Towards 30% Efficiency by 2030 of Eco-Designed Building Integrated Photovoltaics

Abstract

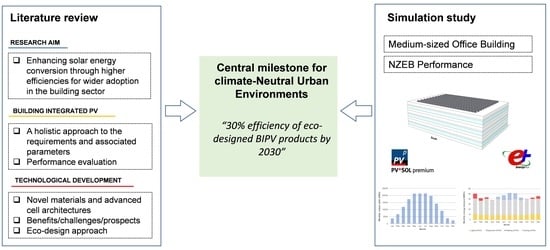

:1. Introduction

2. Methods

3. Building Integrated PV

3.1. Requirements and Characteristics of BIPV and Built Environment Integrated PV

3.2. Performance Evaluation of Current BIPV Technologies

3.2.1. Opaque (Roof/Facade)

3.2.2. (S)TPV (Glazings)

4. NZEB Performance

5. Emerging BIPV Technologies

5.1. Opaque

5.1.1. HJI and Modules to Be Produced with Efficiency of up to 25% until 2025

5.1.2. Other Emerging Technologies

5.1.3. Glazings

6. Tandem Cells with Efficiencies of up to 30%

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santamouris, M. Cooling the cities—A review of reflective and green roof mitigation technologies to fight heat island and improve comfort in urban environments. Sol. Energy 2014, 103, 682–703. [Google Scholar] [CrossRef]

- Cuerdo-Vilches, T.; Díaz, J.; López-Bueno, J.A.; Luna, M.Y.; Navas, M.A.; Mirón, I.J.; Linares, C. Impact of urban heat islands on morbidity and mortality in heat waves: Observational time series analysis of Spain’s five cities. Sci. Total Environ. 2023, 890, 164412. [Google Scholar] [CrossRef]

- Eugenio Pappalardo, S.; Zanetti, C.; Todeschi, V. Mapping urban heat islands and heat-related risk during heat waves from a climate justice perspective: A case study in the municipality of Padua (Italy) for inclusive adaptation policies. Landsc. Urban Plan. 2023, 238, 104831. [Google Scholar] [CrossRef]

- Iungman, T.; Cirach, M.; Marando, F.; Barboza, E.P.; Khomenko, S.; Masselot, P.; Quijal-Zamorano, M.; Mueller, N.; Gasparrini, A.; Urquiza, J. Cooling cities through urban green infrastructure: A health impact assessment of European cities. Lancet 2023, 401, 577–589. [Google Scholar] [CrossRef]

- Skandalos, N.; Wang, M.; Kapsalis, V.; D’Agostino, D.; Parker, D.; Bhuvad, S.S.; Udayraj; Peng, J.; Karamanis, D. Building PV integration according to regional climate conditions: BIPV regional adaptability extending Köppen-Geiger climate classification against urban and climate-related temperature increases. Renew. Sustain. Energy Rev. 2022, 169, 112950. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Solar PV Technology Deep Dive. Available online: https://www.iea.org/reports/solar-pv (accessed on 21 February 2023).

- Castellanos, S.; Sunter, D.A.; Kammen, D.M. Exploring rooftop solar photovoltaics deployment and energy injustice in the US through a data-driven approach. In Data Science Applied to Sustainability Analysis; Elsevier: Amsterdam, The Netherlands, 2021; pp. 109–128. [Google Scholar]

- Kammen, D.M.; Sunter, D.A. City-integrated renewable energy for urban sustainability. Science 2016, 352, 922–928. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romaní, J.; Pérez-Rodríguez, A.; Salom, J. Performance of prototype tandem UV filter and organic transparent photovoltaic windows. J. Build. Eng. 2023, 68, 106111. [Google Scholar] [CrossRef]

- Tian, X.; Wang, J.; Ji, J.; Wang, C.; Ke, W.; Yuan, S. A multifunctional curved CIGS photovoltaic/thermal roof system: A numerical and experimental investigation. Energy 2023, 273, 127259. [Google Scholar] [CrossRef]

- Koh, T.M.; Wang, H.; Ng, Y.F.; Bruno, A.; Mhaisalkar, S.; Mathews, N. Halide perovskite solar cells for building integrated photovoltaics: Transforming building façades into power generators. Adv. Mater. 2022, 34, 2104661. [Google Scholar] [CrossRef]

- Nguyen, D.C.; Sato, K.; Hamada, M.; Murata, F.; Ishikawa, Y. Annual output energy harvested by building-integrated photovoltaics based on the optimized structure of 2-terminal perovskite/silicon tandem cells under realistic conditions. Sol. Energy 2022, 241, 452–459. [Google Scholar] [CrossRef]

