Fault Coverage-Aware Metrics for Evaluating the Reliability Factor of Solar Tracking Systems

Abstract

1. Introduction

2. Literature Review

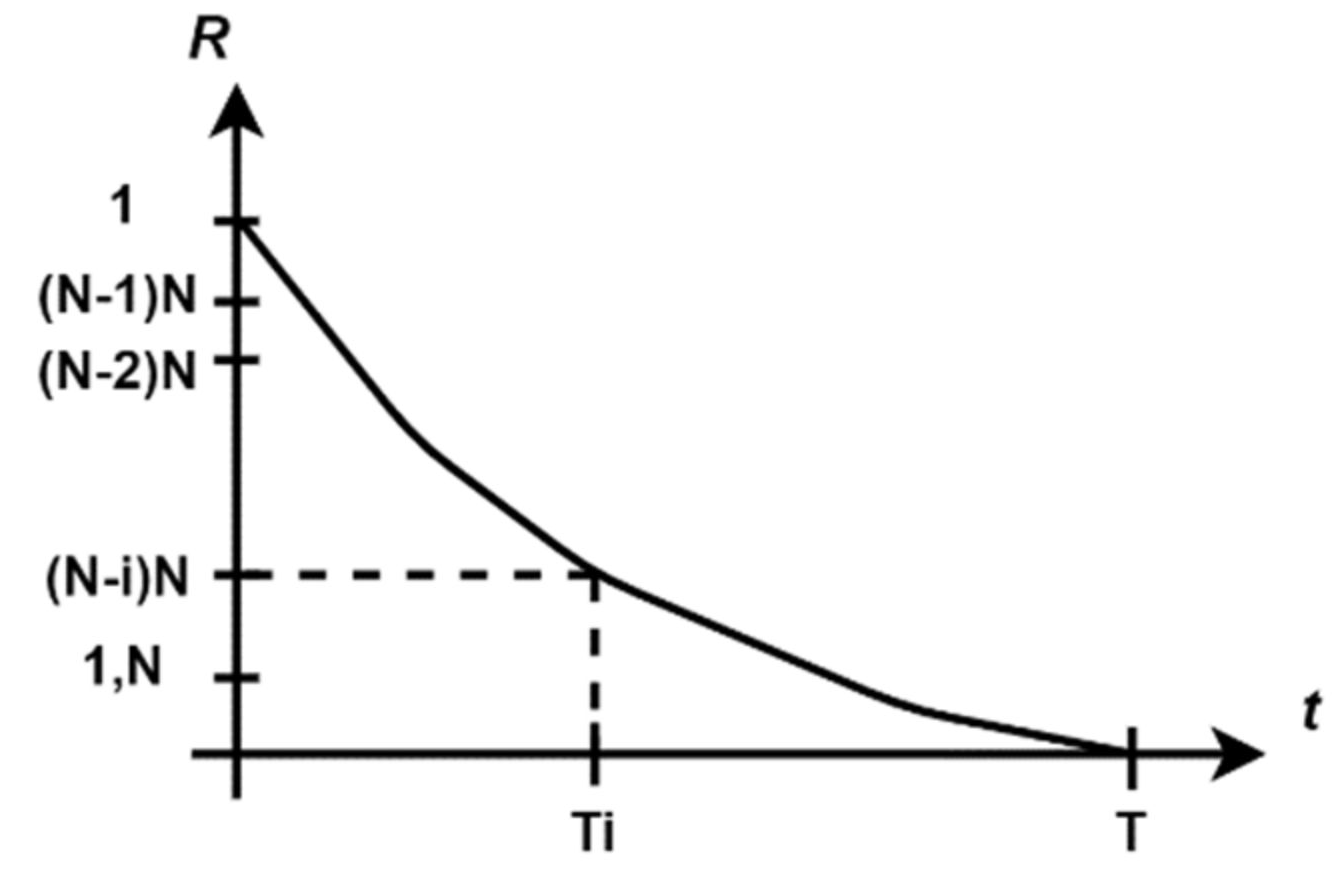

3. The Weibull Distribution Model for Calculating the Reliability of Dual-Axis Solar Tracking Systems

3.1. Failure Frequency (Hazard Rate)

3.2. Availability (Efficiency)

3.3. Typical Variation Form of the Hazard Rate (Bathtub Curve)

3.4. Applications

4. Proposed Fault Coverage-Aware Model for Calculating the Solar Reliability Factor

4.1. Fault-Coverage Aware Metric for Determining the Reliability of Electronic Components with the Help of BIST Devices

- (1)

