Microstructure of Selective Laser Melted 316L under Non-Equilibrium Solidification Conditions

Abstract

:1. Introduction

2. Material and Methods

2.1. Material and Specimen Preparation

2.2. Microstructural Characterization

3. Results

4. Discussion

4.1. Microstructural Evolution

4.2. Solidification Structures

5. Conclusions

- (1)

- According to the XRD analysis, the prevailing phase in the microstructure is austenite;

- (2)

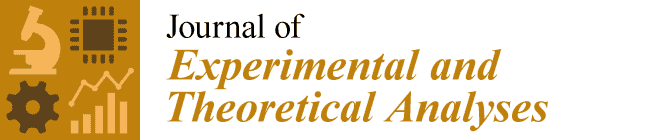

- The high cooling rates and constitutional undercooling lead to the formation of very fine grains, sub-grain structures and cellular structures;

- (3)

- Colonies of cellular structures with different orientations form due to the complex heat flow within the melt pools;

- (4)

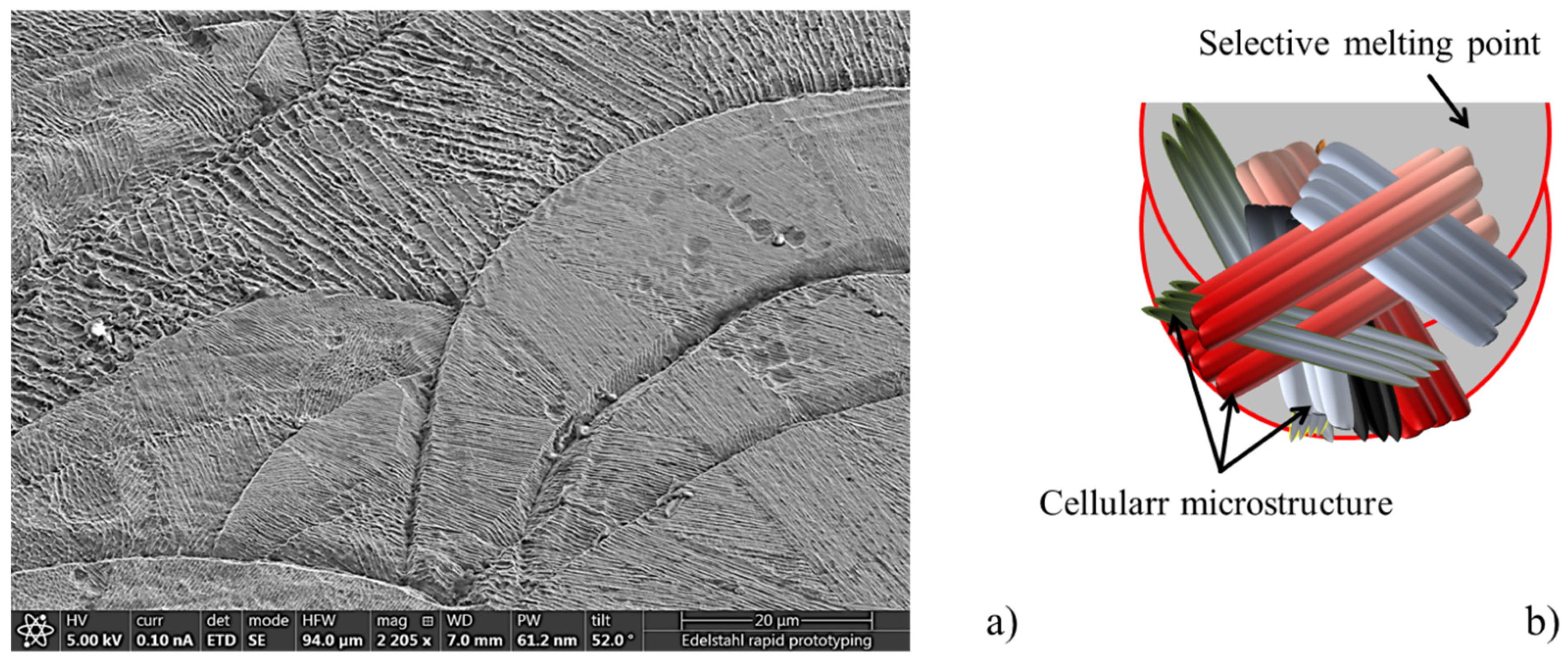

- Micro-segregation occurs and results in an enrichment of the sub-grain boundaries with most of the alloying elements;

- (5)

- Using the atomic resolution HR-TEM analysis, ferrite could be determined in the enriched area of the sub-grain boundaries.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Dadbakhsh, S.; Vrancken, B.; Kempen, K.; Vleugels, J.; van Humbeeck, J. Additive Manufacturing of Metals via Selective Laser Melting: Process Aspects and Material Developments. In Additive Manufacturing: Innovations, Advances, and Applications; Srivatsan, T.S., Sudarshan, T.S., Eds.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Kruth, J.-P.; Levy, G.; Klocke, F.; Childs, T. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann.—Manuf. Technol. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Sumita, M.; Hanawa, T.; Teoh, S.H. Development of nitrogen-containing nickel-free austenitic stainless steels for metallic biomaterials—Review. Mater. Sci. Eng. C 2004, 24, 753–760. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuźnicka, B.; Chlebus, E. Correlation between process parameters, microstructure and properties of 316 L stainless steel processed by selective laser melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Sedriks, A.J. Corrosion of Stainless Steels. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 1707–1708. [Google Scholar]