- D’Agostino, D.; Parker, D.; Melià, P.; Dotelli, G. Optimizing photovoltaic electric generation and roof insulation in existing residential buildings. Energy Build. 2022, 255, 111652. [Google Scholar] [CrossRef]

- Garshasbi, S.; Khan, A.; Santamouris, M. On the building cooling energy penalty of photovoltaic solar panels in Sydney. Energy Build. 2023, 294, 113259. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C.; Drolsum Røkenes, H. Building integrated photovoltaic products: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 100, 69–96. [Google Scholar] [CrossRef] [Green Version]

- Pillai, D.S.; Shabunko, V.; Krishna, A. A comprehensive review on building integrated photovoltaic systems: Emphasis to technological advancements, outdoor testing, and predictive maintenance. Renew. Sustain. Energy Rev. 2022, 156, 111946. [Google Scholar] [CrossRef]

- Polverini, D.; Amillo, A.G.; Taylor, N.; Sample, T.; Salis, E.; Dunlop, E.D. Building Criteria for Energy Labeling of Photovoltaic Modules and Small Systems. Sol. RRL 2022, 6, 2100518. [Google Scholar] [CrossRef]

- Wade, A.; Neuhaus, H.; Probst, L.; Sauer, T.; Moser, D.; Rohr, C.; Rossi, R.; Wirth, H. Expert Input Paper-Eco-Design & Energy Labelling for Photovoltaic Modules, Inverters and Systems in the EU; Secretariat of the European Technology and Innovation Platform for Photovoltaics: Brussels, Belgium, 2021. [Google Scholar] [CrossRef]

- Ecodesign-European Commission to Examine New Rules on Environmental Impact of Photovoltaics. Available online: https://ec.europea.eu (accessed on 11 July 2023).

- Commission, E. Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonized conditions for the marketing of construction products and repealing Council Directive 89/106/EEC. Off. J. Eur. Union 2011, 88, 5–43. [Google Scholar]

- ICARES; CSTB; SUPSI; TECNALIA; TULiPPS. Regulatory Framework for BIPV, Report of Project BIPVboost; 2019. Report of the Horizon Project BIPV Boost. Available online: https://bipvboost.eu/public-reports/?page=2 (accessed on 6 July 2023).

- Haegel, N.M.; Verlinden, P.; Victoria, M.; Altermatt, P.; Atwater, H.; Barnes, T.; Breyer, C.; Case, C.; De Wolf, S.; Deline, C. Photovoltaics at multi-terawatt scale: Waiting is not an option. Science 2023, 380, 39–42. [Google Scholar] [CrossRef]

- Skandalos, N.; Karamanis, D. PV glazing technologies. Renew. Sustain. Energy Rev. 2015, 49, 306–322. [Google Scholar] [CrossRef]

- Skandalos, N.; Tywoniak, J. Influence of PV facade configuration on the energy demand and visual comfort in office buildings. J. Phys. Conf. Ser. 2019, 1343, 012094. [Google Scholar] [CrossRef]

- Skandalos, N.; Kichou, S.; Wolf, P. Energy sufficiency of an administrative building based on real data from one year of operation. In Proceedings of the 2018 Smart City Symposium Prague (SCSP), Prague, Czech Republic, 24–25 May 2018; pp. 1–8. [Google Scholar]

- Ballif, C.; Haug, F.-J.; Boccard, M.; Verlinden, P.J.; Hahn, G. Status and perspectives of crystalline silicon photovoltaics in research and industry. Nat. Rev. Mater. 2022, 7, 597–616. [Google Scholar] [CrossRef]

- Victoria, M.; Haegel, N.; Peters, I.M.; Sinton, R.; Jäger-Waldau, A.; del Canizo, C.; Breyer, C.; Stocks, M.; Blakers, A.; Kaizuka, I. Solar photovoltaics is ready to power a sustainable future. Joule 2021, 5, 1041–1056. [Google Scholar] [CrossRef]

- Lin, H.; Yang, M.; Ru, X.; Wang, G.; Yin, S.; Peng, F.; Hong, C.; Qu, M.; Lu, J.; Fang, L. Silicon heterojunction solar cells with up to 26.81% efficiency achieved by electrically optimized nanocrystalline-silicon hole contact layers. Nat. Energy 2023, 1–11. [Google Scholar] [CrossRef]

- O’regan, B.; Grätzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 1991, 353, 737–740. [Google Scholar] [CrossRef]

- Photovoltaic Research|NREL, “Best Research-Cell Efficiency Chart”. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 1 June 2023).

