Construction Methods and Lessons Learned for a Non-Proprietary Ultra-High Performance Concrete Overlay

Abstract

1. Introduction and Background

2. Methodology

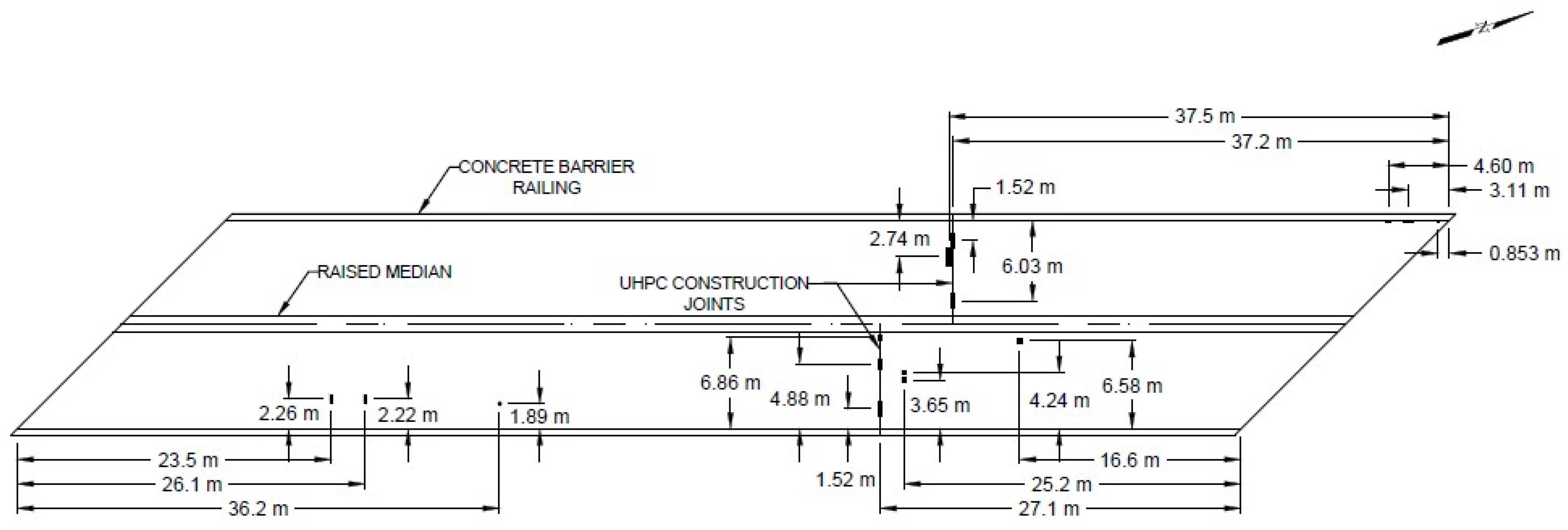

2.1. Bridge Description

2.2. Condition of Existing Concrete Bridge Deck

2.3. Removal of Deteriorated Concrete and Design of Rehabilitated Bridge Deck

