Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites

Abstract

:1. Introduction

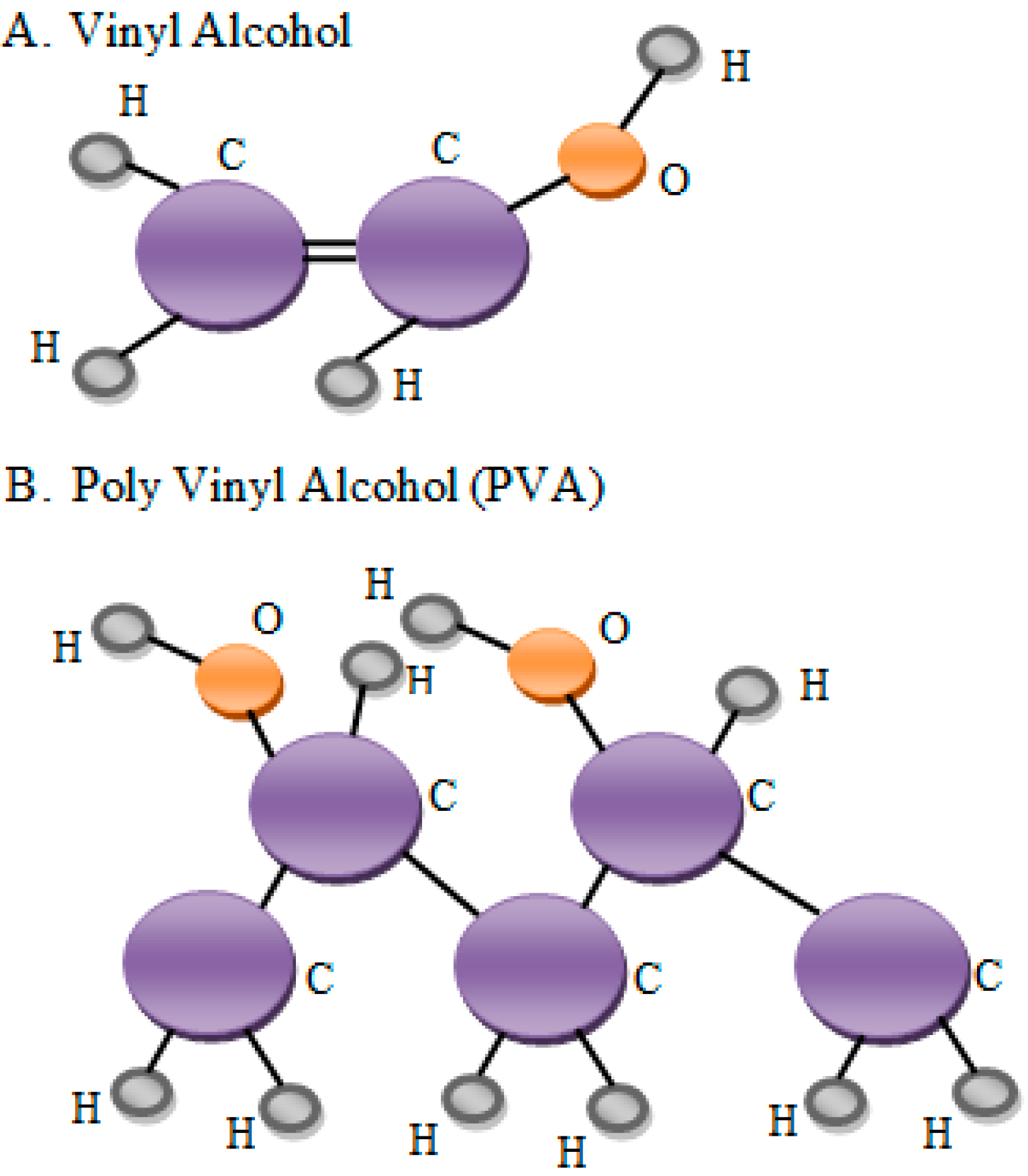

2. Chemical Structure of PVA

3. Chemical and Physical Properties of PVA

4. Chemical Structure of HNTs

5. Advantages and Disadvantages of PVA and HNTs

| No. | HNTs | PVA |

|---|---|---|

| 1 | Natural, nontoxic [51,52] | Non-toxic [48,49] |

| 2 | Non-swelling [51,52] | Hydrogels exhibit swelling feature in water with the peculiar characteristics of retaining water within its matrix without dissolving [50]. |

