Improving Strength by Increased Compaction of Gypsum—Enriched Soil under Long-Term Soaking Conditions

Abstract

1. Introduction

2. Aim of the Study

3. Compaction Effort

4. Soil Properties

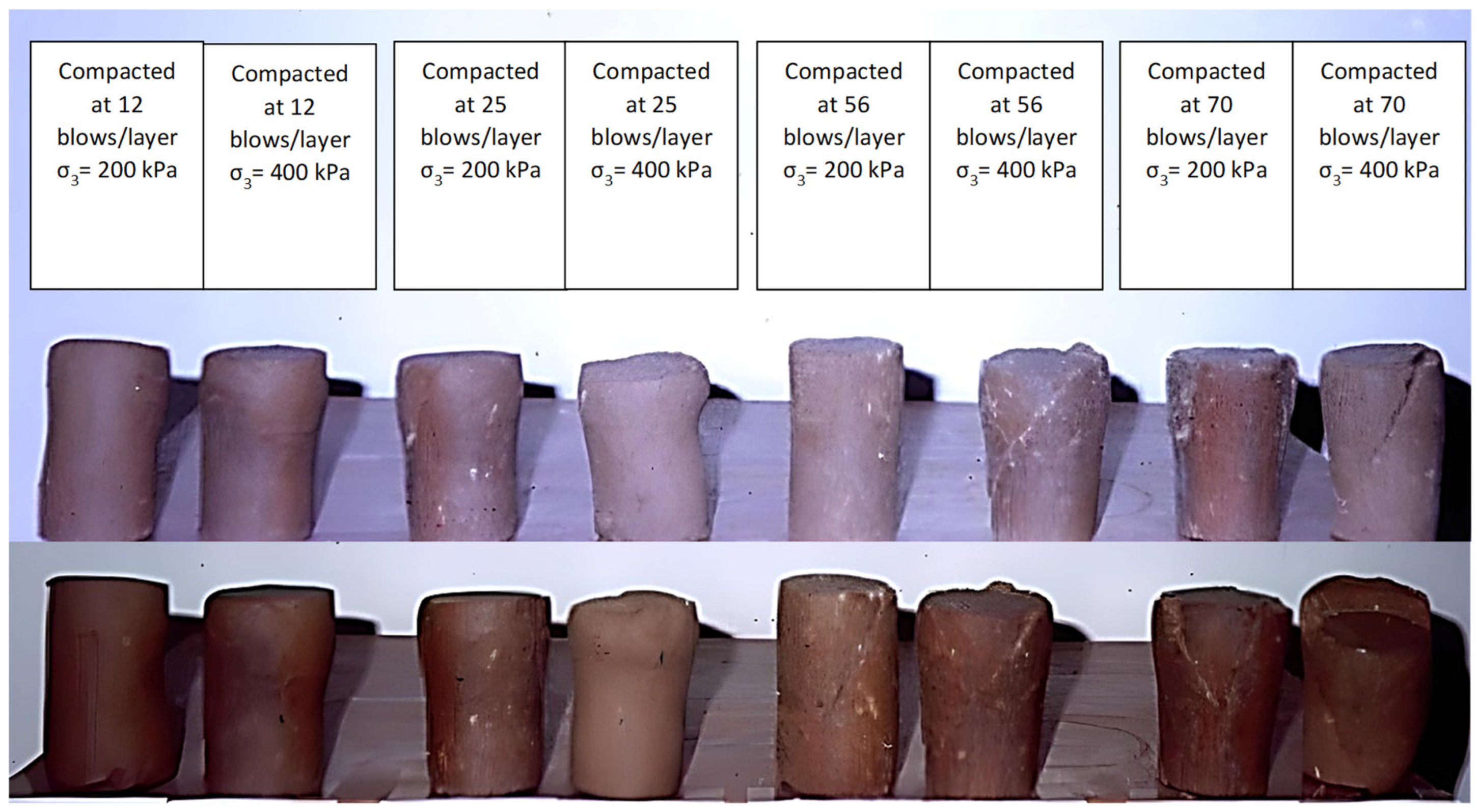

5. Preparation of Triaxial Soil Samples

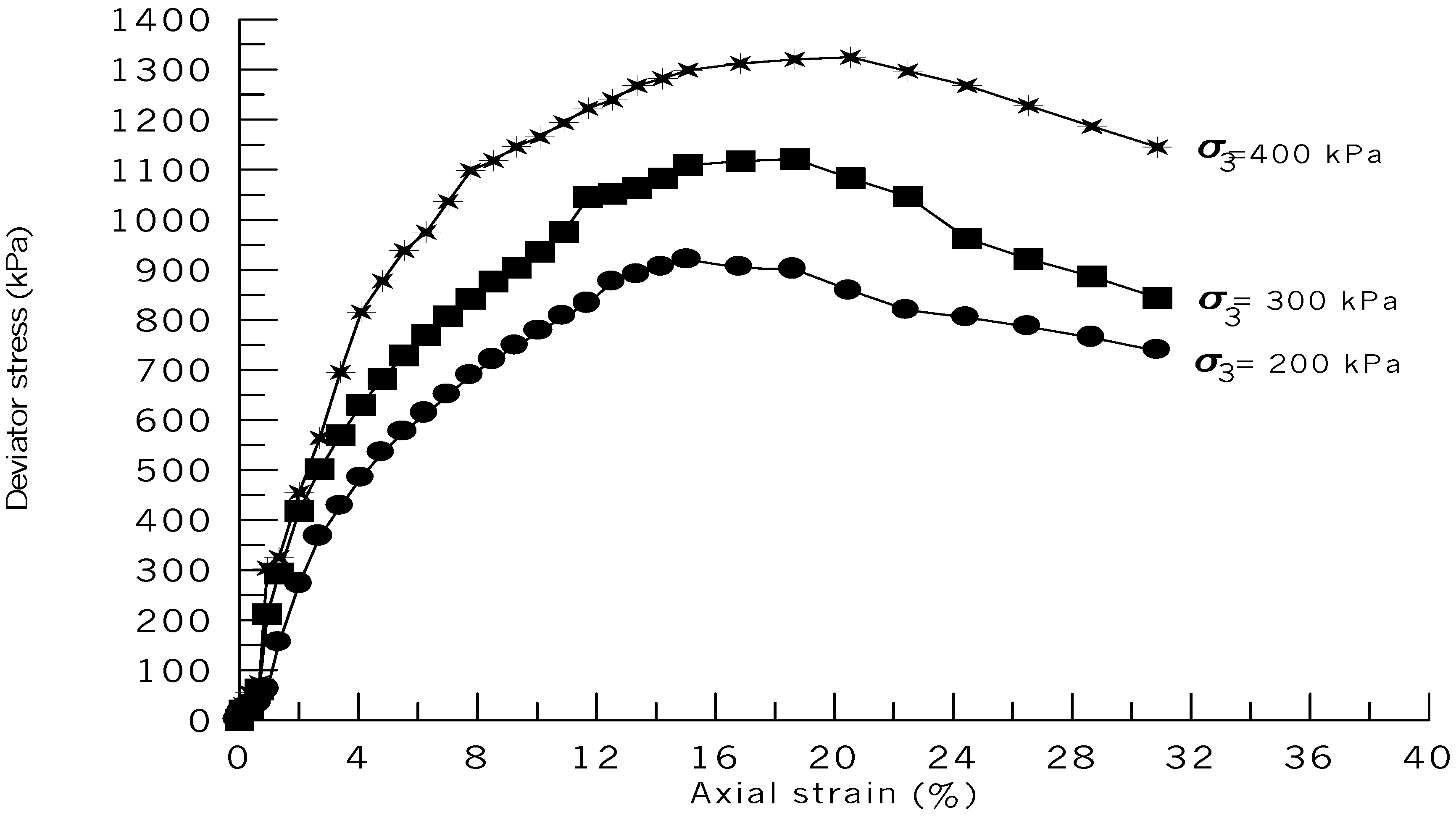

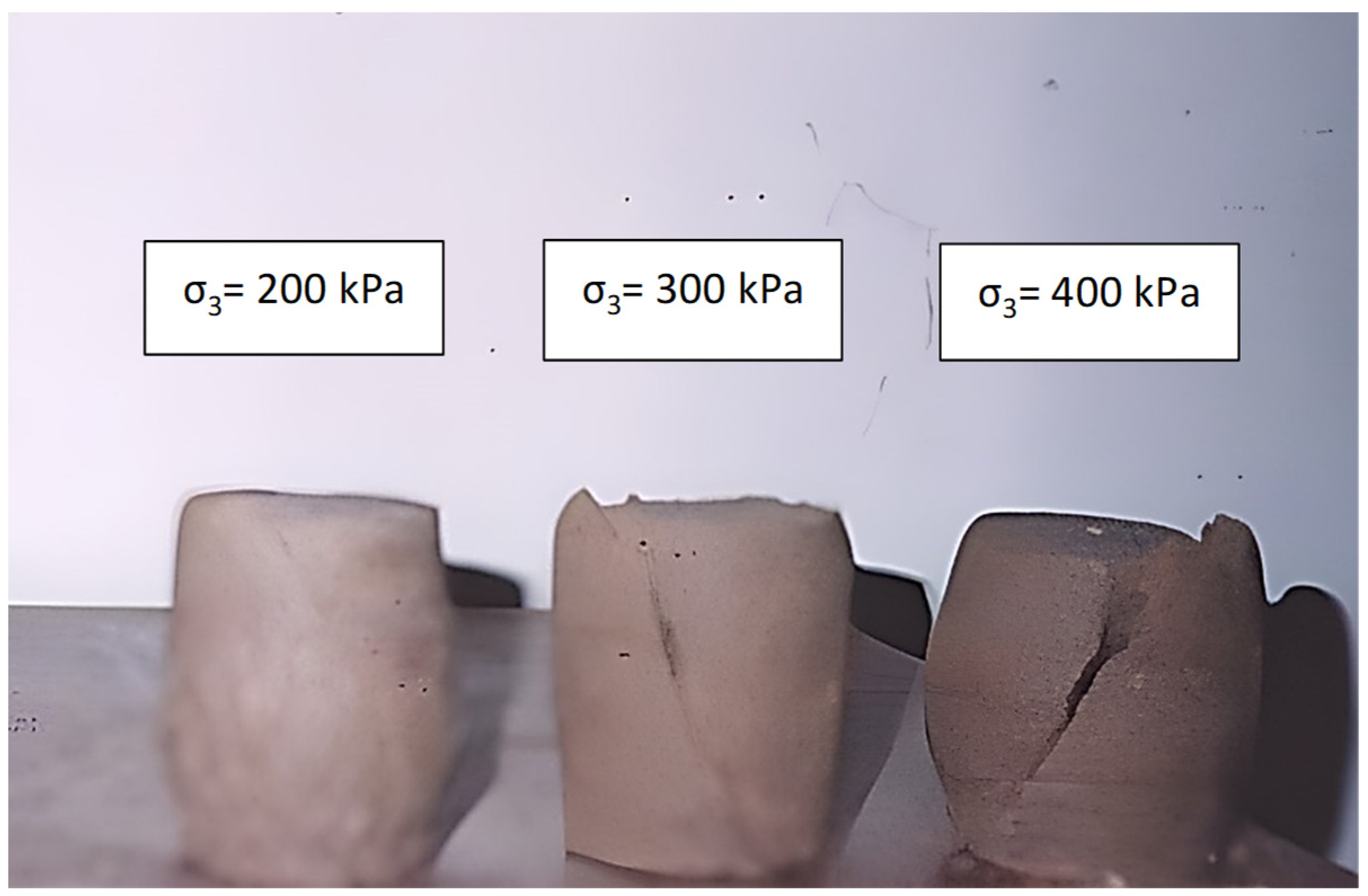

6. Unconsolidated Undrained Triaxial Tests

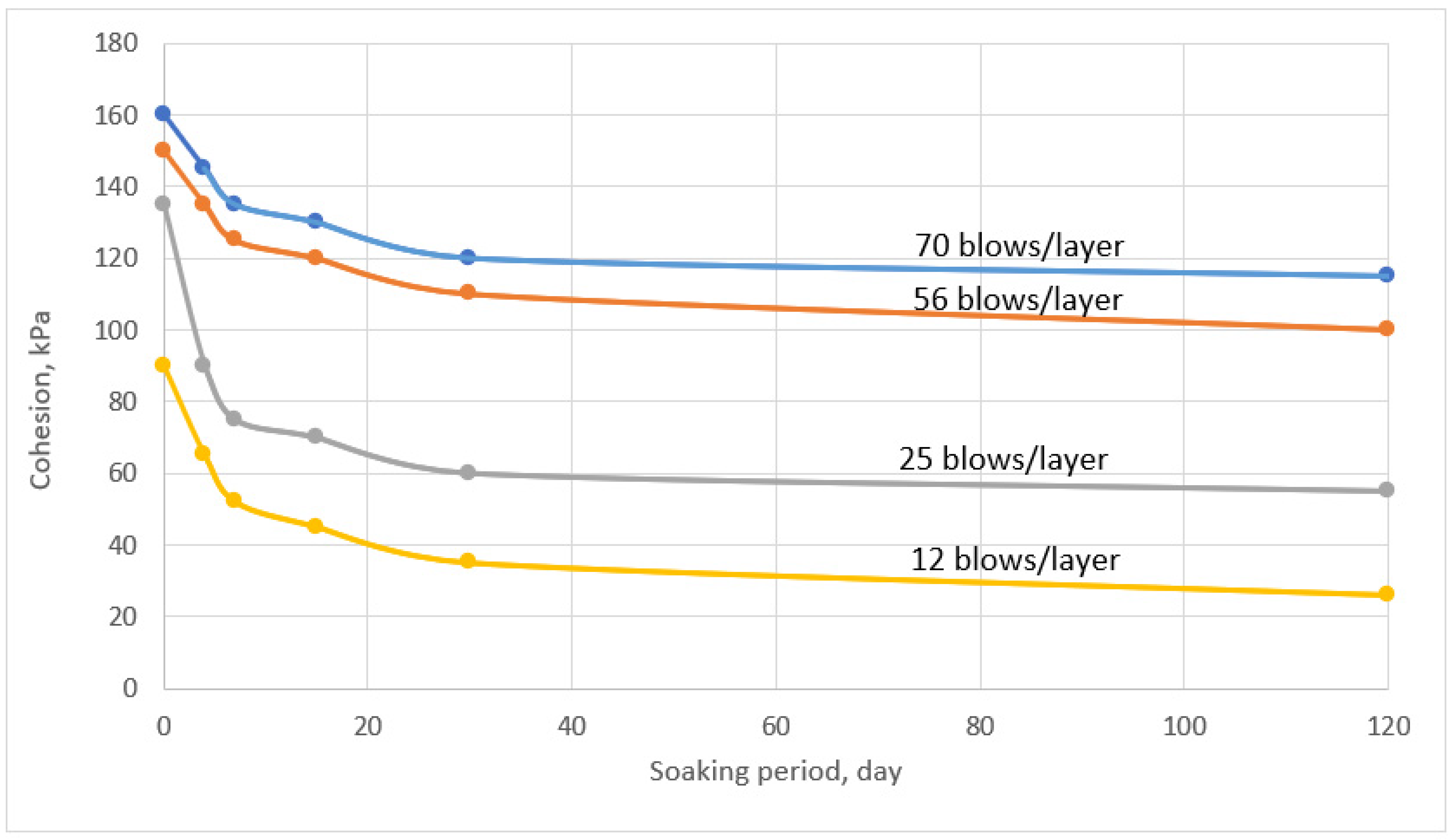

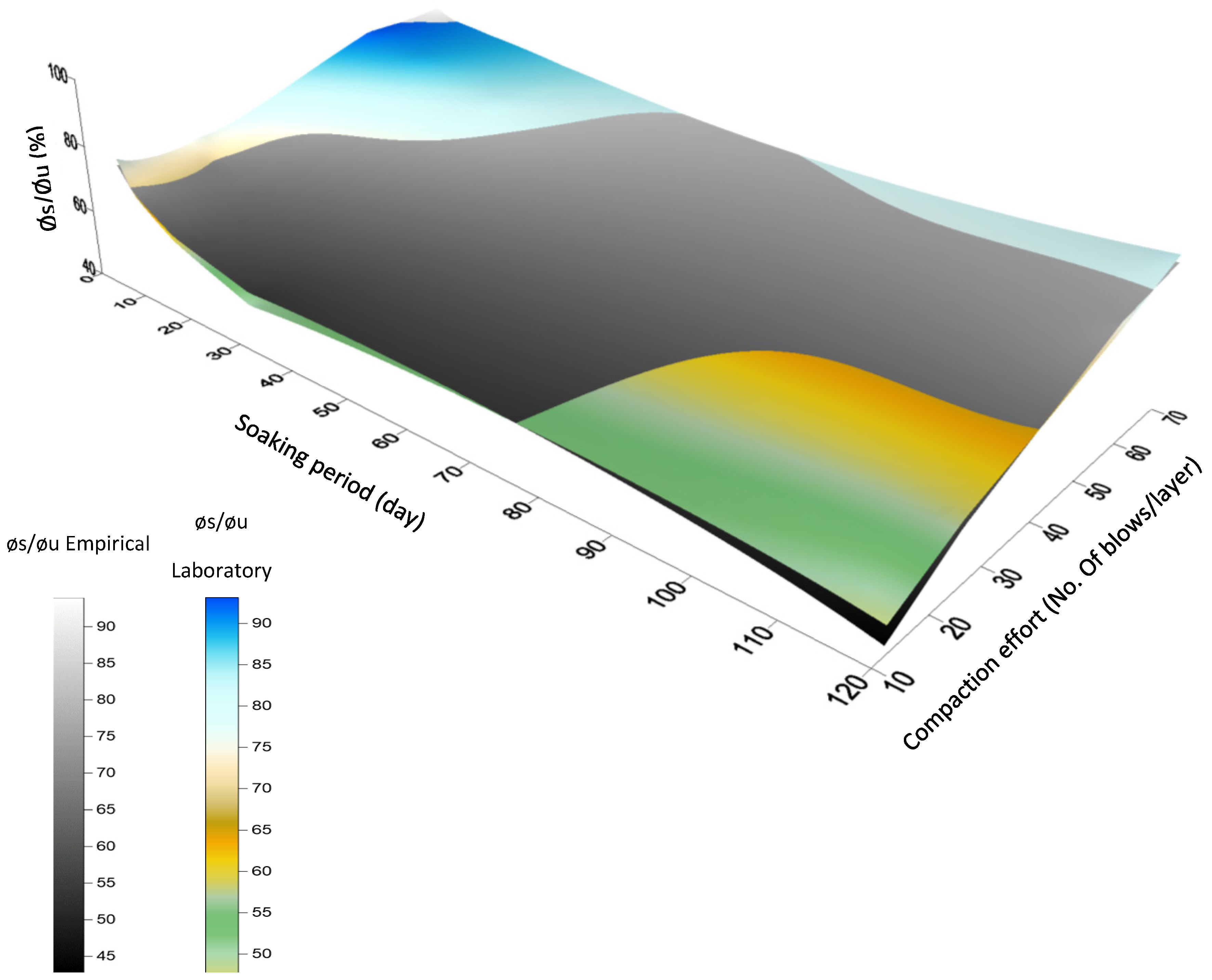

7. Cohesion and Angle of Shear Strength

8. Correlating Soil Parameters with Soaking Period and Compaction Effort

9. Conclusions and Recommendations

- In terms of compaction effort, the study shows that increasing the compaction effort from 12 to 24 blows significantly improves the shear strength