Formation and Alterations of the Potentially Harmful Maillard Reaction Products during the Production and Storage of Brown Fermented Milk

Abstract

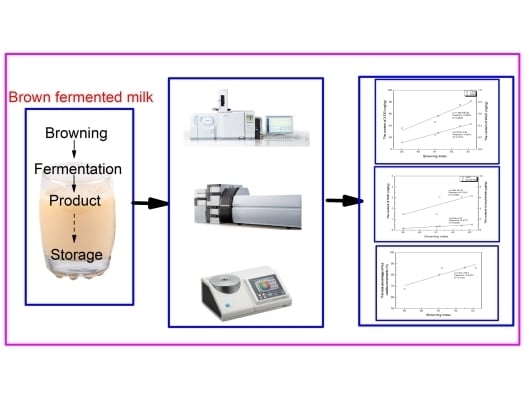

:1. Introduction

2. Results and Discussion

2.1. Formation and Alterations of the MRPs in BFM

2.2. Formation and Alterations in the Flavour Components of BFM

2.3. BFM Colour Alterations

2.4. Relationships between BIs, MRP Levels and Flavour Component Levels during the Browning of BFM

3. Materials and Methods

3.1. Materials

3.2. BFM Preparation

3.2.1. Browning Stage

3.2.2. Fermentation Stage

3.2.3. Quantification of 3-DG and MGO

3.2.4. Quantification of HMF

3.2.5. Acrylamide Quantification

3.2.6. Colour Analysis

3.2.7. Flavour Components Analysis

3.2.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhi-Yuan, X.U.; Yan, W.U.; Guo, B.H.; Zhou, L.H.; Wang, Y.Y.; Lian-Zhong, A.I. Research and preparation of a brown milk drink with probiotic. Sci. Technol. Food Industry 2010, 31, 242–244. [Google Scholar]

- Asikin, Y.; Kamiya, A.; Mizu, M.; Takara, K.; Tamaki, H.; Wada, K. Changes in the physicochemical characteristics, including flavour components and Maillard reaction products, of non-centrifugal cane brown sugar during storage. Food Chem. 2014, 149, 170–177. [Google Scholar] [CrossRef] [PubMed]

- Silva, H.L.A.; Balthazar, C.F.; Esmerino, E.A.; Neto, R.P.C.; Rocha, R.S.; Moraes, J.; Cavalcanti, R.N.; Franco, R.M.; Tavares, M.I.B.; Santos, J.S.; et al. Partial substitution of NaCl by KCl and addition of flavor enhancers on probiotic Prato cheese: A study covering manufacturing, ripening and storage time. Food Chem. 2018, 248, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Rowland, I.; Thomas, L.V.; Yaqoob, P. Immunomodulatory effects of a probiotic drink containing Lactobacillus casei Shirota in healthy older volunteers. Eur. J. Nutr. 2013, 52, 1853–1863. [Google Scholar] [CrossRef] [PubMed]

- Ford, A.C.; Quigley, E.M.M.; Lacy, B.E.; Lembo, A.J.; Saito, Y.A.; Schiller, L.R.; Soffer, E.E.; Spiegel, B.M.R.; Moayyedi, P. Efficacy of Prebiotics, Probiotics, and Synbiotics in Irritable Bowel Syndrome and Chronic Idiopathic Constipation: Systematic Review and Meta-analysis. Am. J. Gastroentero. 2014, 109, 1547–1561. [Google Scholar] [CrossRef] [PubMed]

- Balthazar, C.F.; Silva, H.L.A.; Esmerino, E.A.; Rocha, R.S.; Moraes, J.; Carmo, M.A.V.; Azevedo, L.; Camps, I.K.D.; Abud, Y.; Sant’Anna, C.; et al. The addition of inulin and Lactobacillus casei 01 in sheep milk ice cream. Food Chem. 2018, 246, 464–472. [Google Scholar] [CrossRef]