| 3 | Compatibility polymers oriented, such as polypropylene and polyethylene [51,52] | PVA is more biologically compatible [48,49] |

| 4 | Excellent mechanical properties such as tensile strength with 5 wt % HNTs increase 300% and thermal stability because HNTs are stable even at very high temperatures [3,53] in PVA film. | PVA has relatively low strength and thermal stability for some applications, excellent mechanical properties such as: strength (1.6 ± 0.1 GPa), elastic modulus (48 ± 3 GPa), strain (6.5% ± 1.4%), and toughness (40 ± 6 J·g−1) [54] and flexibility in dry state [47] |

| 5 | Formula [Al2Si2O5(OH)4∙nH2O] [55] | Formula [-CH2CHOH-]n |

| 6 | HNT is naturally occurring, will also have the benefit to reinforce PVA and impart other biological properties to the bionanocomposites, such as drug/gene delivery capacity without fear of being carcinogenic [53] | To overcome the limited biological performance and to enhance the mechanical properties of PVA, a new class of engineering designed PVA bionanocomposites has been introduced recently [53] |

6. Applications of PVA and HNTs

6.1. Biomedical Applications of PVA and HNTs

| Device Type | Product PVA | Product HNTs |

|---|---|---|

| Non-implant devices | Surgical sponges and packing | Diuretic drug transportation to remove hazardous species |

| Eye wetting drops | Sustained release of drugs, food additives, and fragrances | |

| Contact lenses | Antimicrobial agents | |

| Implantable devices | Hydrophilic coatings (Catheters, leads, etc.) | Human breast cells |

| Vascular embolic agents | Fibroblasts | |

| Tissue adhesion barriers | Corrosion protection implant alloys | |

| Nerve guides | Biosensors | |

| Cartilage replacements | Used in advanced ceramic materials, especially biocompatible implants |

6.2. General Applications of PVA and HNTs

7. Fabrication Approaches for PVA-HNTs Composites

7.1. Dispersion Processing

7.2. Electrospinning

8. Characterization of PVA–HNT Composites

8.1. Morphological Studies of PVA–HNT Nanocomposites

8.2. Thermal Properties of PVA-HNT Nanocomposites

| HNTs (wt %) | Form | Property Improvements (Percentage %) | Ref. | |||

|---|---|---|---|---|---|---|

| Tc (°C) | Tg (°C) | Tm (°C) | TGA (°C) | |||

| 0, 2, 10, 40 & 53 | Film | - | 12.3 | - | 28.6 | [3] |

| 0 & 10 | Film | 12 | - | 1.8 | - | [6,7] |

| 0, 3.75, 7.5 & 15 | Modification | - | - | - | 14.3 | [7,19] |

| 0, 5, 10 & 20 | Reinforce | - | 12.8 | 5.2 | 30 | [9] |

| 0, 1, 2.5 & 5 | Reinforce | 2.6 | 3.9 | 0.5 | 8.8 | [47] |

| 0, 2, 5, 7.5 & 10 | Film | - | - | 0.2 | - | [53] |

| 0, 0.25, 0.5, 1, 3 & 5 | Film | - | - | - | 14.5 | [72] |

8.3. Mechanical Properties of PVA-HNT Nanocomposites

| HNTs (wt %) | Form | Property Improvements (Percentage %) | Ref. | ||

|---|---|---|---|---|---|

| Tensile Strength | Young’s Modulus | Elong. at Break (mm/mm) | |||

| 0, 3.75, 7.5 & 15 | Modification | 13.6 | - | - | [7,19] |

| 0, 5, 10 & 20 | Reinforce | 22.7 | 407.1 | - | [9] |

| 0, 2, 5, 7.5 & 10 | Film | 81.8 | - | - | [53] |

| 0, 2, 4, 6, 8, 10 & 12 | Film | 6.4 | 80.2 | - | [66] |

| 0, 0.25, 0.5, 1, 3 & 5 | Film | 20 | 94.9 | 82.9 | [72] |

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Razzak, M.T.; Darwis, D.; Zainuddin; Sukirno. Irradiation of polyvinyl alcohol and polyvinyl pyrrolidone blended hydrogel for wound dressing. Radiat. Phys. Chem. 2001, 62, 107–113. [Google Scholar] [CrossRef]

