Emulsion Stabilization with Functionalized Cellulose Nanoparticles Fabricated Using Deep Eutectic Solvents

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Cellulose Nanoparticles Using DES Pre-Treatments

2.2.1. Chemically Unmodified CNFs

2.2.2. Surface Functionalized CNFs

2.2.3. Surface Functionalized CNCs

2.3. Determination of Acidic Groups and Calculation of Nanoparticle Yields

2.4. Transmission Electron Microscopy (TEM)

2.5. Diffuse Reflectance Infrared Fourier Transform (DRIFT) Spectroscopy

2.6. Water Contact Angles of Self-Standing Cellulose Nanoparticle Films

2.7. Surface Tension by Tensiometer

2.8. Fabrication of Nanoparticle-Stabilized o/w Emulsions

2.9. Properties of the Stabilized o/w Emulsions

3. Results and Discussion

3.1. Characterization of Cellulose Nanoparticles

3.2. Wetting Characteristics of Cellulose Nanoparticle Films

3.3. Surface Tension of Nanoparticle Solutions

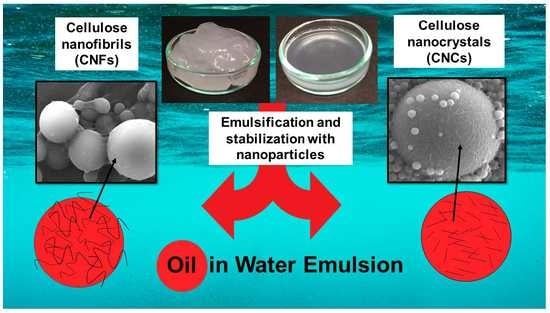

3.4. Properties of Oil Droplets in Nanoparticle-Stabilized Emulsions

3.5. Stability of o/w Emulsions

3.6. Stabilization Mechanisms of Cellulose Nanoparticles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tadros, T.F. Topics in colloid and interface science. In Emulsion Formation and Stability; Wiley-VCH: Weinheim, Germany, 2013; ISBN 9783527319916 3527319913. [Google Scholar]

- Bouyer, E.; Mekhloufi, G.; Rosilio, V.; Grossiord, J.-L.; Agnely, F. Proteins, polysaccharides, and their complexes used as stabilizers for emulsions: Alternatives to synthetic surfactants in the pharmaceutical field? Int. J. Pharm. 2012, 436, 359–378. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Vogel, R.; Werner, S.; Heinrich, G.; Clausse, D.; Dutschk, V. Influence of the particle type on the rheological behavior of Pickering emulsions. Colloids Surf. Physicochem. Eng. Asp. 2011, 382, 238–245. [Google Scholar] [CrossRef]

- Zhu, Y.; Jiang, J.; Liu, K.; Cui, Z.; Binks, B.P. Switchable pickering emulsions stabilized by silica nanoparticles hydrophobized in Situ with a conventional cationic surfactant. Langmuir 2015, 31, 3301–3307. [Google Scholar] [CrossRef] [PubMed]

- Xhanari, K.; Syverud, K.; Stenius, P. Emulsions stabilized by microfibrillated cellulose: The effect of hydrophobization, concentration and o/w ratio. J. Dispers. Sci. Technol. 2011, 32, 447–452. [Google Scholar] [CrossRef]

- Wang, L.-J.; Yin, S.-W.; Wu, L.-Y.; Qi, J.-R.; Guo, J.; Yang, X.-Q. Fabrication and characterization of Pickering emulsions and oil gels stabilized by highly charged zein/chitosan complex particles (ZCCPs). Food Chem. 2016, 213, 462–469. [Google Scholar] [CrossRef] [PubMed]

- Pickering, S.U. CXCVI.—Emulsions. J. Chem. Soc. Trans. 1907, 91, 2001–2021. [Google Scholar] [CrossRef]