2.4. Sensor Instrumentation

2.5. HPD Placement

2.6. UHPC Overlay Placement

2.6.1. Substrate Surface Preparation

2.6.2. Material Preparation and Mixing

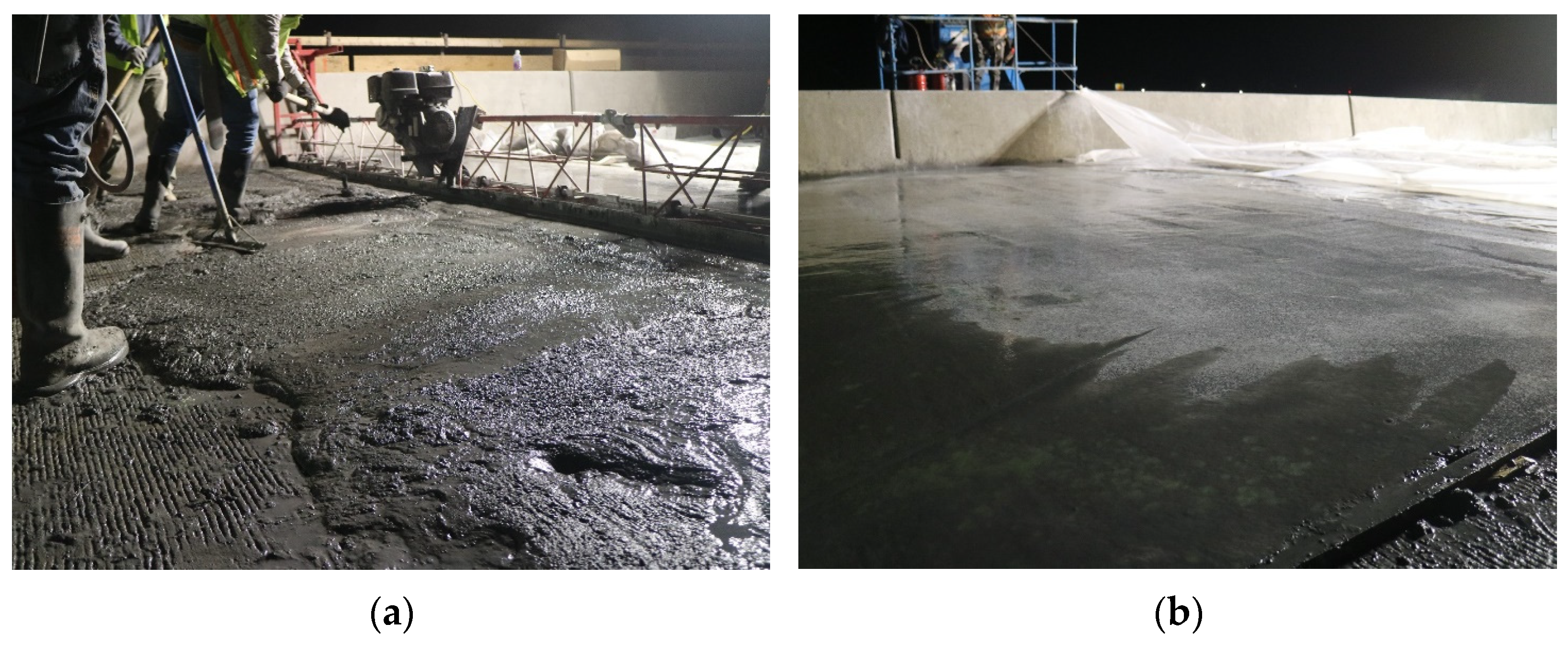

2.6.3. Production Placements

2.6.4. Preparation of Specimens and Curing Procedures

2.7. Test Methodology

