Grid Impact of Wastewater Resource Recovery Facilities-Based Community Microgrids

Abstract

:1. Introduction

1.1. Background and Objectives

- (1)

- Discuss the energy and power requirements of WRRFs;

- (2)

- Develop approaches to assess the siting and sizing of distributed energy resources within WRRF community microgrids (CMGs);

- (3)

- Assess the benefits of WRRF community microgrids to communities and the electric grid;

- (4)

- Propose a practical way to achieve city resilience, catalyzing collaboration between critical infrastructure (CI) managers, which can ultimately result in a better understanding of CI interdependencies.

1.2. Sustainability and Resiliency Goals in New York

2. Literature Review

2.1. Microgrids

2.2. Community Microgrids

- (1)

- At high penetration levels of renewable energy sources, the power grid will be negatively impacted. For instance, a high capacity of photovoltaic leads to overgeneration (i.e., local generation exceeding demand) during the noon period. This overgeneration, if not handled with energy storage, can lead to overvoltage and eventually, the produced energy must be curtailed. In addition, noon overgeneration changes the shape of the load curve (leading to a so-called duck curve) where the demand decreases during the morning–afternoon hours and sharply increases by late afternoon through sunset. The duck curve makes it more challenging to plan unit commitment and generator dispatch and to operate the distribution grid [20,21,22]. At even higher penetration levels of bulk renewable energy deployment, synchronous generators are likely to be phased out. With fewer rotating masses in the system, the inertia needed to instantaneously stabilize frequency variations is reduced. This deteriorates the angle stability and voltage security of the transmission system. ESSs can buffer the impact of renewable energy on the grid by providing ramp control. Community microgrids can play a key role in mitigating the aforementioned negative impacts since they enable community-scale coordination of DERs.

- (2)

- Some entities may be interested in deploying microgrids (e.g., data centers and other critical facilities with high power failure costs, or cities with sustainability and resiliency goals) [15]; however, the space available to place DERs is limited. Community microgrids can contribute to making more space collectively available for DER deployment. Having large space potentially available, WRRFs can play a key role as central community resiliency hubs.

- (3)

- (4)

- Community microgrids can be built to develop a community-level mesh telecommunications network. This network gives an opportunity to individuals/households that are normally isolated to connect to other members of the community or potentially to the internet. Since community microgrids guarantee a sustainable power supply during blackouts, this local network can play a vital role during natural disasters [25,26].

- (5)