- Ramsden, W. Separation of solids in the surface-layers of solutions and “suspensions” (Observations on surface-membranes, bubbles, emulsions, and mechanical coagulation)—Preliminary Account. Proc. R. Soc. Lond. 1903, 72, 156–164. [Google Scholar] [CrossRef]

- Rayner, M.; Marku, D.; Eriksson, M.; Sjöö, M.; Dejmek, P.; Wahlgren, M. Biomass-based particles for the formulation of Pickering type emulsions in food and topical applications. Colloids Surf. Physicochem. Eng. Asp. 2014, 458, 48–62. [Google Scholar] [CrossRef]

- Chen, T.; Colver, P.J.; Bon, S.A.F. Organic–inorganic hybrid hollow spheres prepared from TiO2-stabilized Pickering emulsion polymerization. Adv. Mater. 2007, 19, 2286–2289. [Google Scholar] [CrossRef]

- Reger, M.; Sekine, T.; Hoffmann, H. Pickering emulsions stabilized by amphiphile covered clays. Colloids Surf. Physicochem. Eng. Asp. 2012, 413, 25–32. [Google Scholar] [CrossRef]

- Matos, M.; Marefati, A.; Bordes, R.; Gutiérrez, G.; Rayner, M. Combined emulsifying capacity of polysaccharide particles of different size and shape. Carbohydr. Polym. 2017, 169, 127–138. [Google Scholar] [CrossRef] [PubMed]

- Rayner, M.; Sjöö, M.; Timgren, A.; Dejmek, P. Quinoa starch granules as stabilizing particles for production of Pickering emulsions. Faraday Discuss. 2012, 158, 139–155. [Google Scholar] [CrossRef] [PubMed]

- Aditya, N.P.; Hamilton, I.E.; Norton, I.T. Amorphous nano-curcumin stabilized oil in water emulsion: Physico chemical characterization. Food Chem. 2017, 224, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Leclercq, L.; Nardello-Rataj, V. Pickering emulsions based on cyclodextrins: A smart solution for antifungal azole derivatives topical delivery. Eur. J. Pharm. Sci. 2016, 82, 126–137. [Google Scholar] [CrossRef] [PubMed]

- Binks, B.P. Particles as surfactants—similarities and differences. Curr. Opin. Colloid Interface Sci. 2002, 7, 21–41. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, Z.; Chen, X.; Zhang, W.; Xie, Y.; Chen, Y.; Liu, Z.; Yuan, W. An overview of Pickering emulsions: Solid-particle materials, classification, morphology, and applications. Front. Pharmacol. 2017, 8, 287. [Google Scholar] [CrossRef] [PubMed]

- Crossley, S.; Faria, J.; Shen, M.; Resasco, D.E. Solid nanoparticles that catalyze biofuel upgrade reactions at the water/oil interface. Science 2010, 327, 68–72. [Google Scholar] [CrossRef] [PubMed]

- Hiebler, K.; Lichtenegger, G.J.; Maier, M.C.; Park, E.S.; Gonzales-Groom, R.; Binks, B.P.; Gruber-Woelfler, H. Heterogeneous Pd catalysts as emulsifiers in Pickering emulsions for integrated multistep synthesis in flow chemistry. Beilstein J. Org. Chem. 2018, 14, 648–658. [Google Scholar] [CrossRef] [PubMed]

- Pera-Titus, M.; Leclercq, L.; Clacens, J.-M.; De Campo, F.; Nardello-Rataj, V. Pickering interfacial catalysis for biphasic systems: From emulsion design to green reactions. Angew. Chem. Int. Ed. 2015, 54, 2006–2021. [Google Scholar] [CrossRef] [PubMed]

- Qu, Y.; Huang, R.; Qi, W.; Su, R.; He, Z. Interfacial polymerization of dopamine in a Pickering emulsion: Synthesis of cross-linkable colloidosomes and enzyme immobilization at oil/water interfaces. ACS Appl. Mater. Interfaces 2015, 7, 14954–14964. [Google Scholar] [CrossRef] [PubMed]