- The number of errors NE is always equal, lower, or greater than TV in any test scenario regardless of the noise factors that are considered, and can be expressed mathematically as in (35):

- (2)

- The number of test vectors TV is always equal to or lower than the total number of test patterns TP given by the expression (36):

- (3)

- The total number of test patterns is calculated with the Equation (37):

- (4)

- If no errors are detected during the testing routines, the STF parameter will be 0 resulting in 100% reliability and availability of the tested equipment, expressed in Equation (38):

4.2. Fault-Coverage Aware Metric for Determining the Reliability of Electronic Components with the Help of WBST Methods

- (1)

- The number of errors NE is always equal, lower, or greater than TV in any test scenario regardless of the number of considered breakpoints, and can be expressed mathematically as in statement (47):

- (2)

- The number of test vectors TV is always equal to or lower than the total number of test patterns TP given by the expression (48):

- (3)

- If no errors are detected during the testing routines the STF parameter will be 0 resulting in 100% reliability and availability of the tested equipment, expressed as in Equation (49):

4.3. Fault-Coverage Aware Metric for Determining the Reliability of Electronic Components with the Help of ICT Methods

- (1)

- The number of errors NE is always equal, lower, or greater than TR in any test scenario regardless of the number of probes that are used during testing, and can be expressed mathematically as in expression (54):

- (2)

- The number of test rounds TR is always equal to or lower than the total number of test routines NR, given by the expression (55):

- (3)

- If no errors are detected during the testing routines the STF parameter will be 0 resulting in 100% reliability and availability of the tested equipment, expressed as in relation (56):

5. Experimental Setup and Results

5.1. Fault Coverage-Aware Metrics Equation Reduction for Computing the Reliability Test Factor

5.2. Fault Coverage-Aware Metrics for BIST, WBST, and ICT Test Scenarios

5.3. Fault Coverage-Aware Metrics Comparison with Other Related Works

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xiaoling, O.; Boqiang, L. Levelized cost of electricity (LCOE) of renewable energies and required subsidies in China. Energy Policy 2014, 70, 64–73. [Google Scholar]

- Levelized Cost of Energy and Levelized Cost of Storage. Available online: https://www.lazard.com/perspective/levelized-cost-of-energy-and-levelized-cost-of-storage-2020/ (accessed on 7 December 2020).

- Aldersey-Williams, J.; Rubert, T. Levelised cost of energy—A theoretical justification and critical assessment. Energy Policy 2019, 124, 169–179. [Google Scholar] [CrossRef]

- Rotar, R.; Jurj, S.L.; Opritoiu, F.; Vladutiu, M. Position Optimization Method for a Solar Tracking Device Using the Cast-Shadow Principle. In Proceedings of the IEEE 24th International Symposium for Design and Technology in Electronic Packaging (SIITME), Iasi, Romania, 25–28 October 2018; pp. 61–70. [Google Scholar] [CrossRef]

- EL-Shimy, M. Analysis of Levelized Cost of Energy (LCOE) and grid parity for utility-scale photovoltaic generation systems. In Proceedings of the 15th International Middle East Power Systems Conference (MEPCON’12), Alexandria, Egypt, 23–25 December 2012. [Google Scholar] [CrossRef]

- Jurj, S.L.; Rotar, R.; Opritoiu, F.; Vladutiu, M. White-Box Testing Strategy for a Solar Tracking Device Using NodeMCU Lua ESP8266 Wi-Fi Network Development Board Module. In Proceedings of the IEEE 24th International Symposium for Design and Technology in Electronic Packaging (SIITME), Iasi, Romania, 25–28 October 2018; pp. 53–60. [Google Scholar] [CrossRef]

- Jurj, S.L.; Rotar, R.; Opritoiu, F.; Vladutiu, M. Online Built-In Self-Test Architecture for Automated Testing of a Solar Tracking Equipment. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Jurj, S.L.; Rotar, R.; Opritoiu, F.; Vladutiu, M. Affordable Flying Probe-Inspired In-Circuit-Tester for Printed Circuit Boards Evaluation with Application in Test Engineering Education. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Qingcai, L.; Xuechun, W. LCOE Analysis of Solar Tracker Application in China. Comput. Water Energy Environ. Eng. 2020, 9, 87–100. [Google Scholar] [CrossRef]

- Single-Axis Bifacial PV Offers Lowest LCOE in 93.1% of World’s Land Area. Available online: https://www.pv-magazine.com/2020/06/05/single-axis-bifacial-pv-offers-lowest-lcoe-in-93-1-of-worlds-land-area/ (accessed on 7 December 2020).