3. The Role of Community Microgrids in Future Power Grids

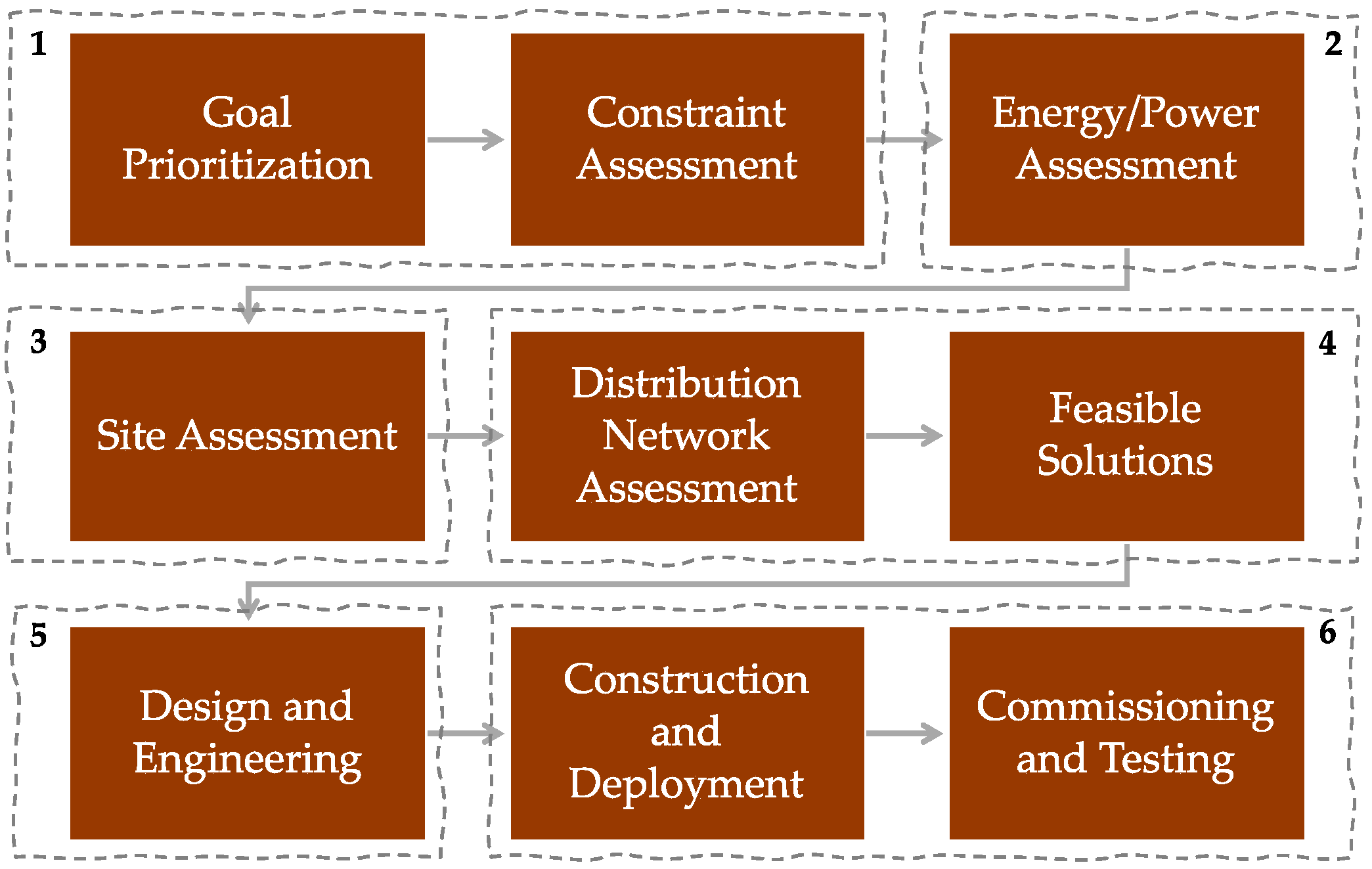

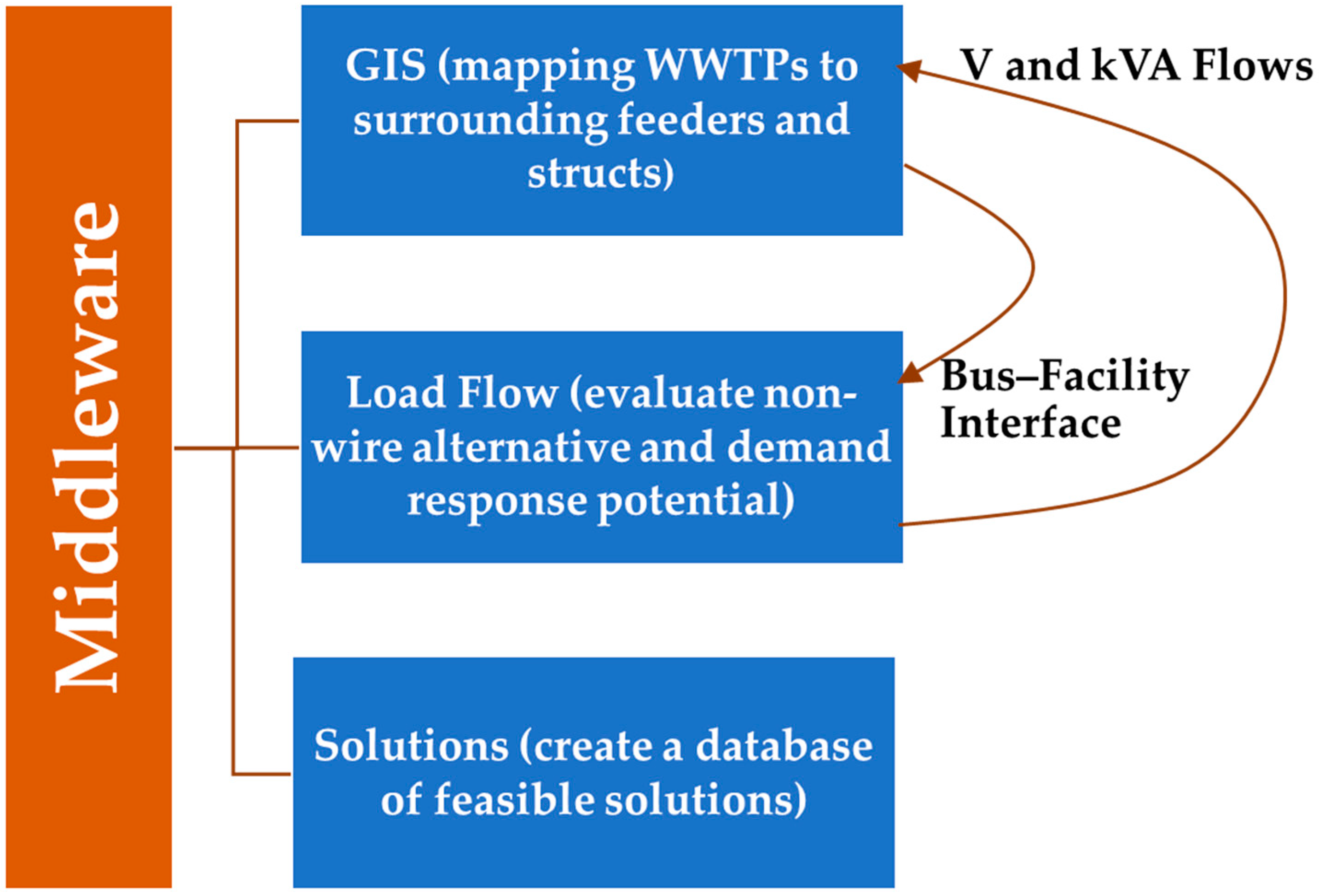

3.1. Proposed Assessment Procedure

3.2. Case Study: New York City

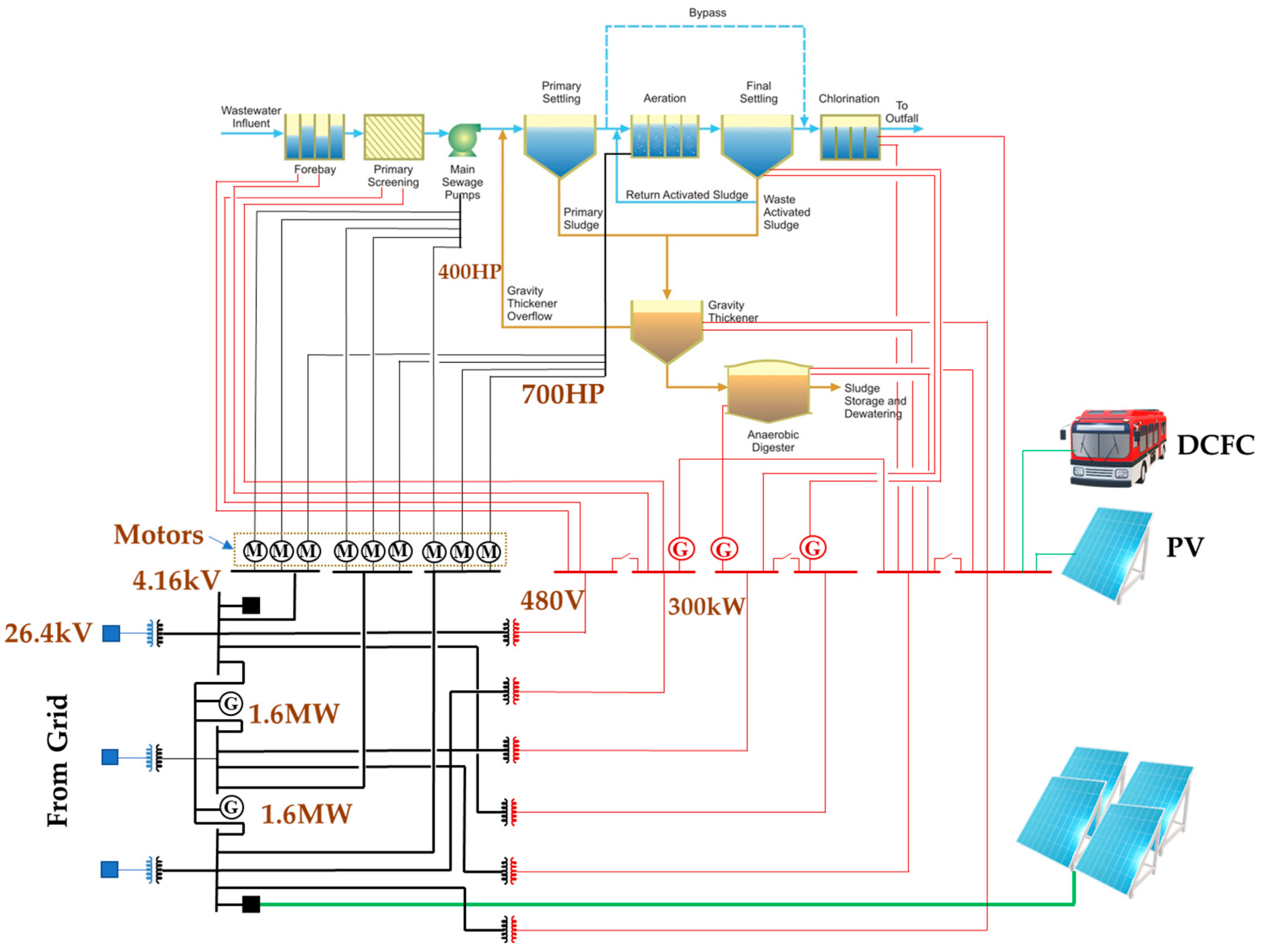

4. An Overview of WRRFs in NYC

4.1. The Treatment Process

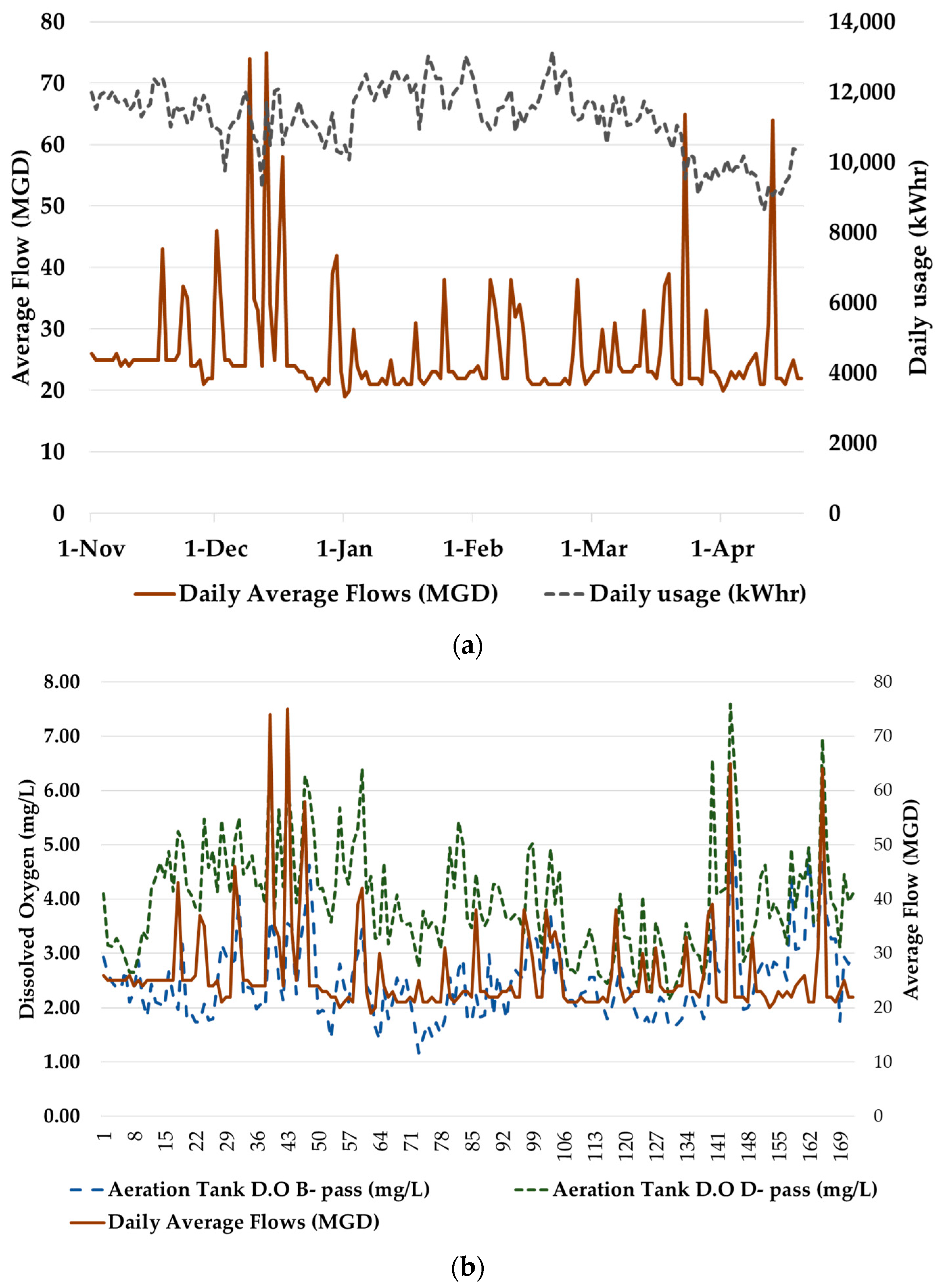

- (1)

- Monitor DO level: The DO level depends on the time of day, organic loading, temperature, and the type of diffusers. Without proper automation, it may take half an hour or more for the DO to be reduced to zero. To make process improvements and save money, fine-tuning aeration (maintaining proper DO levels) is necessary. In automatic systems, DO in each aeration tank is measured using sensors installed at each pass (aeration tanks are divided into four passes) periodically at, for instance, 15 min intervals. The data from the DO sensors are delivered to modulating valves, by which the amount of air that is blown into the aeration basin is controlled. A DO setpoint is programmed into the DO sensors, and once the DO levels rise above or drop below the setpoint, the amount of air injected into the basin is adjusted. In some WRRFs, the DO sensors are not connected to modulating valves and operators must manually control the blower output based on DO readings. Having an automatic system increases the accuracy of this control and the overall efficiency of the WRRF;

- (2)

- Adding a denitrification step: Adding a denitrification step may save energy and chemicals and benefit the environment. The nitrification process consumes a lot of energy through aeration and consumes alkalinity. On the other hand, denitrification occurs under anoxic conditions. By decreasing the DO, nitrate is further reduced to nitrogen gas;

- (3)

- Trained operators: There are some important considerations in the operation stage in terms of the successful implementation of energy efficiency measures;

- (4)

- Manual control system: WWTPs with manual controlling systems consume more energy. On the other hand, energy-efficient motors and variable frequency drives (VFDs) used by online DO analyzers and installation and maintenance equipment save cost;

- (5)

- Materials and methods: When designing an aeration tank, the key points may be listed as follows: to provide low DO in aeration tanks, to provide less mixing intensity, or to use fine- or micro-bubble aeration diffusers. The usage of fine-/micro-bubble diffusers or enhancing tank depth will increase the solubility of gases.

