A Simple Calibration Method for a Fringe Projection System Embedded within an Additive Manufacturing Machine

Abstract

:1. Introduction

2. Materials and Methods

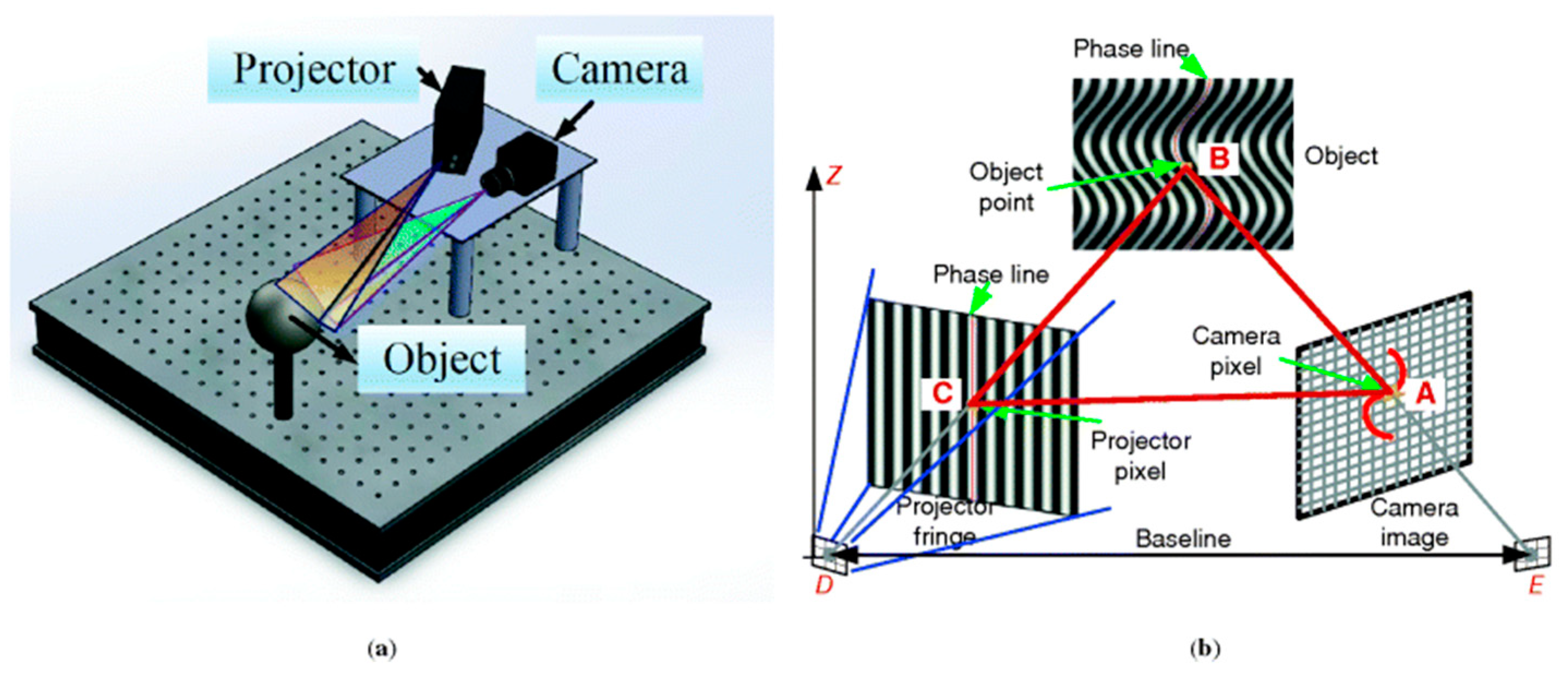

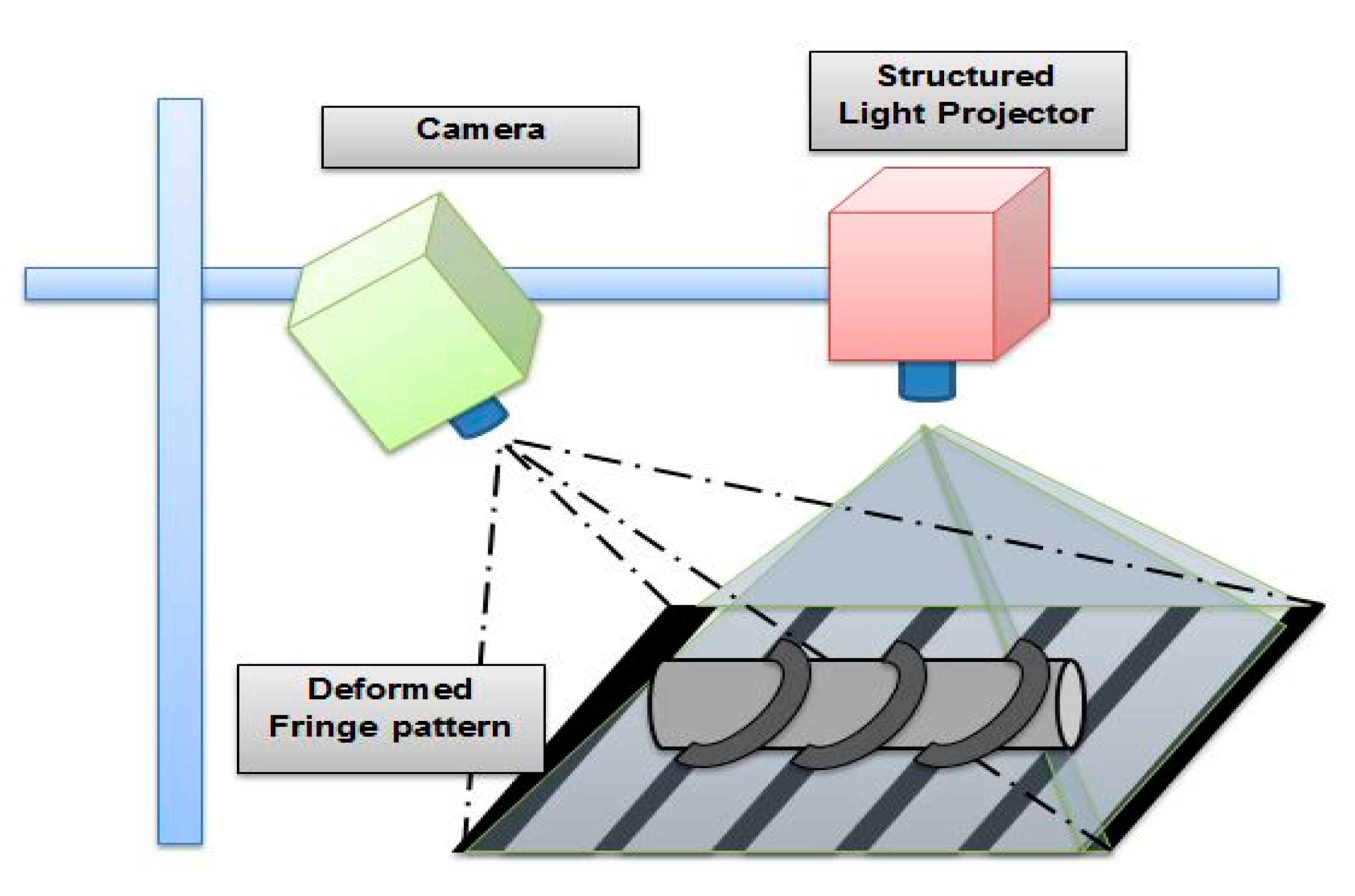