- Martins, S.; Jongen, W.; van Boekel, M. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Degen, J.; Hellwig, M.; Henle, T. 1,2-Dicarbonyl Compounds in Commonly Consumed Foods. J. Agric. Food Chem. 2012, 60, 7071–7079. [Google Scholar] [CrossRef]

- Rakete, S.; Klaus, A.; Glomb, M.A. Investigations on the Maillard Reaction of Dextrins during Aging of Pilsner Type Beer. J. Agric. Food Chem. 2014, 62, 9876–9884. [Google Scholar] [CrossRef]

- Rannou, C.; Laroque, D.; Renault, E.; Prost, C.; Sérot, T. Mitigation strategies of acrylamide, furans, heterocyclic amines and browning during the Maillard reaction in foods. Food Res. Int. 2016, 90, 154–176. [Google Scholar] [CrossRef]

- Katsaiti, T.; Granby, K. Mitigation of the processing contaminant acrylamide in bread by reducing asparagine in the bread dough. Food Addit. Contam. Part A. 2016, 33, 1402–1410. [Google Scholar] [CrossRef] [PubMed]

- Mottram, D.S.; Wedzicha, B.L.; Dodson, A.T. Food chemistry: Acrylamide is formed in the Maillard reaction. Nature 2002, 419, 448–449. [Google Scholar] [CrossRef] [PubMed]

- Dan, T.; Wang, D.; Jin, R.L.; Zhang, H.P.; Zhou, T.T.; Sun, T.S. Characterization of volatile compounds in fermented milk using solid-phase microextraction methods coupled with gas chromatography-mass spectrometry. J. Dairy Sci. 2017, 100, 2488–2500. [Google Scholar] [CrossRef] [PubMed]

- Abordo, E.A.; Minhas, H.S.; Thornalley, P.J. Accumulation of α-oxoaldehydes during oxidative stress: A role in cytotoxicity. Biochem. Pharmacol. 1999, 58, 641–648. [Google Scholar] [CrossRef]

- Cornelis, T.; Eloot, S.; Vanholder, R.; Glorieux, G.; van der Sande, F.M.; Scheijen, J.L.; Leunissen, K.M.; Kooman, J.P.; Schalkwijk, C.G. Protein-bound uraemic toxins, dicarbonyl stress and advanced glycation end products in conventional and extended haemodialysis and haemodiafiltration. Nephrol. Dial. Transplant. 2015, 30, 1395–1402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Navarro, M.; Atzenbeck, L.; Pischetsrieder, M.; Morales, F.J. Investigations on the Reaction of C3 and C6 α-Dicarbonyl Compounds with Hydroxytyrosol and Related Compounds under Competitive Conditions. J. Agric. Food Chem. 2016, 64, 6327–6332. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Z.; Zou, Y.; Wu, T.; Huang, C.; Pei, K.; Zhang, G.; Lin, X.; Bai, W.; Ou, S. Chlorogenic acid increased 5-hydroxymethylfurfural formation when heating fructose alone or with aspartic acid at two pH levels. Food Chem. 2016, 190, 832–835. [Google Scholar] [CrossRef]

- Nguyen, H.T.; van der Fels-Klerx, H.J.; van Boekel, M. Acrylamide and 5-hydroxymethylfurfural formation during biscuit baking. Part II: Effect of the ratio of reducing sugars and asparagine. Food Chem. 2017, 230, 14–23. [Google Scholar] [CrossRef]

- Capuano, E.; Fogliano, V. Acrylamide and 5-hydroxymethylfurfural (HMF): A review on metabolism, toxicity, occurrence in food and mitigation strategies. LWT Food Sci. Technol. 2011, 44, 793–810. [Google Scholar] [CrossRef]

- Akıllıoglu, H.G.; Mogol, B.A.; Gökmen, V. Degradation of 5-hydroxymethylfurfural during yeast fermentation. Food Addit. Contam. Part A. 2011, 28, 1629–1635. [Google Scholar] [CrossRef]

