| Domain | |||||||

|---|---|---|---|---|---|---|---|

| Articles | Time | Frequency | Time-Frequency | Pca/Kpca | Signal | A.I. Methods | Performance |

| [8] | x | x | x | Cutting force, power and current | FCNN with MAML | Prediction error | |

| [10] | x | Sound | CNN with SGD | Predictive accuracy | |||

| [11] | x | x | Current | SVM, LDA; KNN, NN, NB, DT | Accuaracy. | ||

| [12] | different feature | Cutting force, vibration and acoustic emission | HMM | MAPE, Mean and Accuracy | |||

| [13] | x | x | Sound | CART, RF, KNN, SVM with EBCA and without EBCA | accuracy with training set 50–60–70–80% | ||

| [14] | x | x | Cutting force | RVM, SVM | Accuracy | ||

| [15] | x | x | Cutting force | dGAM | k-fold cross and accuracy | ||

| [16] | statistical feature | Cutting force | ANN | R, MRE, R² | |||

| [17] | x | x | Cutting force,vibration | FCM | FBE | ||

| [19] | x | x | x | Cutting force,vibration | EAM ARTMAP, FUZZY ARTMAP (FAM) | averaging recognition rate | |

| [20] | images for force | Cutting force | CNN, AC | Predicted Rapid initial wear, Predicted Uniform wear, Predicted Failure wear Accuracy % | |||

| [22] | different feature | Cutting force, vibration and acoustic emission | SSAE | Average accuracy | |||

| [25] | x | x | x | Cutting force, vibration | PGGM | RMSE, MAE | |

| [27] | x | x | x | x | Cutting force | RVM with KPCA-IRBF | RMSE, PCC, CI_widht/CI_var |

| [32] | raw data | Cutting force | CNN+BILSTM and CNN+BIGRU | MAE, RMSE | |||

| [33] | x | Vibration | ANN, SVM and KNN | Score, recall and precision | |||

| [34] | different feature | Cutting force | Kalman filter | RMSE | |||

| [35] | different feature | Acoustic emission | CRF and HMM | accuracy rate | |||

| [37] | x | Power | R² | ||||

| [38] | feature mapping | x | Power and current | BP | formula tool life predicting | ||

| [39] | x | x | x | Cutting force, current | SVM, RF and feedforrward NN | Score, RMSE and Accuracy | |

| [41] | x | x | Vibration, acoustic emission, current | DBILSTM | MAE and RMSE | ||

| [42] | x | x | Cutting force, vibration and sound | TAKELM, BDE | MAE, MAPE, RMSE | ||

| [44] | x | Sound | GAN | accuracy, non-confroming tool | |||

| [45] | x | Vibration | K-star | positive rate (TP rate) and false positive rate (FP rate) and accuracy | |||

| [46] | x | Sound | DCNN | accuracy | |||

| [47] | x | x | x | Cutting force, vibration | SVR, CNN, LSTM, GRU | RMSE and MAE | |

| [48] | feature vector | Sound | HMM | SR | |||

| [50] | x | x | x | x | Cutting force, vibration | PF, AR-PF, SVR-PF | RMSE |

| [52] | images feature | Power | NN inconrporate CNN and RNN NN incorporate RNN | accuracy | |||

| [53] | harmonic feature | Cutting force | ARTMAP (GAM) | accuracy | |||

| [54] | raw data | Power | Kalman filter | RMSE, average percent error | |||

| [56] | x | x | Vibration and emission acoustic | LR, DF, BLR, DT, NN | RMSE, RelSE and R² | ||

| [57] | x | x | Vibration, emission acoustic and sound | BP, SVM, ANFIS | RMSE, COV and R² | ||

| [58] | x | x | x | x | Cutting force, vibration | KPCA, LLE, ISOMAP, mRMR | RMSE, PCC, MAE and MAPE |

| [60] | Feature based fusion | Cutting force | VARX-L, SVR, RF, XGBOOST | NRMSE | |||

| [61] | x | x | x | Cutting force | DE-SVR | Accuracy VB and Acccuracy RUL | |

| [62] | raw data | Sound | SVM | maximum shape error | |||

| [63] | x | x | Vibration | SVM with TIPM SVM without TIPM | accuracy | ||

| [64] | holder exponent feature | Vibration | SVM | RMSE and accuracy | |||

| [65] | raw data | Specific Cutting Forces | DNN, LR | R² and RMSE | |||

| [71] | force and vibration feature | Cutting force, vibration | ELM, SW-ELM, ESN | R² | |||

| [72] | x | x | Cutting force | NB | R² | ||

| [73] | DWT features, EMD features, statistical features | Sound | SVM, ANN, NB, K-star | true positive rate (TP rate) false positive rate (FP rate) | |||

| [74] | energy feature vector | Cutting force, current | CHMM | accuracy | |||

| [75] | raw data | Vibration and current | R² | ||||

| [76] | x | x | x | Vibration | NFN, BP, RBFN | MSE, MAPE and R² | |

| [77] | harmonic feature | Cutting force | ARTMAP | Incremental learning | |||

| [78] | raw data | Cutting force, vibration and emission acoustic | HMM | MSE, accuracy | |||

| [81] | x | x | x | Cutting force, vibration and emission acoustic | GA with KELM | R², RMSE | |

Appendix C

| DOMAIN | |||||||

|---|---|---|---|---|---|---|---|

| Articles | Time | Frequency | Time-Frequency | Pca/Kpca | Signal | Neural Network | Performance |

| [18] | x | x | x | x | Cutting force | KPCA_IRBF | GPR model, MAE, RMSE, MAPE, PCC, CI |

| [21] | feature vector | Cutting force, torque, vibration acoustic emission | NN | SR | |||

| [23] | x | x | Vibration signal | TBTCD, FCM Classifier, Lasso classifier | recognition accuracy | ||

| [24] | x | Cutting force, vibration | ANFIS algorithm | MAPE | |||

| [26] | x | x | Cutting force, vibration | GUI | Different between measured wear and calculated wear | ||

| [28] | feature vector | x | Cutting force, vibration and acoustic emission | NN with PCA | SR | ||

| [30] | statistical feature | Vibration | K-star | TP rate’ and ‘FP rate define the accuracy | |||

| [31] | raw data | Acoustic emission | TSK | RMSE | |||

| [36] | different feature | Cutting force | TSK, NN, Mandami FL, NF | RMSE and MAX | |||

| [40] | x | x | x | Vibration and power | FBNF | R² and RMSE | |

| [59] | Sensorial features, feature pattern vector. | x | Cutting force, vibration and emission acoustic | NN, FFBP | Consumed tool life% average error % | ||

| [68] | x | Vibration and emission acoustic | ANN | Accuracy | |||

| [70] | raw data | Cuttin force and emission acoustic | DENFIS, TWNFIS, ANFIS | SSE, NSSE, FPE, ENV, SBC, TAE and average error | |||

| [79] | x | Vibration, emission acoustic and current | proportional hazard model | logarithmic means and logarithmic standard deviations | |||

| [80] | x | x | x | Cutting force, vibration and emission acoustic | Decision-making algorithm | R², RMSE | |