properties of the soil. Cohesion increases from 50 kPa to 70 kPa, and the angle of shear increases from 25 degrees to 30 degrees. A longer soaking period is found to be detrimental to the shear strength of the soil. After 24 h of soaking, the cohesion decreases to 40 kPa, and the angle of shear strength decreases to 20 degrees.

- With regard to gypsum dissolution, the results indicate that gypsum dissolution during soaking plays a significant role in the change in soil strength. The decrease in cohesion and the angle of shear strength with the increasing soaking period indicates that gypsum is leaching from the soil. Correspondingly, the regression models developed in the current study establish strong correlations between soaked and unsoaked strength properties, compaction effort and soaking period. These models allow engineers to estimate the cohesion and angle of shear strength from compaction effort and soaking time. For important structures on gypsum-rich soils, it is recommended that the allowable bearing capacity of foundations should be based on soaked conditions. For less important structures in hot dry climates with a very low probability of long-term soaking, a safety factor of not less than 3 based on unsoaked conditions is recommended to give a factor of safety slightly greater than 1 based on soaked conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Notation

| c | cohesion with respect to total stress |

| cs | cohesion for soaked conditions |

| cu | cohesion for unsoaked conditions |

| cs/cu | cohesion ratio (%) |

| CBR | California Bearing Ratio |