- Demerlis, C.C.; Schoneker, D.R. Review of the oral toxicity of polyvinyl alcohol (PVA). Food Chem. Toxicol. 2003, 41, 319–326. [Google Scholar] [CrossRef]

- Liu, M.; Guo, B.; Du, M.; Jia, D. Drying induced aggregation of halloysite nanotubes in polyvinyl alcohol/halloysite nanotubes solution and its effect on properties of composite film. Appl. Phys. A Mater. Sci. Process. 2007, 88, 391–395. [Google Scholar] [CrossRef]

- Limpan, N.; Prodpran, T.; Benjakul, S.; Prasarpran, S. Influences of degree of hydrolysis and molecular weight of poly (vinyl alcohol)(PVA) on properties of fish myofibrillar protein/PVA blend films. Food Hydrocoll. 2012, 29, 226–233. [Google Scholar] [CrossRef]

- Maria, T.M.; Carvalho, R.A.; Sobral, P.J.; Habitantea, A.M.; Solorza-Feriab, J. The effect of the degree of hydrolysis of the PVA and the plasticizer concentration on the color, opacity, and thermal and mechanical properties of films based on PVA and gelatin blends. J. Food Eng. 2008, 87, 191–199. [Google Scholar] [CrossRef]

- Qiu, K.; Netravali, A.N. A Composting Study of Membrane-Like Polyvinyl Alcohol Based Resins and Nanocomposites. J. Polym. Environ. 2013, 21, 658–674. [Google Scholar] [CrossRef]

- Tang, Y.; Zhou, D.; Zhang, J. Novel polyvinyl alcohol/styrene butadiene rubber latex/carboxymethyl cellulose nanocomposites reinforced with modified halloysite nanotubes. J. Nanomater. 2013, 2013, 128. [Google Scholar] [CrossRef]

- Qiu, K.; Netravali, A.N. Fabrication and characterization of biodegradable composites based on microfibrillated cellulose and polyvinyl alcohol. Compos. Sci. Technol. 2012, 72, 1588–1594. [Google Scholar] [CrossRef]

- Qiu, K.; Netravali, A.N. Halloysite nanotube reinforced biodegradable nanocomposites using noncrosslinked and malonic acid crosslinked polyvinyl alcohol. Polym. Compos. 2013, 34, 799–809. [Google Scholar] [CrossRef]

- Cho, D.; Netravali, A.N.; Joo, Y.L. Mechanical properties and biodegradability of electrospun soy protein Isolate/PVA hybrid nanofibers. Polym. Degrad. Stab. 2012, 97, 747–754. [Google Scholar] [CrossRef]

- Luo, S.; Netravali, A.N. A study of physical and mechanical properties of poly (hydroxybutyrate-co-hydroxyvalerate) during composting. Polym. Degrad. Stab. 2003, 80, 59–66. [Google Scholar] [CrossRef]

- Chiellini, E.; Corti, A.; D’Antone, S.; Solaro, R. Biodegradation of poly (vinyl alcohol) based materials. Prog. Polym. Sci. 2003, 28, 963–1014. [Google Scholar] [CrossRef]

- Solaro, R.; Corti, A.; Chiellini, E. Biodegradation of poly (vinyl alcohol) with different molecular weights and degree of hydrolysis. Polym Adv. Technol. 2000, 11, 873–878. [Google Scholar] [CrossRef]

- Vijayalakshmi, S.P.; Madras, G. Effects of the pH, concentration, and solvents on the ultrasonic degradation of poly (vinyl alcohol). J. Appl. Polym. Sci. 2006, 100, 4888–4892. [Google Scholar] [CrossRef]

- Corti, A.; Solaro, R.; Chiellini, E. Biodegradation of poly (vinyl alcohol) in selected mixed microbial culture and relevant culture filtrate. Polym. Degrad. Stab. 2002, 75, 447–458. [Google Scholar] [CrossRef]