Appendix D

| DOMAIN | |||||||

|---|---|---|---|---|---|---|---|

| Articles | Time | Frequency | Time-Frequency | Pca/Kpca | Signal | Neural Network | Performance |

| [9] | x | Cutting force, acoustic emission | K-means | Sum Squared Error | |||

| [29] | different feature | Cutting force and power | LM, CGD and BI | MSE and the R² | |||

| [43] | raw data | Current and power | RF | accuracy, R², MAE,RMSE | |||

| [49] | x | Vibration | K-star | accuracy | |||

| [51] | raw data | Cutting force | RBFN with GA | MSE and % MSE | |||

References

- Zhang, C.; Zhang, J. On-line tool wear measurement for ball-end milling cutter based on machine vision. Comput. Ind. 2013, 64, 708–719. [Google Scholar] [CrossRef]

- Barreiro, J.; Fernández-Abia, A.; González-Laguna, A.; Pereira, O. TCM system in contour milling of very thick very large steel plates based on vibration and AE signal. J. Mater. Process. Technol. 2017, 246, 144–157. [Google Scholar] [CrossRef]

- Rehorn, A.; Jiang, J.; Orban, P.; Bordatchev, E. State-of-the-art methods and results in tool condition monitoring: A review. Int. J. Adv. Manuf. Technol. 2004, 26, 942. [Google Scholar] [CrossRef] [Green Version]

- Dimla, D. Sensor signals for tool wear monitoring in metal cutting operations a review of methods. Int. J. Mach. Tool. Manuf. 2000, 40, 1073–1098. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Lu, X.; Wang, S.; Wang, W.; Li, W.D. A multi-sensor based online tool condition monitoring system for milling process. Procedia CIRP 2018, 72, 1136–1141. [Google Scholar] [CrossRef]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P): Elaboration and explanation. BMJ 2015, 349, g7647. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ISO 1832:2012; Indexable Inserts for Cutting Tools—Designation. ISO: Geneva, Switzerland. Available online: https://standards.iteh.ai/catalog/standards/iso/1777acf9-65d1-40f2-ac15-02b7c1ead78a/iso-1832-2004 (accessed on 23 July 2011).

- Li, Y.; Liu, C.; Hua, J.; Gao, J.; Maropoulos, P. A novel method for accurately monitoring and predicting tool wear under varying cutting conditions based on meta-learning. CIRP Ann. 2019, 68, 487–490. [Google Scholar] [CrossRef]

- Klocke, F.; Döbbeler, B.; Pullen, T.; Bergs, T. Acoustic emission signal source separation for a flank wear estimation of drilling tools. Procedia CIRP 2019, 79, 57–62. [Google Scholar] [CrossRef]

- Kothuru, A.; Nooka, S.P.; Liu, R. Application of deep visualization in CNN-based tool condition monitoring for end milling. Procedia Manuf. 2019, 34, 995–1004. [Google Scholar] [CrossRef]

- Hassan, M.; Damir, A.; Attia, H.; Thomson, V. Benchmarking of Pattern Recognition Techniques for Online Tool Wear Detection. Procedia CIRP 2018, 72, 1451–1456. [Google Scholar] [CrossRef]

- Tobon-Mejia, D.A.; Medjaher, B.K.; Zerhouni, N. CNC machine tool’s wear diagnostic and prognostic by using dynamic Bayesian networks. Mech. Syst. Signal Process. 2012, 28, 167–182. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Liu, R.; Wu, D. Data-driven smart manufacturing: Tool wear monitoring with audio signals and machine learning. J. Manuf. Process. 2019, 48, 66–76. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; Xie, Q.; Zhang, Y. Force based tool wear monitoring system for milling process based on relevance vector machine. Adv. Eng. Softw. 2014, 71, 46–51. [Google Scholar] [CrossRef]

- Wang, G.; Guo, Z.; Yang, Y. Force sensor based online tool wear monitoring using distributed Gaussian ARTMAP network. Sens. Actuators A Phys. 2013, 192, 111–118. [Google Scholar] [CrossRef]

- Kaya, B.; Oysu, C.; Ertunc, H.M. Force-torque based on-line tool wear estimation system for CNC millingof Inconel 718 using neural networks. Adv. Eng. Softw. 2011, 42, 76–84. [Google Scholar] [CrossRef]

- Fua, P.; Li, W.; Guo, L. Fuzzy Clustering and Visualization Analysis of Tool Wear Status Recognition. Procedia Eng. 2011, 23, 479–486. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N. Gaussian process regression for tool wear prediction. Mech. Syst. Signal Process. 2018, 104, 556–574. [Google Scholar] [CrossRef]

- Liu, C.; Wang, G.F.; Li, Z.M. Incremental learning for online tool condition monitoring using Ellipsoid ARTMAP network model. Appl. Soft Comput. 2015, 35, 186–198. [Google Scholar] [CrossRef]

- Gouarir, A.; Martinez-Arellano, G.; Terrazas, G.; Benardos, P.; Ratchev, S. In process tool wear prediction system based on machine learning techniques and force analysis. Procedia CIRP 2018, 77, 501–504. [Google Scholar] [CrossRef]

- Segreto, T.; Simeone, A.; Teti, R. Multiple sensor monitoring in nickel alloy turning for tool wear assessment via sensor fusion. Procedia CIRP 2013, 12, 85–90. [Google Scholar] [CrossRef]

- Ochoa, L.E.E.; Quinde, I.B.R.; Sumba, J.P.C.; Guevara, A.J.V.; Menendez, R.M. New Approach based on Autoencoders to Monitor the Tool Wear Conditionin HSM. IFAC-PapersOnLine 2019, 52, 206–211. [Google Scholar] [CrossRef]