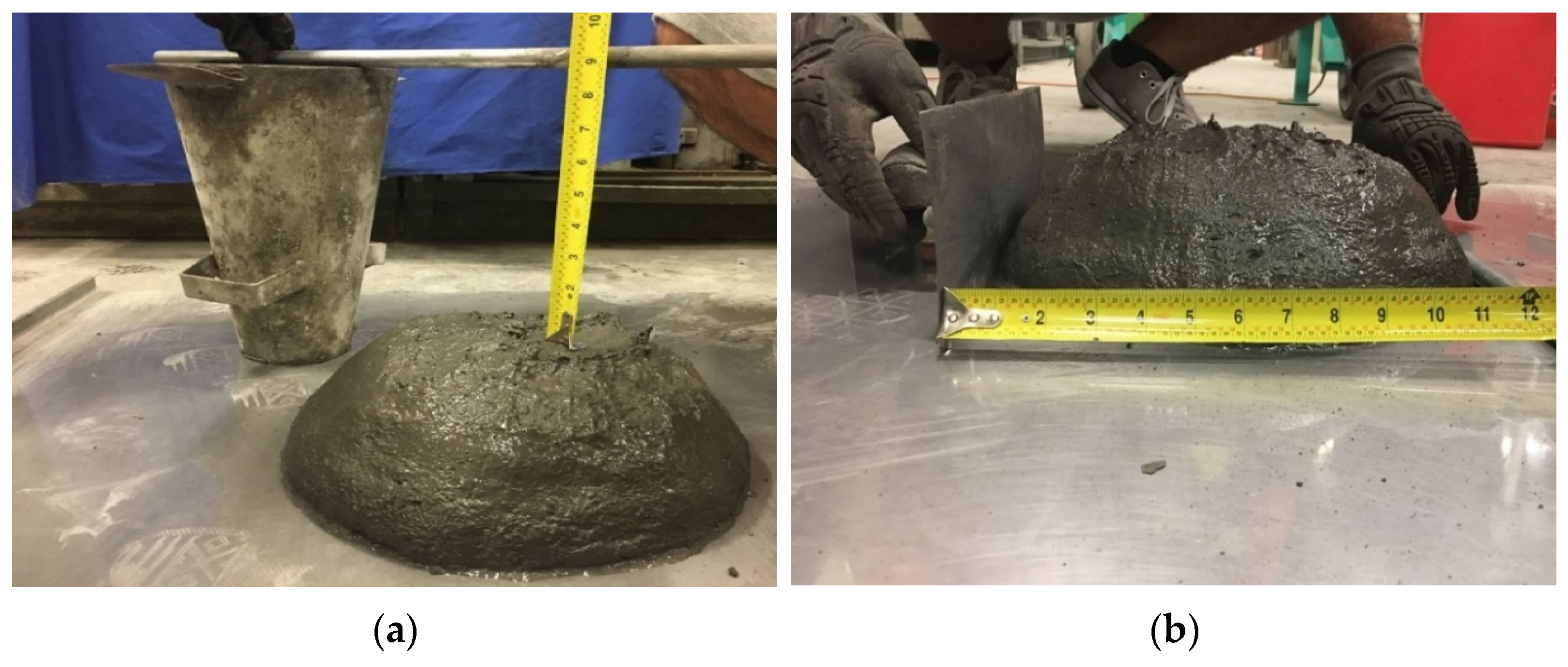

2.7.1. Slump and Slump-Flow Testing

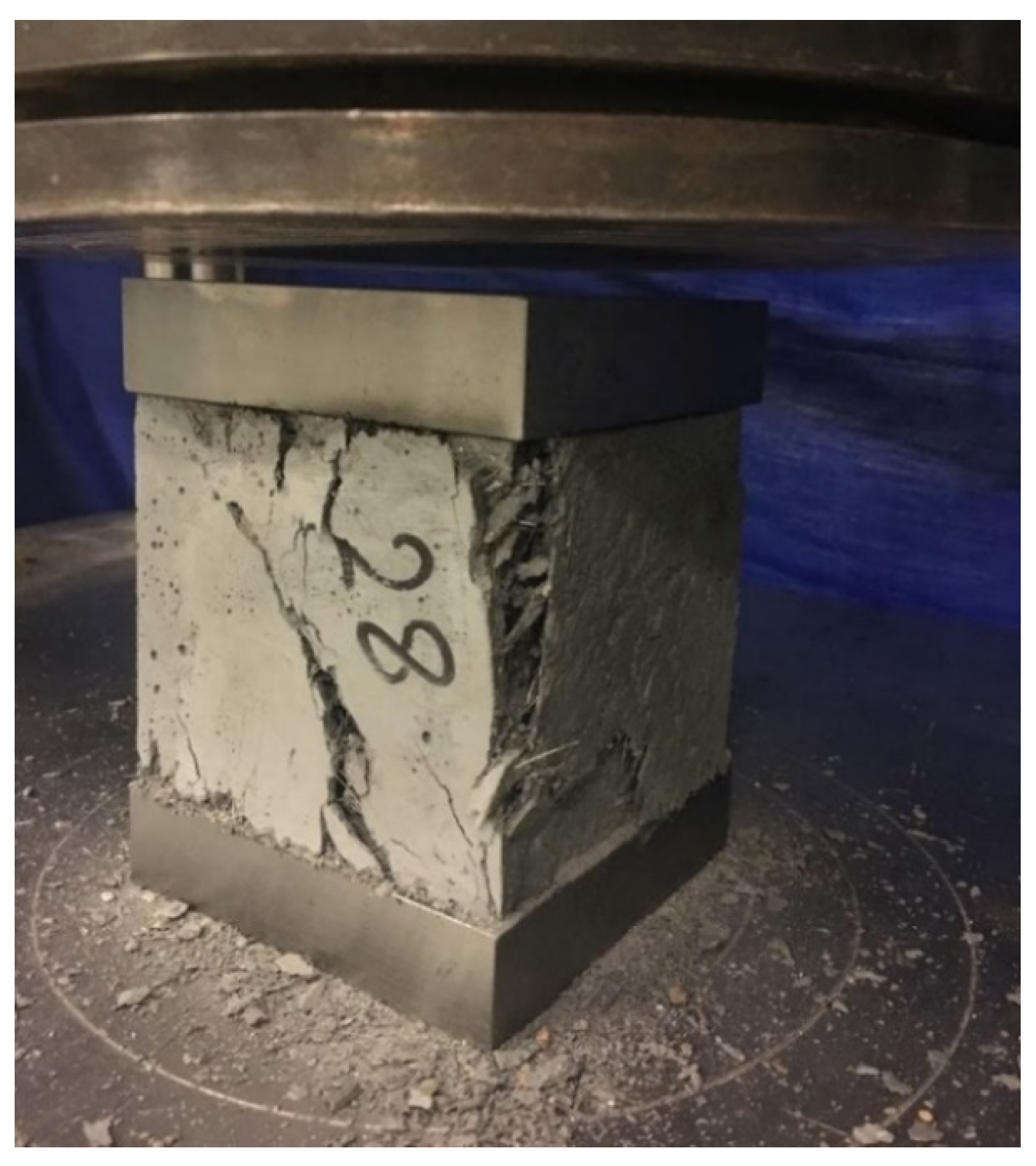

2.7.2. Compressive Strength Testing

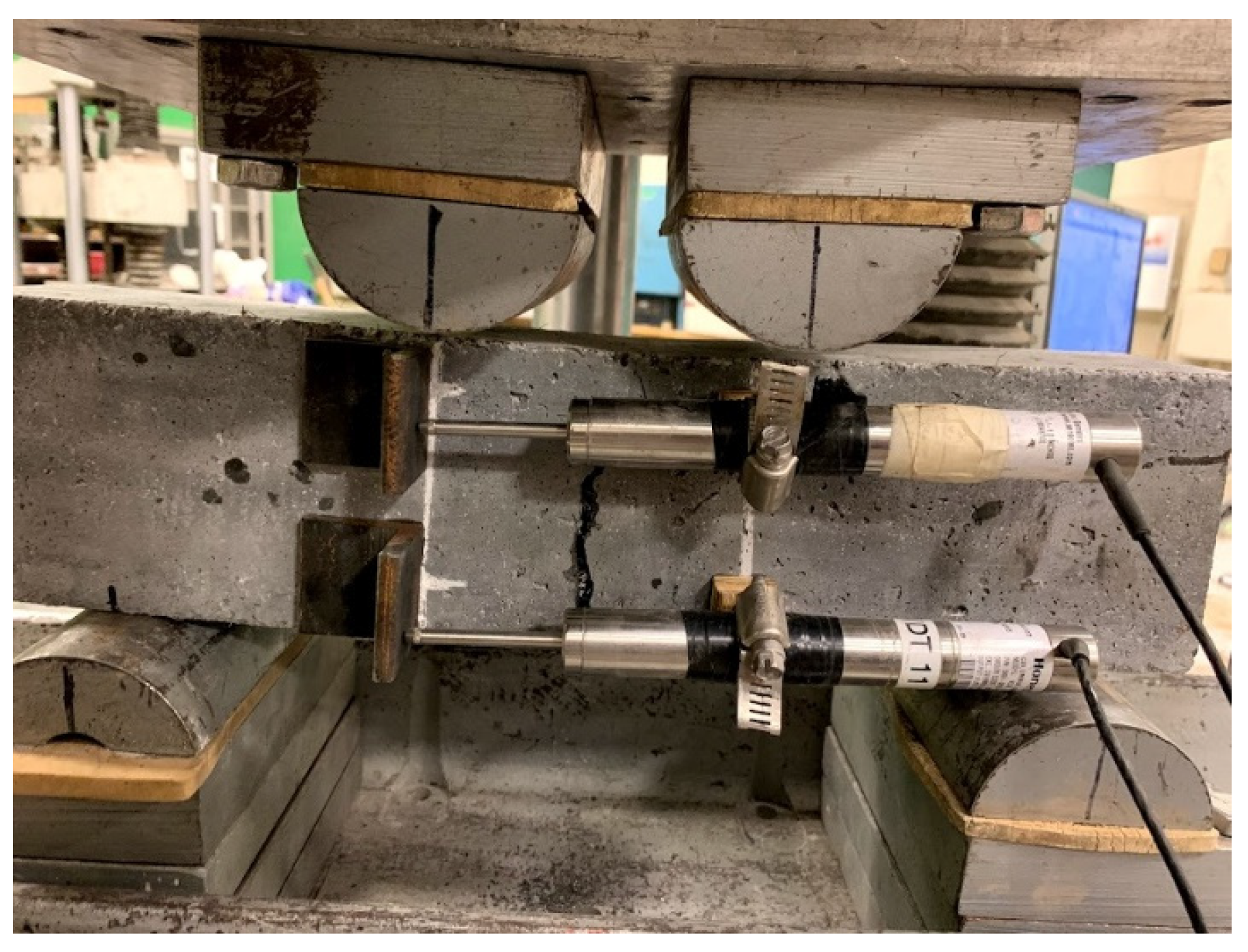

2.7.3. Flexural Strength Testing

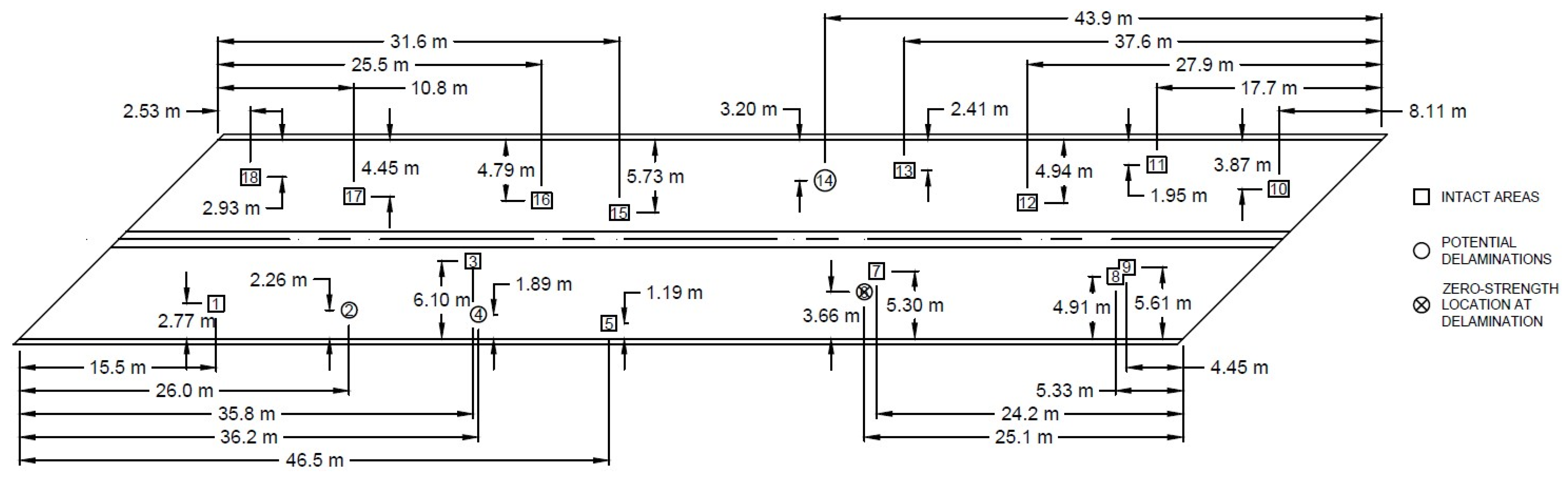

2.7.4. Chain Dragging and Pull-Off Testing