| CE | compaction energy |

| Gs | specific gravity of soil particles |

| h | drop height of the hammer |

| k | compaction effect factor |

| LL | liquid limit |

| MR | resilient modulus |

| Nb | number of blows per layer |

| Nl | number of layers |

| OMC | optimum moisture content |

| PI | plasticity index |

| PL | plastic limit |

| R, R2 | coefficient of correlation, coefficient of determination |

| S | soaking period (days) |

| UU | unconsolidated undrained triaxial test |

| V | volume of compacted soil sample |

| W | weight of hammer |

| β | compaction effort factor |

| ϕ | angle of shear strength with respect to total stress |

| ϕs | angle of shear strength for soaked conditions |

| ϕu | angle of shear strength for unsoaked conditions |

| ϕs/ϕu | angle of shear strength ratio (%) |

| σ1 | major principal stress |

| σ3 | minor principal stress (confining pressure) |

References

- Bjerrum, L. Engineering geology of Norwegian normally consolidated marine clay as related to settlement of building. Geotechnique 1967, 17, 83–118. [Google Scholar] [CrossRef]

- Torrance, J.K. Laboratory investigation of the effect of leaching on compressibility and shear strength of Norwegian marine clay. Geotechnique 1974, 24, 155–173. [Google Scholar] [CrossRef]

- Blight, G.E. Migration of subgrade salts damages thin pavements. Transp. Eng. J. ASCE 1976, 102, 779–791. [Google Scholar] [CrossRef]

- James, A.N.; Lupton, A.R.R. Gypsum and anhydrite in foundations of hydraulic structures. Geotechnique 1978, 28, 249–272. [Google Scholar] [CrossRef]