- Antic, A.; Popovic, B.; Krstanovic, L.; Obradovic, R.; Miloševic, M. Novel texture-based descriptors for tool wear condition monitoring. Mech. Syst. Signal Process. 2018, 98, 1–15. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. Online tool wear prediction system in the turning process using an adaptive neuro-fuzzy inference system. Appl. Soft Comput. 2013, 13, 1960–1968. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Zhao, R.; Gao, R.X. Physics guided neural network for machining tool wear prediction. J. Manuf. Syst. 2020, 57, 298–310. [Google Scholar] [CrossRef]

- Mali, R.; Telsang, M.T.; Gupta, T.V.K. Real Time Tool Wear Condition Monitoring in Hard Turning of Inconel 718 Using Sensor Fusion System. Mater. Today Proc. 2017, 4, 8605–8612. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N.; Duan, C.; Lu, L.; Chen, D. Relevance vector machine for tool wear prediction. Mech. Syst. Signal Process. 2019, 127, 573–594. [Google Scholar] [CrossRef]

- Segreto, T.; Simeone, A.; Teti, R. Sensor Fusion for Tool State Classification in Nickel Superalloy High Performance Cutting. Procedia CIRP 2012, 1, 593–598. [Google Scholar] [CrossRef]

- Corne, R.; Nath, C.; El Mansori, M.; Kurfess, T. Study of spindle power data with neural network for predictingreal-time tool wear/breakage during inconel drilling. J. Manuf. Syst. 2017, 43, 287–295. [Google Scholar] [CrossRef]

- Painuli, S.; Elangovan, M.; Sugumaran, V. Tool condition monitoring using K-star algorithm. Expert. Syst. Appl. 2014, 41, 2638–2643. [Google Scholar] [CrossRef]

- Ren, Q.; Baron, L.; Balazinski, M.; Botez, R.; Bigras, P. Tool wear assessment based on type-2 fuzzy uncertainty estimation on acoustic emission. Appl. Soft Comput. 2015, 31, 14–24. [Google Scholar] [CrossRef]

- Ma, J.; Luo, D.; Liao, X.; Zhang, Z.; Huang, Y.; Lu, J. Tool wear mechanism and prediction in milling TC18 titanium alloy using deep learning. Measurement 2021, 173, 108554. [Google Scholar] [CrossRef]

- Hesser, D.F.; Markert, B. Tool wear monitoring of a retrofitted CNC milling machine using artificial neural networks. Manuf. Lett. 2019, 19, 1–4. [Google Scholar] [CrossRef]

- Tiwari, K.; Shaik, A.; Arunachalam, N. Tool wear prediction in end milling of Ti-6Al-4V through Kalman filter based fusion of texture features and cutting forces. Procedia Manuf. 2018, 26, 1459–1470. [Google Scholar] [CrossRef]

- Wangn, G.; Feng, X. Tool wear state recognition based on linear chain conditional random field model. Eng. Appl. Artif. Intell. 2013, 26, 1421–1427. [Google Scholar] [CrossRef]

- Ren, Q.; Balazinski, M.; Baron, L.; Jemielniak, K. TSK fuzzy modeling for tool wear condition in turning processes: An experimental study. Eng. Appl. Artif. Intell. 2011, 24, 260–265. [Google Scholar] [CrossRef]

- Goodall, P.; Pantazis, D.; West, A. A cyber physical system for tool condition monitoring using electrical power and a mechanistic model. Comput. Ind. 2020, 118, 103223. [Google Scholar] [CrossRef]

- Bao, J.; Yuan, G.; Zheng, X.; Zhang, J.; Xia, J. A Data Driven Model for Predicting Tool Health Condition in High Speed Milling of Titanium Plates Using Real-Time SCADA. Procedia CIRP 2017, 61, 317–322. [Google Scholar] [CrossRef]

- An, Q.; Tao, Z.; Xu, X.; El Mansori, M.; Chen, M. A data-driven model for milling tool remaining useful life prediction with convolutional and stacked LSTM network. Measurement 2020, 154, 107461. [Google Scholar] [CrossRef]

- Zhang, B.; Shin, Y.C. A multimodal intelligent monitoring system for turning processes. J. Manuf. Process. 2018, 35, 547–558. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Li, Z.; Dong, L.; Li, Q. A novel approach for predicting tool remaining useful life using limited data. Mech. Syst. Signal Process. 2020, 143, 106832. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, B.; Sun, W. A tool condition monitoring method based on two-layer angle kernelextreme learning machine and binary differential evolution for milling. Measurement 2020, 166, 108186. [Google Scholar] [CrossRef]

- Oberlè, R.; Schorr, S.; Yi, L.; Glatt, M.; BaHre, D.; Aurich, J.C. A Use Case to Implement Machine Learning for Life Time Prediction of Manufacturing tools. Procedia CIRP 2020, 93, 1484–1489. [Google Scholar] [CrossRef]

- Cooper, C.; Zhang, J.; Gao, R.X.; Wang, P.; Ragai, I. Anomaly detection in milling tools using acoustic signals and generative adversarial networks. Procedia Manuf. 2020, 48, 372–378. [Google Scholar] [CrossRef]

- Madhusudana, C.K.; Kumar, H.; Narendranath, S. Condition monitoring of face milling tool using K-star algorithm and histogram features of vibration signal. Eng. Sci. Technol. Int. J. 2016, 19, 1543–1551. [Google Scholar] [CrossRef] [Green Version]

- Cooper, C.; Wang, P.; Zhang, J.; Gao, R.X.; Roney, T.; Ragai, I.; Shaffer, D. Convolutional neural network-based tool condition monitoring in vertical milling operations using acoustic signals. Procedia Manuf. 2020, 49, 105–111. [Google Scholar] [CrossRef]

- Wang, J.; Yan, J.; Li, C.; Gao, R.X.; Zhao, R. Deep heterogeneous GRU model for predictive analytics in smart manufacturing: Application to tool wear prediction. Comput. Ind. 2019, 111, 1–14. [Google Scholar] [CrossRef]

- Boutros, T.; Liang, M. Detection and diagnosis of bearing and cutting tool faults using hidden Markov models. Mech. Syst. Signal Process. 2011, 25, 2102–2124. [Google Scholar] [CrossRef]

- Simon, G.D.; Deivanathan, R. Early detection of drilling tool wear by vibration data acquisition and classification. Manuf. Lett. 2019, 21, 60–65. [Google Scholar] [CrossRef]

- Wanga, J.; Wang, P.; Gao, R.X. Enhanced particle filter for tool wear prediction. J. Manuf. Syst. 2015, 36, 35–45. [Google Scholar] [CrossRef]