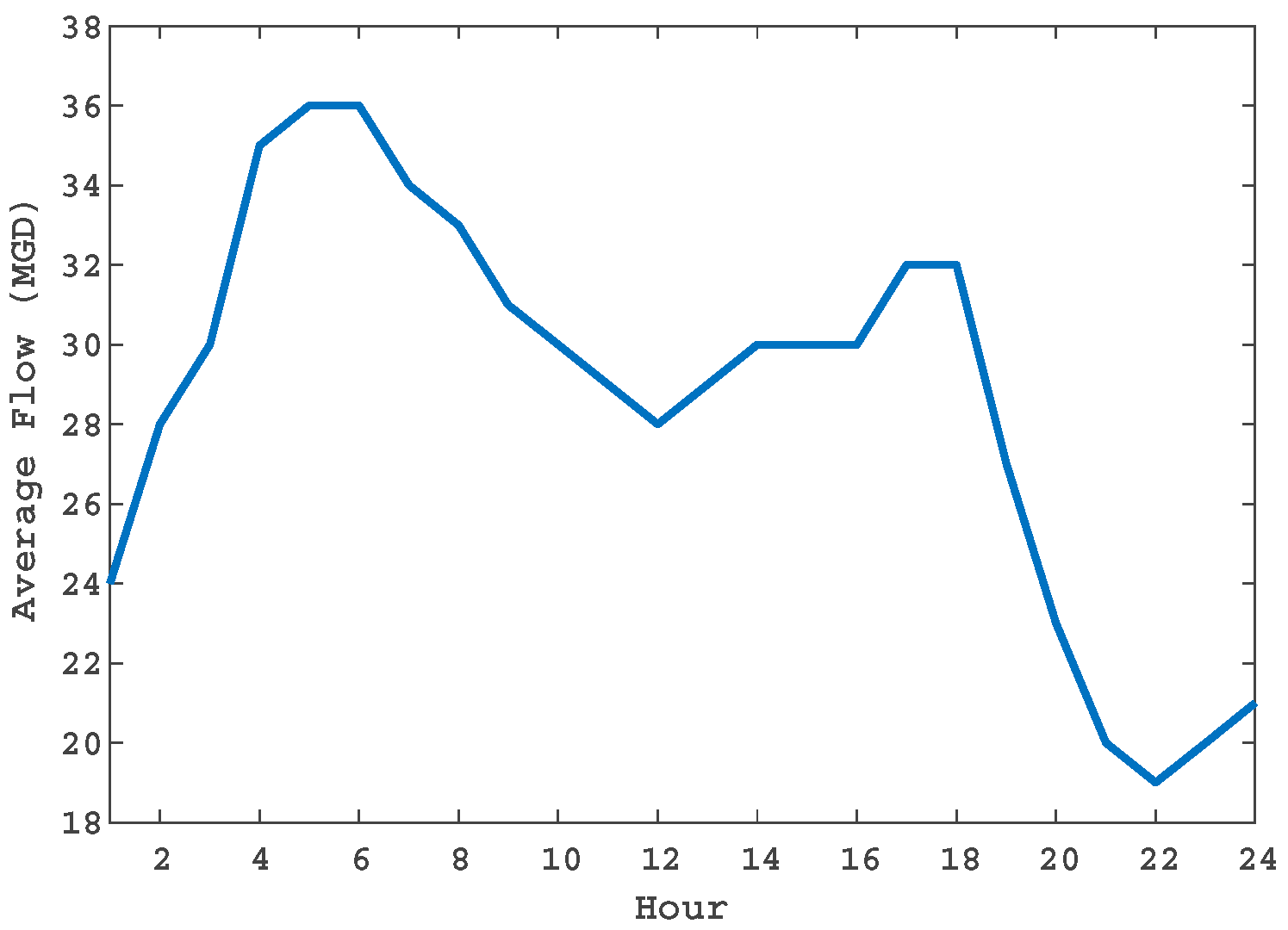

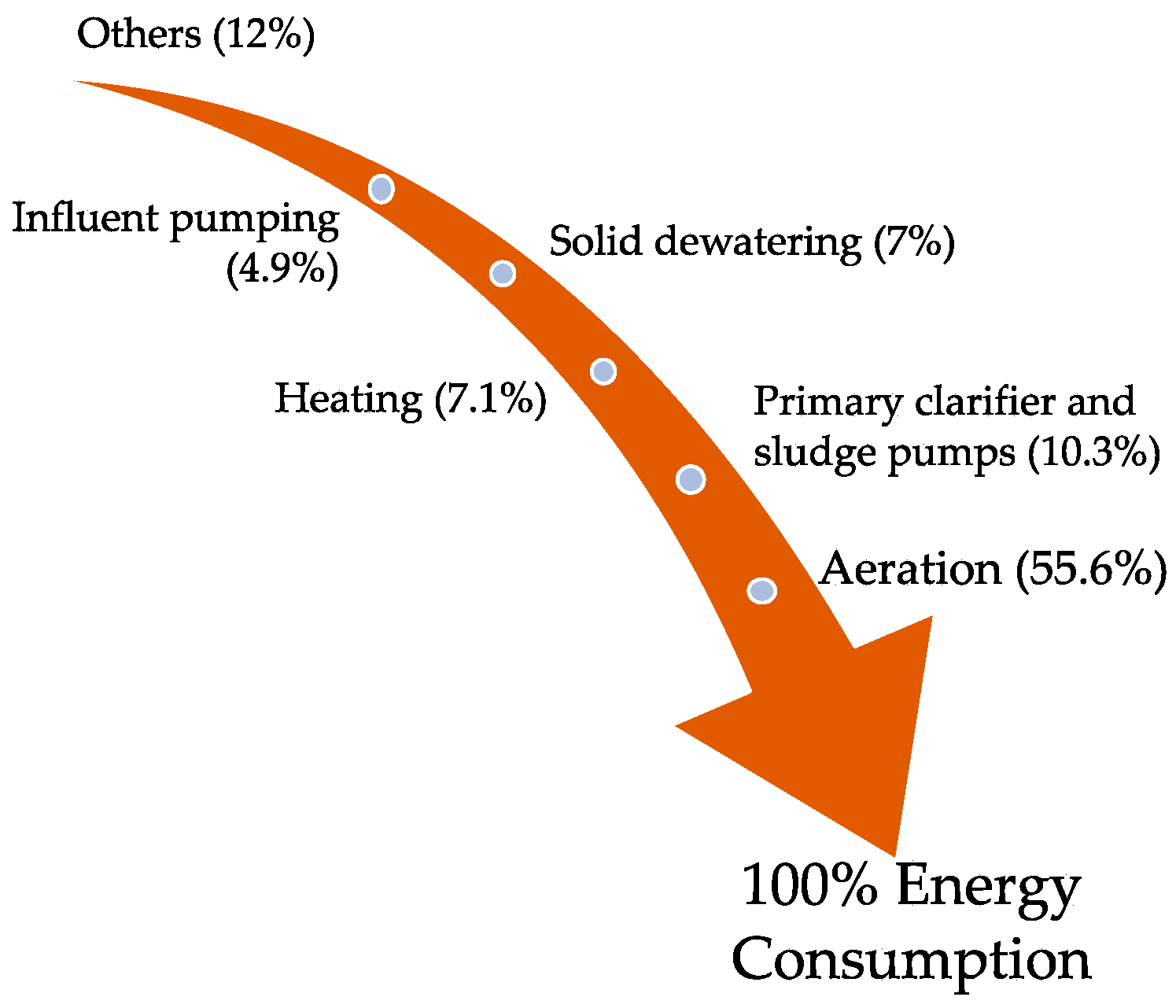

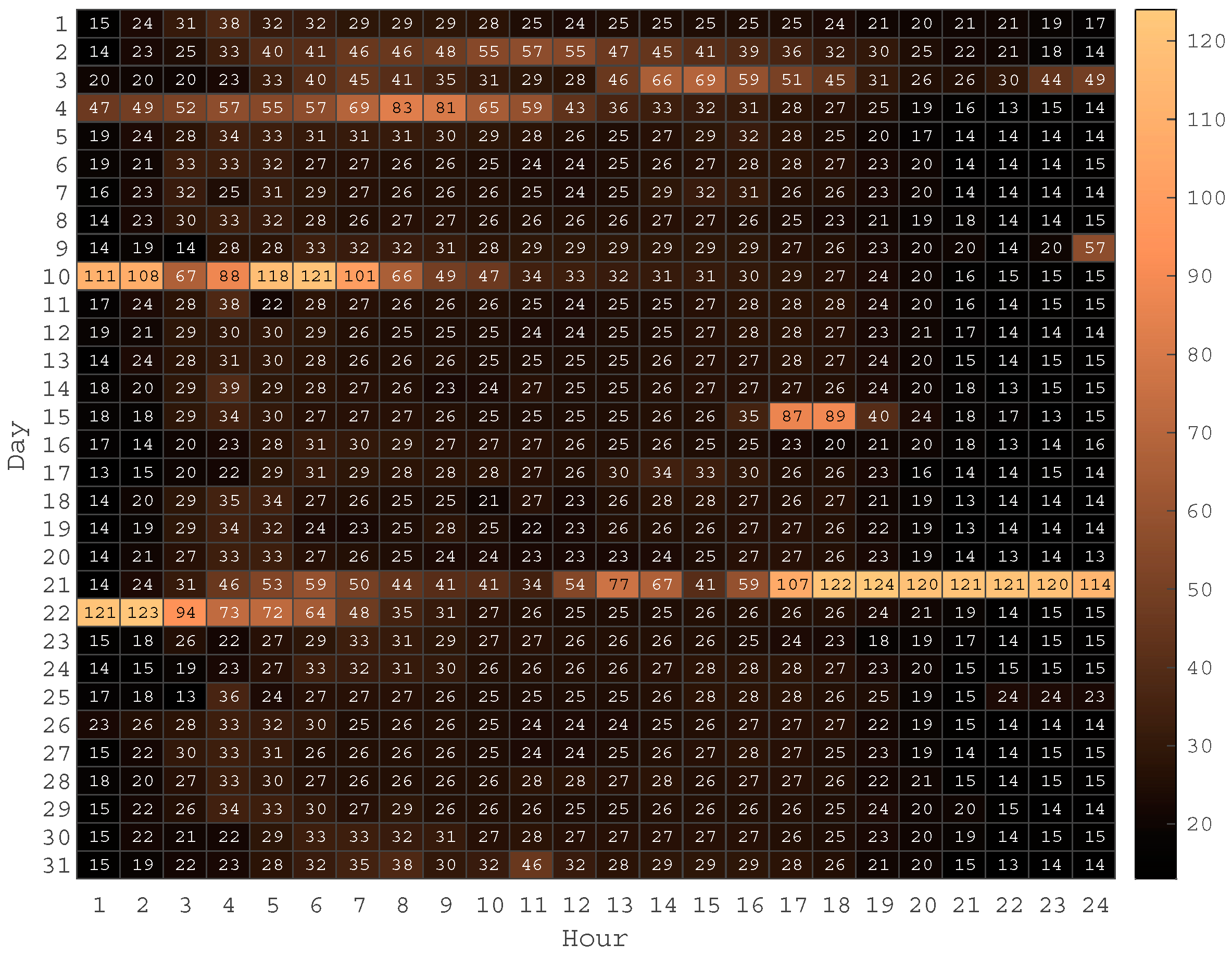

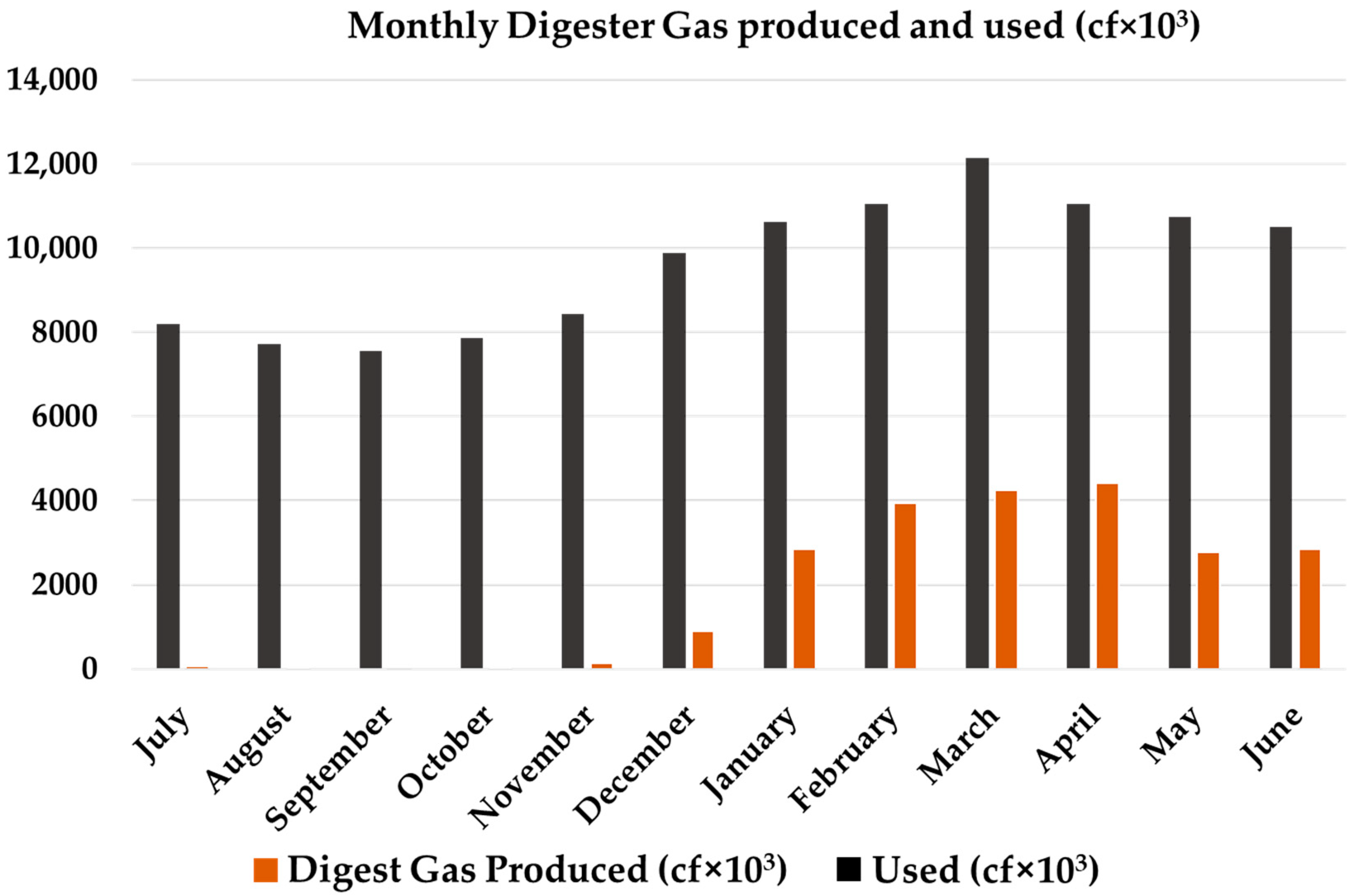

4.2. Power/Energy Assessment

5. Case Study Results and Discussion

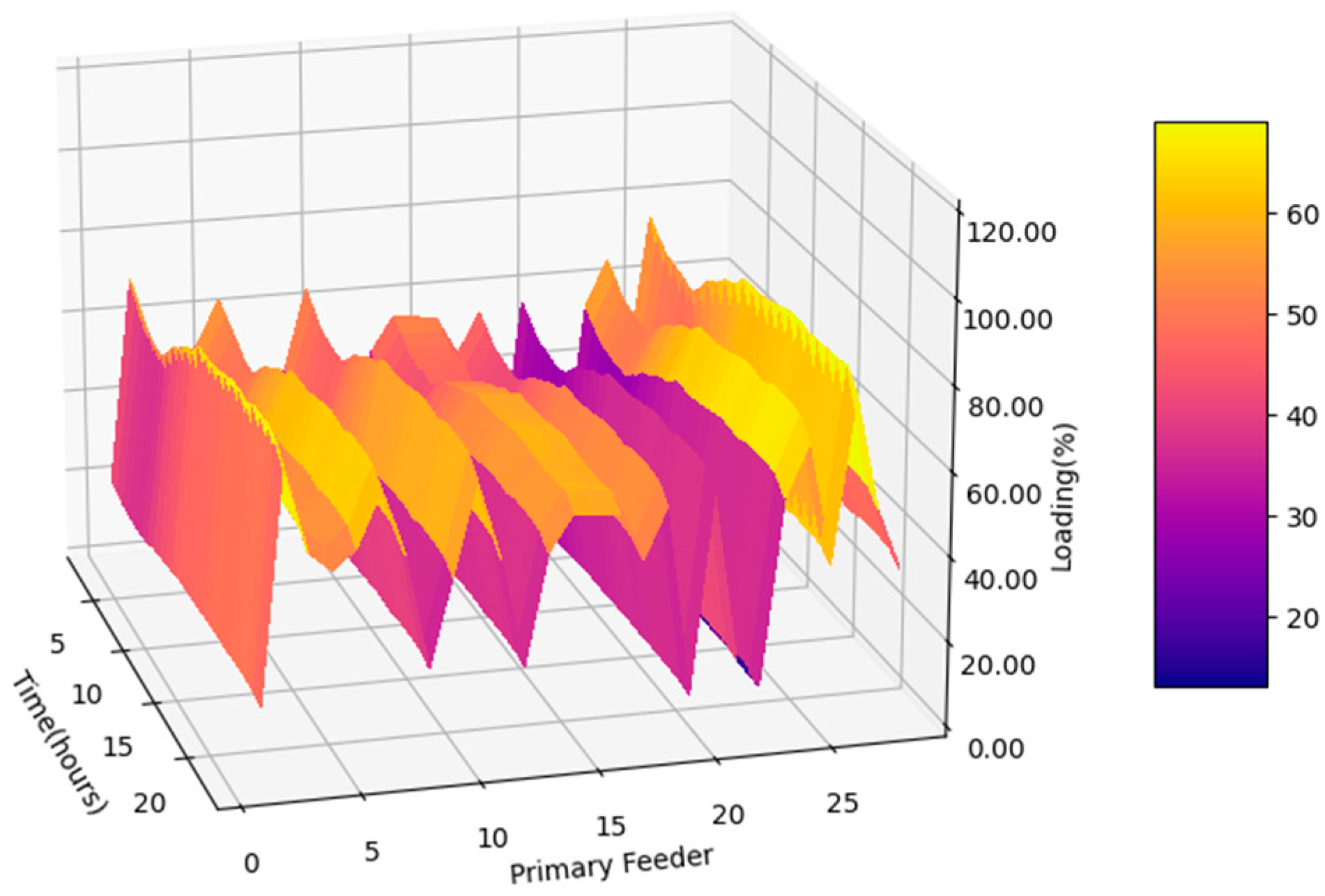

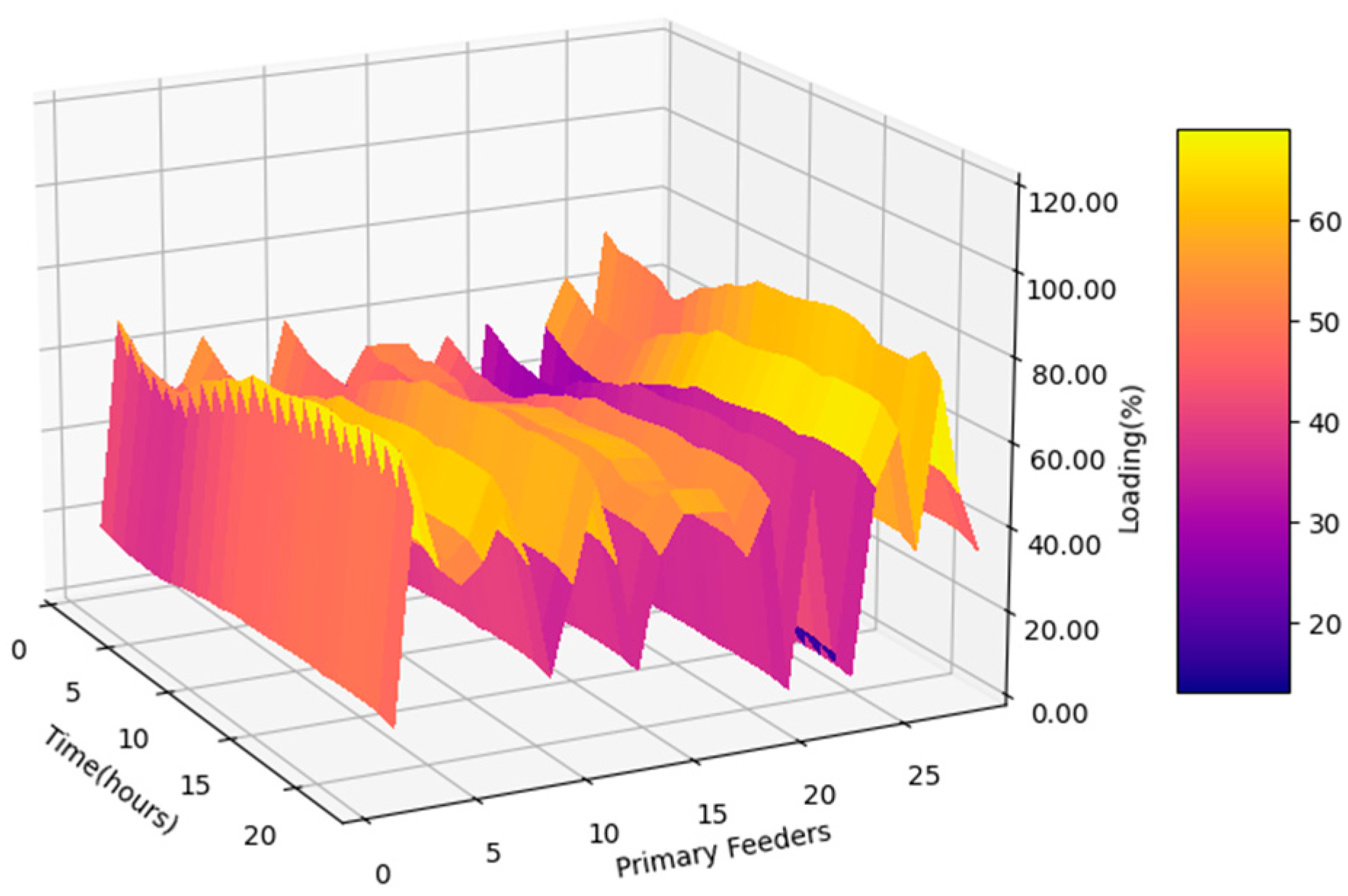

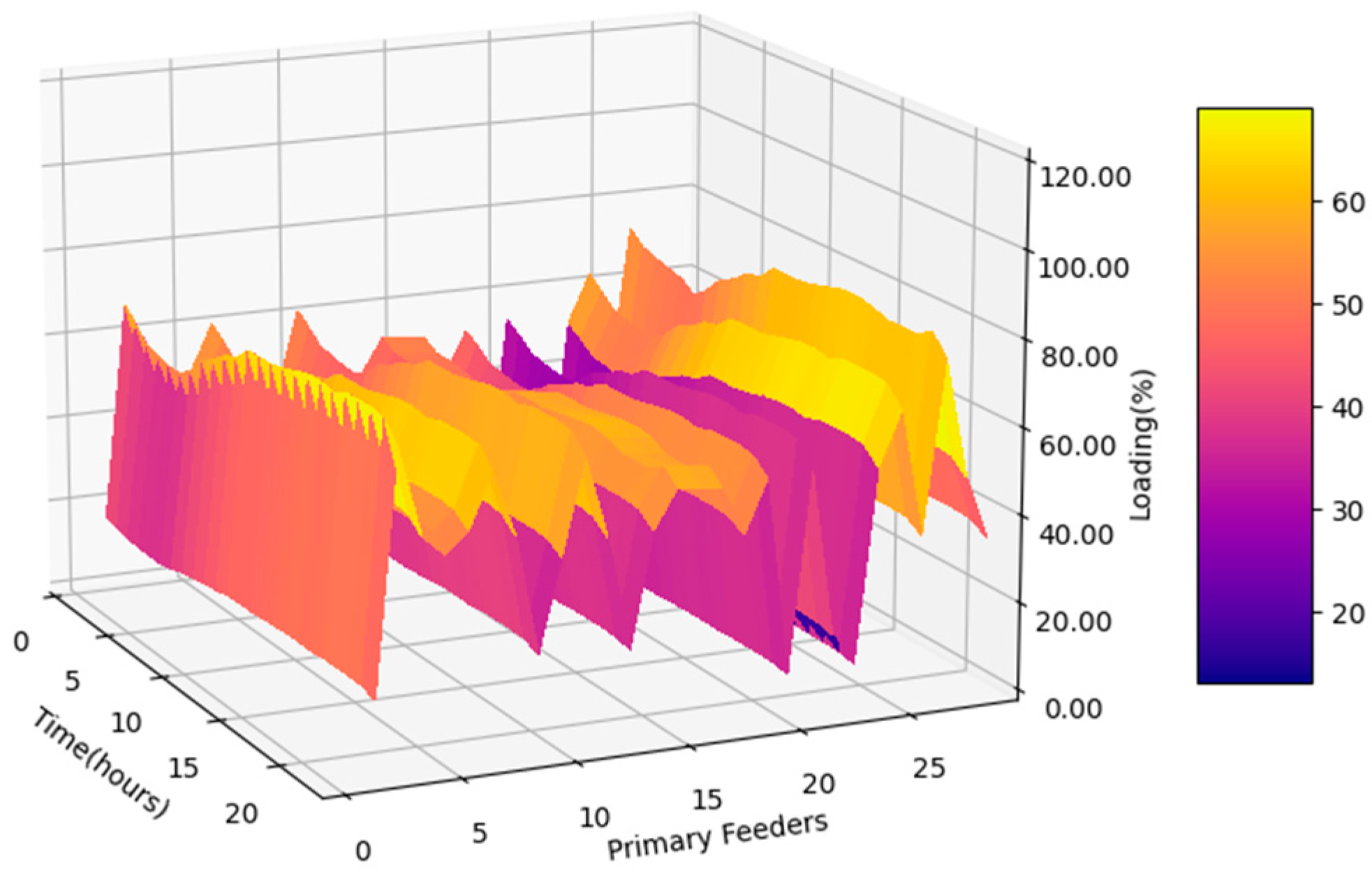

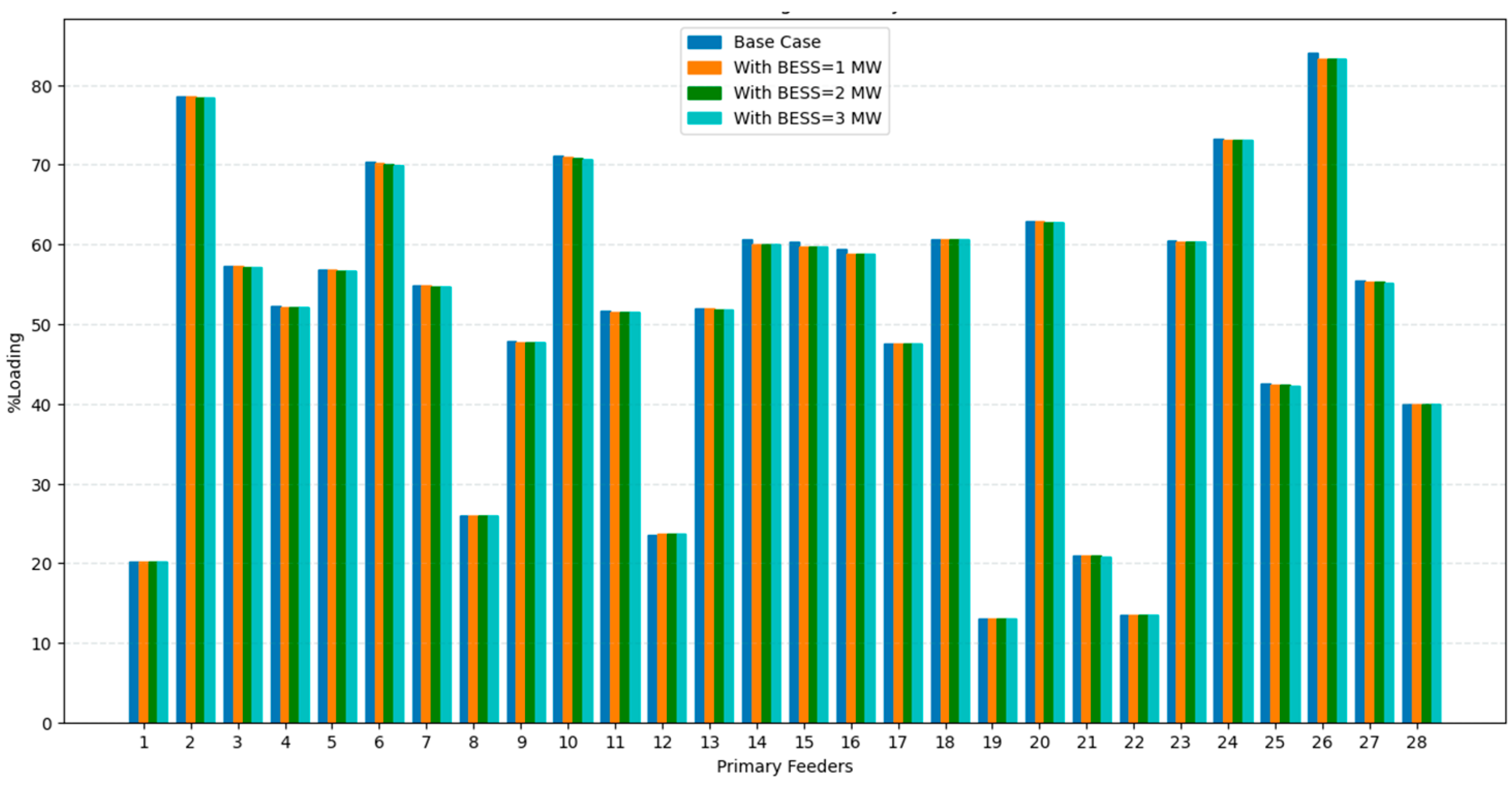

5.1. Distribution Network Assessment

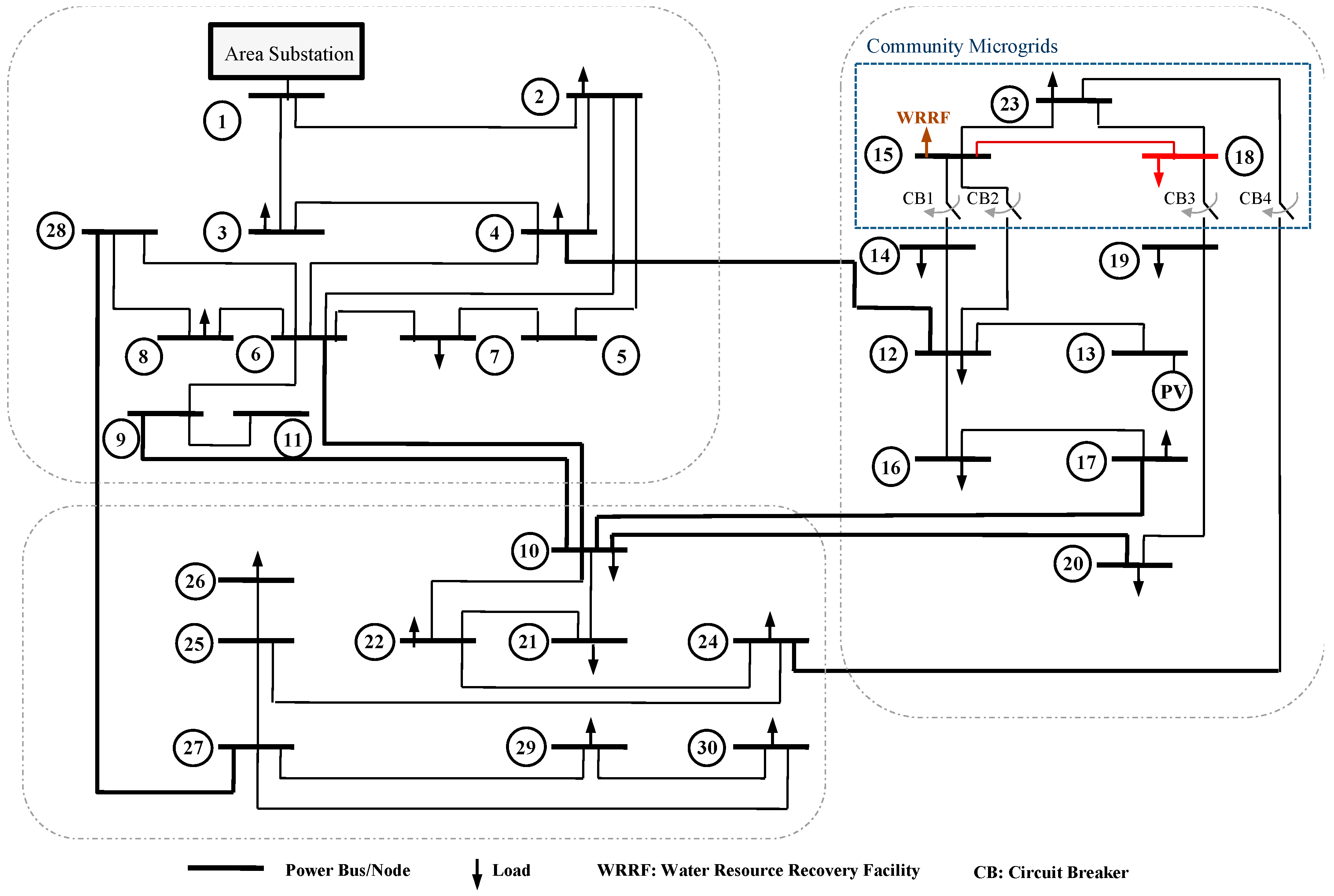

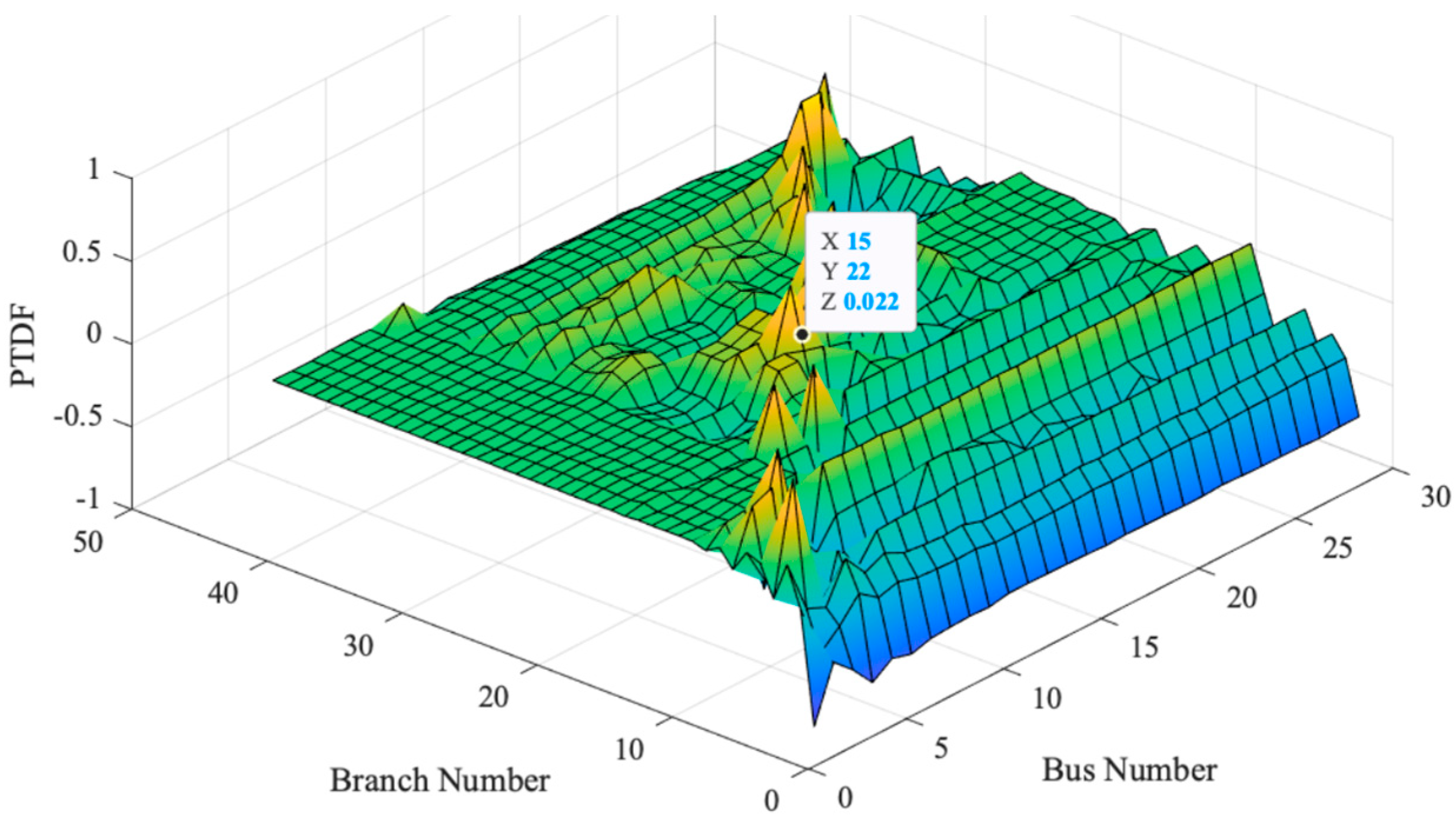