- Baardseth, P.; Blom, H.; Skrede, G.; Mydland, L.T.; Skrede, A.; Slinde, E. Lactic acid fermentation reduces acrylamide formation and other Maillard reactions in french fries. J. Food Sci. 2006, 71, 28–33. [Google Scholar] [CrossRef]

- Reps, A.; Hammond, E.G.; Glatz, B.A. Carbonyl Compounds Produced by the Growth of Lactobacillus bulgaricus1. J Dairy Sci. 1987, 70, 559–562. [Google Scholar] [CrossRef]

- Bartkiene, E.; Jakobsone, I.; Juodeikiene, G.; Vidmantiene, D.; Pugajeva, I.; Bartkevics, V. Study on the reduction of acrylamide in mixed rye bread by fermentation with bacteriocin-like inhibitory substances producing lactic acid bacteria in combination with Aspergillus niger glucoamylase. Food Control. 2013, 30, 35–40. [Google Scholar] [CrossRef]

- Wang, S.; Yu, J.; Xin, Q.; Wang, S.; Copeland, L. Effects of starch damage and yeast fermentation on acrylamide formation in bread. Food Control. 2017, 73, 230–236. [Google Scholar] [CrossRef]

- Arena, E.; Ballistreri, G.; Tomaselli, F.; Fallico, B. Survey of 1,2-Dicarbonyl Compounds in Commercial Honey of Different Floral Origin. J. Food Sci. 2011, 76, 1203–1210. [Google Scholar] [CrossRef] [PubMed]

- Arribas-Lorenzo, G.; Morales, F.J. Analysis, Distribution, and Dietary Exposure of Glyoxal and Methylglyoxal in Cookies and Their Relationship with Other Heat-Induced Contaminants. J. Agric. Food Chem. 2010, 58, 2966–2972. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hellwig, M.; Degen, J.; Henle, T. 3-deoxygalactosone, a “new” 1,2-dicarbonyl compound in milk products. J. Agric. Food Chem. 2010, 58, 10752–10760. [Google Scholar] [CrossRef]

- Mesías, M.; Morales, F. Effect of Different Flours on the Formation of Hydroxymethylfurfural, Furfural, and Dicarbonyl Compounds in Heated Glucose/Flour Systems. Foods 2017, 6, 14. [Google Scholar] [CrossRef]

- Van Der Fels-Klerx, H.J.; Capuano, E.; Nguyen, H.T.; Ataç Mogol, B.; Kocadağlı, T.; Göncüoğlu, T.N.; Hamzalıoğlu, A.; Van Boekel, M.; Gökmen, V. Acrylamide and 5-hydroxymethylfurfural formation during baking of biscuits: NaCl and temperature–time profile effects and kinetics. Food Res. Int. 2014, 57, 210–217. [Google Scholar] [CrossRef]

- Mogol, B.A.; Gokmen, V. Effect of chitosan on the formation of acrylamide and hydroxymethylfurfural in model, biscuit and crust systems. Food Funct. 2016, 7, 3431–3436. [Google Scholar] [CrossRef]

- Stadler, R.H.; Blank, I.; Varga, N.; Robert, F.; Hau, J.; Guy, P.A.; Robert, M.-C.; Riediker, S. Food chemistry: Acrylamide from Maillard reaction products. Nature 2002, 419, 449–450. [Google Scholar] [CrossRef] [PubMed]

- Arvanitoyannis, I.S.; Dionisopoulou, N. Acrylamide: Formation, Occurrence in Food Products, Detection Methods, and Legislation. Crit. Rev. Food Sci. Nutr. 2014, 54, 708–733. [Google Scholar] [CrossRef] [PubMed]

- Anese, M.; Manzocco, L.; Calligaris, S.; Nicoli, M.C. Industrially Applicable Strategies for Mitigating Acrylamide, Furan, and 5-Hydroxymethylfurfural in Food. J. Agric. Food Chem. 2013, 61, 10209–10214. [Google Scholar] [CrossRef] [PubMed]