- Cunha, A.G.; Mougel, J.-B.; Cathala, B.; Berglund, L.A.; Capron, I. Preparation of double Pickering emulsions stabilized by chemically tailored nanocelluloses. Langmuir 2014, 30, 9327–9335. [Google Scholar] [CrossRef] [PubMed]

- Kalashnikova, I.; Bizot, H.; Bertoncini, P.; Cathala, B.; Capron, I. Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter 2013, 9, 952–959. [Google Scholar] [CrossRef]

- Tasset, S.; Cathala, B.; Bizot, H.; Capron, I. Versatile cellular foams derived from CNC-stabilized Pickering emulsions. RSC Adv 2014, 4, 893–898. [Google Scholar] [CrossRef]

- Wen, C.; Yuan, Q.; Liang, H.; Vriesekoop, F. Preparation and stabilization of d-limonene Pickering emulsions by cellulose nanocrystals. Carbohydr. Polym. 2014, 112, 695–700. [Google Scholar] [CrossRef] [PubMed]

- Winuprasith, T.; Suphantharika, M. Microfibrillated cellulose from mangosteen (Garcinia mangostana L.) rind: Preparation, characterization, and evaluation as an emulsion stabilizer. Food Hydrocoll. 2013, 32, 383–394. [Google Scholar] [CrossRef]

- Capron, I.; Rojas, O.J.; Bordes, R. Behavior of nanocelluloses at interfaces. Curr. Opin. Colloid Interface Sci. 2017, 29, 83–95. [Google Scholar] [CrossRef]

- Espino-Pérez, E.; Domenek, S.; Belgacem, N.; Sillard, C.; Bras, J. Green process for chemical functionalization of nanocellulose with carboxylic acids. Biomacromolecules 2014, 15, 4551–4560. [Google Scholar] [CrossRef] [PubMed]

- Visanko, M.; Liimatainen, H.; Sirviö, J.A.; Heiskanen, J.P.; Niinimäki, J.; Hormi, O. Amphiphilic cellulose nanocrystals from acid-free oxidative treatment: Physicochemical characteristics and use as an oil–water stabilizer. Biomacromolecules 2014, 15, 2769–2775. [Google Scholar] [CrossRef] [PubMed]

- Xiao, M.; Xu, A.; Zhang, T.; Hong, L. Tailoring the wettability of colloidal particles for Pickering emulsions via surface modification and roughness. Front. Chem. 2018, 6, 225. [Google Scholar] [CrossRef] [PubMed]

- Habibi, Y. Key advances in the chemical modification of nanocelluloses. Chem. Soc. Rev. 2014, 43, 1519–1542. [Google Scholar] [CrossRef] [PubMed]

- Ojala, J.; Sirviö, J.A.; Liimatainen, H. Nanoparticle emulsifiers based on bifunctionalized cellulose nanocrystals as marine diesel oil–water emulsion stabilizers. Chem. Eng. J. 2016, 288, 312–320. [Google Scholar] [CrossRef]

- Binks, B.P.; Lumsdon, S.O. Influence of particle wettability on the type and stability of surfactant-free emulsions. Langmuir 2000, 16, 8622–8631. [Google Scholar] [CrossRef]

- Aveyard, R.; Binks, B.P.; Clint, J.H. Emulsions stabilised solely by colloidal particles. Adv. Colloid Interface Sci. 2003, 100–102, 503–546. [Google Scholar] [CrossRef]

- Horozov, T.S.; Binks, B.P. Particle-stabilized emulsions: A bilayer or a bridging monolayer? Angew. Chem. Int. Ed. 2006, 45, 773–776. [Google Scholar] [CrossRef] [PubMed]