- de OS Horta, J.C. Salt heaving in the Sahara. Geotechnique 1985, 35, 329–337. [Google Scholar] [CrossRef]

- Subhi, H.M. The Properties of Salt Contaminated Soils and Their Influence on the Performance of Roads in Iraq. Ph.D. Thesis, University of London, London, UK, 1987. [Google Scholar]

- Hunter, D. Lime-induced heave in sulfate-bearing clay soils. J. Geotech. Eng. 1988, 114, 150–167. [Google Scholar] [CrossRef]

- Abduljauwad, S.; Al-Amoudi, O. Geotechnical behaviour of saline sabkha soils. Geotechnique 1995, 45, 425–445. [Google Scholar] [CrossRef]

- Ismael, N.F.; Mollah, M.A. Leaching effects on properties of cemented sands in Kuwait. ASCE J. Geotech. Geoenvironmental Eng. 1998, 124, 997–1004. [Google Scholar] [CrossRef]

- Obika, B.; Freer-Hewish, R.J.; Fookes, P.G. Soluble salt damage to thin bituminous road and runway surfaces. Q. J. Eng. Geol. 1989, 22, 59–73. [Google Scholar] [CrossRef]

- Eswaran, H.; Gong, Z.-T. Properties, genesis, classification, and distribution of soilswith gypsum. In Occurrence, Characteristics, and Genesis of Carbonate, Gypsum, and Silica Accumulations in Soils; Nettleton, W.D., Ed.; SSSA Special Publication; Soil Science Society of America: Madison, WI, USA, 1991; pp. 89–119. [Google Scholar]

- Herrero, J. Revisiting the definitions of gypsic and petrogypsic horizons in SoilTaxonomy and World Reference Base for Soil Resources. Geoderma 2004, 120, 1–5. [Google Scholar] [CrossRef]

- Ahmed, K.I. Effect of Gypsum on the Hydro-Mechanical Characteristics of Partially Saturated Sand Soil. Ph.D. Thesis, Cardiff Cardiff University, Cardiff, UK, 2013. [Google Scholar]

- Salih, N.B. Stability of Dams Constructed on Problematic Substrates. Ph.D. Thesis, Brunel University, London, UK, 2013. [Google Scholar]

- Fookes, P.C.; French, W.J.; Rice, S.M.M. The Influence of Ground and Groundwater Geochemistry on Construction in the Middle East. Q. J. Eng. Geol. 1985, 18, 101–128. [Google Scholar] [CrossRef]

- James, A.N.; Kirkpatrick, I.M. Design of foundations of dams containing soluble rocks and soils. Q. J. Eng. Geol. 1980, 13, 189–198. [Google Scholar] [CrossRef]

- Moore, M.J.; Mota, J.F.; Douglas, N.A.; Flores-Olvera, H.; Ochoterena, H. The ecology, assembly, and evolution of gypsophile floras. In Plant Ecology and Evolution in Harsh Environments; Rajakaruna, N., Boyd, R., Harris, T., Eds.; Nova Science Publishers: Hauppauge, NY, USA, 2014; pp. 97–128. [Google Scholar]

- Van Alphen, J.G.; Romero, F.D.R. Gypsiferous Soils—Notes on Their Characteristics and Management; Bulletin 12; International Institute for Land Reclamation and Improvement: Wageningen, The Netherlands, 1971. [Google Scholar]

- Hawkins, A.B.; Pinches, C.M. Expansion due to gypsum growth. In Proceedings of the 6th International Conference on Expansive Soils, New Delhi, India, 1–4 December 1987; pp. 183–187. [Google Scholar]

- Cooper, A.H.; Saunders, J.M. Road and bridge construction across gypsum karst in England. Eng. Geol. 2002, 65, 217–223. [Google Scholar] [CrossRef]

- Heukelom, W.; Foster, C.R. Dynamic testing of pavements. J. Soil Mech. Found Div. 1960, 86, 2368–2372. [Google Scholar] [CrossRef]

- Paterson, W.D.L. Background Supplement to Draft TRH4; Technical Report RP/6/78; National Institute for Transport and Road Research: Pretoria, South Africa, 1978. [Google Scholar]

- Powell, W.D.; Potter, J.F.; Mayhew, H.C.; Nunn, M.E. The Structural Design of Bituminous Roads; TRRL Report LR; Transport and Road Research Laboratory: Crowthorne, Berkshire, UK, 1984; Volume 62, p. 1132. [Google Scholar]

- Drumm, E.C.; Boateng-Poku, Y.; Pierce, T.J. Estimation of subgrade resilient modulus from standard test. J. Geotech. Eng. 1990, 116, 774–789. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Edil, T.B. Light-weight deflectometer for mechanistic quality control of base course materials. Proc. Inst. Civ. Eng. Geotech. Eng. 2013, 166, 441–450. [Google Scholar] [CrossRef]