5.1.1. IEEE Standard Test Feeder

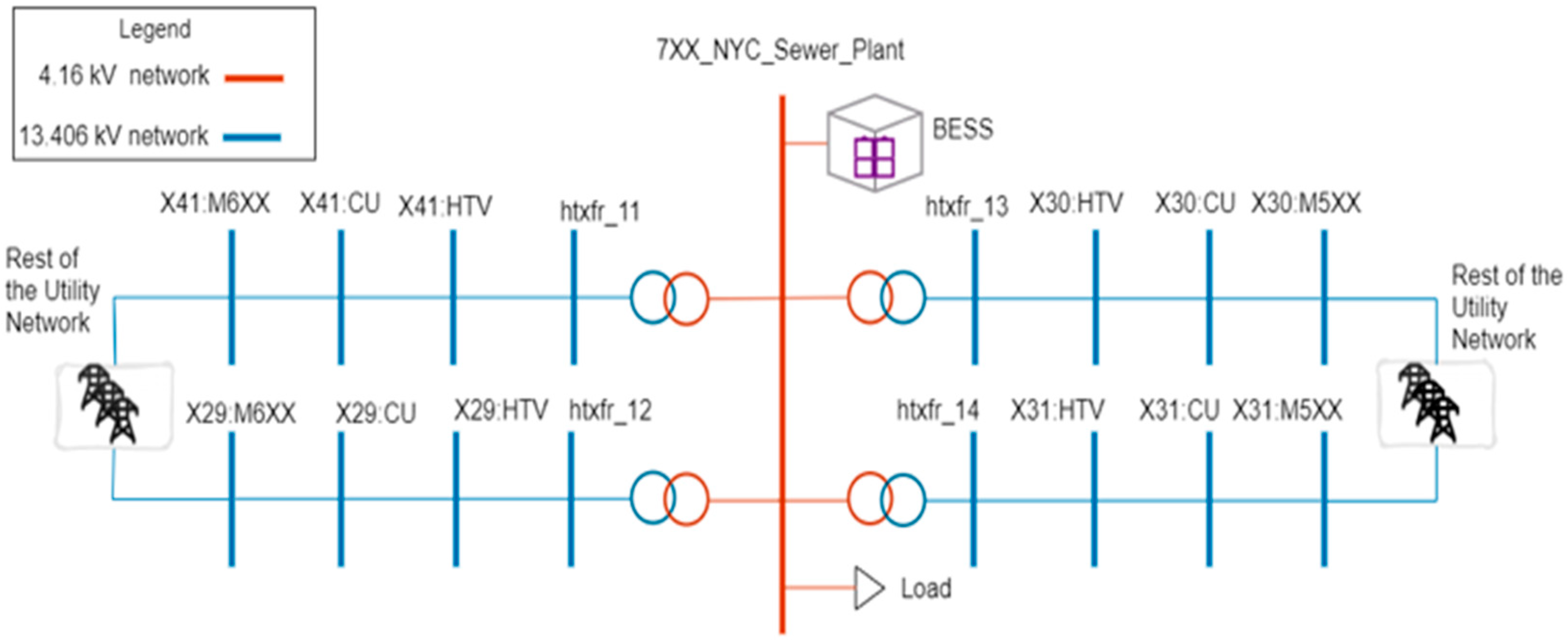

5.1.2. The NYC Power Grid

- Power is generated at power plants at 13.8 kV;

- Using step-up transformers, the voltage is stepped up to transmission voltages of 345 kV, 500 kV, or 765 kV;

- Electricity is then transferred over long distances to transmission substations or switching stations. At this point, the voltage is stepped down to sub-transmission voltages of 230 kV, 138 kV, or 69 kV;

- It is then fed into area substations, which further step the voltage down to the distribution level. Depending on the area, the voltage can vary between 13.8 kV, 27 kV, and 33 kV;

- At this point, electricity will flow through the distribution feeders emanating from the area substations. Depending on the area, these feeders can supply power to an underground network/mesh load or an overhead radial load;

- ○

- In the underground mesh network, the feeders supply power to network transformers, which step the primary distribution voltage down to 120/208 V or, in the case of high-tension customers, 265/480 V.