- Chiellini, E.; Corti, A.; Solaro, R. Biodegradation of poly (vinyl alcohol) based blown films under different environmental conditions. Polym. Degrad. Stab. 1999, 64, 305–312. [Google Scholar] [CrossRef]

- Jayasekara, R.; Harding, I.; Bowater, I.; Christie, G.B.; Lonergan, G.T. Biodegradation by composting of surface modified starch and PVA blended films. J. Polym. Environ. 2003, 11, 49–56. [Google Scholar] [CrossRef]

- Matsumura, S.; Tanaka, T. Novel malonate-type copolymers containing vinyl alcohol blocks as biodegradable segments and their builder performance in detergent formulations. J. Environ. Polym. Degrad. 1994, 2, 89–97. [Google Scholar] [CrossRef]

- Ashori, A.; Raverty, W.D.; Harun, J. Effect of chitosan addition on the surface properties of kenaf (Hibiscus cannabinus) paper. Fibers Polym. 2005, 6, 174–179. [Google Scholar] [CrossRef]

- Zainuddin; Hill, D.J.; Le, T.T. An ESR study on γ-irradiated poly (vinyl alcohol). Rad. Phys. Chem. 2001, 62, 283–291. [Google Scholar] [CrossRef]

- Pal, K.; Banthia, A.K.; Majumdar, D.K. Preparation and characterization of polyvinyl alcohol-gelatin hydrogel membranes for biomedical applications. Am. Assoc. Pharm. Sci. PharmSciTech 2007, 8, E142–E146. [Google Scholar] [CrossRef] [PubMed]

- Horii, F.; Hu, S.; Ito, T.; Odani, H.; Kitamaru, R.; Matsuzawa, S.; Yamaura, K. Cross polarization/magic angle spinning 13C-NMR study of solid structure and hydrogen bonding of poly (vinyl alcohol) films with different tacticities. Polymer 1992, 33, 2299–2306. [Google Scholar] [CrossRef]

- Albdiry, M.T.; Yousif, B.F. Morphological structures and tribological performance of unsaturated polyester based untreated/silane-treated halloysite nanotubes. Mater. Des. 2013, 48, 68–76. [Google Scholar] [CrossRef]

- Peppas, N.A.; Merrill, E.W. Development of semicrystalline poly (vinyl alcohol) hydrogels for biomedical applications. J. Biomed. Mater. Res. 1977, 11, 423–434. [Google Scholar] [CrossRef] [PubMed]

- Paradossi, G.; Cavalieri, F.; Chiessi, E.; Spagnoli, C.; Cowman, M.K. Poly (vinyl alcohol) as versatile biomaterial for potential biomedical applications. J. Mater. Sci. Mater. Med. 2003, 14, 687–691. [Google Scholar] [CrossRef] [PubMed]

- Baker, M.I.; Walsh, S.P.; Schwartz, Z.; Boyan, B.D. A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications. J. Biomed. Mater. Res. B Appl. Biomater. 2012, 100, 1451–1457. [Google Scholar] [CrossRef] [PubMed]

- Vergaro, V.; Abdullayev, E.; Lvov, Y.M.; Zeitoun, A.; Cingolani, R.; Rinaldi, R.; Leporatti, S. Cytocompatibility and uptake of halloysite clay nanotubes. Biomacromolecules 2010, 11, 820–826. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Tsai, H.Y.; Yates, M.Z. Steric stabilization of thermally responsive N-isopropylacrylamide particles by poly (vinyl alcohol). Langmuir 2010, 26, 18055–18060. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.J.; Tong, Y.W. The effect of protein structural conformation on nanoparticle molecular imprinting of ribonuclease a using miniemulsion polymerization. Langmuir 2007, 23, 2722–2730. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.M.; Su, W.Y.; Leu, T.L.; Yang, M.C. Evaluation of chitosan/PVA blended hydrogel membranes. J. Membr. Sci. 2004, 236, 39–51. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, D.; Wei, S.; Wang, Z.; Karki, A.B.; Li, Y.; Bernazzani, P.; Young, D.P.; Gomes, J.A.; Cocke, D.L.; et al. Effects of iron oxide nanoparticles on polyvinyl alcohol: Interfacial layer and bulk nanocomposites thin film. J. Nanopart. Res. 2010, 12, 2415–2426. [Google Scholar] [CrossRef]