- Varanasi, S.; Henzel, L.; Mendoza, L.; Prathapan, R.; Batchelor, W.; Tabor, R.; Garnier, G. Pickering emulsions electrostatically stabilized by cellulose nanocrystals. Front. Chem. 2018, 6, 409. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Sisler, J.; Grishkewich, N.; Tam, K.C. Functionalization of cellulose nanocrystals for advanced applications. J. Colloid Interface Sci. 2017, 494, 397–409. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Grishkewich, N.; Mohammed, N.; Tang, J.; Tam, K.C. Recent advances in the application of cellulose nanocrystals. Curr. Opin. Colloid Interface Sci. 2017, 29, 32–45. [Google Scholar] [CrossRef]

- De France, K.J.; Hoare, T.; Cranston, E.D. Review of hydrogels and aerogels containing nanocellulose. Chem. Mater. 2017, 29, 4609–4631. [Google Scholar] [CrossRef]

- Prince, R.C. Oil spill dispersants: Boon or bane? Environ. Sci. Technol. 2015, 49, 6376–6384. [Google Scholar] [CrossRef] [PubMed]

- Ojala, J.; Sirviö, J.A.; Liimatainen, H. Preparation of cellulose nanocrystals from lignin-rich reject material for oil emulsification in an aqueous environment. Cellulose 2018, 25, 293–304. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Lee, S.-Y.; Wei, T.; Li, J.; Fan, Z. Nanocellulose: A promising nanomaterial for advanced electrochemical energy storage. Chem. Soc. Rev. 2018, 47, 2837–2872. [Google Scholar] [CrossRef] [PubMed]

- Sirviö, J.A.; Visanko, M.; Liimatainen, H. Deep eutectic solvent system based on choline chloride-urea as a pre-treatment for nanofibrillation of wood cellulose. Green Chem. 2015, 17, 3401–3406. [Google Scholar] [CrossRef]

- Sirviö, J.A.; Visanko, M.; Liimatainen, H. Acidic deep eutectic solvents as hydrolytic media for cellulose nanocrystal production. Biomacromolecules 2016, 17, 3025–3032. [Google Scholar] [CrossRef] [PubMed]

- Selkälä, T.; Sirviö, J.A.; Lorite, G.S.; Liimatainen, H. Anionically stabilized cellulose nanofibrils through succinylation pretreatment in urea-lithium chloride deep eutectic solvent. ChemSusChem 2016, 9, 3074–3083. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Sirviö, J.A.; Haapala, A.; Liimatainen, H. Cellulose nanofibrils from nonderivatizing urea-based deep eutectic solvent pretreatments. ACS Appl. Mater. Interfaces 2017, 9, 2846–2855. [Google Scholar] [CrossRef] [PubMed]

- Laitinen, O.; Ojala, J.; Sirviö, J.A.; Liimatainen, H. Sustainable stabilization of oil in water emulsions by cellulose nanocrystals synthesized from deep eutectic solvents. Cellulose 2017, 24, 1679–1689. [Google Scholar] [CrossRef]

- Hayyan, M.; Abo-Hamad, A.; AlSaadi, M.A.; Hashim, M.A. Functionalization of graphene using deep eutectic solvents. Nanoscale Res. Lett. 2015, 10, 324. [Google Scholar] [CrossRef] [PubMed]

- AlOmar, M.K.; Alsaadi, M.A.; Hayyan, M.; Akib, S.; Ibrahim, M.; Hashim, M.A. Allyl triphenyl phosphonium bromide based DES-functionalized carbon nanotubes for the removal of mercury from water. Chemosphere 2017, 167, 44–52. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; De Oliveira Vigier, K.; Royer, S.; Jérôme, F. Deep eutectic solvents: Syntheses, properties and applications. Chem. Soc. Rev. 2012, 41, 7108–7146. [Google Scholar] [CrossRef] [PubMed]

- Katz, S.; Beatson, R.P.; Scallan, A.M. The determination of strong and weak acidic groups in sulfite pulps. Sven. Papperstidning 1984, 6, R48–R53. [Google Scholar]