- Kapsalis, V.; Kyriakopoulos, G.; Zamparas, M.; Tolis, A. Investigation of the photon to charge conversion and its implication on photovoltaic cell efficient operation. Energies 2021, 14, 3022. [Google Scholar] [CrossRef]

- Wang, Z.; Song, Z.; Yan, Y.; Liu, S.; Yang, D. Perovskite—A perfect top cell for tandem devices to break the S–Q limit. Adv. Sci. 2019, 6, 1801704. [Google Scholar] [CrossRef]

- Rühle, S. Tabulated values of the Shockley–Queisser limit for single junction solar cells. Sol. Energy 2016, 130, 139–147. [Google Scholar] [CrossRef]

- Gao, L.; Xu, C.; Su, Y.; Liu, A.; Ma, T. Cascaded band gap design for highly efficient electron transport layer-free perovskite solar cells. Chem. Commun. 2022, 58, 6749–6752. [Google Scholar] [CrossRef] [PubMed]

- Badran, G.; Dhimish, M. Potential Induced Degradation in Photovoltaic Modules: A Review of the Latest Research and Developments. Solar 2023, 3, 322–346. [Google Scholar] [CrossRef]

- Song, Z.; McElvany, C.L.; Phillips, A.B.; Celik, I.; Krantz, P.W.; Watthage, S.C.; Liyanage, G.K.; Apul, D.; Heben, M.J. A technoeconomic analysis of perovskite solar module manufacturing with low-cost materials and techniques. Energy Environ. Sci. 2017, 10, 1297–1305. [Google Scholar] [CrossRef]

- Li, T.T.; Yang, Y.B.; Li, G.R.; Chen, P.; Gao, X.P. Two-Terminal Perovskite-Based Tandem Solar Cells for Energy Conversion and Storage. Small 2021, 17, 2006145. [Google Scholar] [CrossRef]

- Kim, D.H.; Muzzillo, C.P.; Tong, J.; Palmstrom, A.F.; Larson, B.W.; Choi, C.; Harvey, S.P.; Glynn, S.; Whitaker, J.B.; Zhang, F. Bimolecular additives improve wide-band-gap perovskites for efficient tandem solar cells with CIGS. Joule 2019, 3, 1734–1745. [Google Scholar] [CrossRef]

- Hwang, S.K.; Park, I.J.; Seo, S.W.; Park, J.H.; Park, S.J.; Kim, J.Y. Electrochemically deposited CZTSSe thin films for monolithic perovskite tandem solar cells with efficiencies over 17%. Energy Environ. Mater. 2023, e12489. [Google Scholar] [CrossRef]

- Salhi, B.; Wudil, Y.; Hossain, M.; Al-Ahmed, A.; Al-Sulaiman, F. Review of recent developments and persistent challenges in stability of perovskite solar cells. Renew. Sustain. Energy Rev. 2018, 90, 210–222. [Google Scholar] [CrossRef]

- Djurišić, A.; Liu, F.; Ng, A.M.; Dong, Q.; Wong, M.K.; Ng, A.; Surya, C. Stability issues of the next generation solar cells. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2016, 10, 281–299. [Google Scholar] [CrossRef]

- Bati, A.S.; Zhong, Y.L.; Burn, P.L.; Nazeeruddin, M.K.; Shaw, P.E.; Batmunkh, M. Next-generation applications for integrated perovskite solar cells. Commun. Mater. 2023, 4, 2. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Seo, J.-Y.; Domanski, K.; Correa-Baena, J.-P.; Nazeeruddin, M.K.; Zakeeruddin, S.M.; Tress, W.; Abate, A.; Hagfeldt, A. Cesium-containing triple cation perovskite solar cells: Improved stability, reproducibility and high efficiency. Energy Environ. Sci. 2016, 9, 1989–1997. [Google Scholar] [CrossRef] [Green Version]

- Syzgantseva, O.A.; Saliba, M.; Grätzel, M.; Rothlisberger, U. Stabilization of the perovskite phase of formamidinium lead triiodide by methylammonium, Cs, and/or Rb doping. J. Phys. Chem. Lett. 2017, 8, 1191–1196. [Google Scholar] [CrossRef]