- Garg, S.; Patra, K.; Khetrapal, V.; Pal, S.K.; Chakraborty, D. Genetically evolved radial basis function network based prediction of drill flank wear. Eng. Appl. Artif. Intell. 2010, 23, 1112–1120. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Gao, R.X.; Guo, Y. Heterogeneous data-driven hybrid machine learning for tool condition prognosis. CIRP Ann. 2019, 68, 455–458. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; Guo, Z. Hybrid learning based Gaussian ARTMAP network for tool conditionmonitoring using selected force harmonic features. Sens. Actuators A Phys. 2013, 203, 394–404. [Google Scholar] [CrossRef]

- Niaki, F.A.; Ulutan, D.; Mears, L. In-Process Tool Flank Wear Estimation in Machining Gamma-Prime Strengthened Alloys Using Kalman Filter. Procedia Manuf. 2015, 1, 696–707. [Google Scholar] [CrossRef] [Green Version]

- Nath, C. Integrated Tool Condition Monitoring Systems and Their Applications: A Comprehensive Review. Procedia Manuf. 2020, 48, 852–863. [Google Scholar] [CrossRef]

- Traini, E.; Bruno, G.; D’Antonio, G.; Lombardi, F. Machine Learning Framework for Predictive Maintenance in Milling. IFAC-PapersOnLine 2019, 52, 177–182. [Google Scholar] [CrossRef]

- Wu, J.; Su, Y.; Cheng, Y.; Shao, X.; Deng, C.; Liu, C. Multi-sensor information fusion for remaining useful life prediction of machining tools by adaptive network based fuzzy inference system. Appl. Soft Comput. 2018, 68, 13–23. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Zhao, R.; Zhang, L.; Duan, L. Multisensory fusion based virtual tool wear sensing for ubiquitous manufacturing. Robot. Comput. Int. Manuf. 2017, 45, 47–58. [Google Scholar] [CrossRef] [Green Version]

- Karam, S.; Centobelli, P.; D’Addona, D.M.; Teti, R. Online prediction of cutting tool life in turning via cognitive decision making. Procedia CIRP 2016, 41, 927–932. [Google Scholar] [CrossRef]

- Finkeldey, F.; Saadallah, A.; Wiederkehr, P.; Morik, K. Real-time prediction of process forces in milling operations using synchronized data fusion of simulation and sensor data. Eng. Appl. Artif. Intell. 2020, 94, 103753. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Y.; Huang, Z.; Chen, N.; Li, L.; Jiang, Y.; He, N. Research on the milling tool wear and life prediction by establishing an integrated predictive model. Measurement 2019, 145, 178–189. [Google Scholar] [CrossRef]

- Denkena, B.; Dittrich, M.A.; Mainka, J. Simulation-based feed rate adaptation considering tool wear condition. Procedia Manuf. 2020, 52, 133–137. [Google Scholar] [CrossRef]

- Wang, G.F.; Yang, Y.W.; Zhang, Y.C.; Xie, Q.L. Vibration sensor based tool condition monitoring using supportvector machine and locality preserving projection. Sens. Actuators A Phys. 2014, 209, 24–32. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, B.; Guo, K.; Liu, J.; Sun, J.; Song, G.; Zhu, S.; Sun, C.; Jiang, Z. Vibration singularity analysis for milling tool condition monitoring. Int. J. Mech. Sci. 2020, 166, 105254. [Google Scholar] [CrossRef]

- Peng, B.; Bergs, T.; Schraknepper, D.; Klocke, F.; Döbbeler, B. A hybrid approach using machine learning to predict the cutting forces under consideration of the tool wear. Procedia CIRP 2019, 82, 302–307. [Google Scholar] [CrossRef]

- Siddhpura, A.; Paurobally, R. A review of flank wear prediction methods for tool condition monitoring in a turning process. Int. J. Adv. Manuf. Technol. 2013, 65, 371–393. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, W. Review of tool condition monitoring methods in milling processes. Int. J. Adv. Manuf. Technol. 2018, 96, 2509–2523. [Google Scholar] [CrossRef]

- Lee, S.S. Tool condition monitoring system in turning operation utilizing wavelet signal processiing and multi-learning ANNs algorithm methodology. Int. J. Eng. Res. Innov. 2010, 2, 49. [Google Scholar]

- Downey, J.; O’Sullivan, D.; Nejmen, M.; Bombinski, S.; O’Leary, P.; Raghavendra, R.; Jemielniak, K. Real time monitoring of the CNC process in a production environment the data collection & analysis phase. Procedia CIRP 2016, 41, 920–926. [Google Scholar] [CrossRef] [Green Version]

- Gajate, A.; Haber, R.; Del Toro, R.; Vega, P.; Bustillo, A. Tool wear monitoring using neuro-fuzzy techniques: A comparative study in a turning process. J. Intell. Manuf. 2012, 23, 869–882. [Google Scholar] [CrossRef] [Green Version]

- Karandikar, J.; McLeay, T.; Turner, S.; Schmitz, T. Tool wear monitoring and prognostics challenges: A comparison of connectionist methods toward an adaptive ensemble model. J. Intell. Manuf. 2018, 29, 1873–1890. [Google Scholar] [CrossRef]

- Karandikar, J.; McLeay, T.; Turner, S.; Schmitz, T. Tool wear monitoring using naïve Bayes classifiers. Int. J. Adv. Manuf. Technol. 2015, 77, 1613–1626. [Google Scholar] [CrossRef]

- Madhusudana, C.K.; Kumar, H.; Narendranath, S. Face milling tool condition monitoring using sound signal. Int. J. Syst. Assur. Eng. Manag. 2017, 8, S1643–S1653. [Google Scholar] [CrossRef]

- Wang, M.; Wang, J. CHMM for tool condition monitoring and remaining useful life prediction. Int. J. Adv. Manuf. Technol. 2012, 59, 463–471. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Vasiliadis, E.; Chryssolouris, G. Tool wear predictability estimation in milling based on multi-sensorial data. Int. J. Adv. Manuf. Technol. 2016, 82, 509–521. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Yao, X.; Zhang, J.; Jin, H. Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations. Sensors 2016, 16, 795. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, G.; Guo, Z.; Qian, L. Online incremental learning for tool condition classification using modified Fuzzy ARTMAP network. J. Intell. Manuf. 2014, 25, 1403–1411. [Google Scholar] [CrossRef]