- Pfeifer, Y.V.; Haase, P.T.; Kroh, L.W. Reactivity of Thermally Treated α-Dicarbonyl Compounds. J. Agric. Food Chem. 2013, 61, 3090–3096. [Google Scholar] [CrossRef] [PubMed]

- Gobert, J.; Glomb, M.A. Degradation of Glucose: Reinvestigation of Reactive α-Dicarbonyl Compounds. J. Agric. Food Chem. 2009, 57, 8591–8597. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.-L.; Jin, S.-Y.; Chen, C.-S. Relative reactivities of glucose and galactose in browning and pyruvaldehyde formation in sugar/glycine model systems. Food Chem. 2005, 92, 597–605. [Google Scholar] [CrossRef]

- Albalá-Hurtado, S.; Veciana-Nogués, M.T.; Mariné-Font, A.; Vidal-Carou, M.C. Changes in Furfural Compounds during Storage of Infant Milks. J. Agric. Food Chem. 1998, 46, 2998–3003. [Google Scholar] [CrossRef]

- Hee, C.I.; Lee, S.; Jun, H.-R.; Roh, H.-J.; Kim, Y.-S. Comparison of volatile Maillard reaction products from tagatose and other reducing sugars with amino acids. Food Sci. Biotechnol. 2010, 19, 431–438. [Google Scholar]

- Devi, A.F.; Buckow, R.; Singh, T.; Hemar, Y.; Kasapis, S. Colour change and proteolysis of skim milk during high pressure thermal–processing. J. Food Eng. 2015, 147, 102–110. [Google Scholar] [CrossRef]

- Tosun, I.; Sule Ustun, N. Nonenzymic browning during storage of white hard grape pekmez (Zile pekmezi). Food Chem. 2003, 80, 441–443. [Google Scholar] [CrossRef]

- Lo, C.-Y.; Li, S.; Wang, Y.; Tan, D.; Pan, M.-H.; Sang, S.; Ho, C.-T. Reactive dicarbonyl compounds and 5-(hydroxymethyl)-2-furfural in carbonated beverages containing high fructose corn syrup. Food Chem. 2008, 107, 1099–1105. [Google Scholar] [CrossRef]

- Kocadağli, T.; Gökmen, V. Multiresponse kinetic modelling of Maillard reaction and caramelisation in a heated glucose/wheat flour system. Food Chem. 2016, 211, 892–902. [Google Scholar] [CrossRef] [PubMed]

- Rufian-Henares, J.A.; Arribas-Lorenzo, G.; Morales, F.J. Acrylamide content of selected Spanish foods: Survey of biscuits and bread derivatives. Food Addit. Contam. Part A. 2007, 24, 343–350. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roldan, M.; Loebner, J.; Degen, J.; Henle, T.; Antequera, T.; Ruiz-Carrascal, J. Advanced glycation end products, physico-chemical and sensory characteristics of cooked lamb loins affected by cooking method and addition of flavour precursors. Food Chem. 2015, 168, 487–495. [Google Scholar] [CrossRef] [PubMed]

- Contador, R.; Delgado, F.J.; García-Parra, J.; Garrido, M.; Ramírez, R. Volatile profile of breast milk subjected to high-pressure processing or thermal treatment. Food Chem. 2015, 180, 17–24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Sample Availability: Not available. |

| Browning Stage | Time (min) | 3-DG (mg·L−1) | MGO (mg·L−1) | HMF (mg·L−1) | Acrylamide (μg·L−1) |

| 60 | 35.90 ± 0.97 a | 0.12 ± 0.04 a | 0.16 ± 0.03 a | - | |

| 90 | 46.19 ± 1.11 b | 0.24 ± 0.02 b | 0.32 ± 0.02 b | - | |

| 120 | 56.91 ± 1.62 c | 0.32 ± 0.02 c | 0.38 ± 0.03 b c | - | |

| 150 | 75.57 ± 1.41 d | 0.40 ± 0.03 d | 0.42 ± 0.04 c | 9.32 ± 0.10 a | |

| 180 | 82.04 ± 0.64 e | 0.46 ± 0.01 d | 0.53 ± 0.03 d | 9.45 ± 0.12 b | |

| Fermentation Stage | Time (h) | 3-DG (mg·L−1) | MGO (mg·L−1) | HMF (mg·L−1) | Acrylamide (μg·L−1) |