- Deng, L.L.; Xie, S.Y.; Gao, F. Fullerene-Based Materials for Photovoltaic Applications: Toward Efficient, Hysteresis-Free, and Stable Perovskite Solar Cells. Adv. Electron. Mater. 2018, 4, 1700435. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Zhang, Z.; Tang, Z.; Su, C.; Huang, W.; Li, Y.; Xing, G. Polymer strategies for high-efficiency and stable perovskite solar cells. Nano Energy 2021, 82, 105712. [Google Scholar] [CrossRef]

- Proppe, A.H.; Johnston, A.; Teale, S.; Mahata, A.; Quintero-Bermudez, R.; Jung, E.H.; Grater, L.; Cui, T.; Filleter, T.; Kim, C.-Y. Multication perovskite 2D/3D interfaces form via progressive dimensional reduction. Nat. Commun. 2021, 12, 3472. [Google Scholar] [CrossRef]

- You, J.; Meng, L.; Song, T.-B.; Guo, T.-F.; Yang, Y.; Chang, W.-H.; Hong, Z.; Chen, H.; Zhou, H.; Chen, Q. Improved air stability of perovskite solar cells via solution-processed metal oxide transport layers. Nat. Nanotechnol. 2016, 11, 75–81. [Google Scholar] [CrossRef]

- Sun, W.; Li, Y.; Ye, S.; Rao, H.; Yan, W.; Peng, H.; Li, Y.; Liu, Z.; Wang, S.; Chen, Z. High-performance inverted planar heterojunction perovskite solar cells based on a solution-processed CuO x hole transport layer. Nanoscale 2016, 8, 10806–10813. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.; Sun, W.; Li, Y.; Yan, W.; Peng, H.; Bian, Z.; Liu, Z.; Huang, C. CuSCN-based inverted planar perovskite solar cell with an average PCE of 15.6%. Nano Lett. 2015, 15, 3723–3728. [Google Scholar] [CrossRef] [PubMed]

- Matteocci, F.; Cinà, L.; Lamanna, E.; Cacovich, S.; Divitini, G.; Midgley, P.A.; Ducati, C.; Di Carlo, A. Encapsulation for long-term stability enhancement of perovskite solar cells. Nano Energy 2016, 30, 162–172. [Google Scholar] [CrossRef] [Green Version]

- Pulli, E.; Rozzi, E.; Bella, F. Transparent photovoltaic technologies: Current trends towards upscaling. Energy Convers. Manag. 2020, 219, 112982. [Google Scholar] [CrossRef]

- Yang, C.; Liu, D.; Bates, M.; Barr, M.C.; Lunt, R.R. How to accurately report transparent solar cells. Joule 2019, 3, 1803–1809. [Google Scholar] [CrossRef]

- Giannouli, M. Current Status of Emerging PV Technologies: A Comparative Study of Dye-Sensitized, Organic, and Perovskite Solar Cells. Int. J. Photoenergy 2021, 2021, 6692858. [Google Scholar] [CrossRef]

- Zhou, Z.; Yuan, Z.; Yin, Z.; Xue, Q.; Li, N.; Huang, F. Progress of semitransparent emerging photovoltaics for building integrated applications. Green Energy Environ. 2023. [Google Scholar] [CrossRef]

- Inganäs, O. Organic Photovoltaics over Three Decades. Adv. Mater. 2018, 30, 1800388. [Google Scholar] [CrossRef]

- Liu, X.; Zhong, Z.; Zhu, R.; Yu, J.; Li, G. Aperiodic band-pass electrode enables record-performance transparent organic photovoltaics. Joule 2022, 6, 1918–1930. [Google Scholar] [CrossRef]

- Jing, J.; Dong, S.; Zhang, K.; Zhou, Z.; Xue, Q.; Song, Y.; Du, Z.; Ren, M.; Huang, F. Semitransparent organic solar cells with efficiency surpassing 15%. Adv. Energy Mater. 2022, 12, 2200453. [Google Scholar] [CrossRef]

- Roy, A.; Sujatha Devi, P.; Karazhanov, S.; Mamedov, D.; Mallick, T.K.; Sundaram, S. A review on applications of Cu2ZnSnS4 as alternative counter electrodes in dye-sensitized solar cells. AIP Adv. 2018, 8, 070701. [Google Scholar] [CrossRef]

- Richhariya, G.; Kumar, A.; Tekasakul, P.; Gupta, B. Natural dyes for dye sensitized solar cell: A review. Renew. Sustain. Energy Rev. 2017, 69, 705–718. [Google Scholar] [CrossRef]