- Bernstein, I.M. Handbook of Stainless Steels; McGraw-Hill: New York, NY, USA; Düsseldorf, Germany, 1977. [Google Scholar]

- Davis, J.R. (Ed.) Stainless Steels, 1st ed.; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Schaeffler, A. Constitution Diagramm for Stainless Steel Weld Metal. Met. Prog. 1949, 56, 680. [Google Scholar]

- Kotecki, D.J.; Siewert, T.A. WRC-1992 Constitution Diagram for Stainless Steel Weld Metals: A Modification of the WRC-1988 Diagram: Refined constitution diagram offers more accurate FN prediction for Cu-containing stainless steel and dissimilar joints. Weld. Res. Suppl. 1992, 71, 171–178. [Google Scholar]

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; Wiley-Interscience: Hoboken, NJ, USA, 2005. [Google Scholar]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Stefanescu, D.; Ruxanda, R. Fundamentals of Solidification; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

- Brooks, J.A.; Baskes, M.I. Microsegregation modeling and transformation in rapidly solidified austenitic stainless steels welds; ASM International: Materials Park, OH, USA. Recent Trends Weld. Sci. Technol. 1990, 153–158. [Google Scholar]

- Elmer, J.W.; Allen, S.M.; Eagar, T.W. The influence of cooling rate on the ferrite content of stainless steel alloys. Recent Trends Weld. Sci. Technol. 1990, 165–170. [Google Scholar]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; van Humbeeck, J. Microstructure and mechanical properties of a novel β titanium metallic composite by selective laser melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Rafi, H.K.; Pal, D.; Patil, N.; Starr, T.L.; Stucker, B.E. Microstructure and Mechanical Behavior of 17-4 Precipitation Hardenable Steel Processed by Selective Laser Melting. J. Mater. Eng. Perform. 2014, 23, 4421–4428. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Luo, H.; Li, R.; Wang, L.; Man, C.; Li, X. The passivity of selective laser melted 316L stainless steel. Appl. Surf. Sci. 2020, 504, 144495. [Google Scholar] [CrossRef]

- De Bellefon, G.M.; Bertsch, K.M.; Chancey, M.R.; Wang, Y.Q.; Thoma, D.J. Influence of solidification structures on radiation-induced swelling in an additively-manufactured austenitic stainless steel. J. Nucl. Mater. 2019, 523, 291–298. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [PubMed]

- RWTH Aachen. Werkstoffkunde Stahl für Studium und Praxis, 3rd ed.; Aachen: Mainz, Germany, 2010. [Google Scholar]

| 316L | C % | Si % | Mn % | P % | S % | Cr % | Mo % | Ni % | Fe % |

|---|---|---|---|---|---|---|---|---|---|

| Specimen | 0.03 | 0.67 | 0.92 | 0.02 | 0.00 | 16.10 | 2.35 | 11.00 | Balanced |

| DIN EN 10088-3 | Max 0.03 | Max 1.00 | Max 2.00 | Max 0.05 | Max 0.03 | 16.50–18.50 | 2.00–2.50 | 10.00–13.00 | Balanced |

| Elements | Area 1 [%] | Area 2 [%] | Area 3 [%] |

|---|---|---|---|

| Si | 1.13 ± 0.10 | 0.72 ± 0.10 | 0.88 ± 0.10 |

| Cr | 17.61 ± 0.35 | 16.49 ± 0.35 | 16.81 ± 0.35 |

| Mn | 1.09 ± 0.18 | 0.86 ± 0.18 | 0.66 ± 0.18 |

| Fe | 66.14 ± 0.20 | 68.48 ± 0.20 | 67.97 ± 0.20 |

| Ni | 11.72 ± 0.10 | 11.59 ± 0.10 | 11.75 ± 0.10 |

| Mo | 2.31 ± 0.08 | 1.85 ± 0.08 | 1.94 ± 0.08 |

| Elements | k0 (γ/L) |

|---|---|

| Fe | 1 |

| Cr | 0.83 |

| Ni | 0.90 |

| Si | 0.52 |

| Mn | 0.78 |

| Mo | 0.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Özel, E.F.; Pede, D.; Müller, C.; Thomann, Y.; Thomann, R.; Mozaffari-Jovein, H. Microstructure of Selective Laser Melted 316L under Non-Equilibrium Solidification Conditions. J. Exp. Theor. Anal. 2023, 1, 64-73. https://doi.org/10.3390/jeta1020005

Özel EF, Pede D, Müller C, Thomann Y, Thomann R, Mozaffari-Jovein H. Microstructure of Selective Laser Melted 316L under Non-Equilibrium Solidification Conditions. Journal of Experimental and Theoretical Analyses. 2023; 1(2):64-73. https://doi.org/10.3390/jeta1020005

Chicago/Turabian StyleÖzel, Emre Firat, Dennis Pede, Claas Müller, Yi Thomann, Ralf Thomann, and Hadi Mozaffari-Jovein. 2023. "Microstructure of Selective Laser Melted 316L under Non-Equilibrium Solidification Conditions" Journal of Experimental and Theoretical Analyses 1, no. 2: 64-73. https://doi.org/10.3390/jeta1020005

APA StyleÖzel, E. F., Pede, D., Müller, C., Thomann, Y., Thomann, R., & Mozaffari-Jovein, H. (2023). Microstructure of Selective Laser Melted 316L under Non-Equilibrium Solidification Conditions. Journal of Experimental and Theoretical Analyses, 1(2), 64-73. https://doi.org/10.3390/jeta1020005