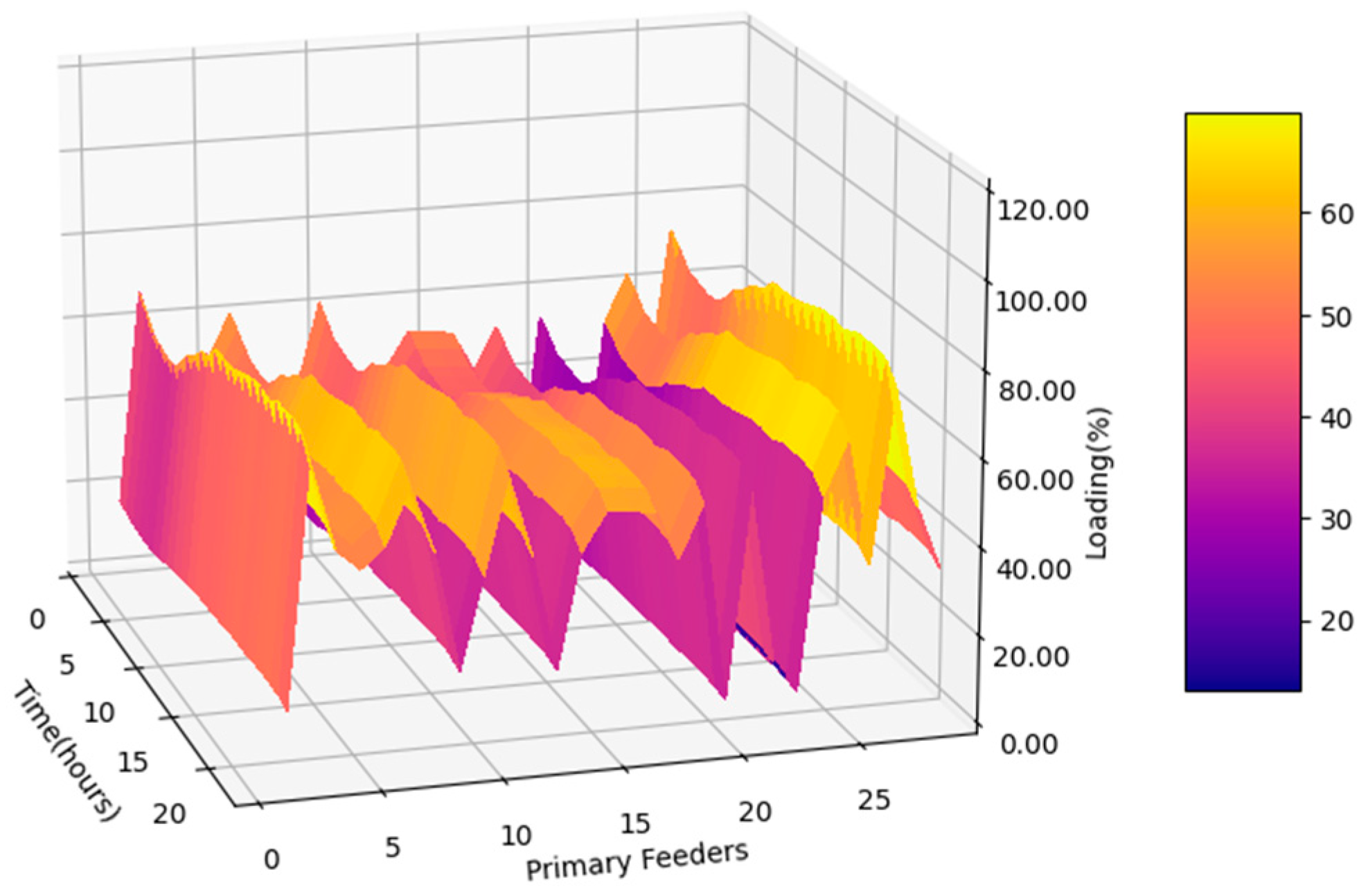

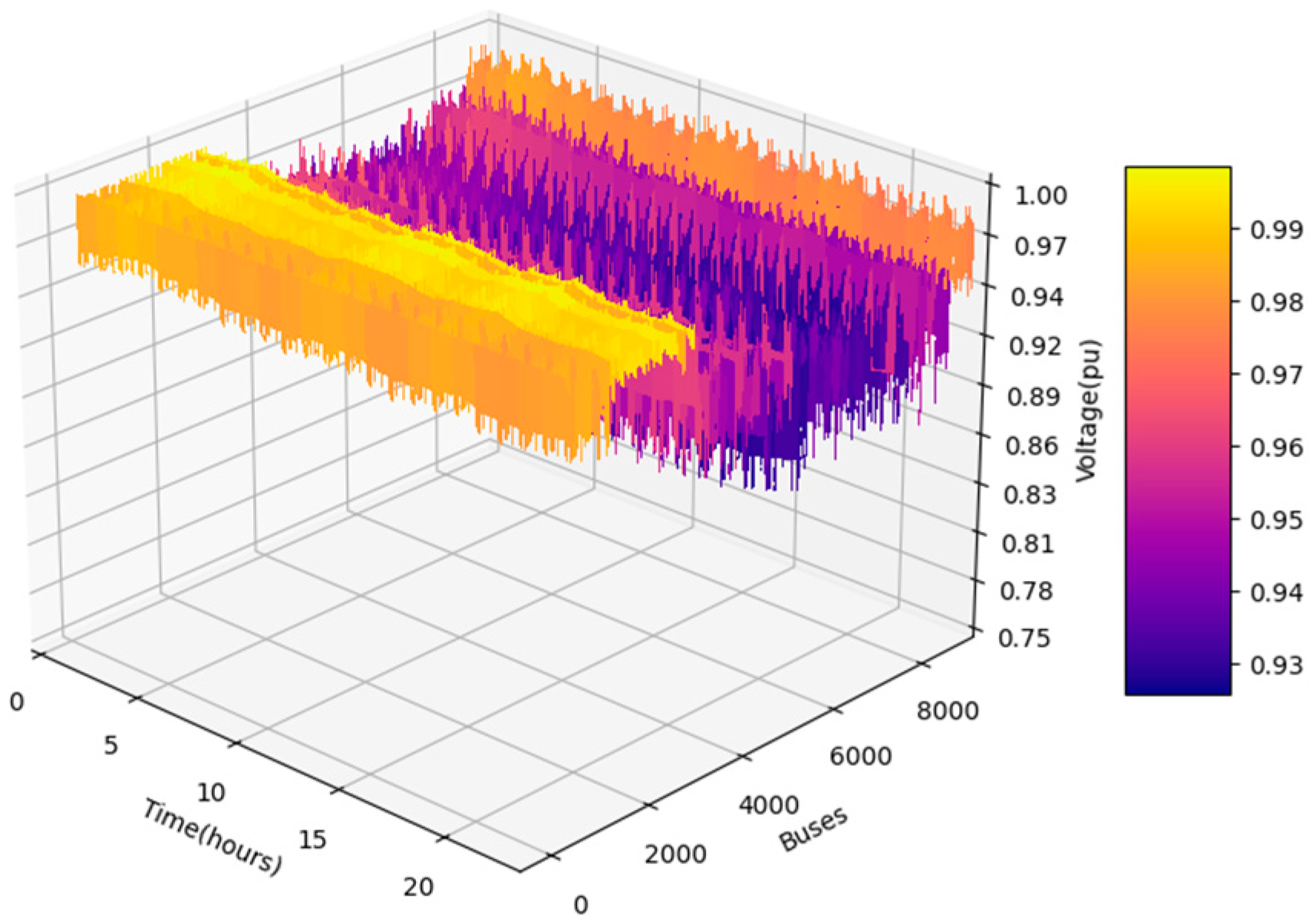

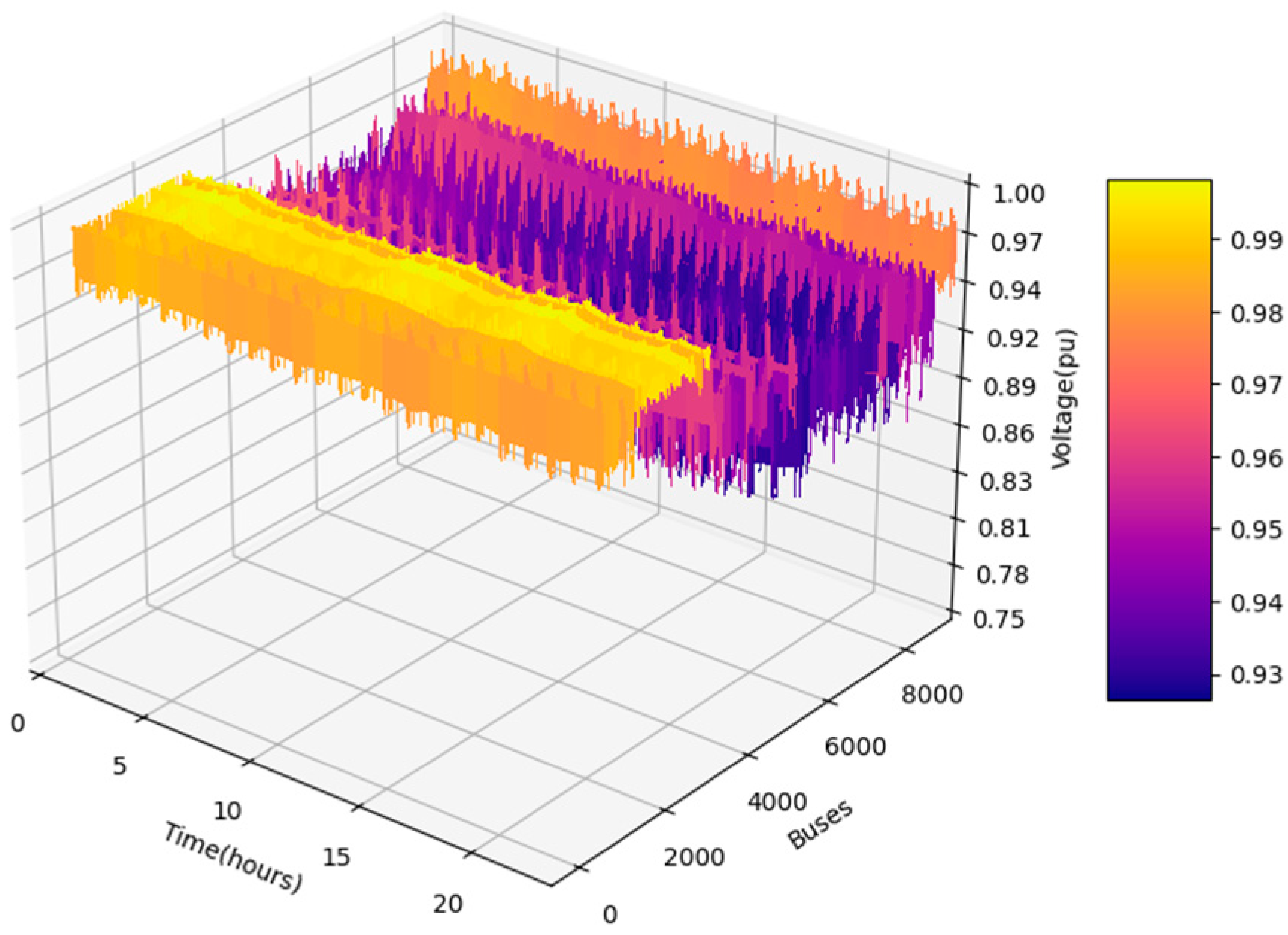

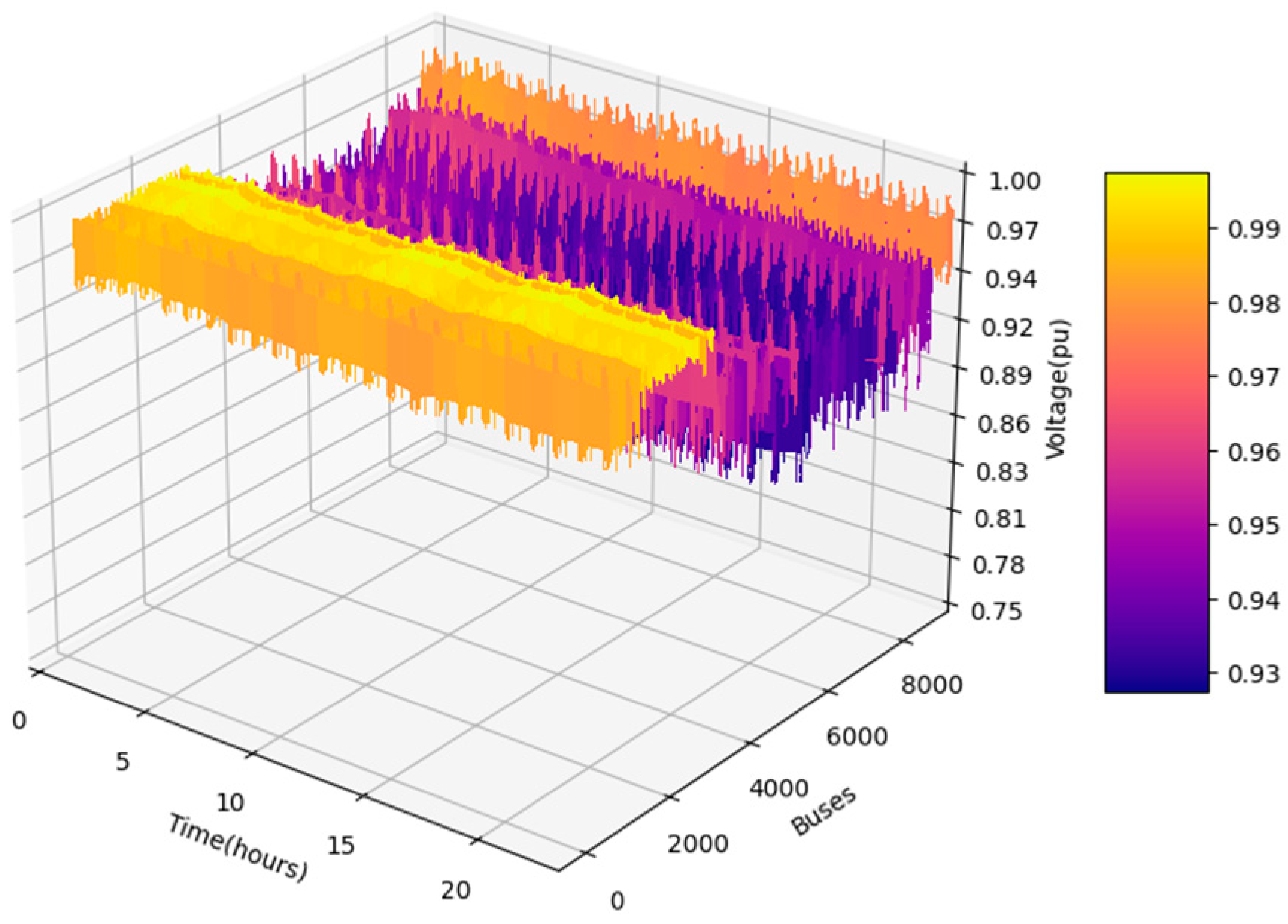

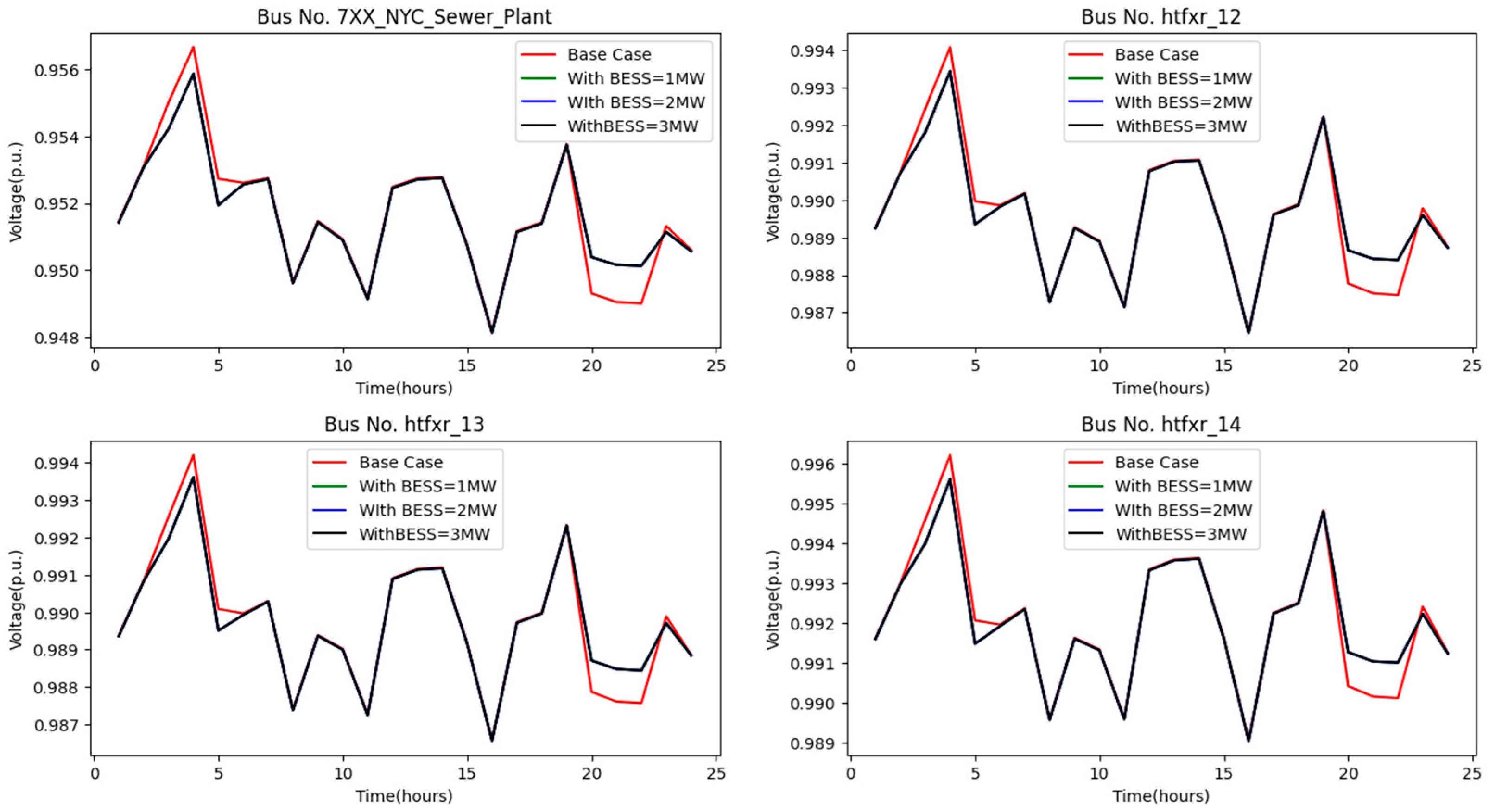

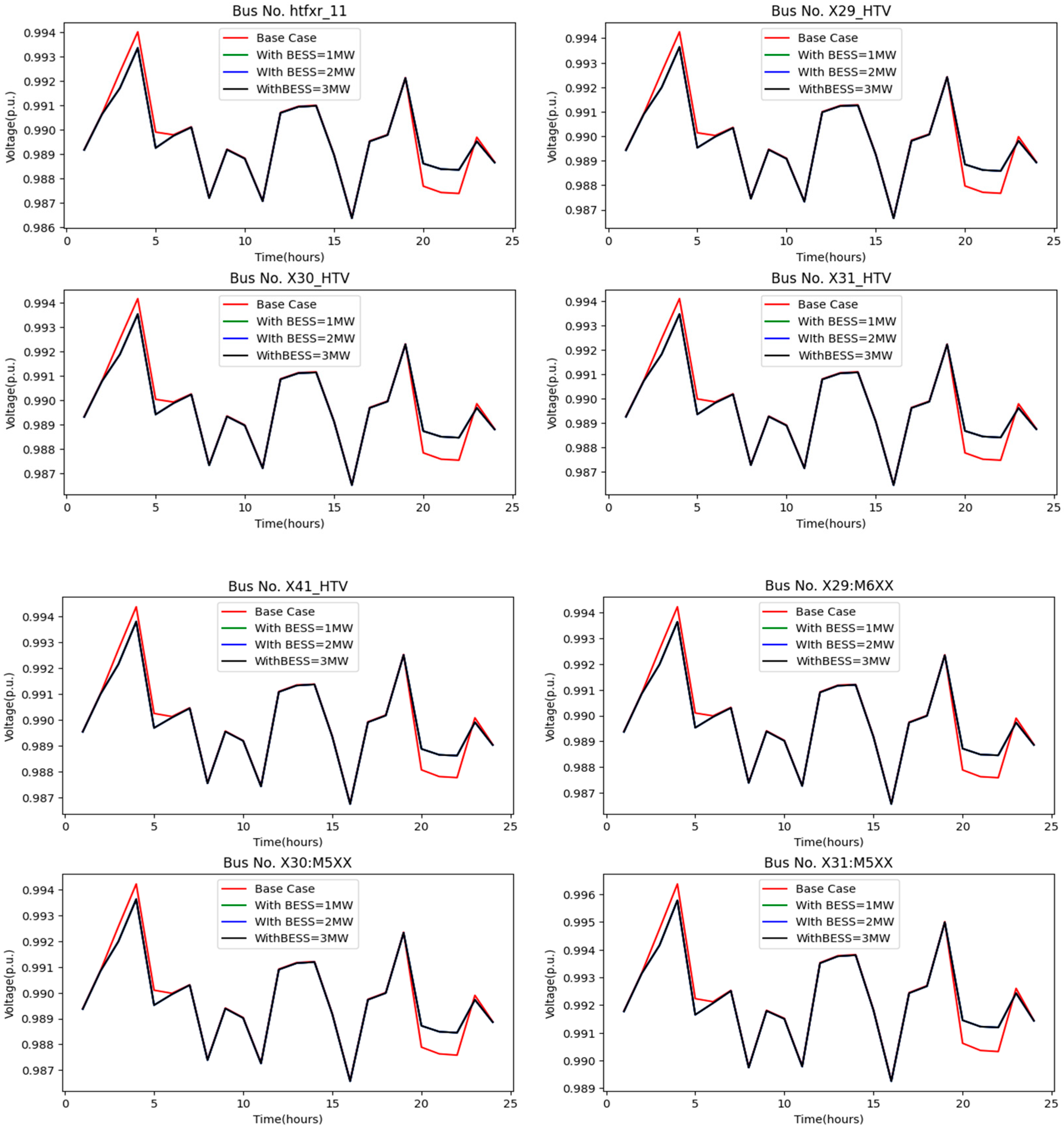

5.1.3. Real NYC System

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Bus | PD | QD | Bus | PD | QD | Bus | PD | QD |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 11 | 0 | 0 | 21 | 6 | 1 |

| 2 | 32.55 | 19.05 | 12 | 16.8 | 11.25 | 22 | 3 | 0.5 |

| 3 | 3.6 | 1.8 | 13 | 0 | 0 | 23 | 0 | 0 |

| 4 | 11.4 | 2.4 | 14 | 9.3 | 2.4 | 24 | 13.05 | 10.05 |

| 5 | 0 | 0 | 15 | 0 | 0 | 25 | 0 | 0 |

| 6 | 0 | 0 | 16 | 5.25 | 2.7 | 26 | 5.25 | 3.45 |

| 7 | 34.2 | 16.35 | 17 | 13.5 | 8.7 | 27 | 0 | 0 |

| 8 | 20 | 15 | 18 | 0 | 0 | 28 | 0 | 0 |

| 9 | 0 | 0 | 19 | 14.25 | 5.1 | 29 | 3.6 | 1.35 |

| 10 | 5.8 | 2 | 20 | 3.3 | 1.05 | 30 | 15.9 | 2.85 |

| Branch | From Bus | To Bus | r | x | b | Capacity |

|---|---|---|---|---|---|---|

| 1 | 1 | 2 | 0.02 | 0.06 | 0.03 | 130 |

| 2 | 1 | 3 | 0.05 | 0.19 | 0.02 | 130 |

| 3 | 2 | 4 | 0.06 | 0.17 | 0.02 | 65 |

| 4 | 3 | 4 | 0.01 | 0.04 | 0 | 130 |

| 5 | 2 | 5 | 0.05 | 0.2 | 0.02 | 130 |

| 6 | 2 | 6 | 0.06 | 0.18 | 0.02 | 65 |

| 7 | 4 | 6 | 0.01 | 0.04 | 0 | 90 |

| 8 | 5 | 7 | 0.05 | 0.12 | 0.01 | 70 |

| 9 | 6 | 7 | 0.03 | 0.08 | 0.01 | 130 |

| 10 | 6 | 8 | 0.01 | 0.04 | 0 | 32 |

| 11 | 6 | 9 | 0 | 0.21 | 0 | 65 |

| 12 | 6 | 10 | 0 | 0.56 | 0 | 32 |

| 13 | 9 | 11 | 0 | 0.21 | 0 | 65 |

| 14 | 9 | 10 | 0 | 0.11 | 0 | 65 |

| 15 | 4 | 12 | 0 | 0.26 | 0 | 65 |

| 16 | 12 | 13 | 0 | 0.14 | 0 | 65 |