- Godfroy, M.; Liotier, J.; Mwalukuku, V.M.; Joly, D.; Huaulmé, Q.; Cabau, L.; Aumaitre, C.; Kervella, Y.; Narbey, S.; Oswald, F. Benzothiadiazole-based photosensitizers for efficient and stable dye-sensitized solar cells and 8.7% efficiency semi-transparent mini-modules. Sustain. Energy Fuels 2021, 5, 144–153. [Google Scholar] [CrossRef]

- Roy, A.; Ghosh, A.; Bhandari, S.; Sundaram, S.; Mallick, T.K. Perovskite solar cells for BIPV application: A review. Buildings 2020, 10, 129. [Google Scholar] [CrossRef]

- Yu, J.C.; Li, B.; Dunn, C.J.; Yan, J.; Diroll, B.T.; Chesman, A.S.R.; Jasieniak, J.J. High-Performance and Stable Semi-Transparent Perovskite Solar Cells through Composition Engineering. Adv. Sci. 2022, 9, 2201487. [Google Scholar] [CrossRef]

- Bernardoni, P.; Mangherini, G.; Gjestila, M.; Andreoli, A.; Vincenzi, D. Performance Optimization of Luminescent Solar Concentrators under Several Shading Conditions. Energies 2021, 14, 816. [Google Scholar] [CrossRef]

- Debije, M.G.; Verbunt, P.P.C. Thirty Years of Luminescent Solar Concentrator Research: Solar Energy for the Built Environment. Adv. Energy Mater. 2012, 2, 12–35. [Google Scholar] [CrossRef]

- Slooff, L.H.; Bende, E.E.; Burgers, A.R.; Budel, T.; Pravettoni, M.; Kenny, R.P.; Dunlop, E.D.; Büchtemann, A. A luminescent solar concentrator with 7.1% power conversion efficiency. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2008, 2, 257–259. [Google Scholar] [CrossRef] [Green Version]

- Goldschmidt, J.C.; Peters, M.; Bösch, A.; Helmers, H.; Dimroth, F.; Glunz, S.W.; Willeke, G. Increasing the efficiency of fluorescent concentrator systems. Sol. Energy Mater. Sol. Cells 2009, 93, 176–182. [Google Scholar] [CrossRef]

- Richter, A.; Hermle, M.; Glunz, S.W. Reassessment of the limiting efficiency for crystalline silicon solar cells. IEEE J. Photovolt. 2013, 3, 1184–1191. [Google Scholar] [CrossRef]

- Mailoa, J.P.; Bailie, C.D.; Johlin, E.C.; Hoke, E.T.; Akey, A.J.; Nguyen, W.H.; McGehee, M.D.; Buonassisi, T. A 2-terminal perovskite/silicon multijunction solar cell enabled by a silicon tunnel junction. Appl. Phys. Lett. 2015, 106, 121105. [Google Scholar] [CrossRef] [Green Version]

- Köhnen, E.; Wagner, P.; Lang, F.; Cruz, A.; Li, B.; Roß, M.; Jošt, M.; Morales-Vilches, A.B.; Topič, M.; Stolterfoht, M. 27.9% efficient monolithic perovskite/silicon tandem solar cells on industry compatible bottom cells. Sol. RRL 2021, 5, 2100244. [Google Scholar] [CrossRef]

- Duan, L.; Walter, D.; Chang, N.; Bullock, J.; Kang, D.; Phang, S.P.; Weber, K.; White, T.; Macdonald, D.; Catchpole, K.; et al. Stability challenges for the commercialization of perovskite–silicon tandem solar cells. Nat. Rev. Mater. 2023, 8, 261–281. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Domanski, K.; Seo, J.-Y.; Ummadisingu, A.; Zakeeruddin, S.M.; Correa-Baena, J.-P.; Tress, W.R.; Abate, A.; Hagfeldt, A. Incorporation of rubidium cations into perovskite solar cells improves photovoltaic performance. Science 2016, 354, 206–209. [Google Scholar] [CrossRef] [PubMed]

- Domanski, K.; Correa-Baena, J.-P.; Mine, N.; Nazeeruddin, M.K.; Abate, A.; Saliba, M.; Tress, W.; Hagfeldt, A.; Grätzel, M. Not all that glitters is gold: Metal-migration-induced degradation in perovskite solar cells. ACS Nano 2016, 10, 6306–6314. [Google Scholar] [CrossRef]