- Yu, J.; Liang, S.; Tang, D.; Liu, H. A weighted hidden Markov model approach for continuous-state tool wear monitoring and tool life prediction. Int. J. Adv. Manuf. Technol. 2017, 91, 201–211. [Google Scholar] [CrossRef]

- Ding, F.; He, Z. Cutting tool wear monitoring for reliability analysis using proportional hazards model. Int. J. Adv. Manuf. Technol. 2011, 57, 565–574. [Google Scholar] [CrossRef]

- Jemielniak, K.; Urbański, T.; Kossakowska, J.; Bombiński, S. Tool condition monitoring based on numerous signal features. Int. J. Adv. Manuf. Technol. 2019, 59, 73–81. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Xue, W. A Multisensor Fusion Method for Tool Condition Monitoring in Milling. Sensors 2018, 18, 3866. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mia, M.; Królczyk, G.; Maruda, R.; Wojciechowski, S. Intelligent Optimization of Hard-Turning Parameters Using Evolutionary Algorithms for Smart Manufacturing. Materials 2019, 12, 879. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, K.; Niu, Z.-C.; Wang, R.C.; Rakowski, R.; Bateman, R. Smart Cutting Tools and Smart Machining: Development Approaches, and Their Implementation and Application Perspectives. Chin. J. Mech. Eng. 2017, 30, 1162–1176. [Google Scholar] [CrossRef] [Green Version]

- Colantonio, L.; Equeter, L.; Dehombreux, P.; Ducobu, F. A Systematic Literature Review of Cutting Tool Wear Monitoring in Turning by Using Artificial Intelligence Techniques. Machines 2021, 9, 351. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Wojciechowski, S.; Sharma, V.S.; Gupta, M.K.; Kuntoğlu, M. Artificial intelligence systems for tool condition monitoring in machining: Analysis and critical review. J. Intell. Manuf. 2022, 34, 2079–2121. [Google Scholar] [CrossRef]

- Mohanraj, T.; Shankar, S.; Rajasekar, R.; Sakthivel, N.R.; Pramanik, A. Tool condition monitoring techniques in milling process—A review. J. Mater. Res. Technol. 2020, 9, 1032–1042. [Google Scholar] [CrossRef]

| Research Level | Items | Total Articles Found | Database Reasearch |

|---|---|---|---|

| FIRST | Research title: tool wear Years of publication: 2010–2020 Thematic areas: engineering Type of article: review article and research article | 21,760 | SCOPUS, GOOGLE SCHOLAR, WEB OF SCIENCES. Based on DOI |

| SECOND | Research title: tool wear monitoring, learning Years of publication: 2010–2020 Thematic areas: engineering Type of article: review article and research article | 2959 | |

| THIRD | Research title: tool wear monitoring, learning Years of publication: 2010–2020 Thematic areas: engineering, no micro cutting Type of article: review article and research article | 116 | |

| FOURTH | Research title: tool wear monitoring, learning Years of publication: 2010–2020 Thematic areas: engineering, no micro cutting, only metal materials Type of article: review article and research article | 97 | |

| FIFTH | Research title: tool wear monitoring, learning Years of publication: 2010–2020 Thematic areas: engineering, no micro cutting, only metal materials Type of article: review article and research article. In direct and indirect methods of tool wear measurement, measurement through images, i.e., cameras, optical measurements, is not considered | 77 |

| General and Essential Requirements | |||||

|---|---|---|---|---|---|

| Machining Operations | Articles | Type of Wear | Type of Tool | Type of Material | Type of Machine |

| Milling | [8] | VB | high speed steel mill | Super alloy: Titanium alloy | vertical machine |

| Drilling | [9] | VB | carbide drill | Super alloy and Steel: Inconel718 and C45 | vertical machine |

| Milling | [10] | VB | high speed steel mill | Alluminium: Hardened 6061 | vertical machine |

| Milling | [11] | VB | insert mill | Alluminium: alluminimu alloy | vertical machine |

| Milling | [12] | VB and RUL | insert mill | / | vertical machine |

| Milling | [13] | VB | carbide mill | Alluminium: 6061 alluminium | vertical machine |

| Milling | [14] | VB | insert mill | Super alloy: Titanium alloy | vertical machine |

| Milling | [15] | VB | insert mill | / | vertical machine |

| Milling | [16] | VB | insert mill | Super alloy: Inconel 718 | vertical machine |

| Milling | [17] | VB | insert mill | Steel: C45 | vertical machine |

| Turning | [18] | VB | cemented carbide tool inserts | / | lathe machine |

| Milling | [19] | VB | insert mill | Super alloy: Ti6Al4V | vertical machine |

| Milling | [20] | VB | carbide mill | Steel: Stainless steel | vertical machine |

| Turning | [21] | VB | uncoated carbide inserts CNMG120408 | Super alloy: Inconel 718 | lathe machine |

| Milling | [22] | VB | high speed steel mill | Alluminium: aluminum alloys 5053-H111, 6082-T6, 2024-T3, 7022-T6, 7075-T6 | vertical machine |

| Turning | [23] | VB | tool inserts TNMM 110408 P25 | Steel: 42CrMo4 | lathe machine |

| Turning | [24] | VB | insert CNMG120404-MB NC30P grade 5 | Steel: JIS S45C carbon steel | lathe machine |

| Milling | [25] | VB | insert mill | / | vertical machine |

| Turning | [26] | VB | coated carbide insert CNMG120408 SM 1105 | Super alloy: Inconel 718 | lathe machine |

| Milling | [27] | VB | insert mill | Super alloy: Ti-6AI-4V | vartical machine |

| Turning | [28] | VB | turning tool | Super alloy: Inconel 718 | lathe machine |

| Drilling | [29] | VB | high speed steel drill | Super alloy: Inconel 625 | vertical machine |

| Turning | [30] | VB | carbide insert TNMG160408 | Steel: Mild steel | lathe machine |

| Turning | [31] | VB | carbide insert CNMG120408 MF1 CP200 | Super alloy: Titanium Metal matrix Composite (Ti MMC) 10 wt% TiC/Ti-6Al-4V | lathe machine |

| Milling | [32] | VB | insert mill | Super alloy: Titanium alloy Ti-5Al-5Mo-5V-1Cr-1Fe | vertical machine |

| Milling | [33] | VB | carbide mill | Steel: steel block of S235JR | vertical machine |

| Milling | [34] | VB | insert mill | Super alloy: Ti-6Al-4V | vertical machine |

| Milling | [35] | VB | insert mill | Super alloy: Ti-6Al-4V | vertical machine |