| 12 | 55.06 ± 1.20 a | 0.48 ± 0.01 a | 0.55 ± 0.02 a | 9.63 ± 0.10 NS | |

| 24 | 43.23 ± 0.52 b | 0.58 ± 0.04 b | 0.60 ± 0.03 a b | 9.56 ± 0.14 | |

| 36 | 35.92 ± 0.79 c | 0.81 ± 0.04 c | 0.62 ± 0.01 b c | 9.61 ± 0.18 | |

| 48 | 33.04 ± 0.56 d | 0.86 ± 0.09 c d | 0.67 ± 0.03 c d | 9.49 ± 0.19 | |

| 60 | 16.12 ± 1.40 e | 1.02 ± 0.11 d | 0.70 ± 0.02 d e | 9.59 ± 0.23 | |

| 72 | 15.34 ± 0.58 e | 1.62 ± 0.07 e | 0.75 ± 0.01 e | 9.68 ± 0.14 | |

| Commercial Storage Stage | Time (days) | 3-DG (mg·L−1) | MGO (mg·L−1) | HMF (mg·L−1) | Acrylamide (μg·L−1) |

| 0 | 8.77 ± 0.52 a | 0.94 ± 0.04 a | 0.20 ± 0.02 NS | - | |

| 5 | 10.31 ± 1.12 b | 1.16 ± 0.11 b | 0.24 ± 0.04 | - | |

| 10 | 7.61 ± 0.47 c | 1.34 ± 0.08 b | 0.18 ± 0.04 | - | |

| 15 | 7.75 ± 0.43 c | 1.32 ± 0.05 b | 0.22 ± 0.03 | - | |

| 21 | 7.41 ± 0.37 c | 1.38 ± 0.06 b | 0.21 ± 0.02 | - |

| Number | Flavour Component | Browning Stage (180 min) % | Fermentation Stage (72 h) % | RI | Rt (min) |

|---|---|---|---|---|---|

| Alcohols | |||||

| 1 | 1-Hexanol | 2.42 ± 0.12 | 0.23 ± 0.09 | 867 | 14.63 |

| 2 | 1-Octanol | 0.62 ± 0.19 | 0.18 ± 0.08 | 984 | 20.24 |

| 3 | Trans-2-dodecen-1-ol | 2.41 ± 0.21 | - | 1307 | 9.10 |

| 4 | 2-Furanmethanol | 4.70 ± 0.34 | 4.54 ± 0.15 | 862 | 23.86 |

| 5 | 1-Dodecanol | 0.64 ± 0.07 | - | 1277 | 19.03 |

| 6 | Tridecyl alcohol | 2.01 ± 0.04 | 2.14 ± 0.18 | 1140 | 19.86 |

| 7 | 3,7-Dimethyl-2,6-octadiex-1-ol | 0.23 ± 0.06 | - | 987 | 10.82 |

| 8 | (2,5-Dimethyl-3-furyl) methanol | 0.20 ± 0.02 | 0.13 ± 0.02 | 1735 | 7.38 |