| 17 | 12 | 14 | 0.12 | 0.26 | 0 | 32 |

| 18 | 12 | 15 | 0.07 | 0.13 | 0 | 32 |

| 19 | 12 | 16 | 0.09 | 0.2 | 0 | 32 |

| 20 | 14 | 15 | 0.22 | 0.2 | 0 | 16 |

| 21 | 16 | 17 | 0.08 | 0.19 | 0 | 16 |

| 22 | 15 | 18 | 0.11 | 0.22 | 0 | 16 |

| 23 | 18 | 19 | 0.06 | 0.13 | 0 | 16 |

| 24 | 19 | 20 | 0.03 | 0.07 | 0 | 32 |

| 25 | 10 | 20 | 0.09 | 0.21 | 0 | 32 |

| 26 | 10 | 17 | 0.03 | 0.08 | 0 | 32 |

| 27 | 10 | 21 | 0.03 | 0.07 | 0 | 32 |

| 28 | 10 | 22 | 0.07 | 0.15 | 0 | 32 |

| 29 | 21 | 22 | 0.01 | 0.02 | 0 | 32 |

| 30 | 15 | 23 | 0.1 | 0.2 | 0 | 16 |

| 31 | 22 | 24 | 0.12 | 0.18 | 0 | 16 |

| 32 | 23 | 24 | 0.13 | 0.27 | 0 | 16 |

| 33 | 24 | 25 | 0.19 | 0.33 | 0 | 16 |

| 34 | 25 | 26 | 0.25 | 0.38 | 0 | 16 |

| 35 | 25 | 27 | 0.11 | 0.21 | 0 | 16 |

| 36 | 28 | 27 | 0 | 0.4 | 0 | 65 |

| 37 | 27 | 29 | 0.22 | 0.42 | 0 | 16 |

| 38 | 27 | 30 | 0.32 | 0.6 | 0 | 16 |

| 39 | 29 | 30 | 0.24 | 0.45 | 0 | 16 |

| 40 | 8 | 28 | 0.06 | 0.2 | 0.02 | 32 |

| 41 | 6 | 28 | 0.02 | 0.06 | 0.01 | 32 |

References

- Mohamed, A. A Synthetic Case Study for Analysis of the Rising Interdependency between the Power Grid and E-Mobility. IEEE Access 2019, 7, 58802–58809. [Google Scholar] [CrossRef]

- Mohamed, A.; Kanwhen, O.; Bobker, M. Distributed Energy Resources for Water Resource Recovery Facilities: A Metropolitan City Case Study. Appl. Energy 2022, 327, 120059. [Google Scholar] [CrossRef]

- NYC Wants More Rooftop Solar. Its Fire Code Is Getting in the Way. Available online: https://grist.org/cities/nyc-wants-more-rooftop-solar-its-fire-code-is-getting-in-the-way/ (accessed on 21 June 2023).