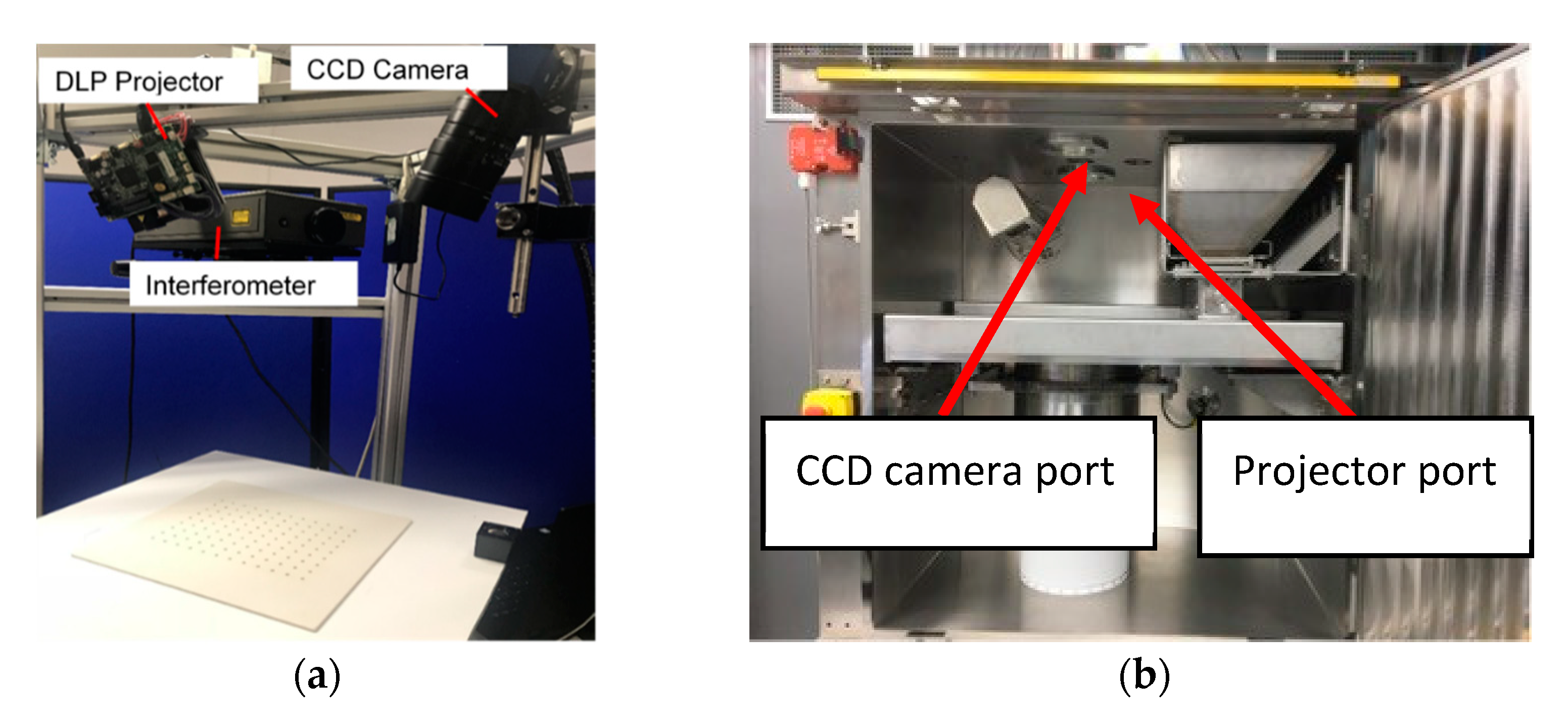

2.1. The Setup of Fringe Projection System

2.2. Measurement Principle of Fringe Projection System

2.3. Phase Analyses Methods

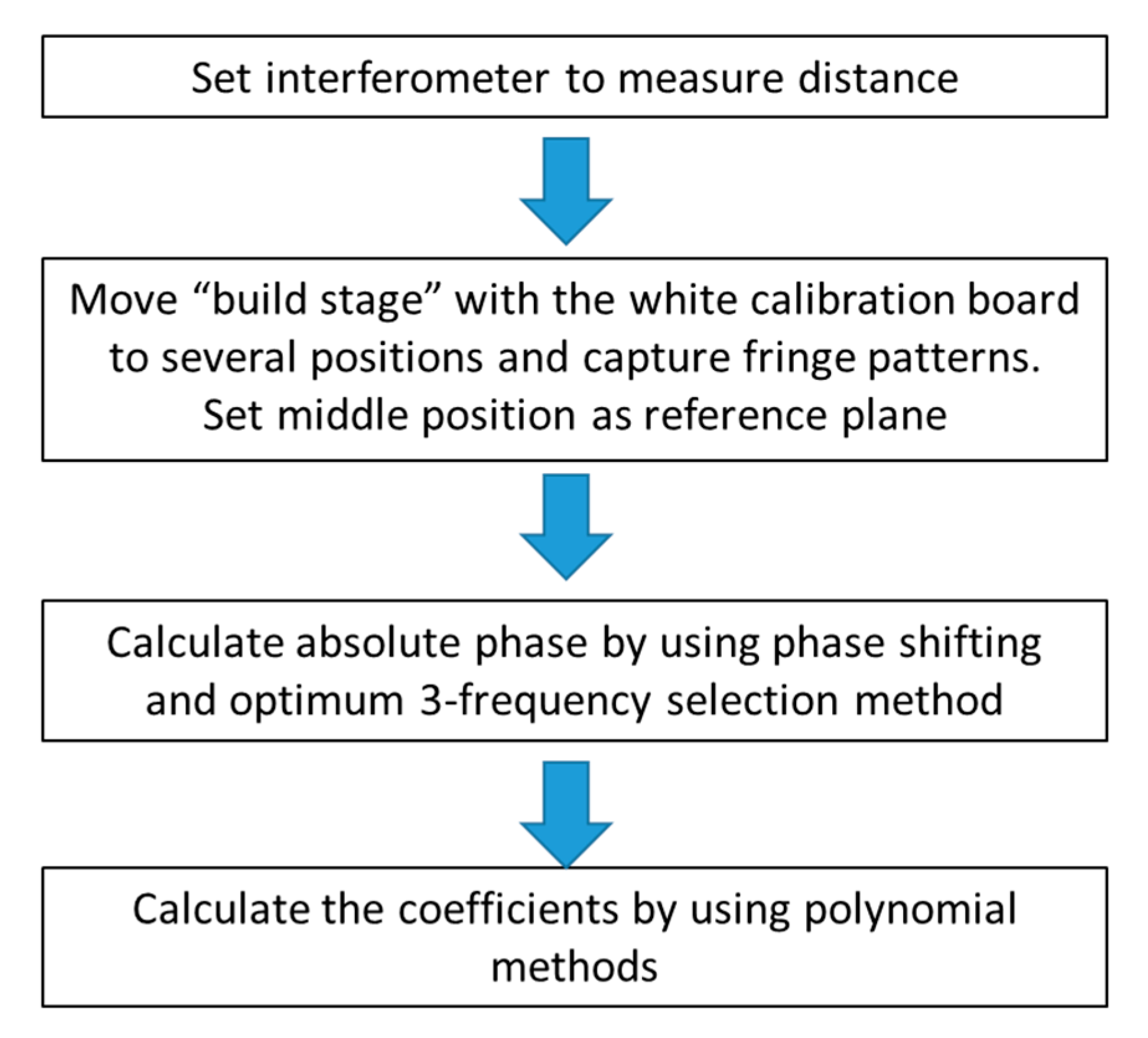

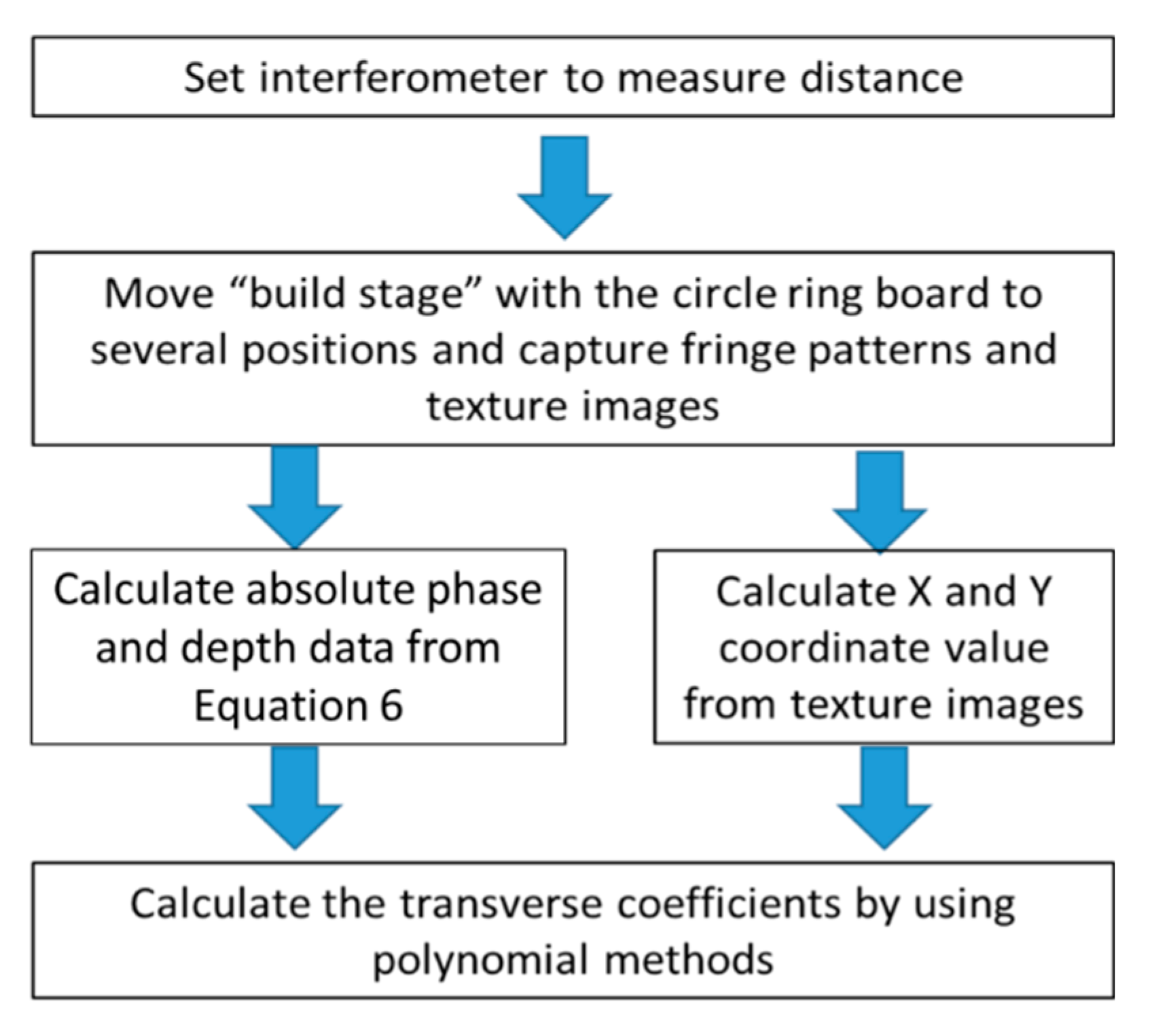