- Wang, R.; Mujahid, M.; Duan, Y.; Wang, Z.K.; Xue, J.; Yang, Y. A review of perovskites solar cell stability. Adv. Funct. Mater. 2019, 29, 1808843. [Google Scholar] [CrossRef]

- Chen, H.; Ye, F.; Tang, W.; He, J.; Yin, M.; Wang, Y.; Xie, F.; Bi, E.; Yang, X.; Grätzel, M. A solvent-and vacuum-free route to large-area perovskite films for efficient solar modules. Nature 2017, 550, 92–95. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Qin, Z.; Miao, Y.; Zhao, Y. Recent Progress in Large-Area Perovskite Photovoltaic Modules. Trans. Tianjin Univ. 2022, 28, 323–340. [Google Scholar] [CrossRef]

- Yan, J.; Savenije, T.J.; Mazzarella, L.; Isabella, O. Progress and challenges on scaling up of perovskite solar cell technology. Sustain. Energy Fuels 2022, 6, 243–266. [Google Scholar] [CrossRef]

- Shen, H.; Walter, D.; Wu, Y.; Fong, K.C.; Jacobs, D.A.; Duong, T.; Peng, J.; Weber, K.; White, T.P.; Catchpole, K.R. Monolithic perovskite/Si tandem solar cells: Pathways to over 30% efficiency. Adv. Energy Mater. 2020, 10, 1902840. [Google Scholar] [CrossRef]

- Babics, M.; De Bastiani, M.; Ugur, E.; Xu, L.; Bristow, H.; Toniolo, F.; Raja, W.; Subbiah, A.S.; Liu, J.; Torres Merino, L.V.; et al. One-year outdoor operation of monolithic perovskite/silicon tandem solar cells. Cell Rep. Phys. Sci. 2023, 4, 101280. [Google Scholar] [CrossRef]

- Luo, X.; Luo, H.; Li, H.; Xia, R.; Zheng, X.; Huang, Z.; Liu, Z.; Gao, H.; Zhang, X.; Li, S. Efficient Perovskite/Silicon Tandem Solar Cells on Industrially Compatible Textured Silicon. Adv. Mater. 2023, 35, 2207883. [Google Scholar] [CrossRef]

- VDMA. International Technology Roadmap for Photovoltaic (ITRPV), Results Including Maturity Report. 2022. Available online: https://itrpv.vdma.org/ (accessed on 6 July 2023).

- Han, Q.; Hsieh, Y.-T.; Meng, L.; Wu, J.-L.; Sun, P.; Yao, E.-P.; Chang, S.-Y.; Bae, S.-H.; Kato, T.; Bermudez, V. High-performance perovskite/Cu (In, Ga) Se2 monolithic tandem solar cells. Science 2018, 361, 904–908. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jošt, M.; Köhnen, E.; Al-Ashouri, A.; Bertram, T.; Tomšič, S.P.; Magomedov, A.; Kasparavicius, E.; Kodalle, T.; Lipovšek, B.; Getautis, V. Perovskite/CIGS tandem solar cells: From certified 24.2% toward 30% and beyond. ACS Energy Lett. 2022, 7, 1298–1307. [Google Scholar] [CrossRef]

- Singh, A.K.; Chauhan, M.S.; Patel, S.P.; Singh, R.S.; Singh, V.K. MAPbI3-on-CuInSe2 two-terminal monolithically integrated and four-terminal mechanically stacked tandem solar cells: A Theoretical Investigation Using SCAPS-1D. Results Opt. 2023, 10, 100358. [Google Scholar] [CrossRef]

- Madan, J.; Singh, K.; Pandey, R. Comprehensive device simulation of 23.36% efficient two-terminal perovskite-PbS CQD tandem solar cell for low-cost applications. Sci. Rep. 2021, 11, 19829. [Google Scholar] [CrossRef]

- Abdollahi Nejand, B.; Ritzer, D.B.; Hu, H.; Schackmar, F.; Moghadamzadeh, S.; Feeney, T.; Singh, R.; Laufer, F.; Schmager, R.; Azmi, R. Scalable two-terminal all-perovskite tandem solar modules with a 19.1% efficiency. Nat. Energy 2022, 7, 620–630. [Google Scholar] [CrossRef]

- He, R.; Wang, W.; Yi, Z.; Lang, F.; Chen, C.; Luo, J.; Zhu, J.; Thiesbrummel, J.; Shah, S.; Wei, K. Improving interface quality for 1-cm2 all-perovskite tandem solar cells. Nature 2023, 618, 80–86. [Google Scholar] [CrossRef]