3. Results and Discussion

3.1. Temperature and Workability of the UHPC

3.2. UHPC Strength Results

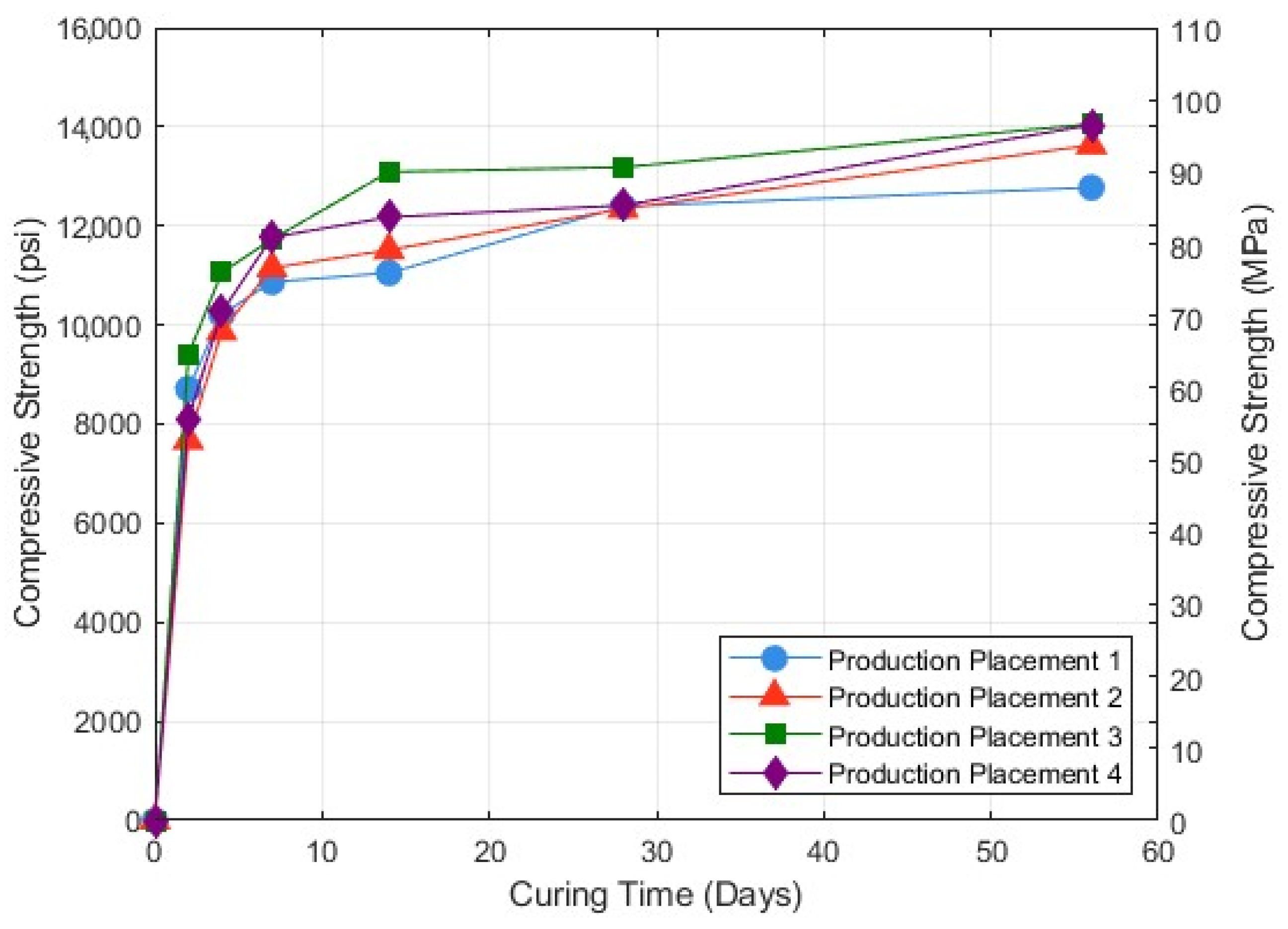

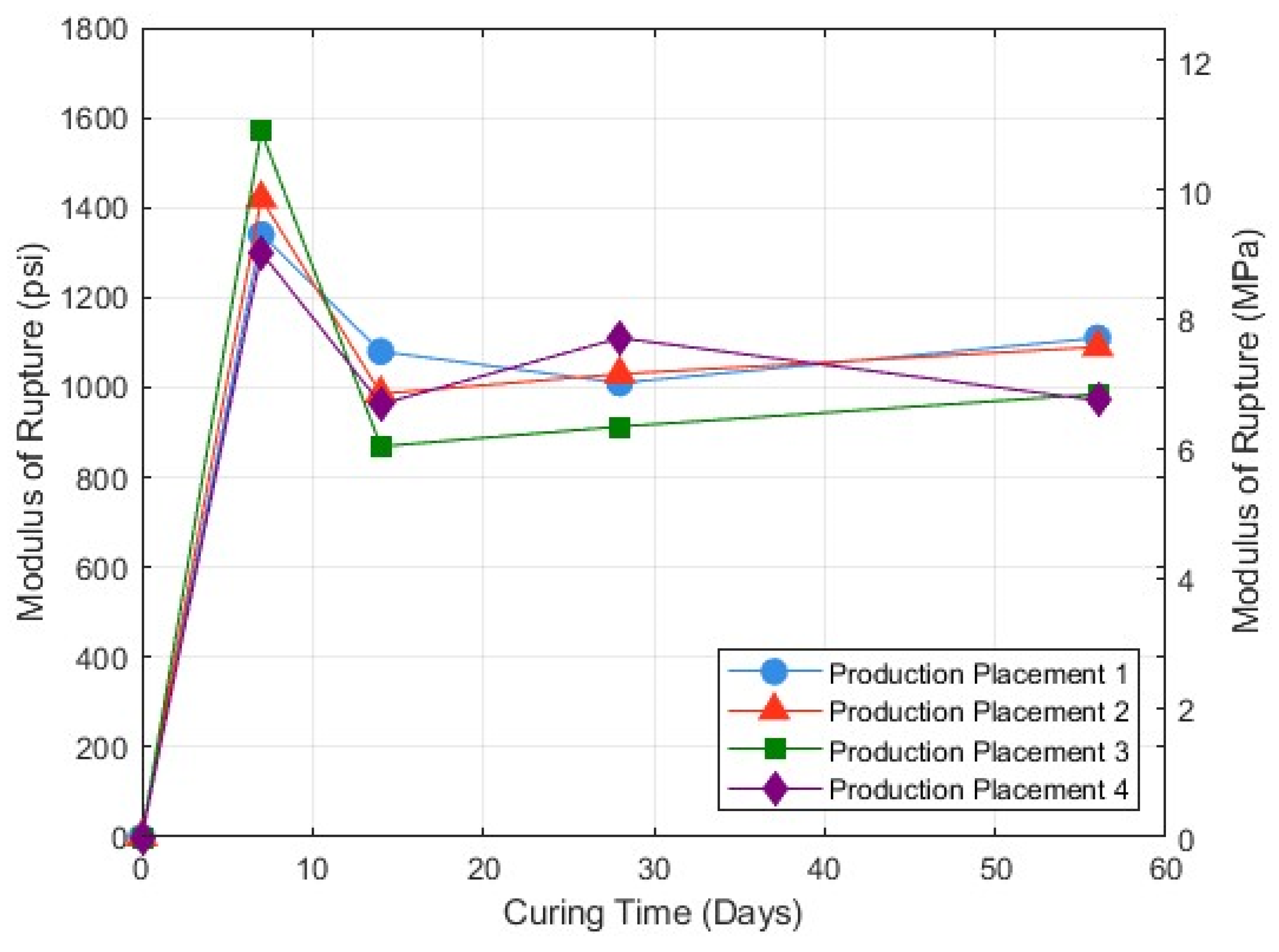

3.3. Overlay–Substrate Bond Assesment

4. Conclusions and Lessons Learned

4.1. Selection of Materials

4.2. Substrate Surface Preparation

4.3. Placement Preparation

4.4. Handling of Materials

4.5. UHPC Mixing

4.6. UHPC Placement

4.7. Overlay Curing

4.8. Quality Assurance

4.9. Sensor Instrumentation

4.10. General Contracts

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Batch No. | Temperature (°C) | Slump (mm) | Spread (mm) | ACCEPTED/REJECTED |