| Turning | [36] | VB | coated sintered carbide insert SNUN120408 | / | lathe machine |

| Milling | [37] | VB | high speed steel mill | Alluminium:6082 Alluminium | vertical machine |

| Milling | [38] | VB and RUL | carbide mill | Super alloy: Titanium alloy | vertical machine |

| Milling | [39] | RUL | carbide mill | Super alloy: Titanium alloy | vertical machine |

| Turning | [40] | VB | Uncoated carbide inserts SPGN 422, grade K68. Ceramic inserts Greenleaf SNGN 452, grade WG-300 | Steel and Super alloy: 4140 steel (HRC35), Inconel 718 and Ti-6Al-4V | lathe machine |

| Milling | [41] | VB and RUL | insert mill | Steel: stainless-steel | vertical machine |

| Milling | [42] | VB | carbide mill | Stell and Super alloy: C45 steel, Inconel 718 | vertical machine |

| Drilling | [43] | VB | carbide drill | / | vertical machine |

| Milling | [44] | VB | insert mill | Steel: 1018 steel at 121 HB hardness | vertical machine |

| Milling | [45] | VB, breakage and chipping | insert mill | Steel: 42CrMo4 | vertical machine |

| Milling | [46] | VB | insert mill | Steel: 1018 steel at 121 HB hardness | vertical machine |

| Milling | [47] | VB | carbide mill | / | vertical machine |

| Milling | [48] | VB and tool breakage. | high speed steel mill | Steel: 1040 cold rolled steel | vertical machine |

| Drilling | [49] | VB | high speed steel drill | Steel: AISI 316 stainless steel plate | vertical machine |

| Milling | [50] | VB | insert mill | Steel: stainless steel, HRC52 | vertical machine |

| Drilling | [51] | VB | high speed steel drill | Steel: mild-steel | vertical machine |

| Milling | [52] | VB and roughness | insert mill | Stell and Super alloy: H13 steel and Inconel 718 | vertical machine |

| Milling | [53] | VB | insert mill | Super alloy: titanium alloy | vertical machine |

| Milling | [54] | VB | insert mill | / | vertical machine |

| Milling Turning Drilling | [55] | VB, RUL chipping, breakage, corner wear, rake wear, notch wear | milling tool, turning tool, drilling tool | Ti- and Ni-based alloys, hardened steels, aluminum alloys | vertical machine, turning machine |

| Milling | [56] | VB and RUL | insert mill | cast iron: cast iron and stainless steel J45 | vertical machine |

| Milling | [57] | RUL | insert mill | cast iron: cast iron and stainless steel J45 | vertical machine |

| Milling | [58] | VB | carbide mill | Steel: stainless steel, HRC52 | vertical machine |

| Turning | [59] | VB | carbide insert | Steel: AISI 316 stainless steel | lathe machine |

| Milling | [60] | VB | carbide mill | Steel: material AISI M3:2, hardened to 62 HRC | vertical machine |

| Milling | [61] | VB | carbide mill | Super alloy: Ti-6Al-4V titanium | vertical machine |

| Milling | [62] | VB | carbide mill | Steel: Tempered steel C45 | vertical machine |

| Milling | [63] | VB | insert mill | Super alloy: Ti6Al4V alloy | vertical machine |

| Milling | [64] | VB | insert mill | Super alloy: Ti–6Al–4V | vertical machine |

| Milling | [65] | VB | carbide mill | Super alloy: Inconel 718 | vertical machine |

| Turning | [66] | VB, roughness and breakage | turning tool | Metal alloy | lathe machine |

| Milling | [67] | VB, breakage, light wear, middle wear, severe wear, sharp tool, worn tool, chipping | Carbide mill, insert mill, high speed steel mill | Super alloy, steel alloy and alluminium alloy | vertical machine |

| Turning | [68] | VB | Carbide insert CNMG-432 | Alluminium: aluminum alloy 6061 | lathe machine |

| Turning | [69] | VB | Carbide WNMG 084 08- QM | Steel alloy: stainless steel AISI 316 | lathe machine |

| Turning | [70] | Tool wear rate | uncoated carbide insert CCMT 060204 TT. | cast iron: cast iron (grey cast iron-FG 15) and an alloy steel (En 24) | lathe machine |

| Milling | [71] | VB | carbide mill | Super alloy: Inconel 718 | vertical machine |

| Milling | [72] | VB | insert mill | Steel: 1018 steel | vertical machine |

| Milling | [73] | VB | insert mill | Steel: 42CrMo4 | vertical machine |

| Milling | [74] | VB | insert mill | Steel: ASSAB718HH | vertical machine |

| Milling | [75] | VB | insert mill | cast iron: CGI 450 | vertical machine |

| Milling | [76] | RUL | carbide mill | Steel: tempered steel (HRC52) | vertical machine |

| Milling | [77] | tool wear status | insert mill | Super alloy: Ti-6Al-4V | vertical machine |

| Milling | [78] | tool wear rate, RUL | carbide mill | / | vertical machine |

| Turning | [79] | VB | ceramic insert CNMG120408-HM | Steel: C45 steel | lathe machine |

| Turning | [80] | VB | round ceramic inserts RNGN CC670 | Super alloy: Inconel 625 | lathe machine |

| Milling | [81] | VB | carbide mill | Super alloy; Inconel 718 | vertical machine |

| Turning | [82] | roughness | coated carbide insert TiCN/Al2O3/TiN | Steel: AISI 1060 | lathe machine |

| Turning | [83] | VB | carbide insert | Alluminium: alluminum alloy | lathe machine |

| Cutting Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Machining Operations | Articles | Cutting SPEED | Spindle Speed | Depht of Cut, Radial Depht of Cut and Axial Depht of Cut | Feed, Feed Rate, Feed for Tooth | Diameter of Tool | Lubrificant |