- Araya, A.A.; Huurman, M.; Molenaar, A.A.A.; Houben, L.J.M. Investigation of the resilient behavior of granular base materials with simple test apparatus. Mater. Struct. 2011, 45, 695–705. [Google Scholar] [CrossRef][Green Version]

- Hossain, M.S.; Kim, W.S. Estimation of Subgrade Resilient Modulus Using the Unconfined Compression Test; Final Report VCTIR 15-R12; Virginia Center for Transportation Innovation and Research: Charlottesville, VA, USA, 2014.

- Nguyen, B.T.; Mohajerani, A. Resilient modulus of fine-grained soil and a simple testing and calculation method for determining an average resilient modulus value for pavement design. Transp. Geotech. 2016, 7, 59–70. [Google Scholar] [CrossRef]

- Mousavi, S.H.; Gabr, M.A.; Borden, R.H. Subgrade resilient modulus prediction using light-weight deflectometer data. Can. Geotech. J. 2017, 54, 304–312. [Google Scholar] [CrossRef]

- Titi, H.H.; Matar, M.G. Estimating resilient modulus of base aggregates for mechanistic-empirical pavement design and performance evaluation. Transp. Geotech. 2018, 17, 141–153. [Google Scholar] [CrossRef]

- Zhao, G.; Yao, Y.; Li, S.; Jiang, Y. Maximum Allowable Deflection by Light Weight Deflectometer and Its Calibration and Verification; Joint Transportation Research Program Publication No. FHWA/IN/JTRP-2018/21; Purdue University: West Lafayette, IN, USA, 2018. [Google Scholar] [CrossRef]

- Khasawneh, M.A.; Al-jamal, N.F. Modeling resilient modulus of fine-grained materials using different statistical techniques. Transp. Geotech. 2019, 21, 100263. [Google Scholar] [CrossRef]

- Kuttah, D. Determining the resilient modulus of sandy subgrade using cyclic light weight deflectometer test. Transp. Geotech. 2020, 27, 100482. [Google Scholar] [CrossRef]

- Pasand, S.A.; Nasrollahi, N.; Asghari-Kaljahi, E.; Majidian, S. Effect of fine material content on the CBR of Iran saturated soils. Innov. Infrastruct. Solut. 2022, 7, 365. [Google Scholar] [CrossRef]

- Bastola, N.R.; Vechione, M.M.; Elshaer, M.; Souliman, M.I. Artificial neural network prediction model for in situ resilient modulus of subgrade soils for pavement design applications. Innov. Infrastruct. Solut. 2021, 7, 54. [Google Scholar] [CrossRef]

- Liu, W.; Huang, X.; Feng, X.; Xie, Z. Compaction and bearing characteristics of untreated and treated lateritic soils with varying moisture content. Constr. Build. Mater. 2023, 392, 131893. [Google Scholar] [CrossRef]

- Razouki, S.S.; El-Janabi, O.A. Decrease in the CBR of a gypsiferous soil due to long-term soaking. Q. J. Eng. Geol. 1999, 32, 87–89. [Google Scholar] [CrossRef]

- Razouki, S.S.; Kuttah, D.K. Effect of Soaking Period and Surcharge Load on Resilient Modulus and California Bearing Ratio of Gypsiferous soils. Q. J. Eng. Geol. Hydrogeol. 2004, 37, 155–164. [Google Scholar] [CrossRef]

- ASTM D2487-1; American Society for Testing and Materials. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). Book of Standards. ASTM International: West Conshohocken, PA, USA, 2017.

- Razouki, S.; Kuttah, D.K.; Al-Damluji, O.; Nashat, I. Improving fine-grained gypsiferous soil by increased compaction. Int. J. Pavement Eng. 2012, 13, 32–38. [Google Scholar] [CrossRef]

- AASHTO M 145-86; Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes. Standard Specification for Transportation Materials and Methods of Sampling and Testing. American Association of State Highway and Transportation Officials: Washington, DC, USA, 1986.

- Razouki, S.S.; Ibrahim, A.N. Improving the resilient modulus of a gypsum sand roadbed soil by increased compaction. Int. J. Pavement Eng. 2017, 20, 432–438. [Google Scholar] [CrossRef]

- Razouki, S.S.; Kuttah, D.K.; Al-Damluji, O.A.; Nashat, I.H. Strength erosion of a fine-grained gypsiferous soil during soaking. Arab. J. Sci. Eng. 2007, 32, 147–152. [Google Scholar]

- ASTM (2012) D1557-12e1; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56000 ft-lbf/ft3 (2700 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012.