|---|---|---|---|---|

| 1 | 20.9 | 270 | 560 | ACCEPTED |

| 2 | - | - | - | REJECTED |

| 3 | 22.2 | 250 | 490 | ACCEPTED |

| 4 | 20.2 | 235 | 445 | ACCEPTED |

| 5 | 22.1 | 230 | 390 | ACCEPTED |

| 6 | 22.7 | 220 | 385 | ACCEPTED |

| 7 | 19.5 | 205 | 355 | ACCEPTED |

| 8 | 23.9 | 220 | 380 | ACCEPTED |

| 9 | 24.4 | 220 | 385 | ACCEPTED |

| 10 | 24.7 | 230 | 395 | ACCEPTED |

| 11 | 23.0 | 220 | 385 | ACCEPTED |

| 12 | 20.6 | 235 | 420 | ACCEPTED |

| 13 | 22.4 | 235 | 415 | ACCEPTED |

| 14 | 19.3 | 240 | 455 | ACCEPTED |

| 15 | 18.2 | 235 | 410 | ACCEPTED |

| 16 | 18.6 | 240 | 445 | ACCEPTED |

| 17 | 21.8 | 215 | 340 | ACCEPTED |

| 18 | 20.6 | 250 | 490 | ACCEPTED |

| 19 | 21.6 | 250 | 475 | ACCEPTED |

| 20 | 21.1 | 240 | 380 | ACCEPTED |

| 21 | 21.7 | 230 | 370 | ACCEPTED |

| 22 | 20.6 | 205 | 355 | ACCEPTED |

| 23 | 21.4 | 230 | 380 | ACCEPTED |

| 24 | 22.2 | 255 | 385 | ACCEPTED |

| 25 | 22.0 | 240 | 430 | ACCEPTED |

| 26 | 22.2 | 255 | 380 | ACCEPTED |

| 27 | 23.8 | 240 | 410 | ACCEPTED |

| 28 | 23.3 | 250 | 435 | ACCEPTED |

| 29 | 23.4 | 235 | 415 | ACCEPTED |

| 30 | 19.8 | 255 | 440 | ACCEPTED |

| 31 | - | - | - | REJECTED |

| 32 | 20.6 | 260 | 435 | ACCEPTED |

| 33 | 21.2 | 270 | 440 | ACCEPTED |

| 34 | 22.3 | 235 | 415 | ACCEPTED |

| 35 | 24.4 | 240 | 385 | ACCEPTED |

| 36 | 24.9 | 230 | 360 | ACCEPTED |

| 37 | 25.4 | 215 | 340 | ACCEPTED |

| 38 | 24.4 | 255 | 380 | ACCEPTED |

| 39 | 24.0 | 235 | 420 | ACCEPTED |

| 40 | 24.2 | 240 | 415 | ACCEPTED |

| 41 | 24.7 | 250 | 460 | ACCEPTED |

| 42 | 25.4 | 240 | 440 | ACCEPTED |

| 43 | 25.5 | 240 | 420 | ACCEPTED |

| 44 | 25.1 | 250 | 450 | ACCEPTED |

| 45 | 27.0 | 215 | 360 | ACCEPTED |

| 46 | - | - | - | REJECTED |

| 47 | 22.9 | 240 | 440 | ACCEPTED |

| 48 | 24.6 | 240 | 435 | ACCEPTED |

| 49 | 23.8 | 240 | 400 | ACCEPTED |

| 50 | 23.9 | 240 | 435 | ACCEPTED |

| 51 | 20.2 | 190 | 295 | ACCEPTED |

| 52 | - | - | - | REJECTED |

| 53 | 24.2 | 235 | 380 | ACCEPTED |

| 54 | 26.5 | 250 | 400 | ACCEPTED |

| 55 | 23.4 | 240 | 380 | ACCEPTED |

| 56 | 21.9 | 260 | 430 | ACCEPTED |

| 57 | 21.1 | 250 | 400 | ACCEPTED |

| 58 | 19.0 | 250 | 430 | ACCEPTED |

| 59 | 16.5 | 230 | 385 | ACCEPTED |

| 60 | 19.4 | 240 | 435 | ACCEPTED |

| 61 | 17.8 | 240 | 410 | ACCEPTED |

| 62 | 20.6 | 235 | 415 | ACCEPTED |

| 63 | 22.0 | 215 | 365 | ACCEPTED |

| 64 | 20.6 | 215 | 340 | ACCEPTED |

| 65 | 20.8 | 205 | 335 | ACCEPTED |

| 66 | 20.9 | 215 | 360 | ACCEPTED |

| 67 | 20.4 | 235 | 380 | ACCEPTED |

| 68 | 19.6 | 240 | 405 | ACCEPTED |

| 69 | Not tested | Not tested | Not tested | ACCEPTED |

| 70 | 20.4 | 240 | 430 | ACCEPTED |

| 71 | 18.5 | 240 | 430 | ACCEPTED |

| 72 | 19.8 | 240 | 390 | ACCEPTED |

| 73 | 18.2 | 240 | 410 | ACCEPTED |

| 74 | 19.1 | 240 | 415 | ACCEPTED |

| 75 | 18.7 | 250 | 430 | ACCEPTED |

| 76 | Not tested | Not tested | Not tested | ACCEPTED |

| 77 | 26.4 | 235 | 370 | ACCEPTED |

| 78 | 23.8 | 240 | 400 | ACCEPTED |

| 79 | 23.4 | 230 | 375 | ACCEPTED |

| 80 | 24.5 | 240 | 420 | ACCEPTED |

| 81 | 25.4 | 235 | 380 | ACCEPTED |

| 82 | 25.4 | 230 | 385 | ACCEPTED |

| 83 | 25.4 | 240 | 410 | ACCEPTED |

| 84 | 24.3 | 235 | 380 | ACCEPTED |

| 85 | 25.5 | 230 | 375 | ACCEPTED |

| 86 | 20.7 | 235 | 395 | ACCEPTED |

| 87 | 21.1 | 230 | 360 | ACCEPTED |

| 88 | 21.7 | 240 | 380 | ACCEPTED |

| 89 | 21.2 | 240 | 420 | ACCEPTED |

| 90 | 22.6 | 230 | 375 | ACCEPTED |

| 91 | 24.2 | 230 | 380 | ACCEPTED |

| 92 | Not tested | Not tested | Not tested | ACCEPTED |

| 93 | 22.2 | 240 | 430 | ACCEPTED |

| 94 | Not tested | Not tested | Not tested | ACCEPTED |

| 95 | Not tested | Not tested | Not tested | ACCEPTED |

| 96 | 22.1 | 230 | 375 | ACCEPTED |

| 97 | Not tested | Not tested | Not tested | ACCEPTED |

| 98 | Not tested | Not tested | Not tested | ACCEPTED |

| 99 | 21.9 | 240 | 430 | ACCEPTED |

| 100 | 24.0 | 250 | 440 | ACCEPTED |

| 101 | Not tested | Not tested | Not tested | ACCEPTED |

| 102 | 24.0 | 230 | 380 | ACCEPTED |

| 103 | 20.8 | 235 | 435 | ACCEPTED |

| 104 | Not tested | Not tested | Not tested | ACCEPTED |

| 105 | Not tested | Not tested | Not tested | ACCEPTED |

| 106 | 20.9 | 235 | 385 | ACCEPTED |

| 107 | 22.6 | 210 | 340 | ACCEPTED |

| 108 | Not tested | Not tested | Not tested | ACCEPTED |

| 109 | Not tested | Not tested | Not tested | ACCEPTED |

| 110 | Not tested | Not tested | Not tested | Not placed |

References

- Sritharan, S.; Doiron, G.; Bierwagen, D.; Keierleber, B.; Abu-Hawash, A. First Application of UHPC Bridge Deck Overlay in North America. Transp. Res. Rec. 2018, 2672, 40–47. [Google Scholar] [CrossRef]

- Muzenski, S.; Graybeal, B. Structural Performance of UHPC Overlays. In Proceedings of the International Interactive Symposium on Ultra-High Performance Concrete, Wilmington, DE, USA, 4–7 June 2023; Volume 3. [Google Scholar] [CrossRef]

- Haber, Z.B.; Munoz, J.F.; Graybeal, B.A. Field Testing of an Ultra-High Performance Concrete Overlay; FHWA-HRT-17-096; Federal Highway Administration: Washington, DC, USA, 2017. [Google Scholar]