3. System Calibration

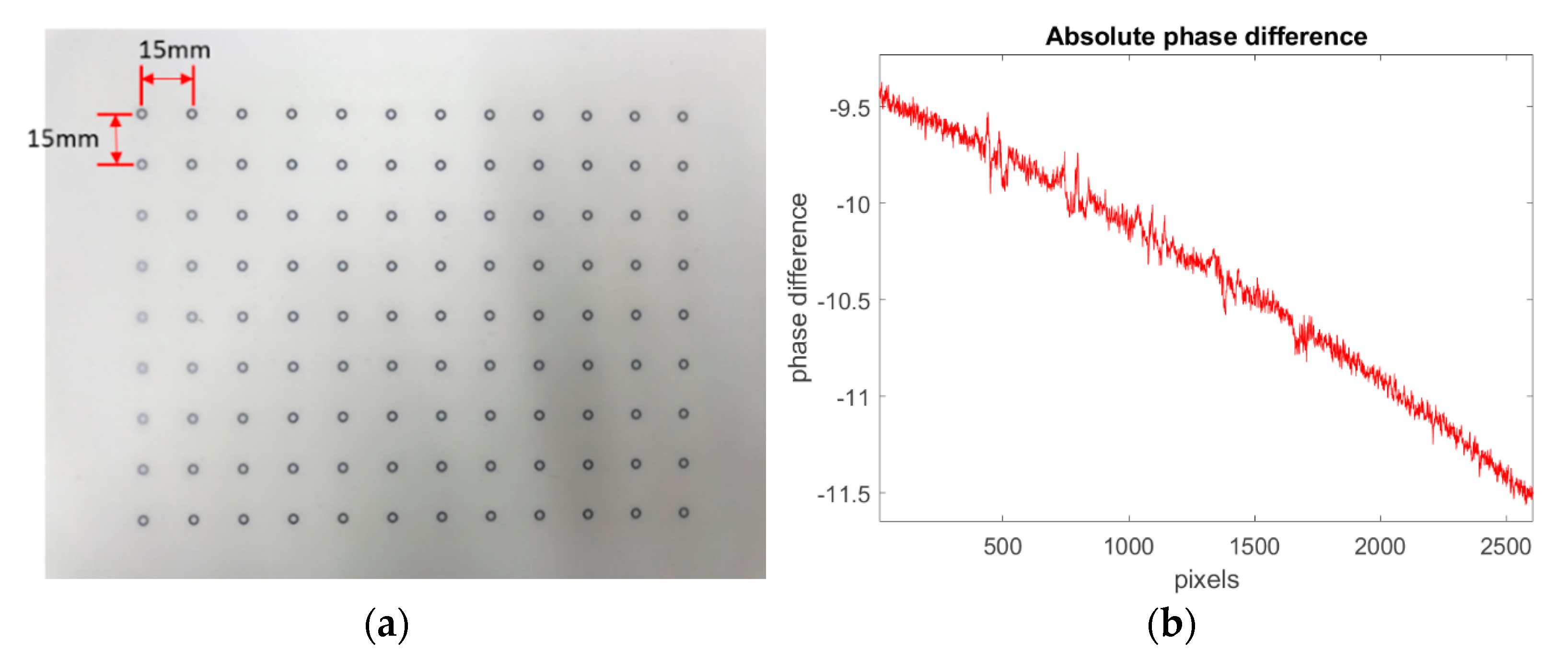

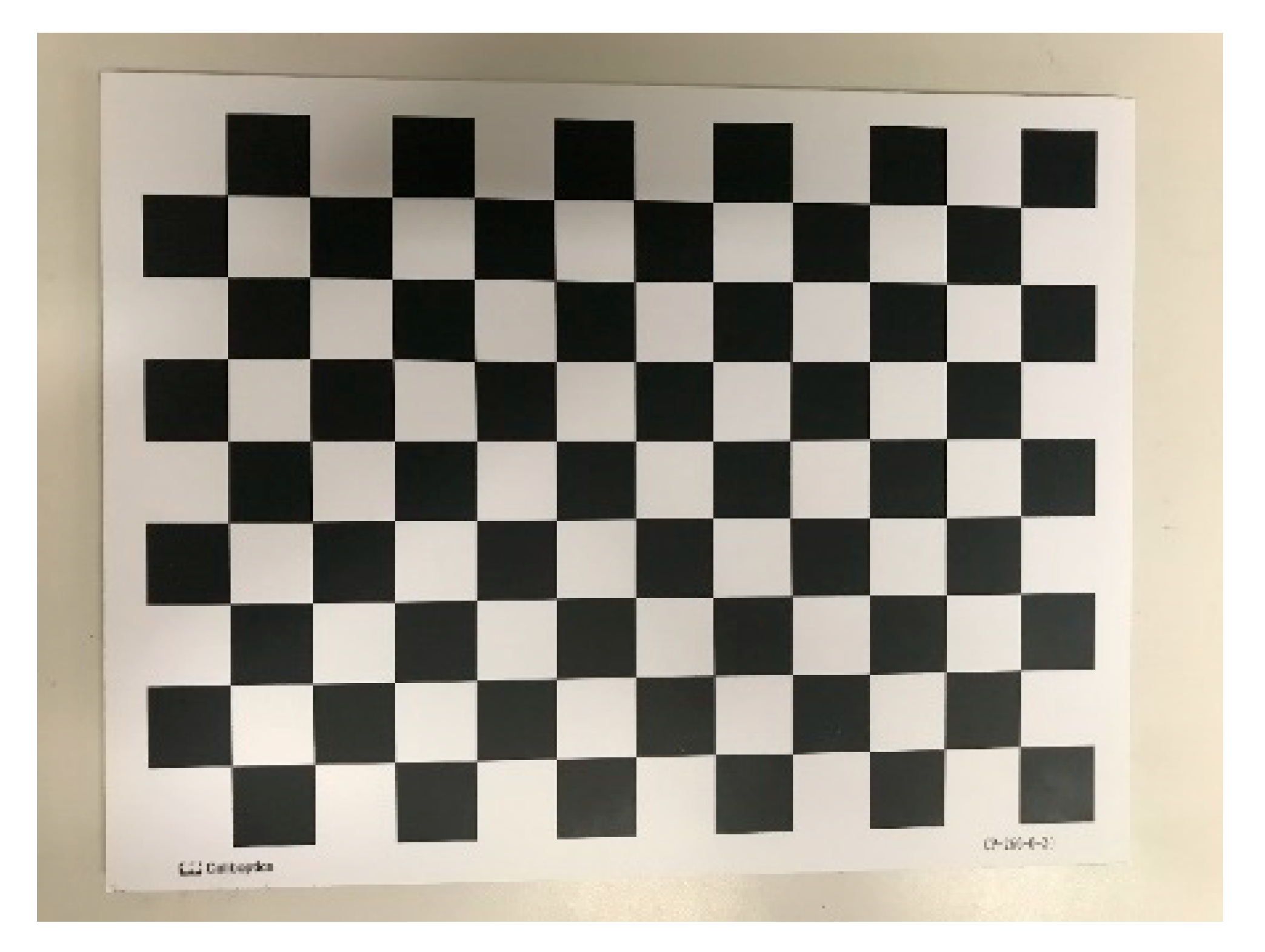

3.1. Calibration Method

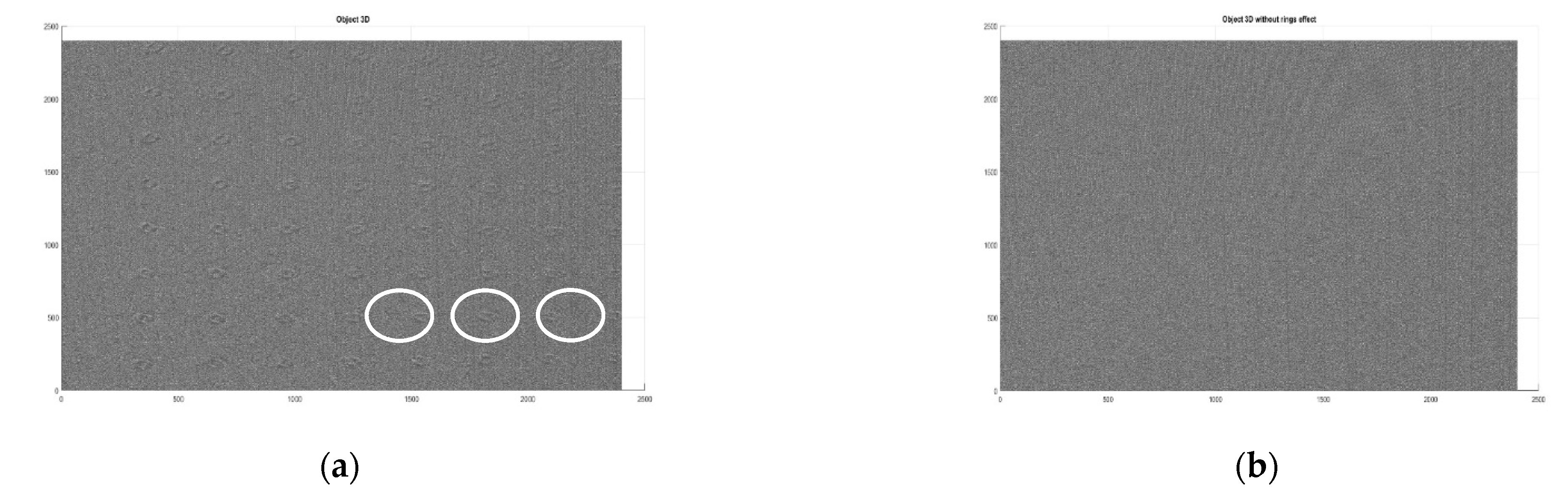

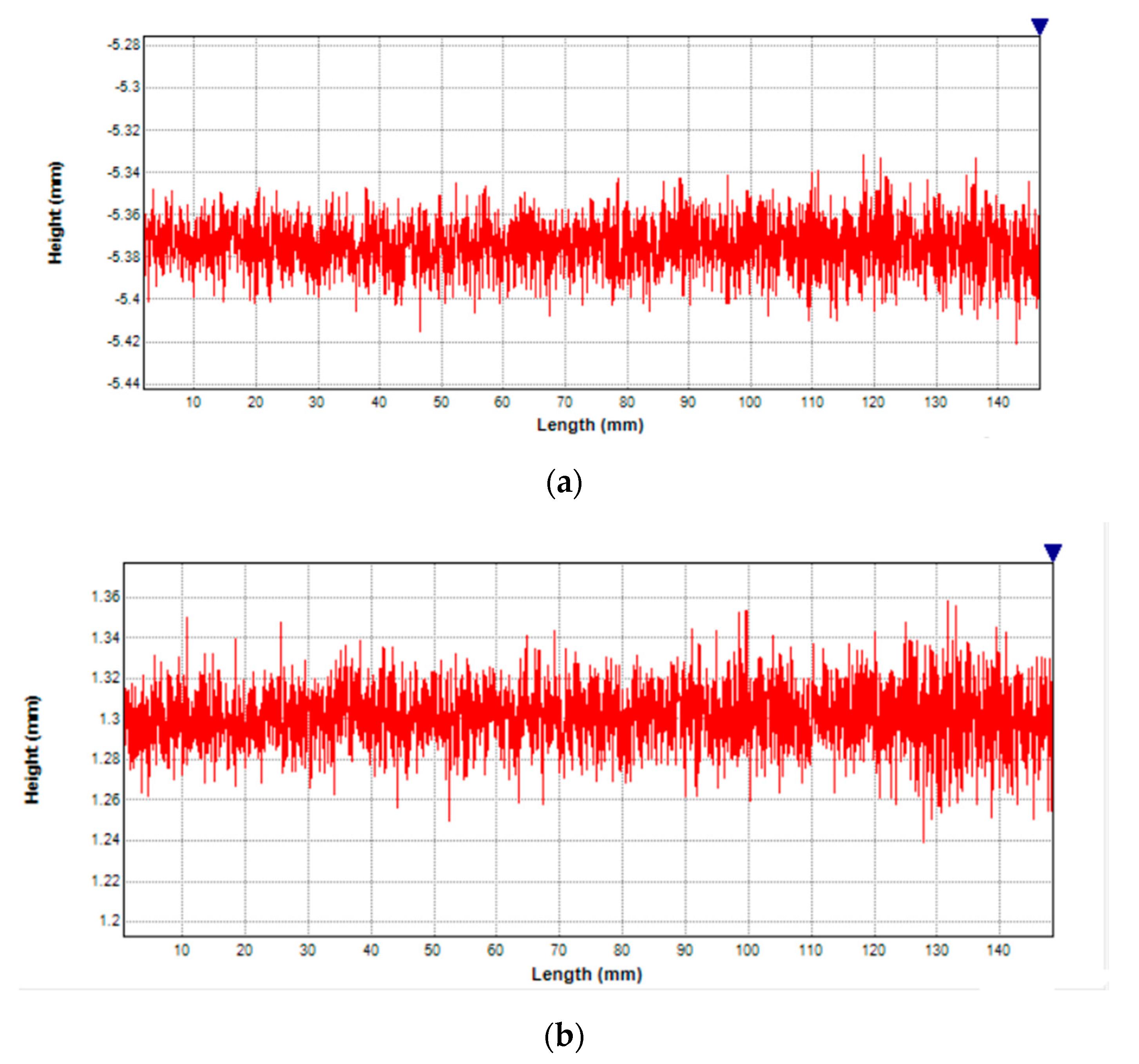

3.2. Calibration Results

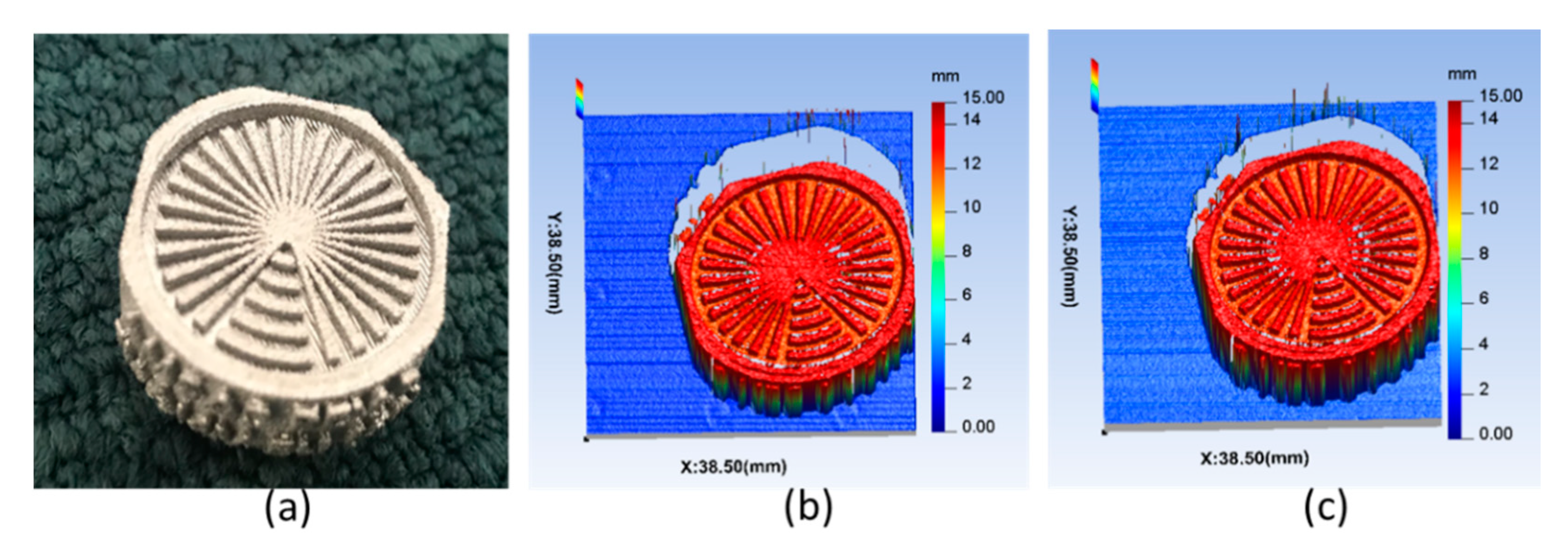

4. Experiments and Implementation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.K.; Taylor, J.S. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef] [Green Version]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, S. Status, challenges, and future perspectives of fringe projection profilometry. Optics Lasers Eng. 2020, 135, 106193. [Google Scholar] [CrossRef]

- Liu, Y.; Blunt, L.A.; Gao, F.; Jiang, X.J. High-dynamic-range 3D measurement for E-beam fusion additive manufacturing based on SVM intelligent fringe projection system. Surf. Topogr. Metrol. Prop. 2021, 9, 034002. [Google Scholar] [CrossRef]

- Feng, S.; Zuo, C.; Zhang, L.; Tao, T.; Hu, Y.; Yin, W.; Qian, J.; Chen, Q. Calibration of fringe projection profilometry: A comparative review. Opt. Lasers Eng. 2021, 143, 106622. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, D.; Peng, X. Performance analysis of a 3D full-field sensor based on fringe projection. Opt. Lasers Eng. 2004, 42, 341–353. [Google Scholar] [CrossRef]