| 9 | 1-Nonanol | - | 0.82 ± 0.17 | 1171 | 16.85 |

| 10 | Cyclopropyl carbinol | - | 0.64 ± 0.09 | 859 | 11.48 |

| 11 | 1-Undecylalcohol | - | 0.20 ± 0.05 | 1329 | 17.36 |

| 12 | Decylalcohol | - | 0.69 ± 0.06 | 1259 | 18.94 |

| 13 | 5-Decen-1-ol | - | 0.31 ± 0.02 | 1139 | 19.34 |

| 14 | 1-Cyclododecanol | - | 0.20 ± 0.03 | 1027 | 21.29 |

| 15 | 1-Hexadecanol | - | 0.97 ± 0.12 | 1530 | 20.54 |

| Carboxylic acids | |||||

| 16 | Phthalic acid | 16.6 ± 0.68 | 1.88 ± 0.24 | 2719 | 29.47 |

| 17 | Hexanoic acid | 4.17 ± 0.44 | 5.28 ± 0.05 | 1946 | 28.99 |

| 18 | Butanoic acid | 23.46 ± 1.14 | 27.19 ± 0.32 | 801 | 23.10 |

| 19 | Octanoic acid | - | 5.73 ± 0.85 | 2189 | 34.23 |

| 20 | Acetic acid | - | 22.17 ± 1.06 | 1463 | 15.79 |

| 21 | Benzoic acid | - | 4.21 ± 0.79 | 2589 | 18.93 |

| 22 | Propionic acid | 0.72 ± 0.15 | - | 1595 | 16.48 |

| 23 | n-Decanoic acid | - | 1.76 ± 0.24 | 1349 | 40.12. |

| Aldehydes | |||||

| 24 | Tridecanal | 5.52 ± 0.82 | 1.18 ± 0.13 | 1103 | 44.12 |

| 25 | Acetaldehyde | 4.12 ± 0.24 | 3.13 ± 0.05 | 707 | 1.42 |

| 26 | Octanal | 1.60 ± 0.28 | - | 1292 | 28.34 |

| 27 | Furfural | 1.65 ± 0.08 | 1.05 ± 0.18 | 834 | 17.83 |

| 28 | 1-Nonanal | 3.22 ± 0.39 | - | 1091 | 35.30 |

| 29 | Benzaldehyde | 2.84 ± 0.33 | - | 964 | 14.92 |

| Ketones | |||||

| 30 | Acetone | - | 2.31 ± 0.12 | 812 | 6.91 |

| 31 | 5-Undecanone | - | 0.21 ± 0.12 | 1597 | 43.66 |

| 32 | 2-Tridecanone | 0.99 ± 0.19 | 0.31 ± 0.05 | 1423 | 38.23 |

| 33 | Nonanone | 0.98 ± 0.13 | 0.13 ± 0.01 | 1389 | 15.45 |

| 34 | 2-Pentadecanone | 2.75 ± 0.37 | 0.24 ± 0.04 | 2022 | 41.23 |

| 35 | 2H-Pyran-2-one | 2.71 ± 0.15 | 2.12 ± 0.02 | 1306 | 32.49 |

| 36 | Nonalactone | 0.82 ± 0.19 | 0.3 ± 0.08 | 1507 | 37.12 |

| 37 | 6-Methyl-5-hepten-2-one | 0.8 ± 0.22 | - | 845 | 22.34 |

| Others | |||||

| 38 | 2-[2-(2-methoxyethoxy)ethoxy]-2-methylpropane | - | 0.34 ± 0.09 | 1458 | 7.96 |

| 39 | 4-Dodecanolide | 0.63 ± 0.15 | - | 1302 | 15.68 |

| 40 | Dibutylphthalate | 2.82 ± 0.42 | 0.26 ± 0.06 | 2107 | 36.59 |

| 41 | Dodecane | 1.05 ± 0.30 | 0.11 ± 0.02 | 1200 | 14.58 |

| Browning Stage | Time (min) | a* | b* | L* | ΔE* | BI |

| 60 | −2.16 ± 0.15 a | 10.32 ± 0.08 a | 88.79 ± 0.2 a | - | 59.01 ± 0.31 a | |

| 90 | 0.15 ± 0.21 b | 13.59 ± 0.18 b | 85.96 ± 0.11 b | 4.90 ± 0.28 a | 61.01 ± 0.14 b | |

| 120 | 0.35 ± 0.26 b | 13.74 ± 0.21 b | 85.66 ± 0.13 b | 5.27 ± 0.19 a | 61.19 ± 0.46 b | |