- Energy Core Report. Available online: https://www1.nyc.gov/assets/dcas/downloads/pdf/energy/archive/EnergyCoreReport_2016.pdf (accessed on 21 June 2023).

- Mayor’s Office of Sustainability, Inventory of NYC GHG Emissions 2015. Available online: https://www.dec.ny.gov/docs/administration_pdf/nycghg.pdf (accessed on 21 June 2023).

- Mohamed, A.A.A.; Kamaludeen, M.K.; Barros, F.; Imperial, Z. Dissecting the Levelized Cost of Storage—“Adders” for New York City. Sustainability 2020, 14, 3768. [Google Scholar] [CrossRef]

- Saude, B.; LaSart, N.; Blair, J.; Beik, O. Microgrid-Based Wind and Solar Power Generation on Moon and Mars. IEEE Trans. Smart Grid 2023, 14, 1329–1332. [Google Scholar] [CrossRef]

- Liang, Z.; Dong, Z.; Li, C.; Wu, C.; Chen, H. A Data-Driven Convex Model for Hybrid Microgrid Operation With Bidirectional Converters. IEEE Trans. Smart Grid 2023, 14, 1313–1316. [Google Scholar] [CrossRef]

- Chen, K.; Baran, M. Robust Controller for Community Microgrids for Stability Improvement in Islanded Mode. IEEE Trans. Power Syst. 2023, 38, 2472–2484. [Google Scholar] [CrossRef]

- Shirsat, A.; Muthukaruppan, V.; Hu, R.; Paduani, V.D.; Xu, B.; Song, L.; Li, Y.; Lu, N.; Baran, M.; Lubkeman, D.; et al. A Secure and Adaptive Hierarchical Multi-Timescale Framework for Resilient Load Restoration Using a Community Microgrid. IEEE Trans. Sustain. Energy 2023, 14, 1057–1075. [Google Scholar] [CrossRef]

- Schwaegerl, C.; Tao, L. Micrgrid Automation and Control, 1st ed.; Wiley Onlime Library: Hoboken, NJ, USA, 2013; Chapter 1, The Microgrids Concept. [Google Scholar] [CrossRef]

- Marchgraber, J.; Gawlik, W. Investigation of Black-Starting and Islanding Capabilities of a Battery Energy Storage System Supplying a Microgrid Consisting of Wind Turbines, Impedance- and Motor-Loads. Energies 2020, 13, 5170. [Google Scholar] [CrossRef]

- Jain, H.; Seo, G.-S.; Lockhart, E.; Gevorgian, V.; Kroposki, B. Blackstart of Power Grids with Inverter-Based Resources. In Proceedings of the IEEE Power & Energy Society General Meeting (PESGM), Montreal, QC, Canada, 2–6 August 2020. [Google Scholar] [CrossRef]

- Barakat, S.; Emam, A.; Samy, M.M. Investigating grid-connected green power systems’ energy storage solutions in the event of frequent blackouts. Energy Rep. 2022, 8, 5177–5191. [Google Scholar] [CrossRef]

- Khodaei, A.; Bahramirad, S.; Shahidehpour, M. Microgrid planning under uncertainty. IEEE Trans. Power Syst. 2014, 30, 2417–2425. [Google Scholar] [CrossRef]

- Gholami, A.; Aminifar, F.; Shahidehpour, M. Front lines against the darkness: Enhancing the resilience of the electricity grid through microgrid facilities. IEEE Electrif. Mag. 2016, 4, 18–24. [Google Scholar] [CrossRef]

- Wong, L.A.; Ramachandaramurthy, V.K.; Walker, S.L.; Ekanayake, J.B. Optimal placement and sizing of battery energy storage system considering the duck curve phenomenon. IEEE Access 2020, 8, 197236–197248. [Google Scholar] [CrossRef]

- Stadler, M.; Cardoso, G.; Mashayekh, S.; Forget, T.; DeForest, N.; Agarwal, A.; Schönbein, A. Value streams in microgrids: A literature review. Appl. Energy 2016, 162, 980–989. [Google Scholar] [CrossRef]

- Yang, W.; Sparrow, S.N.; Ashtine, M.; Wallom, D.C.H.; Morstyn, T. Resilient by design: Preventing wildfires and blackouts with microgrids. Appl. Energy 2022, 313, 118793. [Google Scholar] [CrossRef]

- Masrur, H.; Sharifi, A.; Islam, M.R.; Hossain, M.A.; Senjyu, T. Optimal and economic operation of microgrids to leverage resilience benefits during grid outages. Int. J. Electr. Power Energy Syst. 2021, 132, 107137. [Google Scholar] [CrossRef]

- Krietemeyer, B.; Dedrick, J.; Sabaghian, E.; Rakha, T. Managing the duck curve: Energy culture and participation in local energy management programs in the United States. Energy Res. Soc. Sci. 2021, 79, 102055. [Google Scholar] [CrossRef]

- Hou, Q.; Zhang, N.; Du, E.; Miao, M.; Peng, F.; Kang, C. Probabilistic duck curve in high PV penetration power system: Concept, modeling, and empirical analysis in China. Appl. Energy 2019, 242, 205–215. [Google Scholar] [CrossRef]

- Aros-Vera, F.; Gillian, S.; Rehmar, A.; Rehmar, L. Increasing the resilience of critical infrastructure networks through the strategic location of microgrids: A case study of Hurricane Maria in Puerto Rico. Int. J. Disaster Risk Reduct. 2021, 55, 102055. [Google Scholar] [CrossRef]

- Asimakopoulou, G.E.; Hatziargyriou, N.D. Evaluation of economic benefits of DER aggregation. IEEE Trans. Sustain. Energy 2017, 9, 499–510. [Google Scholar] [CrossRef]

- Mutani, G.; Santantonio, S.; Brunetta, G.; Caldarice, O.; Demichela, M. An energy community for territorial resilience: Measurement of the risk of an energy supply blackout. Energy Build. 2021, 240, 110906. [Google Scholar] [CrossRef]

- Baca, M.; Schenkman, B.; Hightower, M. Use of advanced microgrids to support community resilience. Nat. Hazards Rev. 2021, 22, 05021012. [Google Scholar] [CrossRef]

- Vine, D.; Morsch, A. Microgrids: What Every City Should Know; Center for Climate and Energy Solutions: Arlington, VA, USA, 2017. [Google Scholar]

- Gharieh, K.; Jafari, M.A.; Mahani, K. Public-Private Partnership (PPP) Financing Model for Micro-Grids. In Proceedings of the Dynamic Energy Landscape, 33rd USAEE/IAEE North American Conference, Pittsburgh, PA, USA, 25–28 October 2015; International Association for Energy Economics: Cleveland, OH, USA, 2015. [Google Scholar]

- Batidzirai, B.; Trotter, P.A.; Brophy, A.; Stritzke, S.; Moyo, A.; Twesigye, P.; Puranasamriddhi, A.; Madhlopa, A. Towards people-private-public partnerships: An integrated community engagement model for capturing energy access needs. Energy Res. Soc. Sci. 2021, 74, 101975. [Google Scholar] [CrossRef]

- Feasibility Study for Developing a Microgrid at the Ithaca Area Waste Water Treatment Facility to Serve the Ithaca Nort Energy District. Available online: http://www.lightlink.com/francis/IthacaNEDReportFall2015.pdf (accessed on 21 June 2023).

- Norouzi, F.; Hoppe, T.; Elizondo, L.R.; Bauer, P. A review of socio-technical barriers to Smart Microgrid development. Renew. Sustain. Energy Rev. 2022, 167, 112674. [Google Scholar] [CrossRef]

- Bellido, M.H.; Rosa, L.P.; Pereira, A.O.; Falcao, D.M.; Ribeiro, S.K. Barriers, challenges and opportunities for microgrid implementation: The case of Federal University of Rio de Janeiro. J. Clean. Prod. 2018, 188, 203–216. [Google Scholar] [CrossRef]

- Soshinskaya, M.; Crijns-Graus, W.H.J.; Guerrero, J.M.; Vasquez, J.C. Microgrids: Experiences, barriers and success factors. Renew. Sustain. Energy Rev. 2014, 40, 659–672. [Google Scholar] [CrossRef]

- Yuan, C.; Illindala, M.S.; Khalsa, A.S. Co-Optimization Scheme for Distributed Energy Resource Planning in Community Microgrids. IEEE Trans. Sustain. Energy 2017, 8, 1351–1360. [Google Scholar] [CrossRef]

- Silva-Rodriguez, J.; Li, X. Water-Energy Co-Optimization for Community-Scale Microgrids. In Proceedings of the 2021 North American Power Symposium (NAPS), College Station, TX, USA, 14–16 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Sambor, D.J.; Bishop, S.C.M.; Dotson, A.; Aggarwal, S.; Jacobson, M.Z. Optimizing demand response of a modular water reuse system in a remote Arctic microgrid. J. Clean. Prod. 2022, 346, 131110. [Google Scholar] [CrossRef]

- Tomin, N.; Shakirov, V.; Kozlov, A.; Sidorov, D.; Kurbatsky, V.; Rehtanz, C.; Lora, E.E.S. Design and optimal energy management of community microgrids with flexible renewable energy sources. Renew. Energy 2022, 183, 903–921. [Google Scholar] [CrossRef]

- Bey, M.; Hamidat, A.; Nacer, T. Eco-energetic feasibility study of using grid-connected photovoltaic system in wastewater treatment plant. Energy 2021, 216, 119217. [Google Scholar] [CrossRef]

| Ref | Objectives | System under Consideration | Proposed DER Solutions | Tools Used | Grid Impact Analysis on Real-Time System |

|---|---|---|---|---|---|

| [34] | Co-optimization strategy for planning DERs to minimize total annualized cost | A village at AEP Ohio with 4.5 MW peak load | Solar PV, wind turbine, natural gas CHP, and biomass CHP | Homer | No |

| [35] | WECoOp model for co-optimization of both water and power resources | 60 residential and 2 commercial units in Houston area | Microgrid energy mangement and water management | MATLAB | No |

| [36] | Energy optimization model | Remote Alaska community | Solar PV and battery; WRRF as dispatchable | Julia | No |

| [37] | Fraamework for optimal managemnt of CMG | Transbaikal National Park (Russia) | Solar PV, wind, and biomass gasifier | Bilevel Programming, Reinforcement Learning, Homer Pro, Python optimization, and machine learning | No |

| [38] | Economic analysis of grid-connected PV system at wastewater treatment facility | Sebdou, North Algeria (town and commune) | 670 kWp solar PV | A computational optmization program is developed | No |

| Present Work | Grid impact of WWRFs on CMG | West Harlem, NYC (Dense urban area) | Renewable biogas, PV arrays, energy storage, and cogeneration | MATPOWER/OpenDSS | Yes |

| Process | Energy (%) |

|---|---|

| Secondary treatment aeration | 55.6 |

| Primary clarifier and sludge pumps | 10.3 |

| Heating | 7.1 |

| Solid dewatering | 7.0 |

| Influent pumping | 4.9 |

| Effluent filter and process | 4.5 |

| Secondary clarifier and RAS | 3.7 |

| Lighting | 2.2 |

| Thickening and sludge pumping | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, A.A.A.; Zafar, K.; Vaidya, D.; Salmeron, L.; Kanwhen, O.; Esa, Y.; Kamaludeen, M. Grid Impact of Wastewater Resource Recovery Facilities-Based Community Microgrids. Smart Cities 2023, 6, 3427-3453. https://doi.org/10.3390/smartcities6060152

Mohamed AAA, Zafar K, Vaidya D, Salmeron L, Kanwhen O, Esa Y, Kamaludeen M. Grid Impact of Wastewater Resource Recovery Facilities-Based Community Microgrids. Smart Cities. 2023; 6(6):3427-3453. https://doi.org/10.3390/smartcities6060152

Chicago/Turabian StyleMohamed, Ahmed Ali A., Kirn Zafar, Dhavalkumar Vaidya, Lizzette Salmeron, Ondrea Kanwhen, Yusef Esa, and Mohamed Kamaludeen. 2023. "Grid Impact of Wastewater Resource Recovery Facilities-Based Community Microgrids" Smart Cities 6, no. 6: 3427-3453. https://doi.org/10.3390/smartcities6060152