- Kenawy, E.R.; Kamoun, E.A.; Eldin, M.S.; El-Meligya, M.A. Physically crosslinked poly (vinyl alcohol)-hydroxyethyl starch blend hydrogel membranes: Synthesis and characterization for biomedical applications. Arab. J. Chem. 2014, 7, 372–380. [Google Scholar] [CrossRef]

- Kamoun, E.A.; Chen, X.; Eldin, M.S.; Kenawy, E.R. Crosslinked poly (vinyl alcohol) hydrogels for wound dressing applications: A review of remarkably blended polymers. Arab. J. Chem. 2015, 8, 1–14. [Google Scholar] [CrossRef]

- Zhao, L.; Mitomo, H.; Zhai, M.; Yoshii, F.; Nagasawa, N.; Kume, T. Synthesis of antibacterial PVA/CM-chitosan blend hydrogels with electron beam irradiation. Carbohydr. Polym. 2003, 53, 439–446. [Google Scholar] [CrossRef]

- Muggli, D.S.; Burkoth, A.K.; Anseth, K.S. Crosslinked polyanhydrides for use in orthopedic applications: Degradation behavior and mechanics. J. Biomed. Mater. Res. 1999, 46, 271–278. [Google Scholar] [CrossRef]

- Hyon, S.H.; Cha, W.I.; Ikada, Y.; Kita, M.; Ogura, Y.; Honda, Y. Poly (vinyl alcohol) hydrogels as soft contact lens material. J. Biomater. Sci. Polym. Ed. 1994, 5, 397–406. [Google Scholar] [CrossRef] [PubMed]

- Kaity, S.; Isaac, J.; Ghosh, A. Interpenetrating polymer network of locust bean gum-poly (vinyl alcohol) for controlled release drug delivery. Carbohydr. Polym. 2013, 94, 456–467. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Mensire, R.; Cohen, R.E.; Rubner, M.F. Strategies for hydrogen bonding based layer-by-layer assembly of poly (vinyl alcohol) with weak polyacids. Macromolecules 2011, 45, 347–355. [Google Scholar] [CrossRef]

- Ghebaur, A.; Garea, S.A.; Iovu, H. New polymer–halloysite hybrid materials—potential controlled drug release system. Int. J. Pharm. 2012, 436, 568–573. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Yan, L.; Chen, W.; Li, W. Preparation of chitosan/graphene oxide composite film with enhanced mechanical strength in the wet state. Carbohydr. Polym. 2011, 83, 653–658. [Google Scholar] [CrossRef]

- Mutsuo, S.; Yamamoto, K.; Furuzono, T.; Kimura, T.; Ono, T.; Kishida, A. Release behavior from hydrogen-bonded polymer gels prepared by pressurization. J. Appl. Polym. Sci. 2011, 119, 2725–2729. [Google Scholar] [CrossRef]

- Shuai, C.; Mao, Z.; Lu, H.; Nie, Y.; Hu, H.; Peng, S. Fabrication of porous polyvinyl alcohol scaffold for bone tissue engineering via selective laser sintering. Biofabrication 2013, 5, 015014. [Google Scholar] [CrossRef] [PubMed]

- Ng, K.W.; Wanivenhaus, F.; Chen, T.; Hsu, H.C.; Allon, A.A.; Abrams, V.D.; Torzilli, P.A.; Warren, R.F.; Maher, S.A. A novel macroporous polyvinyl alcohol scaffold promotes chondrocyte migration and interface formation in an in vitro cartilage defect model. Tissue Eng. A 2012, 18, 1273–1281. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Ng, K.M.; Chan, C.M.; Sun, G.; Wu, J. High-impact polystyrene/halloysite nanocomposites prepared by emulsion polymerization using sodium dodecyl sulfate as surfactant. J. Coll. Interface Sci. 2011, 358, 423–429. [Google Scholar] [CrossRef] [PubMed]