| Milling | [8] | x | x | x | |||

| Drilling | [9] | x | |||||

| Milling | [10] | x | x | ||||

| Milling | [11] | x | x | x | |||

| Milling | [12] | x | x | x | |||

| Milling | [13] | x | x | ||||

| Milling | [14] | x | x | x | |||

| Milling | [15] | x | x | x | |||

| Milling | [16] | x | x | x | |||

| Milling | [17] | x | x | x | |||

| Turning | [18] | x | x | x | |||

| Milling | [19] | x | x | x | |||

| Milling | [20] | x | x | x | |||

| Turning | [21] | x | x | x | |||

| Milling | [22] | x | x | x | |||

| Turning | [23] | x | x | ||||

| Turning | [24] | x | x | x | |||

| Milling | [25] | x | x | ||||

| Turning | [26] | x | x | x | |||

| Milling | [27] | x | x | x | |||

| Turning | [28] | x | x | x | |||

| Drilling | [29] | x | x | ||||

| Turning | [30] | x | x | x | |||

| Turning | [31] | x | x | x | |||

| Milling | [32] | x | x | x | |||

| Milling | [33] | x | x | x | |||

| Milling | [34] | x | x | x | |||

| Milling | [35] | x | x | ||||

| Turning | [36] | x | |||||

| Milling | [37] | x | x | x | |||

| Milling | [38] | x | x | ||||

| Milling | [39] | x | x | x | |||

| Turning | [40] | x | x | x | |||

| Milling | [41] | x | x | x | |||

| Milling | [42] | x | x | x | |||

| Milling | [44] | x | x | ||||

| Milling | [45] | x | x | x | |||

| Milling | [46] | x | x | ||||

| Milling | [47] | x | x | x | |||

| Milling | [48] | x | x | ||||

| Drilling | [49] | x | x | x | |||

| Milling | [50] | x | x | x | |||

| Drilling | [51] | x | x | x | |||

| Milling | [52] | x | x | x | |||

| Milling | [53] | x | x | x | |||

| Milling | [54] | x | x | x | |||

| Milling Turning Drilling | [55] | x | x | x | x | ||

| Milling | [56] | x | x | x | |||

| Milling | [57] | x | x | ||||

| Milling | [58] | x | x | x | |||

| Turning | [59] | x | |||||

| Milling | [60] | x | x | ||||

| Milling | [61] | x | x | x | |||

| Milling | [62] | x | x | x | |||

| Milling | [63] | x | x | ||||

| Milling | [64] | x | x | x | |||

| Milling | [65] | x | x | x | |||

| Turning | [66] | x | x | x | |||

| Milling | [67] | x | x | x | |||

| Turning | [68] | x | x | x | |||

| Turning | [69] | x | x | ||||

| Turning | [70] | x | x | x | |||

| Milling | [71] | x | x | ||||

| Milling | [72] | x | x | x | |||

| Milling | [73] | x | x | x | |||

| Milling | [74] | x | x | x | |||

| Milling | [75] | x | x | x | |||

| Milling | [76] | x | x | x | |||

| Milling | [77] | x | x | x | |||

| Milling | [78] | x | x | x | |||

| Turning | [79] | x | x | x | |||

| Turning | [80] | x | x | x | |||

| Milling | [81] | x | x | x | |||

| Turning | [82] | x | x | x | |||

| Turning | [83] | x | x | x | |||

| TURNING | Articles | Cutting Force Signal | Vibration | Acoustic Emission Signal | Sound | Current | Power | Number of Signals |

| [18] | x | 1 | ||||||

| [21] | x | x | x | 3 | ||||

| [23] | x | 1 | ||||||

| [24] | x | x | 2 | |||||

| [26] | x | x | 2 | |||||

| [27] | x | 1 | ||||||

| [28] | x | x | x | 3 | ||||

| [30] | x | 1 | ||||||

| [31] | x | 1 | ||||||

| [36] | x | 1 | ||||||

| [40] | x | x | 2 | |||||

| [59] | x | x | x | 3 | ||||

| [68] | x | x | 2 | |||||

| [70] | x | x | 2 | |||||

| [79] | x | x | x | 3 | ||||

| [80] | x | x | x | 3 | ||||

| [83] | x | x | 2 |

| Articles | Cutting Force Signal | Vibration | Acoustic Emission Signal | Sound | Current | Power | Number of Signals |

|---|---|---|---|---|---|---|---|

| [8] | x | x | x | 2 | |||

| [10] | x | 1 | |||||

| [11] | x | 2 | |||||

| [12] | x | x | x | 3 | |||

| [13] | x | 1 | |||||

| [14] | x | 1 | |||||

| [15] | x | 1 | |||||

| [17] | x | x | 2 | ||||

| [19] | x | x | 2 | ||||

| [20] | x | 1 | |||||

| [22] | x | x | x | 3 | |||

| [25] | x | x | 2 | ||||

| [27] | x | 1 | |||||

| [32] | x | 1 | |||||

| [33] | x | 1 | |||||

| [34] | x | 1 | |||||

| [35] | x | 1 | |||||

| [37] | x | 1 | |||||

| [38] | x | x | 2 | ||||

| [39] | x | x | 2 | ||||

| [41] | x | x | x | 3 | |||

| [42] | x | x | x | 3 | |||

| [44] | x | 1 | |||||

| [45] | x | 1 | |||||

| [46] | x | 1 | |||||

| [47] | x | x | 2 | ||||

| [48] | x | 1 | |||||

| [50] | x | x | 2 | ||||

| [52] | x | 1 | |||||

| [53] | x | 1 | |||||

| [54] | x | 1 | |||||

| [56] | x | x | 2 | ||||

| [57] | x | x | x | 3 | |||

| [58] | x | x | 2 | ||||

| [60] | x | 1 | |||||

| [61] | x | 1 | |||||

| [62] | x | 1 | |||||

| [63] | x | 1 | |||||

| [64] | x | 1 | |||||

| [65] | x | 1 | |||||

| [71] | x | x | 2 | ||||

| [72] | x | 1 | |||||

| [73] | x | 1 | |||||

| [74] | x | x | 2 | ||||

| [75] | x | x | 2 | ||||

| [76] | x | 1 | |||||

| [77] | x | 1 | |||||

| [78] | x | x | x | 3 | |||

| [81] | x | x | x | 3 |

| Studies | Cutting Force Signal | Vibration | Acoustic Emission Signal | Sound | Current | Power | Number of Signals | |

|---|---|---|---|---|---|---|---|---|

| DRILLING | [9] | x | x | 2 | ||||

| [29] | x | x | 2 | |||||

| [43] | x | x | 2 | |||||

| [49] | x | 1 | ||||||

| [51] | x | 1 |

| Articles | Signal | A.I. Methods | Performance | Performance Data |

|---|---|---|---|---|

| [10] | Sound | CNN with SGD | Predictive accuracy | (1) CNN predictive accuracy 81% |

| [11] | Current | SVM, LDA; KNN, NN, NB, DT | Accuracy | (1) SVM accuaracy 90% (2) LDA accuaracy 90% (3) DT accuaracy 84.1% (4) BN accuaracy 85% (5) NN accuaracy 85% |