- Rattaz, A.; Mishra, S.P.; Chabot, B.; Daneault, C. Cellulose nanofibres by sonocatalysed-TEMPO-oxidation. Cellulose 2011, 18, 585–593. [Google Scholar] [CrossRef]

- Yuan, Y.; Lee, T.R. Contact angle and wetting properties. In Surface Science Techniques; Bracco, G., Holst, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 51, pp. 3–34, ISBN 978-3-642-34242-4, 978-3-642-34243-1. [Google Scholar]

- Du Nouy, P.L. An interfacial tensiometer for universal use. J. Gen. Physiol. 1925, 7, 625–631. [Google Scholar] [CrossRef] [PubMed]

- Alduncin, J.A.; Forcada, J.; Asua, J.M. Miniemulsion polymerization using oil-soluble initiators. Macromolecules 1994, 27, 2256–2261. [Google Scholar] [CrossRef]

- Sadeghifar, H.; Filpponen, I.; Clarke, S.P.; Brougham, D.F.; Argyropoulos, D.S. Production of cellulose nanocrystals using hydrobromic acid and click reactions on their surface. J. Mater. Sci. 2011, 46, 7344–7355. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, X.; Zhu, J.Y. Kinetics of strong acid hydrolysis of a bleached kraft pulp for producing cellulose nanocrystals (CNCs). Ind. Eng. Chem. Res. 2014, 53, 11007–11014. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Gong, J.; Kuang, Y.; Mo, L.; Song, T. Cellulose nanocrystals (CNCs) with different crystalline allomorph for oil in water Pickering emulsions. Carbohydr. Polym. 2018, 183, 303–310. [Google Scholar] [CrossRef] [PubMed]

- Visanko, M.; Liimatainen, H.; Sirviö, J.A.; Haapala, A.; Sliz, R.; Niinimäki, J.; Hormi, O. Porous thin film barrier layers from 2,3-dicarboxylic acid cellulose nanofibrils for membrane structures. Carbohydr. Polym. 2014, 102, 584–589. [Google Scholar] [CrossRef] [PubMed]

- Huminic, G.; Huminic, A.; Dumitrache, F.; Fleaca, C.; Morjan, I. Experimental study of thermo-physical properties of nanofluids based on γ-Fe2O3 nanoparticles for heat transfer applications. Heat Transf. Eng. 2017, 38, 1496–1505. [Google Scholar] [CrossRef]

- Tanvir, S.; Qiao, L. Surface tension of Nanofluid-type fuels containing suspended nanomaterials. Nanoscale Res. Lett. 2012, 7, 226. [Google Scholar] [CrossRef] [PubMed]

- Vafaei, S.; Purkayastha, A.; Jain, A.; Ramanath, G.; Borca-Tasciuc, T. The effect of nanoparticles on the liquid–gas surface tension of Bi2Te3 nanofluids. Nanotechnology 2009, 20, 185702. [Google Scholar] [CrossRef] [PubMed]

- Andresen, M.; Stenius, P. Water-in-oil emulsions stabilized by hydrophobized microfibrillated cellulose. J. Dispers. Sci. Technol. 2007, 28, 837–844. [Google Scholar] [CrossRef]

- Gestranius, M.; Stenius, P.; Kontturi, E.; Sjöblom, J.; Tammelin, T. Phase behaviour and droplet size of oil-in-water Pickering emulsions stabilised with plant-derived nanocellulosic materials. Colloids Surf. Physicochem. Eng. Asp. 2017, 519, 60–70. [Google Scholar] [CrossRef]

- Kalashnikova, I.; Bizot, H.; Cathala, B.; Capron, I. New Pickering emulsions stabilized by bacterial cellulose nanocrystals. Langmuir ACS J. Surf. Colloids 2011, 27, 7471–7479. [Google Scholar] [CrossRef] [PubMed]