- Lin, S.; Azari, H.; Meng, D.; Shams, S. Nondestructive Evaluation of Concrete Bridge Decks with Overlays; Final Report No. FHWA-HRT-21-023; Federal Highway Administration: Washington, DC, USA, 2021. [Google Scholar]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; FHWA-HRT-06-103; Federal Highway Administration: Washington, DC, USA, 2006. [Google Scholar]

- Graybeal, B.; Davis, M. Cylinder or Cube: Strength Testing of 80 to 200 MPa (11.6 to 29 ksi) Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2008, 105, 603–609. [Google Scholar] [CrossRef]

- Song, M.; Wang, C.; Cui, Y.; Li, Q.; Gao, A. Mechanical Performance and Microstructure of Ultra-High-Performance Concrete Modified by Calcium Sulfoaluminate Cement. Adv. Civ. Eng. 2021, 2021, 400253. [Google Scholar] [CrossRef]

- Graybeal, B.A.; Haber, Z. Ultra-High Performance Concrete for Bridge Deck Overlays; FHWA-HRT-17-097; Federal Highway Administration: Washington, DC, USA, 2018. [Google Scholar]

- Nault, G.; Samson, E. UHPC: A Durable Concrete Overlay Solution for Bridge Decks. In Proceedings of the 2019 IABSE Congress, New York, NY, USA, 4–6 September 2019. [Google Scholar]

- Kuncoro, A.; Pranoto, H.D.; Sacca, L.W.; Antoni, A.; Hardjito, D.; Tanojo, E. Evaluation of Bonding Performance of Ultra-High Performance Concrete with Fly Ash Content as Overlay on Normal Strength Concrete. IOP Conf. Ser. Earth Environ. Sci. 2023, 1195, 012020. [Google Scholar] [CrossRef]

- Haber, Z.B.; Foden, A.; McDonagh, M.; Ocel, J.; Zmetra, K.; Graybeal, B. Design and Construction of UHPC-Based Bridge Preservation and Repair Solutions; FHWA-HRT-22-065; Federal Highway Administration: Washington, DC, USA, 2022. [Google Scholar]

- Weldon, B.; Jauregui, D.; Newtson, C.; Montoya, K.; Taylor, C.; Allena, S.; Muro, J.; Tahat, M.; Lyell, E.; Visage, E.T. Feasibility Analysis of Ultra-High Performance Concrete for Prestressed Concrete Bridge Applications—Phase II; NMDOT Report No. NM09MSC-01; Federal Highway Administration: Washington, DC, USA, 2012. [Google Scholar]

- Newtson, C.M.; Weldon, B.D.; Al-Basha, A.J.; Manning, M.P.; Toledo, W.K.; Davila, L.D. Bridge Deck Overlays Using Ultra-High Performance Concrete; Final Report Project No. 17CNMS01; Transportation Consortium of South Central States (TranSET): Baton Rouge, LA, USA, 2018. [Google Scholar]

- Khayat, K.H.; Valipour, M. Design and Performance of Cost-Effective Ultra High Performance Concrete for Bridge Deck Overlays; MoDOT Final Project No. TR201704; Missouri Department of Transportation: Jefferson City, MI, USA, 2018. [Google Scholar]

- Newtson, C.M.; Weldon, B.D.; Toledo, W.K.; Alvarez, A.; Manning, M.P. Field Implementation and Monitoring of an Ultra-High Performance Concrete Deck Overlay; Final Report Project No. 19CNMS01; Transportation Consortium of South Central States (TranSET): Baton Rouge, LA, USA, 2021. [Google Scholar]

- ASTM A820; Standard Specification for Steel Fibers for Fiber-Reinforced Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- Delatte, N.J.; Wade, D.M.; Fowler, D.W. Laboratory and Field Testing of Concrete Bond Development for Expedited Bonded Concrete Overlays. ACI Mater. J. 2000, 97, 272–280. [Google Scholar]

- Delatte, N.J.; Williamson, M.S.; Fowler, D.W. Bond Strength Gain with Maturity of High Early Strength Bonded Concrete Overlays. ACI Mater. J. 2000, 97, 201–207. [Google Scholar]

- Delatte, N.; Chen, S.; Davidson, J.; Sehdev, A.; Amer, N.; Endfinger, M. Design and Quality Control of Concrete Overlays; UTCA Final Report No. 01220; University Transportation Center for Alabama: Tuscaloosa, AL, USA, 2001. [Google Scholar]

- Alhassan, M.A.; Issa, M.A. Long-Term Protection of Bridge-Deck Systems with Structural Latex-Modified Concrete Overlays. PCI J. 2008, 55, 122–137. [Google Scholar] [CrossRef]

- Federal Highway Administration. Specifications for the National Bridge Inventory; FHWA-HIF-22-017; Federal Highway Administration: Washington, DC, USA, 2022. [Google Scholar]

- ACI Committee 546. Guide to Materials Selection for Concrete Repair; American Concrete Institute ACI546.3R-14; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Toledo, W.K.; Alvarez, A.; Newtson, C.M.; Weldon, B.D. Effects of Substrate Texture and Moisture Conditions on Overlay Bond Strength; Transportation Consortium of South Central States (TranSET): Baton Rouge, LA, USA, 2021. [Google Scholar]

- Toledo, W.K.; Alvarez, A.; Gonzales, G.J.; Newtson, C.M.; Weldon, B.D. Substrate Influence on Ultra-High Performance Concrete Bond Strength. ACI Mater. J. 2022, 119, 189–196. [Google Scholar] [CrossRef]

- Pulkit, K.; Saini, B.; Chalak, H.D. Factors Affecting the Bond Between Substrate-Overlay Material. A Review. J. Eng. Sci. Technol. Rev. 2022, 15, 55–69. [Google Scholar] [CrossRef]

- ASTM C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C1611; Standard Test Method for Slump Flow of Self-Consolidating Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- BS 1881-116; Testing Concrete—Part 116: Method for Determination of Compressive Strength of Concrete Cubes. British Standards Institution: London, UK, 1983.

- ASTM C1609; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third Point Loading). ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C1583; Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-Off Method). ASTM International: West Conshohocken, PA, USA, 2010.