- Loewen, J. LCOE is an undiscounted metric that inaccurately disfavors renewable energy resources. Electr. J. 2020, 33, 106769. [Google Scholar] [CrossRef]

- Zhang, J.; Florita, A.; Hodge, B.-M.; Lu, S.; Hamann, H.F.; Banunarayanan, V.; Brockway, A.M. A suite of metrics for assessing the performance of solar power forecasting. Sol. Energy 2015, 111, 157–175. [Google Scholar] [CrossRef]

- Miller, N.W.; Pajic, S.; Clark, K. Concentrating Solar Power Impact on Grid Reliability. Available online: https://www.nrel.gov/docs/fy18osti/70781.pdf (accessed on 7 December 2020).

- Woodhouse, M.; Walker, A.; Fu, R.; Jordan, D.; Kurtz, S. The Role of Reliability and Durability in Photovoltaic System Economics. Available online: https://www.nrel.gov/docs/fy19osti/73751.pdf (accessed on 7 December 2020).

- Wang, H.; Li, H.; Tang, C.; Ye, L.; Chen, X.; Tang, H.; Ci, S. Modeling, metrics, and optimal design for solar energy-powered base station system. EURASIP J. Wirel. Commun. Netw. 2015, 2015, 39. [Google Scholar] [CrossRef]

- UN Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 7 December 2020).

- Lee, J.T.; Callaway, D.S. The cost of reliability in decentralized solar power systems in sub-Saharan Africa. Nat. Energy 2018, 3, 960–968. [Google Scholar] [CrossRef]

- Klise, G.T.; Hill, R.; Walker, A.; Dobos, A.; Freeman, J. PV system “Availability” as a reliability metric—Improving standards, contract language and performance models. In Proceedings of the IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 1719–1723. [Google Scholar] [CrossRef]

- Collins, E.; Dvorack, M.; Mahn, J.; Mundt, M.; Quintana, M. Reliability and availability analysis of a fielded photovoltaic system. In Proceedings of the 34th IEEE Photovoltaic Specialists Conference (PVSC), Philadelphia, PA, USA, 7–12 June 2009. [Google Scholar] [CrossRef]

- Abernethy, R.B. The New Weibull Handbook Fifth Edition, Reliability and Statistical Analysis for Predicting Life, Safety, Supportability, Risk, Cost and Warranty Claims. 2006. Available online: https://www.amazon.com/Handbook-Reliability-Statistical-Predicting-Supportability/dp/0965306232/ (accessed on 8 February 2021).

- Reliability and MTBF Overview. Vicor Reliability Engineering. Available online: http://www.vicorpower.com/documents/quality/Rel_MTBF.pdf (accessed on 8 February 2021).

| Failure Moments (Ti) | Ti (Days) |

|---|---|

| T1 | 125 |

| T2 | 170.83 |

| T3 | 220.83 |

| T4 | 283.3 |

| T5 | 291.6 |

| T6 | 341.6 |

| T7 | 375 |

| T8 | 512.5 |

| T9 | 541.6 |

| T10 | 583.3 |

| T11 | 625 |

| T12 | 666.6 |

| T13 | 687.5 |

| T14 | 741.6 |

| T15 | 795.83 |

| Batches (B) | B1 | B2 | B3 | B4 | B5 | B6 | B7 | B8 |

|---|---|---|---|---|---|---|---|---|

| Maintenance Operation Days | 2 | 4 | 3 | 2 | 7 | 4 | 1 | 6 |

| 3 | 2 | 4 | 3 | 8 | 6 | 5 | 5 | |

| 1 | 5 | 1 | 5 | 1 | 1 | 2 | 1 | |

| 5 | 1 | 1 | 4 | 3 | 2 | 3 | 2 | |

| 6 | 7 | 2 | 1 | 2 | 1 | 4 | 3 |

| Crt. No. | Initial Seed (HEX) | Fault Coverage | Total Test Patterns | Total Detected Errors | |

|---|---|---|---|---|---|

| Single Bit Flip Errors | Single Stuck-at-Faults | ||||

| Last 8 Bits (Mutant) | |||||

| 1 | FFFF | 93.95% | 100 % | 65,535 | 61,570 |

| 2 | 8FFF | 93.93% | 61,557 | ||

| 3 | 8CFF | 93.92% | 61,550 | ||

| 4 | 8C9F | 93.91% | 61,544 | ||

| 5 | 8C94 | 93.94% | 61,563 | ||

| Crt. No. | Total Detected Errors | Total Test Patterns | Error Coverage (%) | |||