- Chen, X.; Jia, Z.; Chen, Z.; Jiang, T.; Bai, L.; Tao, F.; Chen, J.; Chen, X.; Liu, T.; Xu, X. Efficient and reproducible monolithic perovskite/organic tandem solar cells with low-loss interconnecting layers. Joule 2020, 4, 1594–1606. [Google Scholar] [CrossRef]

- Sun, S.Q.; Xu, X.; Sun, Q.; Yao, Q.; Cai, Y.; Li, X.Y.; Xu, Y.L.; He, W.; Zhu, M.; Lv, X. All-Inorganic Perovskite-Based Monolithic Perovskite/Organic Tandem Solar Cells with 23.21% Efficiency by Dual-Interface Engineering. Adv. Energy Mater. 2023, 13, 2204347. [Google Scholar] [CrossRef]

- NREL. Full Record of PV Cell Efficiency Data. Available online: https://www.nrel.gov/pv/assets/docs/cell-efficiency-data-table.xlsx (accessed on 15 June 2023).

- Xie, M.; Liu, X.; Li, Y.; Li, X.A. Two-dimensional InSb/GaAs-and InSb/InP-based tandem photovoltaic device with matched bandgap. Nanoscale 2022, 14, 1954–1961. [Google Scholar] [CrossRef] [PubMed]

- Werner, J.; Niesen, B.; Ballif, C. Perovskite/silicon tandem solar cells: Marriage of convenience or true love story?—An overview. Adv. Mater. Interfaces 2018, 5, 1700731. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Y.; Wang, X.; Sun, Y.; Zhao, Z.; Li, Y.; Zhou, H.; Chen, Q. Cost analysis of perovskite tandem photovoltaics. Joule 2018, 2, 1559–1572. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, K.; Mishima, R.; Uzu, H.; Adachi, D. High efficiency perovskite/heterojunction crystalline silicon tandem solar cells: Towards industrial-sized cell and module. Jpn. J. Appl. Phys. 2023, 62, SK1021. [Google Scholar] [CrossRef]

- Green, M.A. Commercial progress and challenges for photovoltaics. Nat. Energy 2016, 1, 15015. [Google Scholar] [CrossRef]

- Martinho, F. Challenges for the future of tandem photovoltaics on the path to terawatt levels: A technology review. Energy Environ. Sci. 2021, 14, 3840–3871. [Google Scholar] [CrossRef]

- NEXUS Project: Next Generation of Sustainable Perovskite-Silicon Tandem Cells. Available online: https://nexus-pv.eu/ (accessed on 14 July 2023).

- 4SUNS Project: 4-Colours/2-Junctions of III-V Semiconductors on Si to Use in Electronics Devices and Solar Cells. Available online: https://cordis.europa.eu/project/id/758885 (accessed on 12 July 2023).

- Chatzipanagi, A.; Jaeger-Waldau, A.; Cleret, D.; Letout, S.; Latunussa, C.; Mountraki, A.; Georgakaki, A.; Ince, E.; Kuokkanen, A.; Shtjefni, D. Clean Energy Technology Observatory: Photovoltaics in the European Union–2022 Status Report on Technology Development, Trends, Value Chains and Markets; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

| Parameter | Value |

|---|---|

| Floor U-value | 0.45 W/m2K |

| External wall U-value | 0.3 W/m2K |

| Roof U-value | 0.24 W/m2K |

| Roof albedo | 0.25 |

| Double glazing unit | U-value [W/m2K] = 1.493, SHGC = 0.373, Tvis = 0.444 |

| Airtightness | 0.35 ACH |

| Operation | 8 AM–6 PM (weekdays) |

| Heating occupied set-point | 21 °C (15.6 °C unoccupied) |

| COP heating system | 3 (heat pump) |

| Cooling occupied set-point | 24 °C (26.7 °C unoccupied) |

| COP cooling system | 3 (heat pump) |

| Mechanical ventilation | 8 L/s/prs |

| People density | 18.5 m2/prs |

| Max equipment gains | 8.07 W/m2 (variable) |

| Lighting | 10.7 W/m2 (with 500 lx target illuminance) |

| Parameter | Value |

|---|---|

| PV module dimensions | 1134 mm × 1762 mm |

| PMPP | 440 W |

| VMPP | 44 V |

| IMPP | 10 A |

| Module efficiency | 22% |

| Temperature coefficient of PMAX | −0.30%/°C |

| Total installed capacity | 146 kWp |

| PV tilt angle | 15° |

| Specific annual yield | 1042 kWh/kWp |

| Performance ratio | 91.5% |

| Challenges | Overcome Barriers |

|---|---|

| Dual Use Issues, energy generator, and building component | BIPV integration in the building management tools |