- Cherhal, F.; Cousin, F.; Capron, I. Structural description of the interface of Pickering emulsions stabilized by cellulose nanocrystals. Biomacromolecules 2016, 17, 496–502. [Google Scholar] [CrossRef] [PubMed]

| Sample Label | Morphology | DES Treatment | Chemical Reaction | Yield [%] | Anionic Charge [mmol·g−1] |

|---|---|---|---|---|---|

| NON-F-CNF | Fibril | C5H14ClNO/Urea | No surface funct. | >99 | 0.28 |

| SF-CNF | Fibril | Urea/LiCl + succinic anhydride | Succinylation | 93 | 0.67 |

| SF-CNC | Crystal | C2H2O4∙2 H2O/C5H14ClNO | Carboxylation | 75 | 0.17 |

| REF-CNC | Crystal | - | - | - | 0.15 |

| Mean Droplet Diameter [µm] | |||||

|---|---|---|---|---|---|

| Nanoparticle Dosage [wt.-%] | Oil [wt.-%] | NON-F-CNF | SF-CNF | SF-CNC | REF-CNC |

| 0.05 | 5 | 12 ± 4 | 12 ± 3 | 16 ± 4 | 22 ± 5 |

| 0.05 | 10 | 15 ± 4 | 15 ± 4 | 17 ± 4 | 26 ± 6 |

| 0.05 | 20 | 21 ± 4 | 15 ± 4 | 22 ± 5 | 27 ± 6 |

| 0.1 | 5 | 24 ± 6 | 10 ± 2 | 14 ± 4 | 21 ± 5 |

| 0.1 | 10 | 28 ± 7 | 11 ± 3 | 16 ± 4 | 20 ± 5 |

| 0.1 | 20 | 28 ± 7 | 14 ± 3 | 19 ± 5 | 25 ± 6 |

| 0.2 | 5 | 13 ± 5 | 9 ± 2 | 9 ± 3 | 17 ± 5 |

| 0.2 | 10 | 24 ± 6 | 10 ± 3 | 19 ± 5 | 19 ± 5 |

| 0.2 | 20 | 22 ± 6 | 11 ± 3 | 14 ± 4 | 22 ± 6 |

| Sample | Structure | Hydrophilicity Level | Oil Droplet Size in Emulsion | Emulsion Stability against Coalescence | Stabilization Mechanism |

|---|---|---|---|---|---|

| NON-F-CNF | Fibrils | Low | + | not stable | - |

| SF-CNF | Fibrils | Very Low | ++++ | +++ | web-formation |

| SF-CNC | Crystals | Moderate | +++ | ++ | - |

| REF-CNC | Crystals | Moderate | ++ | + | Flat, homogeneous cover on oil surface |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ojala, J.; Visanko, M.; Laitinen, O.; Österberg, M.; Sirviö, J.A.; Liimatainen, H. Emulsion Stabilization with Functionalized Cellulose Nanoparticles Fabricated Using Deep Eutectic Solvents. Molecules 2018, 23, 2765. https://doi.org/10.3390/molecules23112765

Ojala J, Visanko M, Laitinen O, Österberg M, Sirviö JA, Liimatainen H. Emulsion Stabilization with Functionalized Cellulose Nanoparticles Fabricated Using Deep Eutectic Solvents. Molecules. 2018; 23(11):2765. https://doi.org/10.3390/molecules23112765

Chicago/Turabian StyleOjala, Jonna, Miikka Visanko, Ossi Laitinen, Monika Österberg, Juho Antti Sirviö, and Henrikki Liimatainen. 2018. "Emulsion Stabilization with Functionalized Cellulose Nanoparticles Fabricated Using Deep Eutectic Solvents" Molecules 23, no. 11: 2765. https://doi.org/10.3390/molecules23112765

APA StyleOjala, J., Visanko, M., Laitinen, O., Österberg, M., Sirviö, J. A., & Liimatainen, H. (2018). Emulsion Stabilization with Functionalized Cellulose Nanoparticles Fabricated Using Deep Eutectic Solvents. Molecules, 23(11), 2765. https://doi.org/10.3390/molecules23112765