- ACI Committee 303. Guide to Cast-In-Place Architectural Concrete; American Concrete Institute: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM C1856; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C31; Making and Curing Concrete Test Specimens in the Field. ASTM International: West Conshohocken, PA, USA, 2023.

| Constituents | Unit | Unit/m3 |

|---|---|---|

| Cement | kg | 741 |

| Silica fume | kg | 116 |

| Fly ash | kg | 69.4 |

| Fine sand | kg | 951 |

| Steel fibers 1 | kg | 137 |

| HRWRA 2 | L | 42.1 |

| Water | kg | 145 |

| Production Placement | Avg. Temperature (°C) | Avg. Slump (mm) | Avg. Spread (mm) |

|---|---|---|---|

| 1 | 21.8 | 235 | 417 |

| 2 | 23.7 | 239 | 409 |

| 3 | 19.6 | 234 | 399 |

| 4 | 23.2 | 234 | 391 |

| Curing Regimen | Avg. 100 mm Compressive Strength and ±σ (MPa) | Curing Regimen | Avg. MOR and ±σ (MPa) | |||

|---|---|---|---|---|---|---|

| Production Placement 1 | ||||||

| A | 2-day | 4-day | 7-day | “MR” for 7 days, then “A” until testing | 7-day | 14-day |

| 60.1 ±4.49 | 70.4 ±4.96 | 74.9 ±4.96 | 9.20 ±0.16 | 7.42 ±0.554 | ||

| MR | 14-day | 28-day | 56-day | “MR” for 7 days, then “A” until testing | 28-day | 56-day |

| 76.2 ±8.27 | 85.4 ±10.3 | 88.1 ±9.17 | 6.94 ±0.216 | 7.68 ±0.582 | ||

| Production Placement 2 | ||||||

| A | 2-day | 4-day | 7-day | “MR” for 7 days, then “A” until testing | 7-day | 14-day |

| 52.9 ±5.12 | 68.1 ±5.29 | 76.9 ±8.55 | 9.79 ±0.416 | 6.80 ±0.629 | ||

| MR | 14-day | 28-day | 56-day | “MR” for 7 days, then “A” until testing | 28-day | 56-day |

| 79.4 ±8.84 | 85.2 ±8.20 | 94.0 ±5.81 | 7.10 ±0.298 | 7.52 ±0.146 | ||

| Production Placement 3 | ||||||

| A | 2-day | 4-day | 7-day | “MR” for 7 days, then “A” until testing | 7-day | 14-day |

| 64.8 ±4.51 | 76.3 ±3.20 | 80.9 ±1.66 | 10.8 ±0.869 | 5.99 ±0.855 | ||

| MR | 14-day | 28-day | 56-day | “MR” for 7 days, then “A” until testing | 28-day | 56-day |

| 90.3 ±3.61 | 90.9 ±2.53 | 96.9 ±3.55 | 6.29 ±2.20 | 6.79 ±1.25 | ||

| Production Placement 4 | ||||||

| A | 2-day | 4-day | 7-day | “MR” for 7 days, then “A” until testing | 7-day | 14-day |

| 55.8 ±1.50 | 70.7 ±1.43 | 81.2 ±1.52 | 8.96 ±0.570 | 6.64 ±0.383 | ||

| MR | 14-day | 28-day | 56-day | “MR” for 7 days, then “A” until testing | 28-day | 56-day |

| 84.0 ±2.02 | 85.6 ±4.35 | 96.8 ±7.10 | 7.65 ±1.40 | 6.69 ±1.30 | ||

| Core Sample | On Potential Delamination? | Load (kN) | Bond Strength and ±σ (MPa) | Type of Failure |

|---|---|---|---|---|

| Eastbound Lane | ||||

| 1 | - | 2.89 | 1.62 | HPD |

| 2 | Yes | 1.45 | 0.814 | Bond |

| 3 | - | 2.89 | 1.62 | UHPC/Bond |

| 4 | Yes | 0.444 | 0.250 | UHPC |

| 5 | - | 2.45 | 1.37 | UHPC/Epoxy |

| 6 1 | Delam. 1 | - 1 | - 1 | - 1 |

| 7 | - | 4.45 | 2.50 | Bond |

| 8 | - | 1.78 | 1.00 | Bond |

| 9 | - | 4.23 | 2.37 | UHPC/Epoxy |

| Westbound Lane | ||||

| 10 | - | 0.890 | 0.499 | Bond |

| 11 | - | 4.89 | 2.74 | HPD |

| 12 | - | 3.78 | 2.12 | UHPC/Epoxy |

| 13 | Yes | 3.56 | 2.00 | UHPC/Epoxy |

| 14 | - | 3.89 | 2.19 | Bond |

| 15 | - | 3.89 | 2.19 | UHPC/Epoxy |

| 16 | - | 5.03 | 2.81 | UHPC/Epoxy |

| 17 | - | 5.89 | 3.31 | UHPC/Epoxy |

| 18 | - | 4.34 | 2.43 | UHPC/Epoxy |

| Avg. | 3.34 | 1.88 ±0.827 | UHPC/Epoxy | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alvarez, A.; Toledo, W.K.; Weldon, B.D.; Newtson, C.M. Construction Methods and Lessons Learned for a Non-Proprietary Ultra-High Performance Concrete Overlay. Constr. Mater. 2024, 4, 271-291. https://doi.org/10.3390/constrmater4010015

Alvarez A, Toledo WK, Weldon BD, Newtson CM. Construction Methods and Lessons Learned for a Non-Proprietary Ultra-High Performance Concrete Overlay. Construction Materials. 2024; 4(1):271-291. https://doi.org/10.3390/constrmater4010015

Chicago/Turabian StyleAlvarez, Andres, William K. Toledo, Brad D. Weldon, and Craig M. Newtson. 2024. "Construction Methods and Lessons Learned for a Non-Proprietary Ultra-High Performance Concrete Overlay" Construction Materials 4, no. 1: 271-291. https://doi.org/10.3390/constrmater4010015

APA StyleAlvarez, A., Toledo, W. K., Weldon, B. D., & Newtson, C. M. (2024). Construction Methods and Lessons Learned for a Non-Proprietary Ultra-High Performance Concrete Overlay. Construction Materials, 4(1), 271-291. https://doi.org/10.3390/constrmater4010015