- Jia, P.; Kofman, J.; English, C.E. Comparison of linear and nonlinear calibration methods for phase-measuring profilometry. Opt. Eng. 2007, 46, 043601. [Google Scholar]

- Huang, L.; Chua, P.S.; Asundi, A. Least-squares calibration method for fringe projection profilometry considering camera lens distortion. Appl. Opt. 2010, 49, 1539–1548. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Huang, P.S.; Fu, Q.; Chiang, F.P. Calibration of a three-dimensional shape measurement system. Opt. Eng. 2003, 42, 487–493. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, H.; Guo, T.; Zhang, S.; Chen, J. Simple, flexible calibration of phase calculation-based three-dimensional imaging system. Opt. Lett. 2011, 36, 1257–1259. [Google Scholar] [CrossRef] [PubMed]

- Windecker, R.; Fleischer, M.; Körner, K.; Tiziani, H. Testing micro devices with fringe projection and white-light interferometry. Opt. Lasers Eng. 2001, 36, 141–154. [Google Scholar] [CrossRef]

- Sutton, M.; Zhao, W.; McNeill, S.; Schreier, H.; Chao, Y.J. Development and assessment of a single-image fringe projection method for dynamic applications. Exp. Mech. 2001, 41, 205–217. [Google Scholar] [CrossRef]

- Huang, P.S.; Hu, Q.; Jin, F.; Chiang, F.P. Color-encoded digital fringe projection technique for high-speed three-dimensional surface contouring. Opt. Eng. 1999, 38, 1065–1071. [Google Scholar] [CrossRef]

- Quan, C.; He, X.; Wang, C.F.; Tay, C.; Shang, H. Shape measurement of small objects using LCD fringe projection with phase shifting. Opt. Commun. 2001, 189, 21–29. [Google Scholar] [CrossRef]

- Guan, C.; Hassebrook, L.G.; Lau, D.L. Composite structured light pattern for three-dimensional video. Opt. Express 2003, 11, 406–417. [Google Scholar] [CrossRef] [PubMed]

- Reich, C.; Ritter, R.; Thesing, J. 3-D shape measurement of complex objects by combining photogrammetry and fringe projection. Opt. Eng. 2000, 39, 224–231. [Google Scholar] [CrossRef] [Green Version]

- Bell, T.; Li, B.; Zhang, S. Structured light techniques and applications. In Wiley Encyclopedia of Electrical and Electronics Engineering; Wiley Online Library: Hoboken, NJ, USA, 1999; pp. 1–24. [Google Scholar] [CrossRef]

- Liu, Y.; Blunt, L.; Zhang, Z.; Rahman, H.A.; Gao, F.; Jiang, X. In-situ areal inspection of powder bed for electron beam fusion system based on fringe projection profilometry. Addit. Manuf. 2020, 31, 100940. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, J.; Zhang, Q. Complete 3D measurement in reverse engineering using a multi-probe system. Int. J. Mach. Tools Manuf. 2005, 45, 1474–1486. [Google Scholar]

- Zhang, Z.; Huang, S.; Meng, S.; Gao, F.; Jiang, X. A simple, flexible and automatic 3D calibration method for a phase calculation-based fringe projection imaging system. Opt. Express 2013, 21, 12218–12227. [Google Scholar] [CrossRef]

| Directions | Nominal Actual Distance between Each Centre Points (mm) | Number of Centre-to-Centre Measurements | Mean Measured Distance (mm) | Mean Absolute Errors (mm) | Standard Deviation (Precision) (Units: mm) |

|---|---|---|---|---|---|

| X | 15.0007 | 320 | 15.0228 | 0.0228 | 0.0467 |

| Y | 15.0009 | 308 | 14.9971 | 0.0029 | 0.0382 |

| Position(mm) | Mean Measured Distance (mm) | Mean Absolute Error (mm) (Accuracy) | Standard Deviation (mm) (Precision) |

|---|---|---|---|

| −5.3987 | −5.3728 | 0.0259 | 0.0168 |

| 1.2982 | 1.2954 | 0.0028 | 0.0126 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Blunt, L.; Gao, F.; Jiang, X. A Simple Calibration Method for a Fringe Projection System Embedded within an Additive Manufacturing Machine. Machines 2021, 9, 200. https://doi.org/10.3390/machines9090200

Liu Y, Blunt L, Gao F, Jiang X. A Simple Calibration Method for a Fringe Projection System Embedded within an Additive Manufacturing Machine. Machines. 2021; 9(9):200. https://doi.org/10.3390/machines9090200

Chicago/Turabian StyleLiu, Yue, Liam Blunt, Feng Gao, and Xiangqian Jiang. 2021. "A Simple Calibration Method for a Fringe Projection System Embedded within an Additive Manufacturing Machine" Machines 9, no. 9: 200. https://doi.org/10.3390/machines9090200

APA StyleLiu, Y., Blunt, L., Gao, F., & Jiang, X. (2021). A Simple Calibration Method for a Fringe Projection System Embedded within an Additive Manufacturing Machine. Machines, 9(9), 200. https://doi.org/10.3390/machines9090200