| [12] | Cutting force, vibration and acoustic emission | HMM | MAPE, Mean and Accuracy | (1) HMM MAPE = 25.05 for 68% confidence level; (2) HMM MAPE = 18.37 for 95% confidence level; (3) HMM MAPE = 39.68 for 99.7% confidence level |

| [13] | Sound | CART, RF, KNN, SVM with EBCA and without EBCA | Accuracy without EBCA Accuracy with EBCA Accuracy with training set 50–60–70–80% | (1) Accuracy obtained CART, RF, KNN, SVM without EBCA about 94% (2) Accuracy obtained CART, RF, KNN, SVM with EBCA about 96% (3) CART, RF, KNN, SVM: - training set 50% accuracy from 93 to 95% - training set 60% accuracy from 96 to 97% - training set 70% accuracy from 97 to 98% - training set 80% accuracy from 98 to 99% |

| [16] | Cutting force | ANN | R, MRE, R² | (1) ANN R 0.992, (2) ANN MRE 5.42%, (3) ANN R² 0.996 |

| [19] | Cutting force,vibration | EAM ARTMAP, FUZZY ARTMAP (FAM) | Averaging recognition rate | (1) EAM averaging recognition rate 98.67% (2) FAM averaging recognition rate 89.67% |

| [20] | Cutting force | CNN, AC | Predicted Rapid initial wear, Predicted Uniform wear, Predicted Failure wear Accuracy % | (1) CNN accuarcy 90% |

| [27] | Cutting force | RVM with KPCA-IRBF | RMSE, CI_widht/CI_var | (1) KPCA_IRBF can reduce the mean square error (RMSE) of RVM by more than 30%. (2) mean width of CI by more than 90% |

| [34] | Cutting force | Kalman filter | RMSE | (1) RMSE decreases when force data is taken from the measured signal equation. |

| [35] | Acoustic emission | CRF and HMM | Accuracy rate | (1) The accuracy rate of the HMM is lower than the CRF model for each state of tool wear |

| [39] | Cutting force, current | SVM, RF and feedforrward NN | Score, RMSE and Accuracy | (1) RF score 64.04 (2) RF accuaracy 71% (3) RMSE indicating prediction error decreases by 4% and 12% with respect to SVR and feedforward NN |

| Articles | Signal | A.I. Methods | Performance | Performance Data |

| [44] | Sound | GAN | Accuracy, non-conforming tool | (1) GAN accuracy 90.56% (2) GAN non-confroming tool reduced from 16.65% to 4.52% |

| [45] | Vibration | K-star | Positive rate (TP rate) and False positive rate (FP rate) and Accuracy | K-star accuracy 96.5 % |

| [46] | Sound | DCNN | Accuracy | DCNN accuracy from 81% to 100% |

| [52] | Power | NN inconrporate CNN and RNN NN incorporate RNN | Accuracy | (1) NN (CNN and RNN) accuracy from 82% to 90% (2) NN (RNN) accuracy 85% |

| [53] | Cutting force | ARTMAP (GAM) | accuracy | ARTMAP (GAM) accuracy from 89% to 100% |

| [61] | Cutting force | DE-SVR | Accuracy VB and Acccuracy RUL | (1) DE-SVR accuracy VB 88% (2) DE-SVR accuracy RUL 88.5% |

| [62] | Sound | SVM | Maximum shape error | SVM maximum shape error 70% |

| [63] | Vibration | SVM with TIPM SVM without TIPM | Accuracy | (1) SVM with TIPM accuracy 90.8 % (2) SVM with TIPM accuracy 81.9 % |

| [64] | Vibration | SVM | RMSE and Accuracy | (1) SVM RMSE 0.00475 (2) SVM Accuracy 99.6% |

| [18] | Cutting force | KPCA_IRBF | CI | (1) KPACA_IRBF CI 95% |

| [21] | Cutting force, torque, vibration acoustic emission | NN | SR | (1) NN SR force + AE 92.2 % (2) NN SR torque + AE 87.8% (3) NN SR torque + force + AE 98.9% |

| [24] | Cutting force, vibration | ANFIS algorithm | Minimum MAPE Maximum MAPE Average MAPE | In the ANFIS, MAPE depends on cutting speed vc, cutting diameter Dc and feed speed f. (1) Vc 200 mm/min Dc 1.6 mm f 0.25 mm/rev Minimum MAPE 0,48% Maximum MAPE 5.59% Average MAPE 2.3 % (2) Vc 250 mm/min Dc 1.2 mm f 0.25 mm/rev Minimum MAPE 0,96% Maximum MAPE 14.29% Average MAPE 5.08 % (3) Vc 300 mm/min Dc 0.8 mm f 0.25 mm/rev Minimum MAPE 0% Maximum MAPE 19.64% Average MAPE 4.07 % |

| [28] | Cutting force, vibration and acoustic emission | NN with PCA | SR | (1) NN SR between 79% and 98%. (2) NN Only cutting force signals SR 92%. (3) NN Only the three accelerations SR 81% (4) NN Torque and the three cutting forces SR 93% (5) NN Torque with the three accelerations SR 83% |

| [30] | Vibration | K-star | TP rate’ and ‘FP rate define the accuracy | (1) K-star accuracy 78% |

| [68] | Vibration and emission acoustic | ANN | Accuracy | ANN accuracy from 73.65% to 87.78% |

| [43] | Current and power | RF | Accuracy, R², MAE,RMSE | RF accuracy from 84% to 97.4% (1) R² 0.74 (2) RMSE 5.11 (3) MAE 4.25 microns |

| [49] | Vibration | K-star | Accuracy | (1) K-star accuracy 79.56% |

| [51] | Cutting force | RBFN with GA | MSE and % MSE | (1) RBFN MSE 2.0236% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munaro, R.; Attanasio, A.; Del Prete, A. Tool Wear Monitoring with Artificial Intelligence Methods: A Review. J. Manuf. Mater. Process. 2023, 7, 129. https://doi.org/10.3390/jmmp7040129

Munaro R, Attanasio A, Del Prete A. Tool Wear Monitoring with Artificial Intelligence Methods: A Review. Journal of Manufacturing and Materials Processing. 2023; 7(4):129. https://doi.org/10.3390/jmmp7040129

Chicago/Turabian StyleMunaro, Roberto, Aldo Attanasio, and Antonio Del Prete. 2023. "Tool Wear Monitoring with Artificial Intelligence Methods: A Review" Journal of Manufacturing and Materials Processing 7, no. 4: 129. https://doi.org/10.3390/jmmp7040129