- Razouki, S.S.; Kuttah, D.K. Behaviour of fine-grained gypsum-rich soil under triaxial tests. Proc. Inst. Civ. Eng. Constr. Mater. 2021, 174, 240–248. [Google Scholar] [CrossRef]

- Razouki, S.S.; Kuttah, D.K. Challenging choice of safety factor for design of strip footings on gypsum-rich soils. Innov. Infrastruct. Solut. 2020, 5, 52. [Google Scholar] [CrossRef]

- ASTM (2016) D 1883-16; Standard Test Methods for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM (2012) D 698-12 e2; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM (2007) D422-63 e2; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM (2017) D 4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- BSI (1990) BS 1377; Method of Test for Soils for Civil Engineering Purposes. BSI: London, UK, 1990.

- Earth Manual USDOI, 3rd ed.; Water and Power Resources Service: Washington, DC, USA, 1980.

- ASTM (2015) D 285; Standard Test Method for Unconsolidated Undrained Triaxial Compression Test on Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2015.

- Ling, R.F.; Anderson, T.W.; Sclove, S.L. An Introduction to the Statistical Analysis of Data; Houghton Mifflin: Boston, MA, USA, 1978. [Google Scholar]

- Asuero, A.G.; Sayago, A.; González, A.G. The Correlation Coefficient: An Overview. Crit. Rev. Anal. Chem. 2006, 36, 41–59. [Google Scholar] [CrossRef]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics in Engineering Practice, 3rd ed.; Wiley: Hoboken, NJ, USA, 1996. [Google Scholar]

- Bowles, J.E. Foundation Analysis and Design; McGraw-Hill International Editions: New York, NY, USA, 2001. [Google Scholar]

| Compaction Effort (Blows/Layer) | Compaction Effort (kN. m/m3) | Ø (°) Unsoaked Conditions | Ø(°) 120 Days Soaked Conditions | C (kPa) Unsoaked Conditions | C (kPa) 120 Days Soaked Conditions |

|---|---|---|---|---|---|

| 70 | 3421 | 29 | 24 | 160 | 115 |

| 56 | 2737 | 27 | 20 | 150 | 100 |

| 25 | 1222 | 25 | 14.5 | 135 | 55 |

| 12 | 586.4 | 22 | 10.5 | 90 | 26 |

| Compaction Effort (Blows/Layer) | Regression Model Cs/Cu (%) | Coefficient of Determination, R2 | Coefficient of Correlation, R |

|---|---|---|---|

| 70 | Cs/Cu = 97.40 S−0.068 | 0.942 | 0.970 |

| 56 | Cs/Cu = 100.18 S−0.087 | 0.984 | 0.992 |

| 25 | Cs/Cu = 76.00 S−0.14 | 0.923 | 0.961 |

| 12 | Cs/Cu = 100.62 S−0.266 | 0.988 | 0.994 |

| Compaction Effort (Blows/Layer) | Regression Model ϕs/ϕu (%) | Coefficient of Determination, R2 | Coefficient of Correlation, R |

|---|---|---|---|

| 70 | ϕs/ϕu = 97.94 S−0.035 | 0.988 | 0.994 |

| 56 | ϕs/ϕu = 103.50 S−0.066 | 0.954 | 0.977 |

| 25 | ϕs/ϕu = 81.81 S−0.079 | 0.896 | 0.947 |

| 12 | ϕs/ϕu = 90.09 S−0.146 | 0.905 | 0.951 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razouki, S.S.; Kuttah, D. Improving Strength by Increased Compaction of Gypsum—Enriched Soil under Long-Term Soaking Conditions. Geotechnics 2024, 4, 415-429. https://doi.org/10.3390/geotechnics4020023

Razouki SS, Kuttah D. Improving Strength by Increased Compaction of Gypsum—Enriched Soil under Long-Term Soaking Conditions. Geotechnics. 2024; 4(2):415-429. https://doi.org/10.3390/geotechnics4020023

Chicago/Turabian StyleRazouki, Sabah Said, and Dina Kuttah. 2024. "Improving Strength by Increased Compaction of Gypsum—Enriched Soil under Long-Term Soaking Conditions" Geotechnics 4, no. 2: 415-429. https://doi.org/10.3390/geotechnics4020023

APA StyleRazouki, S. S., & Kuttah, D. (2024). Improving Strength by Increased Compaction of Gypsum—Enriched Soil under Long-Term Soaking Conditions. Geotechnics, 4(2), 415-429. https://doi.org/10.3390/geotechnics4020023