| Operating conditions and high cell temperature | The development of safety within certification practices |

| Refurbishment but versatility in colors, transparency, and design | Development of novel BIPV technologies such as perovskite and third-generation solar cells |

| Fire safety | BIPV certification, eco, and energy labeling |

| Reliability and quality of architectural integration | Adaptation to market requirements through customization, energy performance, and economic aspects |

| Outdoor performance | Improving the maintenance and operation procedures |

| Issues with technology development | Dissemination of best practices |

| Ability to replace BIPV components | Reducing public doubt of the technology with neighborhood installation |

| Standardization of BIPV components | Common utility resource and not a product |

| Training by trades | Synergistic positive effect with nature-based solutions such as greenery |

| BIPV Requirements | Category | Characteristics-Parameters |

|---|---|---|

| Intrinsic scientific and technological | Solar cell architecture | Generation |

| Number of p-n junctions | ||

| Performance | Power conversion efficiency | |

| Power output | ||

| Temperature coefficient | ||

| Transparency | ||

| Degradation rate | ||

| Lifetime | ||

| Sustainability | Resources abundance | |

| Embodied energy | ||

| Recycling | ||

| Non-Toxicity (human/ecosystems) | ||

| Climate Impact as g CO2/kW | ||

| Technology Readiness Level | ||

| Manufacturing materials and complexity | Raw and critical materials | |

| Cost | ||

| Basic as construction product and work | Mechanical | Dimensions and Weight |

| Flexibility | ||

| Strength | ||

| Safety | Health | |

| Fire | ||

| Risk | ||

| Security | ||

| Accessibility in use | ||

| Weathering | Maintenance (management, monitoring, cleaning) | |

| Resistance and Replacement | ||

| Product | Cost | |

| Eco-designed and Recycling | ||

| Spatial and energy performance | Place | Global Horizontal Irradiation |

| Sunshine duration | ||

| Building | Use-Typology | |

| Plan shape-Orientation | ||

| Integration | Roof | |

| Facade | ||

| Shading | ||

| Window | ||

| Component | ||

| Energy performance | Electricity generation | |

| Reduction in H and C energy needs | ||

| Ventilation | ||

| Flexibility-Sufficiency-NZEB | ||

| LCOE | ||

| Architectural and aesthetical | Aesthetics aspects | LESO-QSV |

| Bioclimatic design | BIPV climatic design according to the Koppen-Geiger-GHI classification | |

| Comfort | Acoustic | |

| Thermal | ||

| Lighting | ||

| Practical | Easiness, Friendly, Prefabricated | |

| Social | Access | No disparities |

| Energy justice | ||

| Vulnerable prioritization | ||

| Inclusion and equity | ||

| Cloud sharing | ||

| Art and Cultural | Tradition | Sustain traditional aspects |

| Creativity | Stimulate ecological growth and inclusiveness | |

| Urban | Building and Infrastructure | Positive energy needs variation |

| Improvement indoor environment | ||

| Surroundings | No rebound or neighborhood effects | |

| Minimized environmental conditions effects | ||

| Cities | Sustainable and resilient urban climate effects | |

| Integration with nature-based solutions | ||

| Regional/National/Global | Countries/Cross and Beyond | Positive cross-border and boundary effects |

| Sustainability&SDG7 | ||

| Mitigation of climate change |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skandalos, N.; Kapsalis, V.; Ma, T.; Karamanis, D. Towards 30% Efficiency by 2030 of Eco-Designed Building Integrated Photovoltaics. Solar 2023, 3, 434-457. https://doi.org/10.3390/solar3030024

Skandalos N, Kapsalis V, Ma T, Karamanis D. Towards 30% Efficiency by 2030 of Eco-Designed Building Integrated Photovoltaics. Solar. 2023; 3(3):434-457. https://doi.org/10.3390/solar3030024

Chicago/Turabian StyleSkandalos, Nikolaos, Vasileios Kapsalis, Tao Ma, and Dimitris Karamanis. 2023. "Towards 30% Efficiency by 2030 of Eco-Designed Building Integrated Photovoltaics" Solar 3, no. 3: 434-457. https://doi.org/10.3390/solar3030024