- Stasio, F.D.; Korniychuk, P.; Brovelli, S.; Uznanski, P.; McDonnell, S.O.; Winroth, G.; Anderson, H.L.; Tracz, A.; Cacialli, F. Highly Polarized Emission from Oriented Films Incorporating Water-Soluble Conjugated Polymers in a Polyvinyl Alcohol Matrix. Adv. Mater. 2011, 23, 1855–1859. [Google Scholar] [CrossRef] [PubMed]

- Du, M.; Guo, B.; Lei, Y.; Liu, M.; Jia, D. Carboxylated butadiene–styrene rubber/halloysite nanotube nanocomposites: Interfacial interaction and performance. Polymer 2008, 49, 4871–4876. [Google Scholar] [CrossRef]

- Swapna, V.P.; Selvin, T.P.; Suresh, K.I.; Saranya, V.; Rahana, M.P.; Ranimol, S. Thermal properties of poly (vinyl alcohol)(PVA)/halloysite nanotubes reinforced nanocomposites. Int. J. Plast. Technol. 2015. [Google Scholar] [CrossRef]

- Silva, E.D.; Lebrun, L.; Metayer, M. Elaboration of a membrane with bipolar behaviour using the semi-interpenetrating polymer networks technique. Polymer 2002, 43, 5311–5320. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Xu, C.; Zhang, M.; Zhang, X. Preparation of graphene/poly (vinyl alcohol) nanocomposites with enhanced mechanical properties and water resistance. Polym. Int. 2011, 60, 816–822. [Google Scholar] [CrossRef]

- Gopishetty, V.; Tokarev, I.; Minko, S. Biocompatible stimuli-responsive hydrogel porous membranes via phase separation of a polyvinyl alcohol and Na-alginate intermolecular complex. J. Mater. Chem. 2012, 22, 19482–19487. [Google Scholar] [CrossRef]

- Ravindra, K.; Manasi, G.; Sheetal, G.; Kumar, P.B. Halloysite Nanotubes and Applications: A Review. J. Adv. Sci. Res. 2012, 3, 25–29. [Google Scholar]

- Lvov, Y.; Abdullayev, E. Functional polymer-clay nanotube composites with sustained release of chemical agents. Prog. Polym. Sci. 2013, 38, 1690–1719. [Google Scholar] [CrossRef]

- Zhou, W.Y.; Guo, B.; Liu, M.; Liao, R.; Rabie, A.B.; Jia, D. Poly (vinyl alcohol)/halloysite nanotubes bionanocomposite films: Properties and in vitro osteoblasts and fibroblasts response. J. Biomed. Mater. Res. A 2010, 93, 1574–1587. [Google Scholar] [CrossRef] [PubMed]

- Song, K.; Zhang, Y.; Meng, J.; Green, E.C.; Tajaddod, N.; Li, H.; Minus, M.L. Structural polymer-based carbon nanotube composite fibers: Understanding the processing–structure–performance relationship. Materials 2013, 6, 2543–2577. [Google Scholar] [CrossRef]

- Joussein, E.; Petit, S.; Churchman, J.; Theng, B.; Righi, D.; Delvaux, B. Halloysite clay minerals—A review. Clay Miner. 2005, 40, 383–426. [Google Scholar] [CrossRef]

- Chen, D.H.; Leu, J.C.; Huang, T.C. Transport and hydrolysis of urea in a reactor–separator combining an anion-exchange membrane and immobilized urease. J. Chem. Technol. Biotechnol. 1994, 61, 351–357. [Google Scholar] [CrossRef] [PubMed]

- Li, J.K.; Wang, N.; Wu, X.S. Poly (vinyl alcohol) nanoparticles prepared by freezing-thawing process for protein/peptide drug delivery. J. Controll. Release 1998, 56, 117–126. [Google Scholar] [CrossRef]

- Yoshii, F.; Zhanshan, Y.; Isobe, K.; Shinozaki, K.; Makuuchi, K. Electron beam crosslinked PEO and PEO/PVA hydrogels for wound dressing. Radiat. Phys. Chem. 1999, 55, 133–138. [Google Scholar] [CrossRef]

- Yoshii, F.; Makuuchi, K.; Darwis, D.; Iriawan, T.; Razzak, M.T.; Rosiak, J.M. Heat resistance poly (vinyl alcohol) hydrogel. Radiat. Phys. Chem. 1995, 46, 169–174. [Google Scholar] [CrossRef]