| 150 | 2.39 ± 0.09 c | 15.1 ± 0.15 c | 83.37 ± 0.03 c | 8.53 ± 0.37 b | 62.51 ± 0.26 c | |

| 180 | 3.16 ± 0.18 d | 15.8 ± 0.04 d | 82.13 ± 0.13 d | 10.13 ± 0.35 c | 63.15 ± 0.28 d | |

| Fermentation Stage | Time (h) | a* | b* | L* | ΔE* | BI |

| 12 | 4.19 ± 0.06 NS | 16.65 ± 0.05 NS | 80.41 ± 0.04 NS | - | 64.01 ± 0.49 NS | |

| 24 | 4.18 ± 0.11 | 16.63 ± 0.09 | 80.35 ± 0.10 | 0.06 ± 0.03 NS | 64.01 ± 0.35 | |

| 36 | 4.24 ± 0.08 | 16.67 ± 0.11 | 80.38 ± 0.07 | 0.06 ± 0.02 | 64.04 ± 0.58 | |

| 48 | 4.21 ± 0.09 | 16.71 ± 0.14 | 80.33 ± 0.15 | 0.10 ± 0.05 | 64.06 ± 0.26 | |

| 60 | 4.36 ± 0.20 | 16.53 ± 0.23 | 80.24 ± 0.18 | 0.24 ± 0.15 | 64.01 ± 0.32 | |

| 72 | 4.27 ± 0.18 | 16.78 ± 0.06 | 80.23 ± 0.09 | 0.24 ± 0.14 | 64.12 ± 0.36 | |

| Commercial Storage Stage | Time (days) | a* | b* | L* | ΔE* | BI |

| 0 | 2.31 ± 0.16 NS | 14.52 ± 0.13 NS | 85.36 ± 0.34 NS | - | 62.07 ± 0.40NS | |

| 5 | 2.37 ± 0.21 | 14.57 ± 0.19 | 85.25 ± 0.29 | 2.07 ± 0.23 NS | 62.12 ± 0.02 | |

| 10 | 2.29 ± 0.13 | 14.38 ± 0.16 | 85.43 ± 0.33 | 1.95 ± 0.18 | 62.00 ± 0.38 | |

| 15 | 2.26 ± 0.08 | 14.46 ± 0.22 | 85.39 ± 0.36 | 2.18 ± 0.34 | 62.03 ± 0.28 | |

| 21 | 2.35 ± 0.11 | 14.51 ± 0.10 | 85.35 ± 0.45 | 2.12 ± 0.29 | 62.08 ± 0.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Z.; Gao, J.; Wang, X.; Wang, W.; Dong, J.; Zhang, Y.; Wang, S. Formation and Alterations of the Potentially Harmful Maillard Reaction Products during the Production and Storage of Brown Fermented Milk. Molecules 2019, 24, 272. https://doi.org/10.3390/molecules24020272

Han Z, Gao J, Wang X, Wang W, Dong J, Zhang Y, Wang S. Formation and Alterations of the Potentially Harmful Maillard Reaction Products during the Production and Storage of Brown Fermented Milk. Molecules. 2019; 24(2):272. https://doi.org/10.3390/molecules24020272

Chicago/Turabian StyleHan, Zhonghui, Jianxin Gao, Xiaomin Wang, Wenxiang Wang, Jing Dong, Yan Zhang, and Shuo Wang. 2019. "Formation and Alterations of the Potentially Harmful Maillard Reaction Products during the Production and Storage of Brown Fermented Milk" Molecules 24, no. 2: 272. https://doi.org/10.3390/molecules24020272

APA StyleHan, Z., Gao, J., Wang, X., Wang, W., Dong, J., Zhang, Y., & Wang, S. (2019). Formation and Alterations of the Potentially Harmful Maillard Reaction Products during the Production and Storage of Brown Fermented Milk. Molecules, 24(2), 272. https://doi.org/10.3390/molecules24020272