|---|---|---|---|---|---|---|

| Control Flow Errors | Communication Errors | Calculation Errors | Error Handling Faults | |||

| 1 | 395 | 2 | 568 | 736 | 2277 | 74.70 |

| 2 | 175 | 1 | 242 | 299 | 1087 | 65.96 |

| 3 | 118 | 1 | 166 | 214 | 840 | 59.40 |

| 4 | 78 | 0 | 2 | 42 | 130 | 93.84 |

| Crt. No. | Test Type | No. of Test Samples (Parameters) | Fault Coverage (%) |

|---|---|---|---|

| 1 | Multiple Point Testing | 250 | 88.70 |

| 2 | 90 | ||

| 3 | 91.40 | ||

| 4 | 95.70 |

| Crt. No. | Reliability Evaluation Methodologies for Fielded PV Systems | Time (Hours/ Days/ Years) | Availability/ Reliability Factor (%) | |||

|---|---|---|---|---|---|---|

| Major Metrics Models | Tested Components | Particular Metrics/ Distribution Model | Number of Failures/Errors | |||

| 1 | LCOE based Metrics [14] | PV modules | >LCOE | Not specified | 15 Years | 0.5–3 |

| 2 | Weibull Distribution Model [19] | PV 150 Inverter | Not specified | 125 | 0–1095 Days | 100–0 |

| PV module | Lognormal 2-RRX | 29 | ||||

| AC Disconnect | Weibull 2-RRX | 22 | ||||

| Lightning 208/480 | Weibull 2-RRX | 16 | ||||

| Transformer | Lognormal 2-RRX | 4 | ||||

| Row Box | Lognormal 2-RRX | 34 | ||||

| Marshalling Box | Weibull 2-RRX | 2 | ||||

| 480VAC/ 34.5KV Transformer | Weibull 2-RRX | >5 | ||||

| 3 | Proposed Fault Coverage-Aware Metrics | Optocoupler LTV-847 IC | OBIST | 15,392.5 | 0.00138 h | 0.3919 |

| Arduino UNO Development Board | WBST | 4334 | 6.63 h | 0.7912 | ||

| OBIST | 15,387.5 | 0.00083 h | 0.3920 | |||

| FPICT | 957 | 5.178 h | 0.8922 | |||

| L298N Motor Drivers | OBIST | 30,772 | 0.0016 h | 0.3921 | ||

| Crt. Nr. | Weibull Distribution Model | Fault Coverage Aware Metrics | Runtime Execution for Weibull | Runtime Execution for Our Metrics | ||

|---|---|---|---|---|---|---|

| Speed (ms) | Steps (n) | Speed (ms) | Steps (n) | |||

| 1 | Weibull Execution Cycles | Metrics Execution Cycles | 0.1 | 274 | 0.03 | 69 |

| 2 | 0.1 | 274 | 0.02 | 69 | ||

| 3 | 0.09 | 274 | 0.02 | 69 | ||

| 4 | 0.09 | 274 | 0.02 | 69 | ||

| 5 | 0.08 | 274 | 0.02 | 69 | ||

| 6 | 0.08 | 274 | 0.02 | 69 | ||

| 7 | 0.09 | 274 | 0.02 | 69 | ||

| 8 | 0.08 | 274 | 0.02 | 69 | ||

| Average Values | 0.08875 | 274 | 0.02125 | 69 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rotar, R.; Jurj, S.L.; Opritoiu, F.; Vladutiu, M. Fault Coverage-Aware Metrics for Evaluating the Reliability Factor of Solar Tracking Systems. Energies 2021, 14, 1074. https://doi.org/10.3390/en14041074

Rotar R, Jurj SL, Opritoiu F, Vladutiu M. Fault Coverage-Aware Metrics for Evaluating the Reliability Factor of Solar Tracking Systems. Energies. 2021; 14(4):1074. https://doi.org/10.3390/en14041074

Chicago/Turabian StyleRotar, Raul, Sorin Liviu Jurj, Flavius Opritoiu, and Mircea Vladutiu. 2021. "Fault Coverage-Aware Metrics for Evaluating the Reliability Factor of Solar Tracking Systems" Energies 14, no. 4: 1074. https://doi.org/10.3390/en14041074

APA StyleRotar, R., Jurj, S. L., Opritoiu, F., & Vladutiu, M. (2021). Fault Coverage-Aware Metrics for Evaluating the Reliability Factor of Solar Tracking Systems. Energies, 14(4), 1074. https://doi.org/10.3390/en14041074