- Salunkhe, A.B.; Khot, V.M.; Thorat, N.D.; Phadatare, M.R.; Sathish, C.I.; Dhawale, D.S.; Pawar, S.H. Polyvinyl alcohol functionalized cobalt ferrite nanoparticles for biomedical applications. Appl. Surface Sci. 2013, 264, 598–604. [Google Scholar] [CrossRef]

- Lee, J.; Isobe, T.; Senna, M. Preparation of ultrafine Fe3O4 particles by precipitation in the presence of PVA at high pH. J. Coll. Interface Sci. 1996, 177, 490–494. [Google Scholar] [CrossRef]

- Kayal, S.; Ramanujan, R.V. Doxorubicin loaded PVA coated iron oxide nanoparticles for targeted drug delivery. Mater. Sci. Eng. C 2010, 30, 484–490. [Google Scholar] [CrossRef]

- Chu, W.B.; Yang, J.W.; Liu, T.J.; Tiu, C.; Guo, J. The effects of pH, molecular weight and degree of hydrolysis of poly (vinyl alcohol) on slot die coating of PVA suspensions of TiO2 and SiO2. Coll. Surfaces A Physicochem. Eng. Asp. 2007, 302, 1–10. [Google Scholar] [CrossRef]

- Sirousazar, M.; Kokabi, M.; Hassan, Z.M.; Bahramian, A.R. Dehydration kinetics of polyvinyl alcohol nanocomposite hydrogels containing Na-montmorillonite nanoclay. Sci. Iran. 2011, 18, 780–784. [Google Scholar] [CrossRef]

- Sirousazar, M.; Kokabi, M.; Hassan, Z.M. In vivo and cytotoxic assays of a poly (vinyl alcohol)/clay nanocomposite hydrogel wound dressing. J. Biomater. Sci. Polym. Ed. 2011, 22, 1023–1033. [Google Scholar] [CrossRef] [PubMed]

- Fujii, K.; Nakagaito, A.N.; Takagi, H.; Yonekura, D. Sulfuric acid treatment of halloysite nanoclay to improve the mechanical properties of PVA/halloysite transparent composite films. Compos. Interfaces 2014, 21, 319–327. [Google Scholar] [CrossRef]

- Jang, J.; Lee, D.K. Plasticizer effect on the melting and crystallization behavior of polyvinyl alcohol. Polymer 2003, 44, 8139–8146. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Pires, R.A.; Mano, J.F.; Reis, R.L. Bionanocomposites from lignocellulosic resources: Properties, applications and future trends for their use in the biomedical field. Prog. Polym. Sci. 2013, 38, 1415–1441. [Google Scholar] [CrossRef]

- Jayasekara, R.; Harding, I.; Bowater, I.; Christie, G.B.; Lonergan, G.T. Preparation, surface modification and characterisation of solution cast starch PVA blended films. Polym. Test. 2004, 23, 17–27. [Google Scholar] [CrossRef]

- Heuschmid, F.F.; Schuster, P.; Lauer, B.; Fabian, E.; Leibold, E.; Ravenzwaay, B.V. Polyethylene glycol-polyvinyl alcohol grafted copolymer: Study of the bioavailability after oral administration to rats. Food Chem. Toxicol. 2013, 51, S3–S6. [Google Scholar] [CrossRef] [PubMed]

- Ghaffari-Moghaddam, M.; Eslahi, H. Synthesis, characterization and antibacterial properties of a novel nanocomposite based on polyaniline/polyvinyl alcohol/Ag. Arab. J. Chem. 2014, 7, 846–855. [Google Scholar] [CrossRef]

- He, Y.; Kong, W.; Wang, W.; Liu, T.; Liu, Y.; Gong, Q.; Gao, J. Modified natural halloysite/potato starch composite films. Carbohydr. Polym. 2012, 87, 2706–2711. [Google Scholar] [CrossRef]

- Spiridon, I.; Popescu, M.C.; Bodârlău, R.; Vasile, C. Enzymatic degradation of some nanocomposites of poly (vinyl alcohol) with starch. Polym. Degrad. Stab. 2008, 93, 1884–1890. [Google Scholar] [CrossRef]

- Liu, M.; Jia, Z.; Jia, D.; Zhou, C. Recent advance in research on halloysite nanotubes-polymer nanocomposite. Prog. Polym. Sci. 2014, 39, 1498–1525. [Google Scholar] [CrossRef]

- Dong, Y.; Chaudhary, D.; Haroosh, H.; Bickford, T. Development and characterisation of novel electrospun polylactic acid/tubular clay nanocomposites. J. Mater. Sci. 2011, 46, 6148–6153. [Google Scholar] [CrossRef]

- Chang, P.R.; Xie, Y.; Wu, D.; Ma, X. Amylose wrapped halloysite nanotubes. Carbohydr. Polym. 2011, 84, 1426–1429. [Google Scholar] [CrossRef]

- Atabey, E.; Wei, S.; Zhang, X.; Gu, H.; Yan, X.; Huang, Y.; Shao, L.; He, Q.; Zhu, J.; Sun, L.; et al. Fluorescent electrospun polyvinyl alcohol/CdSe@ZnS nanocomposite fibers. J. Compos. Mater. 2013, 47, 3175–3185. [Google Scholar] [CrossRef]

- Pandele, A.M.; Ionita, M.; Crica, L.; Dinescu, S.; Costache, M.; Iovu, H. Synthesis, characterization, and in vitro studies of graphene oxide/chitosan–polyvinyl alcohol films. Carbohydr. Polym. 2014, 102, 813–820. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wang, S.; Guo, Q.; Shen, M.; Shi, X. Hemocompatibility of electrospun halloysite nanotube-and carbon nanotube-doped composite poly (lactic-co-glycolic acid) nanofibers. J. Appl. Polym. Sci. 2013, 127, 4825–4832. [Google Scholar] [CrossRef]

- Sakurada, I. Polyvinyl Alcohol Fiber; Marcel Dekker, Inc.: New York, NY, USA, 1985. [Google Scholar]

- Dong, Y.; Bickford, T.; Haroosh, H.J.; Lau, K.T.; Takagi, H. Multi-response analysis in the material characterisation of electrospun poly (lactic acid)/halloysite nanotube composite fibres based on Taguchi design of experiments: Fibre diameter, non-intercalation and nucleation effects. Appl. Phys. A 2013, 112, 747–757. [Google Scholar] [CrossRef]

- Qi, R.; Cao, X.; Shen, M.; Guo, R.; Yu, J.; Shi, X. Biocompatibility of electrospun halloysite nanotube-doped poly (lactic-co-glycolic acid) composite nanofibers. J. Biomater. Sci. Polym. Ed. 2012, 23, 299–313. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Zheng, G.; Guan, X.; Yan, X.; Guo, J.; Dai, K.; Liu, C.; Shen, C.; Guo, Z. Mechanically Strengthened Polyamide 66 Nanofibers Bundles via Compositing With Polyvinyl Alcohol. Macromol. Mater. Eng. 2015. [Google Scholar] [CrossRef]

© 2015 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaaz, T.S.; Sulong, A.B.; Akhtar, M.N.; Kadhum, A.A.H.; Mohamad, A.B.; Al-Amiery, A.A. Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites. Molecules 2015, 20, 22833-22847. https://doi.org/10.3390/molecules201219884

Gaaz TS, Sulong AB, Akhtar MN, Kadhum AAH, Mohamad AB, Al-Amiery AA. Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites. Molecules. 2015; 20(12):22833-22847. https://doi.org/10.3390/molecules201219884

Chicago/Turabian StyleGaaz, Tayser Sumer, Abu Bakar Sulong, Majid Niaz Akhtar, Abdul Amir H. Kadhum, Abu Bakar Mohamad, and Ahmed A. Al-Amiery. 2015. "Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites" Molecules 20, no. 12: 22833-22847. https://doi.org/10.3390/molecules201219884

APA StyleGaaz, T. S., Sulong, A. B., Akhtar, M. N., Kadhum, A. A. H., Mohamad, A. B., & Al-Amiery, A. A. (2015). Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites. Molecules, 20(12), 22833-22847. https://doi.org/10.3390/molecules201219884